Patents

Literature

47results about How to "Rich color layers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for processing nebular yarns

The invention relates to a method for processing nebular yarns. The method includes the following processing procedures in sequence: raw material preparation, scutching, cotton carding, pre-drawing, scrolling, combing, sliver staining, drawing, roving, spinning, winding, double twisting and spooling, wherein in the procedure of sliver staining, at least one cotton sliver is selected for staining. The stained cotton sliver contains at least two colors, including the white. The invention changes the normal color yarn staining method. By adopting sliver staining, at least one cotton sliver has at least two colors; and at least one cotton sliver stained is drawn with a cotton silver of the original color to be made into a spun-dyed yarn of nonuniform color. Yarn woven fabrics made through the method have nebular effect.

Owner:WUXI NATURAL GREEN FIBER TECH

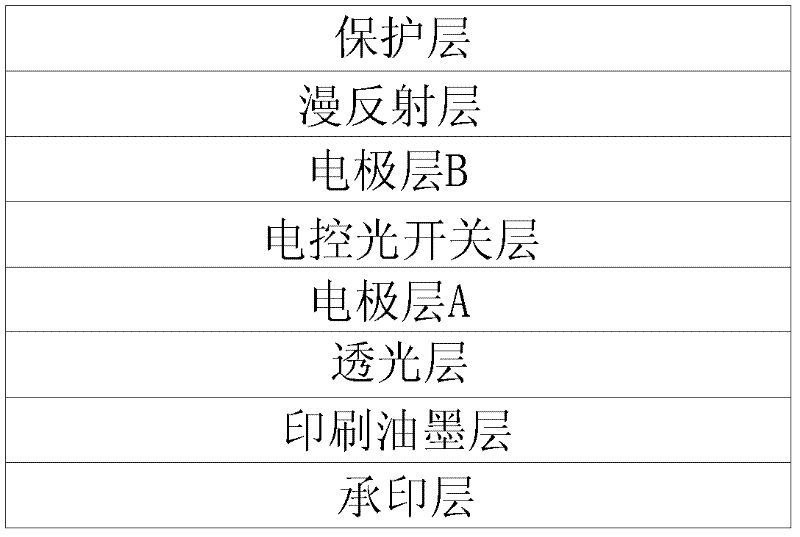

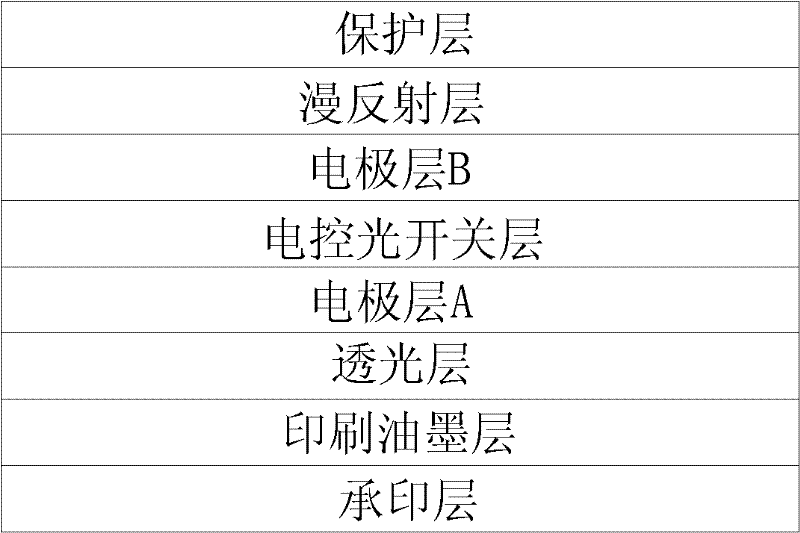

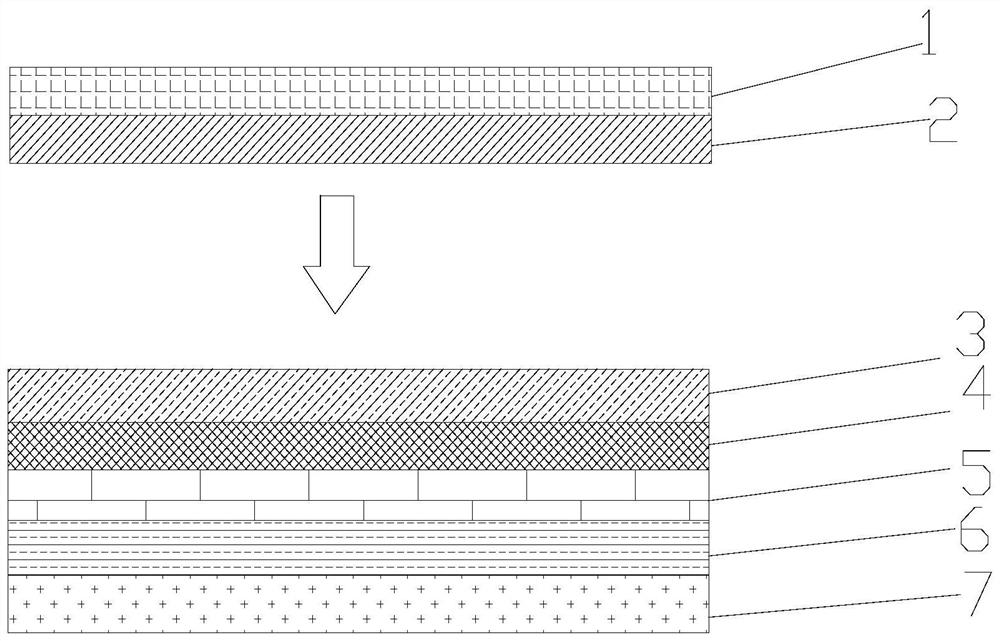

Printed Flexible Display

The invention discloses a printed flexible display screen. The printed flexible display screen comprises a printed layer and a printing ink layer adhered to the printed layer, at least a transparent layer, an electrode layer A, an electric control photoswitch layer and an electrode layer B are adhered to the printing ink layer from bottom to top; the printed layer is made of a foldable and printable flexible insulating material, the printing ink layer is a CMYK (cyan, magenta, yellow and black) ink dot matrix printed on the printed layer, the transparent layer is made of a flexible transparent material, the electric control photoswitch layer is a PDLC (polymer dispersed liquid crystal) film, the electrode layer A and the electrode layer B are both ITO (indium tin oxide) conductive film layers respectively etched with an electrode matrix, and the electrode matrixes of the electrode layer A and the electrode layer B are vertical to each other. The display screen is easy to colorize, has the advantages of short response time, low driving voltage and low production cost and is suitable for reading with human eyes and in the manufacturing process is simple.

Owner:BEIJING SAN WU JIU INVESTMENT

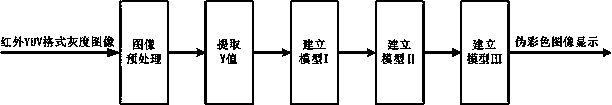

Infrared image pseudo color processing method based on YUV color space

InactiveCN107871302ARich color layersSharp contrastGeometric image transformationRGB color spaceColor space

The invention discloses an infrared image pseudo color processing method based on a YUV color space. The infrared image pseudo color processing method based on the YUC color space comprises steps of using a YUV format gray-scale image obtained from an infrared thermal imaging system, using a gauss low pass filter to perform pretreatment on the YUV format gray-scale image, extracting a value of a Ychannel of the YUV format gray-scale image which is the gray value, establishing a mapping model I between the gray scale value Y and an RGB color space through a gray scale and color conversion method, establishing a mapping model II between the YUV color space and the RGB color space according to an NTSC system standard and establishing a pseudo color processing model III based on the YUV colorspace according to the model I and the model II . The infrared image pseudo color processing method based on the YUV color space can directly convert the gray scale image to the pseudo color image through the established model III. The infrared image pseudo color processing method based on the YUV color space can save conversion time of the color space under a condition that quality and a contrast ratio of the image are constant with a traditional pseudo color processing effect based on the RGB color space and can dramatically improve processing efficiency and instantaneity.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Color photovoltaic module with improved efficiency and preparation method thereof

ActiveCN112406223AAdd dimensionClear color gradationLamination ancillary operationsLaminationColored whiteComputer printing

The invention provides a color photovoltaic module with improved efficiency, which sequentially comprises a pattern part for bearing colors and a solar photovoltaic module from top to bottom, and is characterized in that the pattern part comprises a white ink layer formed by printing and a color ink layer formed by printing. By adjusting the color gradation of a picture with a required pattern, printing software controls the ink output of white ink when a printer prints the white ink layer by identifying different color gradations in the picture, and meanwhile, controls a black place and a white place not to output ink when the printer prints the color ink layer. Through the method, the usage amount of the white ink is reduced, the production cost of the color photovoltaic module is reduced, the shielding effect of the photovoltaic module can be effectively reduced, the reflection of the white ink layer to sunlight is reduced, the efficiency of the photovoltaic module and the safety ofthe photovoltaic module are effectively improved, the black color of the photovoltaic wafer can be fully utilized, and the production cost of the color photovoltaic module is reduced. The stereoscopic impression of the pattern is effectively improved, and the color gradation of the pattern is more obvious and richer.

Owner:新源劲吾(北京)科技有限公司

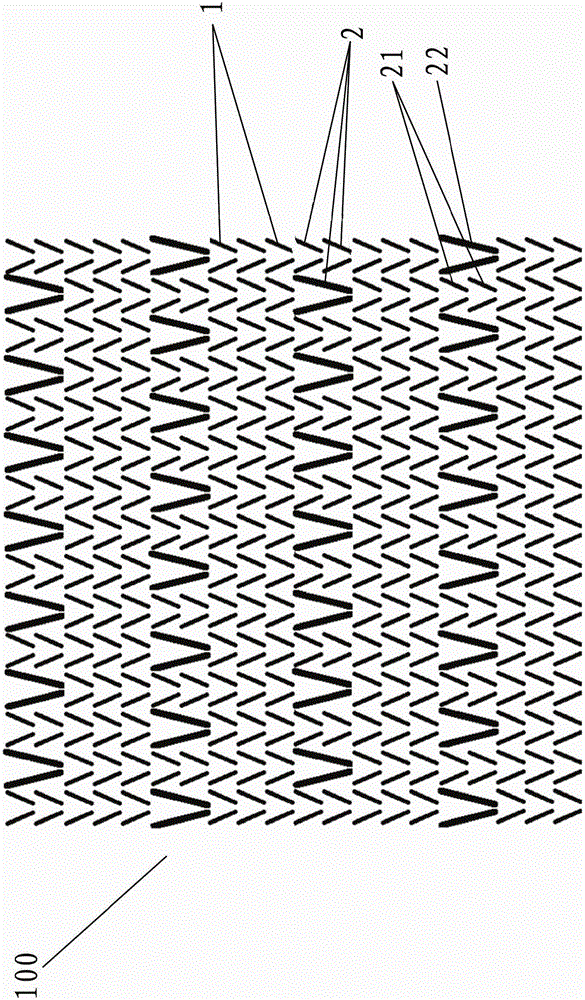

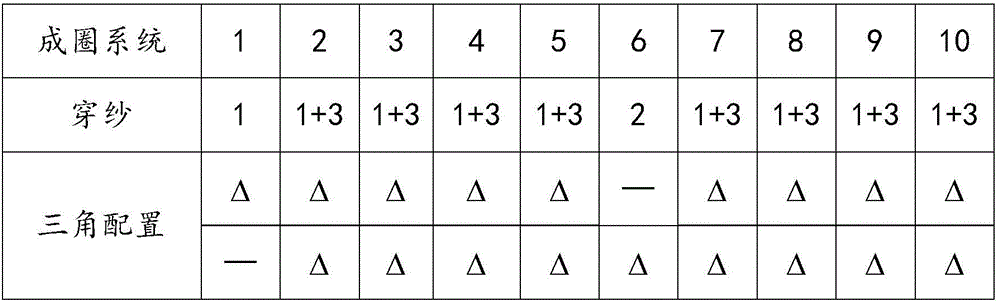

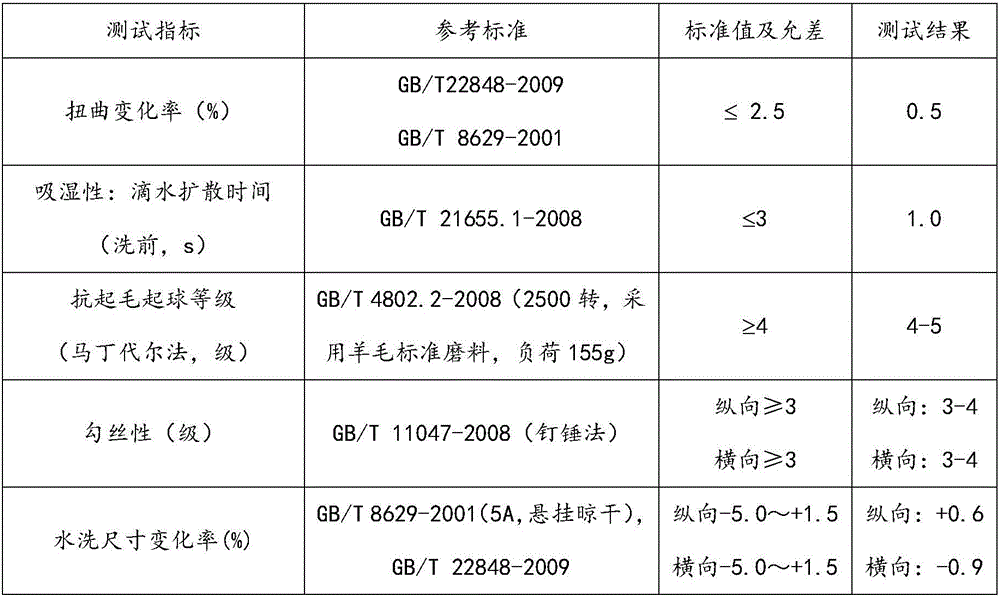

Single-sided weft-knitted fabric with cross-stripe effect and production method of single-sided weft-knitted fabric

ActiveCN106480589AGood bar effectRich fabric surfaceWeft knittingHeating/cooling textile fabricsPolyesterEngineering

The invention provides single-sided weft-knitted fabric with the cross-stripe effect. The single-sided weft-knitted fabric comprises a fabric body with the cross-stripe structure, the cross-stripe structure is formed by first coil rows and second coil rows, the first coil rows and the second coil rows are longitudinally and alternatively arranged, each second coil row behind each first coil row performs 1-stitch displacement, the first coil rows are composed of coils by knitting of three continuous cross-row looped coils protruding the front side of the fabric body, the second coil rows are formed by alternative knitting of looped coils of two cross-row coils protruding the front side of the fabric body and one longitudinal floating-thread stretched coil, the first coil rows are woven by cationic polyester filament and spandex in a doubling manner, and the second coil rows are knitted by half-matting polyester filament. Compared with the prior art, the single-sided weft-knitted fabric has the advantages of remarkable stripe experience, good cross elasticity and extension, good resistance to pilling and the like. The invention further provides a production method of the single-sided weft-knitted fabric with the cross-stripe effect.

Owner:QUANZHOU HAITIAN MATERIAL TECH CORP

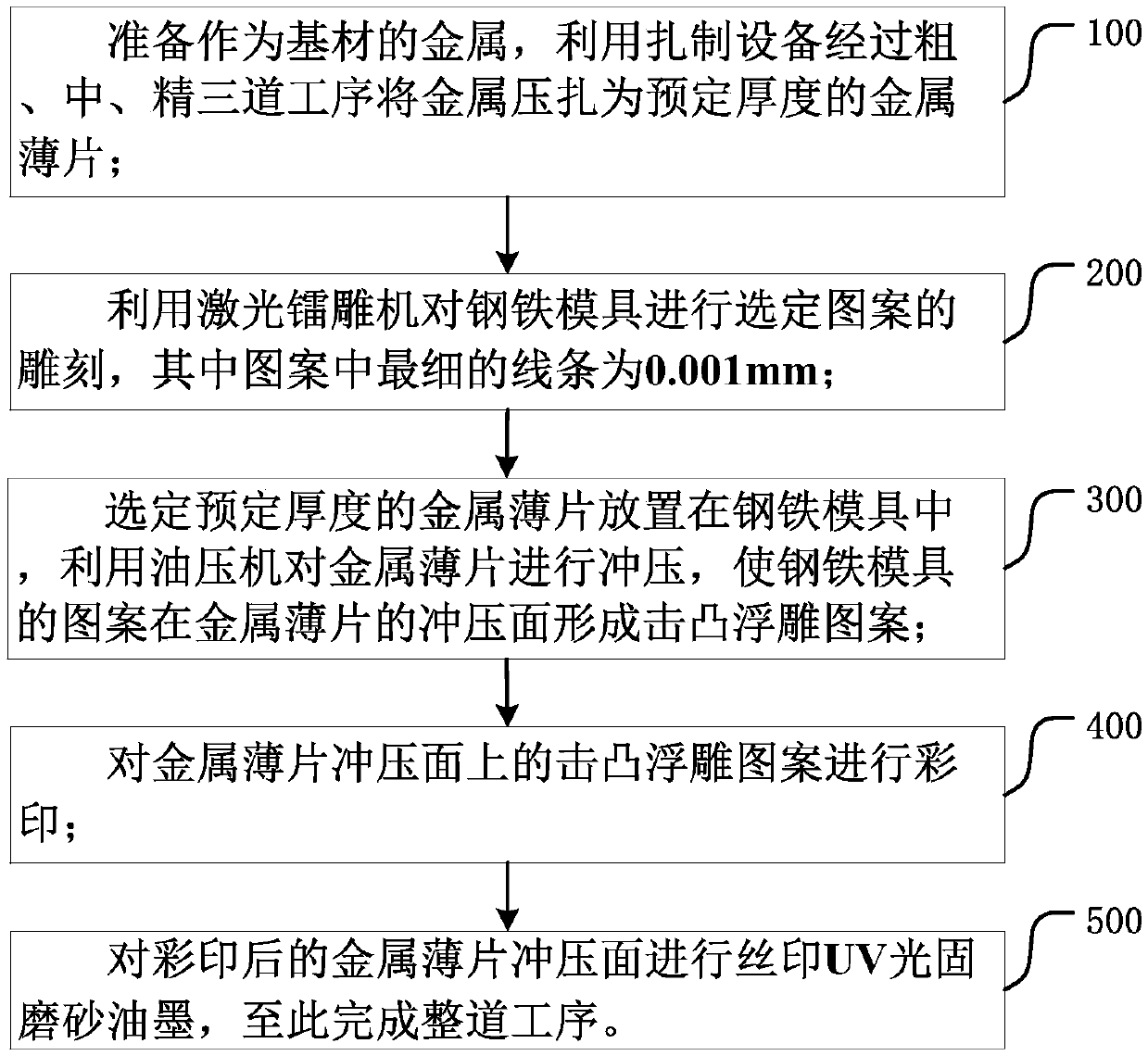

Manufacturing method of embossed metal color print

InactiveCN109532309AMeet high product demandHigh precisionDecorative surface effectsSpecial ornamental structuresScreen printingColor printing

The invention provides a manufacturing method of an embossed metal color print. The manufacturing method comprises the following steps that metal is prepared as a base material, the metal is rolled into a metal sheet with a preset thickness through a rough, medium and fine procedures and by rolling equipment; a laser engraving machine is used for carving a selected pattern on a steel mold; the metal sheet with the preset thickness is selected to be placed in the steel mold, and the metal sheet is punched by using an oil press, so that the pattern of the steel mold forms a raised embossed pattern on the punched surface of the metal sheet; color printing is conducted on the raised embossed pattern on the punched surface of the metal sheet; and silk-screen printing with UV photo-cured frostedink is conducted on the punched surface of the metal sheet after color printing. According to the manufacturing method, the metal sheet can finally realize a raised embossed metal product with the gravure printing effect, so that not only lines in the pattern can be reflected through embossment, but also color printing can be conducted directly on the pattern represented by the lines, and a finalproduct can have a high-precision embossed pattern which can be touched and have rich color levels.

Owner:SHENZHEN JINBAOYING CULTURE

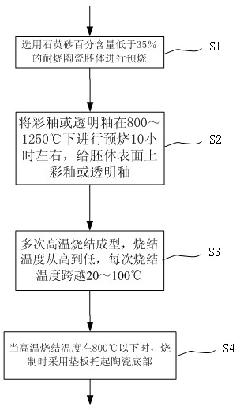

Multi-temperature sintering method for ceramic

The invention discloses a multi-temperature sintering method for ceramic. The method comprises the steps: pre-sintering a ceramic blank body, and coating colour ceramic glaze or transparent glaze on the surface of the blank body; and carrying out multi-high-temperature sintering molding, wherein the percentage content of quartz sand in the ceramic blank body is less than 35%, the colour ceramic glaze or transparent glaze is pre-fired for about 10 hours at the temperature of 800-1250 DEG C; during the multi-high-temperature sintering molding, from high to low, sintering temperature spans over 20-100 DEG C each time. In the multi-temperature sintering method for the ceramic, the blank material with low quartz sand percentage content is used, the calcined colour ceramic glaze or transparent glaze is coated on the surface of the blank body, and multi-high-temperature sintering temperature is controlled, and finally, a decorative ceramic pattern with diverse color levels and bright gloss is formed, and the decorative ceramic pattern does not has the problems of foaming, decoloring and cracking.

Owner:SHANGHAI GAOCHENG CREATIVE TECH GRP

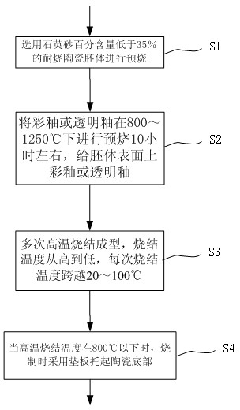

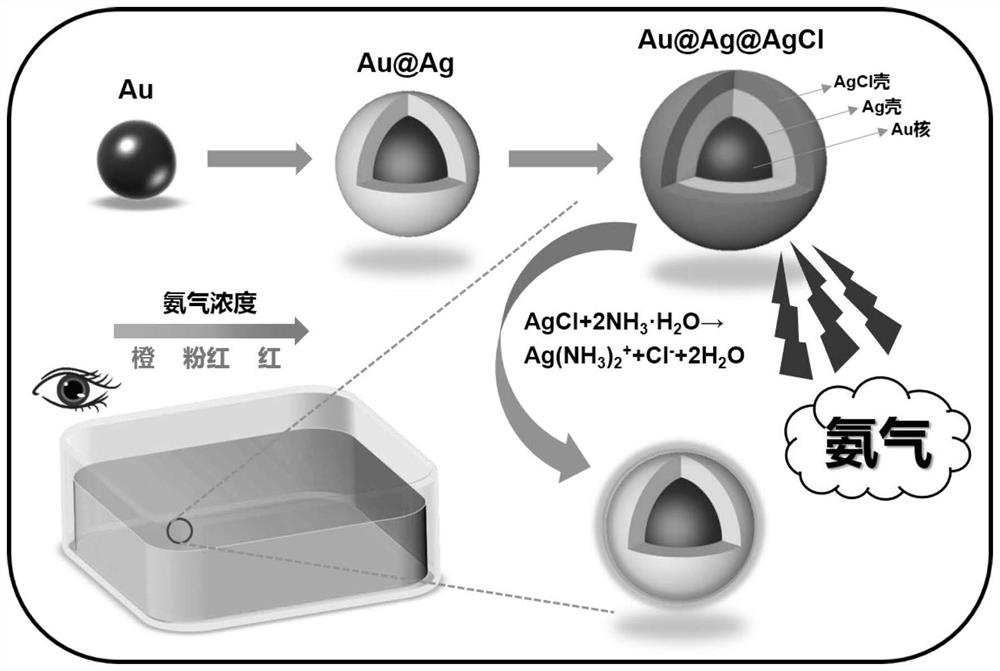

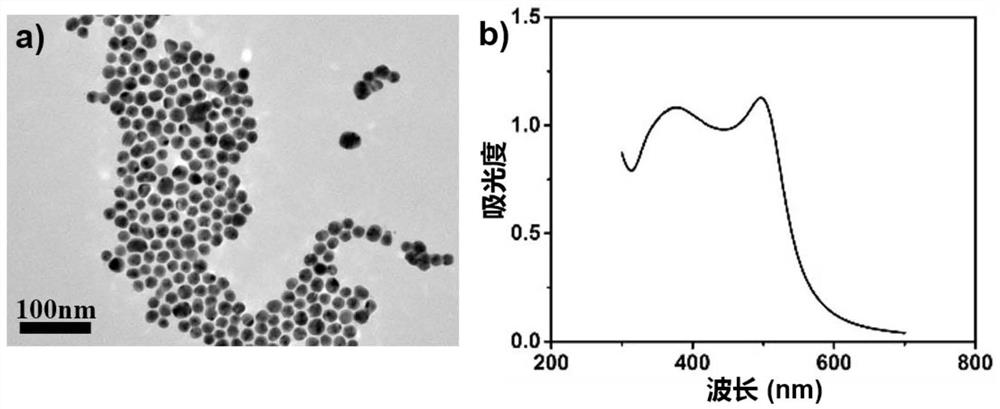

Preparation method of Au@Ag@AgCl nanoparticles and application thereof in colorimetric detection of ammonia

ActiveCN113059175AImprove stabilityRich color layersMaterial nanotechnologyTransportation and packagingNanoprobeNanoparti cles

The invention discloses a preparation method of Au@Ag@AgCl nanoparticles for colorimetric detection of ammonia concentration. The method comprises the following steps: firstly, reducing a HAuCl4 solution in a water phase by taking a sodium citrate solution as a reducing agent to prepare Au nanospheres; then reducing an AgNO3 solution by using ascorbic acid under a weak alkaline condition through an epitaxial growth method, and depositing a layer of silver shell on the prefabricated Au nanospheres; and then depositing a layer of thin AgCl on the Au@Ag nanoparticles through the oxidation etching effect of FeCl3 on the Ag shell to obtain the Au@Ag@AgCl nanoparticles with a three-layer core-shell structure. A nanoparticle probe is subjected to a specific reaction with ammonia, so that the components and the shell components of the nano probe are changed, and the absorbance of the material is obviously changed; and the nano probe is high in specificity and sensitivity to ammonia response, stable in performance, convenient and fast, and rapid qualitative and semi-quantitative analysis of the ammonia concentration can be realized by naked eyes.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Production method of simulation plaque

InactiveCN101828786AThe surface of the product is smoothRich color layersArtificial flowers and garlandsMetallurgyPigment

The invention relates to the field of ceramic crafts, in particular to a production method of simulation plaque, comprising the following steps of: 1, kneading porcelain clay into a flow shape and then biscuiting at 1,270-1,330DEG C; 2. adding a layer of transparent base enamel with the sintering temperature of 1,080-1,150DEG C on a biscuited blank; 3. spraying pigments of various colors on the transparent base enamel; and 4. coating a layer of transparent base enamel with the sintering temperature of 1,080-1,150DEG C and carrying out glaze firing at 1,080-1,150DEG C to obtain a finished product. Compared with the prior art, because the colorization is carried out below the glaze, the plaque product has the advantages of smooth surface, abundant colors and layers, excellent simulation effects, bloom like real flowers and higher grade.

Owner:郑菁菁

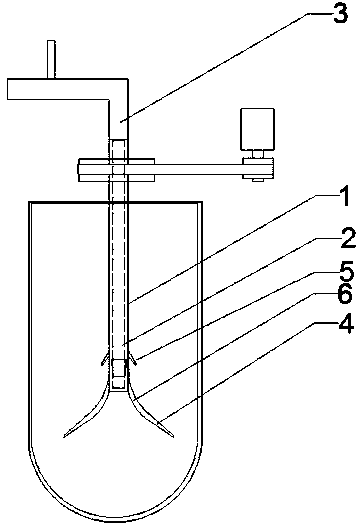

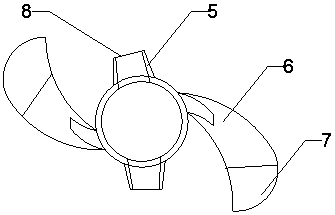

Production technology of photochromic umbrella fabric

InactiveCN109056344AReduce usageAvoid reachingRotary stirring mixersTransportation and packagingScreen printingOrganic solvent

The invention provides a production technology of photochromic umbrella fabric. The production technology comprises the following steps: firstly, preparing coating printing paste; secondly, printing:carrying out photochromic printing on the fabric subjected to coating finishing by using rotary screen printing equipment; thirdly, drying: enabling the printed fabric to enter a dryer and then dryingat 100 to 120 DEG C for 30 to 120 seconds; fourthly, carrying out coating finishing; fifthly, carrying out coating finishing: finishing an outer coating of the fabric on a coating machine by using anouter coating adhesive and drying at 110 to 130 DEG C for 30 to 120 seconds. The formula of the outer coating adhesive is prepared from the following components in parts by weight: 60 to 70 parts ofsolvent type PU adhesive or PA adhesive, 0.5 to 1.5 parts of bridging agent for the coating and 7 to 9 parts of organic solvent; during the preparation of a coating adhesive, firstly, carrying out mixed dispersing on the bridging agent for the coating into the solvent type PU adhesive or PA adhesive and adding the bridging agent for the coating for uniform mixing when the viscosity of a mixture reaches 5000 to 10000mpa. s. According to the production technology disclosed by the invention, by adopting an inner coating and an outer coating, the defect that the discoloration effect of the fabrictreated by an existing production technology for outdoor fabric has short service life is overcome.

Owner:ZHEJIANG SHENGSHAN TECH TEXTILE

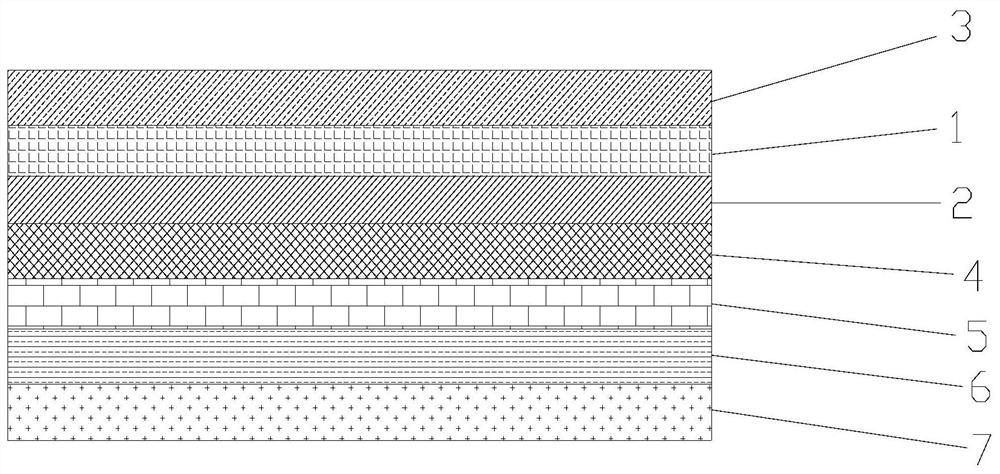

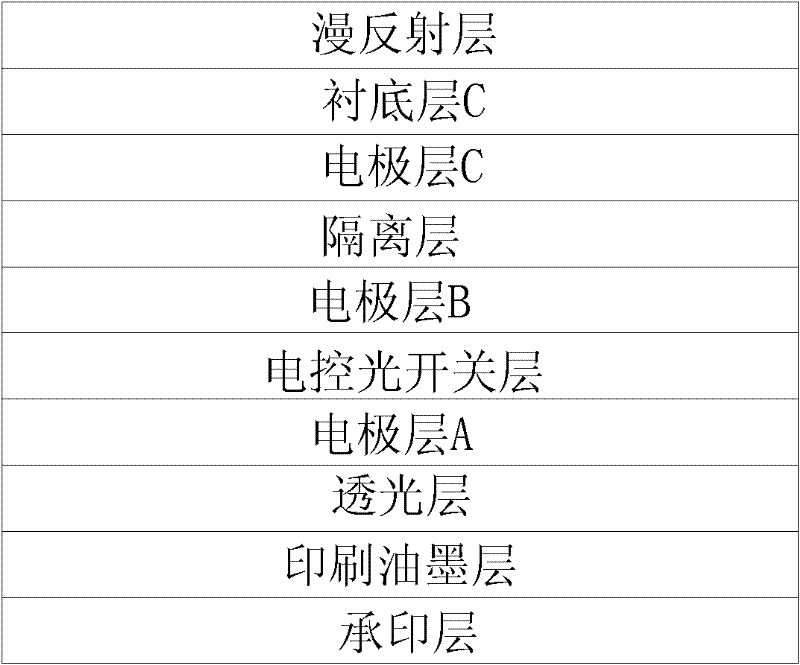

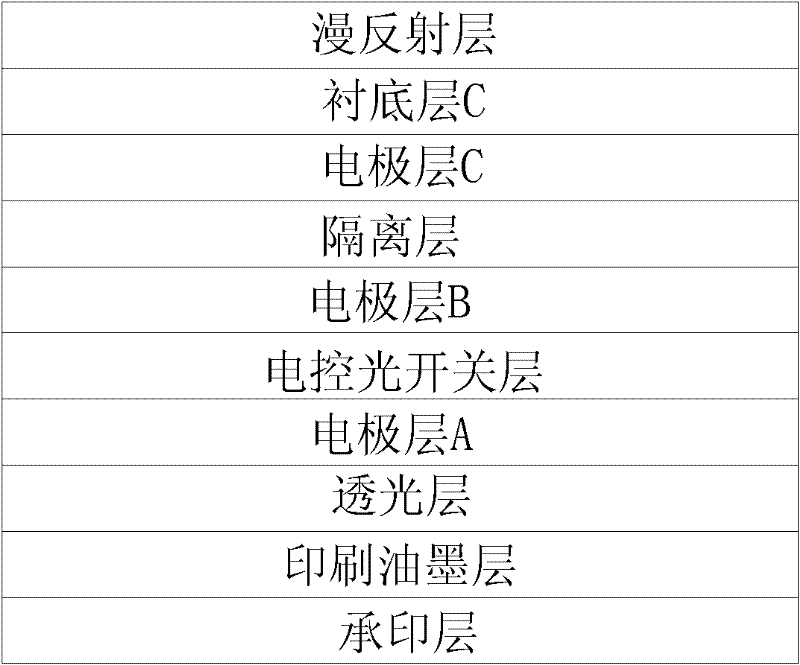

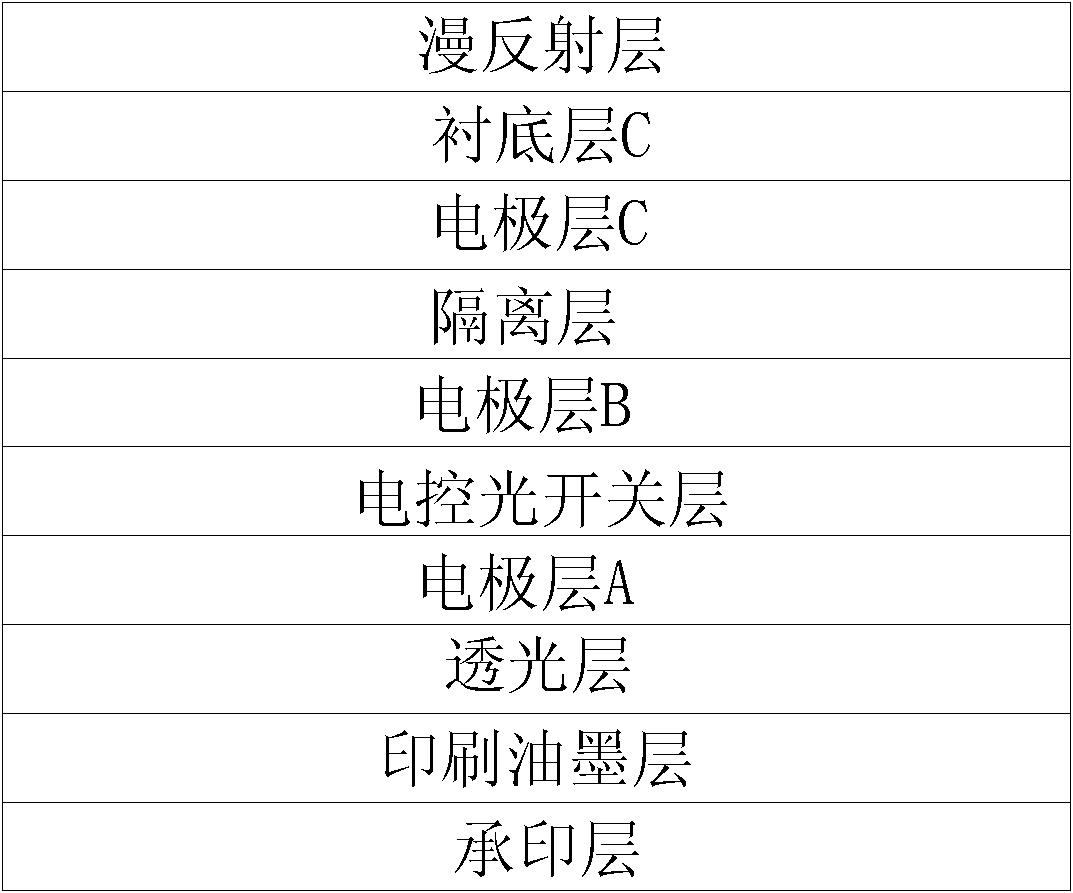

Printed flexible touch display based on resistive effect

InactiveCN102269899AHigh resolutionImprove output accuracyStatic indicating devicesNon-linear opticsOrganic filmDot matrix

The invention discloses a print type flexible contact display screen based on a resistance effect. The print type flexible contact display screen comprises a printing layer, a print ink layer, a light transmitting layer, an electrode layer A, an electric control photo switch layer, an electrode layer B, an isolation layer, an electrode layer C and a substrate layer C, wherein the printing layer is foldable and is made of a printable flexible insulation material; the print ink layer is a CMYK (Cyan, Magenta, Yellow, black) ink dot matrix printed on the printing layer; the light transmitting layer is made of a flexible light transmitting material; the electric control photo switch layer is a PDLC (polymer dispersed cholesteric texture) film; the isolation layer is a hollow flexible transparent latticed film; the substrate layer C is a flexible transparent organic film; the electrode layer A, the electrode layer B and the electrode layer C are ITO (indium tin oxide) films printed with electrode matrixes; and the matrix direction of the electrode layer A is the same with that of the electrode layer C, and the matrix direction of the electrode layer A is vertical to that of the electrode layer B. The display screen provided by the invention has a contact function, is short in response time, low in drive voltage, simple in production technology and low in production cost.

Owner:BEIJING SAN WU JIU INVESTMENT

Process for manufacturing multicolor cross textures on metal surface

The invention relates to a process for manufacturing multicolor cross textures on a metal surface. In an existing treatment process, the form and color are quite single, and the color is lack of the sense of depth and the stereoscopic impression. According to a method of the process, firstly, the surface of a metal product shows an uneven effect, and the surface is subjected to oil removal, rust removal and cleaning treatment; then, according to the pre-designed color layers and sequence, mixed color coating is sequentially sprayed to the surface of the metal product through a pneumatic spray gun; then, the surface of the metal product is ground till irregular blocky metal base materials and multicolor cross texture patterns appear, and the surface of the metal product is washed out; and finally, clear varnish is sprayed to the surface of the metal product, and the metal product with the multicolor cross texture patterns can be obtained after drying. According to the method, the surface of the metal product generates the multicolor cross texture effect; colors are beautiful, layers are rich, and adhesion force is high; the color layers are changeable and are not repeated; and artistic expressive force is high.

Owner:金星铜集团有限公司

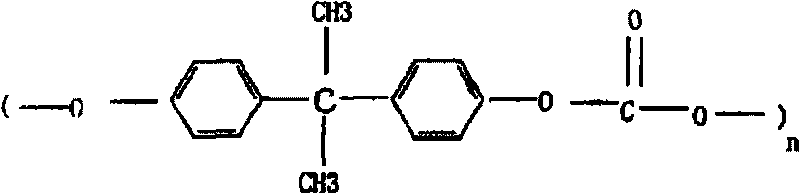

Polycarbonate film with diamond texture

ActiveCN101756470ABeautiful appearanceIdeal anti-scratch performanceOther accessoriesColor effectPrism

The invention relates to a polycarbonate film, in particular to the polycarbonate film with a diamond texture on the surface, which comprises a polycarbonate film main body of which the thickness of is of between 0.1 and 1.5mm. The polycarbonate film main body is provided with a first surface and a second surface, wherein the first surface is provided with rectangular pyramids at intervals of between 0.01 and 0.5mm, and the second surface is a polished surface. Because the surface has a certain roughness, compared with the polished surface, the surface has ideal anti-scratching performance. In addition, diamond textures are repetitive units, similar to prisms, arranged in a certain ratio and at a certain angle, so when the polycarbonate film is used, the problem that the roughness on the surface causes the reduction of glossiness to cause the influence on a color effect is avoided; under the illumination of light rays, the effect of dazzling brilliance is generated by the refraction of the light rays by the repetitive units, so the color levels are richer; and when the polycarbonate film is used in bags and suitcases, the appearance of the bags and the suitcases is more flamboyant.

Owner:苏州奥美材料科技有限公司

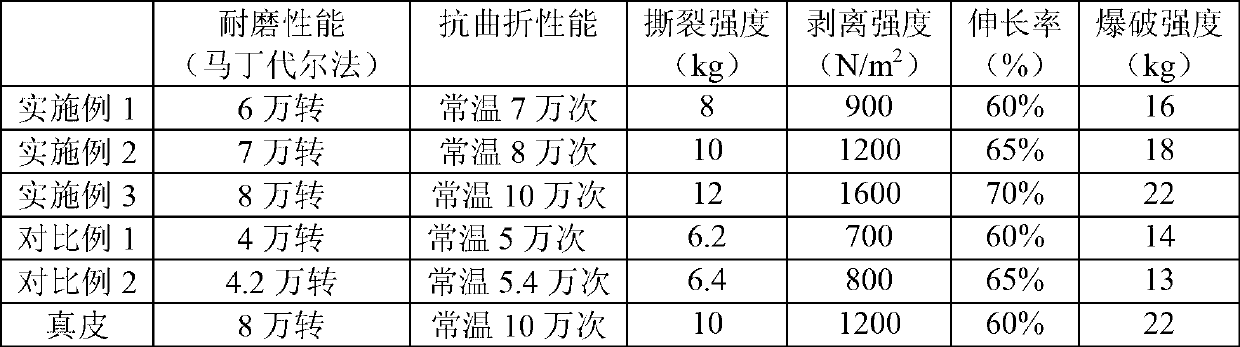

Superfine suede fiber leather and preparation method thereof

InactiveCN102978966AHigh tear strengthHigh peel strengthLamination ancillary operationsSynthetic resin layered productsFiberCooling down

The invention discloses superfine suede fiber leather and a preparation method thereof. The method comprises the following steps: setting a superfine suede fiber base blank; forming a high solid printed layer with set patterns on the superfine suede fiber base blank in accordance with the set patterns; carrying out adhesion transfer membrane treatment on the high solid printed layer; and peeling after being cooled down so as to obtain the superfine suede fiber leather, wherein the solid content of polyurethane resin size used for forming the high solid printed layer is 42-50 percent, and the viscosity is 3,000 pa.s to 6,000 pa.s. By adopting the polyurethane resin size with such viscosity and solid content as the high solid printing size, the high solid printed layer obtained from the printing sufficiently warps the villus of the superfine suede fiber, so that better caking property is maintained, and the superfine suede fiber with good abrasion resistance, tearing and peeling strength is obtained; and meanwhile the physical property of the superfine suede fiber self is reserved with rich color gradation, and the color and the suede feeling have diversity in different angles.

Owner:浙江元新实业有限公司

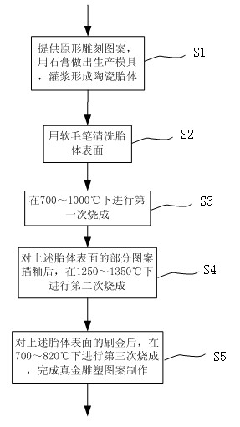

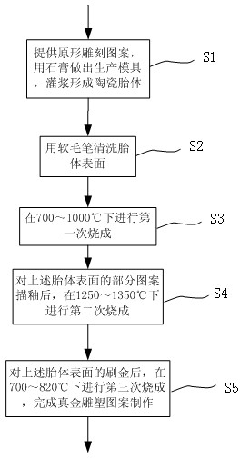

Golden sculpture method for wine bottle

The invention discloses a golden sculpture method for a wine bottle. The method successively comprises the following steps: providing an original sculpture pattern, making a production mould with gypsum, and grouting so as to form a ceramic body; washing the surface of the ceramic body with a soft brush; sintering the ceramic body at the temperature of 700-1000 DEG C for the first time for removing water steam and organic impurities out of the ceramic body so as to increase the surface strength of the ceramic body; coating glaze on partial patterns on the surface of the ceramic body, and then sintering the ceramic body at the temperature of 1250-1350 DEG C for the second time; and after brushing gold on the surface of the ceramic body, sintering the ceramic body at the temperature of 700-820 DEG C for the third time to complete the manufacturing of the golden sculpture pattern. In the golden sculpture method for the wine bottle, glaze coating is used for replacing traditional glaze spraying, gold coating is used for replacing traditional gold spraying, and finally the golden sculpture pattern with diverse color levels, and no defects of foaming, decoloring and crazing can be obtained by carrying multiple sintering processes and controlling sintering temperature.

Owner:SHANGHAI GAOCHENG CREATIVE TECH GRP

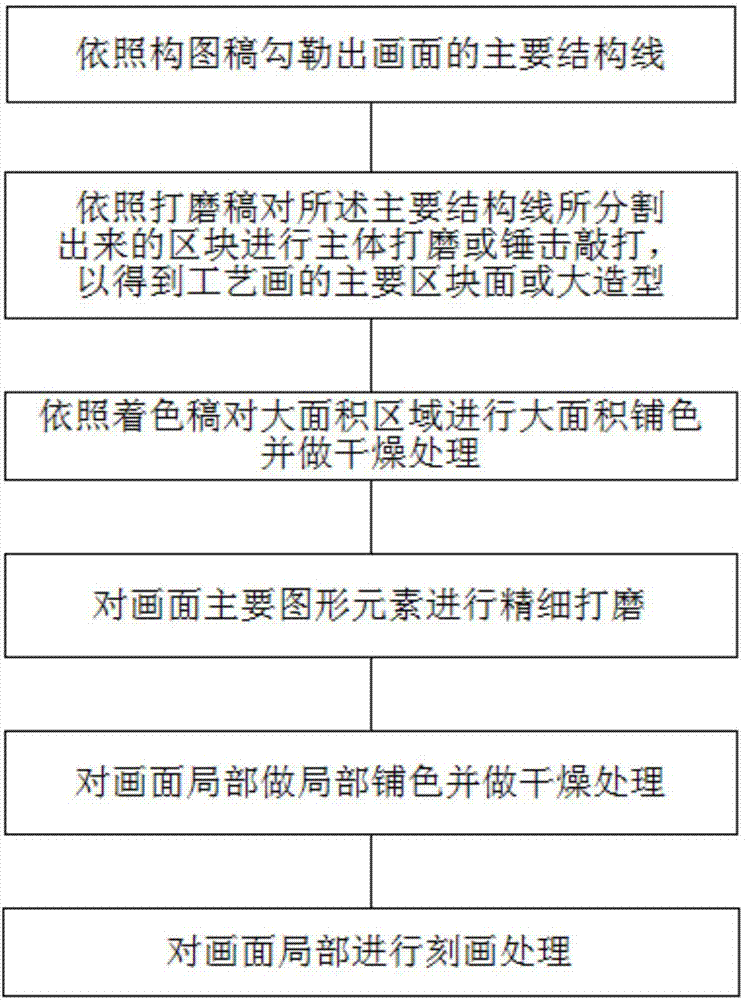

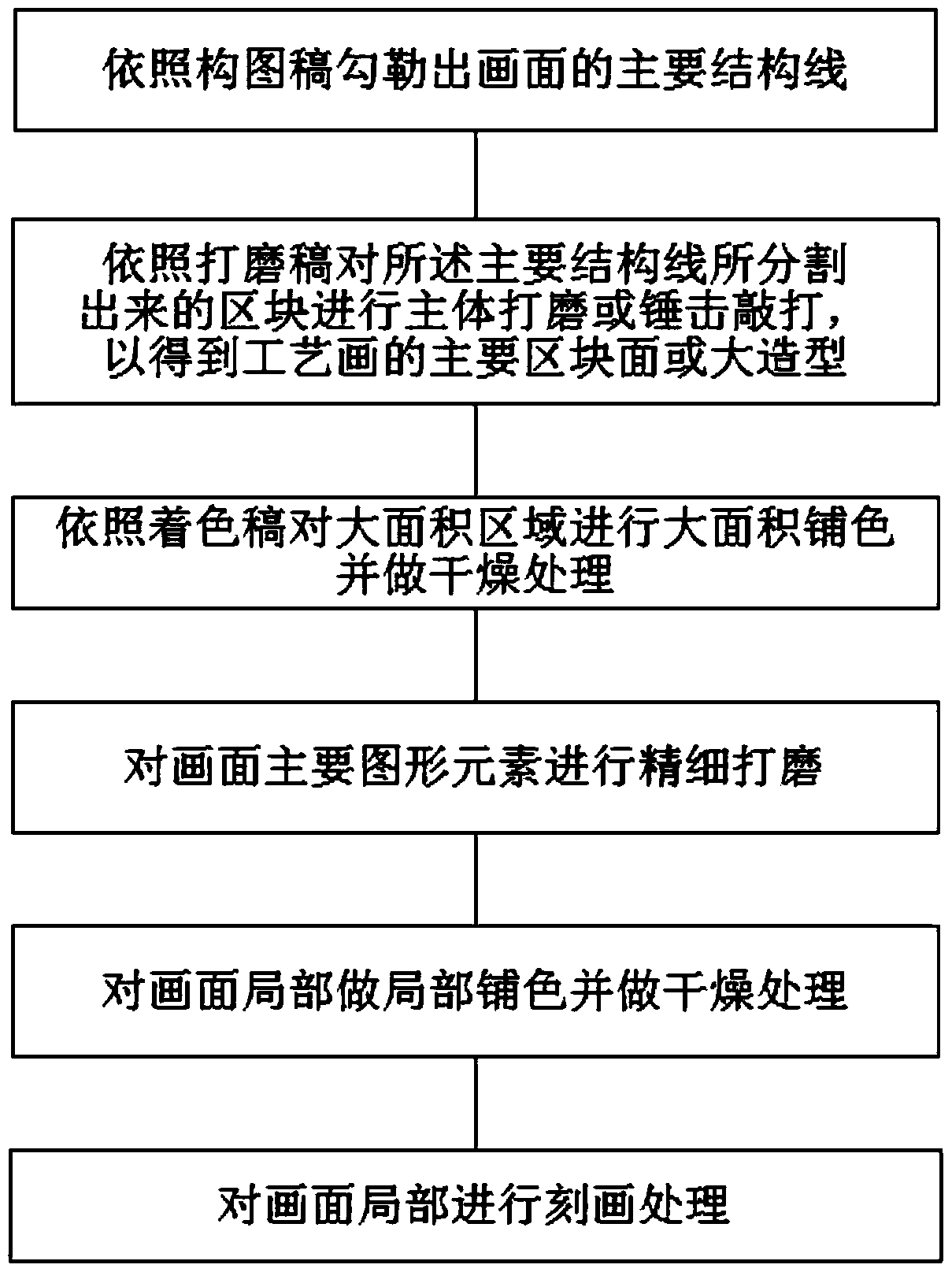

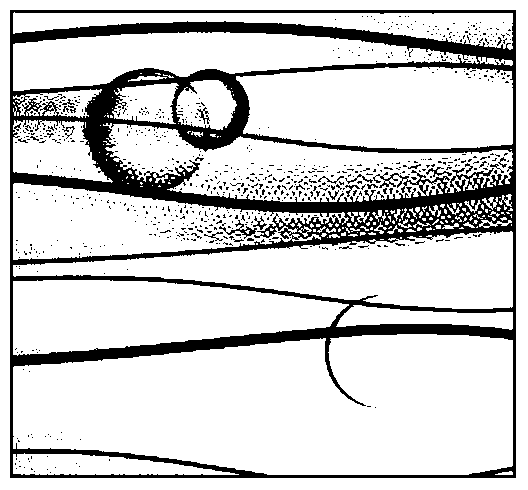

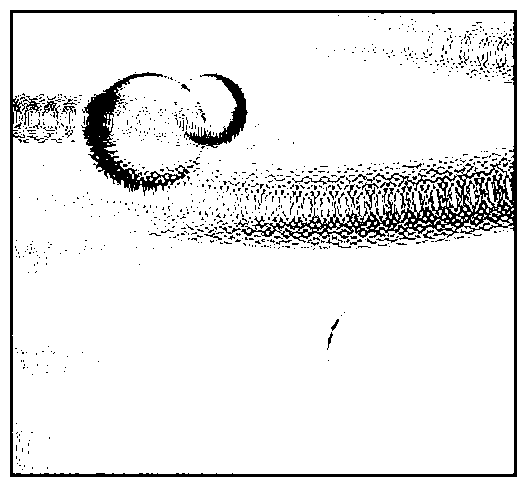

Manufacturing method for metal carrier craft picture

ActiveCN104723784AImprove performanceRich color layersDecorative surface effectsSpecial ornamental structuresGraphicsEngineering

The invention discloses a manufacturing method for a metal carrier craft picture. The manufacturing method comprises the following steps: drawing a main structure line of a picture according to a picture draft; carrying out main body polishing or hammering clicking on blocks divided by the main structure line according to the picture draft to obtain a main block plane or a large shape of the craft picture; carrying out large-area color spreading and drying on a large-area region according to a coloring draft; finely polishing main picture elements of the picture; carrying out partial color spreading and drying on one part of the picture; and carrying out picture engraving treatment on one part of the picture. The craft picture obtained by the manufacturing method is good for enhancing the representing effect of the picture, can show rich color layers and also can be used for effectively representing a polished texture effect, so that the effects of the color and the polished textures are overlapped to realize the representing degree which cannot be reached by a common oil painting; and a technical effect that one picture has more forms can be represented and the craft picture has a certain art collection value.

Owner:SHENZHEN TTA ART CO LTD

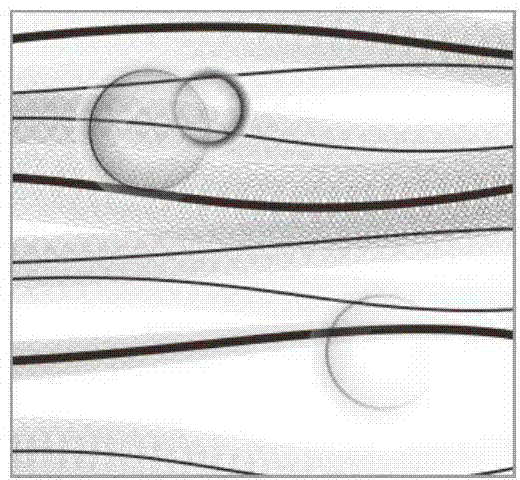

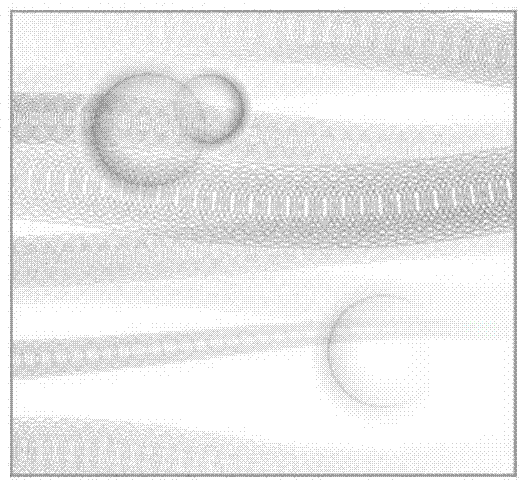

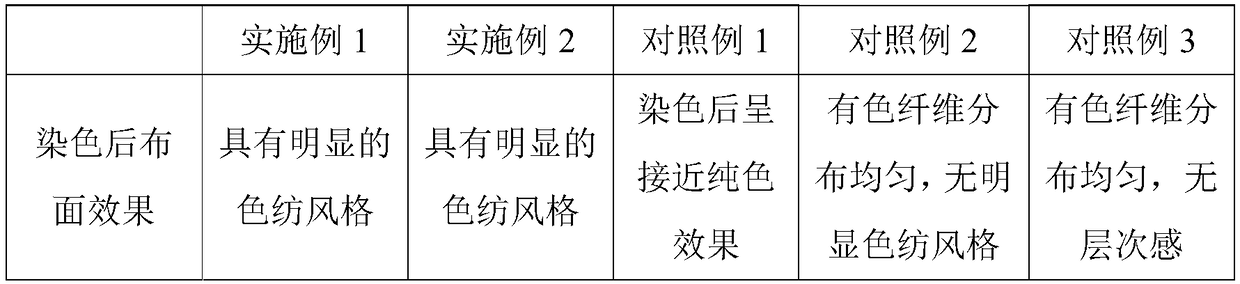

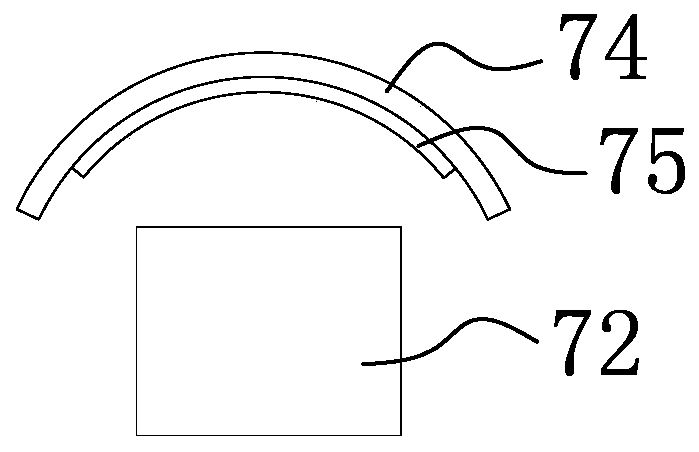

Two-component fabric with color spinning style and processing method thereof

InactiveCN108642644AUneven distribution of fibersUneven distributionWoven fabricsDisperse dyeCarding

The invention discloses a two-component fabric with a color spinning style. The fabric is formed by interweaving warp yarns and weft yarns, the warp yarns and the weft yarns are both a blended yarn, the blended yarn is composed of a first fiber and a second fiber, the content of the first fiber is 75-90%, and the content of the second fiber is 10-25%; the first fiber is a disperse dye non-coloringfiber, and the second fiber is a disperse dye coloring fiber; the second fiber comprises two lengths of fibers, the length of the longer fiber is 50 millimeters, the length of the shorter fiber is 30millimeters; the fineness of the two fibers is both 1.2D. The processing method comprises the steps that opening, lowing and cotton carding are respectively carried out on the two fibers after the two fibers are pretreated, then vortex spinning is carried out on drawing, and lastly, weaving is carried out and dyes are dispersed to dye the two fibers. According to the two-component fabric with thecolor spinning style, the two-component blended yarn is adopted, the fabric is distributed nonuniformly along the axial direction after blending, and a color spinning effect with the depth sense is formed after the fabric is dyed.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

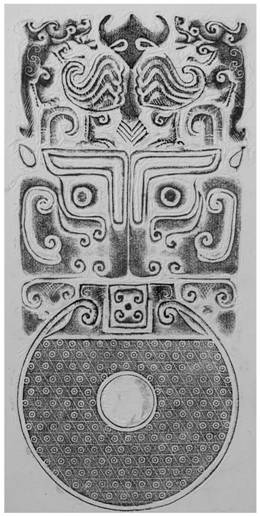

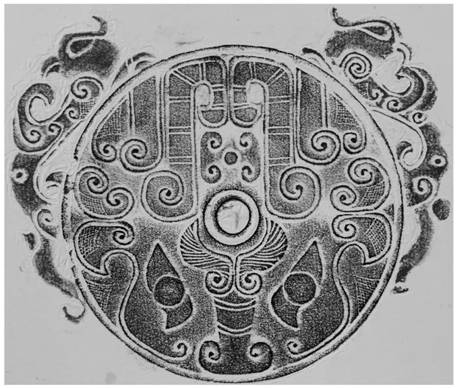

Cultural relic chromatic rubbing method

PendingCN111674174AStrong artistic appreciationHierarchicalInksDuplicating using pressurePolymer scienceBletilla striata

The invention provides a cultural relic chromatic rubbing method. The rubbing method comprises the following steps of researching and studying a cultural relic, decomposing graph groups, preparing color matching, and preparing rubbing paper and tools; making oil paint; preparing bletilla striata water; fixing the cultural relic; gluing and paper feeding; performing chromatic rubbing; taking paper;and color fixing. The method not only creates a chromatic rubbing method in the field of rubbing of cultural relics, enriches the level of the rubbing, enhances the artistic ornamental value of the rubbing and enlarges the audience area of the rubbing, but also solves the problems that when an existing cultural relic rubbing method is used for rubbing, ink permeates through paper and adheres to the cultural relics, so that cultural relics are polluted, and even irreversible damage is caused to cultural relics.

Owner:孙四宝

A kind of manufacturing method of metal carrier craft painting

ActiveCN104723784BImprove performanceRich color layersDecorative surface effectsSpecial ornamental structuresGraphicsEngineering

The invention discloses a method for making a metal carrier art painting, which comprises the following steps: outline the main structural lines of the picture according to the composition draft; perform main body grinding or hammering on the blocks divided by the main structural lines according to the polishing draft Beating to obtain the main block surface or large shape of the craft painting; according to the coloring draft, perform large-scale color paving and drying treatment on large areas; finely polish the main graphic elements of the picture; Drying treatment; the part of the picture is portrayed, the craft painting obtained by the production method of the present invention helps to enhance the performance effect of the picture, can show rich color levels, and can also effectively express the effect of polishing texture, so that the color and polishing texture The superimposition of the effect can reach the performance height that ordinary oil painting can't reach, and can present the technical effect of "one painting with multiple states", which has a certain value of art collection.

Owner:SHENZHEN TTA ART CO LTD

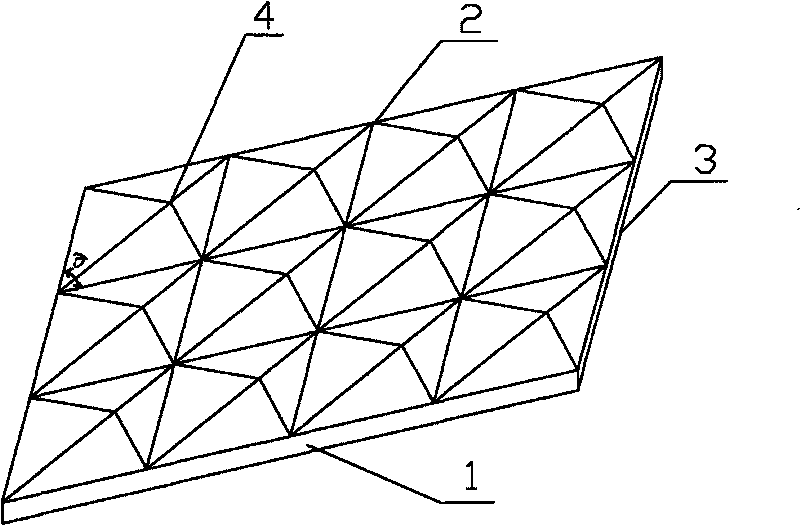

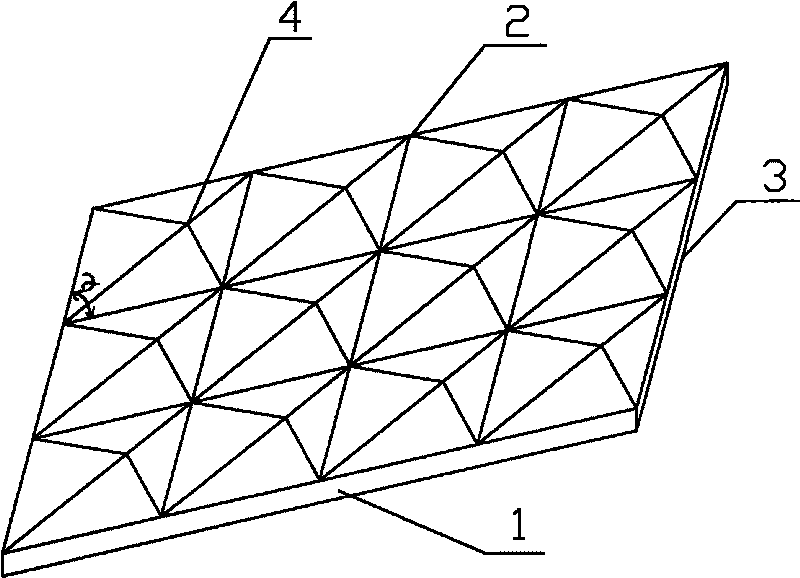

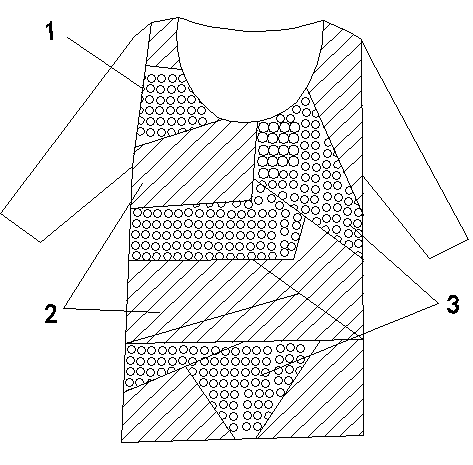

Leather and chiffon spliced brocaded fabric clothes

InactiveCN104207385AIncrease fashionEnhance layeringProtective garmentSpecial outerwear garmentsWeft yarnEngineering

The invention relates to a piece of leather and chiffon spliced brocaded fabric clothes which comprises a clothes body (1). A front piece and a back piece of the clothes body (1) are formed by splicing leather (2) and chiffon (3), and the leather (2) and the chiffon (3) are irregular patterns. A fabric for the clothes body (1) is a 15 / 5 single-layer fabric formed by interweaving a set of warp yarns and a set of weft yarns, and risers are increased in the weft direction in a 1 / 3 and 1 / 5 equal proportion mode and respectively provided with 40 layers and 66 layers. The layering sensation of the clothes is improved, and clothes styles are enriched. The piece of clothes adopting the brocaded fabric is rich in layering sensation, and formed texture images are lifelike and good in ornamental effect.

Owner:JIANGYIN UNI POL

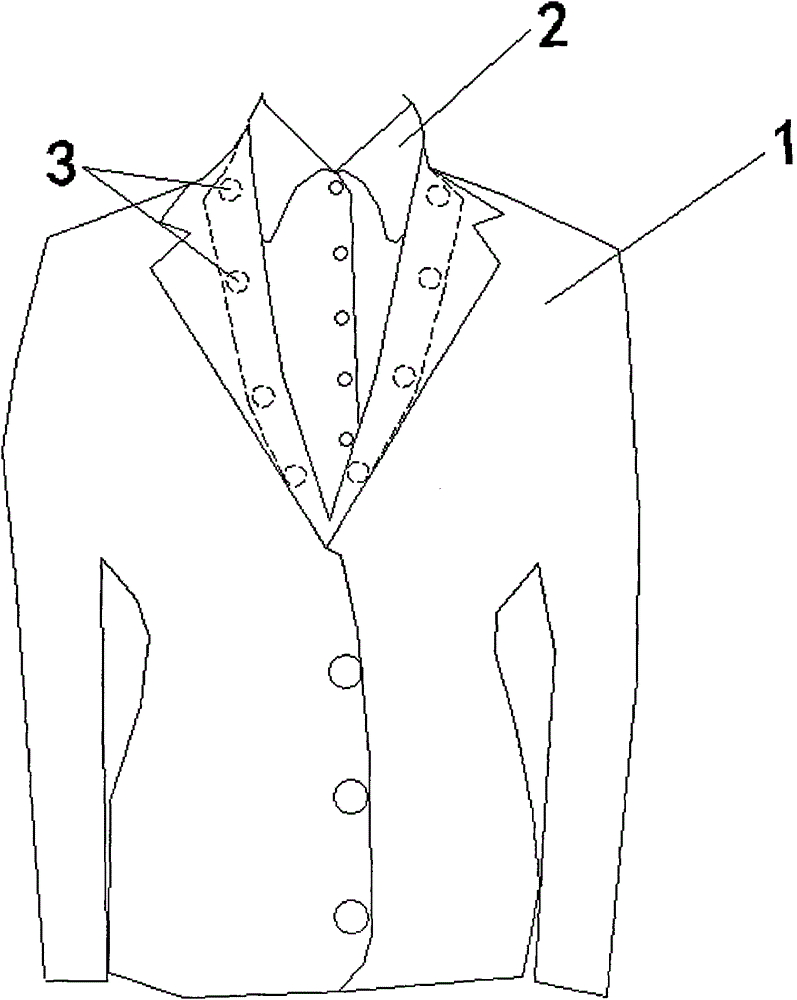

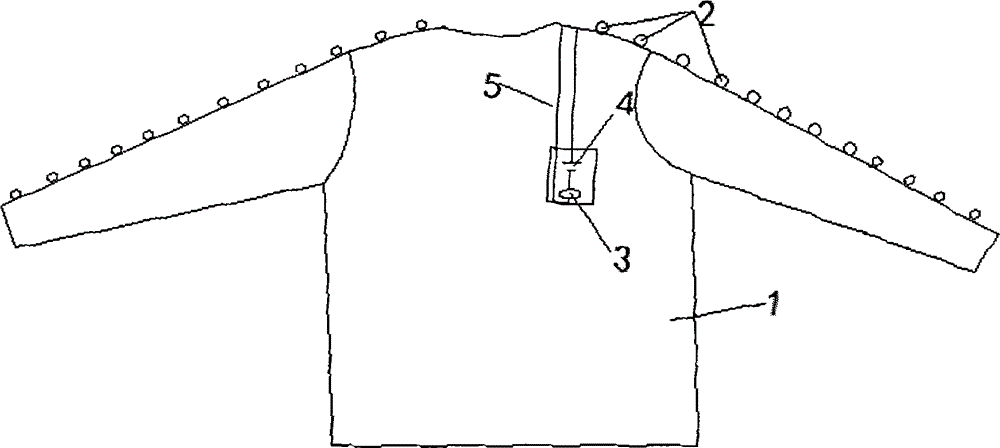

Garment provided with false collar and made of woven photograph fabric

InactiveCN104432821ACompliant with clothing standardsEasy to cleanProtective garmentSpecial outerwear garmentsEngineering

The invention relates to a garment provided with a false collar and made of woven photograph fabric. The garment comprises a garment body (1), wherein the shirt style collar (2) is arranged on the garment body (1) and is detachable, the collar (2) is fastened on a lining of the garment through buttons (3), the fabric adopted by the garment body (1) is 15 / 5 single-layer fabric formed by interweaving of a group of warps and a group of wefts, and risers are added in the weft direction according to the proportion of 1 / 3 or 1 / 5 and have 40 and 66 levels respectively. When people go to work, the collar can be fastened on the garment so that it looks like a shirt is worn inside a suit, requirements for dressing are met, the trouble of wearing a shirt in winter is avoided, and cleaning is convenient. Due to the adoption of the woven photograph fabric, color gradation is rich, an image formed on the fabric is life-like, and ornamental effect is good.

Owner:苏光明

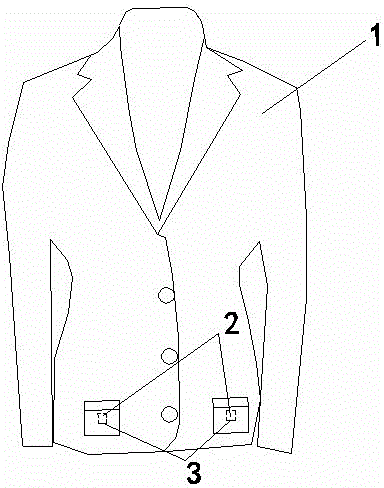

Photographic fabric clothing with change pockets

InactiveCN104413608ARich in colorRealistic imageWoven fabricsProtective garmentStructural engineeringMechanical engineering

The invention relates to photographic fabric clothing with change pockets. The photographic fabric clothing with the change pockets comprises a clothing body (1), change pockets (2) are arranged in waist pockets of the clothing body (1), the two sides of the change pockets (2) are sewn in the waist pockets, and the bottoms of the change pockets are zippers (3); a fabric adopted by the clothing body is a 15 / 5 single-layer fabric which is interwoven by using a group of warps and a group of wefts, wherein risers are increased in equal proportions of 1 / 3 and 1 / 5 in the weft direction and 40 levels and 66 levels are respectively obtained. When coins need to be paid, the zippers at the bottoms of the change pockets are unzipped, the coins fall into the waist pockets, are not lost and can be taken out for payment. The color levels of the photographic fabric adopted by the invention are rich, the formed fabric image is vivid and the ornamental effect is good.

Owner:JIANGYIN HOMEX TEXTILES

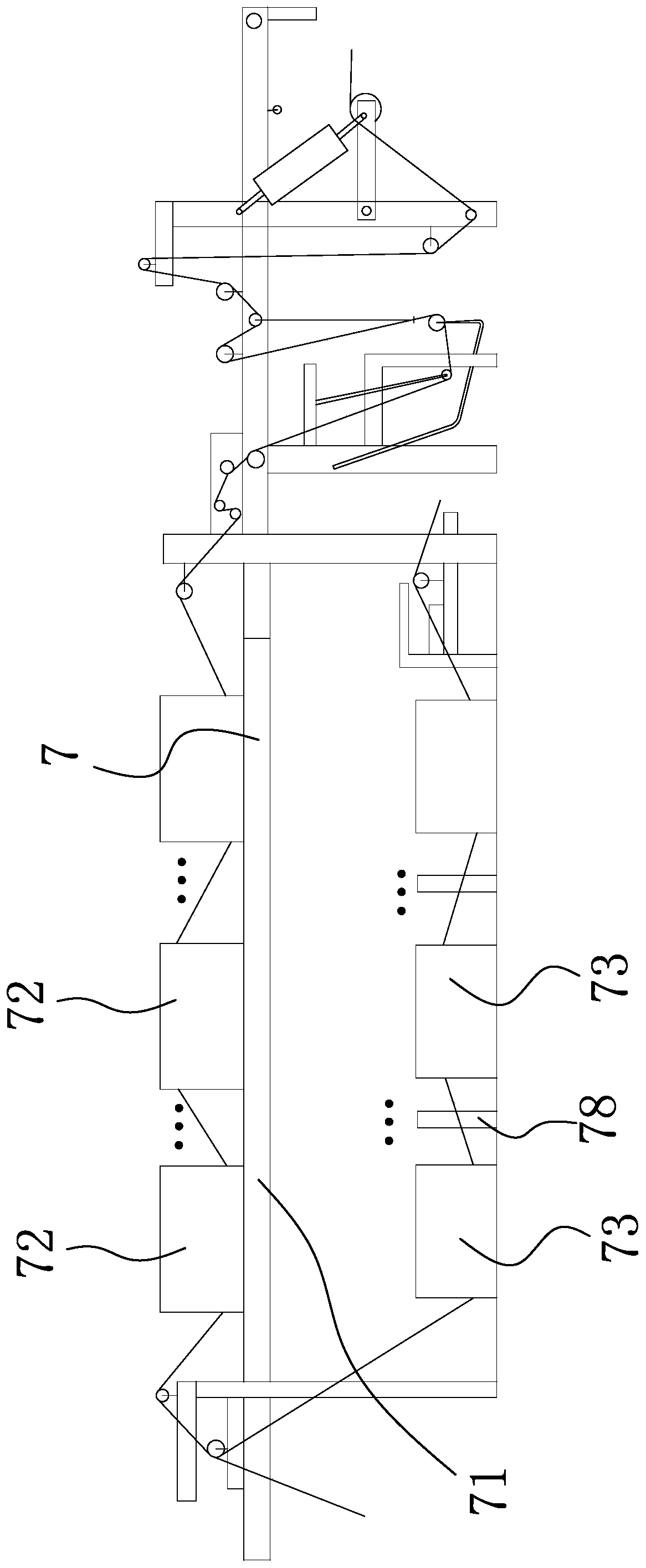

A production process of digital printing base paper

ActiveCN110485204BHigh base strengthDirectional controllableSpecial paperCane mechanical workingFiberPolyester

The invention discloses a production process of digital printing base paper. The digital printing base paper uses 80-100 parts of peeled alpine bamboo yellow, 20-25 parts of polyester fiber, and 28-32 parts of phosphogypsum whiskers as raw materials ; Xylanase water, sodium hydroxide aqueous solution, MJB-NS bamboo silk softener as auxiliary materials, peeled alpine bamboo yellow is first boiled with water, modified, purified and bleached by a compound softener for two times of enzymatic decomposition, and three times of lightening. After carbonization compound activation treatment, it is hot-melted with other raw materials in a protective atmosphere. The invention has the advantages of high uniformity of fiber arrangement, good stiffness, high whiteness, water loss resistance, moderate electrical performance and smooth surface.

Owner:浙江夏王纸业有限公司

Print type flexible contact display screen based on resistance effect

The invention discloses a print type flexible contact display screen based on a resistance effect. The print type flexible contact display screen comprises a printing layer, a print ink layer, a light transmitting layer, an electrode layer A, an electric control photo switch layer, an electrode layer B, an isolation layer, an electrode layer C and a substrate layer C, wherein the printing layer is foldable and is made of a printable flexible insulation material; the print ink layer is a CMYK (Cyan, Magenta, Yellow, black) ink dot matrix printed on the printing layer; the light transmitting layer is made of a flexible light transmitting material; the electric control photo switch layer is a PDLC (polymer dispersed cholesteric texture) film; the isolation layer is a hollow flexible transparent latticed film; the substrate layer C is a flexible transparent organic film; the electrode layer A, the electrode layer B and the electrode layer C are ITO (indium tin oxide) films printed with electrode matrixes; and the matrix direction of the electrode layer A is the same with that of the electrode layer C, and the matrix direction of the electrode layer A is vertical to that of the electrode layer B. The display screen provided by the invention has a contact function, is short in response time, low in drive voltage, simple in production technology and low in production cost.

Owner:BEIJING SAN WU JIU INVESTMENT

Clothing adopting woven photograph fabric and provided with thermal pockets

InactiveCN104413901AStop the spreadTo keep warmGarment special featuresWoven fabricsEngineeringWeft yarn

The invention relates to clothing, in particular to clothing adopting a woven photograph fabric and provided with thermal pockets. The clothing comprises a clothing body (1), and is characterized in that pockets of the clothing body (1) are provided with woolen thermal layers (2); the fabric of the clothing body (1) is a 15-piece 5-fly single-layer fabric formed by interweaving a group of warp yarns and a group of weft yarns, and risers are added in the zonal direction according to the ratios such as 1 / 3 and 1 / 5 and respectively have 40 and 66 layers. According to the clothing adopting the woven photograph fabric and provided with the thermal pockets, the woolen thermal layers are arranged on the pockets; when hands are put into the pockets, a user does not feel cold due to contact with wool; furthermore, the wool can effectively prevent diffusion of heat of the hands, so that the warm-keeping effect is achieved. The woven photograph fabric of the clothing is rich in color layer, so that a formed textile image is vivid, and the ornamental effect is good.

Owner:JIANGYIN YONGTAI PLASTICS CO LTD

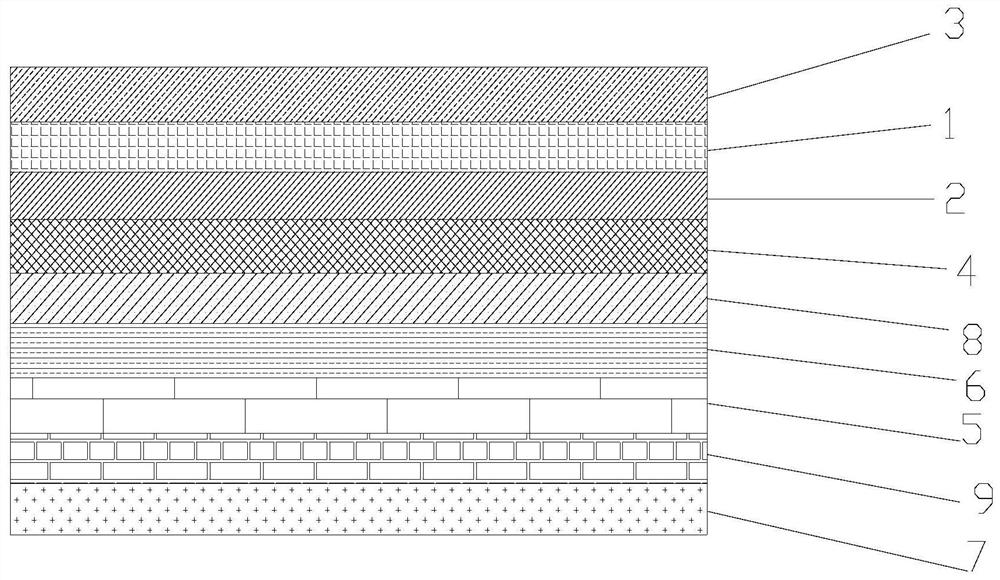

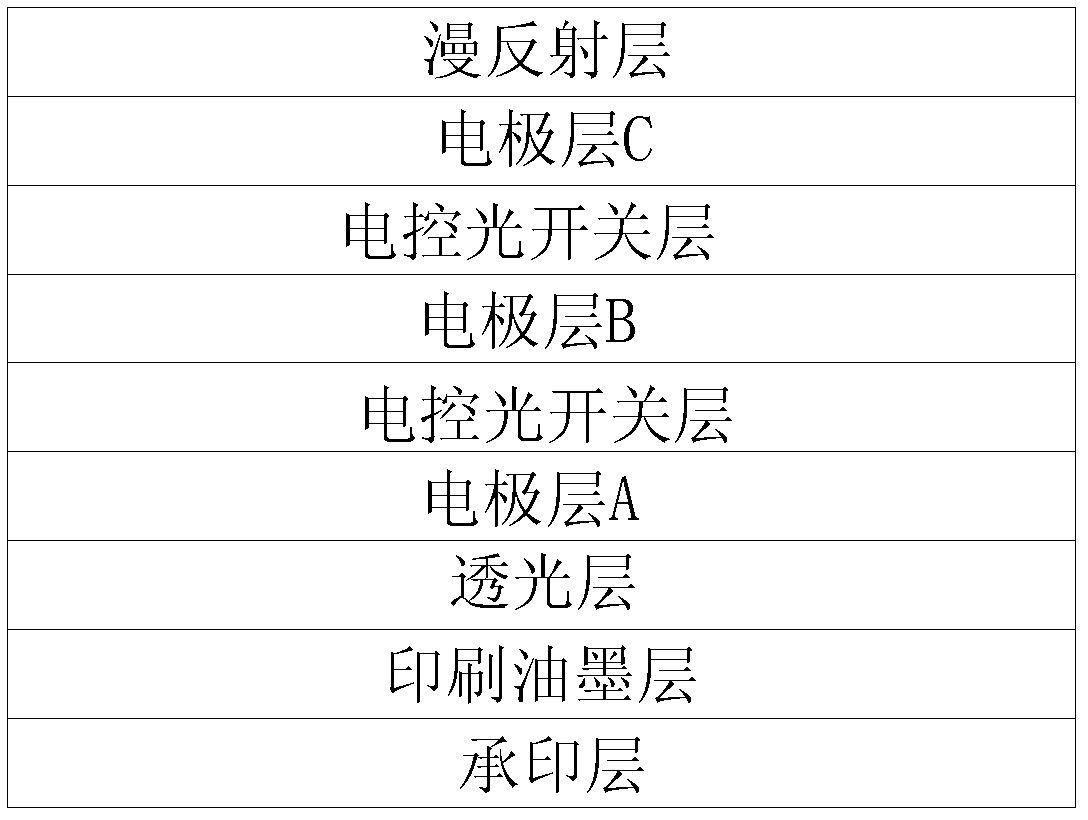

Printed flexible display screen based on double-layer polymer dispersed liquid crystal (PDLC) film

InactiveCN102269888BIncrease contrastReduce light transmittanceNon-linear opticsIndium tin oxidePrinting ink

The invention discloses a printed flexible display screen based on a double-layer polymer dispersed liquid crystal (PDLC) film. The display screen at least comprises a printing layer, a printing ink layer, a photic layer, an electrode layer A, an electronically-controlled optical switch layer, an electrode layer B, an electronically-controlled optical switch layer and an electrode layer C, wherein the printing layer is made of a foldable and printable flexible insulating material; the printing ink layer is a cyan, magenta, yellow and black (CMYK) colored ink lattice; the photic layer is made of a flexible photic material; the electronically-controlled optical switch layer is the PDLC film; the electrode layer A, the electrode layer B and the electrode layer C are indium tin oxide (ITO) conductive films on which electrode matrixes are engraved; and an electrode matrix direction of the electrode layer A is the same as the electrode layer C and is vertical to an electrode matrix direction of the electrode layer B. The display screen has a high contrast ratio, short response time, low driving voltage, low production cost and a simple manufacturing process, makes reading comfortable and is suitable for large-scale mass production.

Owner:BEIJING SAN WU JIU INVESTMENT

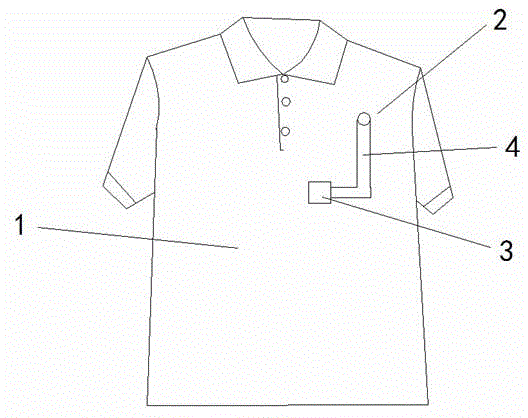

High-ornamental-value garment with mobile phone holder

InactiveCN104413733AAvoid sorenessRich in colorWoven fabricsProtective garmentEngineeringMechanical engineering

The invention relates to a high-ornamental-value garment with a mobile phone holder. The high-ornamental-value garment comprises a garment body (1), a plastic gear (2) is arranged on the front body of the garment body (1), and the mobile phone holder (3) is connected onto a support (4) which is connected onto the plastic gear (2). The garment is made of a fabric which is a single-layer 15 / 3 fabric formed by interweaving a group of warps and a group of wefts, risers are increased in the weft direction in equal proportions of 1 / 3 and 1 / 5, and 40 hierarchies of warps and 66 hierarchies of wefts are formed. A person feeling sore of arms due to holding of a mobile phone for a long time can put the mobile phone on the holder and adjust the support to a proper position, so that hands can get free, and soreness is avoided. The high-ornamental-value garment with the mobile phone holder has the advantages of richness of fabric hierarchy, texture image vividness and high ornamental value.

Owner:JIANGYIN YONGLONG PLASTICS

A kind of processing method of woolen fabric and finished garment with surface gradient color effect

The invention discloses a processing method of a wool fabric and wool ready-to-wear clothes having surface gradient color effect and aims to provide a method by that the gradient color effect is formed from one end to the other end of the wool fabric and wool ready-to-wear clothes. The method includes the steps of: adding a wool chlorination modifier to a penetrating agent solution to prepare a wool chlorination modifying treatment liquid; at constant speed, immersing one end of the wool fabric and wool ready-to-wear clothes in the wool chlorination modifying treatment liquid until the other end is immersed to perform wool chlorination modification to different degrees; dyeing the wool fabric and wool ready-to-wear clothes, after the chlorination modification, to prepare the product, wherein a dark-to-light gradient color effect is formed from one end to the other end of the surfaces of the wool fabric and wool ready-to-wear clothes. The method can form the gradient color effect, whichhas abundant color layers and natural transition, on the wool fabrics, so that color diversification and individuation of wool fabric products is improved.

Owner:山东神州毛纺织有限公司

Printing and dyeing process of thermal fabric with mercerized flocking effect

ActiveCN108456984BAvoid damageVariety of colorsMercerising of indefinite length fabricsWeft knittingTextile printerProcess engineering

The invention belongs to the technical field of fabric processing, and particularly relates to a warm fabric printing and dyeing process with mercerizing flocking effect. The process solves the technical problems of unreasonable design and the like of the prior art. The process includes the following steps of A, weaving; B, degreasing; C, dyeing; D, mercerizing; E, whitening; F, electrostatic flocking; G, printing; H, steaming I; water washing; J, hair grabbing and K, softening and shaping. The process has the advantages of being warm and more reasonable in design.

Owner:ZHEJIANG FURUN DYEING & PRINTING

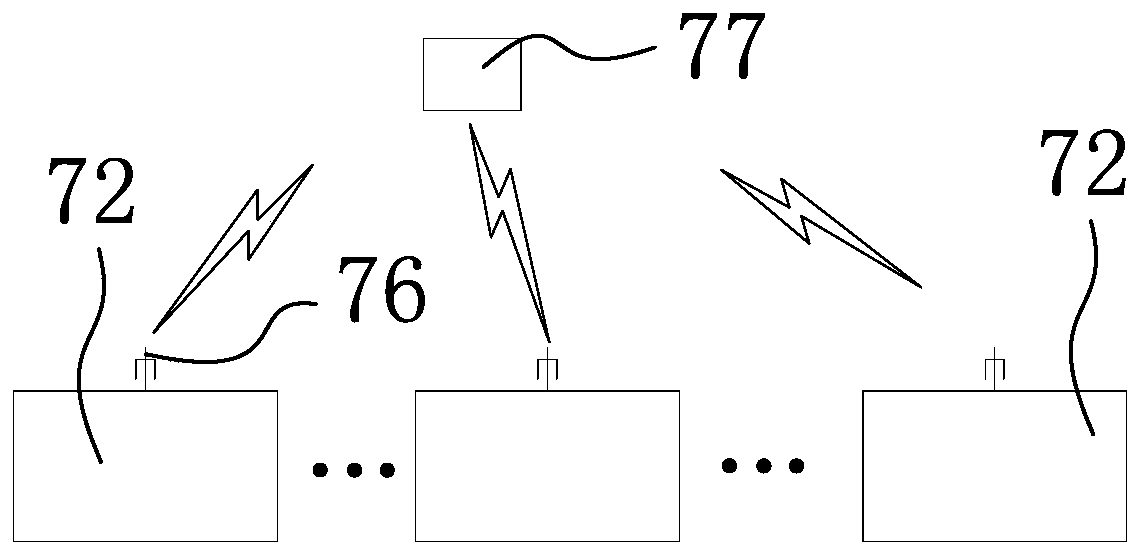

Garment with width showing function made of woven photograph fabric

InactiveCN104432771AReduce accidentsRealistic imageWoven fabricsProtective garmentElectrical resistance and conductanceEngineering

The invention relates to a garment with a width showing function made of woven photograph fabric. The garment comprises a garment body (1), light emitting diodes (2) are arranged on the shoulders and sleeves of the garment body (1) respectively, and a power module (4) provided with a photoresistor (3) is arranged on a chest pocket of the garment body (1); the fabric adopted by the garment body (1) is 15 / 5 single-layer fabric formed by interweaving of a group pf warps and a group of wefts, and risers are added in the weft direction according to the proportion of 1 / 3 or 1 / 5 and have 40 and 66 levels respectively. Under the condition of poor light, the photoresistorcan not sense the light, the power module is started to provide power for the light emitting diodes to enable the light emitting diodes to emit white light, the widths of the white light on two sides are shown to remind people, and therefore the occurrence of accidents is reduced. Due to the adoption of the woven photograph fabric, color gradation is rich, an image formed on the fabric is life-like, and ornamental effect is good.

Owner:刘正华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com