Rosy low-radiation coated glass and preparation method thereof

A low-radiation coating, rose red technology, applied in chemical instruments and methods, glass/slag layered products, layered products, etc., can solve the problems of high price, high production cost, easy discoloration, etc. The effect of maintaining no discoloration and long-term discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

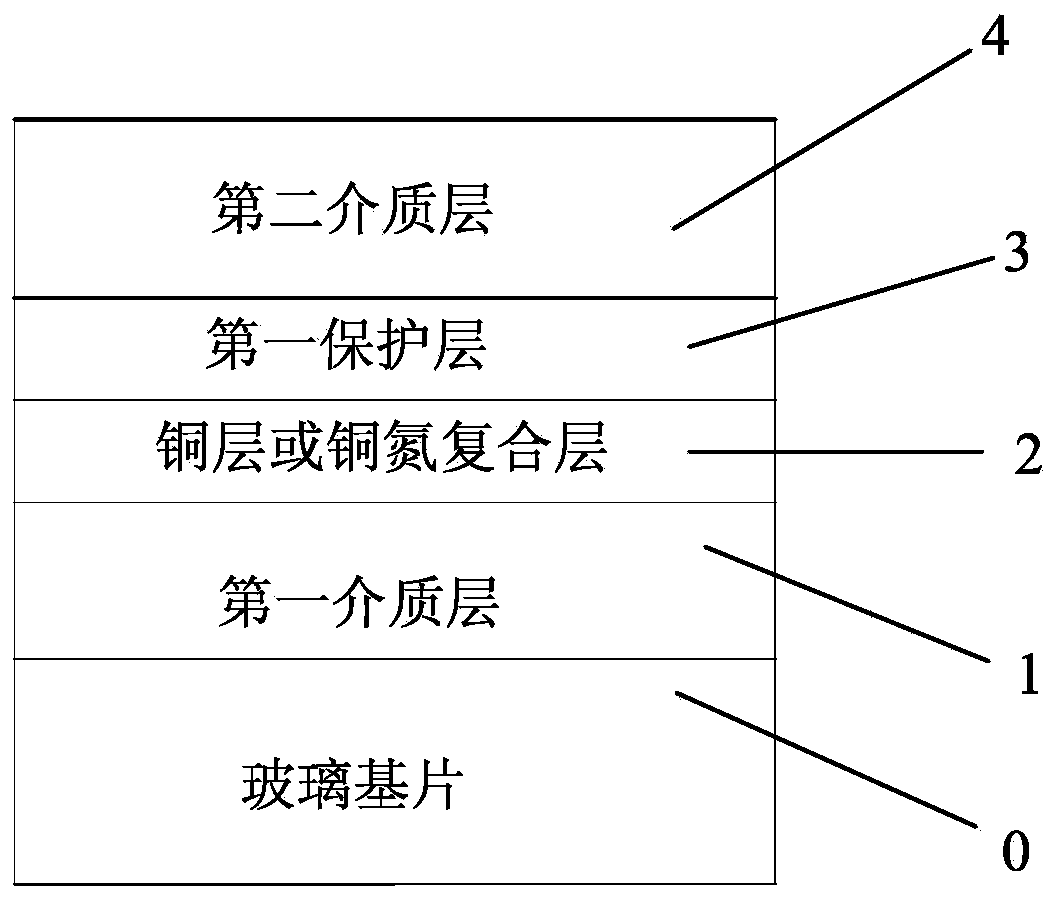

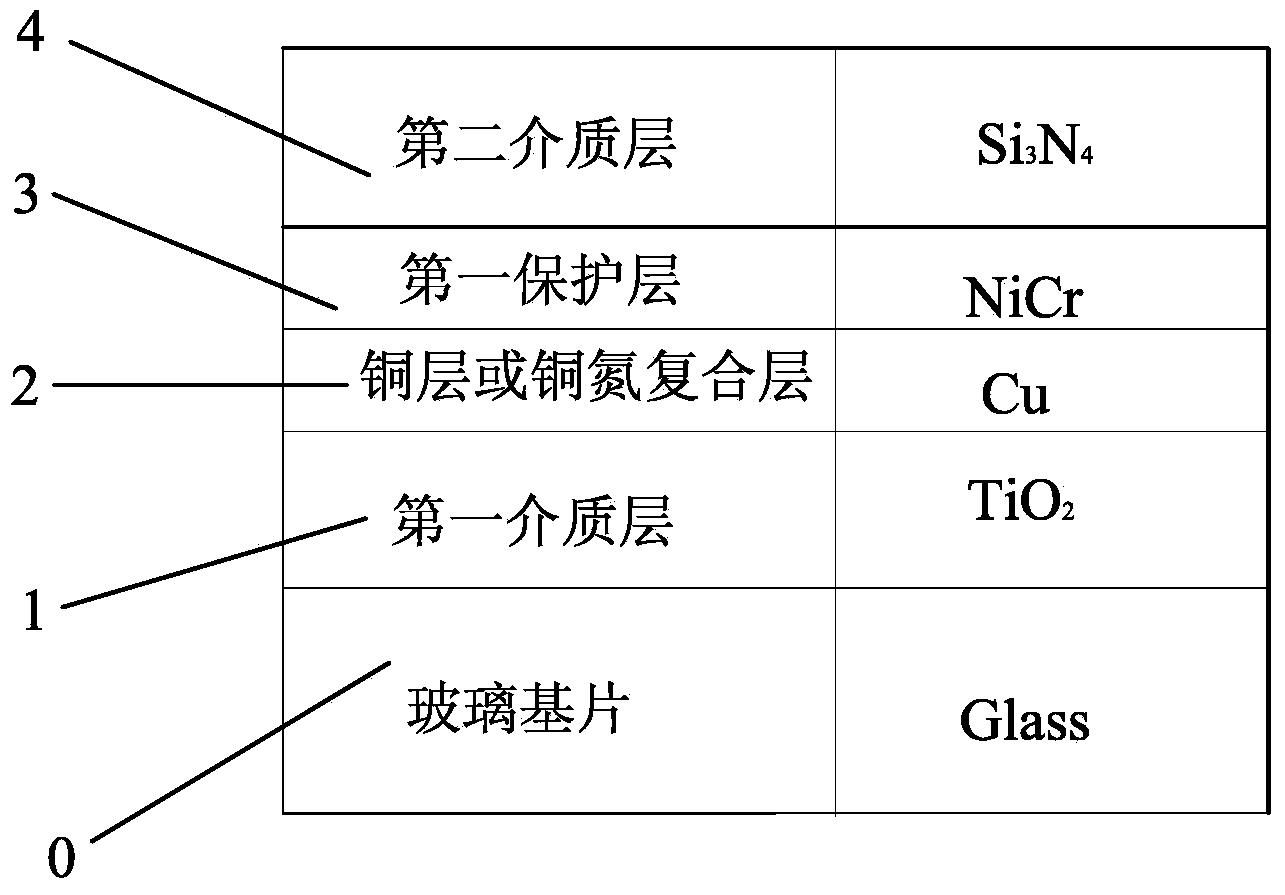

[0038] See figure 2 , a rose-red low-emissivity coated glass, comprising a glass substrate 0 and a coating layer coated on the surface of the glass substrate 0, the coating layer is formed by coating the surface of the glass substrate 0 by magnetron sputtering, and the glass substrate 0 side outwards is the first dielectric layer 1 (TiO 2layer, thickness 20nm), functional layer 2 (copper layer, thickness 25nm), first protective layer 3 (NiCr layer, thickness 5nm) and second dielectric layer 4 (Si 3 N 4 layer with a thickness of 110nm).

[0039] The structure of glass products is: Glass / TiO 2 / Cu / NiCr / Si 3 N 4 .

[0040] Observed by the naked eye, the non-coated surface (observed on the glass surface) presents a bright and uniform golden-red rose red color, and a stable reflection color can be obtained from multiple angles; the glass surface of the coated glass is tested by an instrument Color detection, the color value of the coated glass: L* g is 65.67, a* g is 21.5...

Embodiment 2

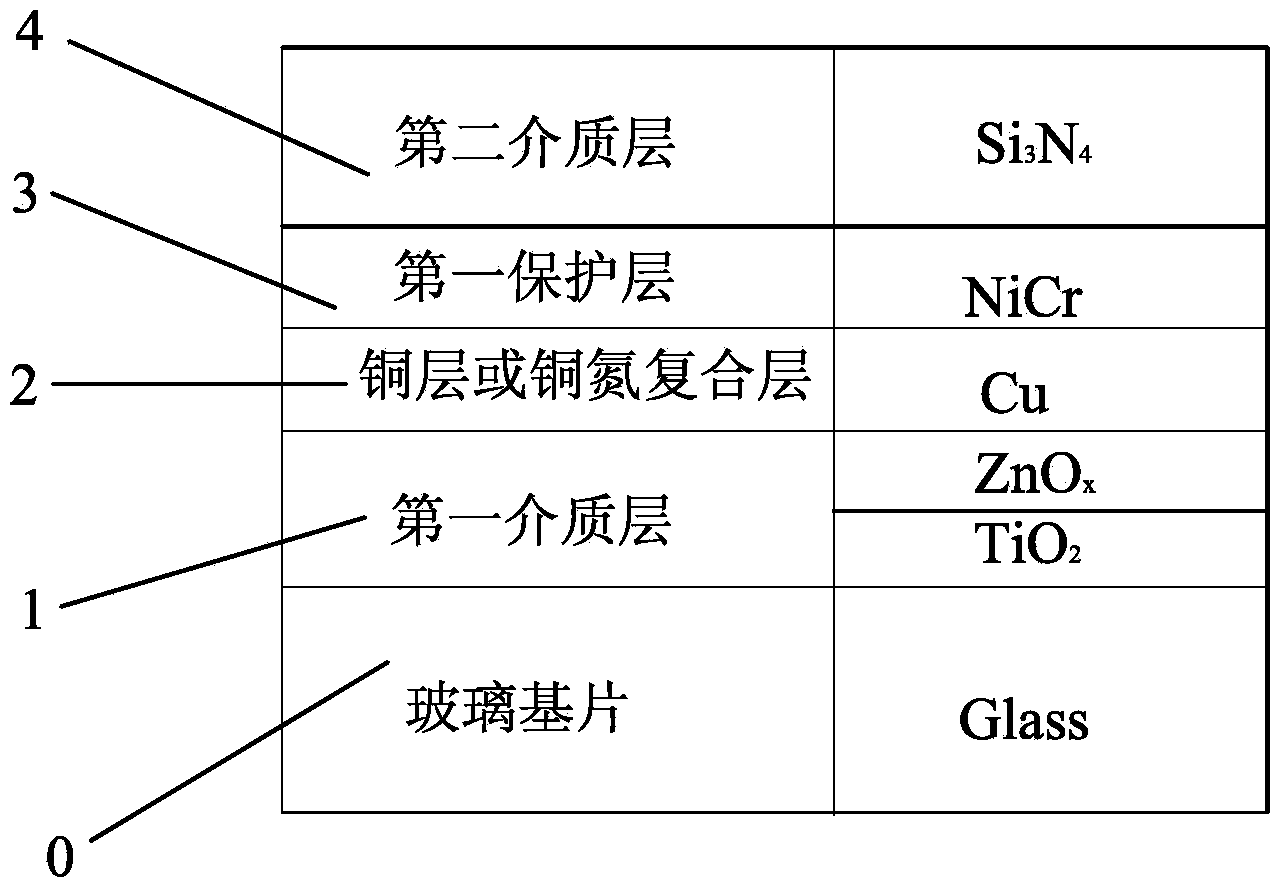

[0042] See image 3 , a rose-red low-emissivity coated glass, which includes a glass substrate 0 and a film layer coated on the surface of the glass substrate 0, the coating layer is formed by coating the surface of the glass substrate 0 by magnetron sputtering, and is made of the glass substrate The first dielectric layer 1 (TiO 2 layer and ZnO X layer, the thickness is 20nm and 15nm respectively), the functional layer 2 (copper layer, the thickness is 30nm), the first protective layer 3 (NiCr layer, the thickness is 5nm) and the second dielectric layer (Si3N 4 layer with a thickness of 130nm).

[0043] The structure of glass products is: Glass / TiO 2 / ZnO X / Cu / NiCr / Si 3 N 4 .

[0044] Observed by the naked eye, the non-coated surface (observed on the glass surface) presents a bright and uniform golden-red rose red color, and a stable reflection color can be obtained from multiple angles; the glass surface of the coated glass is tested by an instrument Color detection...

Embodiment 3

[0046] See Figure 4 , a rose-red low-emissivity coated glass, which includes a glass substrate 0 and a film layer coated on the surface of the glass substrate 0, the coating layer is formed by coating the surface of the glass substrate 0 by magnetron sputtering, and is made of the glass substrate The first dielectric layer 1 (TiO 2 layer, thickness 25nm), second protective layer 5 (NiCr layer, thickness 3nm), functional layer 2 (copper layer, thickness 30nm), first protective layer 3 (NiCr layer, thickness 5nm), second dielectric Layer 4 (ZnO X layer and Si 3 N 4 layer, the thickness is 30nm, 60nm respectively).

[0047] The structure of glass products is: Glass / TiO 2 / NiCr / Cu / NiCr / ZnO X / Si 3 N 4 .

[0048] Observed by the naked eye, the non-coated surface (observed on the glass surface) presents a bright and uniform golden-red rose red color, and a stable reflection color can be obtained from multiple angles; the glass surface of the coated glass is tested by an in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com