Process for manufacturing discoloration color-coating aluminum plate

A manufacturing process and aluminum plate technology, applied in the field of color-changing aluminum plate manufacturing process, can solve problems such as monotony, lack of aesthetics, single color of aluminum plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

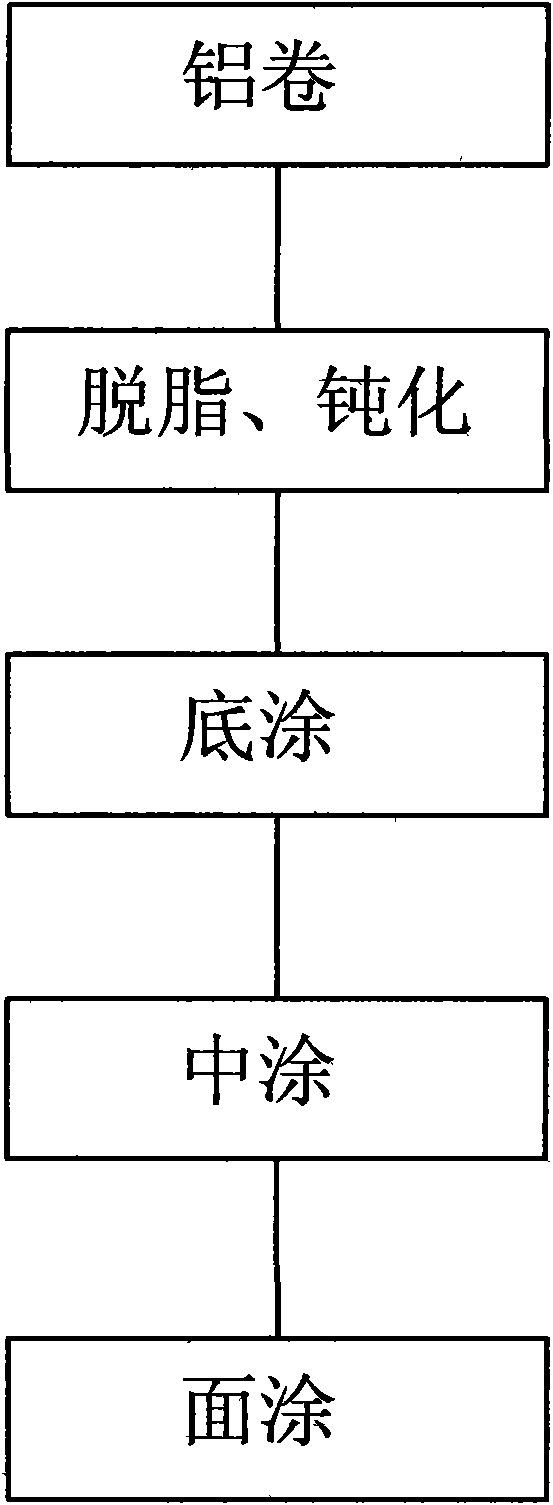

[0021] Embodiment 1: refer to figure 1 Shown, a kind of manufacturing process of changing color coated aluminum plate, this process comprises the following steps

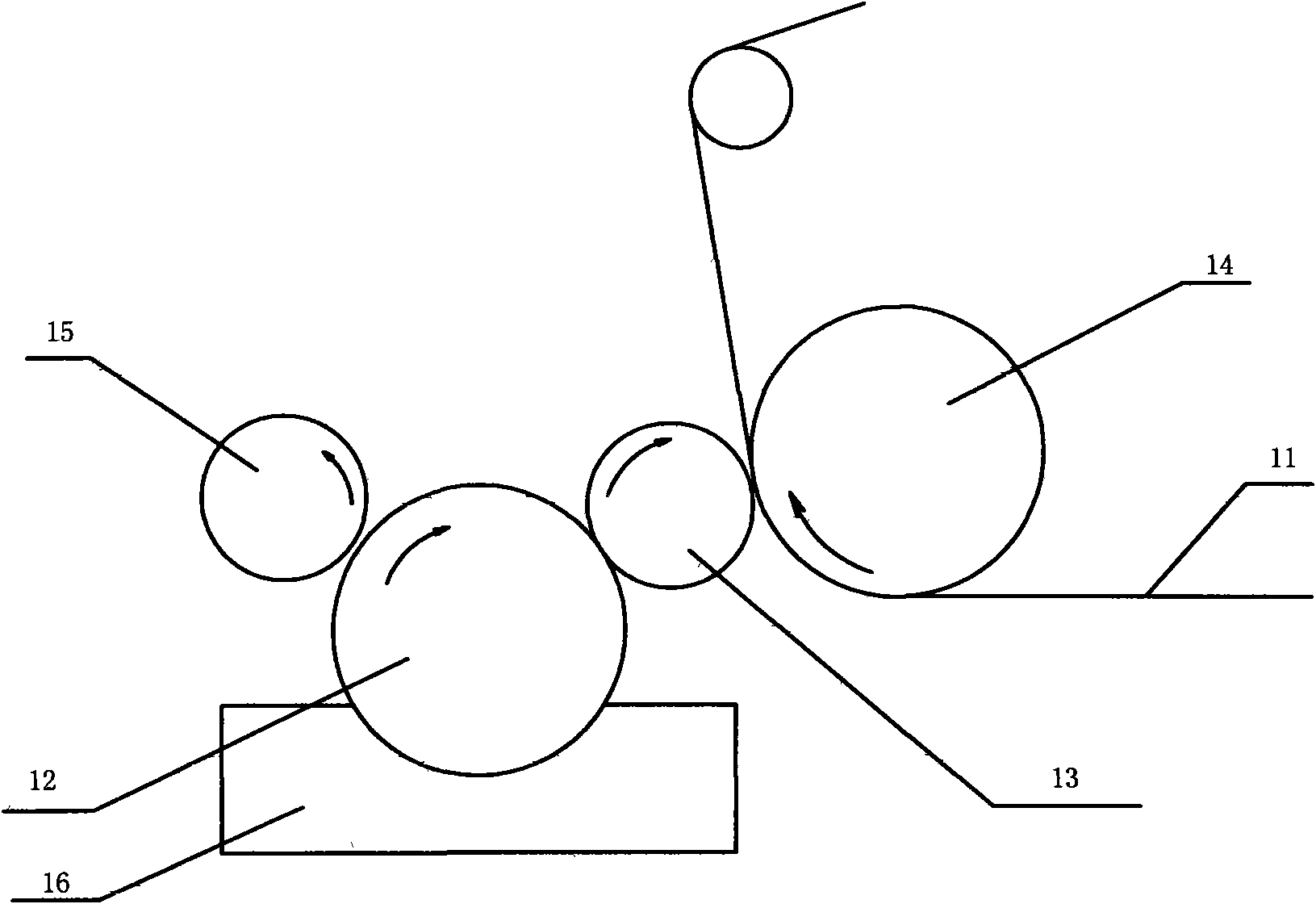

[0022] (1) Perform pretreatment degreasing and passivation processes on the aluminum substrate 11, so that a passivation film layer is formed on the surface of the aluminum substrate 11;

[0023] (2) Carry out primer on passivation film layer, described primer is to coat one deck polyurethane paint on passivation film layer, and it is baked in oven, makes the temperature of aluminum substrate 11 reach 204°C, after baking, a polyurethane organic coating is formed into a film. The viscosity of the polyurethane coating is 60″ (4# Ford cup), and the baking time is 90 seconds;

[0024] (3) After priming, carry out intermediate coating on polyurethane organic coating, described intermediate coating is to coat one deck polyester coating or fluorocarbon coating on polyurethane organic coating, and it is baked in oven Bake...

Embodiment 2

[0030] Embodiment 2: refer to figure 1 Shown, a kind of manufacturing process of changing color coated aluminum plate, this process comprises the following steps

[0031] (1) Perform pretreatment degreasing and passivation processes on the aluminum substrate 11 to form a passivation film on the surface of the aluminum substrate;

[0032] (2) Carry out primer on passivation film layer, described primer is to coat one deck polyurethane paint on passivation film layer, and it is baked in oven, makes the temperature of aluminum substrate 11 reach 207°C, after baking, a polyurethane organic coating is formed into a film. The viscosity of the polyurethane coating is 65″ (4# Ford cup), and the baking time is 60 seconds;

[0033] (3) After priming, carry out intermediate coating on polyurethane organic coating, described intermediate coating is to coat one deck polyester coating or fluorocarbon coating on polyurethane organic coating, and it is baked in oven Bake, make the temperatu...

Embodiment 3

[0036] Embodiment 3: refer to figure 1 Shown, a kind of manufacturing process of changing color coated aluminum plate, this process comprises the following steps

[0037] (1) performing a pretreatment degreasing and passivation process on the aluminum substrate (11), so that a passivation film layer is formed on the surface of the aluminum substrate;

[0038] (2) Carry out primer on passivation film layer, described primer is to coat one deck polyurethane coating on passivation film layer, and it is baked in oven, makes the temperature of aluminum substrate reach 210 ℃, after baking, the polyurethane organic coating is formed into a film. The viscosity of the polyurethane coating is 70 "(4# Ford cup), and the baking time is 45 seconds;

[0039] (3) After priming, carry out intermediate coating on polyurethane organic coating, described intermediate coating is to coat one deck polyester coating or fluorocarbon coating on polyurethane organic coating, and it is baked in oven B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com