Printing and dyeing process of thermal fabric with mercerized flocking effect

A printing and dyeing process, mercerizing technology, applied in the field of fabric processing, can solve the problems of not being suitable for winter wear, unattractive outer wear, single style, etc., and achieve the effect of rich color layers, smooth hand feeling and strong three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

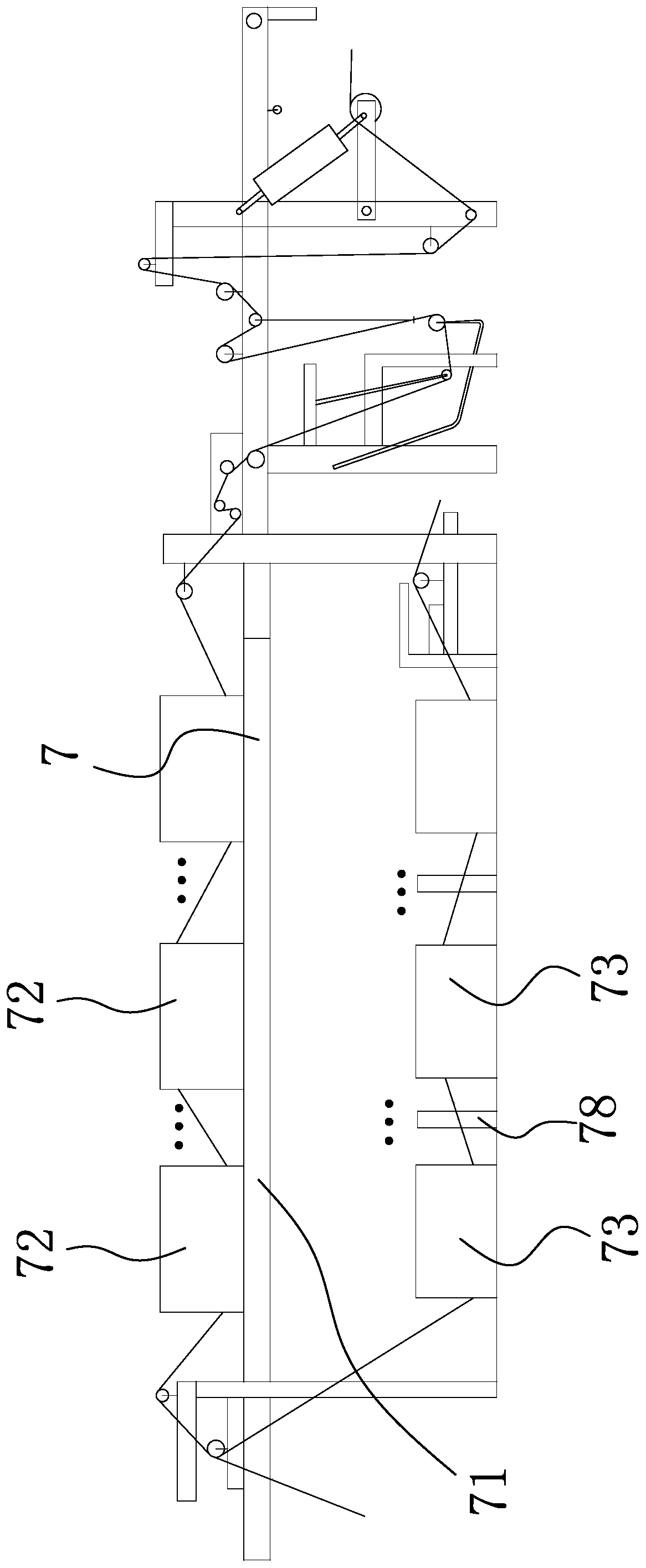

[0068] The thermal fabric printing and dyeing process with mercerized flocking effect comprises the following steps:

[0069] A. Weaving: use 59% blended yarn on the front side and the blended yarn is formed by blending 40 cotton, tencel and cupro ammonia, and 100D / 288F polyester mesh yarn with 41% on the back side, and use a double-sided circular knitting machine Woven into double-layer gray fabric;

[0070] The double-layer gray fabric has high strength, silky and elegant luster, good hygroscopicity, smoothness and antistatic properties.

[0071] B. Degreasing: use FONG'S THEN energy-saving airflow dyeing machine, and use detergent EPD-C for degreasing;

[0072] C. Dyeing: including dyeing and washing and reduction cleaning after dyeing;

[0073] c1. Dyeing polyester includes the following steps: Dyeing with air cylinder, feeding soft water into the cloth, adjusting the dyeing pH to 4.5-5.5, adding disperse dyes, the temperature rises to 130°C, and then keeps warm for 30 m...

Embodiment 2

[0183] The working principle and structure of this embodiment are basically the same as those of Embodiment 1, the different structures are:

[0184] In step C, the dyeing solution used for dyeing comprises the following components:

[0185]

[0186] The reduction cleaning solution used in reduction cleaning includes the following components:

[0187] Soda ash 2g / L

[0188] Hydrosulfite 1.5g / L.

[0189] The concentration of mercerin base during mercerizing in the step D is 180g / L.

[0190] In the described step E, the whitening treatment aid comprises the following components:

[0191]

[0192] In the step G, the reactive color paste comprises the following components:

[0193]

[0194] Composite silicone smoothing agent includes the following components:

[0195]

Embodiment 3

[0197] The working principle and structure of the present embodiment are basically the same as those of the first embodiment, and the different structure is that in step C, the dyeing solution used for dyeing comprises the following components:

[0198]

[0199] The reduction cleaning solution used in reduction cleaning includes the following components:

[0200] Soda ash 4g / L

[0201] Sodium Hydrochloride 2.5g / L.

[0202] The concentration of mercerin base during mercerizing in the step D is 190g / L.

[0203] In the described step E, the whitening treatment aid comprises the following components:

[0204]

[0205]

[0206] In the step G, the reactive color paste comprises the following components:

[0207]

[0208] Composite silicone smoothing agent includes the following components:

[0209]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com