Sports protective fabric based on hemp interval texture structure and production process thereof

A technology of spacer organization and production process, applied in knitting, warp knitting, weft knitting, etc., can solve the problem of anti-mildew and antibacterial properties, poor moisture absorption and anti-ultraviolet performance, poor air permeability, poor ventilation performance, and inability to discharge sweat smoothly, etc. problem, to achieve the effect of good moisture absorption and perspiration function, loose internal structure and excellent anti-ultraviolet function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

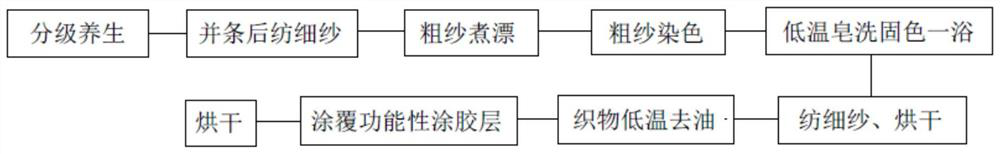

[0030] Such as figure 1 Shown, a kind of sports protection fabric based on hemp spacer structure, sports protection fabric comprises base fabric, base fabric comprises upper synthetic fiber layer, middle fiber layer and lower layer fiber layer, upper layer fiber layer comprises one layer of polyester fiber layer and one layer One layer of low melting point polyester yarn, the middle fiber layer is composed of two synthetic antibacterial fibers intertwined, the lower fiber layer is composed of one fiber pure hemp yarn and another fiber layer, one synthetic antibacterial fiber is connected with the upper fiber layer, and the other synthetic antibacterial The fiber is connected with the lower fiber layer, and the upper synthetic fiber layer is scraped or rolled with a functional adhesive layer. The coating amount of the functional adhesive layer is 3g / ㎡, and the weight of the sports protective fabric after coating is 310g / ㎡. Among them, the polyester fiber is 200D polyester DTY...

Embodiment 2

[0042] Such as figure 1 Shown, a kind of sports protection fabric based on hemp spacer structure, sports protection fabric comprises base fabric, base fabric comprises upper synthetic fiber layer, middle fiber layer and lower layer fiber layer, upper layer fiber layer comprises one layer of polyester fiber layer and one layer One layer of low melting point polyester yarn, the middle fiber layer is composed of two synthetic antibacterial fibers intertwined, the lower fiber layer is composed of one fiber pure hemp yarn and another fiber layer, one synthetic antibacterial fiber is connected with the upper fiber layer, and the other synthetic antibacterial The fiber is connected with the lower fiber layer, and the upper synthetic fiber layer is scraped or rolled with a functional adhesive layer. The coating amount of the functional adhesive layer is 6g / ㎡, and the weight of the sports protective fabric after coating is 315g / ㎡. Among them, the polyester fiber is 100D polyester DTY...

Embodiment 3

[0054] Such as figure 1 Shown, a kind of sports protection fabric based on hemp spacer structure, sports protection fabric comprises base fabric, base fabric comprises upper synthetic fiber layer, middle fiber layer and lower layer fiber layer, upper layer fiber layer comprises one layer of polyester fiber layer and one layer One layer of low melting point polyester yarn, the middle fiber layer is composed of two synthetic antibacterial fibers intertwined, the lower fiber layer is composed of one fiber pure hemp yarn and another fiber layer, one synthetic antibacterial fiber is connected with the upper fiber layer, and the other synthetic antibacterial The fiber is connected with the lower fiber layer, and the upper synthetic fiber layer is scraped or rolled with a functional adhesive layer. The coating amount of the functional adhesive layer is 10g / ㎡, and the weight of the sports protective fabric after coating is 320g / ㎡. Among them, the polyester fiber is 250D polyester DT...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating mass | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com