Manufacturing method of embossed metal color print

A production method and color printing technology, applied in the field of handicrafts, can solve the problems of rough relief patterns, unsatisfactory, lack of relief touch effects, etc., achieve the effect of enriching color levels and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

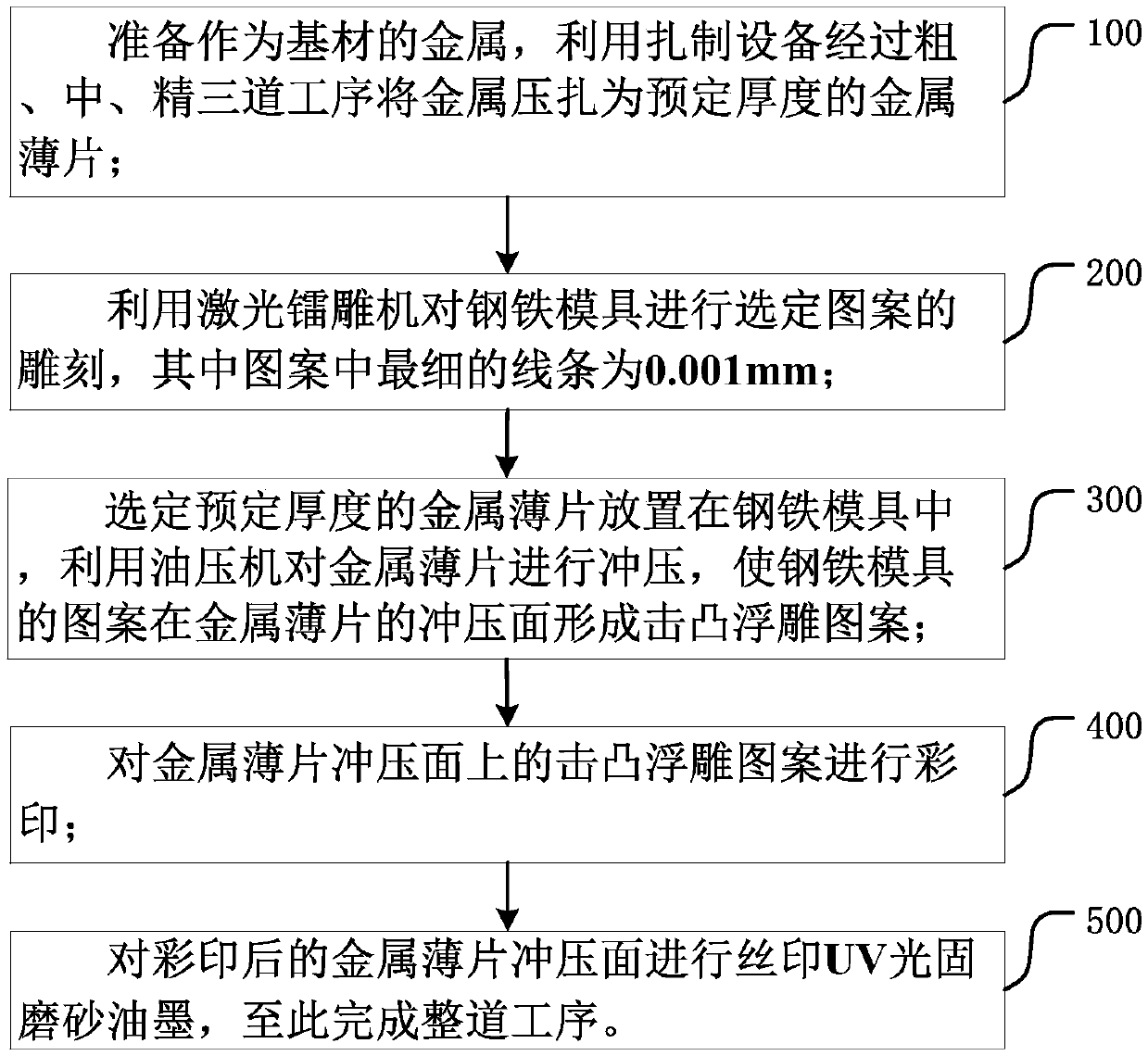

[0022] Such as figure 1 As shown, one embodiment of the present invention discloses a method for making embossed metal color prints, which generally includes the following steps:

[0023] Step 100, prepare the metal as the base material, and press the metal into a metal sheet with a predetermined thickness through three processes of rough, medium and fine by using rolling equipment;

[0024] The metal here is preferably a precious metal such as gold, silver or platinum, so that the product itself has a corresponding value.

[0025] Rough, medium and fine processes refer to the rough step rolling of the selected precious metal plate by the rolling machine to reduce the thickness of the plate to a certain range, and then reduce the thickness of the plate to the reserved thickness by the rolling machine through intermediate rolling. The reserved thickness is the minimum thickness of the optional thickness range of the final product, that is, the thickness of the final product is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com