Printed flexible display screen based on double-layer polymer dispersed liquid crystal (PDLC) film

A flexible display, double-layer technology, applied in nonlinear optics, optics, instruments, etc., can solve the problems of slow response speed, high production cost, difficult color, etc., to achieve the effect of improving contrast, improving contrast, and avoiding negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

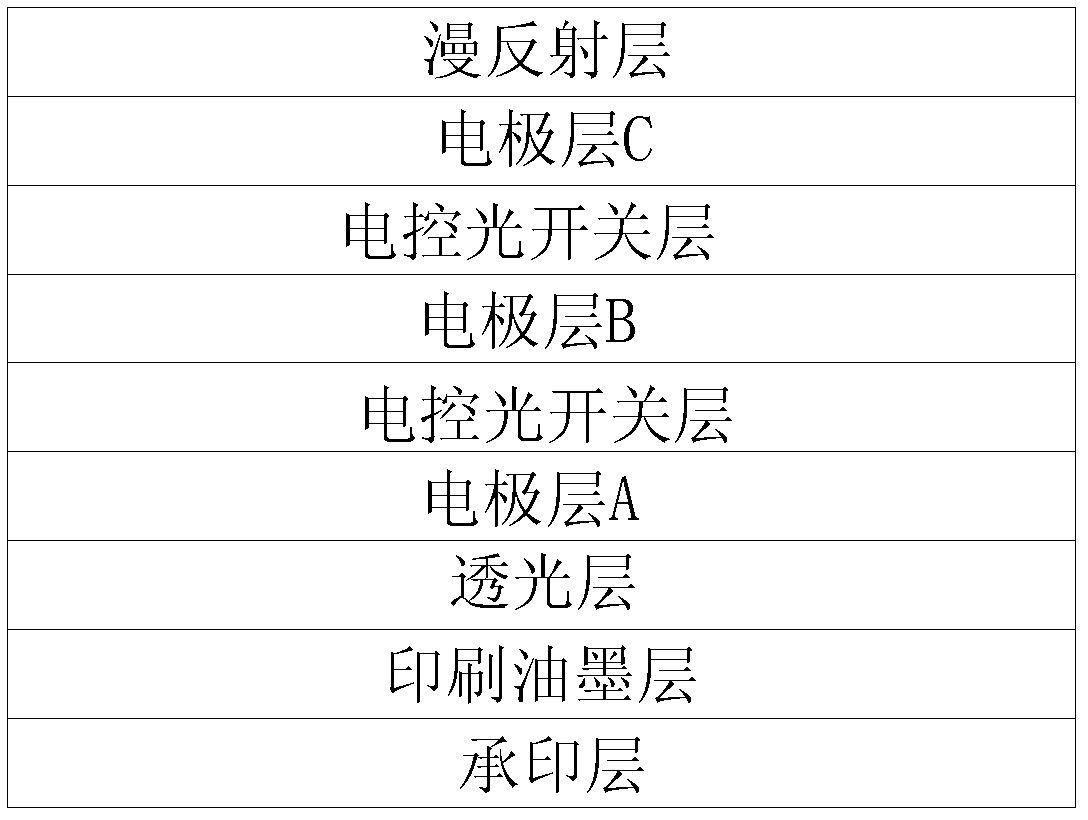

[0022] Such as figure 1 As shown, the bottom layer of the display screen provided in this embodiment is the printing layer, and the printing ink layer is attached to the printing layer, and the light-transmitting layer, electrode layer A, electro-optical switch layer, electrode Layer B, electric control optical switch layer, electrode layer C and diffuse reflection layer, the thickness of the display screen is not more than 5mm.

[0023] The printing layer adopts foldable and printable flexible insulating materials, such as paper, plastic, cloth, etc. Ink is printed on the printing layer to generate CMYK color ink dot matrix to obtain a printing ink layer.

[0024] The light-transmitting layer adopts a flexible light-transmitting material, such as ETEE (ETEE is a copolymer of tetrafluoroethylene and ethylene) plastic film, PET plastic film or shadowless glue, which is used to increase the printing ink layer and the first electric control optical switch layer ( The electric c...

Embodiment 2

[0029] The bottom layer of the display screen provided in this embodiment is the printing layer, and the printing ink layer is attached to the printing layer, and the light-transmitting layer, the substrate layer, the electrode layer A, the electro-optical switch layer, and the electrode layer are attached sequentially from the printing ink layer to the top. Layer B, the electric control optical switch layer and the electrode layer C, the thickness of the display screen is not more than 5mm. In this embodiment, the light-transmitting layer is shadowless glue, and the materials used in other layers are the same as those in Embodiment 1.

[0030] The preparation method of the printed flexible display screen based on the double-layer PDLC film of the present invention is as follows:

[0031] (1) On the printing layer, ink is printed by gravure printing to produce a CMYK color ink dot matrix, and a printing layer attached with a printing ink layer is obtained;

[0032] (2) Coatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com