Preparation method of environment-friendly wrapping paper

A technology for packaging paper and a manufacturing method, applied in the field of papermaking, can solve problems such as poor water resistance and rough surface, and achieve the effects of improved environmental protection performance, full and bright colors, and improved water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

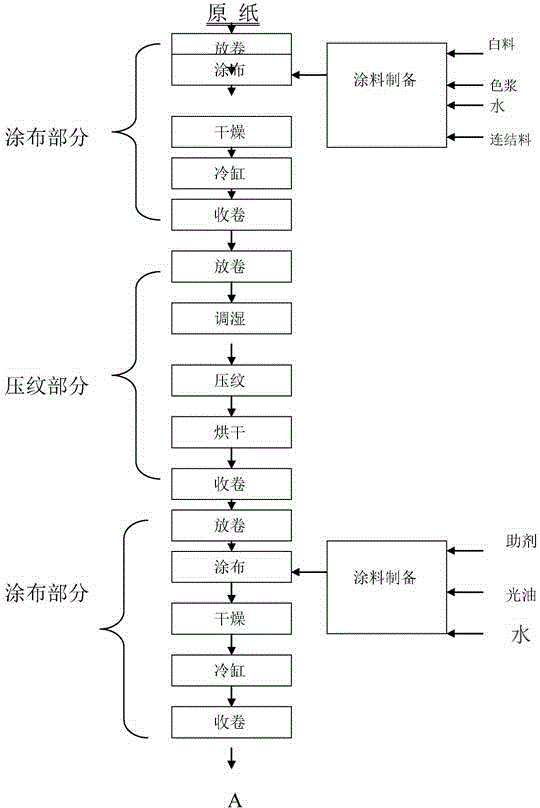

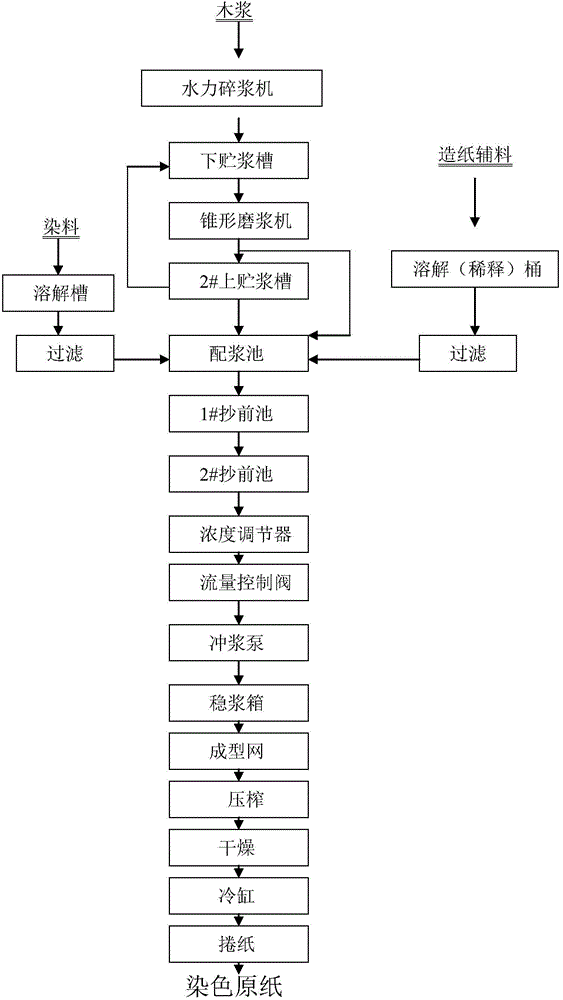

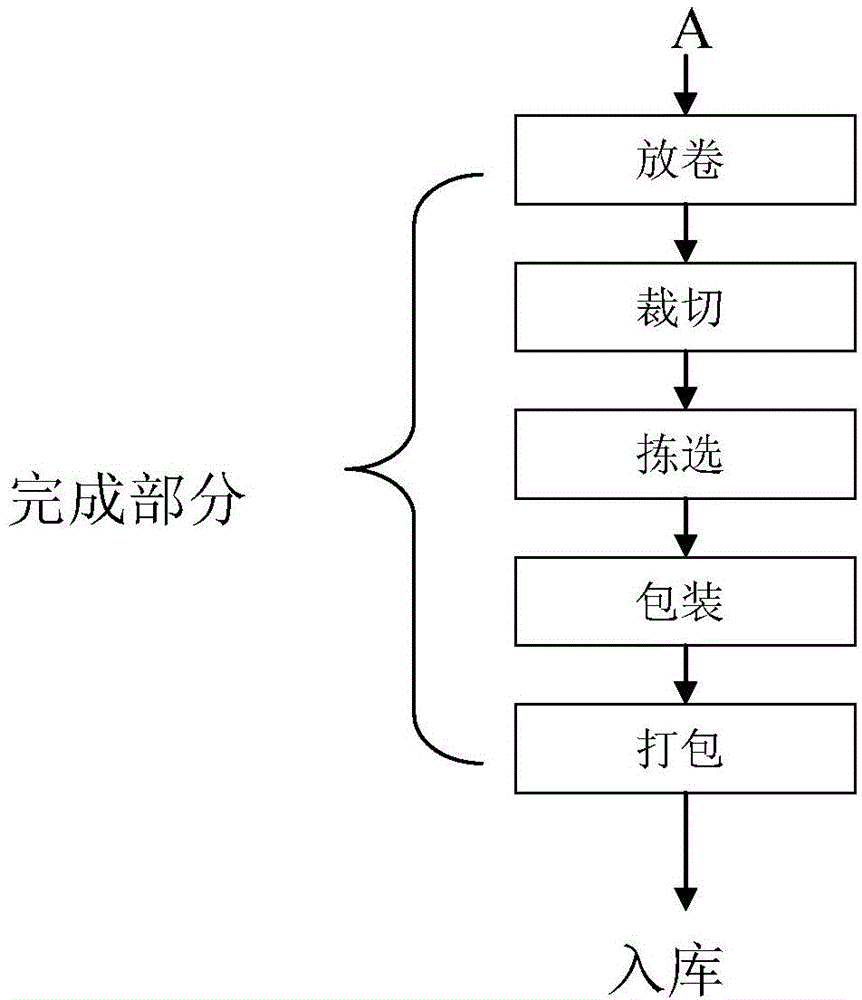

[0028] The present invention will now be further described in conjunction with the accompanying drawings and embodiments.

[0029] Now take the red environmental protection wrapping paper as an example:

[0030] The present invention is a manufacturing method of environment-friendly wrapping paper, comprising base paper making, color layer coating, embossing treatment and surface layer coating, and the surface layer coating comprises the following steps:

[0031] Step 1, complete the preparation of the surface coating in the container, the surface coating is composed of 80 parts of varnish, 18 parts of water and 2 parts of anti-scratch agent in proportion by weight, and the varnish is polyurethane resin, which is scratch-resistant The agent is a trifunctional crosslinking agent;

[0032] Step 2, put the embossed paper in the air knife coater, apply the surface coating after filtering through the 200-mesh screen on the paper surface with the feeding roller, and contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com