Patents

Literature

227results about How to "Long lasting color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

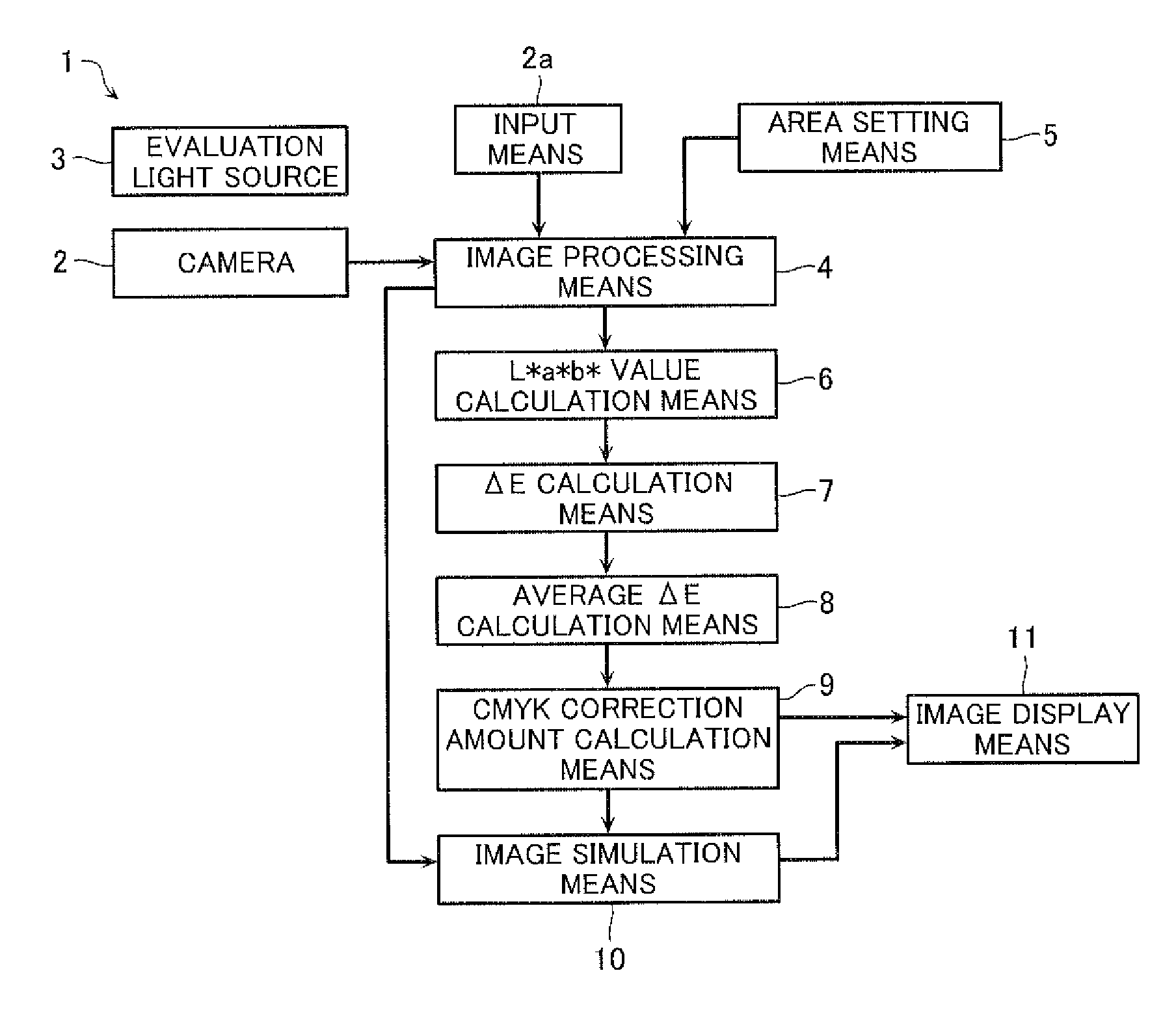

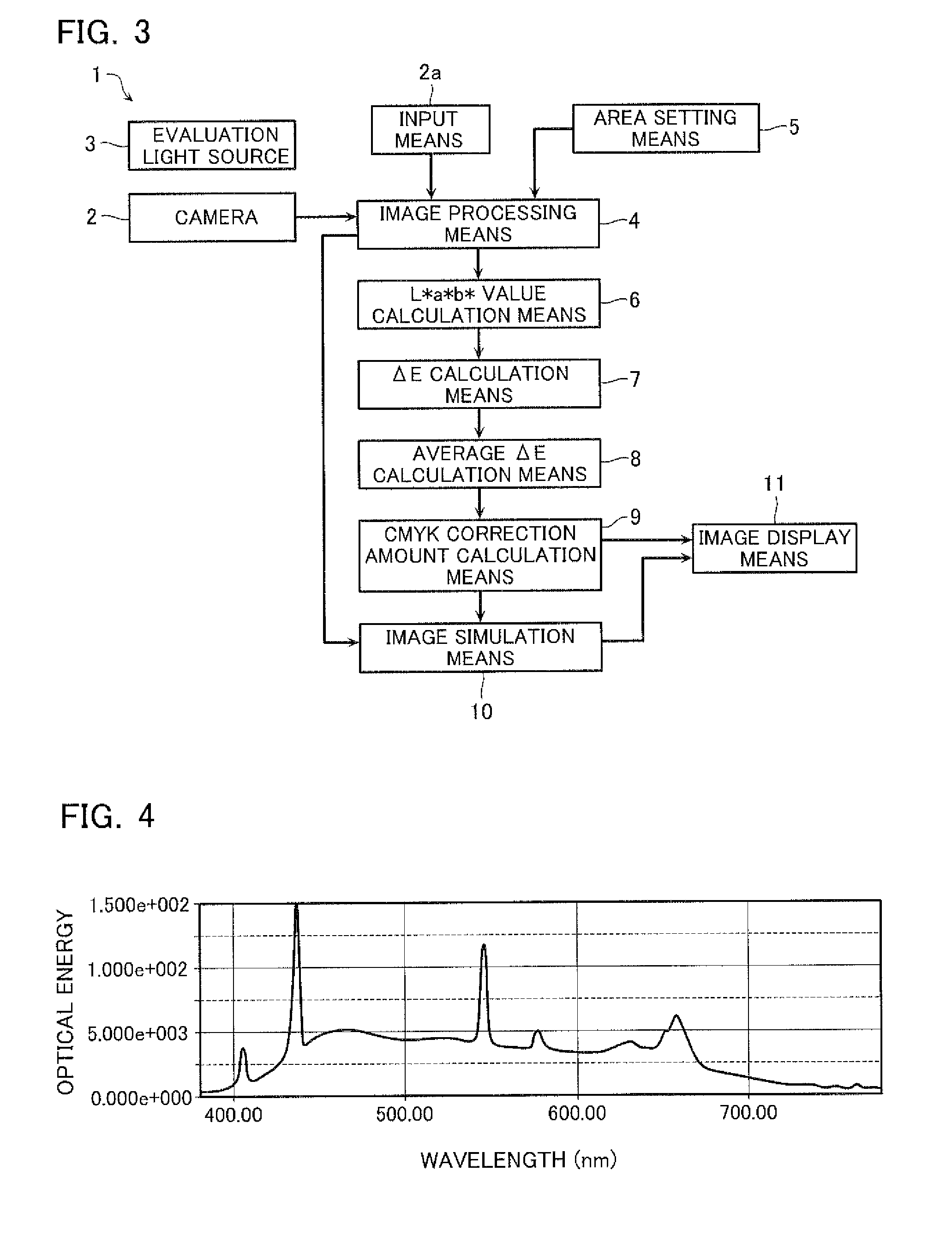

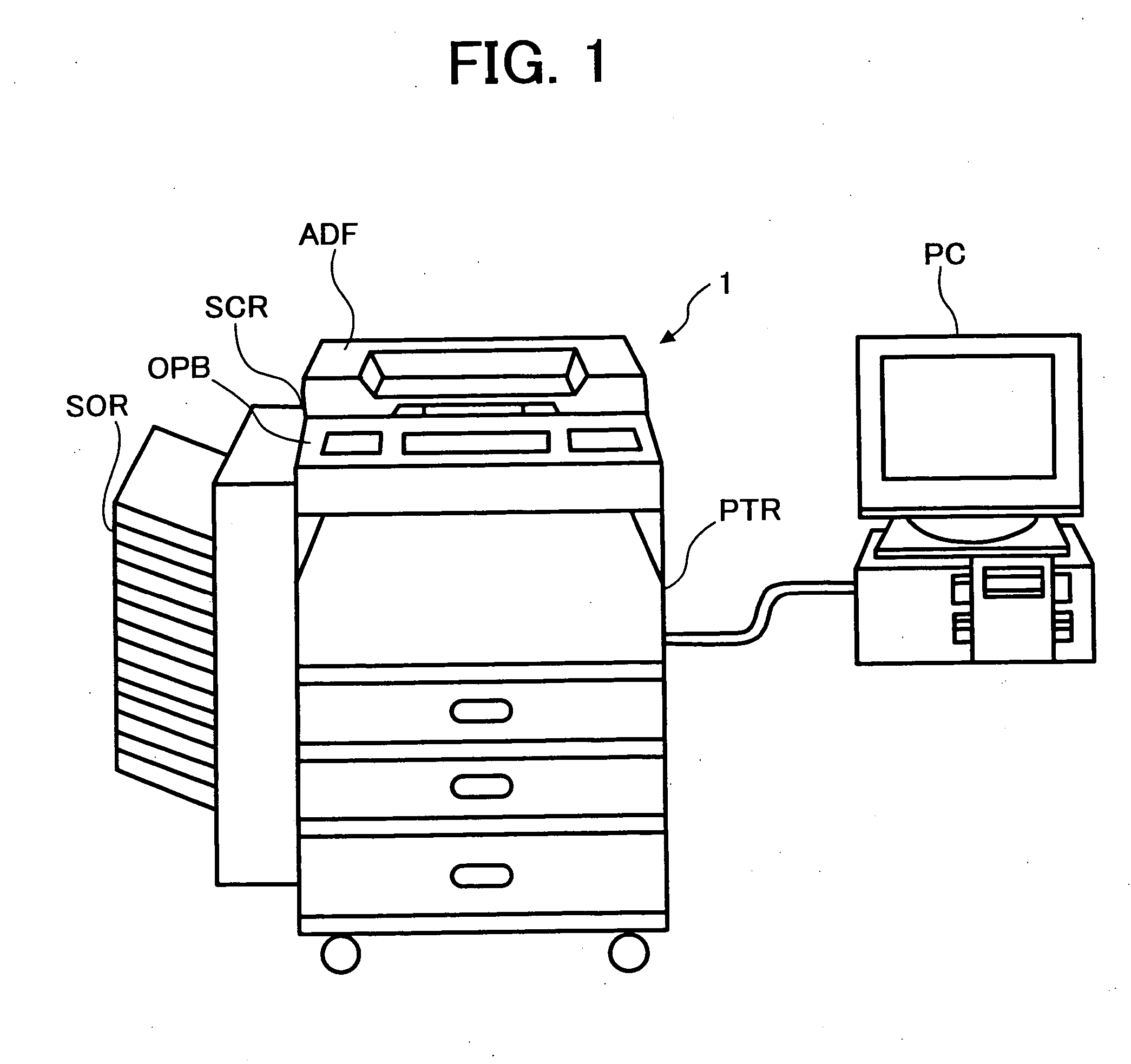

Color information processing method, color information processing apparatus, and color information processing system

ActiveUS20130250322A1Color matchingLong lasting colorDigitally marking record carriersDigital computer detailsInformation processingImage matching

A color information processing method includes: inputting reference data including color information about each pixel or each pixel group of a reference medium and evaluation target data including color information about each pixel or each pixel group of an evaluation medium by an input means; performing an image matching process of image matching the input reference data and evaluation target data; setting a specific area which is a unit of evaluation and includes a plurality of pixels to each data item subjected to the image matching process; and comparing the color information items about each pixel or each pixel group in the reference data and the evaluation target data in the set specific area to calculate a color difference and performing an averaging process to calculate an average evaluation result for the specific area by a calculation means.

Owner:PROSPER CREATIVE

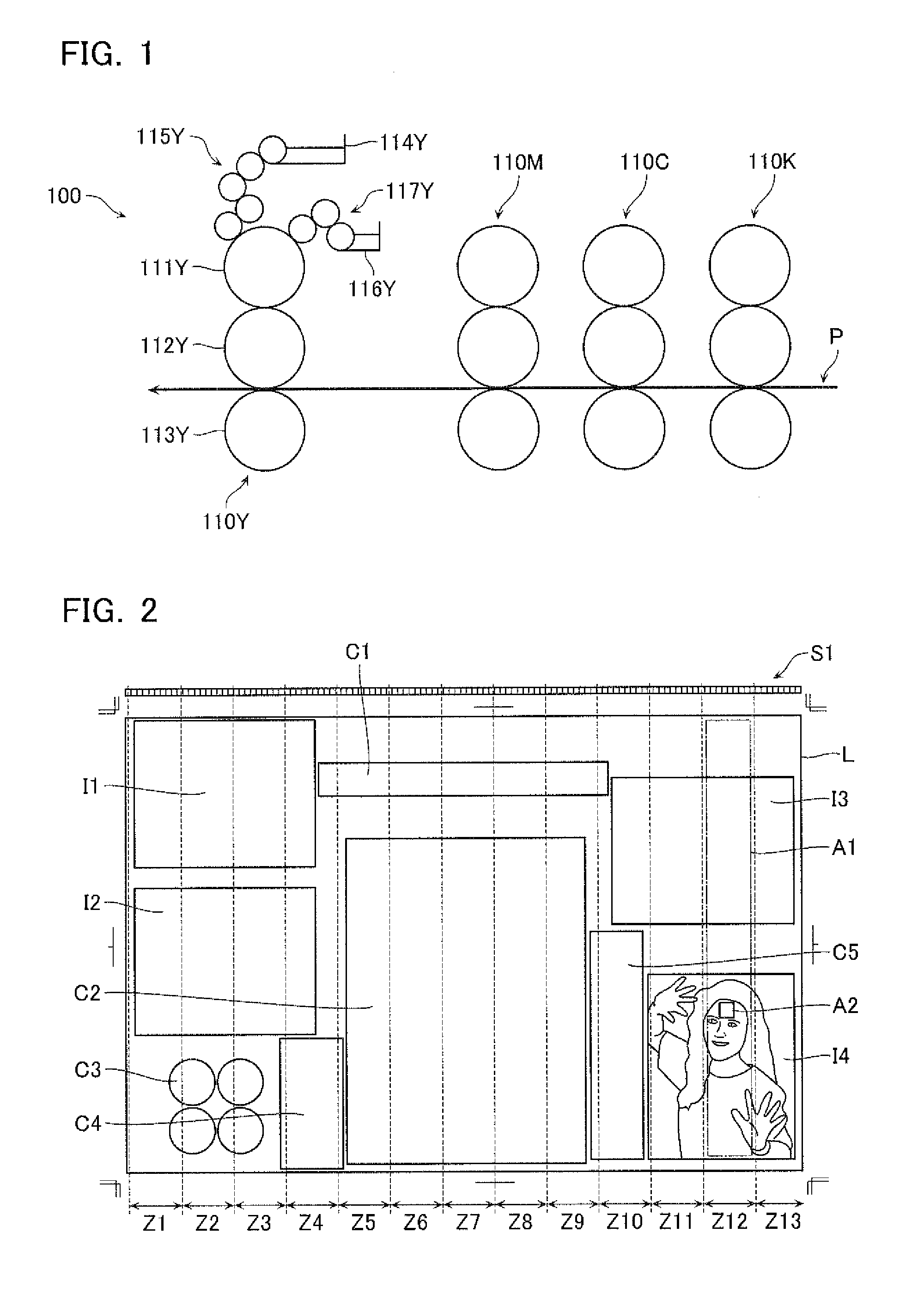

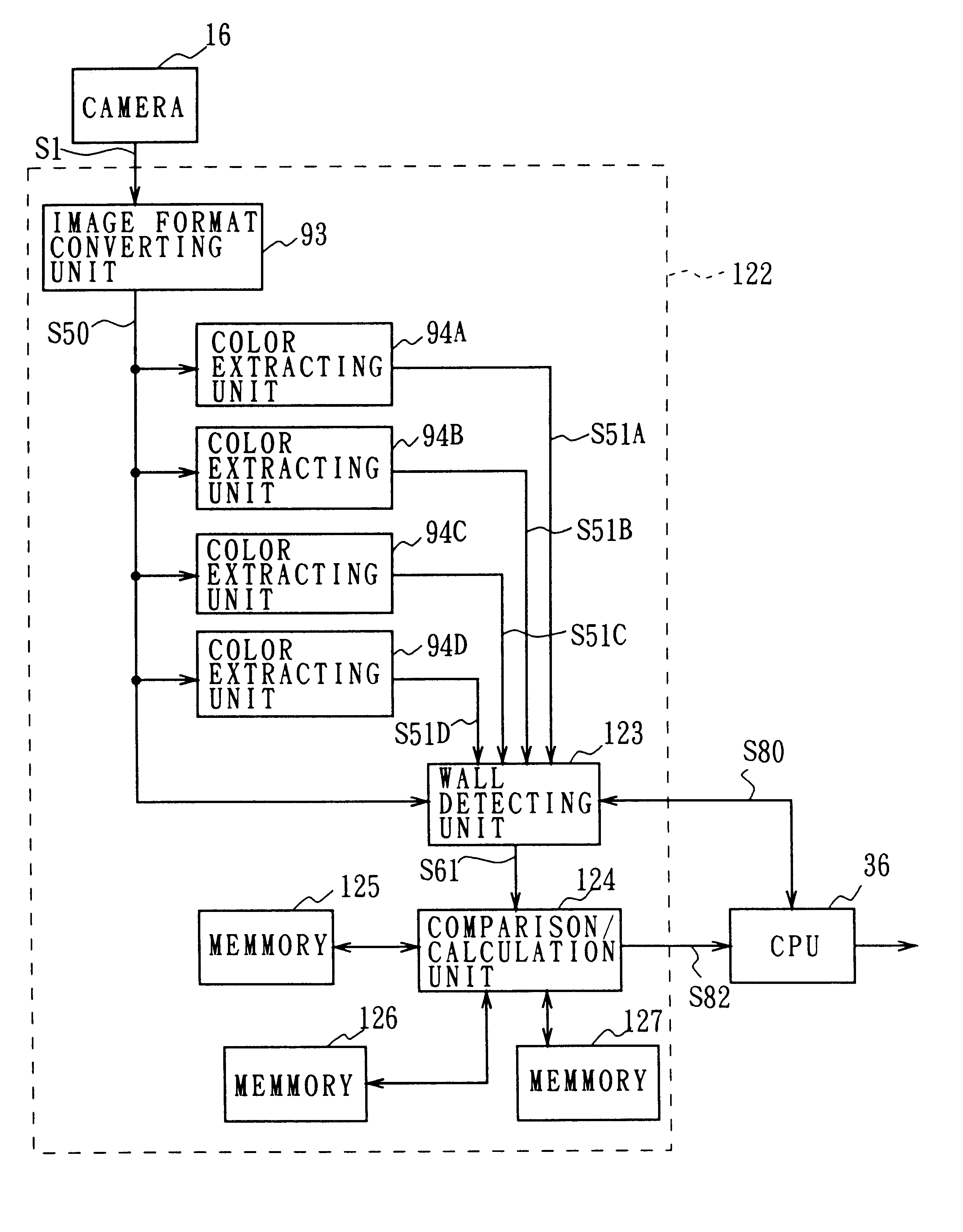

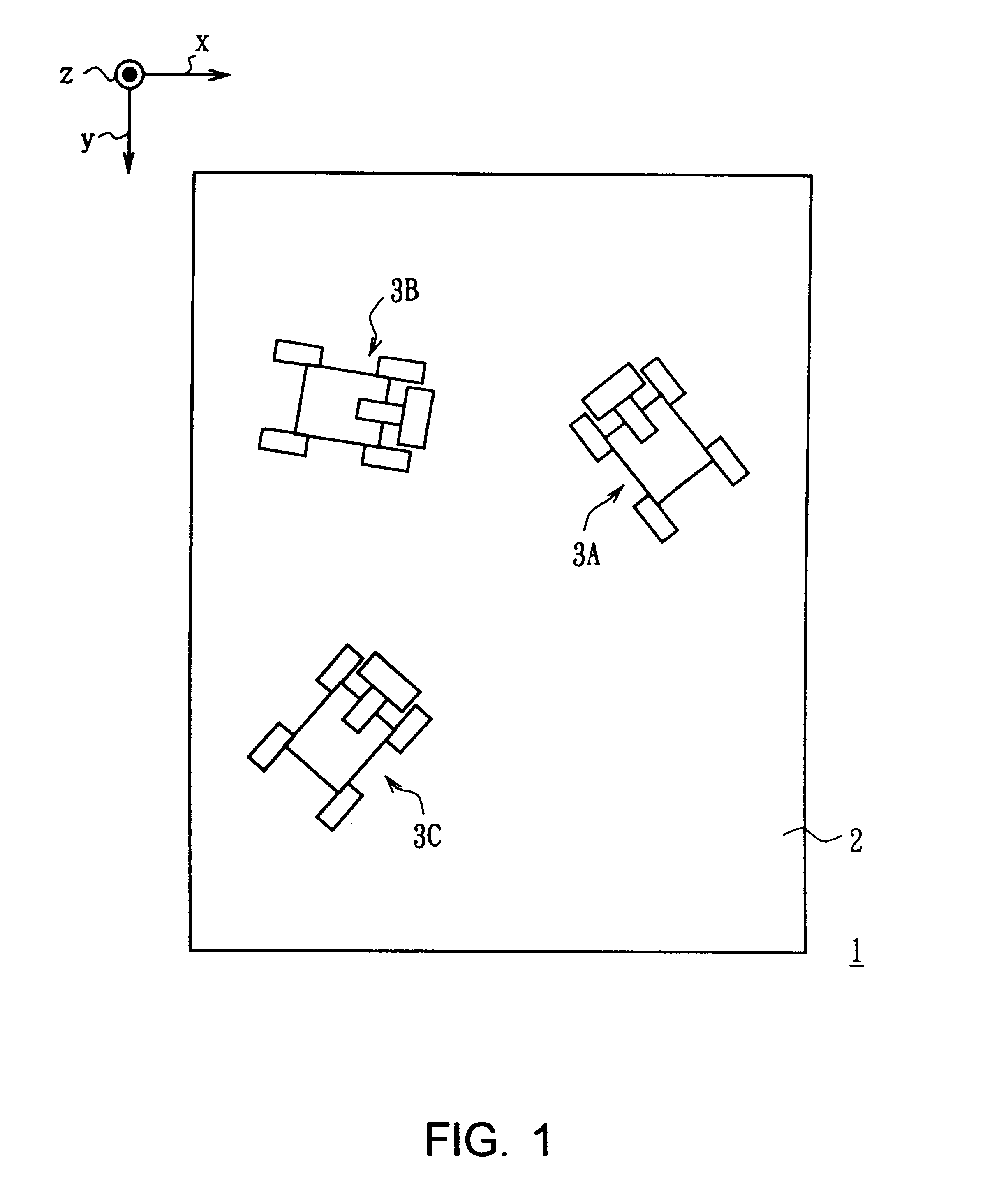

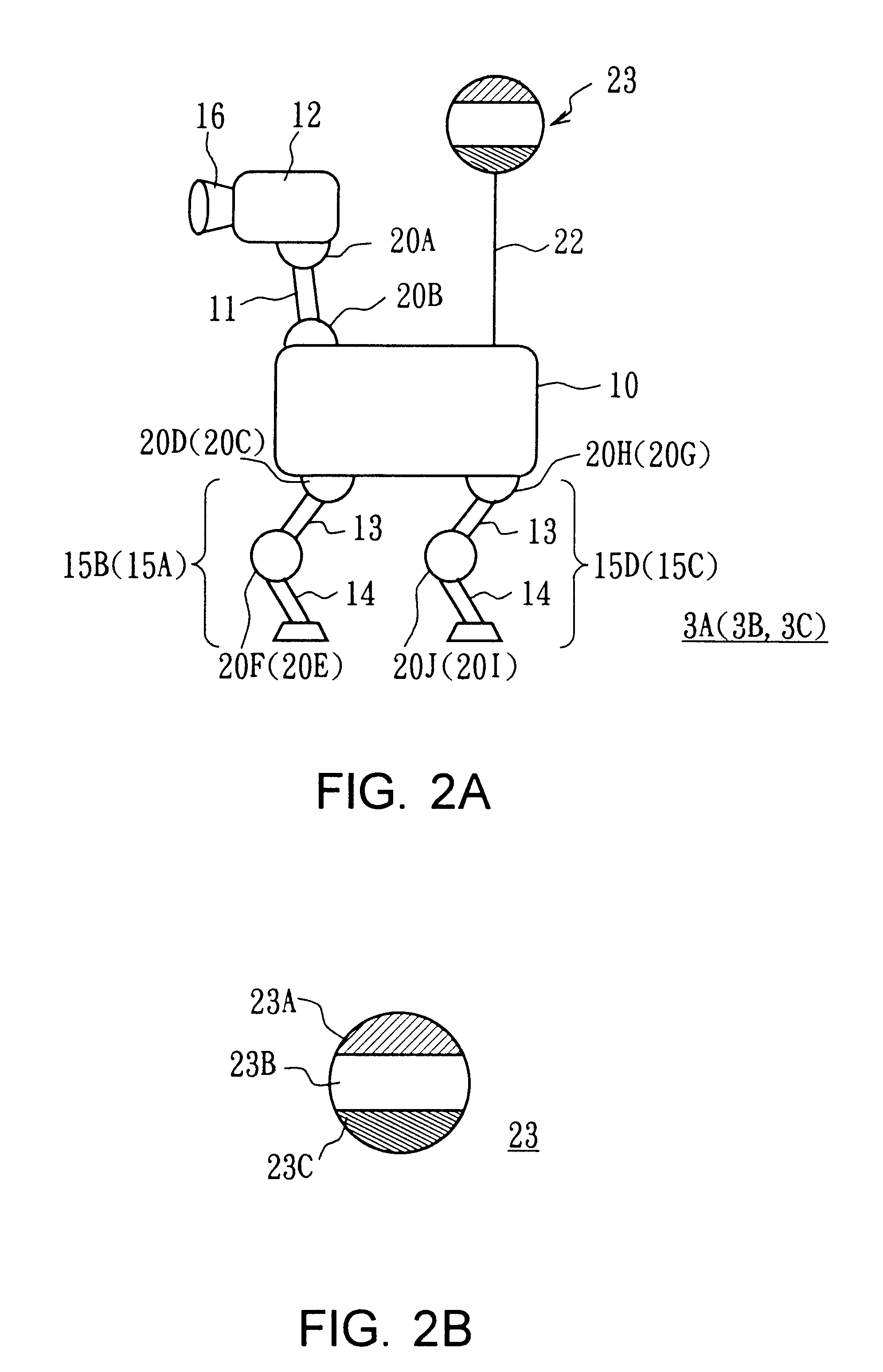

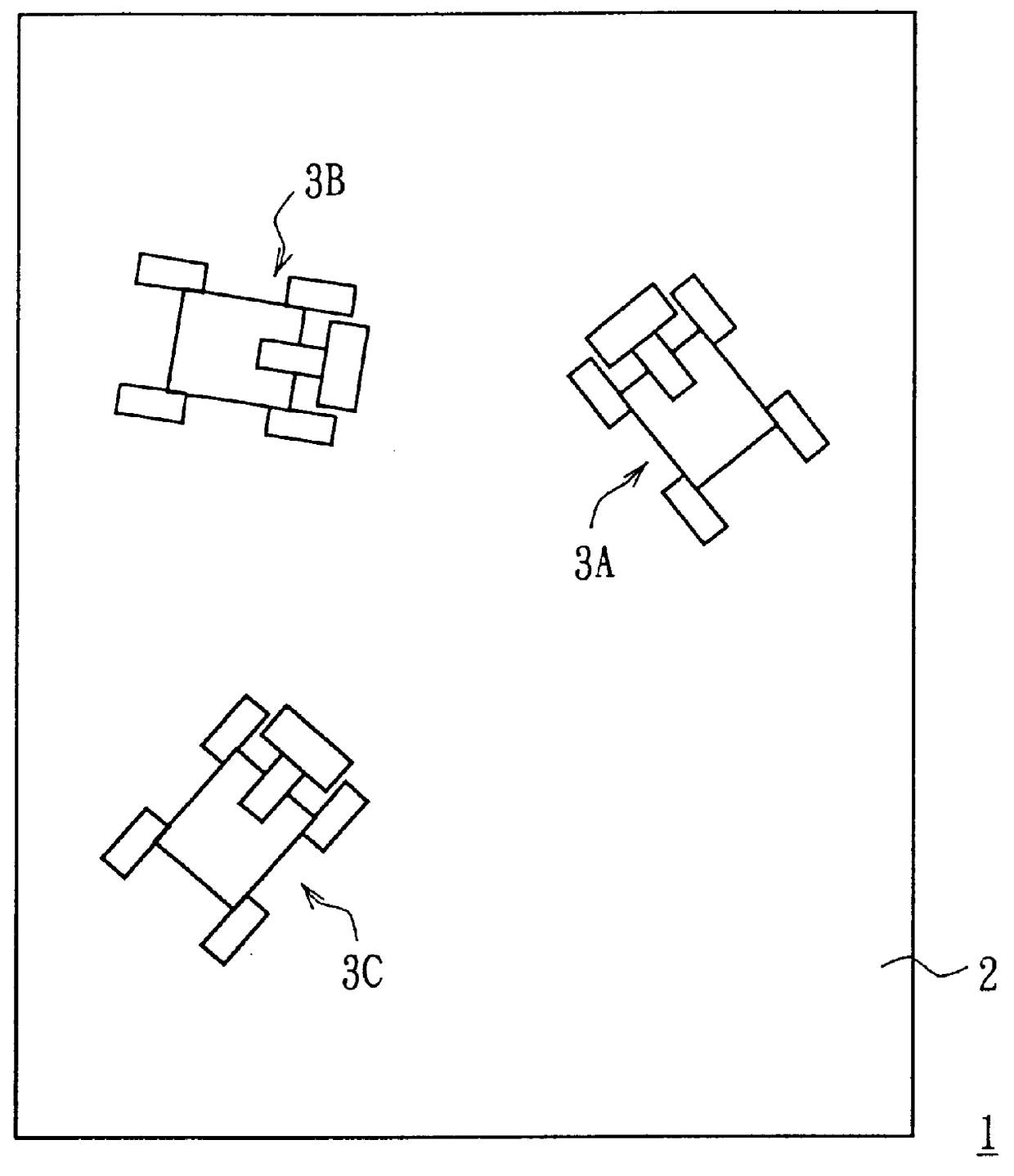

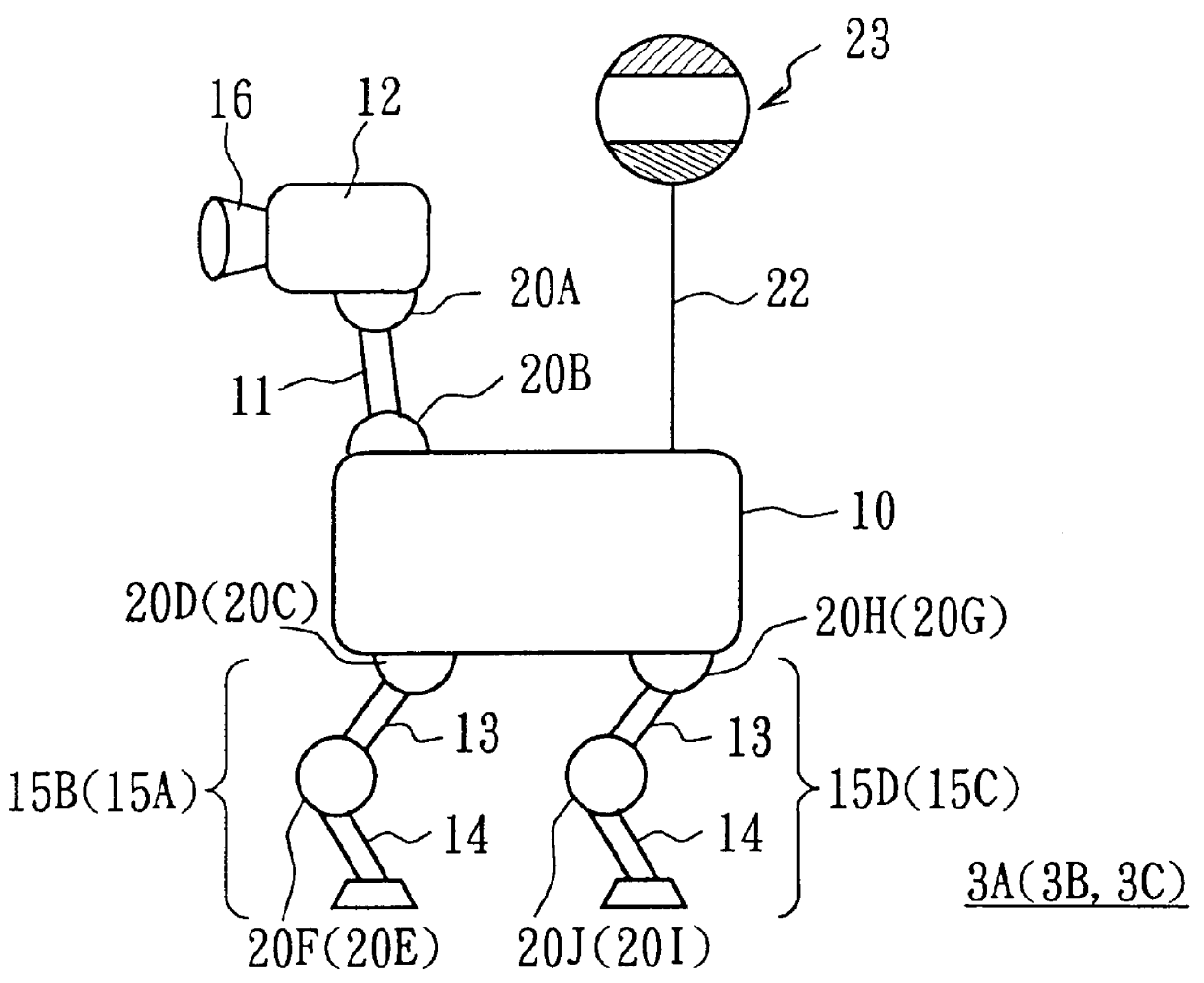

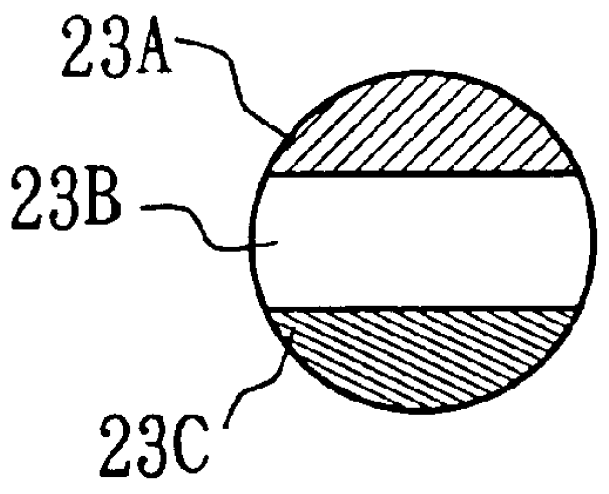

Identifying apparatus and method, position detecting apparatus and method, robot apparatus and color extracting apparatus

InactiveUS6453055B1Readily and reliably identifyLong lasting colorCharacter and pattern recognitionVehicle position/course/altitude controlLocation detectionPattern recognition

An identifying apparatus and method and a robot apparatus capable of reliably identifying other moving objects or other objects, a position detecting apparatus and method and a robot apparatus capable of accurately detecting the position of a moving object or itself within a region, and a color extracting apparatus capable of accurately extracting a desired color are difficult to be realized. Objects are provided with identifiers having different color patterns such that the color patterns are detected and identified through image processing. Also, the objects of interest are given color patterns different from each other, such that the position of the object can be detected by identifying the color pattern through image processing. Further, a plurality of wall surfaces having different colors are provided along the periphery of the region, such that the position of an object is detected on the basis of the colors of the wall surfaces through image processing. Further, a luminance level and color difference levels are sequentially detected for each of pixels to extract a color by determining whether or not the color difference levels are within a predetermined range.

Owner:SONY CORP

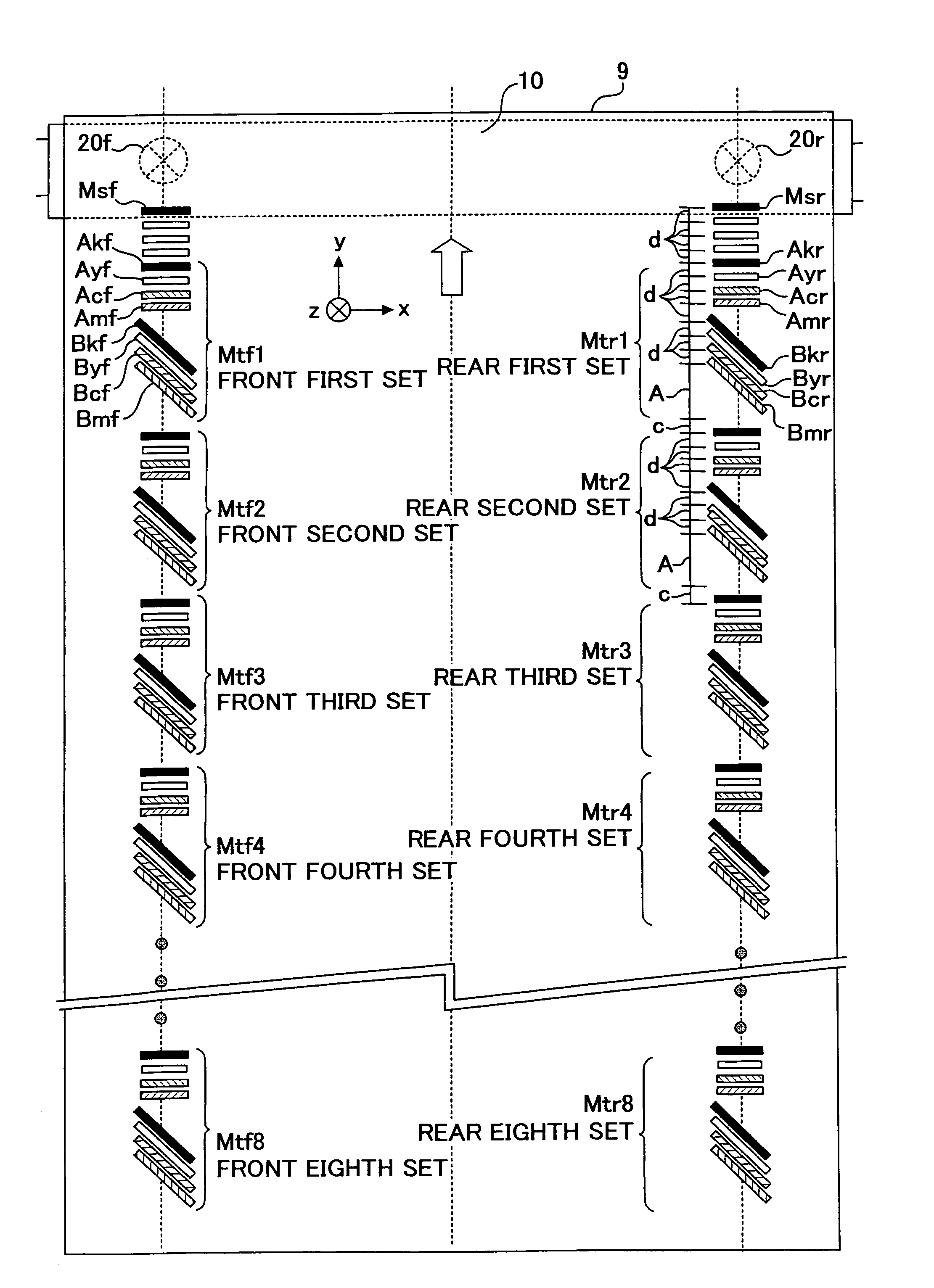

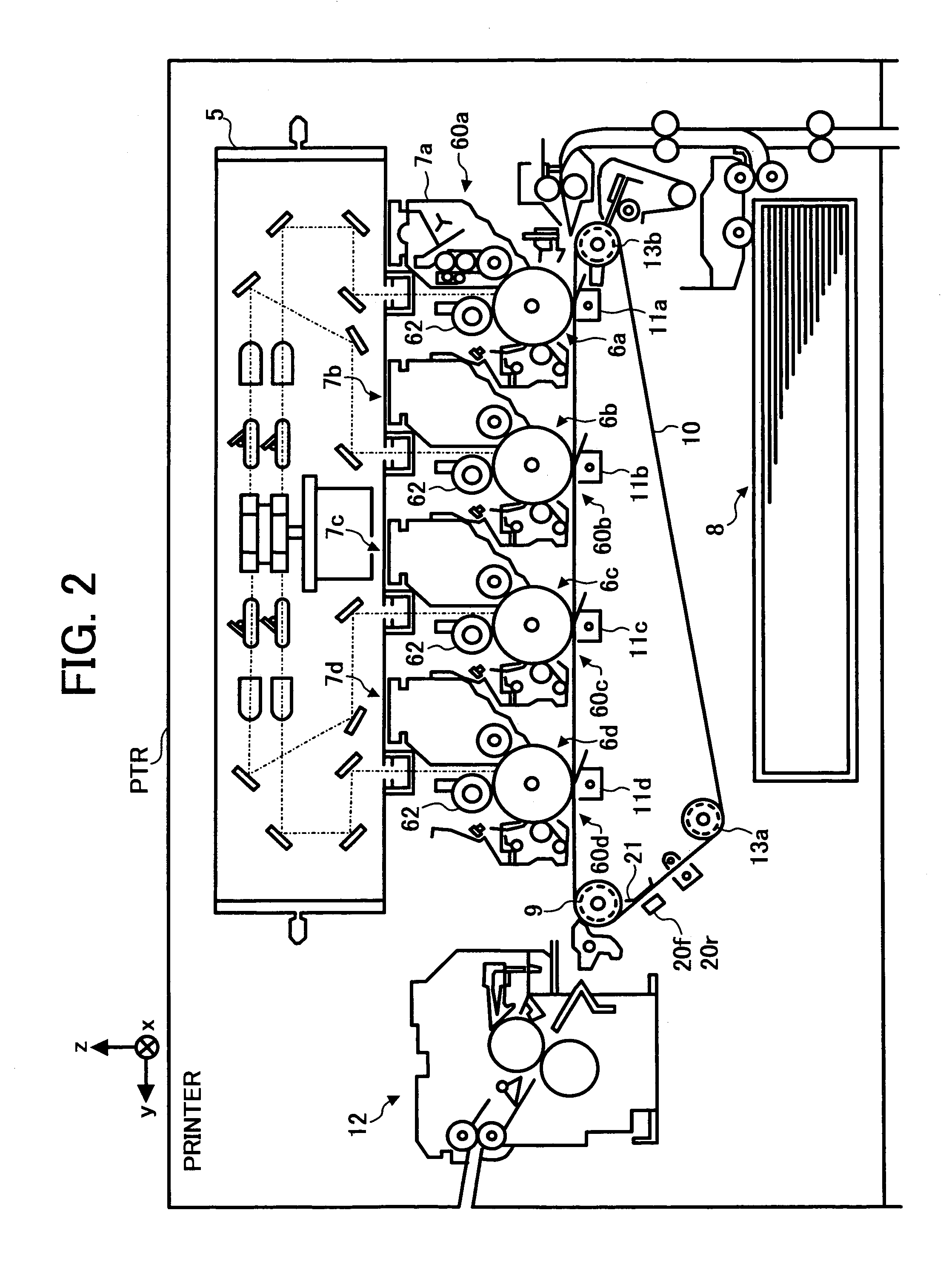

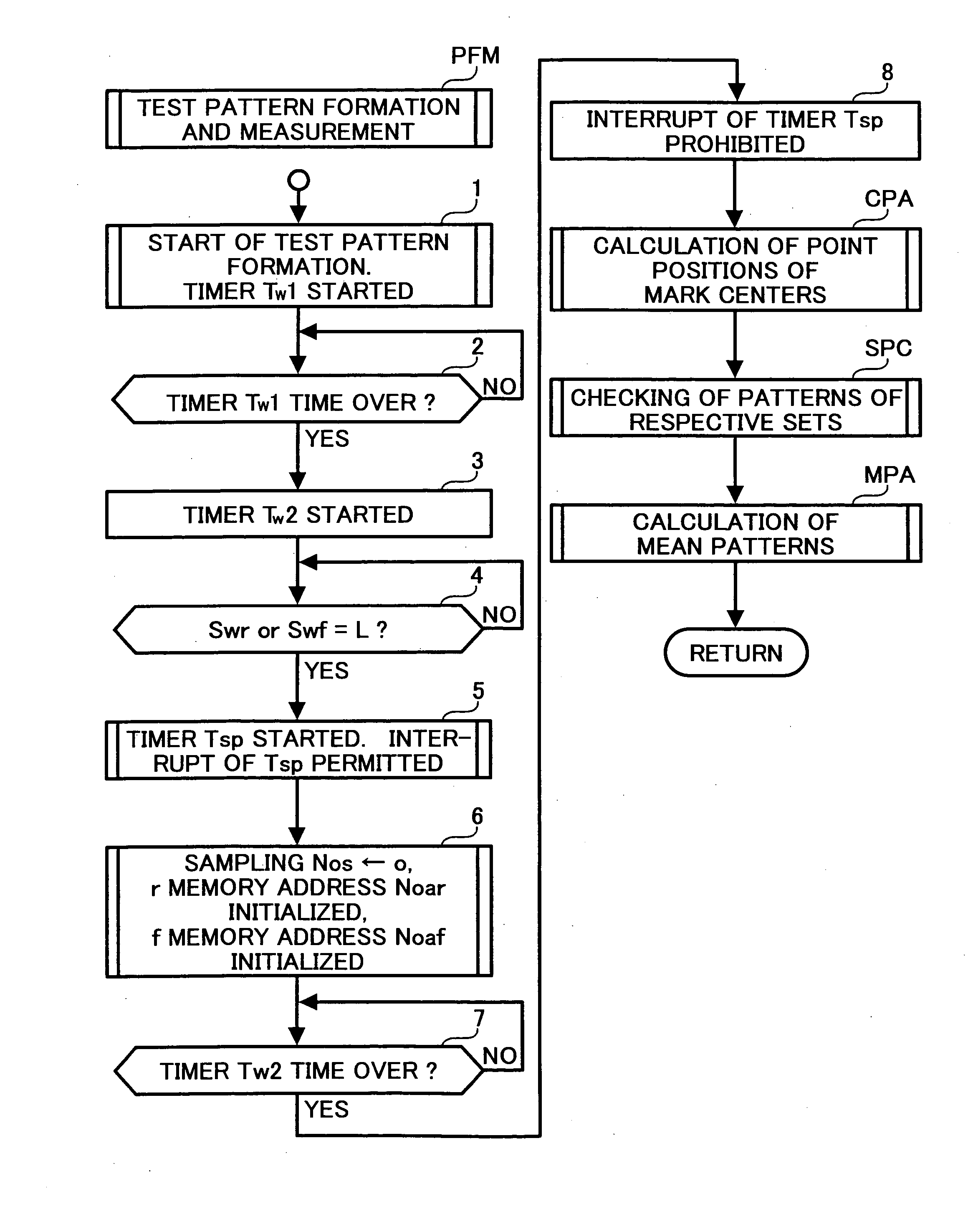

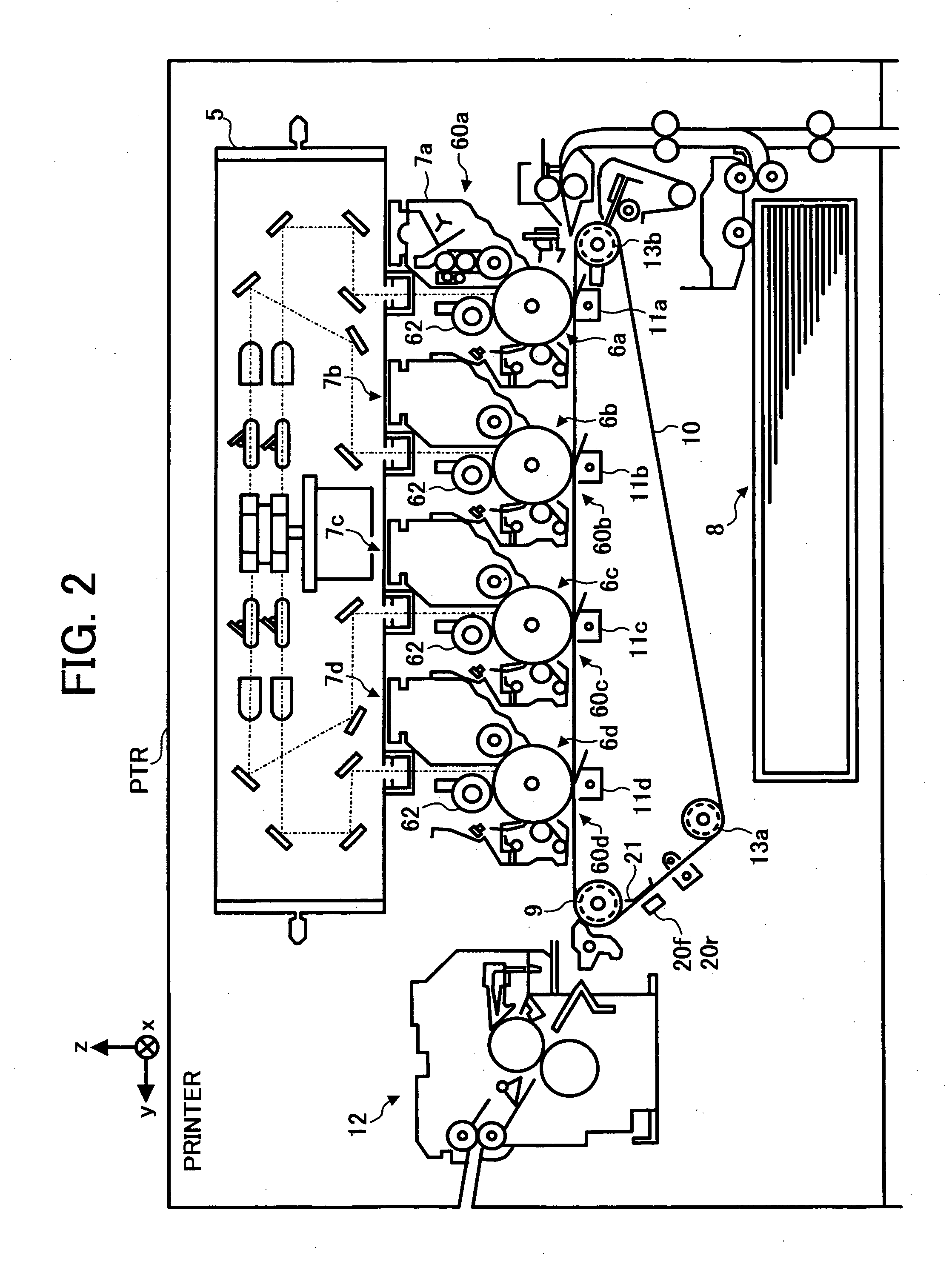

Color image forming device and color deviation detection device for the same

InactiveUS7130551B2Long lasting colorTrue colorElectrographic process apparatusPrintingColor imageCalculation error

A color deviation detection device for a color image forming device which prevents the occurrence of color deviation that is attributable to the fact that the precision of color deviation detection is low, the replacement of photosensitive bodies or developing devices is itself a cause of fluctuation in the color deviation, and the precision of the part before and after replacement is slightly different. In the color deviation detection device, the spacing between marks of the reference color and other colors, the spacing between marks of the same color and the spacing between mark sets are set as the spacing between marks within the mark sets and the spacing between mark sets, so that when the amount of color deviation is calculated for a synthesized wave comprising two or more driving irregularity frequencies that are generated by the image carrying body driving system and the transfer driving system, the calculation error caused by this synthesized wave is within a range that allows correction of the deviation of the image of a plurality of colors.

Owner:RICOH KK

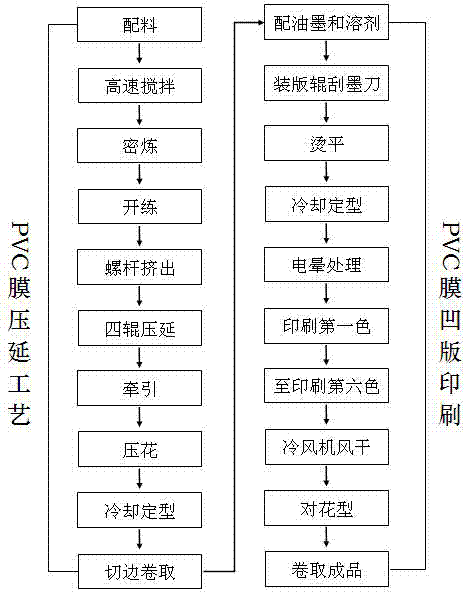

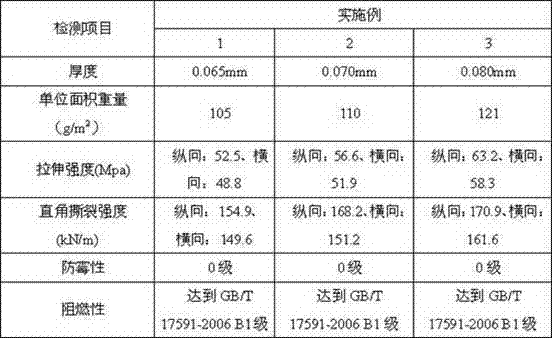

Semi-rigid PVC (polyvinyl chloride) decorative membrane

The invention relates to a semi-rigid PVC (polyvinyl chloride) decorative membrane. The semi-rigid PVC decorative membrane comprises the following main raw materials in parts by weight: 100 parts of PVC resin powder, 18-23 parts of plasticizer, 3-5 parts of stabilizer, 25-35 parts of calcium carbonate, 4-6 parts of flame retardant, 6-9 parts of titanium white, 2-4 parts of soybean oil and 0.1-0.3 part of mold preventive; and the semi-rigid PVC decorative membrane is prepared through a calendering stage and an intaglio printing stage. The product provided by the invention is thin and semi-rigid, can not bubble in case of being laminated with glass and other materials, and can prevent broken glass from splashing and falling when the glass is broken; the addition of the flame retardant and the mold preventive endows the product with high-efficiency flame-retardant and mold-resistant properties, and the flame-retardant property and the mold-resistant property can be respectively up to B1 level and 0 level; and the product has long color retention time and long service life, and can soften bright light, partition space, enhance privacy and create a mild atmosphere.

Owner:ZHEJIANG BOTAI PLASTIC

Identifying apparatus and method, position detecting apparatus and method, robot apparatus and color extracting apparatus

InactiveUS6088469AReadily and reliably identifyLong lasting colorCharacter and pattern recognitionVehicle position/course/altitude controlLocation detectionPattern recognition

An identifying apparatus and method and a robot apparatus capable of reliably identifying other moving objects or other objects, a position detecting apparatus and method and a robot apparatus capable of accurately detecting the position of a moving object or itself within a region, and a color extracting apparatus capable of accurately extracting a desired color are difficult to be realized. Objects are provided with identifiers having different color patterns such that the color patterns are detected and identified through image processing. Also, the objects of interest are given color patterns different from each other, such that the position of the object can be detected by identifying the color pattern through image processing. Further, a plurality of wall surfaces having different colors are provided along the periphery of the region, such that the position of an object is detected on the basis of the colors of the wall surfaces through image processing. Further, a luminance level and color difference levels are sequentially detected for each of pixels to extract a color by determining whether or not the color difference levels are within a predetermined range.

Owner:SONY CORP

Color imgae forming device and color deviation detection device for the same

InactiveUS20050031361A1Long lasting colorTrue colorElectrographic process apparatusPrintingColor imageCalculation error

A color deviation detection device for a color image forming device which prevents the occurrence of color deviation that is attributable to the fact that the precision of color deviation detection is low, the replacement of photosensitive bodies or developing devices is itself a cause of fluctuation in the color deviation, and the precision of the part before and after replacement is slightly different. In the color deviation detection device, the spacing between marks of the reference color and other colors, the spacing between marks of the same color and the spacing between mark sets are set as the spacing between marks within the mark sets and the spacing between mark sets, so that when the amount of color deviation is calculated for a synthesized wave comprising two or more driving irregularity frequencies that are generated by the image carrying body driving system and the transfer driving system, the calculation error caused by this synthesized wave is within a range that allows correction of the deviation of the image of a plurality of colors.

Owner:RICOH KK

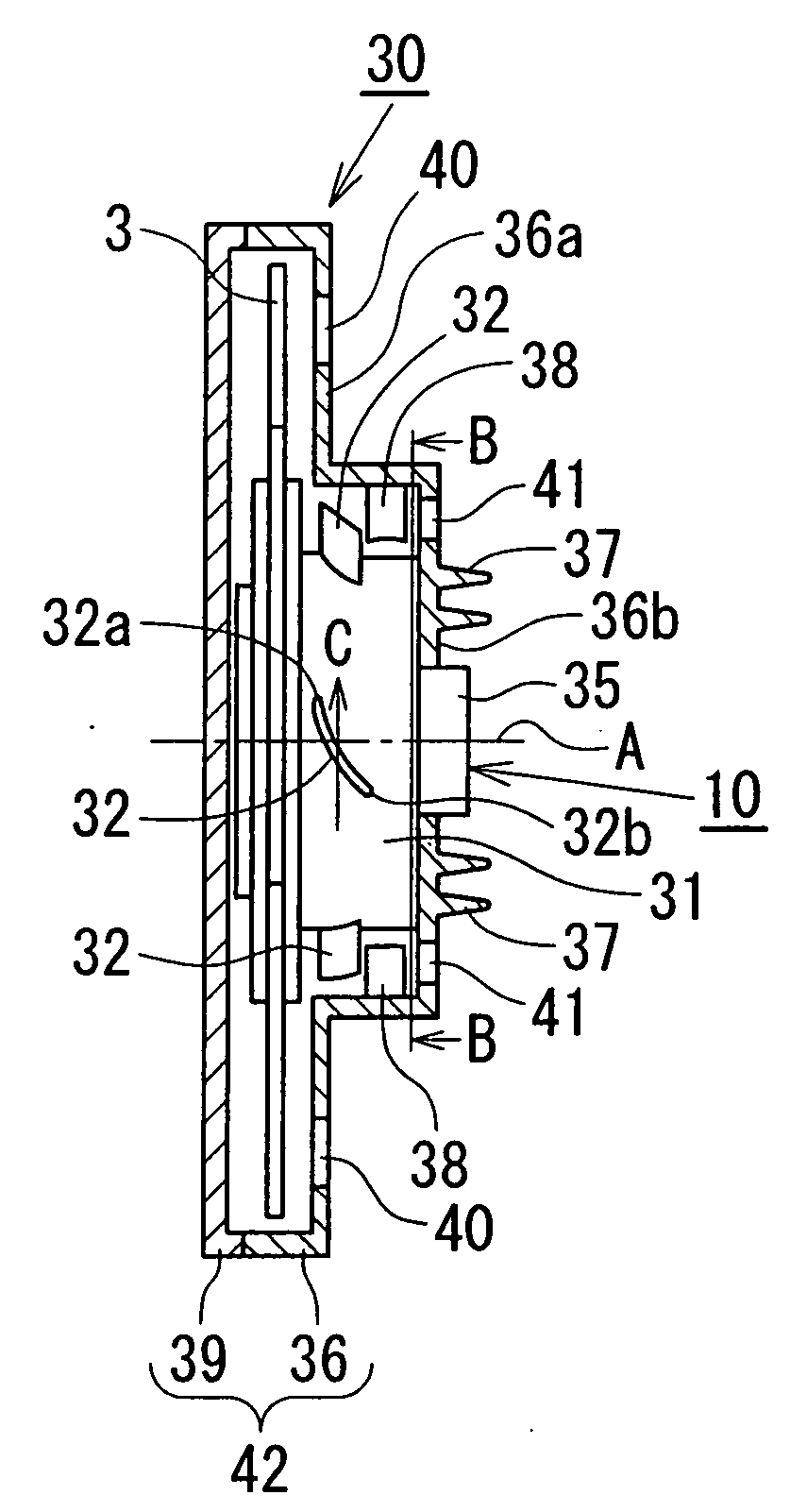

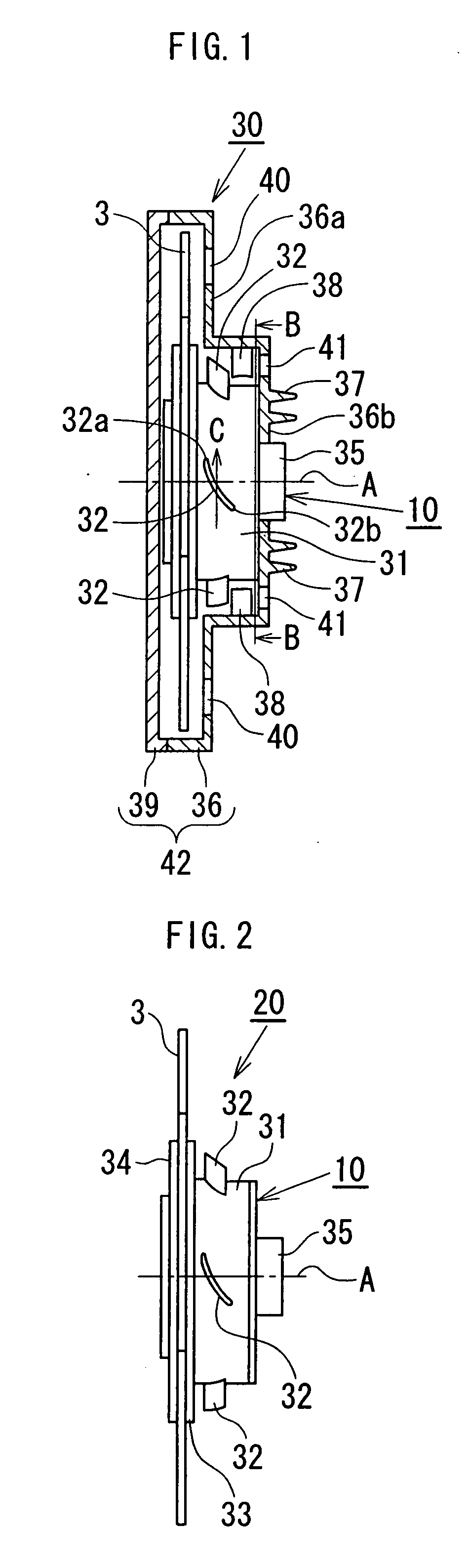

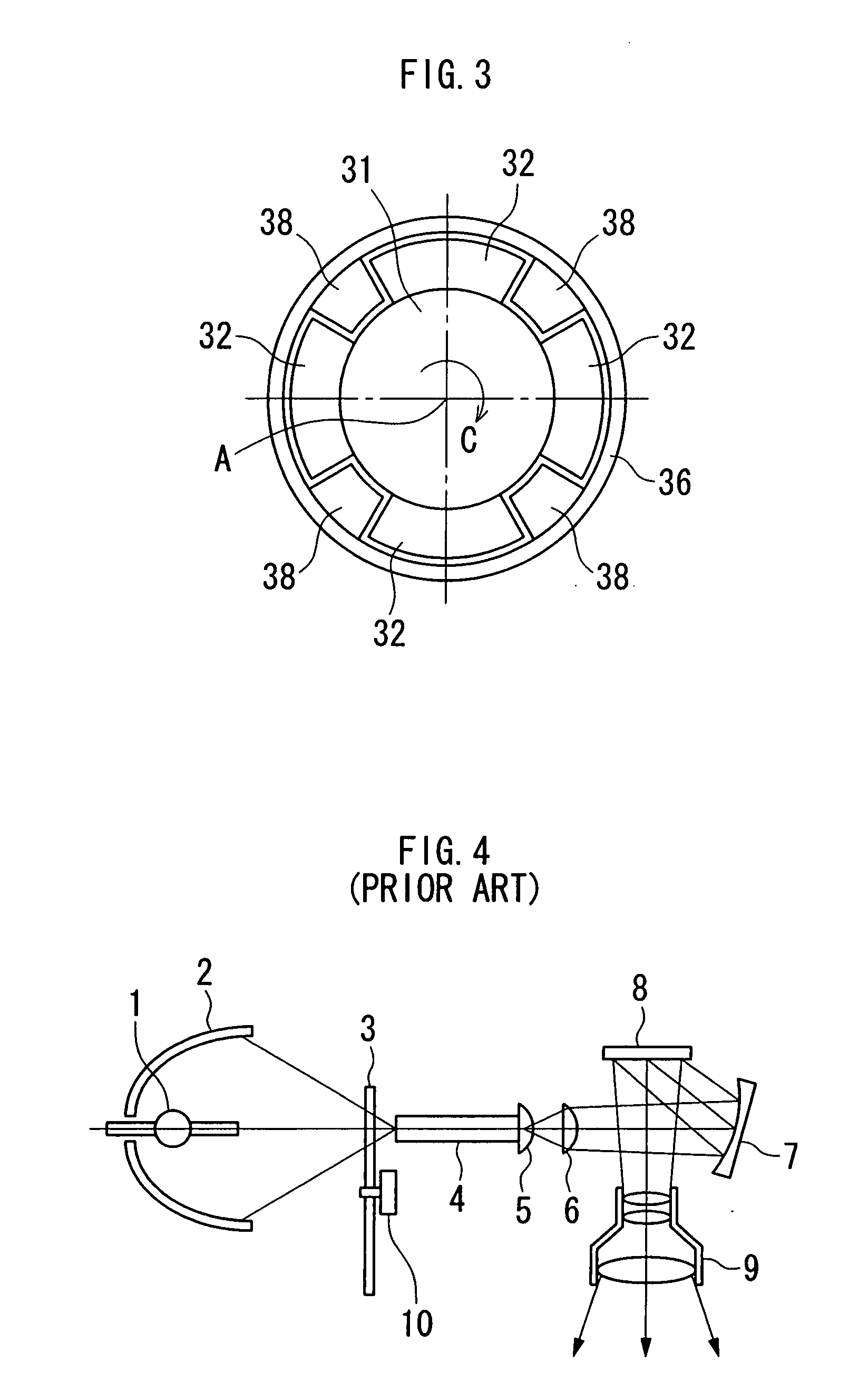

Color wheel unit

A color wheel unit includes: a color wheel including a plurality of color regions; a motor adapted to rotate the color wheel and including a rotor with a rotary shaft; and a case adapted to house the color wheel and the motor and including a heat radiating means disposed at the outer surface of the case. In the color wheel unit, a first protrusion structure extending radially outwardly is disposed at the outer circumferential surface of the rotor, and a second protrusion structure extending radially inwardly is disposed at the inner surface of the case, wherein the projection area of the second protrusion structure on the plane orthogonal to the rotary shaft of the rotor is overlapped at least partly with the projection area of the first protrusion structure on the plane orthogonal to the rotary shaft of the rotor.

Owner:MINEBEA CO LTD

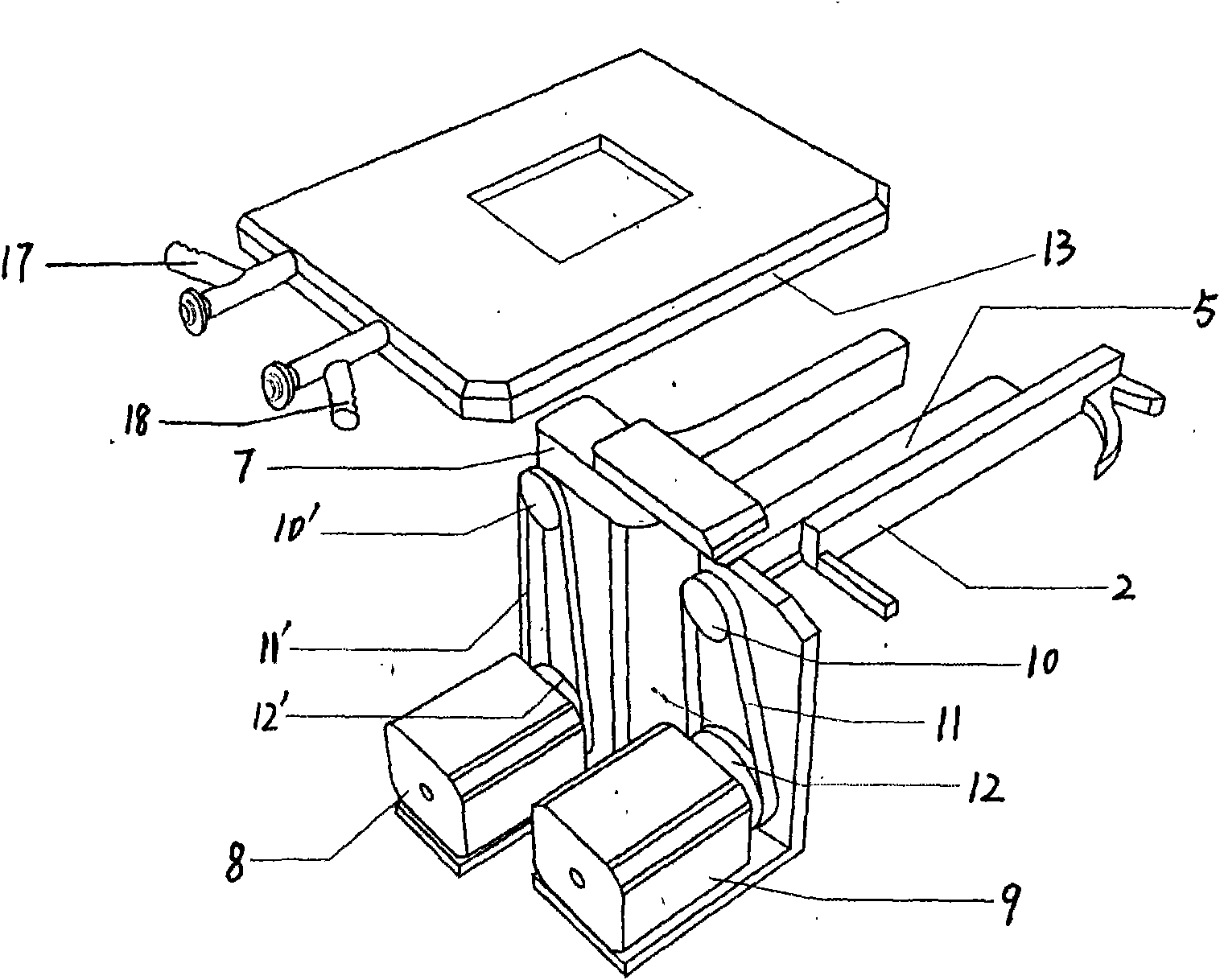

Methods for determining optical characteristics of dental objects

InactiveUS7244122B2Minimal problemMinimizing heightEmission spectroscopyTeeth fillingFiberFluorescence

Owner:RPX CORP +1

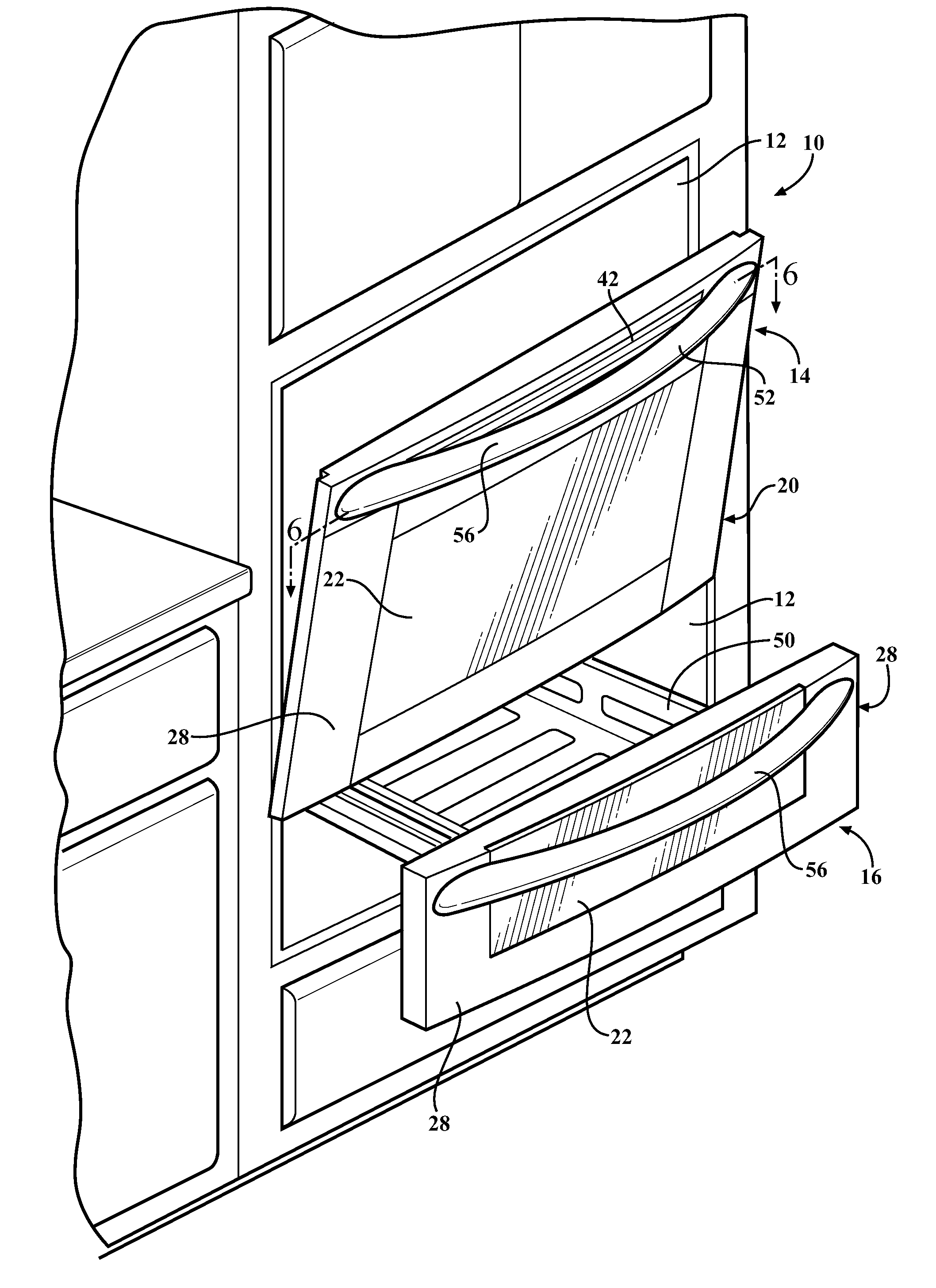

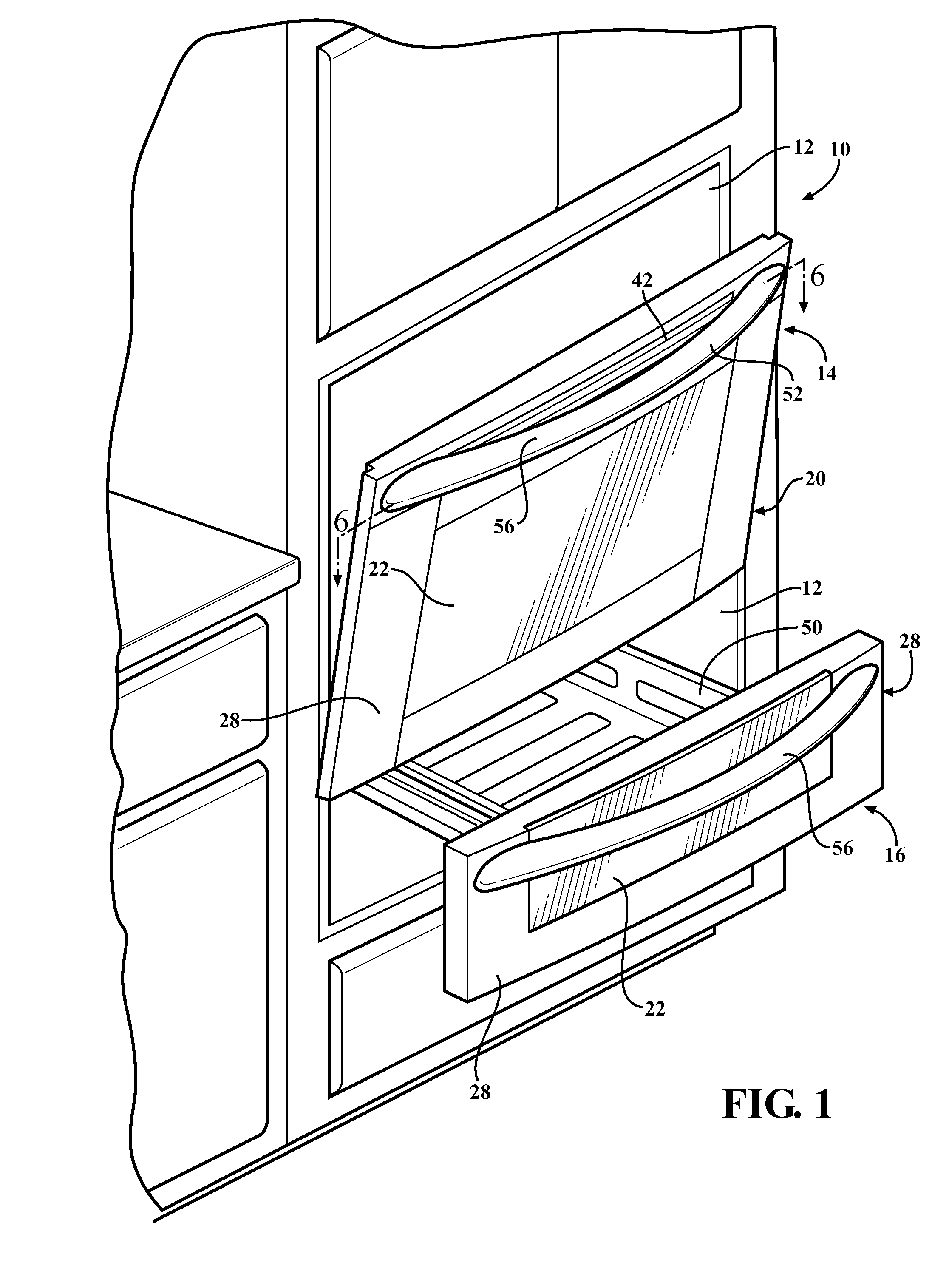

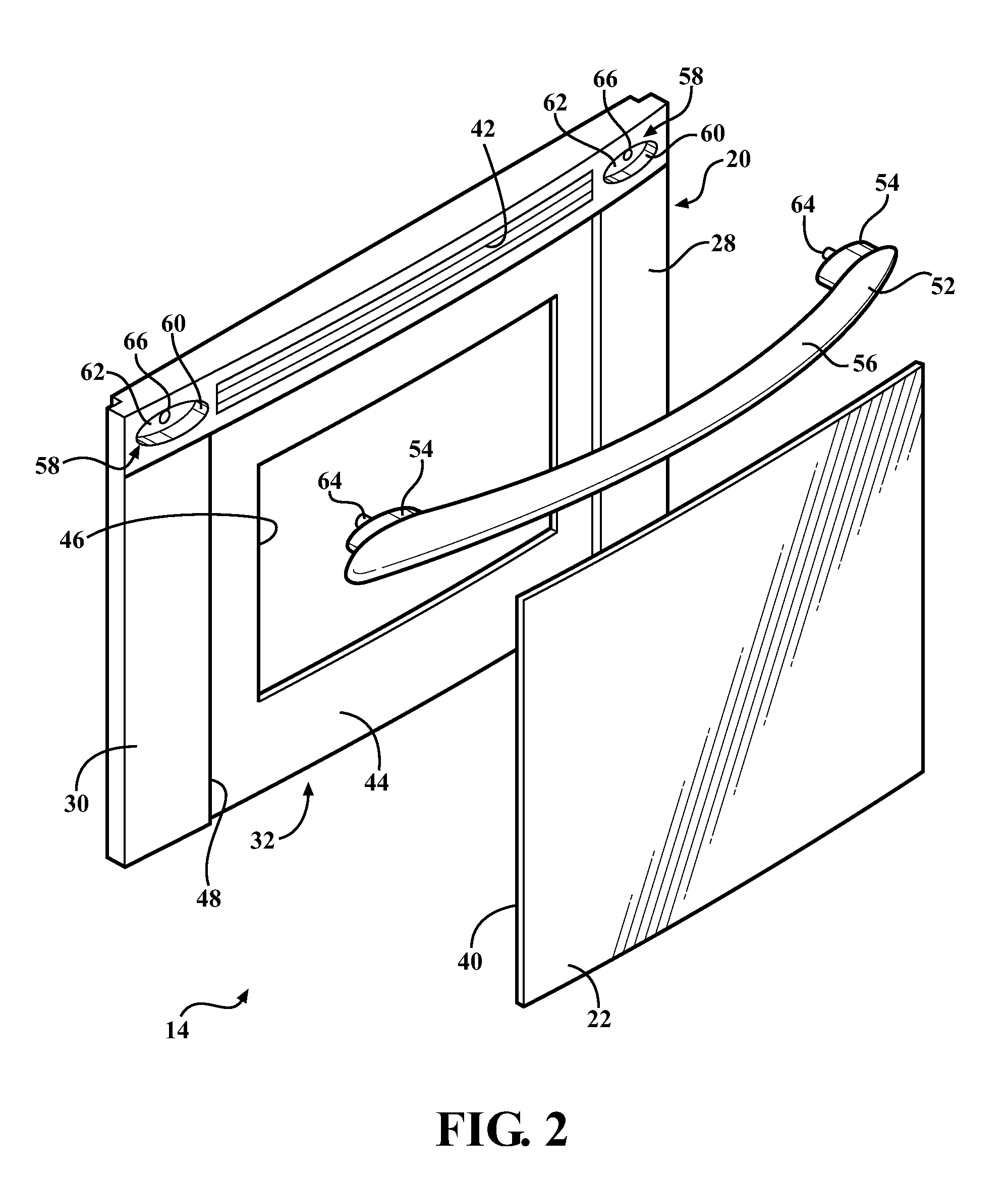

Oven door

InactiveUS20120031389A1Decreasing and eliminating secondary assembly stepReduce the amount requiredDomestic stoves or rangesDoors for stoves/rangesEngineeringGlass sheet

An oven door includes an interior panel and an exterior panel. The interior panel faces the heating chamber and has a glass sheet for viewing the heating chamber. The exterior panel is affixed to the interior panel and includes a frame portion formed of plastic defining an aperture aligned with the glass sheet for viewing the heating chamber. A non-opaque panel is fixed relative to the frame portion and extends across the aperture. The non-opaque panel has an inside surface facing the interior panel and the exterior panel has a masking portion formed of plastic and integrally formed with the frame portion. The masking portion extends from the frame portion into the aperture along the inside surface of the non-opaque panel and defines a window for viewing the heating chamber through the glass sheet.

Owner:BASF AG

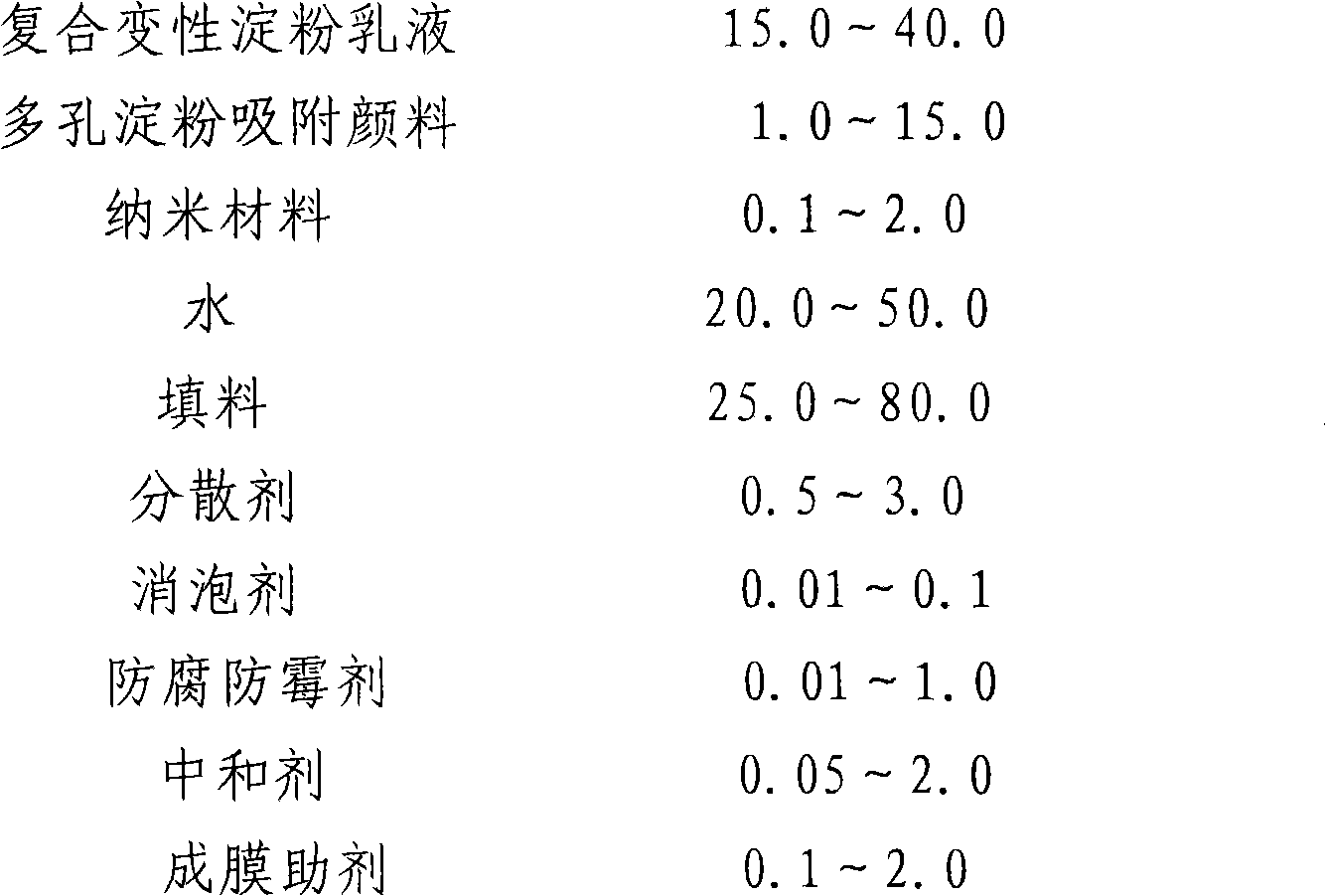

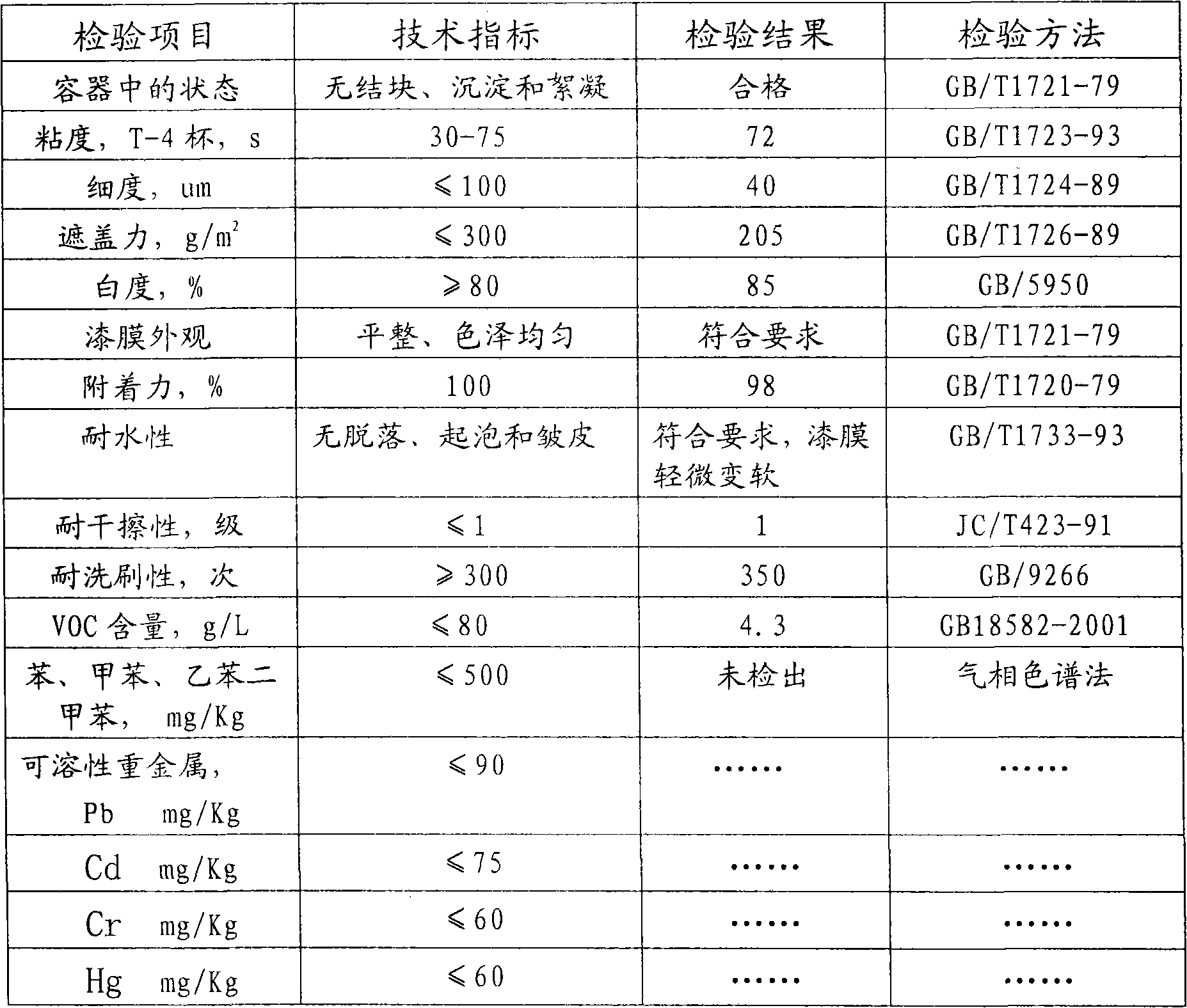

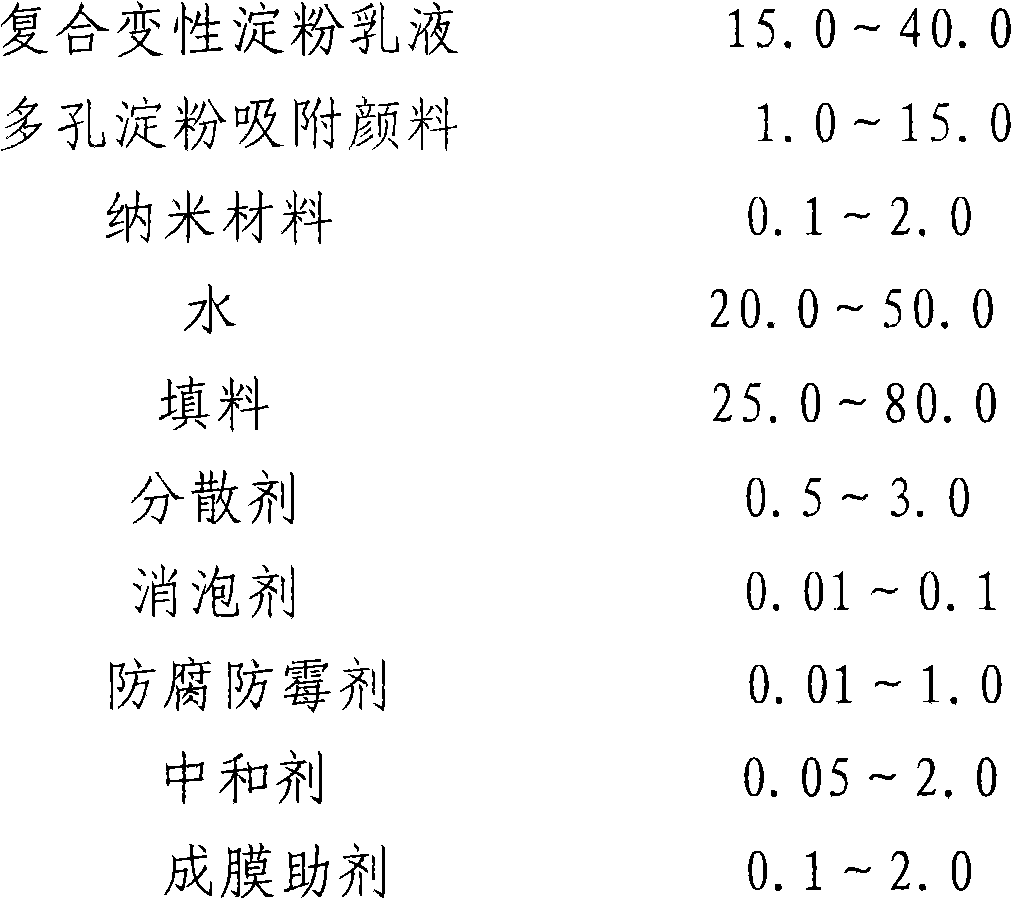

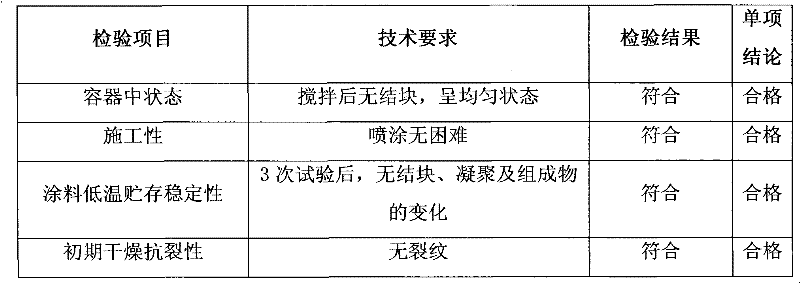

Composite modified starch environmentally-friendly interior wall coating and preparation method thereof

ActiveCN102321410AEnvironmentally friendlyLong-lasting colorStarch dervative coatingsEmulsionEnvironmental resistance

The invention discloses a method for preparing a corn pregelatinization oxidative cross-linking starch environmentally-friendly interior wall coating which is mainly prepared from the following components: corn pregelatinization oxidative cross-linking starch emulsion, nano materials, porous starch absorption pigments, a filler, a dispersion agent, a defoaming agent, an anticorrosion mildew inhibitor, a neutralizer, a filming-forming adjuvant and water. The preparation method comprises the following steps: (1) the preparation of the corn pregelatinization oxidative cross-linking starch; (2) the preparation of the corn pregelatinization oxidative cross-linking starch emulsion; (3) the preparation of porous starch; (4) the preparation of the porous starch absorption pigments; and (5) the preparation of the corn pregelatinization oxidative cross-linking starch interior wall coating material. According to the invention, starch is modified, because the corn pregelatinization oxidative cross-linking starch emulsion and the porous starch absorption pigments are utilized, the prepared coating products have no pollution and are environmentally-friendly, and the color is more endurable and shining; and by adopting a technology of adding nano materials, the performances of the coating material, such as impact resistance, adhesive attraction, aging resistance, corrosion resistance, ultraviolet resistance and the like are improved greatly.

Owner:GANSU GLDARK NEW MATERIAL +1

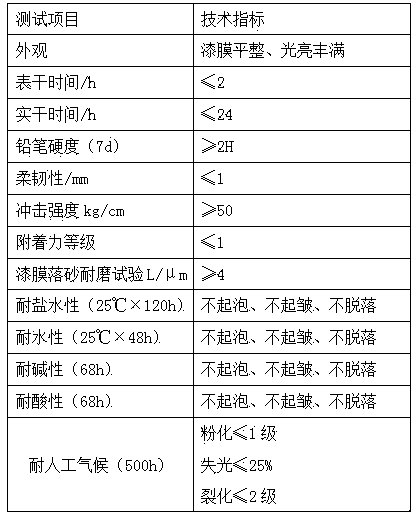

Corrosion proof impregnating varnish used for water-based metal components and manufacturing method thereof

ActiveCN101560351ALong-lasting colorHigh hardnessAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

The invention discloses a corrosion proof impregnating varnish used for water-based metal components and a manufacturing method thereof. The corrosion proof impregnating varnish is made of de-ionized water, propanediol, dispersant, antifoaming agent, wetting agent, carbon black, iron oxide black, water borne acroid resin, water borne epoxy resin, dipropylene glycol butyl ether, propylene glycol ether and polyaniline water solution, polyaniline carrier particles or polyaniline emulsion. The manufacturing method comprises: the propanediol and the de-ionized water are mixed and stirred, and then added with the dispersant, the antifoaming agent, the wetting agent and the polyaniline water solution or the water solution of emulsion or carrier particles to be evenly mixed together; the carbon black and the iron oxide black are added in to the mixed solution to form uniform pigment paste which is then put into a blending tank after being ground to be evenly stirred; the obtained mixture is added with the water borne acroid resin, the water borne epoxy resin, the dipropylene glycol butyl ether and the propylene glycol ether to be stirred; finally, the stirred mixture is added with the de-ionized water to be diluted and ground. The invention has the advantages of high coating efficiency, stable coating quality, uniform paint film of dip coating, flat and smooth paint film, good hardness, strong adhesive attraction, good corrosion proof performance, excellent painting performance at edges and corners, no leaking painting, good salt mist resistance, environmental protection, low cost, etc.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

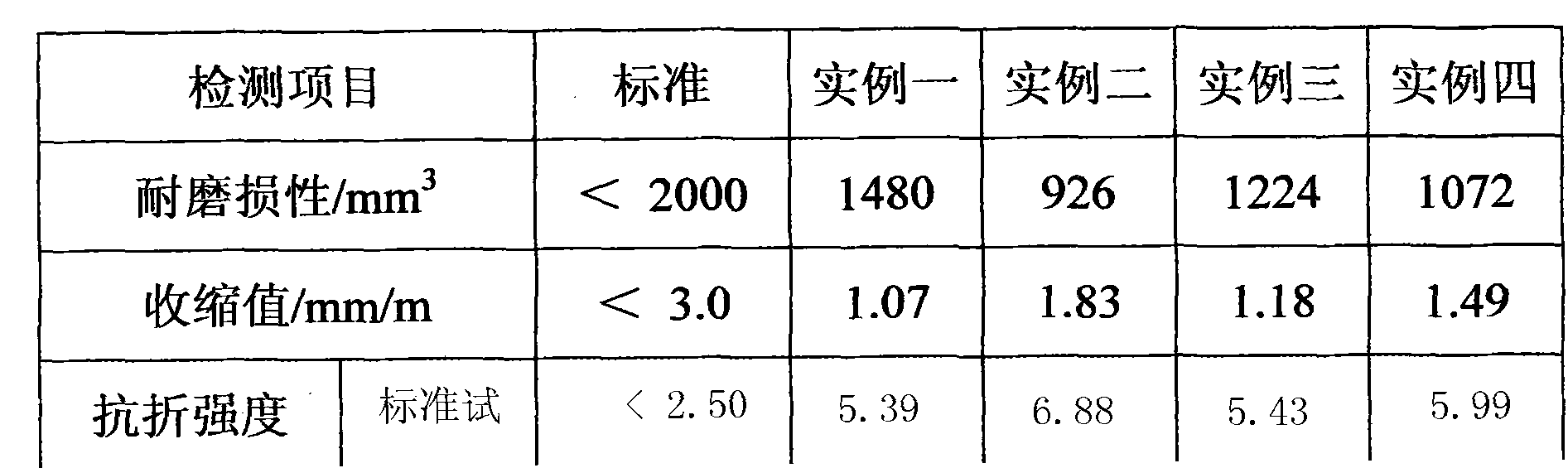

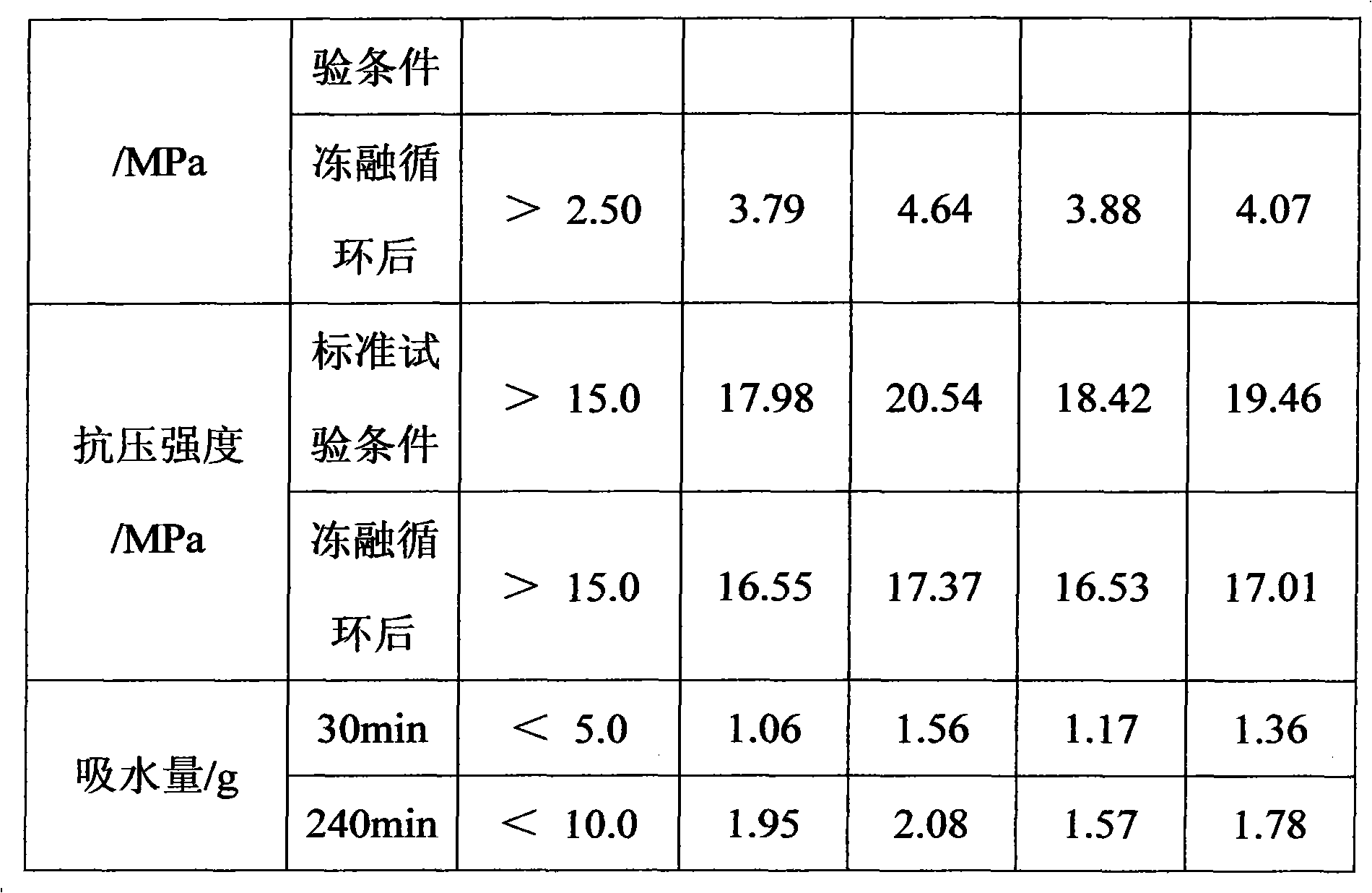

Colorful ceramic tile joint mixture and preparation technology thereof

InactiveCN102167554ALong-lasting colorImprove hydrophobicityCrack resistanceHydroxypropylmethyl cellulose

The invention relates to a colorful ceramic tile joint mixture which comprises the raw materials based on weight percentage as follows: 35%-50% of white portland cement, 45%-60% of quartz powder, 0.05%-0.3% of hydroxypropyl carboxymethyl hydroxypropyl cellulose, 0.055-0.25% of water repellent and 1%-3% of pigment. After the colorful ceramic tile joint mixture is used, the constructability is greatly improved, the deformability is improved, the water resistance is realized, the compactedness is increased, the cracking resistance is improved, and the color is more durable and gorgeous.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +2

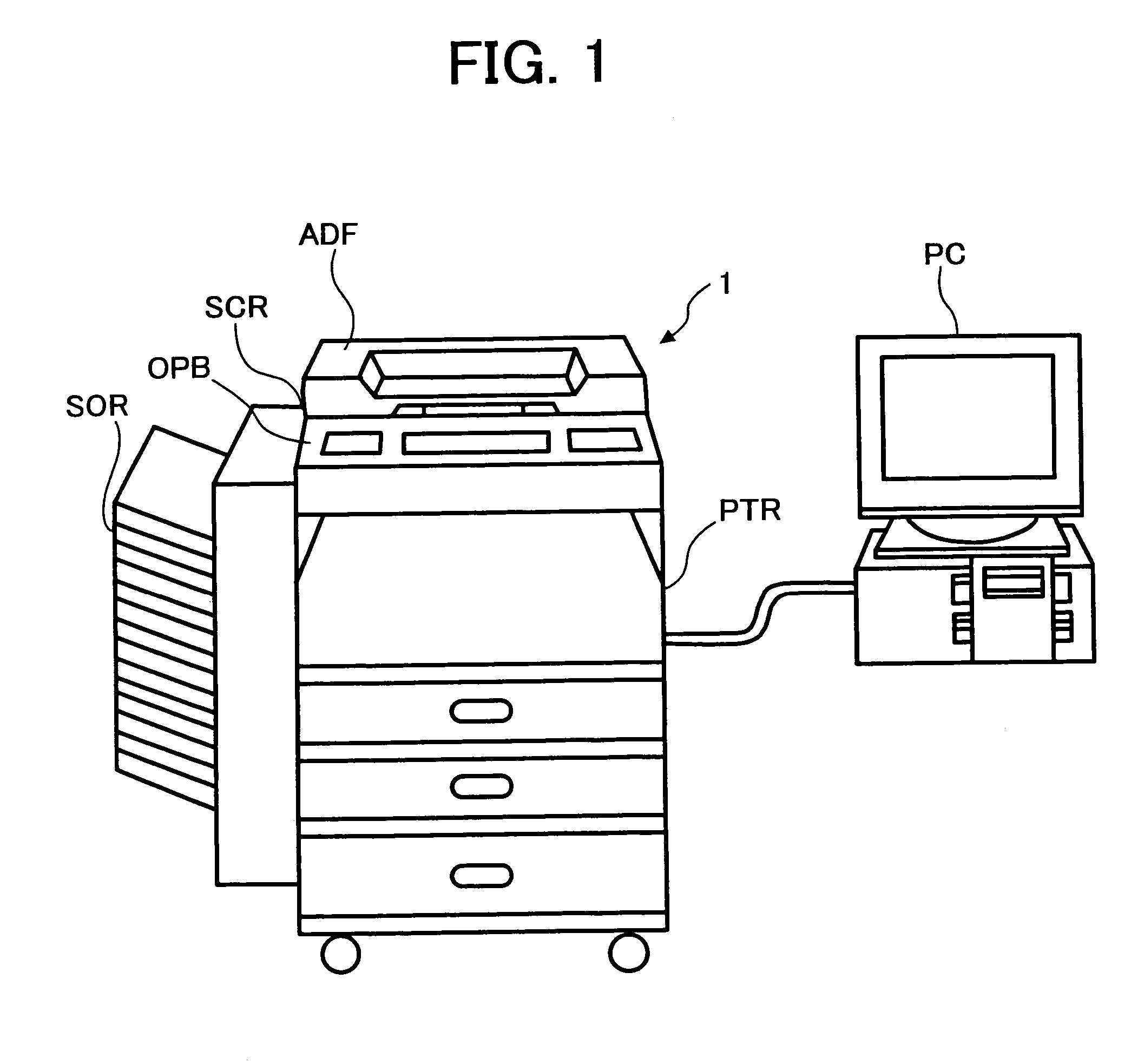

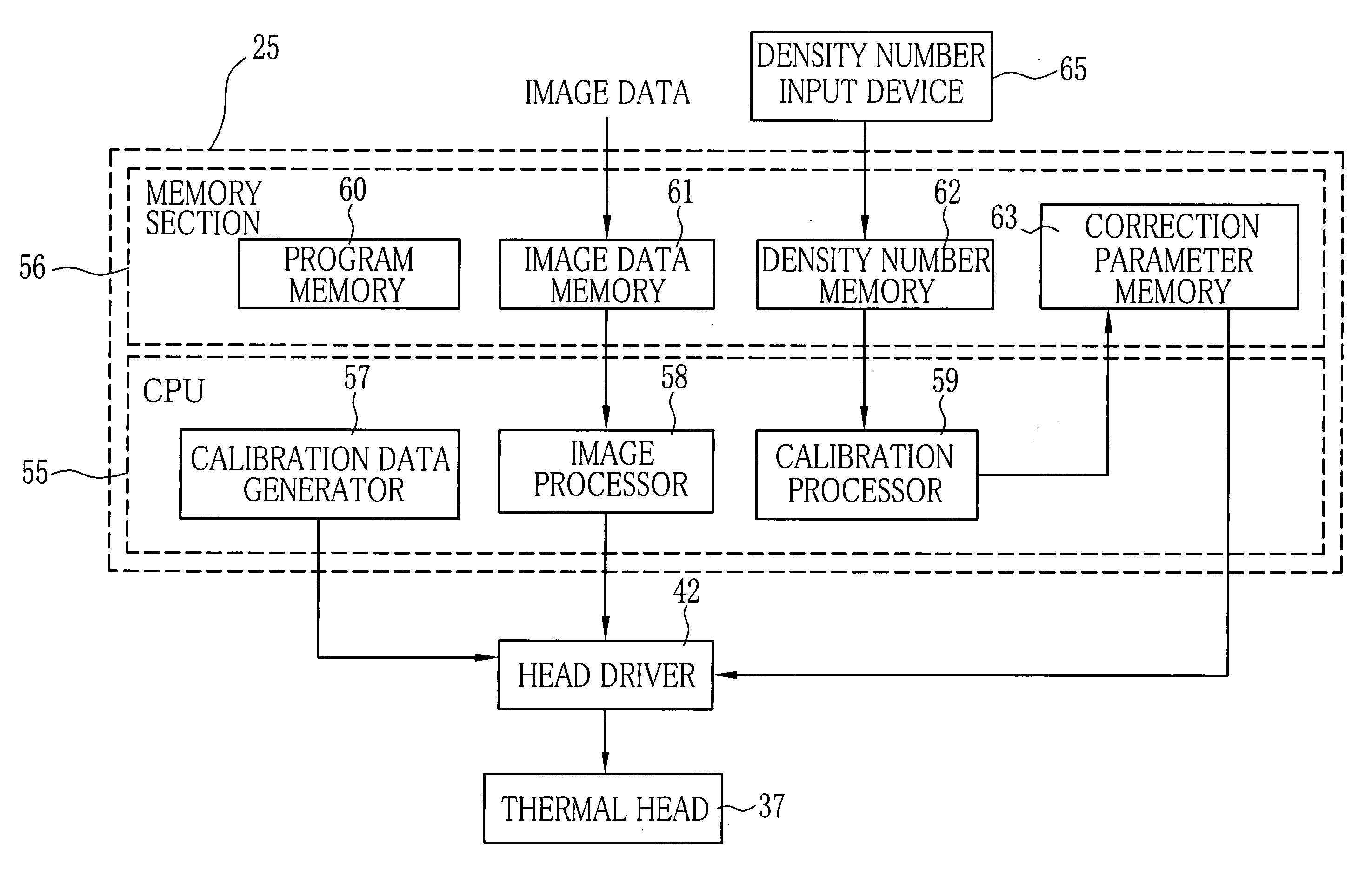

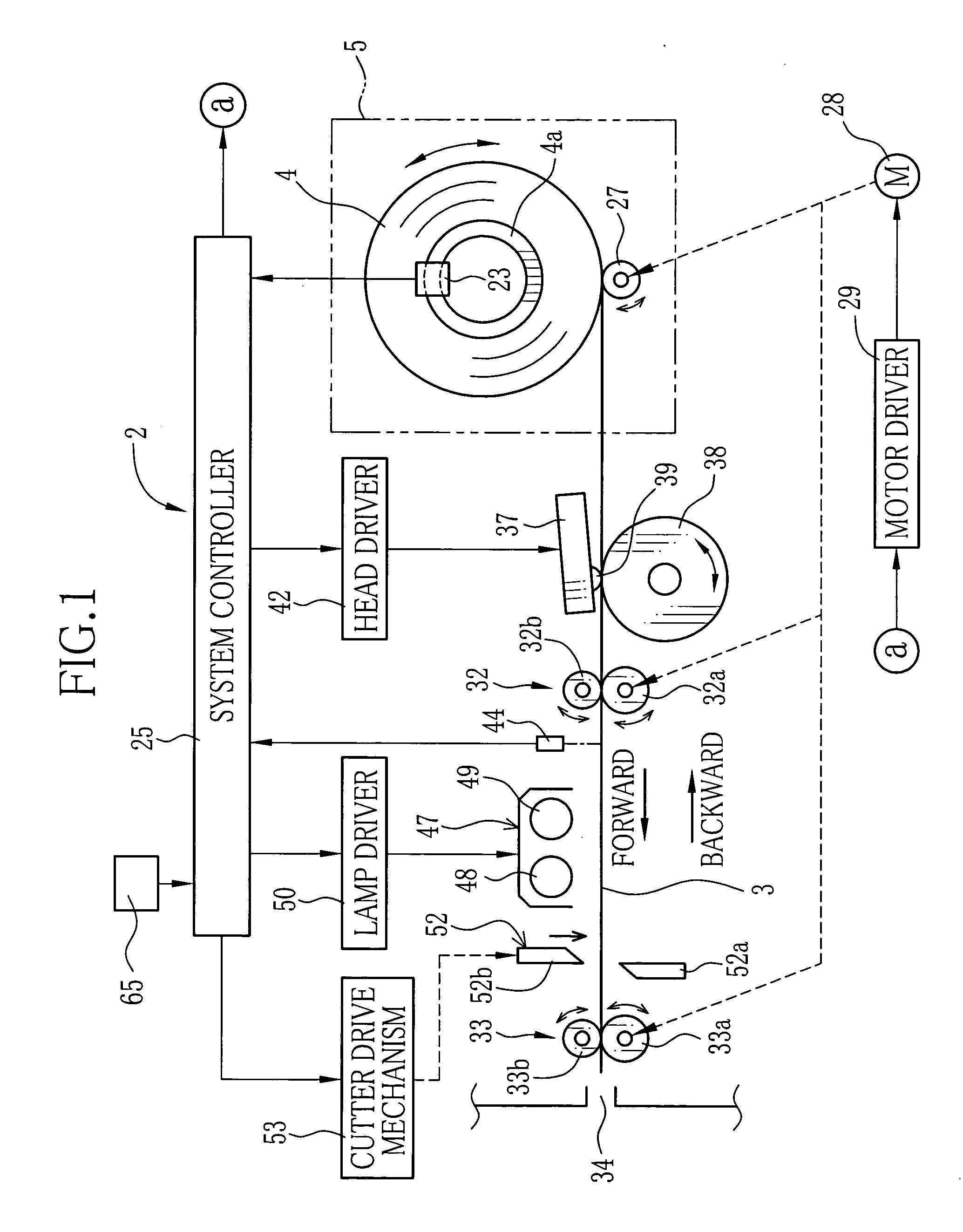

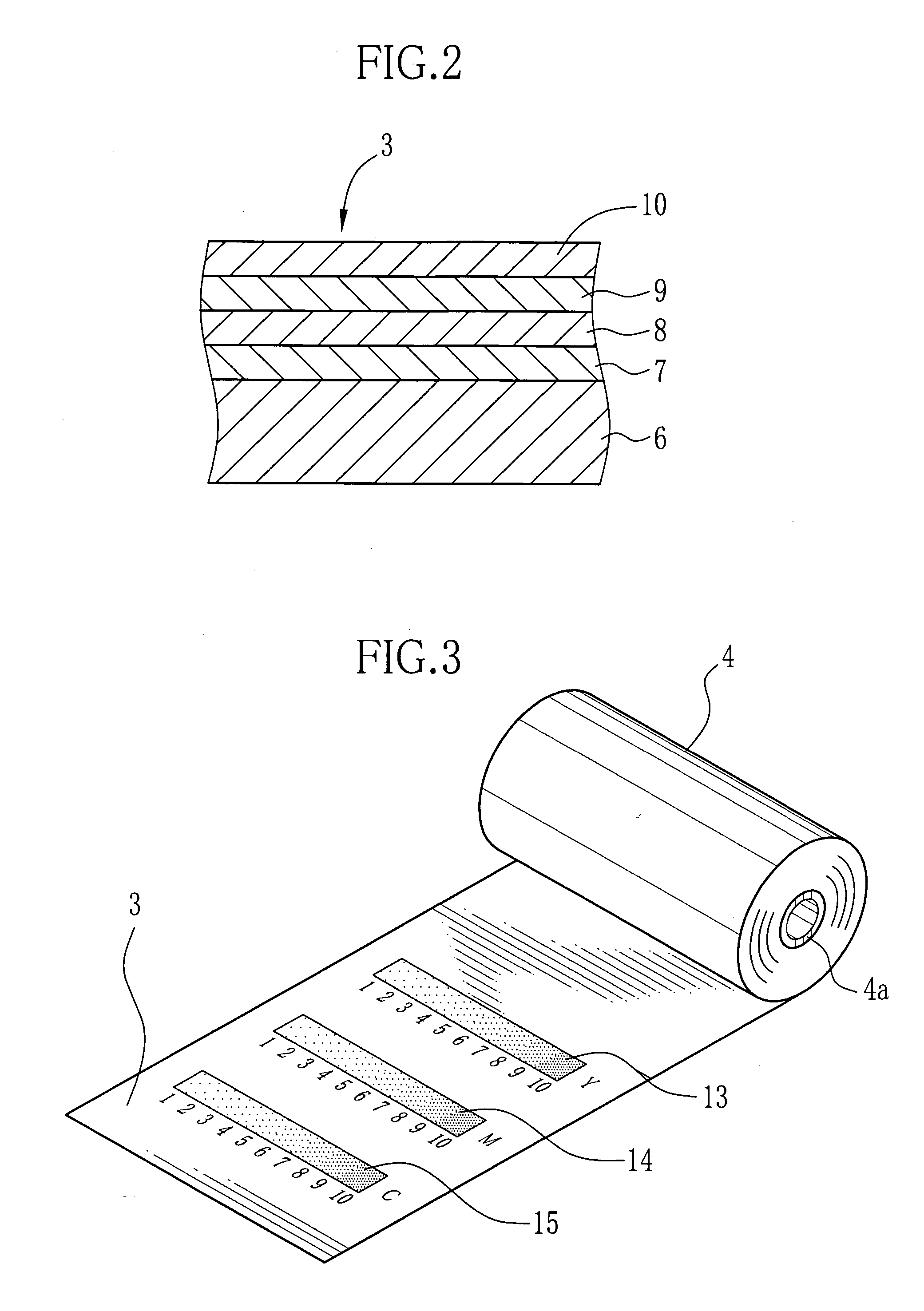

Printer calibration method, printer and recording material

InactiveUS20050105112A1Easy to manufactureCalibration can be slowDigitally marking record carriersDigital computer detailsPattern recognitionComputer printing

Yellow reference patterns, magenta reference patterns and cyan reference patterns are printed as a gradation scale of each color on a leading end of a long web of color heat sensitive recording paper in the factory. Respective density grades of each color are indicated by density numbers. Yellow, magenta and cyan calibration patterns are printed by a color thermal printer to calibrate, at a constant density on the recording paper adjacently to the reference patterns of the corresponding colors. The user compares the calibration pattern of each color to the reference patterns of the corresponding color, to determine the density grade of the actual density of the calibration pattern. By entering the density number of the determined density grade for each color, the color thermal printer automatically corrects three color densities on the basis of the entered density numbers.

Owner:FUJIFILM HLDG CORP +1

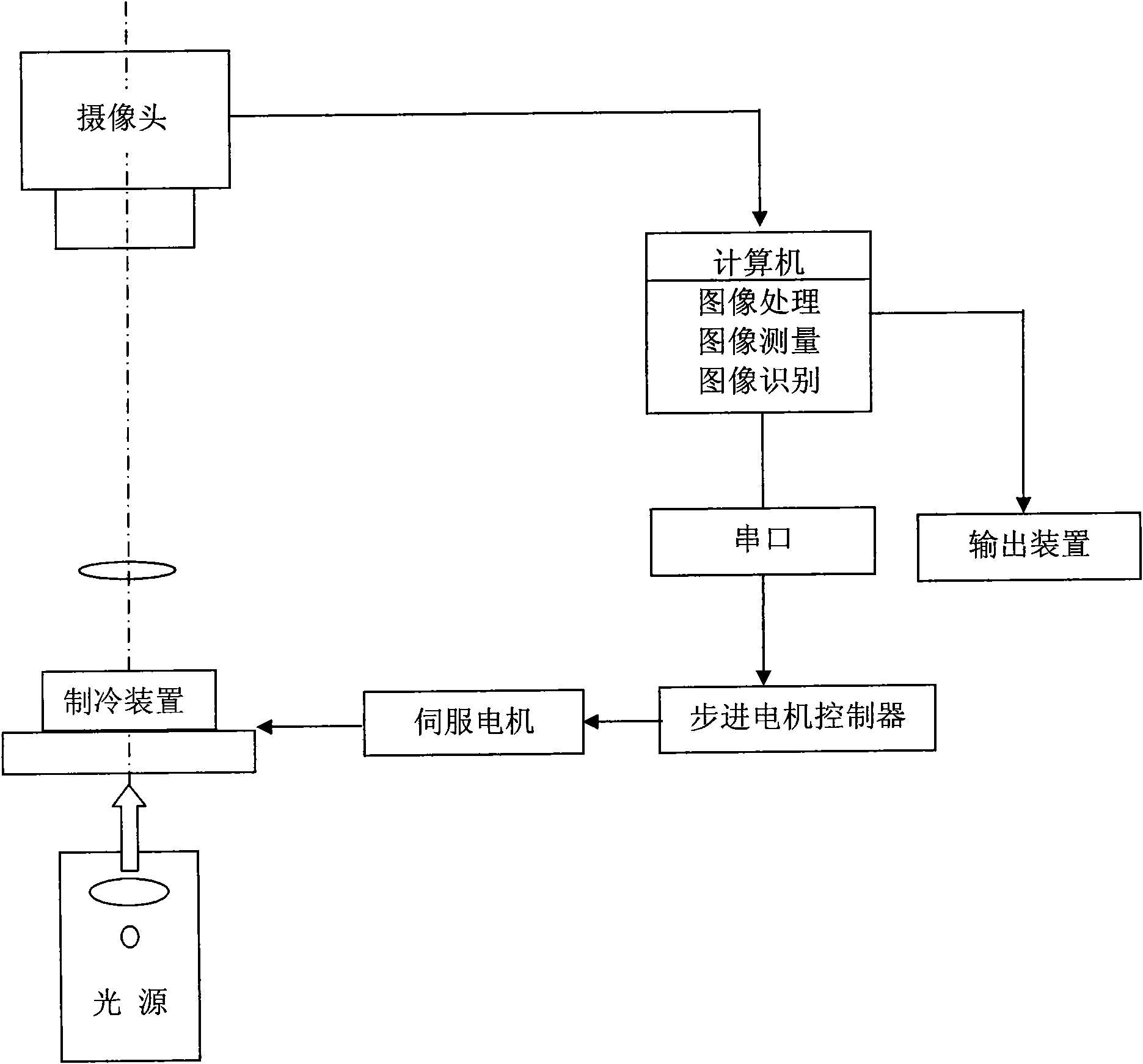

Method, color reagent and system for identifying type of fibers

InactiveCN101907574ARealize fully automatic identificationHigh precisionColor measuring devicesColor/spectral properties measurementsFiberTemperature control

The invention discloses a method for identifying type of fibers which comprises the following steps of: storing a database of dyed fiber color parameters of various fibers in a computer, and dyeing a fiber sample by using a color reagent so as to color the fiber sample; mounting a cooling device which is used for the refrigeration and temperature control of the fiber sample on an objective workbench; amplifying a fiber image by using an optical microscope system at a low temperature, converting the fiber image into a digital image by using an image sensor and transmitting the digital image to the computer; processing the acquired memory image by using the computer, and measuring and calculating the color of a fiber or a pixel point in the digital image to obtain the color parameters of the fiber or the pixel point; comparing the obtained color parameters of the fiber sample with the fiber standard color parameters in the database one by one to obtain a matched result; and making a comprehensive judgment by adopting a statistic rule to obtain the identification result of the fiber classification. The method realizes that the computer fully and automatically identifies the type of the fibers in a textile and that the identification on longer depends on artificial observation. The invention also discloses the color reagent used by the method and an identification system.

Owner:贾立锋

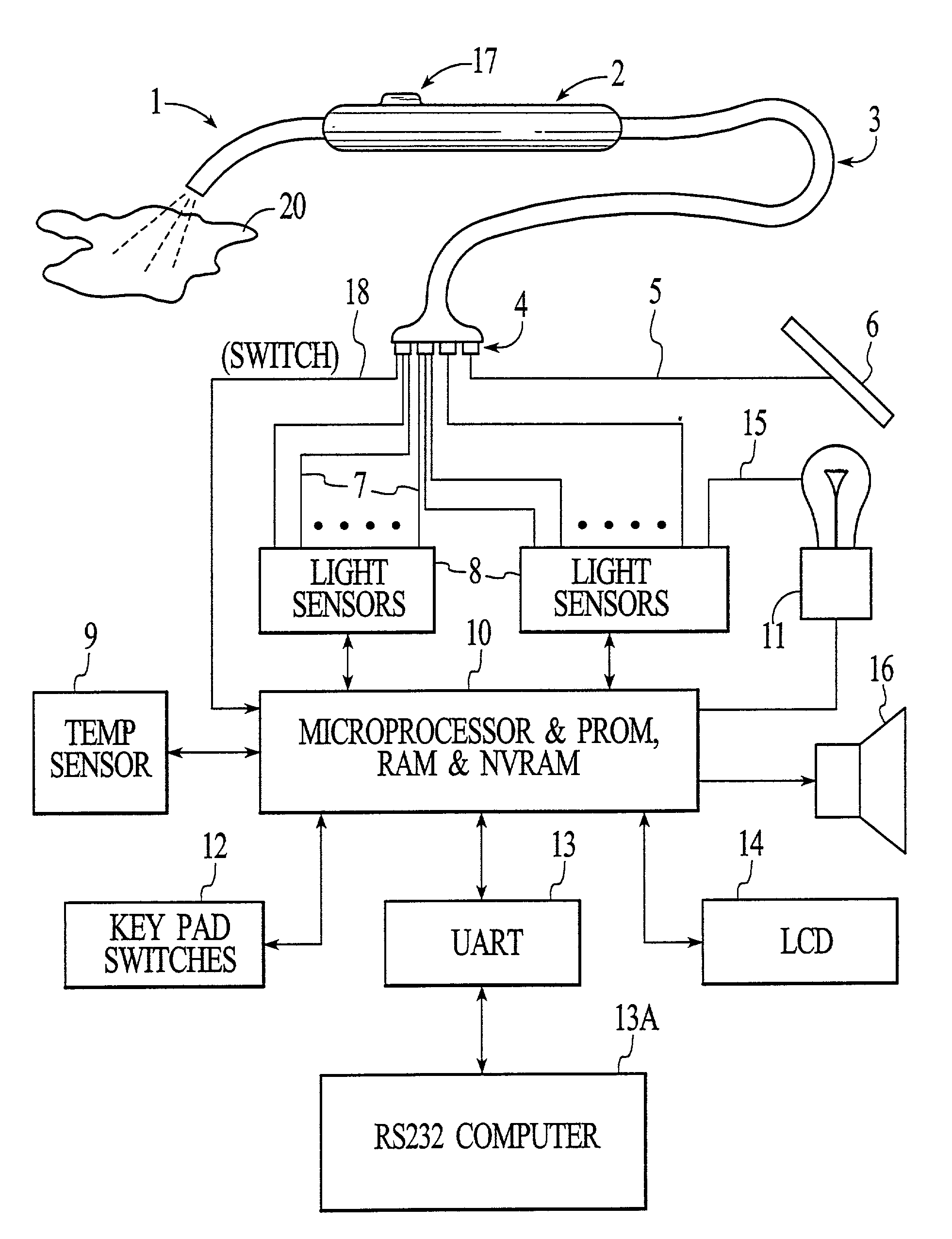

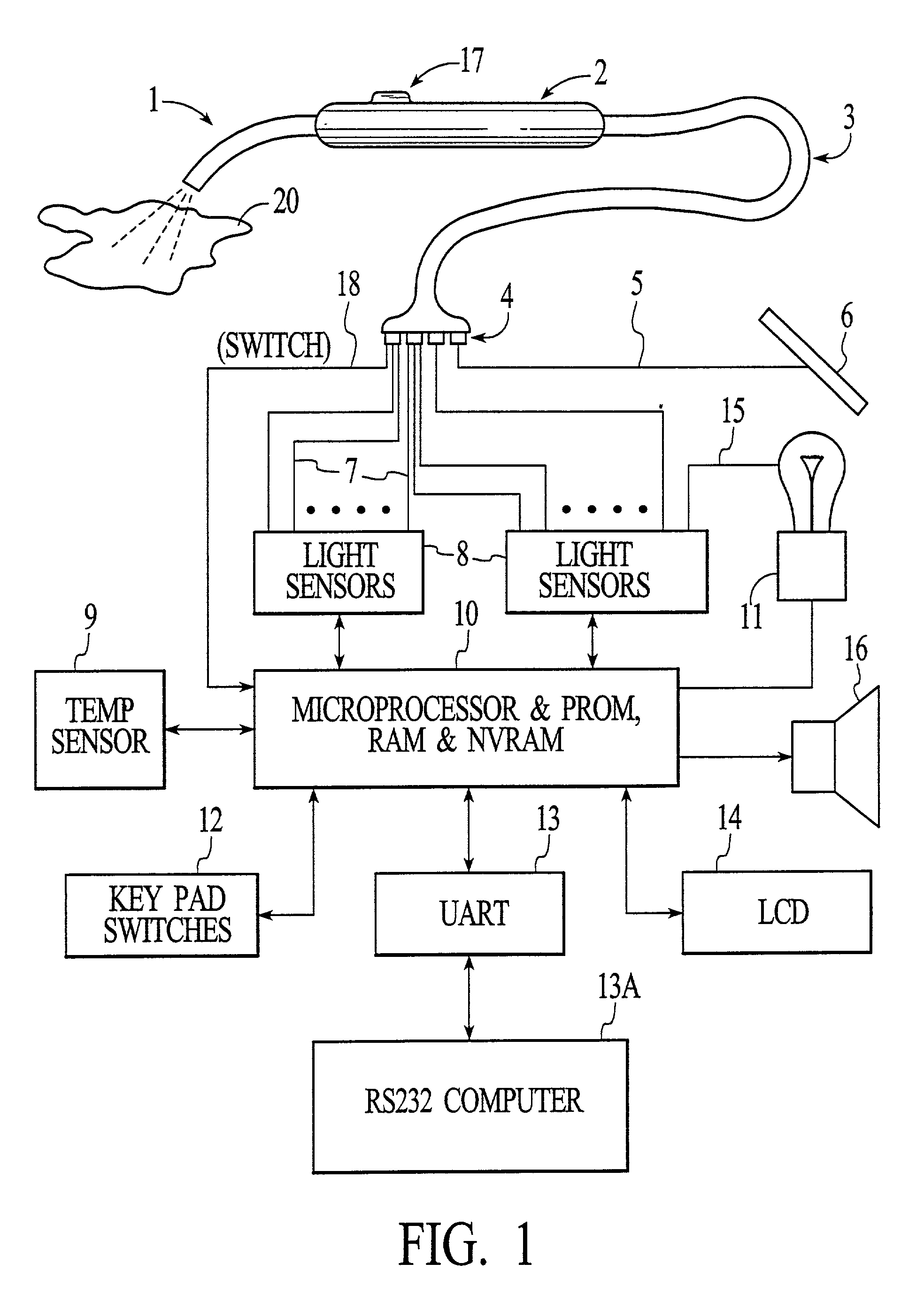

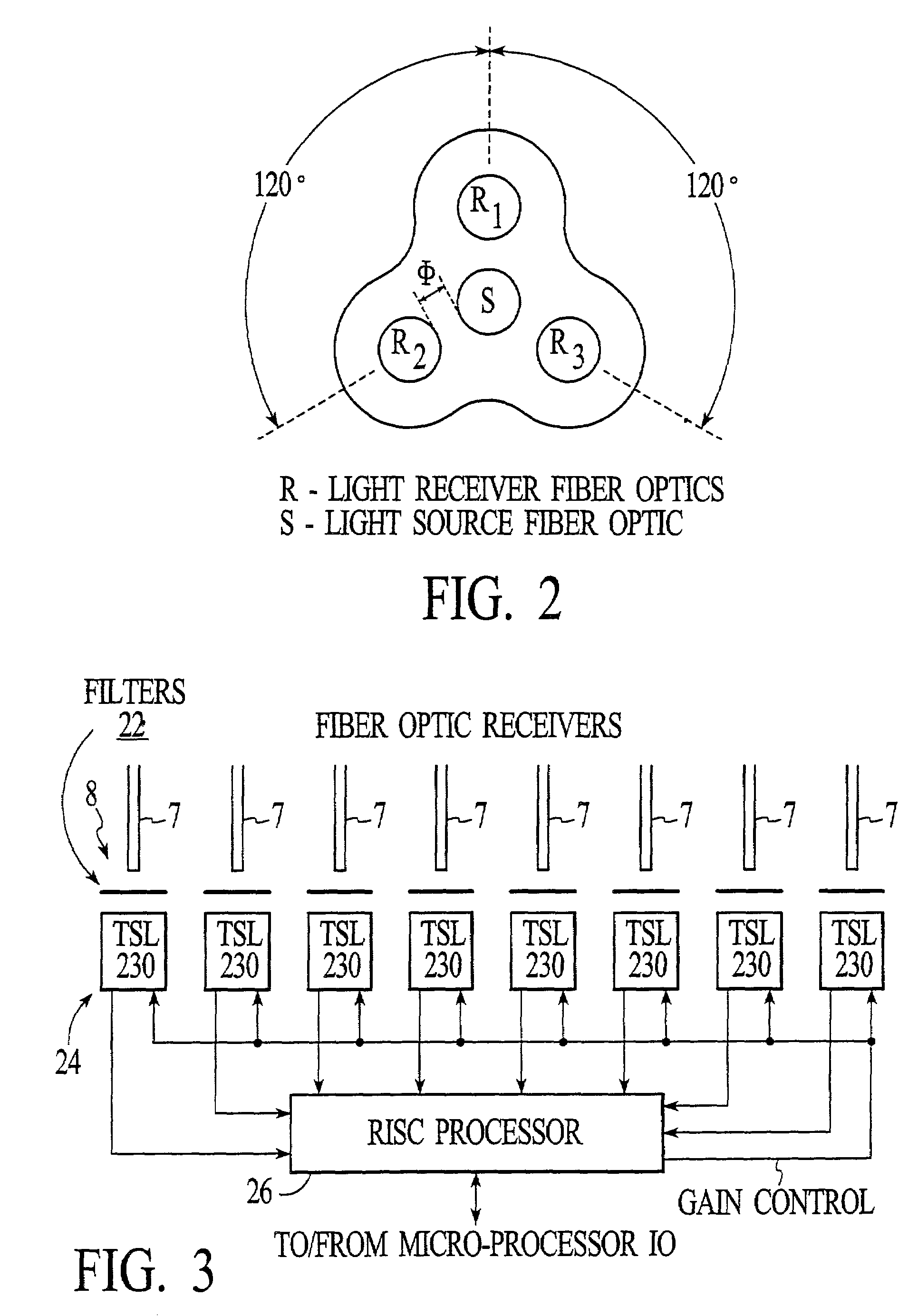

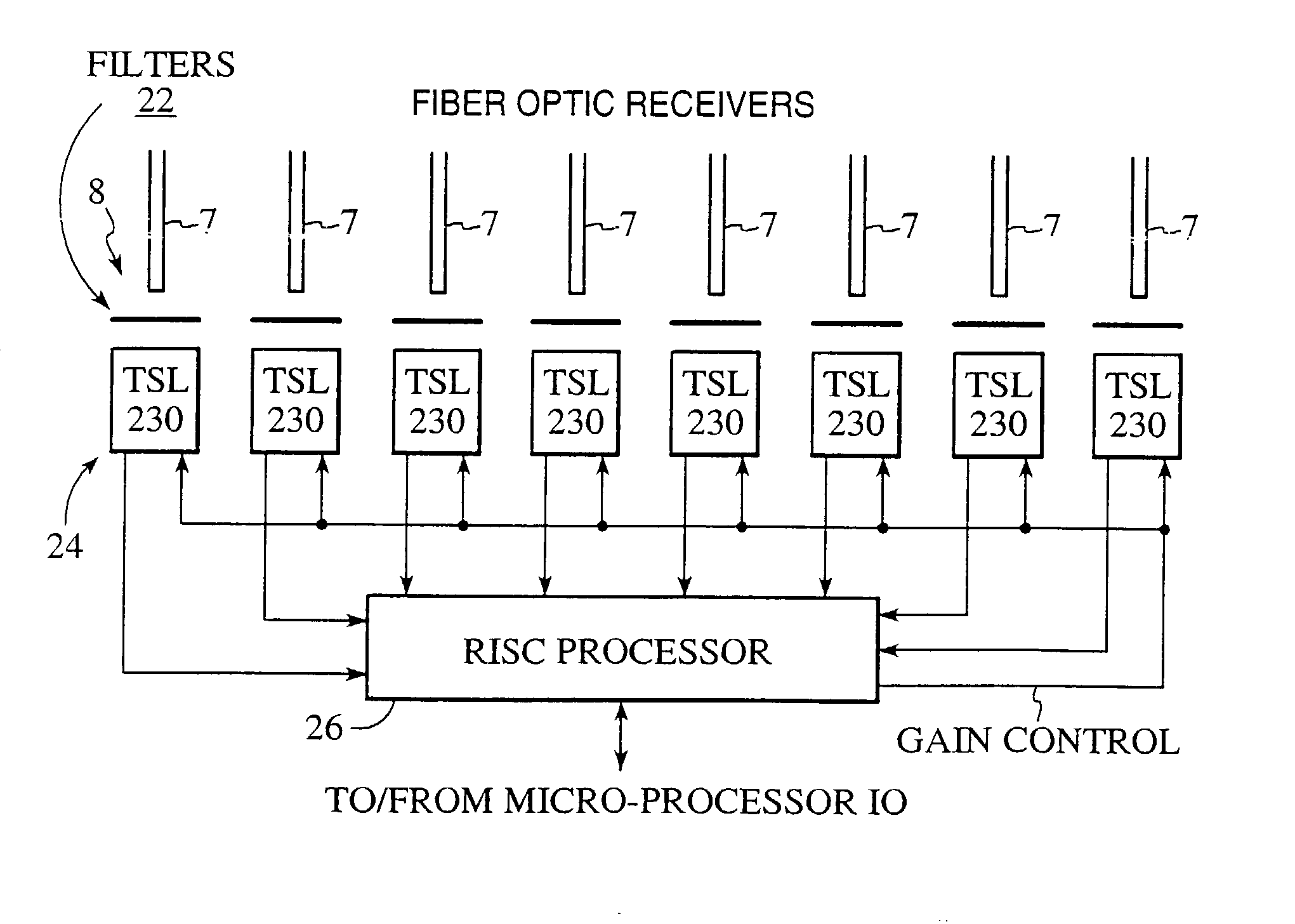

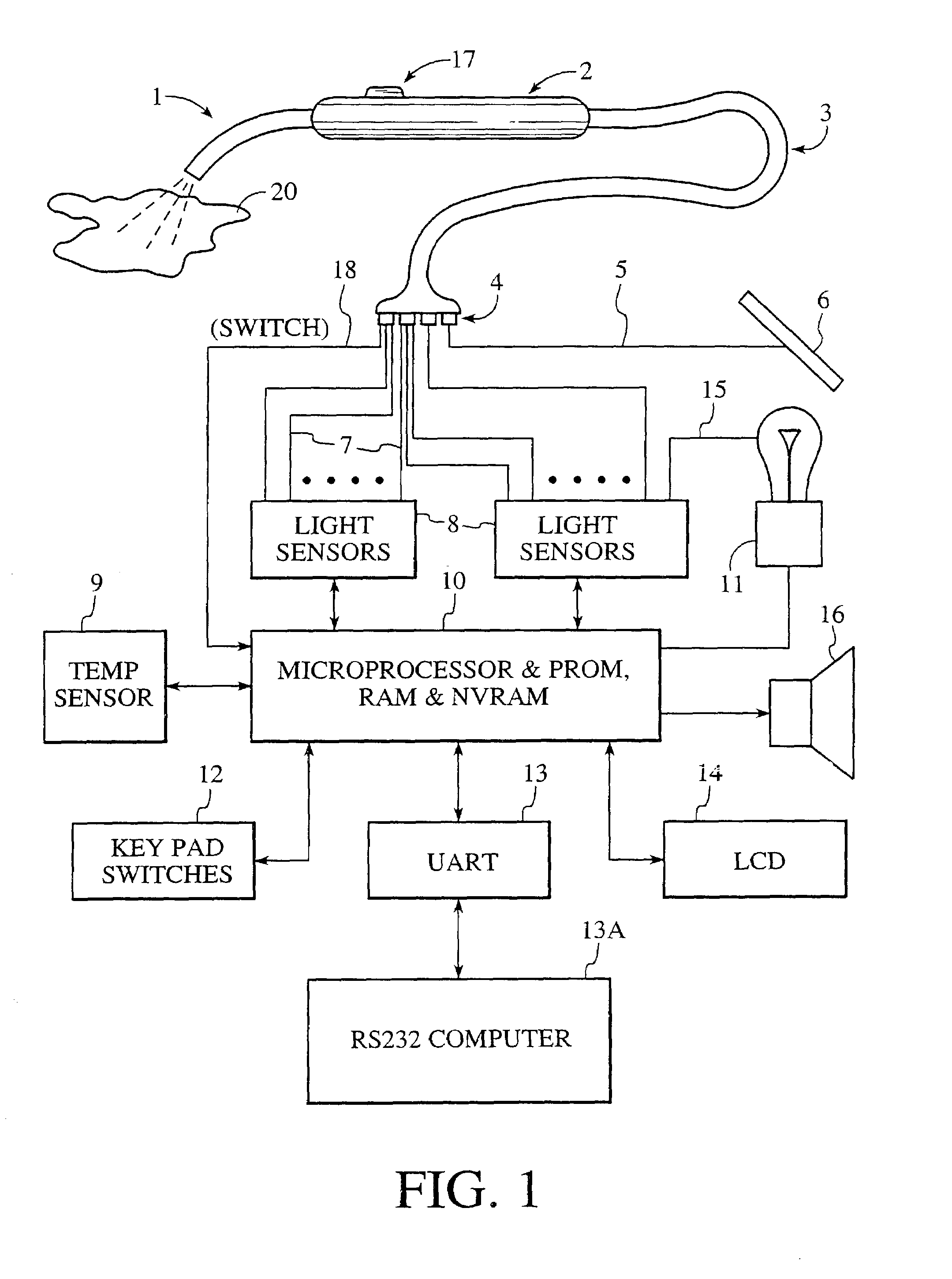

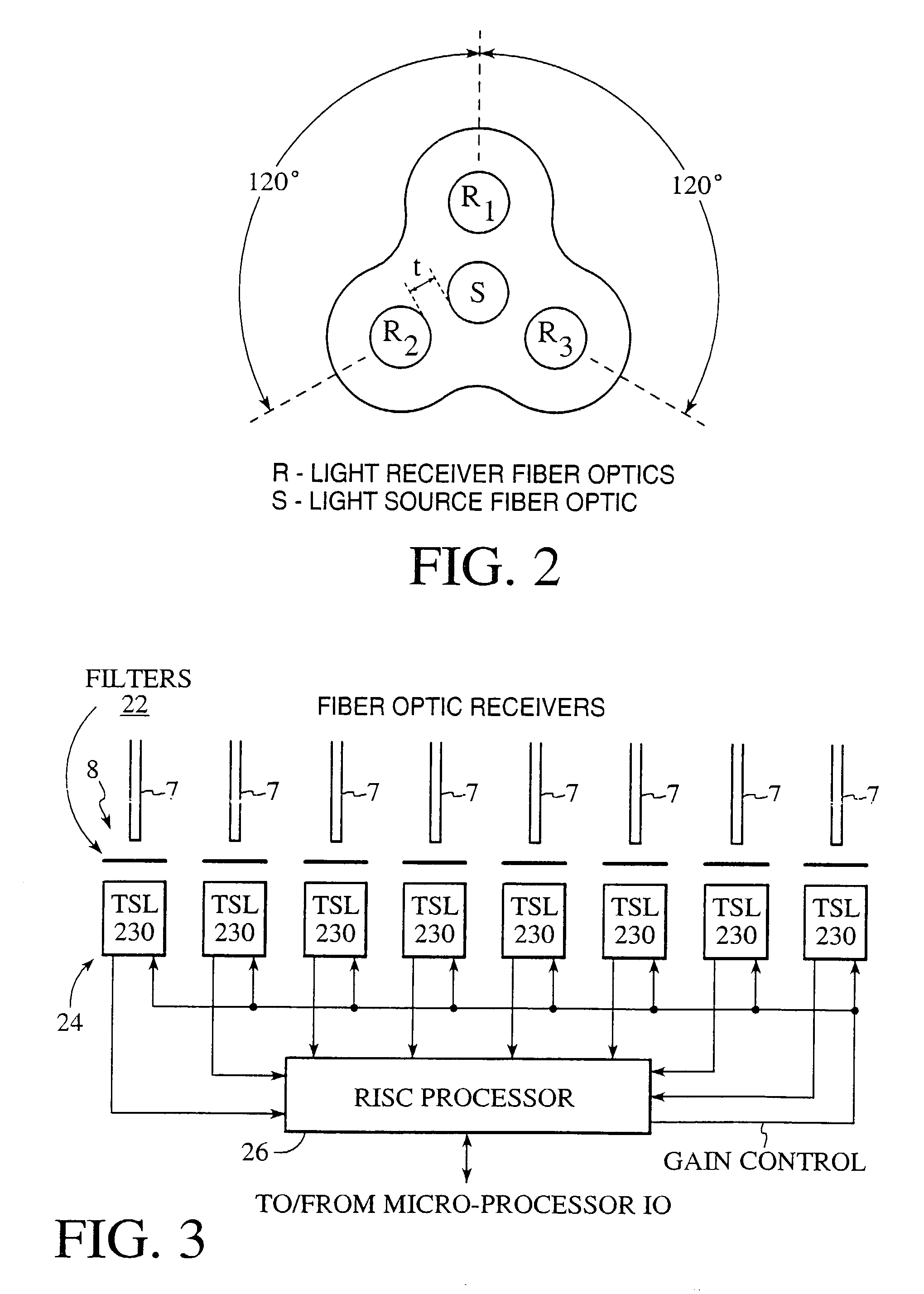

Apparatus and method for measuring color

Color measuring systems and methods are disclosed. Perimeter receiver fiber optics are spaced apart from a central source fiber optic and receive light reflected from the surface of the object being measured. Light from the perimeter fiber optics pass to a variety of filters. The system utilizes the perimeter receiver fiber optics to determine information regarding the height and angle of the probe with respect to the object being measured. Under processor control, the color measurement may be made at a predetermined height and angle. Various color spectral photometer arrangements are disclosed. Translucency, fluorescence and / or surface texture data also may be obtained. Audio feedback may be provided to guide operator use of the system. The probe may have a removable or shielded tip for contamination prevention.

Owner:RPX CORP

Diatom mud

The invention relates to diatom mud which is prepared from fine diatomite, methyl cellulose, bamboo charcoal and shell powder according to a certain weight ratio. With the diatom mud provided by the invention, indoor air can be effectively purified, wall surface reflected lights are natural and gentle; visual fatigue can be retarded, and fading is prevented. With the diatom mud, the wall surface can be kept new for a long time, such that wall surface service life is increased, wall surface decoration frequency is reduced, and household cost is reduced. The diatom mud is non-combustible, and causes no smog such as harmful gas. With the diatom mud, indoor air humidity can be automatically regulated, static electricity is prevented, and dust accumulation on the wall surface is prevented. The diatom mud is suitable to be popularized.

Owner:张维民

Natural color sand decorative mortar

The invention relates to a wall decorative material, and concretely relates to a natural color sand decorative mortar for decorating inner walls and outer walls. The natural color sand decorative mortar comprises 15 to 30 wt% of a synthetic resin emulsion, 10 to 60 wt% of natural color sand grains, 1 to 4 wt% of a film forming assistant, 0.1 to 1 wt% of a thickening agent, 11 to 73 wt% of ceramic grains, 0.1 to 0.2 wt% of an antifoaming agent, 0.1 to 0.2 wt% of an anti-mildew bactericide, and 0.5 to 18 wt% of a pH additive. The natural color sand decorative mortar has the advantages that: various artistic effects can be generated through combination of various natural color sand grains because of strong decoration; the color of the mortar lasts longer than methods of adding toner or other pigments and never fades because of good weatherability and UV- resistance; and pollution resistance, good waterproof effect, and convenient construction are achieved because the mortar can be used with priming paints and finishing varnishes, and has good bonding force with substrates of various materials.

Owner:陈轶 +2

Preparation method of modified composite ultrafine talcum powder

InactiveCN101864199AFine granularityStrong water resistancePigment treatment with organosilicon compoundsPigment physical treatmentSodium stearateMicrometer

The invention discloses a preparation method of modified composite ultrafine talcum powder, which comprises the following steps: (1) breaking raw material, and grinding the broken material to fine powder; (2) adding water and grinding-assistant medicine into the ground material to be configured into pulp with the concentration of 50 to 70 percent and to be uniformly mixed; (3) configuring composite modifier, silane coupling agent and sodium stearate to surface modification solution to be poured into the pulped material so as to modify the material; (4) carrying out the wet-method ultra-fine grinding on the modified material, and requiring the particles with the granularity being less than 2 micrometers for the mineral pulp ultra-fine grinding to be more than 95 percent; (5) forcibly drying and collecting the material after being ultra-fine ground. By utilizing the wet-method ultra-fine grinding and mightiness drying process, the prepared modified composite ultra-fine talcum powder has smaller granularity than that of ordinary talcum powder and wider distribution, resists the insolation and high temperature, has good water resistance, resists pollution, and has strong anti-aging performance.

Owner:朱自学

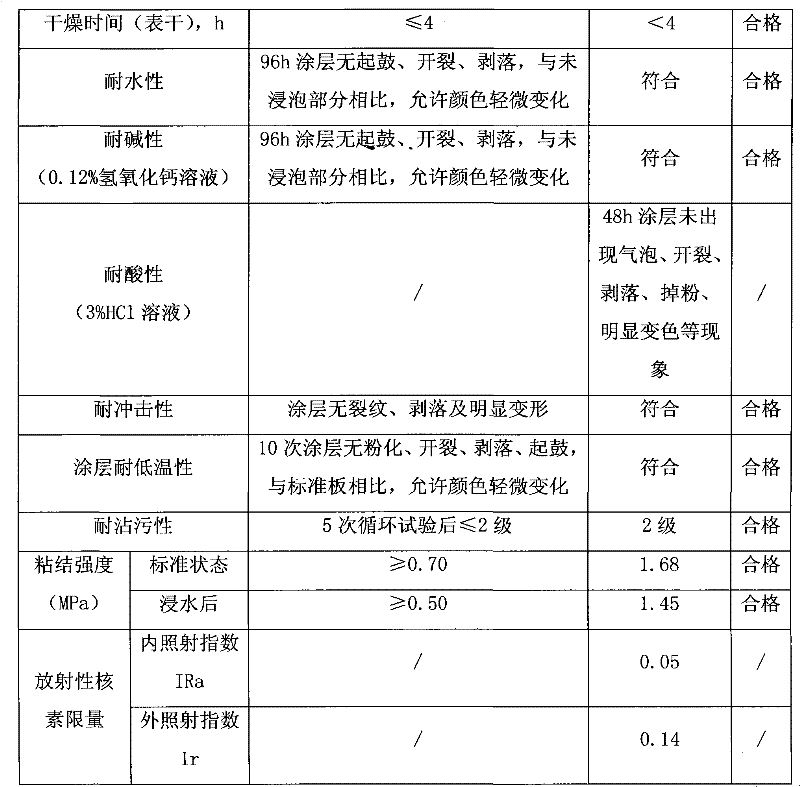

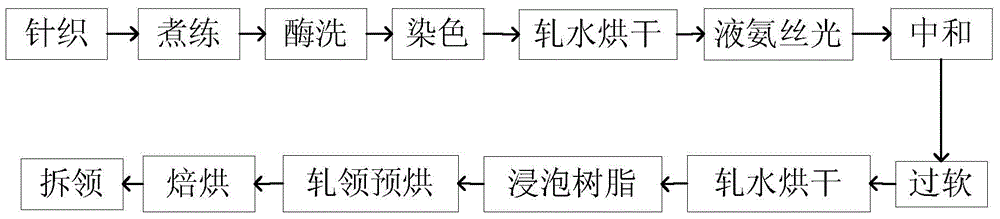

Manufacturing method of washable non-curling knitting collars and cuffs

ActiveCN104358054AGood dimensional stabilityImprove washabilitySucessive textile treatmentsWeft knittingYarnEngineering

The invention provides a manufacturing method of washable non-curling knitting collars and cuffs. The knitting collars and cuffs comprise piece dyeing knitting collars and cuffs and yarn dyeing knitting collars and cuffs; for the piece dyeing knitting collars and cuffs, the method comprises the following steps of knitting, boiling off, enzyme washing, dyeing, squeezing and drying, mercerizing by liquid ammonia, neutralizing, softening, squeezing and drying, soaking in resin, collar rolling and pre-drying, baking, and collar removal; for the yarn dyeing knitting collars and cuffs, the method comprises the following steps of knitting, water washing and oil removal, enzyme washing, squeezing and drying, mercerizing by liquid ammonia, neutralizing, softening, squeezing and drying, soaking in resin, collar rolling and pre-drying, baking, and collar removal. The knitting collars and cuffs manufactured by the method have the advantages that the hand feel is soft after mercerizing by the liquid ammonia, the rebounding property, strength, size stability and washability are obvious improved, the deformation and curling of the collars and the cuffs are avoided after 20 times of water washing, and the good rebounding property is realized; the color change and the fuzzing and pilling resistance respectively reach more than level 4.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Pu'er tea beverage

InactiveCN1515172ALong-lasting colorLong-lasting vivid and clear colorTea extractionTea substituesChemical preservativesZiziphus jujuba

The present invention provides a PuEr tea beverage. The PuEr tea beverage is made up by adopting the processes of pulverizing, spray-wetting, wet-sealing tightly, low-temp. diffusion, low-temp. filtering and adding auxiliary material. The process does not damage useful and effective components in the tea, but also retains the original taste and flavour of said tea self-body, said process also can raise its storage time. The tea has bright jujube red colour and jujube palatefull flavour, it is an unique tea beverage.

Owner:王建平 +1

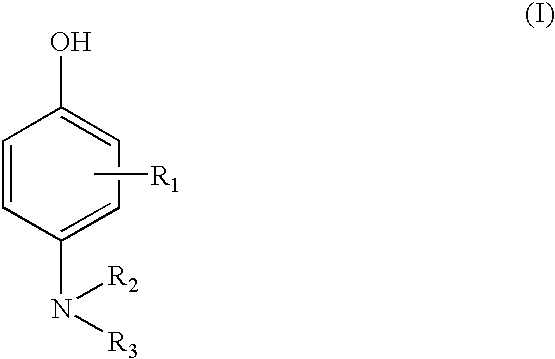

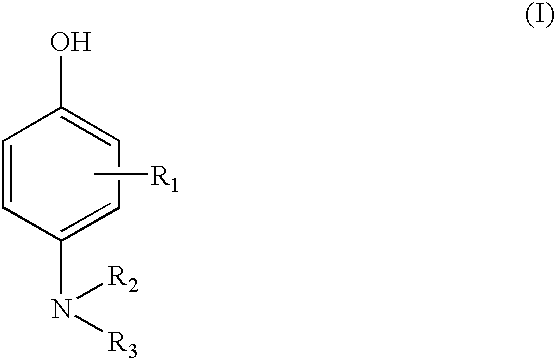

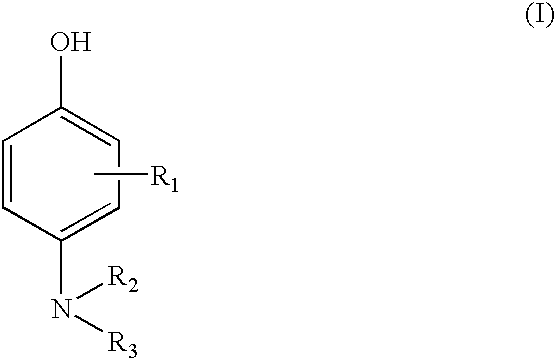

Method for simultaneously dyeing and permanent shaping of hair

InactiveUS6945254B2Faster and more carefullyRenews the color intensity of dyed hairCosmetic preparationsHair removalPolymer scienceM-aminophenol

The method for simultaneously dyeing and permanent shaping of hair includes dividing the hair into strands an winding the strands onto curlers: mixing a hair shaping component (A) containing from 6 to 15 percent by weight of a keratin-reducing substance with a dye component (B) to form a dyeing and shaping composition prior to application on the hair; treating the hair with the dyeing and shaping composition and then allowing it to act on the hair for an acting time sufficient for the permanent shaping; after that, treating the hair with a fixing composition; allowing the fixing composition to act on the hair from 1 to 40 minutes and then subsequently rinsing the hair. The dye component (B) contains at least one oxidative coupler compound and at least one oxidative dyestuff selected from a group consisting of certain 4,5-diamino-pyrazole derivatives and certain aminophenol derivatives.

Owner:WELLA INT OPERATIONS SWITZERLAND SARL

Method and composition for gradual permanent coloring of hair

A method for permanently dyeing hair which comprises subjecting said hair to a number of treatments, having a set time interval between each two consecutive such treatments, wherein each treatment comprises steps a.) and b.) below: a.) contacting said hair, for a period of about 5 seconds to about 5 minutes with a recently made mixture of: i.) an alkaline composition comprising a dye intermediate in a shampoo base or in a conditioner base; and ii.) an acidic composition comprising an oxidating compound in a shampoo base or in a conditioner base; b.) rinsing said mixture from said hair with water;with the proviso that when a conditioner base is present in a.) i.) above, an independently selected conditioner base is also present in a.) ii.) above; and when a shampoo base is present in a.) i.) above, an independently selected shampoo base is also present in a.) ii.) above;and wherein said number of treatments is between about 2 to about 30; and wherein said set time interval between each two consecutive treatments is between about 8 hours and 30 days, is described.

Owner:UNILEVER NV

Anti-aging unsaturated polyester resin and preparation method and application thereof

The invention relates to anti-aging unsaturated polyester resin and a preparation method and application thereof. The anti-aging unsaturated polyester resin is prepared from the following reactants in percentage by weight: 28-35% of dihydric alcohol, 30-50% of dicarboxylic acid or anhydride and 25-35% of thinner, wherein the dicarboxylic acid or anhydride at least comprises 1,4-cyclohexanedicarboxylic acid, and the thinner is the combination of methyl methacrylate and styrene. The preparation method of the anti-aging unsaturated polyester resin comprises the following steps: carrying out a condensation reaction on the dihydric alcohol and the 1,4-cyclohexanedicarboxylic acid until the acid value is 20-40mgKOH / g, decreasing temperature, adding maleic anhydride or fumaric anhydride, slowly increasing temperature to carry out polycondensation reaction until the acid value is 45-55mgKOH / g, reducing pressure to carry out vacuum treatment until the acid value is 25-35mgKOH / g, adding an additive, cooling and adding the thinner. The anti-aging unsaturated polyester resin is used for making artificial stone plates, basins, sanitary ware and sheet molding compound. The content of benzene rings in the unsaturated polyester resin is greatly reduced, and anti-aging performance of the anti-aging unsaturated polyester resin is improved. The anti-aging unsaturated polyester resin has higher color and mechanical performance retention rate under the condition of coexistence of high light, oxygen and water.

Owner:上海新天和树脂有限公司 +2

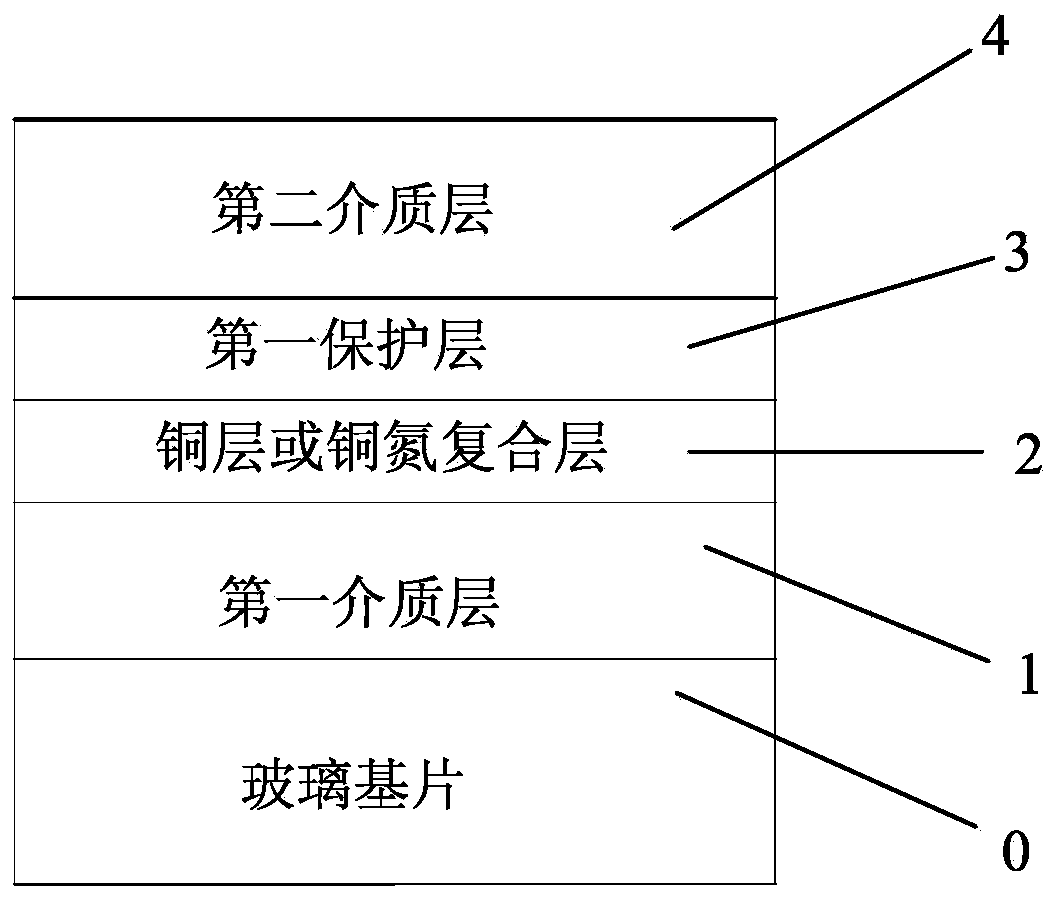

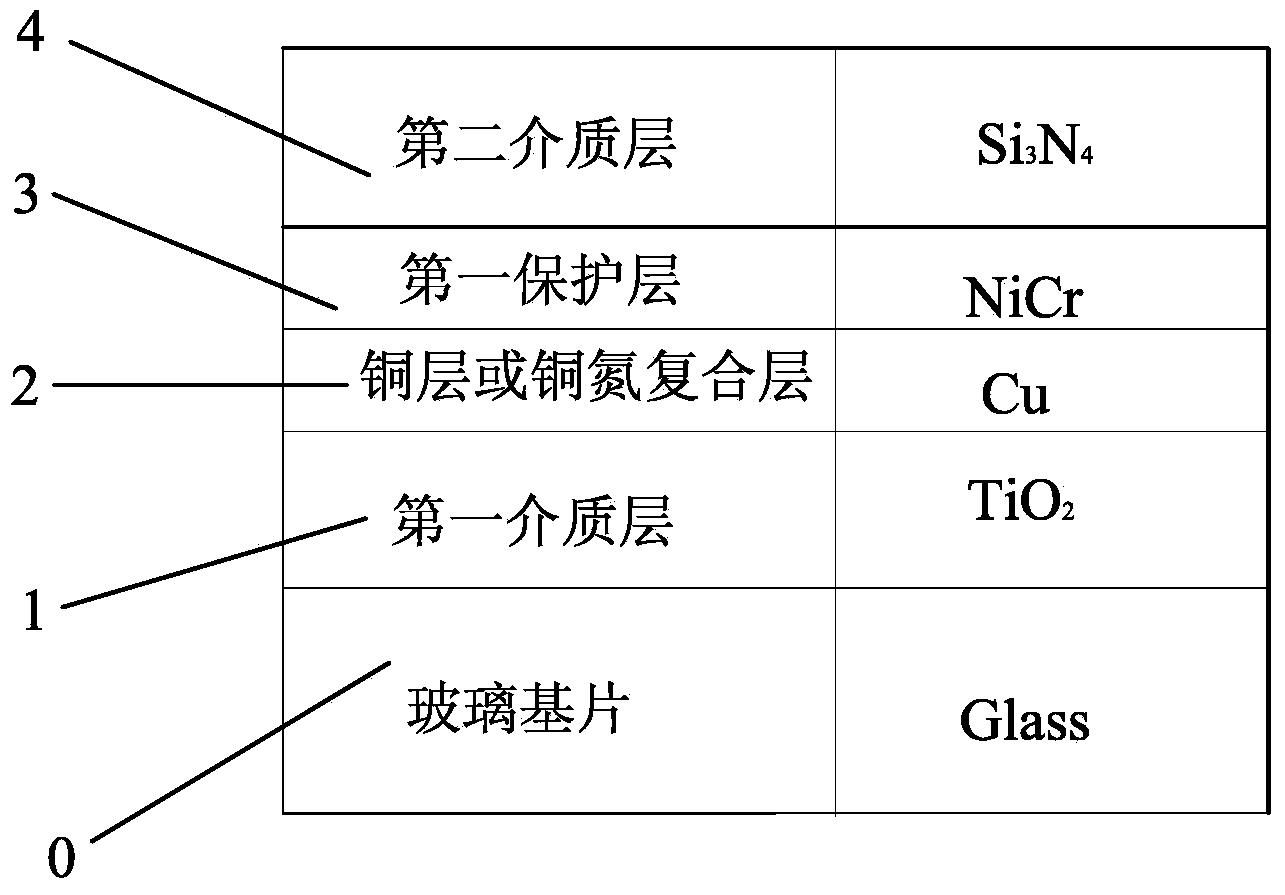

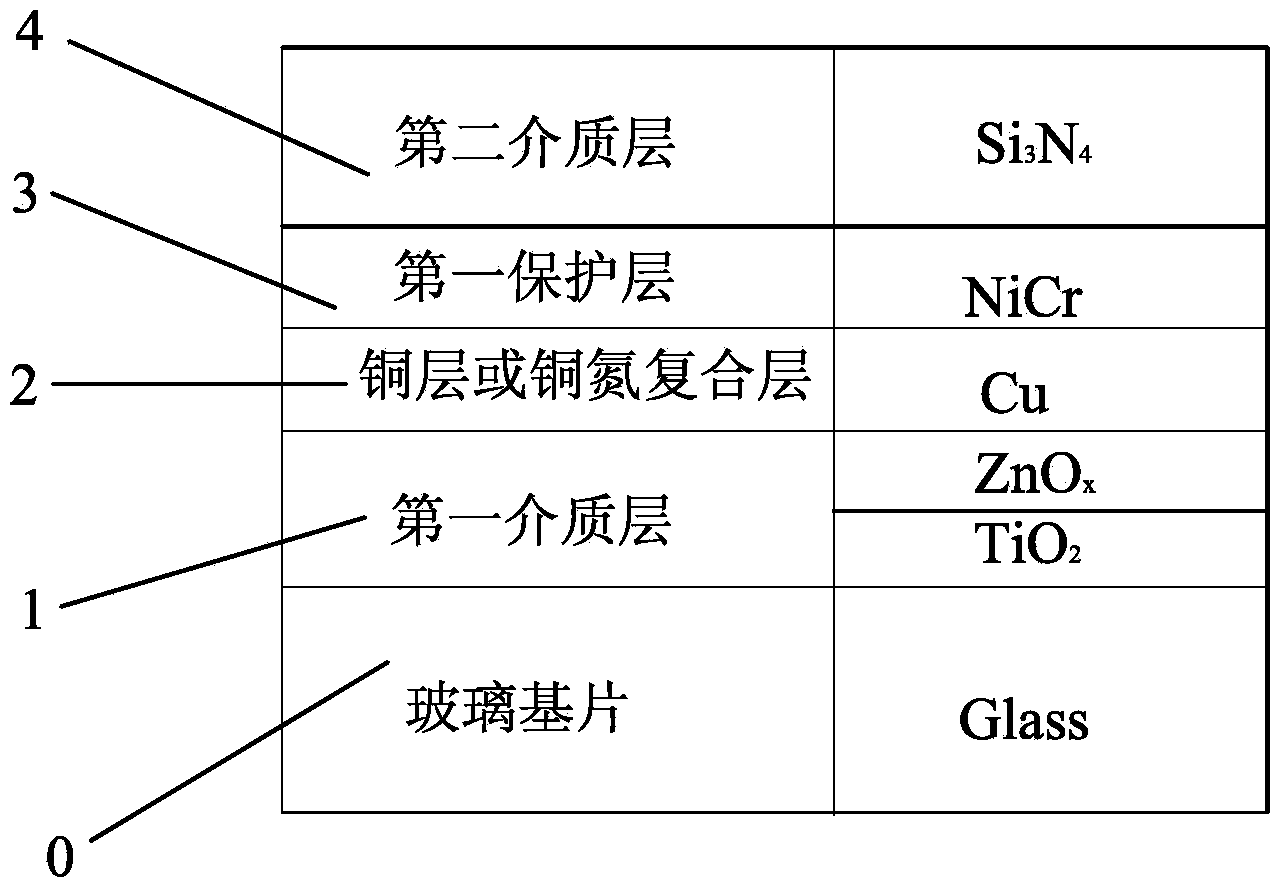

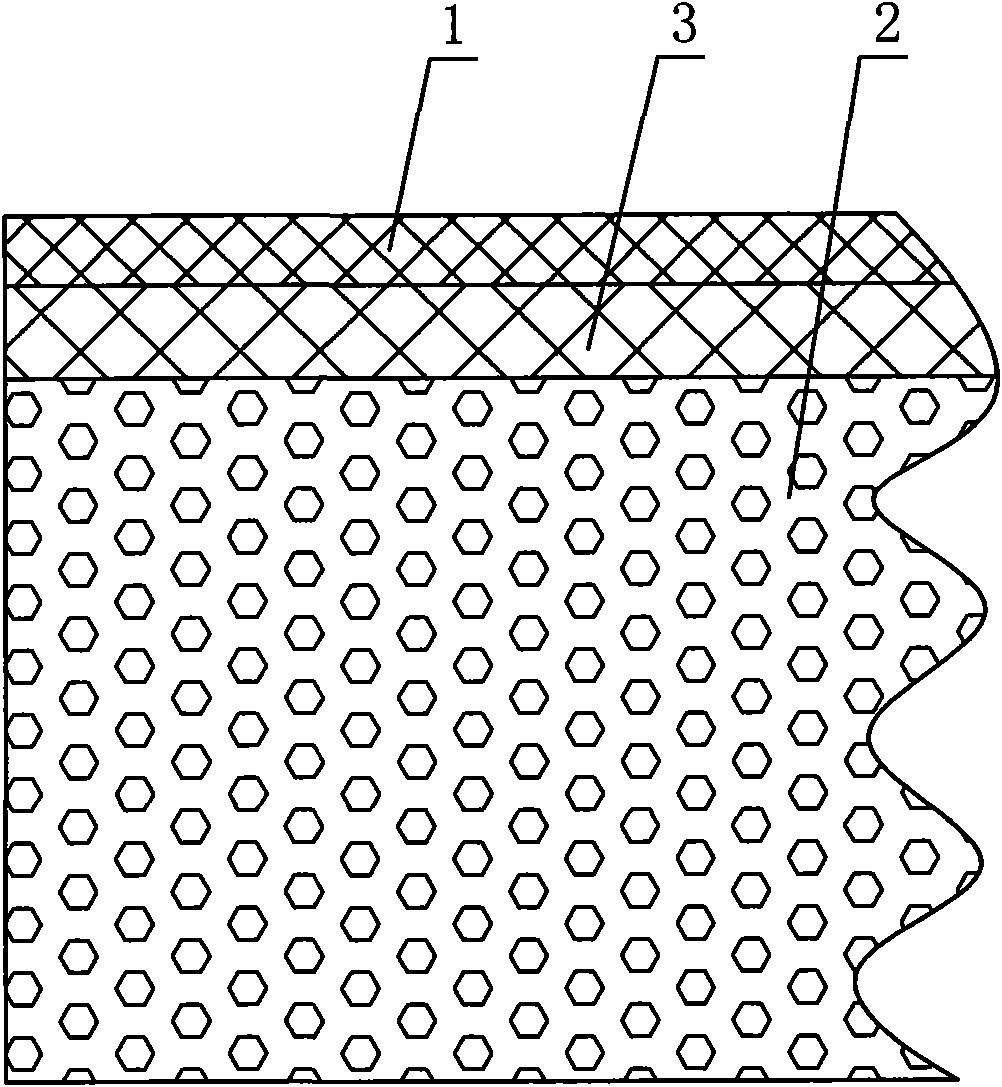

Rosy low-radiation coated glass and preparation method thereof

ActiveCN103448324AStable reflective colorReduce manufacturing costGlass/slag layered productsSputteringNitrogen

The invention relates to the technical field of coated glass and specifically relates to rosy low-radiation coated glass and a preparation method thereof. The rosy low-radiation coated glass is coated with a film by adopting magnetron sputtering and comprises a glass substrate and a coating film layer which is coated on the surface of the glass substrate, wherein the coating film layer comprises a first medium layer, a copper layer or a copper-nitrogen compound layer, a first protective layer and a second medium layer from one side of the glass substrate to the outside in sequence. According to the coated glass, the structure is simple, the production cost of the product is lowered so that the product can be applied widely; moreover, the color is pure and bright and the glass shows stable reflecting color when observed from different angles, and the color is stable. Furthermore, the rosy low-radiation coated glass is stable in structure and is of a long-lasting color during use and can keep the color unchanged for a long time.

Owner:东莞南玻工程玻璃有限公司 +1

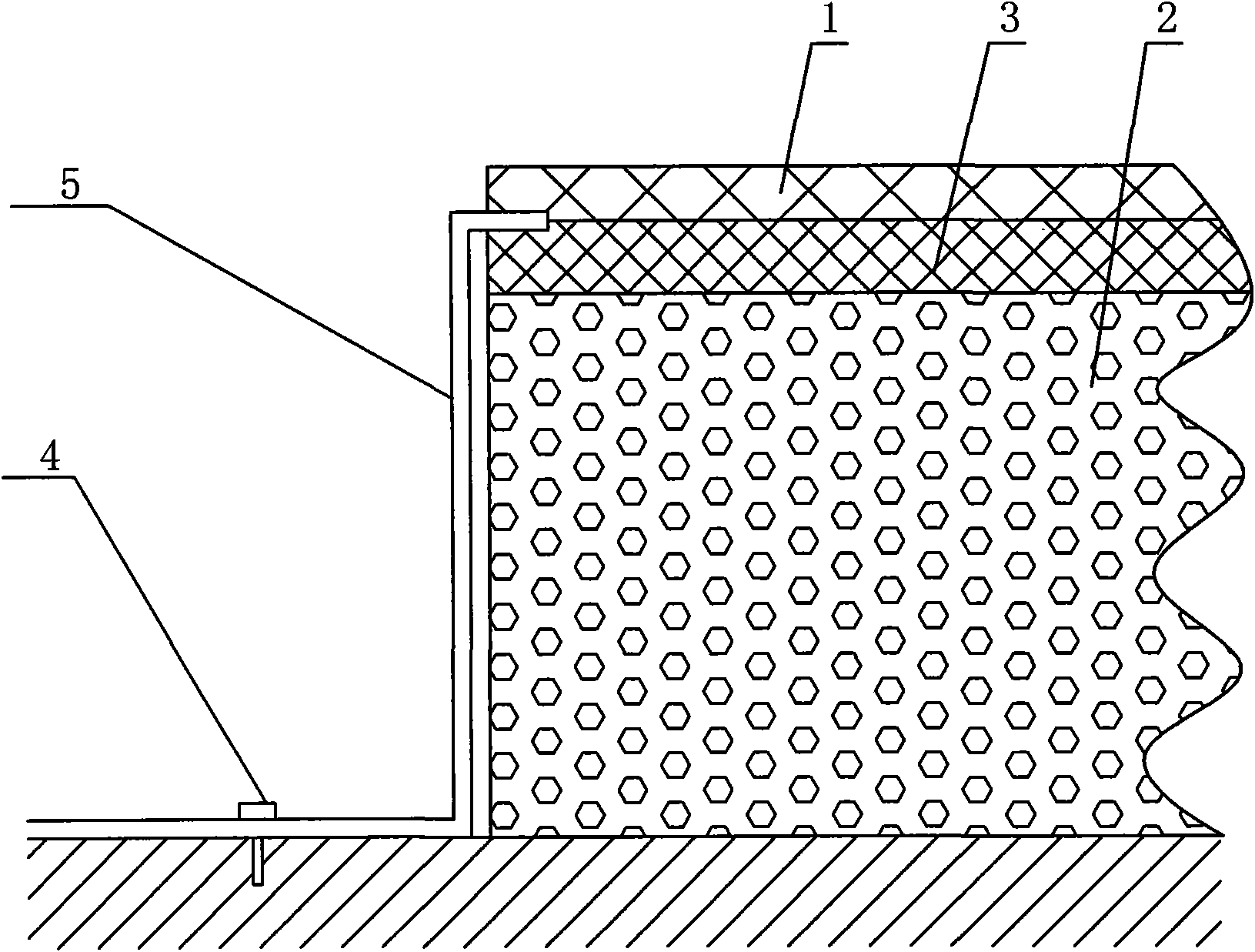

Stone thermal insulating composite panel

InactiveCN101597939ANon-flammableNot easy to burstConstruction materialCovering/liningsSurface layerHigh surface

The invention relates to a stone thermal insulating composite panel which comprises a stone surface layer and is characterized by also comprising a thermal insulating layer and a substrate, wherein a plurality of fine closed holes are distributed inside the thermal insulating layer; the substrate is arranged between the stone surface layer and the thermal insulating layer; and the stone surface layer, the substrate and the thermal insulating layer are integrally fixed by a binding agent. The stone thermal insulating composite panel has the advantages of simple structure, good thermal insulating effect, light weight, convenient installation, good weatherability and high surface rigidity. The stone thermal insulating composite panel of the invention can improve the indoor thermal insulating effect and reduce the energy consumption.

Owner:重庆鑫坚雅装饰材料有限公司

Waterproof wear-resistant polyurethane acrylate oil paint for copper sculpture

InactiveCN104194612AStrong adhesionLong lasting colorAnti-corrosive paintsPolyurea/polyurethane coatingsXylylenePolymer science

The invention relates to oil paint and particularly relates to waterproof wear-resistant polyurethane acrylate oil paint for a copper sculpture. The oil paint is prepared from the following raw materials in parts by weight: 12-15 parts of amino resin, 3-4 parts of boron nitride, 1-2 parts of molybdenum disulfide, 3-4 parts of shell powder, 2-3 parts of citric acid, 1-2 parts of stannous mono-sulphate, 2-3 parts of dicyclopentadiene, 35-40 parts of polyurethane acrylate, 10-12 parts of dipropylene glycol diacrylate, 3-5 parts of allyl glycidyl ether, 1-2 parts of 4-methyl guaiacol, 0.19-0.21 part of an accelerant TT, 5-6 parts of zinc stearate, 4-8 parts of N220 carbon black, 6-9 parts of diamino diphenyl sulfone, 1-2 parts of tributyl tin chloride, 5-6 parts of auxiliaries, 10-12 parts of xylene and 10-12 parts of butyl acetate. The oil paint provided by the invention is strong in adhesive force, bright and full in film, hard and wear-resistant, lasting in color retention, water-permeation-resistant, weatherproof and aging-resistant, long in service life and relatively simple in production process, and can be widely applied to protecting various copper sculpture artware.

Owner:TONNGLING YUANCHENG ART PROD

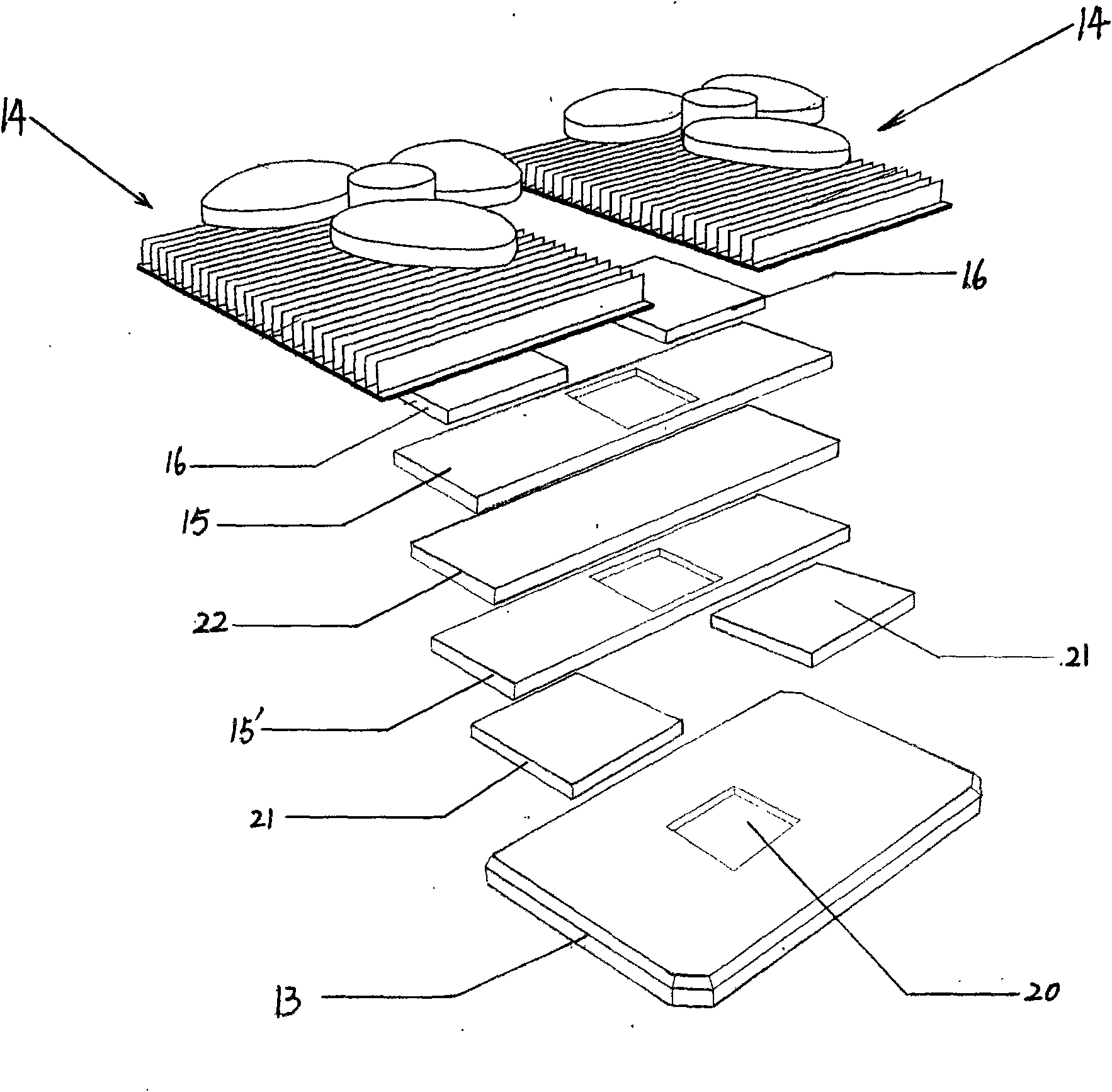

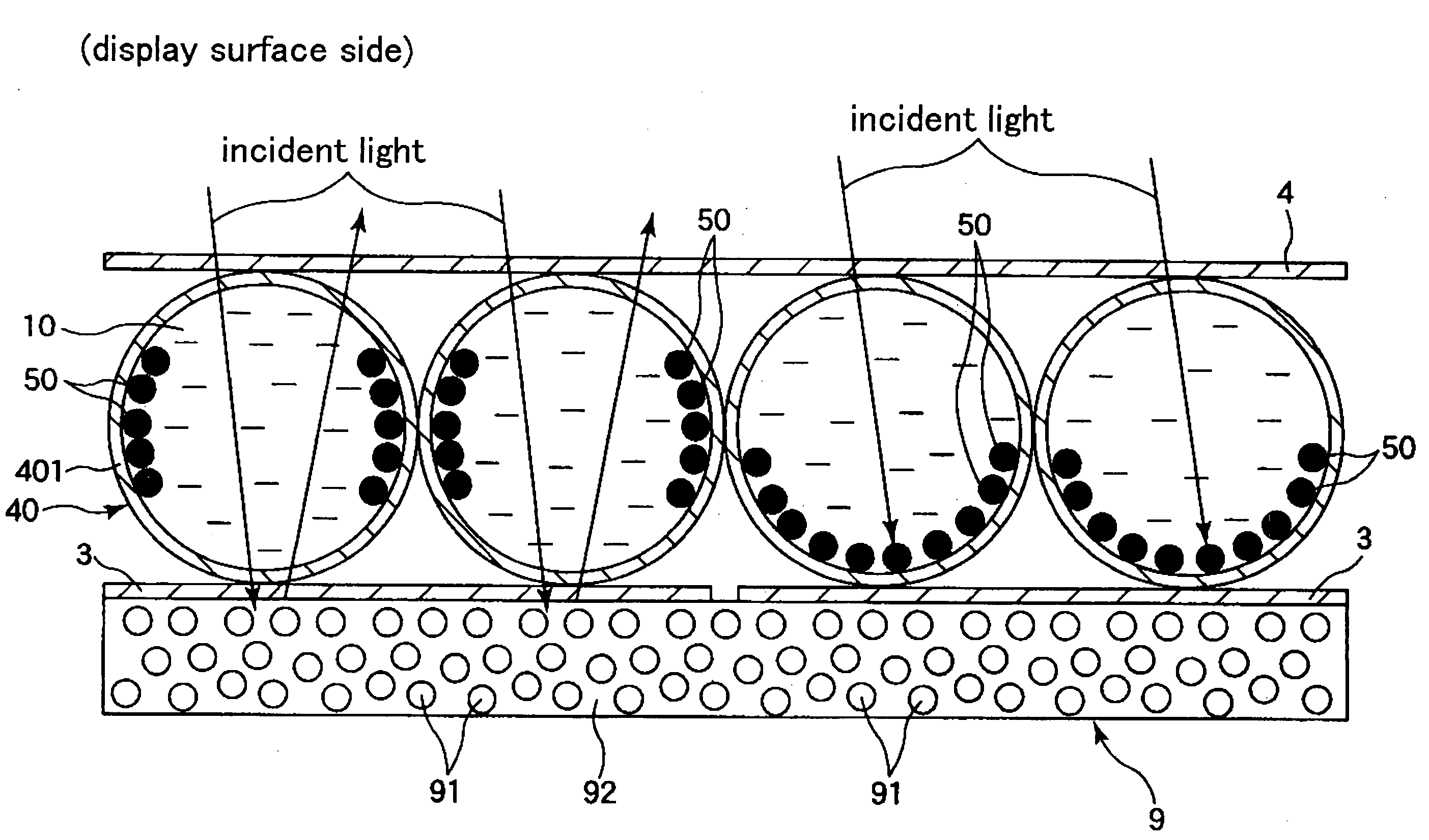

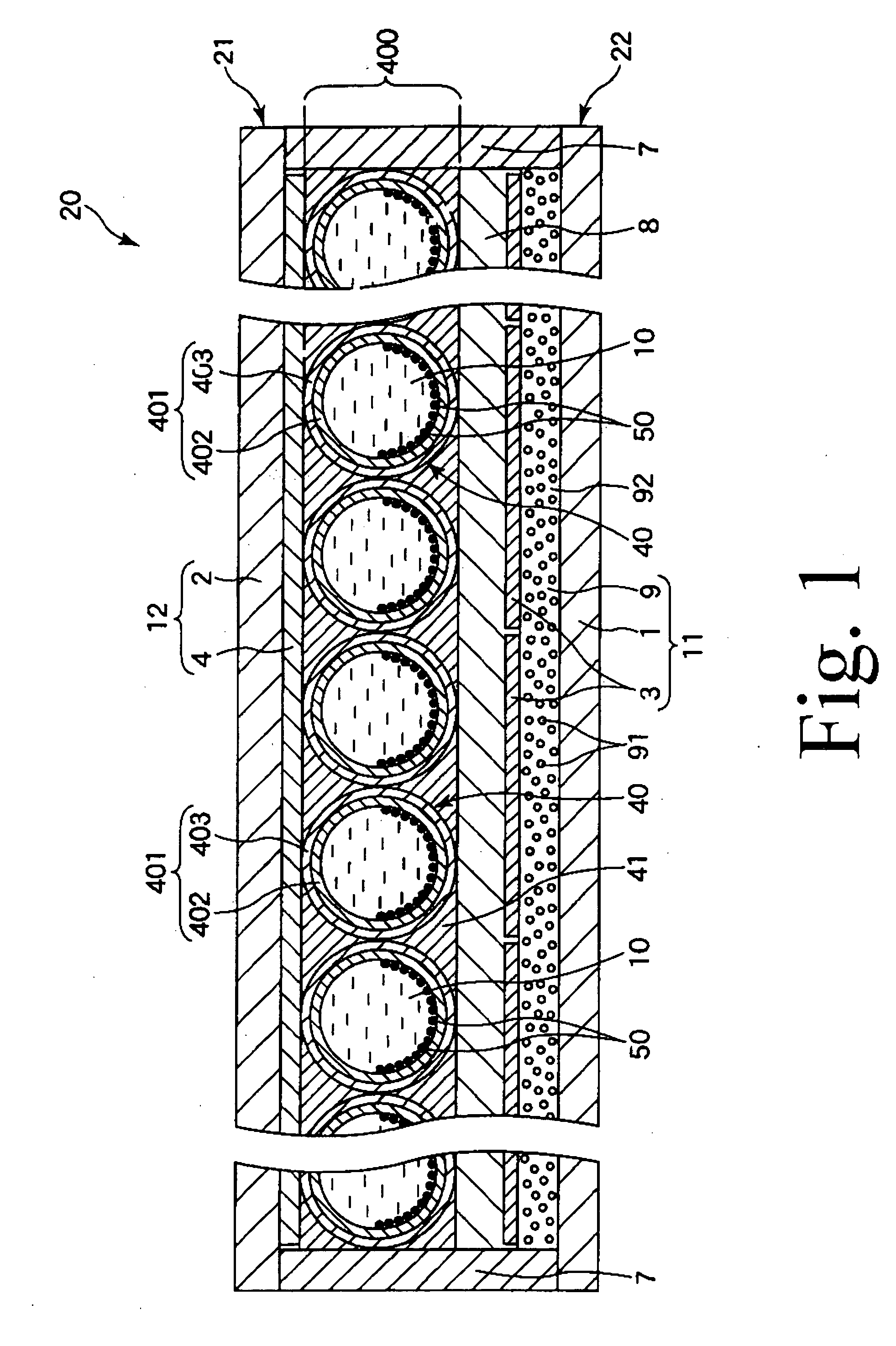

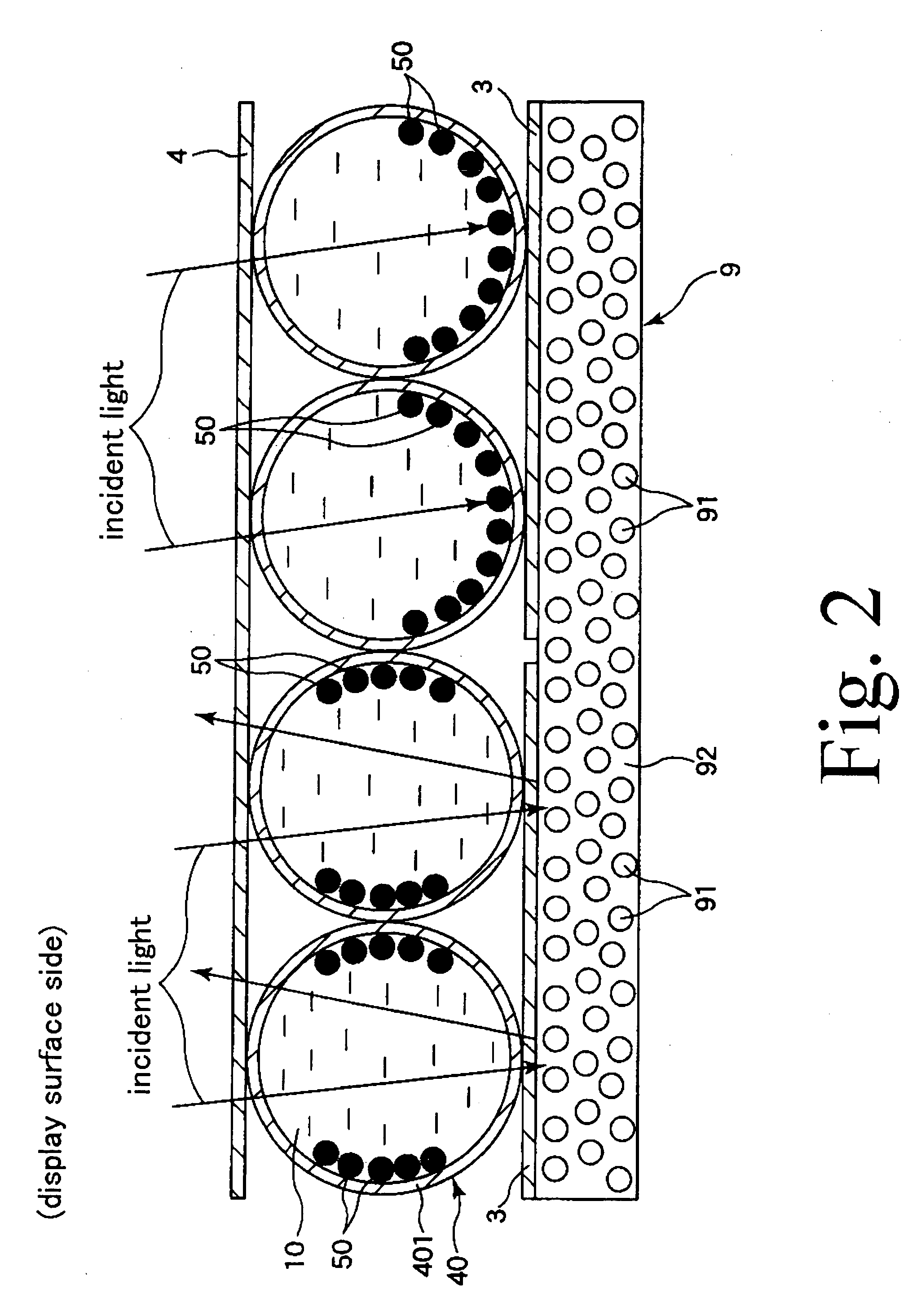

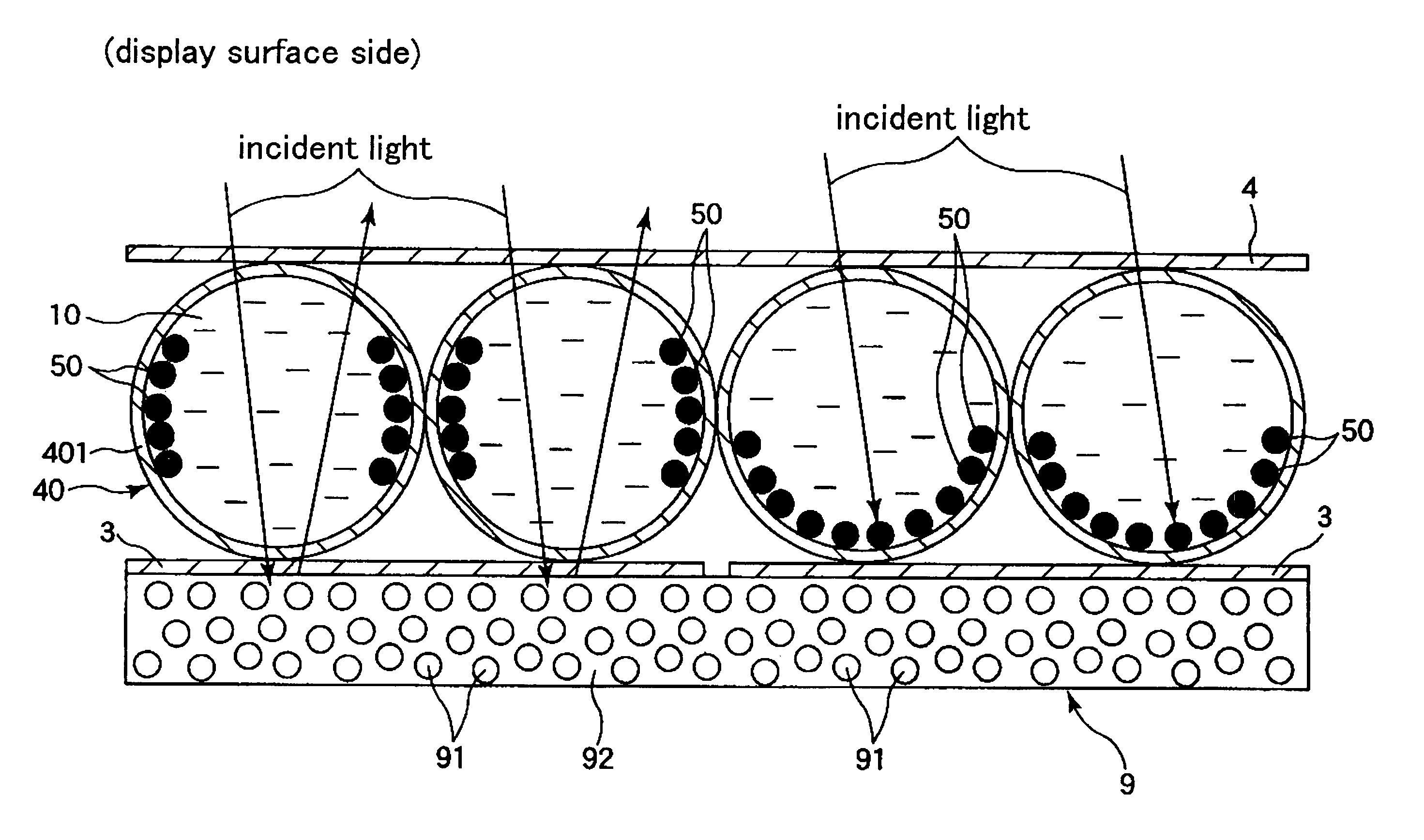

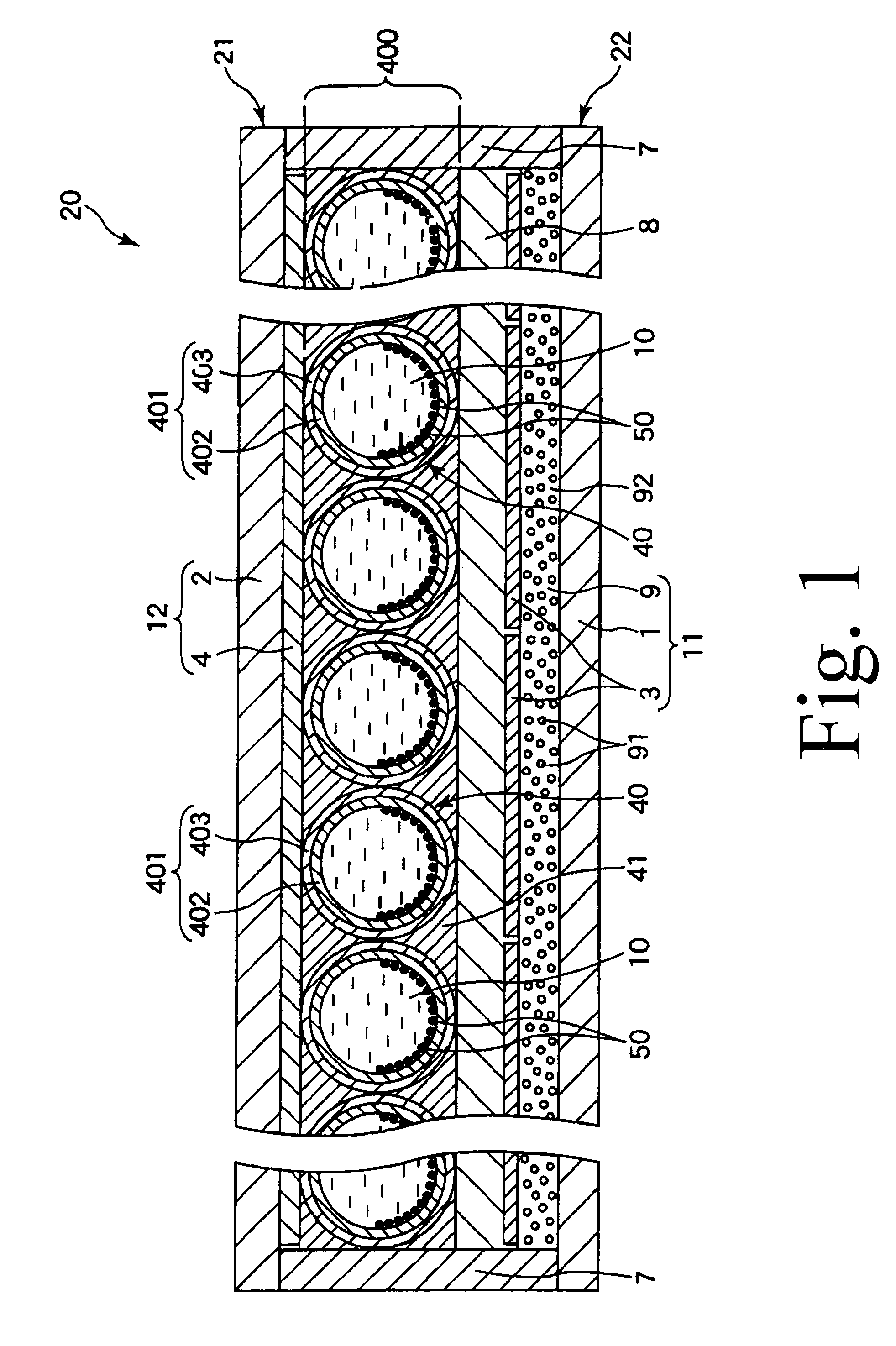

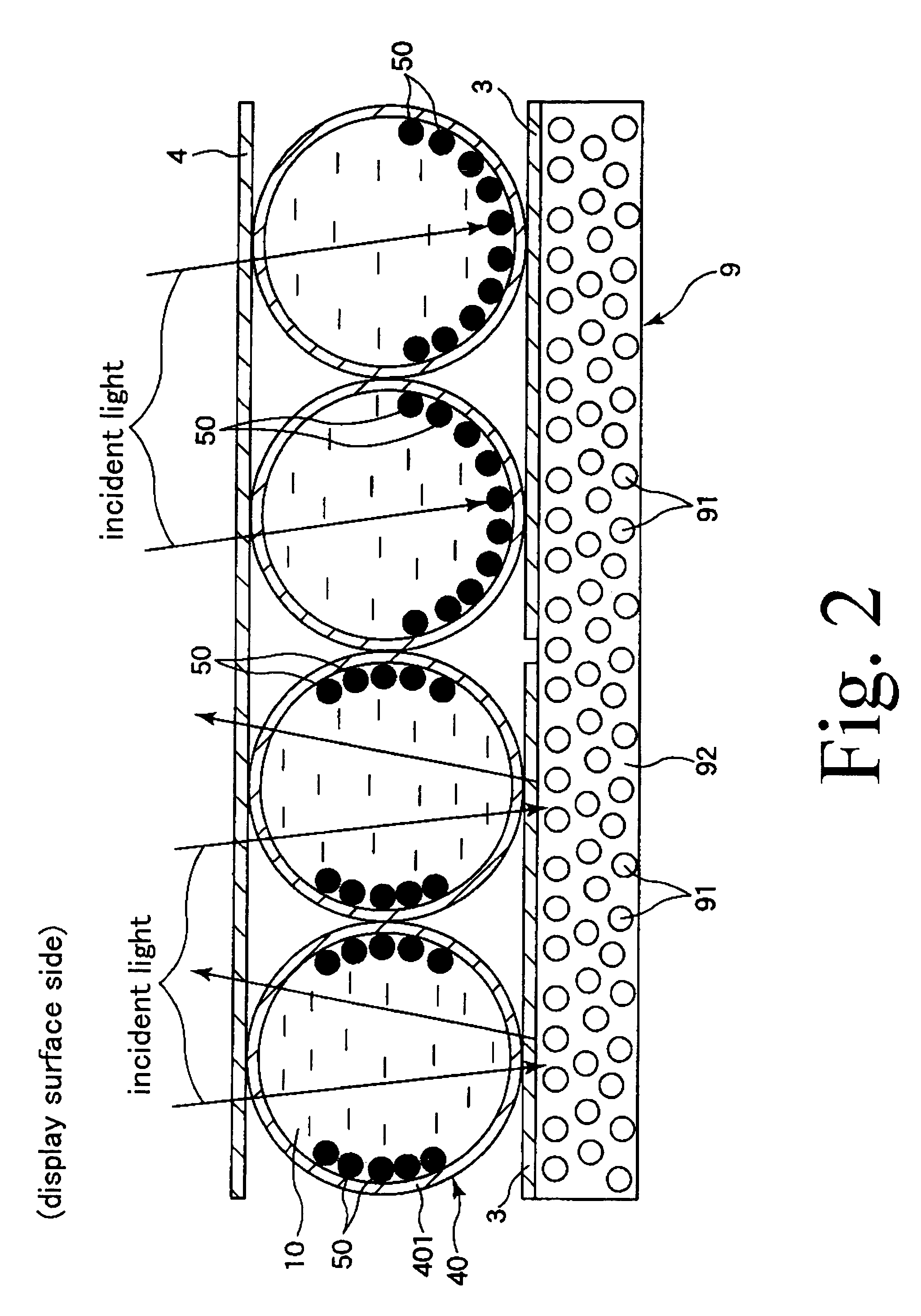

Display device, method of manufacturing display device and electronic apparatus

InactiveUS20090128889A1Improve the display effectEasily and reliably obtaining an intermediate toneStatic indicating devicesNon-linear opticsDisplay deviceEngineering

A display device capable of easily and reliably obtaining an intermediate tone and reliably maintaining individual colors including the intermediate tone even at stoppage of application of an electrical voltage, a manufacturing method of a display device capable of easily and reliably manufacturing the display device, and an electronic apparatus provided with the display device are provided. The display device has a display surface. The display device includes an adsorption particle-containing layer including a wall portion with an inner surface for defining a space, a plurality of electrically charged adsorption particles provided within the space in an adsorbed state that they are adsorbed to the inner surface of the wall portion, and a substantially transparent medium provided within the space, and a pair of electrodes that, when applied with an electrical voltage, generate electrical fields to act on the adsorption particles, wherein in the case where the electrical voltage is applied to between the electrodes, the adsorption particles are moved along the inner surface of the wall portion while maintaining the adsorbed state.

Owner:SEIKO EPSON CORP

Display device, method of manufacturing display device and electronic apparatus

InactiveUS7764420B2Easily and reliably obtaining an intermediate toneLong lasting colorStatic indicating devicesNon-linear opticsDisplay deviceEngineering

A display device capable of easily and reliably obtaining an intermediate tone and reliably maintaining individual colors including the intermediate tone even at stoppage of application of an electrical voltage, a manufacturing method of a display device capable of easily and reliably manufacturing the display device, and an electronic apparatus provided with the display device are provided. The display device has a display surface. The display device includes an adsorption particle-containing layer including a wall portion with an inner surface for defining a space, a plurality of electrically charged adsorption particles provided within the space in an adsorbed state that they are adsorbed to the inner surface of the wall portion, and a substantially transparent medium provided within the space, and a pair of electrodes that, when applied with an electrical voltage, generate electrical fields to act on the adsorption particles, wherein in the case where the electrical voltage is applied to between the electrodes, the adsorption particles are moved along the inner surface of the wall portion while maintaining the adsorbed state.

Owner:SEIKO EPSON CORP

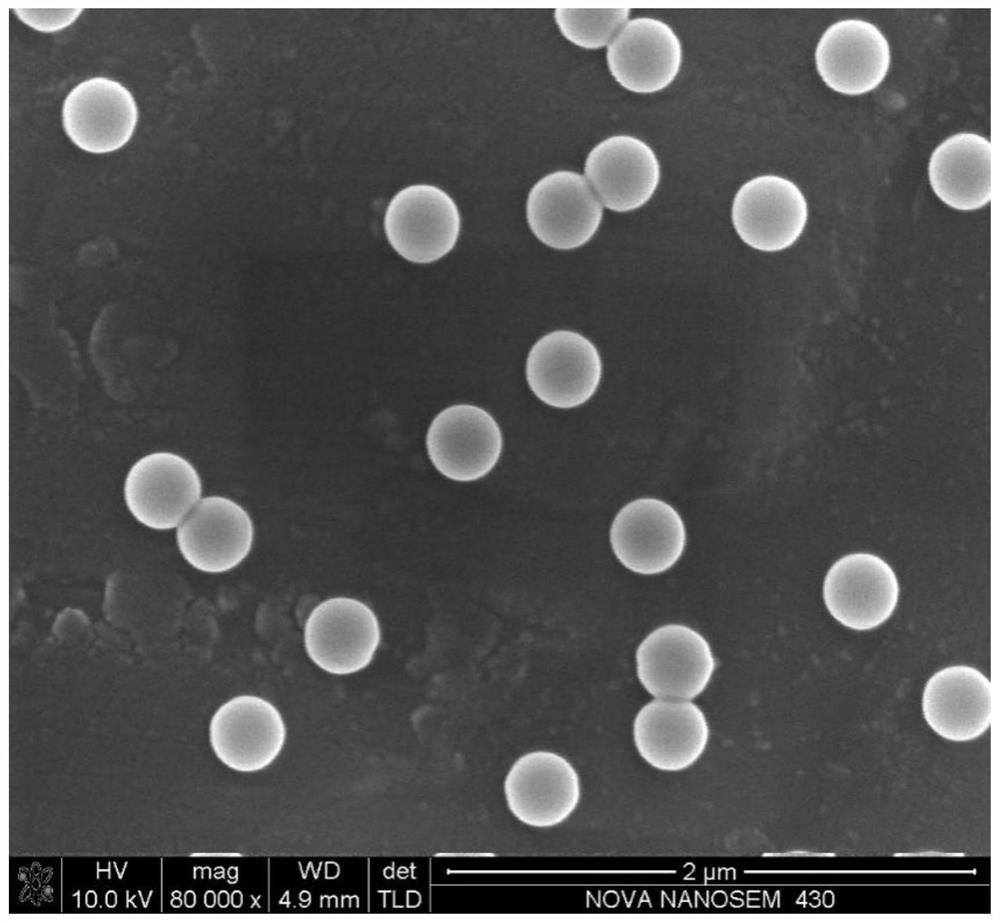

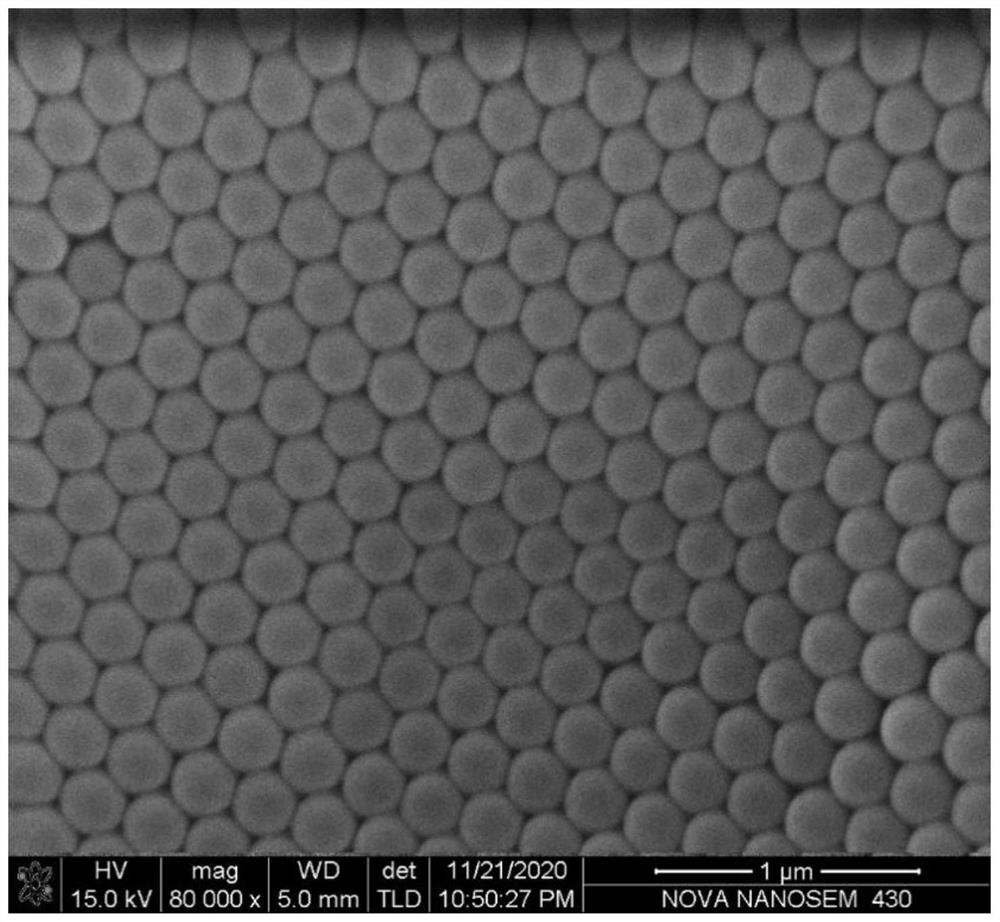

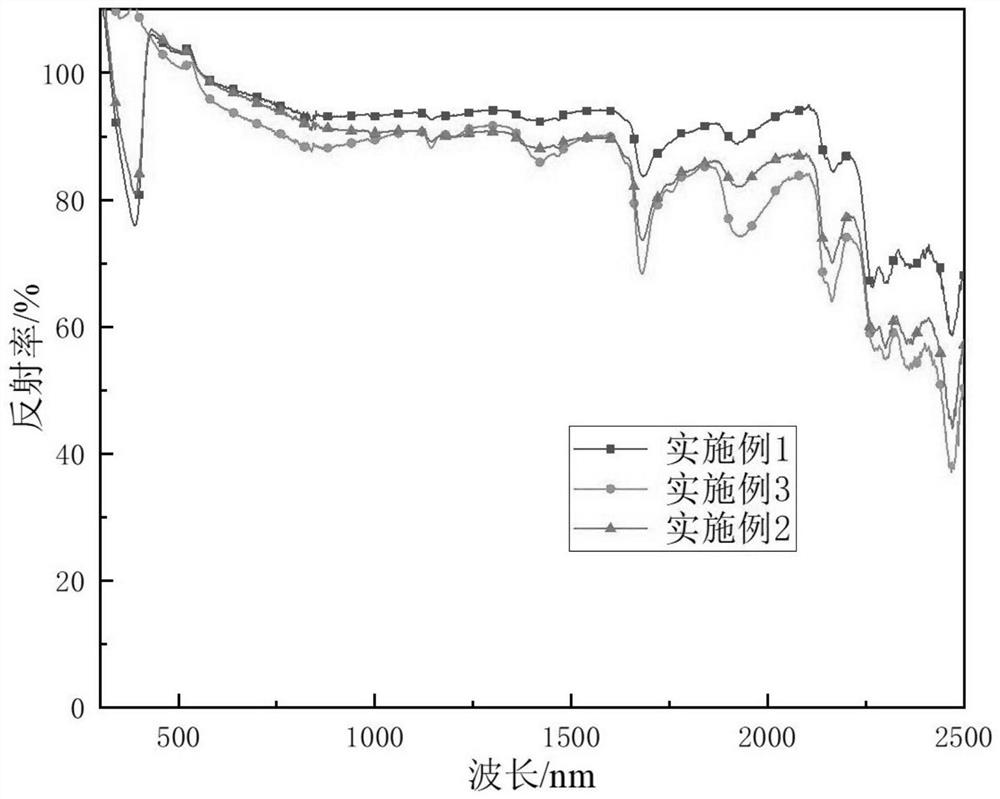

Colored radiation refrigeration film and preparation method thereof

ActiveCN113234367AWon't absorbImprove reflectivityReflecting/signal paintsMulticolor effect coatingsMicrosphereMaterials science

The invention discloses a colored radiation refrigeration film and a preparation method thereof. The colored radiation refrigeration film comprises a radiation refrigeration film layer and a structural color forming layer which are laminated, wherein the radiation refrigeration film layer comprises polyacrylate / water-based polyvinylidene fluoride resin, inorganic filler and auxiliaries, and the structural color forming layer is a self-assembled polystyrene microsphere layer; the composition comprises polystyrene microspheres and polyacrylate / water-based polyvinylidene fluoride resin. The preparation method of the colored radiation refrigeration film comprises the following steps: 1) preparing polystyrene microspheres; 2) preparing a radiation refrigeration film layer; 3) preparing the structural color forming layer. The colored radiation refrigeration film has a beautiful structural color, cannot absorb visible light, is high in sunlight reflectivity and mid-infrared emissivity, has a refrigeration effect and aesthetic characteristics, is simple in preparation process, does not need to be controlled by a precise instrument, and is low in cost.

Owner:SOUTH CHINA UNIV OF TECH

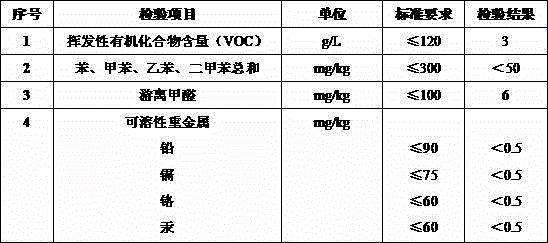

Ecological jade interior wall paint and preparation method thereof

InactiveCN105348938ALow VOC emissionImprove coating efficiencyAntifouling/underwater paintsPaints with biocidesEmulsionTitanium dioxide

The invention discloses ecological jade interior wall paint and a preparation method thereof and belongs to the field of building ornament materials. The paint is prepared from, by weight, 18-22 parts of water, 0.01-0.2 part of cellulose ether, 0.2-0.5 part of pH modifier, 0.1-0.2 part of wetting agent, 0.5-0.7 part of dispersing agent, 0.3-0.5 part of antifoaming agent, 8-14 parts of titanium dioxide, 6-15 parts of kaolin, 32-42 parts of jade powder, 14-22 parts of styrene-acrylic emulsion, 1.5-2.0 parts of coalescing agent and 0.1-0.15 part of antibacterial preservative. The ecological jade interior wall paint reduces emission of VOC and the content of soluble heavy metal, has the effects of desulfuration and air purification, and comprehensively increases the total value of decoration engineering to create a healthy indoor environment.

Owner:张保营

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com