Water-based nano coating-free yellow pigment ink

A yellow pigment, no coating technology, applied in the field of water-based pigment ink, can solve the problems of color desaturation, pigment ink application limitation, ink intolerance to water, etc., and achieve the effect of bright and full color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

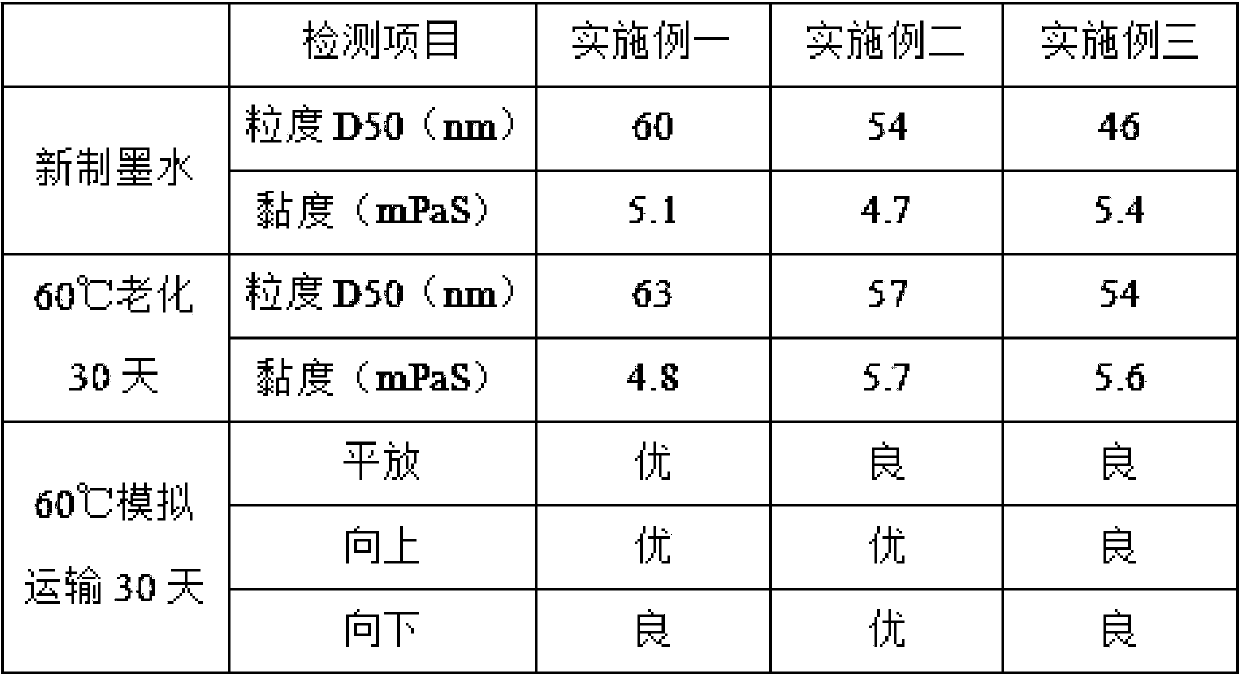

Embodiment 1

[0011] The invention provides a technical solution, the water-based nanometer uncoated yellow pigment ink is composed of the following components by weight percentage: 20%-30% of yellow nano-color paste; 2%-8% of diethylene glycol; glycerin 2%-8%; Antioxidant 5%-10%; Quick-drying agent 8%-12%; Glue 10%-14%; Cross-linking agent 2%-8%; Adhesion promoter 1%-4%; Water for the remaining amount.

[0012] Wherein, in the present embodiment, the described by weight percentage is composed of the following components: 25% of yellow nano-color paste; 5% of diethylene glycol; 5% of glycerol; 8% of antioxidant; %; glue 12%; crosslinking agent 5%; adhesion promoter 3%; water 27%.

[0013] Wherein, in the present embodiment, the preparation method of the ink is: yellow nano-color paste, diethylene glycol, glycerin, antioxidant, quick-drying agent, glue, cross-linking agent, adhesion promoter and water Proportionally added to the dispersion tank, followed by multi-stage separation and shear...

Embodiment 2

[0020] The invention provides a technical solution, the water-based nanometer uncoated yellow pigment ink is composed of the following components by weight percentage: 20%-30% of yellow nano-color paste; 2%-8% of diethylene glycol; glycerin 2%-8%; Antioxidant 5%-10%; Quick-drying agent 8%-12%; Glue 10%-14%; Cross-linking agent 2%-8%; Adhesion promoter 1%-4%; Water for the remaining amount.

[0021] Wherein, in this embodiment, the described by weight percentage is composed of the following components: 20% yellow nano-color paste; 6% diethylene glycol; 6% glycerol; 10% antioxidant; quick-drying agent 8 %; glue 10%; crosslinking agent 2%; adhesion promoter 4%; water 34%.

[0022] Wherein, in the present embodiment, the preparation method of the ink is: yellow nano-color paste, diethylene glycol, glycerin, antioxidant, quick-drying agent, glue, cross-linking agent, adhesion promoter and water Proportionally added to the dispersion tank, followed by multi-stage separation and sh...

Embodiment 3

[0029] The invention provides a technical solution, the water-based nanometer uncoated yellow pigment ink is composed of the following components by weight percentage: 20%-30% of yellow nano-color paste; 2%-8% of diethylene glycol; glycerin 2%-8%; Antioxidant 5%-10%; Quick-drying agent 8%-12%; Glue 10%-14%; Cross-linking agent 2%-8%; Adhesion promoter 1%-4%; Water for the remaining amount.

[0030] Wherein, in the present embodiment, the described by weight percentage is composed of the following components: 30% yellow nano-color paste; 4% diethylene glycol; 4% glycerol; 5% antioxidant; quick-drying agent 12% %; glue 14%; crosslinking agent 6%; adhesion promoter 1%; water 24%.

[0031] Wherein, in the present embodiment, the preparation method of the ink is: yellow nano-color paste, diethylene glycol, glycerin, antioxidant, quick-drying agent, glue, cross-linking agent, adhesion promoter and water Proportionally added to the dispersion tank, followed by multi-stage separatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com