Method for producing a metal part

A technology of metal parts and metals, applied in the field of devices for manufacturing such metal parts, can solve problems such as redundancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

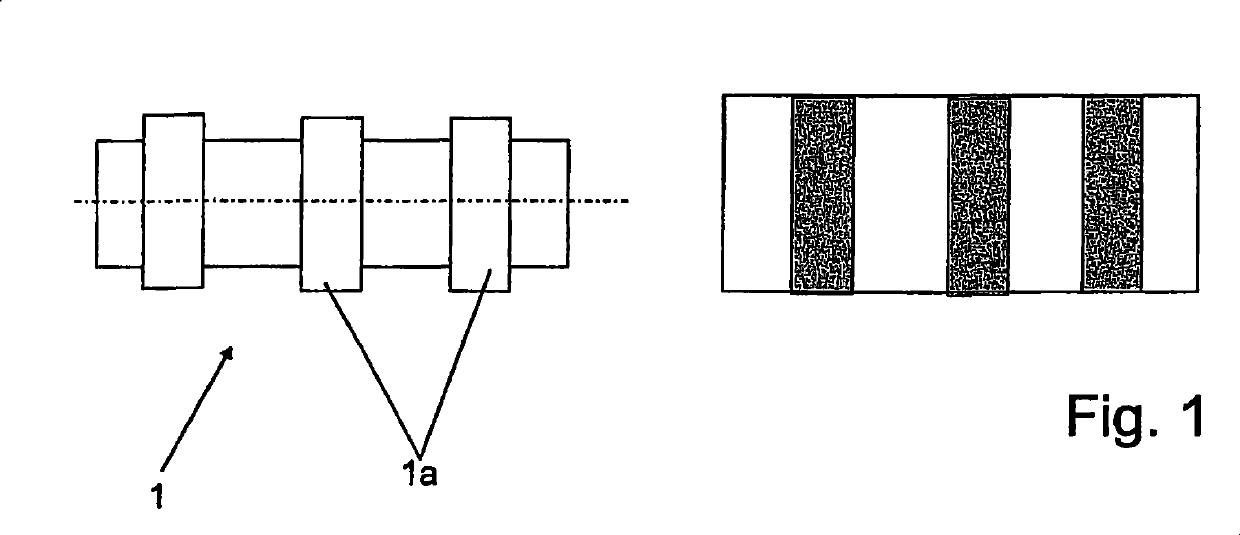

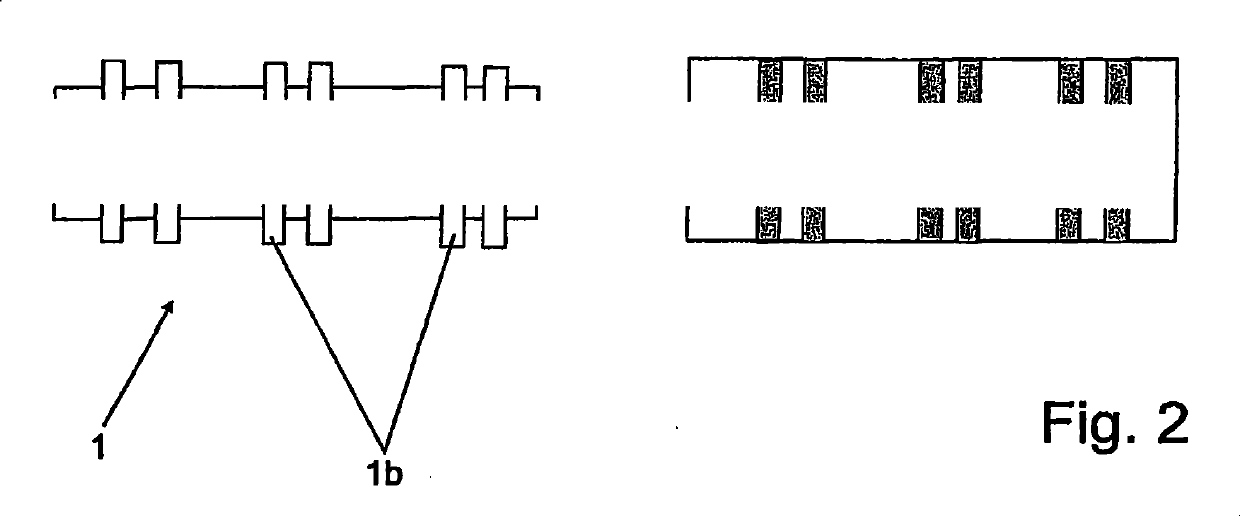

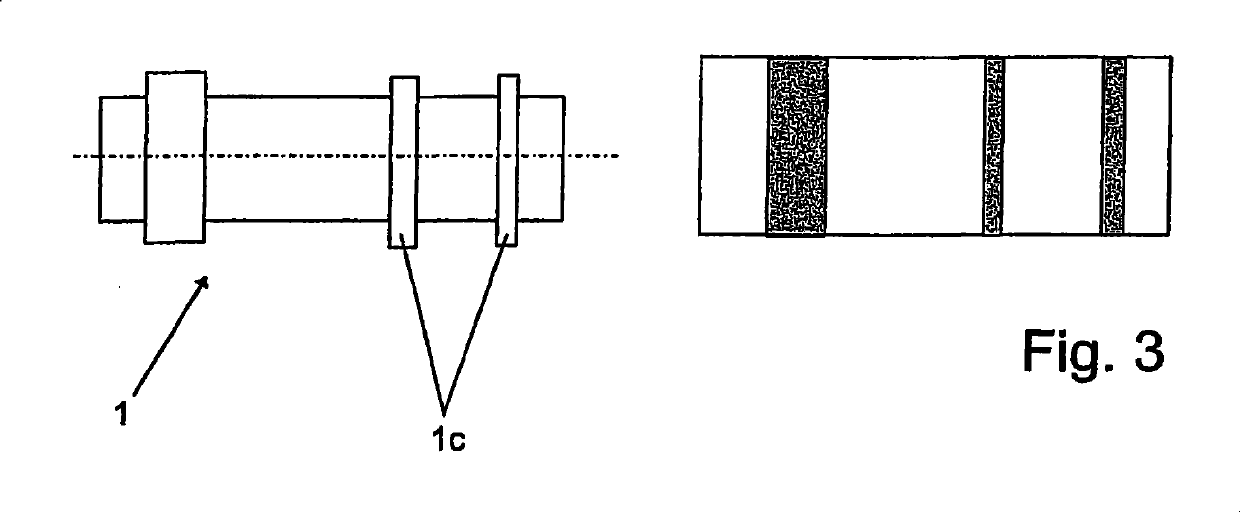

[0026] In the method according to the invention, the strip, which consists of a completely level-coated aluminum sheet with brazing filler metal, first appears in the form of rolled material. The plate is sent to the coating device through the feeding device for automatic coating of the flux composition. The coating device comprises a coating roll 1 which has a structured surface 1a-1g. The flux composition in the form of a paste is taken from the storage container and applied to the applicator roll 1, after which it is transferred to the material web along the moving web by the rolling of the applicator roll.

[0027] Since the applicator roll 1 has a textured surface, the flux composition is only applied via the protruding regions of the textured surface and / or is transferred to the strip only via these regions. In this way, the flux composition is applied to only a limited portion of the continuously passing strip surface.

[0028] In FIGS. 1 to 7 are seven representative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com