Semi-rigid PVC (polyvinyl chloride) decorative membrane

A decorative film and semi-rigid technology, applied in the field of decorative materials, can solve the problems of high cost of lamination, difficulty in lamination, easy occurrence of foaming, etc., and achieves low production cost and lamination cost, and long color retention time. , the effect of creating a soft atmosphere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

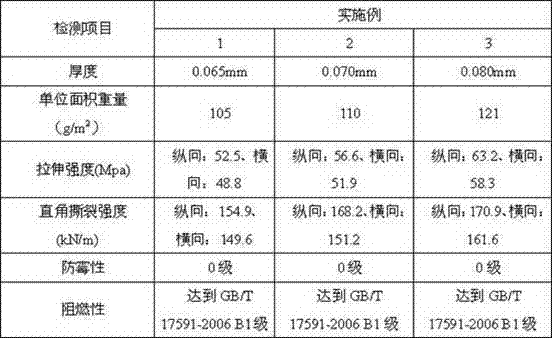

Embodiment 1

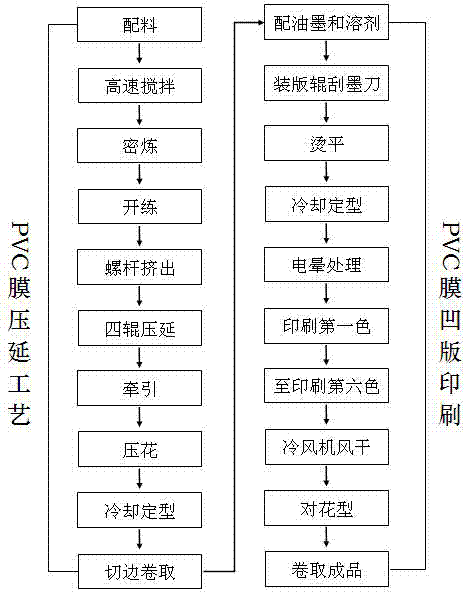

[0072] (1) Calendering stage:

[0073] 100 parts by weight of PVC resin powder, 18 parts by weight of dioctyl phthalate (DOP), 3 parts by weight of composite stabilizer, 25 parts by weight of nano calcium carbonate, 4 parts by weight of antimony trioxide, 6 parts by weight of titanium dioxide, 2 parts by weight of soybean oil and 0.1 part by weight of antifungal agent are the main raw materials, which are prepared through the processes of batching, high-speed stirring, banburying, open refining, screw extrusion, four-roll calendering, traction, embossing, cooling and shaping, and trimming and coiling. Get PVC film; its technological process is as follows figure 1 shown.

[0074] The composite stabilizer is 1 part by weight of a calcium-zinc powder brick stabilizer and 2 parts by weight of a barium-zinc liquid stabilizer.

[0075] The antifungal agent is 10,10'-oxobisphenoxarsenic and diethyl-2,3-epoxypropyl-[3-(methyldimethoxy)]silylpropyl ammonium chloride Mixture, its mas...

Embodiment 2

[0092] (1) Calendering stage:

[0093] 100 parts by weight of PVC resin powder, 22 parts by weight of dioctyl phthalate (DOP), 4 parts by weight of composite stabilizer, 30 parts by weight of nano calcium carbonate, 5 parts by weight of antimony trioxide, 8 parts by weight of titanium dioxide, 3 parts by weight of soybean oil and 0.2 parts by weight of antifungal agent are the main raw materials, which are prepared through the processes of batching, high-speed mixing, banburying, open refining, screw extrusion, four-roll calendering, traction, embossing, cooling and shaping, and edge trimming and coiling. Get the first product of PVC film; its technological process is as follows figure 1 shown.

[0094] The composite stabilizer is 1.3 parts by weight of calcium-zinc powder brick stabilizer and 2.7 parts by weight of barium-zinc liquid stabilizer.

[0095] The antifungal agent is 10,10'-oxobisphenoxarsenic and diethyl-2,3-epoxypropyl-[3-(methyldimethoxy)]silylpropyl ammonium ...

Embodiment 3

[0112] (1) Calendering stage:

[0113] 100 parts by weight of PVC resin powder, 23 parts by weight of dioctyl phthalate (DOP), 5 parts by weight of composite stabilizer, 35 parts by weight of nano calcium carbonate, 6 parts by weight of antimony trioxide, 9 parts by weight of titanium dioxide, 4 parts by weight of soybean oil and 0.3 parts by weight of antifungal agent are the main raw materials, which are prepared through the processes of batching, high-speed stirring, banburying, open refining, screw extrusion, four-roll calendering, traction, embossing, cooling and shaping, and trimming and coiling. Get the first product of PVC film; its technological process is as follows figure 1 shown.

[0114] The composite stabilizer is 2 parts by weight of calcium-zinc powder brick stabilizer and 3 parts by weight of barium-zinc liquid stabilizer.

[0115] The antifungal agent is 10,10'-oxobisphenoxarsenic and diethyl-2,3-epoxypropyl-[3-(methyldimethoxy)]silylpropyl ammonium chlorid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com