Composite modified starch environmentally-friendly interior wall coating and preparation method thereof

A composite modified starch and interior wall coating technology, applied in the field of interior wall coatings, can solve the problems of waterproof, poor stain resistance, non-bacterial, etc., and achieve the effect of lasting bright colors, environmental friendliness, and improved impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

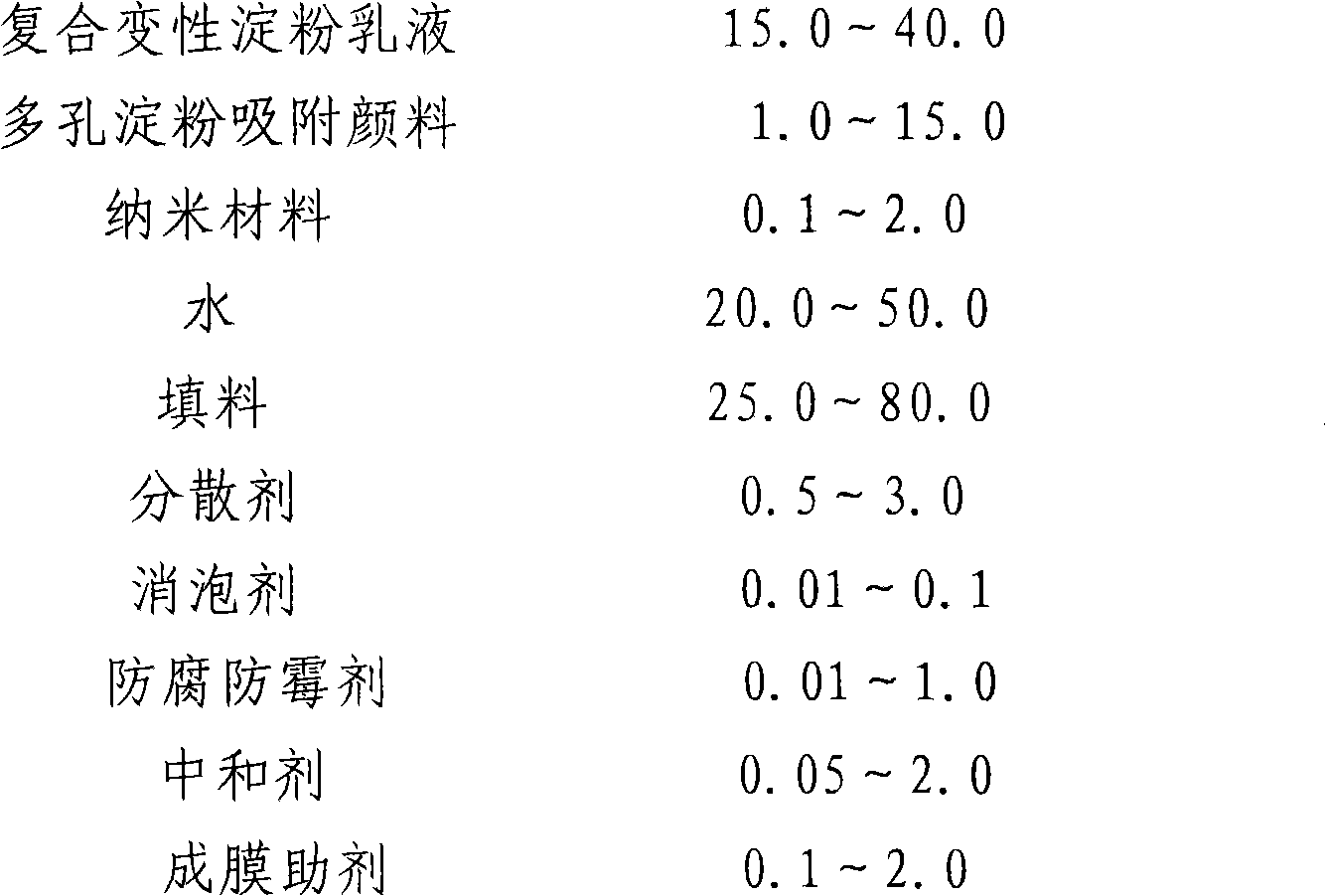

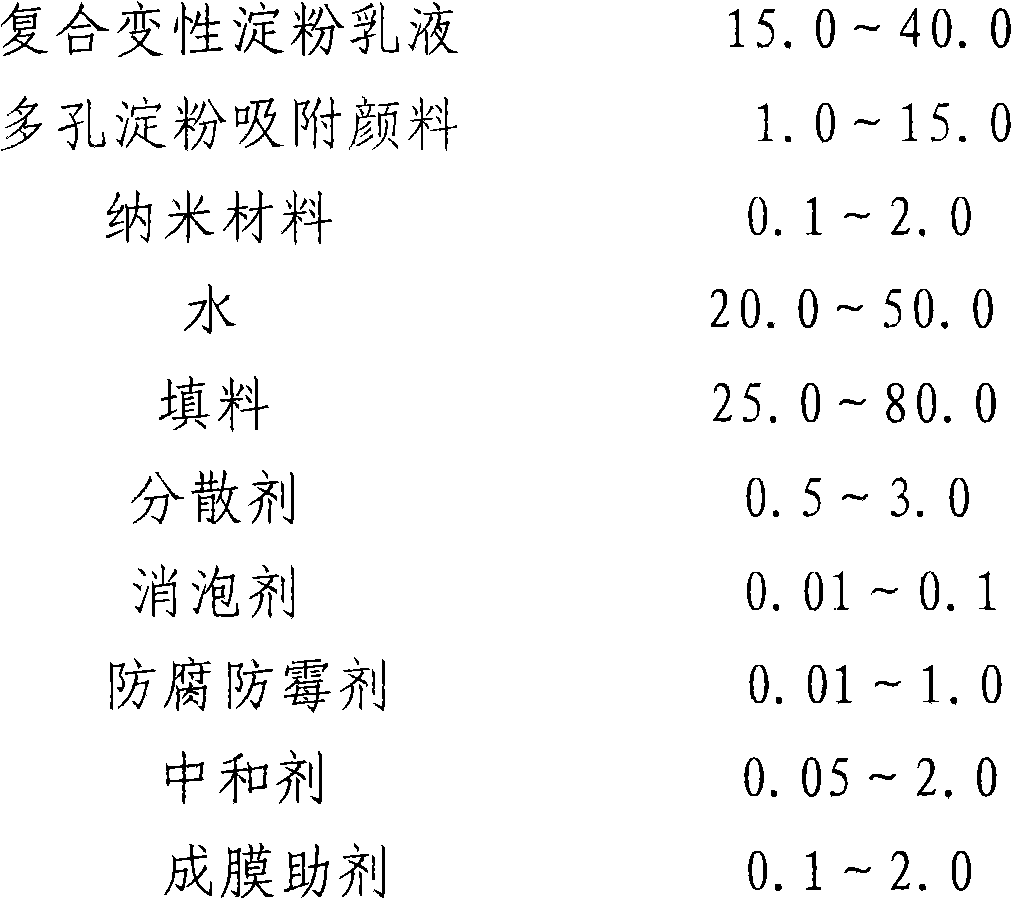

Method used

Image

Examples

Embodiment 1

[0043] (1), 250ml of deionized water, 8g of sodium polycarboxylate, 0.2g of tributyl phosphate, and 1g of 1,2-phenylpropylisothiazolin-3-one were stirred while feeding in the stirring disperser, and the stirring speed 500 rpm, stirring for 12 minutes;

[0044] (2), adjust the stirring speed to 1600 rev / min, successively mix nano-calcium carbonate 3g, nano-silica 3g, porous starch adsorption pigment 30g, heavy calcium carbonate 120g, light calcium 50g, kaolin 100g, talcum powder 50g and mica Put 30g of powder into the batching pot and stir for 1.5h;

[0045] (3), then reduce stirring speed to 400 rpm, add ethylene glycol 8g, 27% ammoniacal liquor 3g and composite modified starch emulsion 80g while stirring, after stirring evenly, then add composite modified starch emulsion 100g, stir evenly, The coating product was then obtained by filtering with an 80-mesh screen.

Embodiment 2

[0047] (1), 2000ml of deionized water, 100g of sodium polyacrylate, 1g of tributyl phosphate, and 6g of 2-n-octyl-4-isothiazolin-3-one were stirred while feeding in the stirring disperser, and the stirring speed 400 rpm, stirring for 10 minutes;

[0048] (2), adjust the stirring speed to 1500 rpm, and successively put 40g of nano-titanium oxide, 50g of nano-calcium carbonate, 100g of porous starch adsorption pigment, 1800g of heavy calcium carbonate, 1500g of kaolin, 600g of talcum powder and 500g of mica powder into the batching pot Inside, stir for 1h;

[0049] (3), reduce stirring speed to 400 revs / min, add ethylene glycol ethyl ether 100g, 27% ammoniacal liquor 50g and composite modified starch emulsion 1000g while stirring, add composite modified starch emulsion 1500g again after stirring, stir evenly, then The paint product was obtained by filtering through a 90-mesh screen.

Embodiment 3

[0051](1), 80L of deionized water, 4kg of ammonium polyacrylate, 0.04kg of tributyl phosphate, and 0.24kg of 2,4,5,6-tetrachloroisophthalonitrile were stirred while feeding in the stirring disperser, stirring The speed is 400 rpm, stirring for 15 minutes;

[0052] (2), adjust the stirring speed to 1500 rev / min, successively mix nano-titanium oxide 2kg, nano-calcium carbonate 2kg, nano-zinc oxide 1kg, porous starch adsorption pigment 4kg, heavy calcium carbonate 75kg, kaolin 60kg, talcum powder 25kg and weight Put 20kg of spar powder into the batching pot and stir for 1.3h;

[0053] (3), reduce stirring speed to 400 rpm, add ethylene glycol 4kg, 27% ammoniacal liquor 2.1kg and compound modified starch emulsion 45kg while stirring, add composite modified starch emulsion 60kg again after stirring, stir evenly, then The paint product was obtained by filtering through a 100 mesh screen.

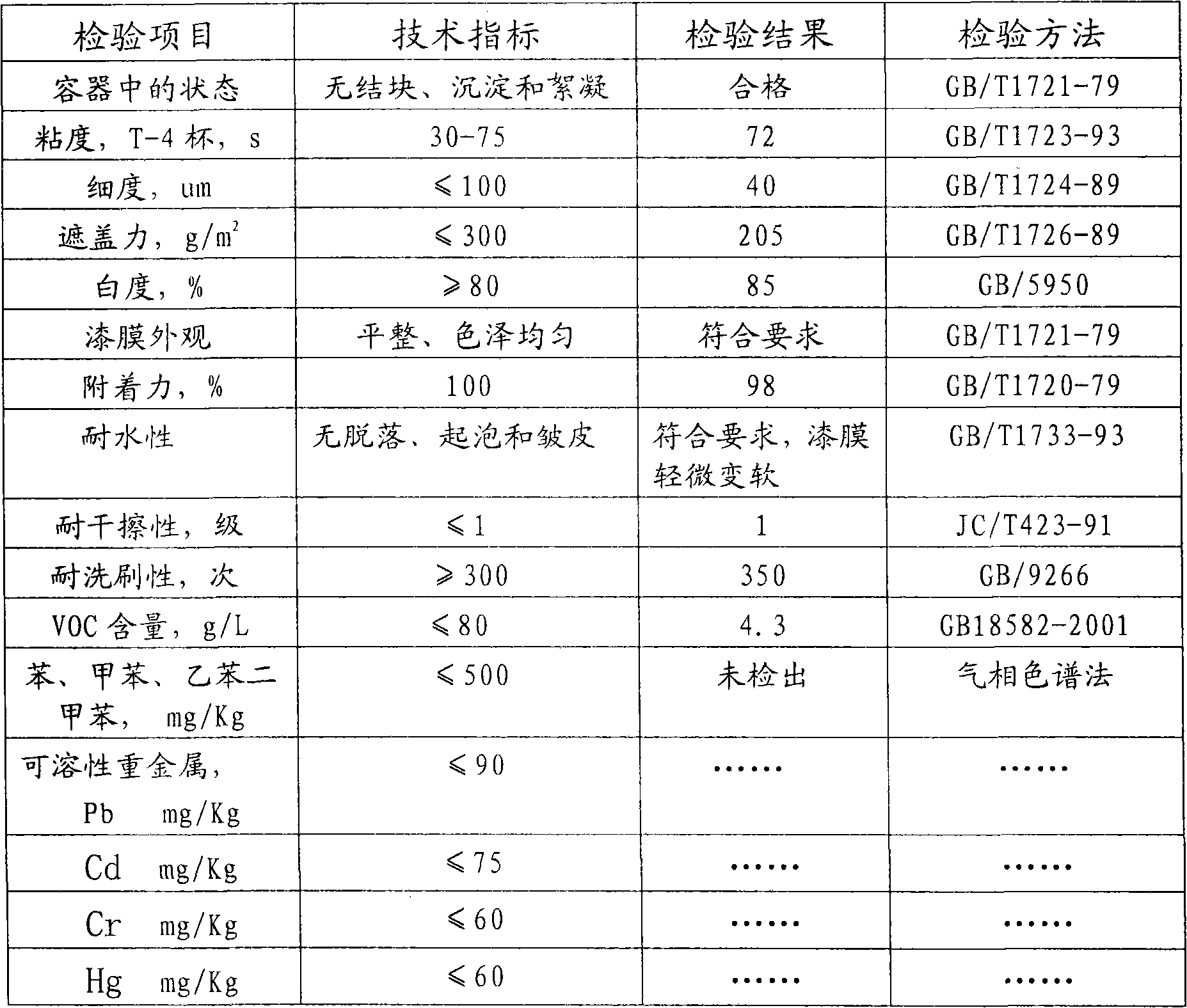

[0054] The product quality inspection data of the coating is detailed in the table below:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com