Patents

Literature

174 results about "Boiler feedwater pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A boiler feedwater pump is a specific type of pump used to pump feedwater into a steam boiler. The water may be freshly supplied or returning condensate produced as a result of the condensation of the steam produced by the boiler. These pumps are normally high pressure units that take suction from a condensate return system and can be of the centrifugal pump type or positive displacement type.

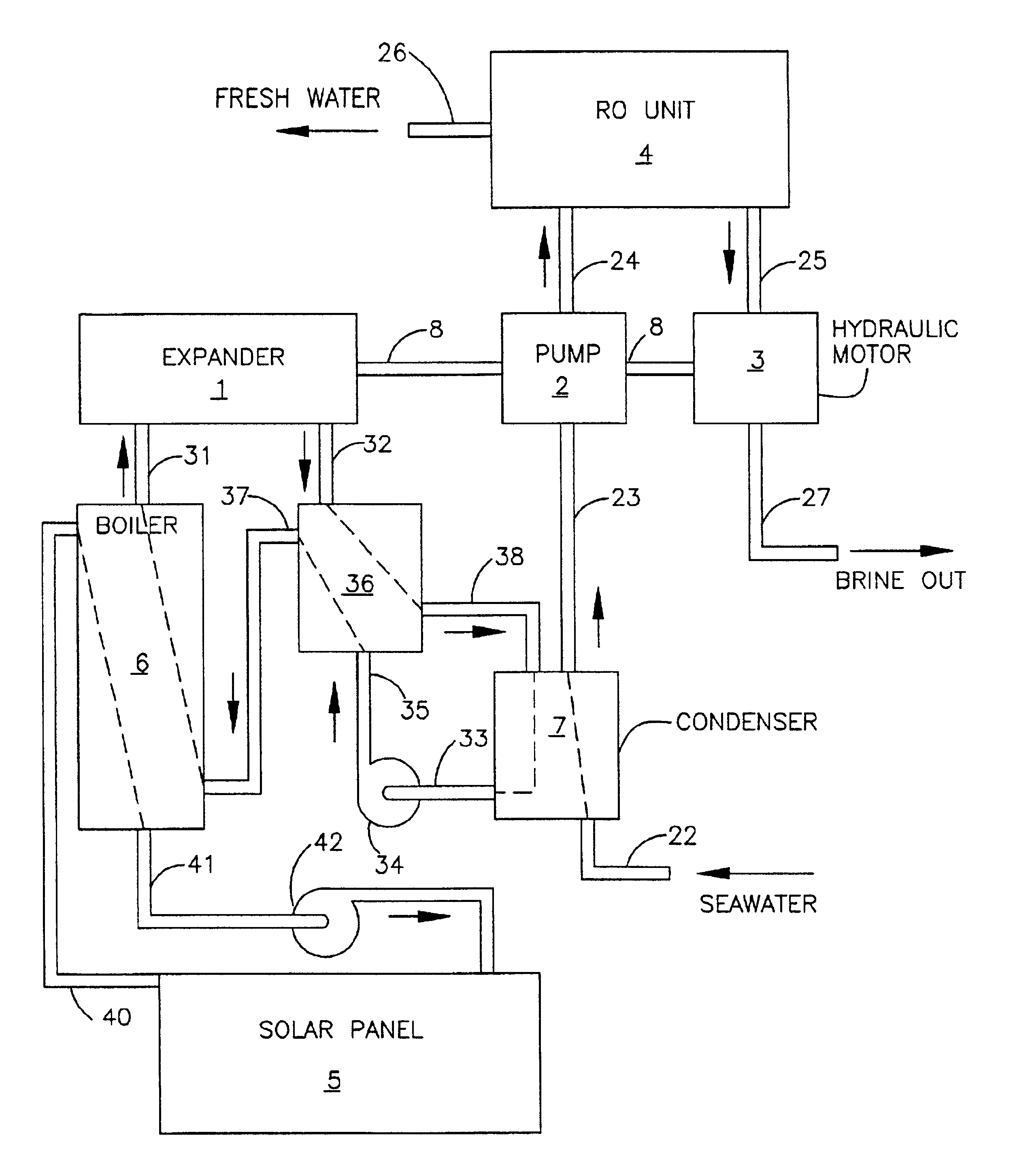

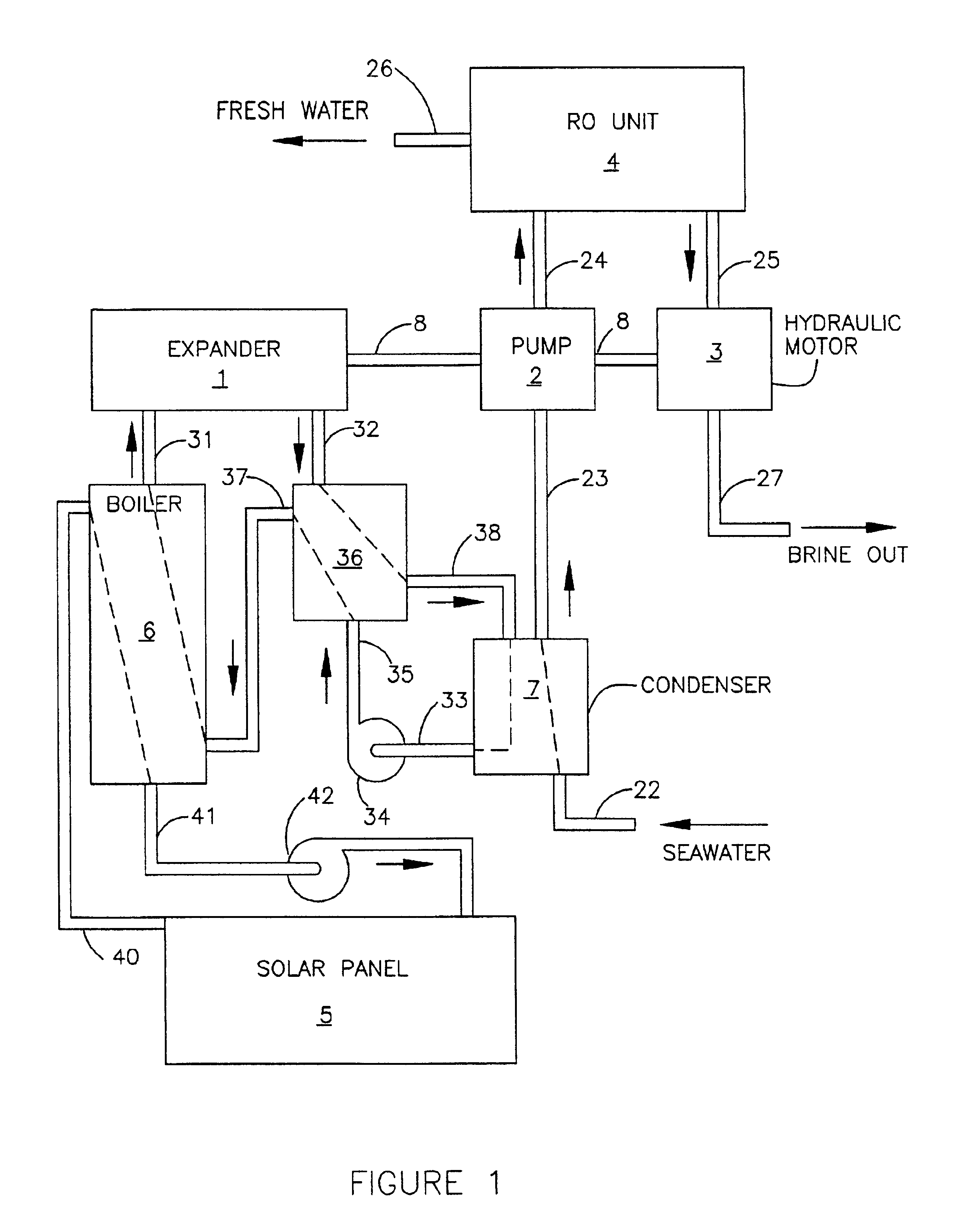

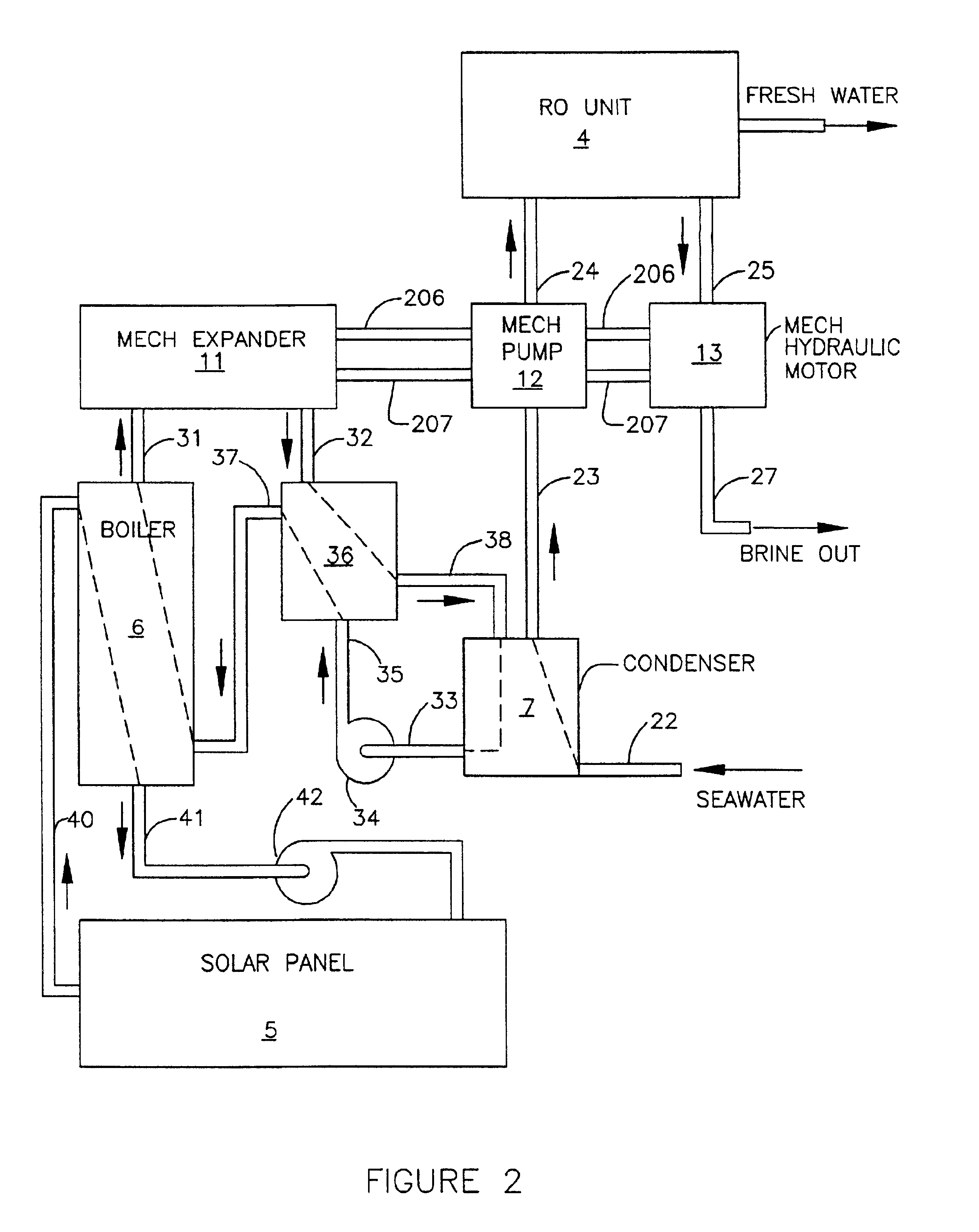

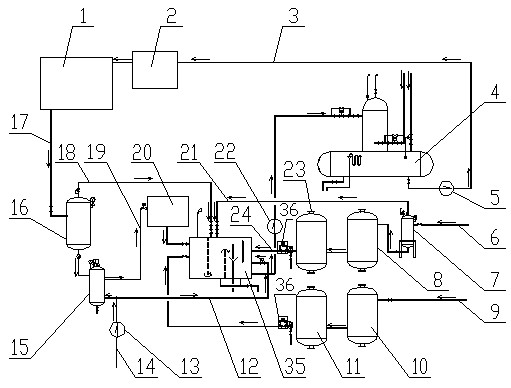

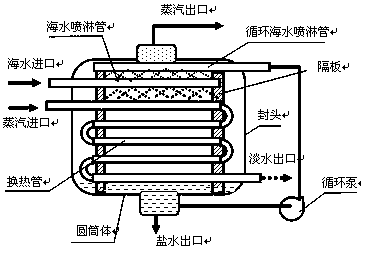

Solar energy desalination system

A desalination system is driven by a solar powered boiler that outputs a pressurized vapor to drive an expander that generates output motive force. A pump is responsive to the motive force to output pressurized saline water. A reverse osmosis unit receives the pressurized saline water to output fresh water and pressurized brine. A recuperator that transfers heat from the expander exhaust to the boiler feed liquid is incorporated to improve the efficiency of the system. In a particular embodiment, a hydraulic motor receives the pressurized brine and outputs an augmenting motive force to the pump. In another embodiment, a novel motorless boiler feed pump is defined.

Owner:PRUEITT MELVIN L

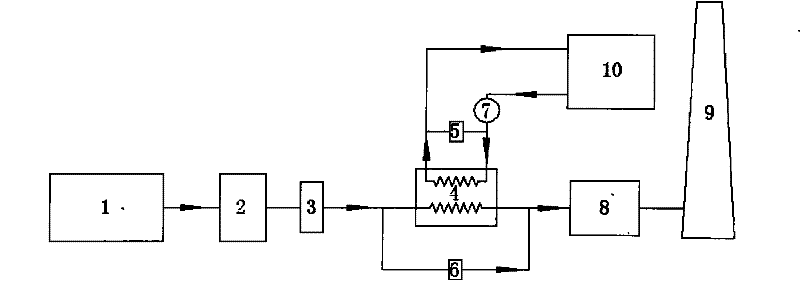

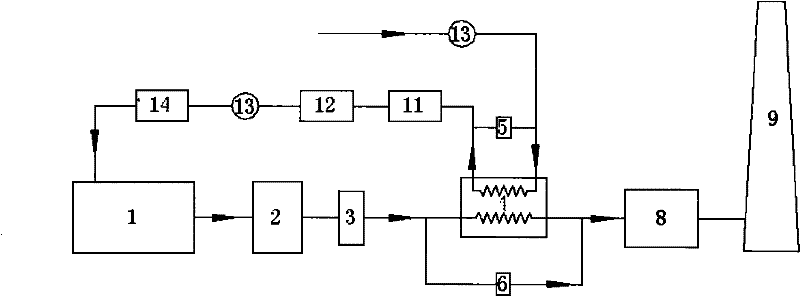

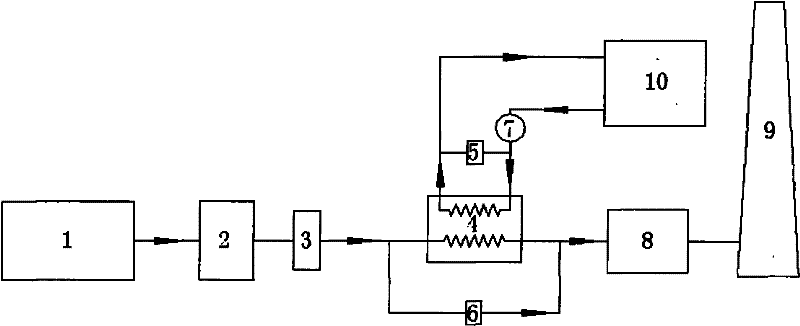

Method for recovery and utilization of waste heat from low temperature flue gas

InactiveCN102269401AReduce heatIncreasing energy efficiencyHot-water central heatingThermal energyBoiler feedwater pump

The invention discloses a method for recovering and utilizing waste heat from low-temperature flue gas. An air-water heat exchanger (4) is connected in series or in parallel in the flue at the rear of the induced draft fan or booster fan (3) of the existing boiler or kiln (1). The inlet port of the hot side of the air-water heat exchanger is connected with the induced draft fan or booster fan (3), the outlet port of the hot side is connected with the desulfurization absorption tower (8) or the chimney (9), and the inlet port of the cold side is circulated with the heat user The outlet pipe or condensate pipe of the water or boiler softened water system is connected, the cold side outlet is connected with the hot user circulating water supply or the boiler feed water pump, and a waterway is connected between the hot side outlet pipe and the cold side inlet pipe of the air-water heat exchanger A bypass pipe, and a waterway bypass regulating valve (5) is arranged on the pipe; a flue gas bypass pipe between the induced draft fan or booster fan and the desulfurization absorption tower (8), and a flue gas bypass pipe A flue bypass regulating valve (6) is arranged on it. By connecting a gas-water heat exchanger in series or in parallel in the flue behind the induced draft fan of the boiler or kiln, the purpose of saving heat energy can be achieved.

Owner:LUOYANG BLUE SEA INDAL

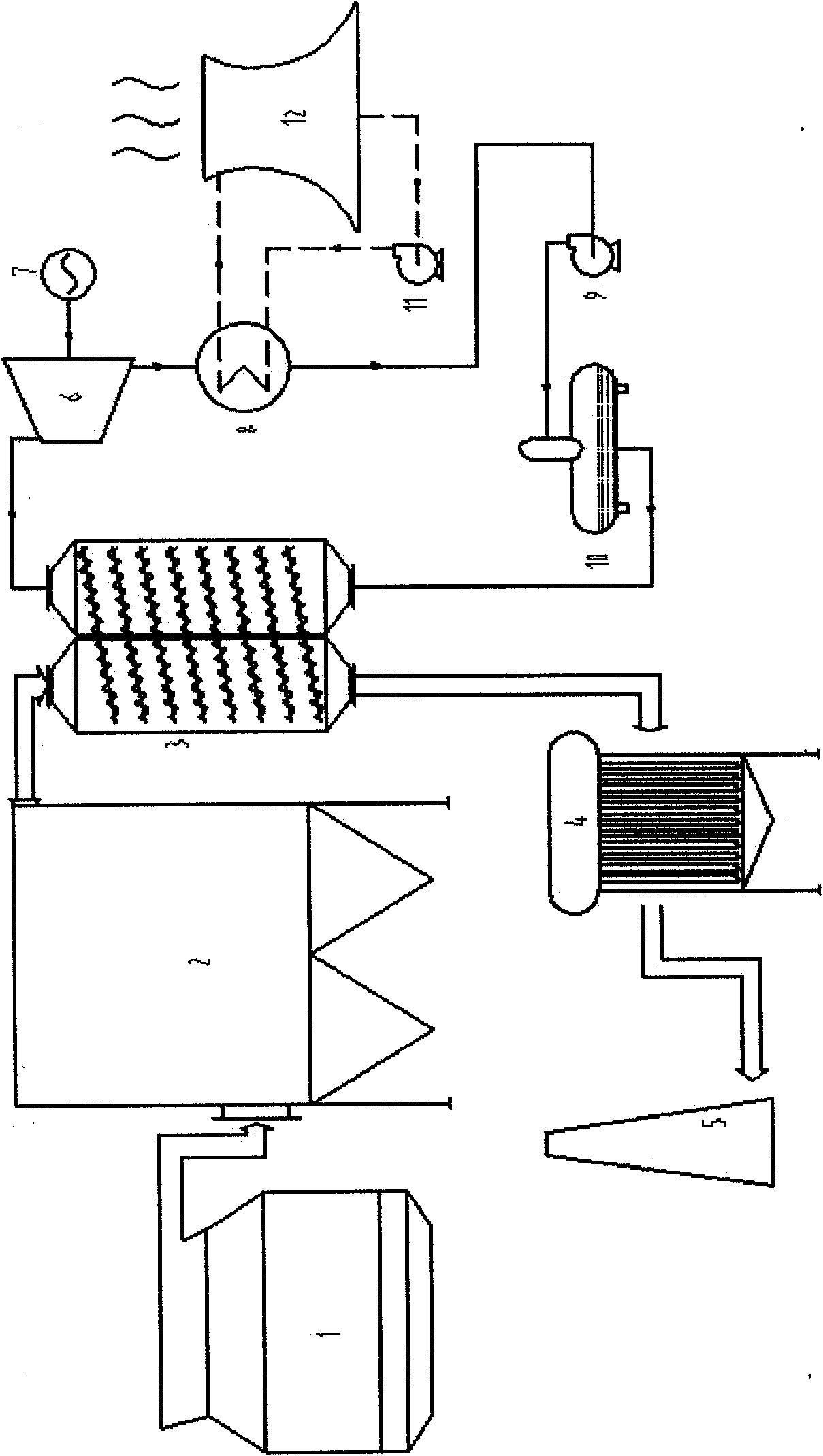

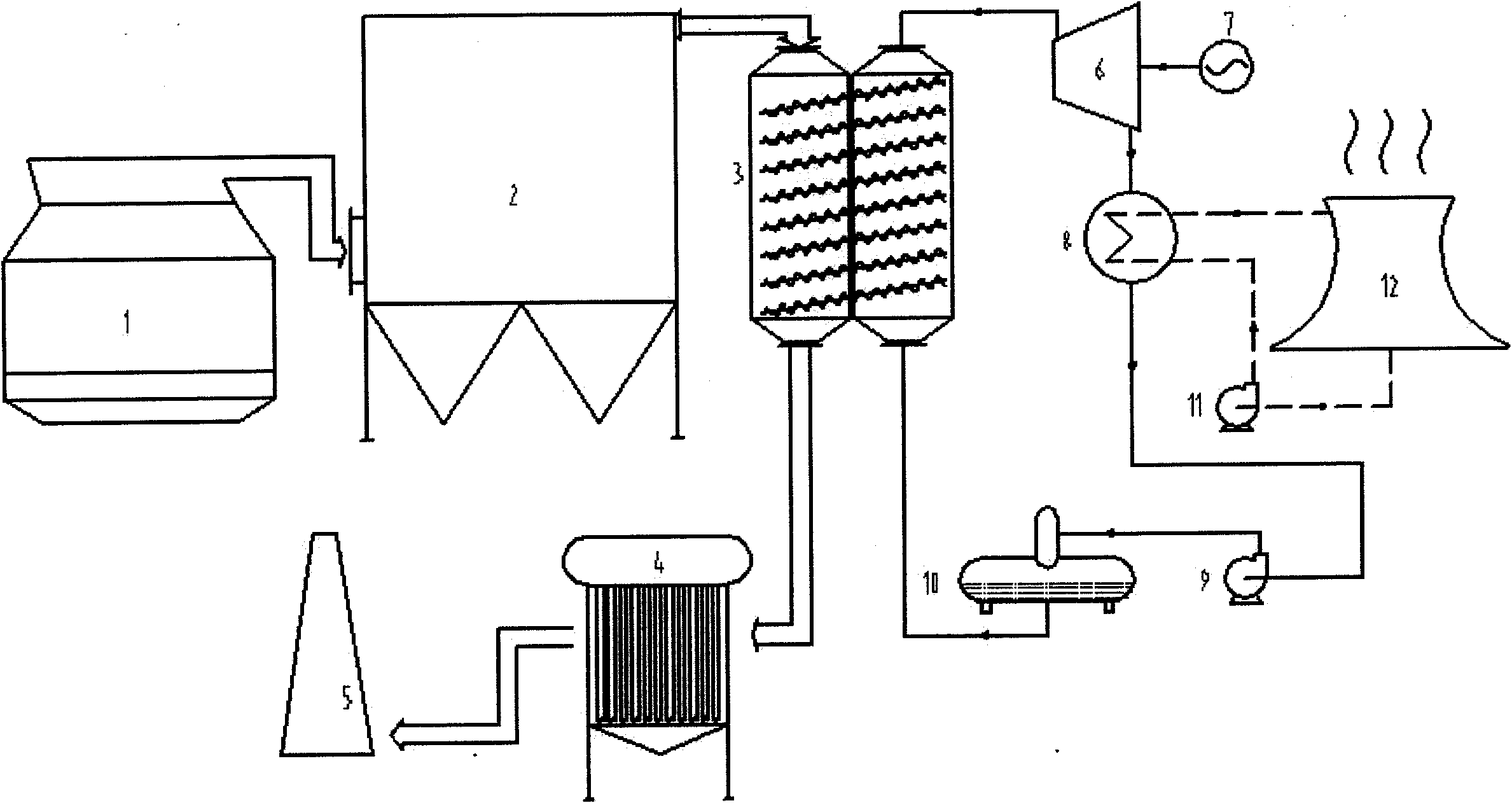

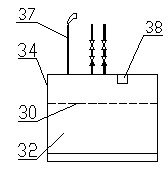

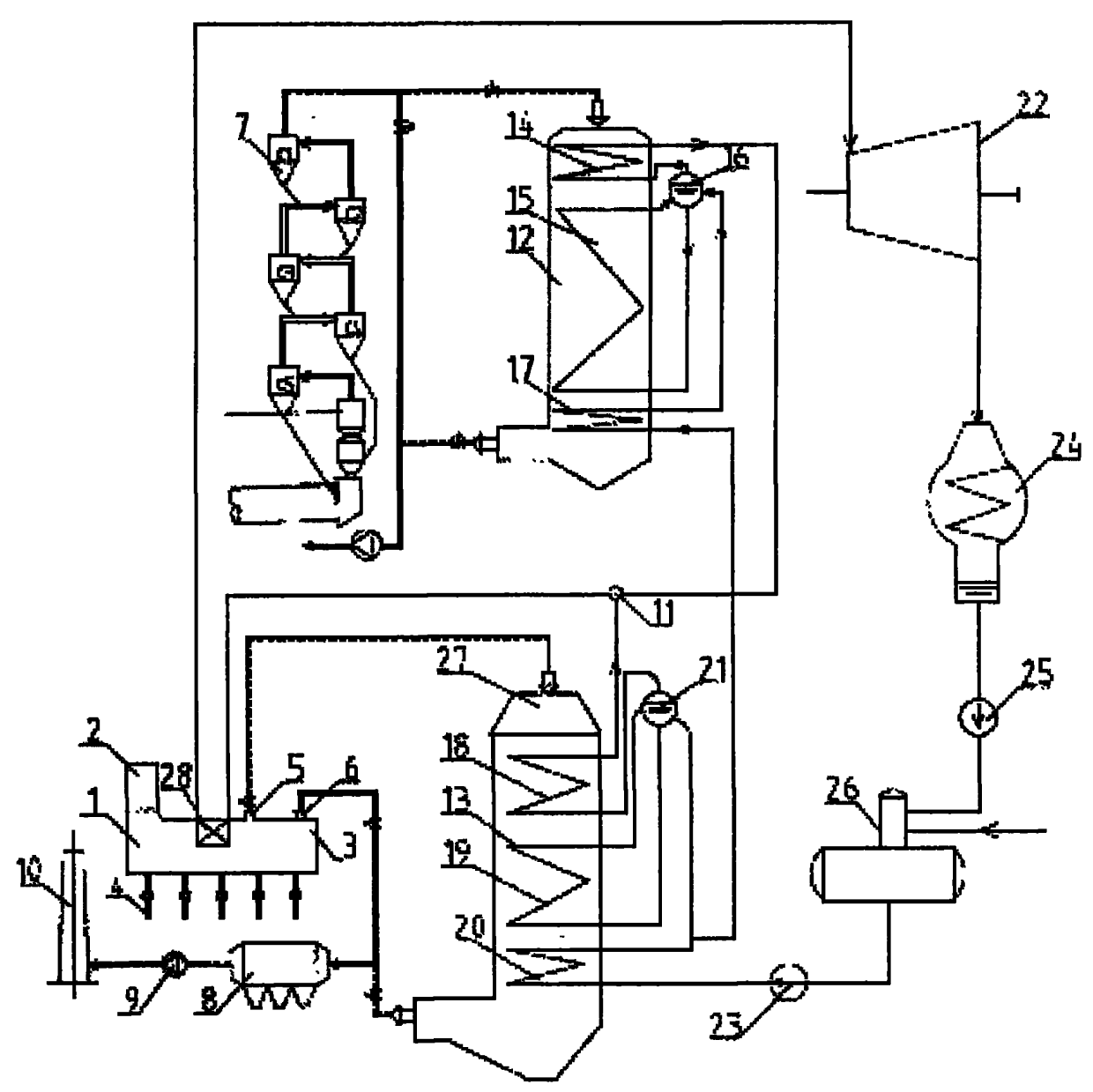

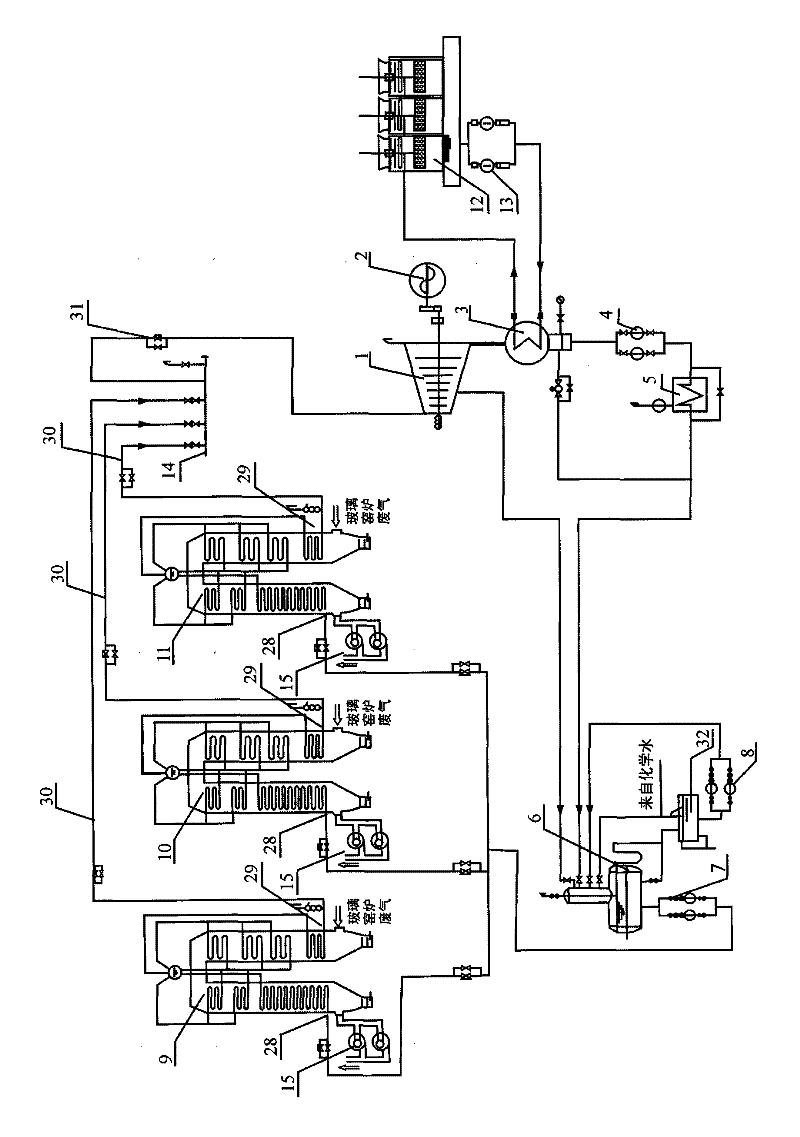

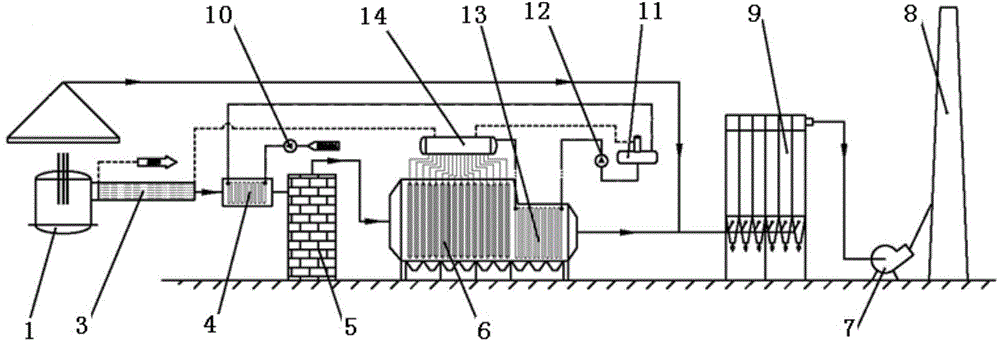

Integrated waste heat generating and heating system and process flow thereof

InactiveCN101852555AAvoid paralysisLow running costValve arrangementsDispersed particle filtrationFiberHeat conducting

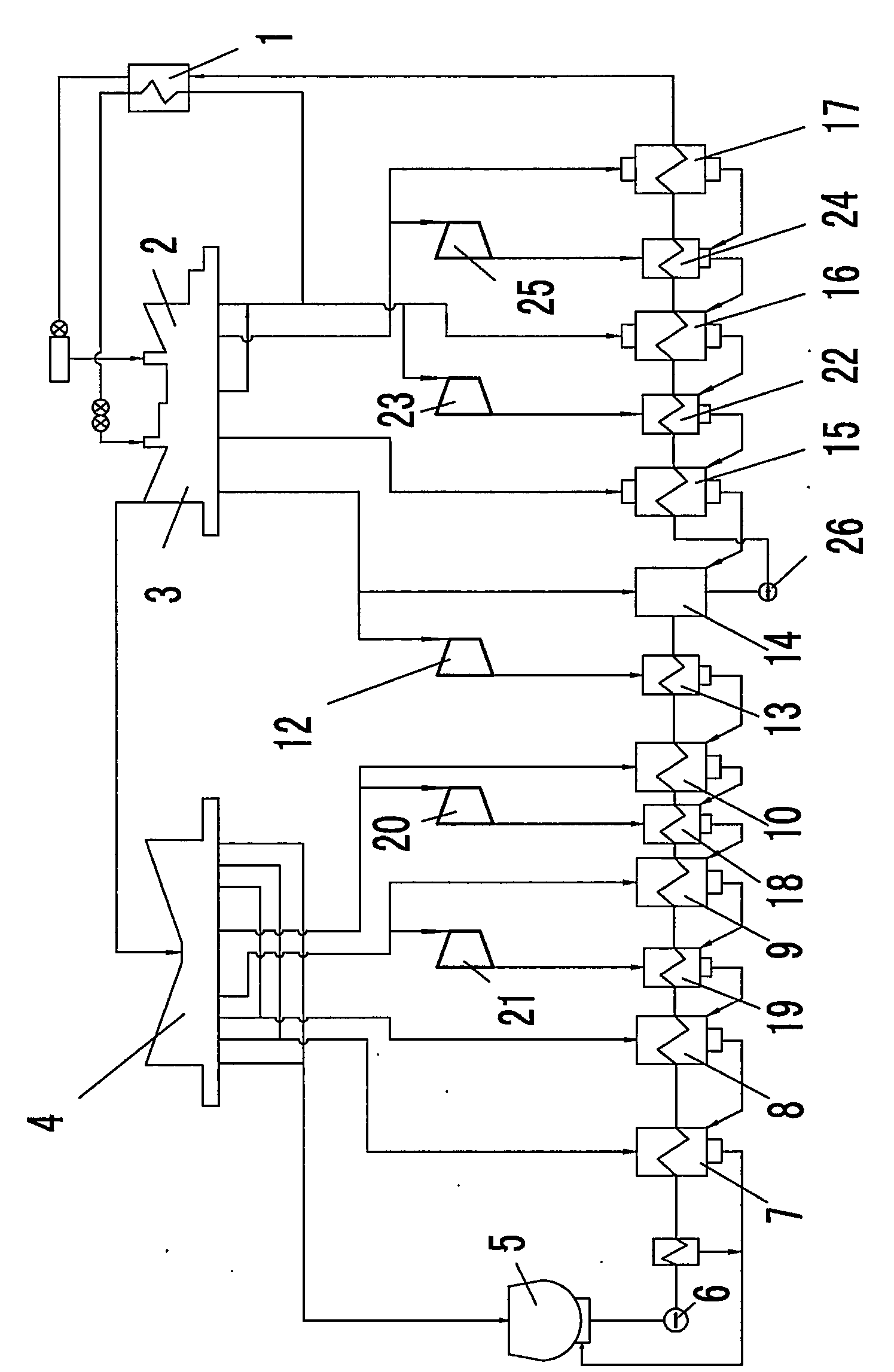

The invention discloses a waste heat generating equipment system and a waste heat generating process. The system comprises a ceramic fiber dust collector (2), a rapid heat conducting heat-pipe waste heat boiler (3), a rapid heat conducting heating device (4), a steam replenishing and condensing steam turbine (6), a condenser (8), a condensing water pump (9) and a vacuum deaerator (10), wherein ceramic fiber dust collector (2) is arranged at a waste heat outlet end; the rapid heat conducting heat-pipe waste heat boiler (3) bears a steam preparing device for power generation; the rapid heat conducting heating device (4) is arranged on the smoke inlet of a boiler; medium and high-pressure main steam generated by a rapid heat conducting heat-pipe waste heat boiler is mixed and enters the steam replenishing and condensing steam turbine (6) through a pipeline; low-pressure steam enters the steam replenishing and condensing steam turbine (6) through a steam replenishing pipeline; waste steam on the tail part of the steam turbine enters the condenser (8); condensed water enters the vacuum deaerator (10) through the condensing water pump (9) and a pipeline; water from which oxygen is removed in the deaerator enters the heat-pipe waste heat boiler (3) through a water supply pump of the boiler; and low-temperature smoke discharged from the back end of the boiler is delivered into the rapid heat conducting heating device (4). The waste heat utilization ratio of the integrated system is enhanced by over 60 percent on average, so unit energy consumption of an enterprise is greatly lowered, the problem of unstable running of the system due to dust blocking of the boiler and wearing of a heat exchange tube in a medium and low temperature waste heat generating system is solved and comprehensive generating efficiency is enhanced by over 30 percent.

Owner:童裳慧

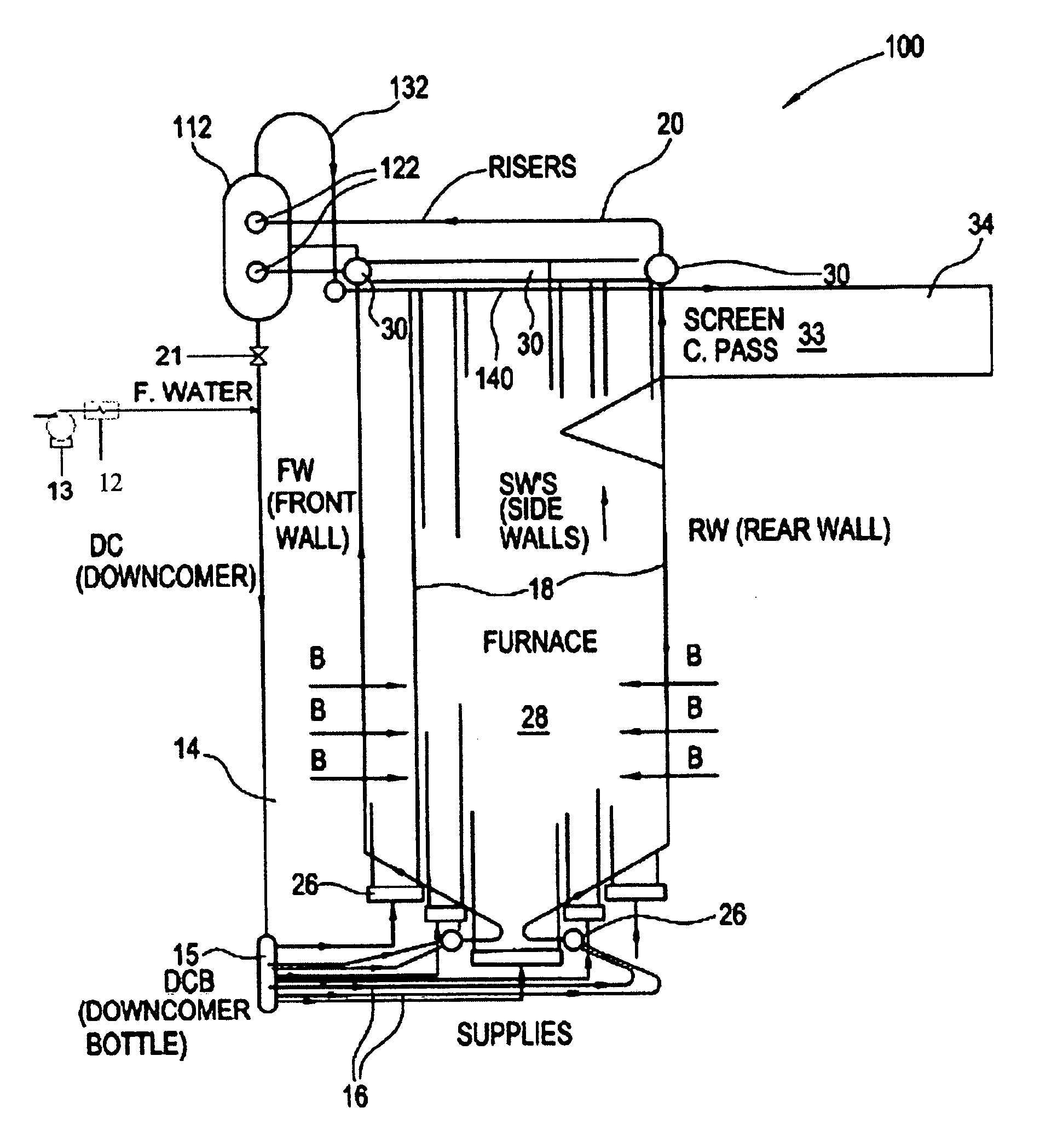

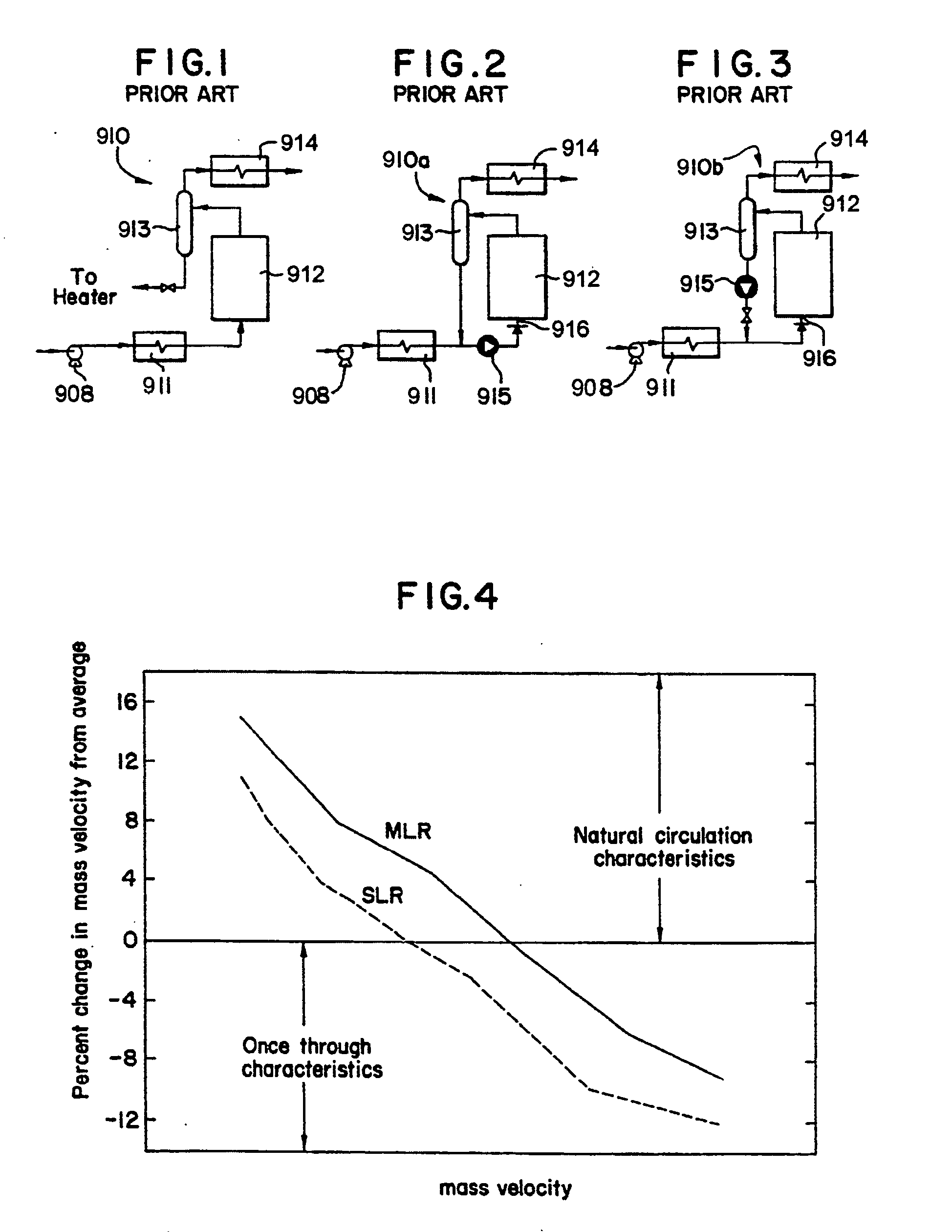

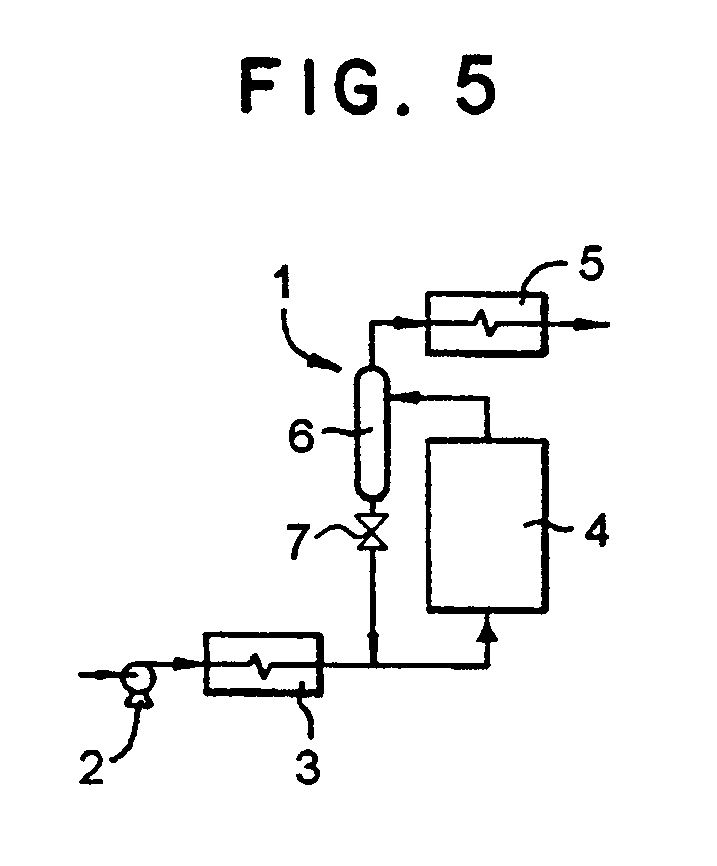

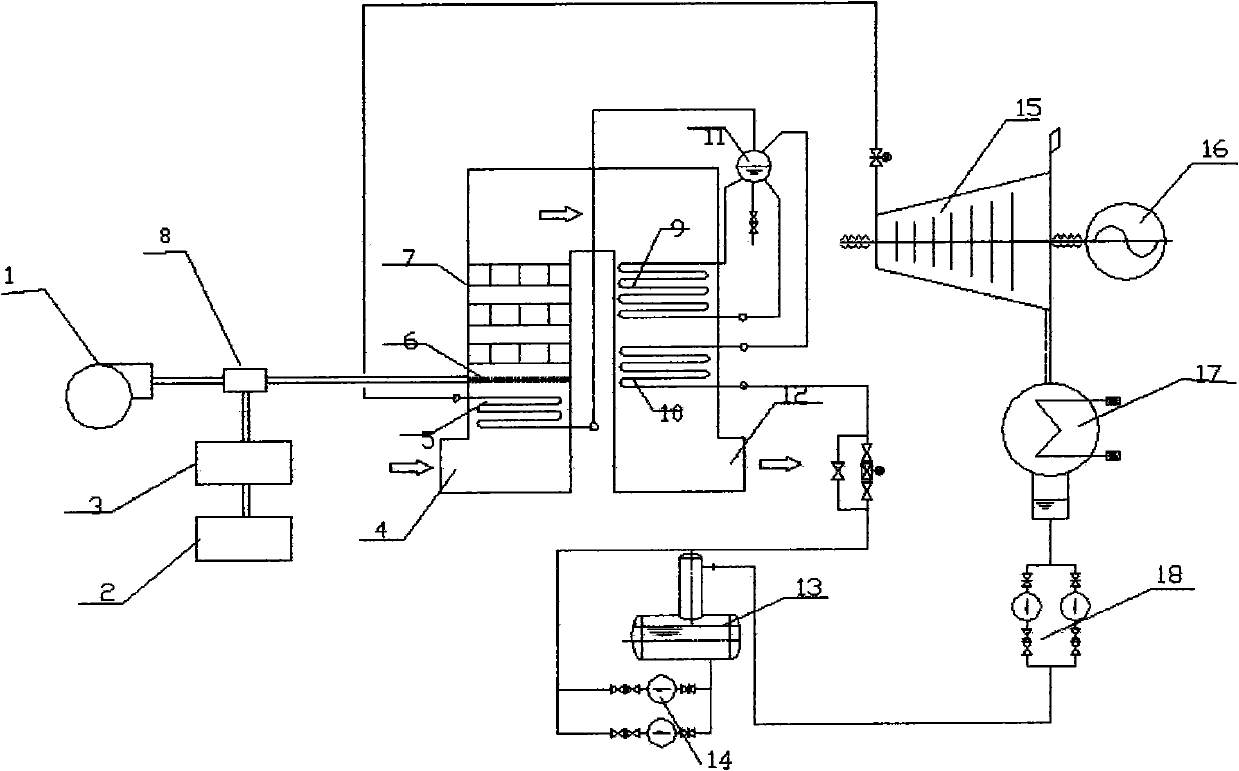

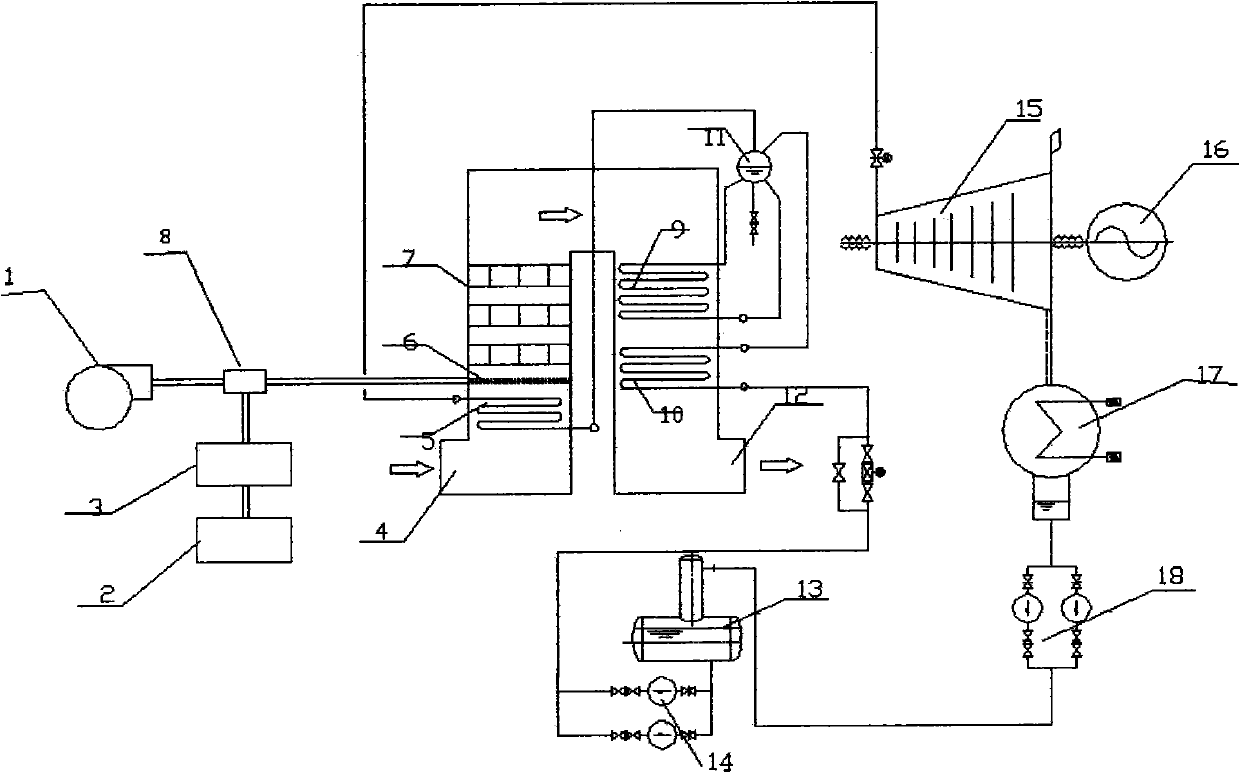

Circulation system for sliding pressure steam generator

InactiveUS20070283906A1High densityImprove abilitiesWater circulationFuel injection apparatusBoiler feedwater pumpEngineering

A steam generator circulation system is provided and includes a boiler feed pump for forcing water through an economizer, and through the waterwall tubes of an evaporator. A separator receives a mixture of steam and water and sends the steam to a steam utilization unit such as a superheater. A valve is provided below the separator. If the valve is open, the saturated water from the separator is mixed with feedwater and recirculated through the tubes of the evaporator. If the valve is closed, recirculation is terminated. At loads below the critical point, the valve below the separator system would be open and the boiler would operate like a natural circulation drum boiler. At loads above the critical point, the valve below the separator system would be closed resulting in a boiler that operates like a once-through boiler.

Owner:THE BABCOCK & WILCOX CO

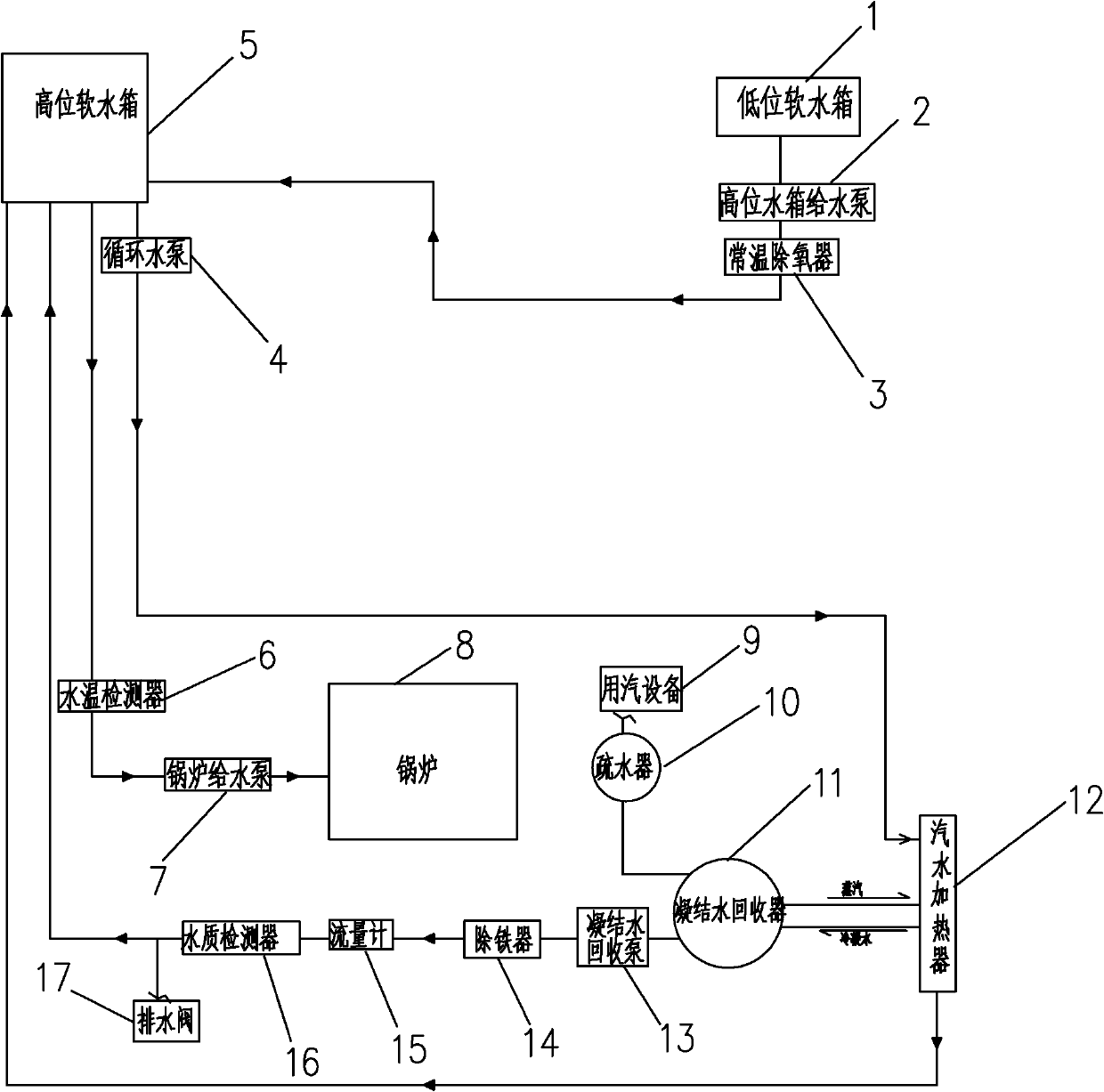

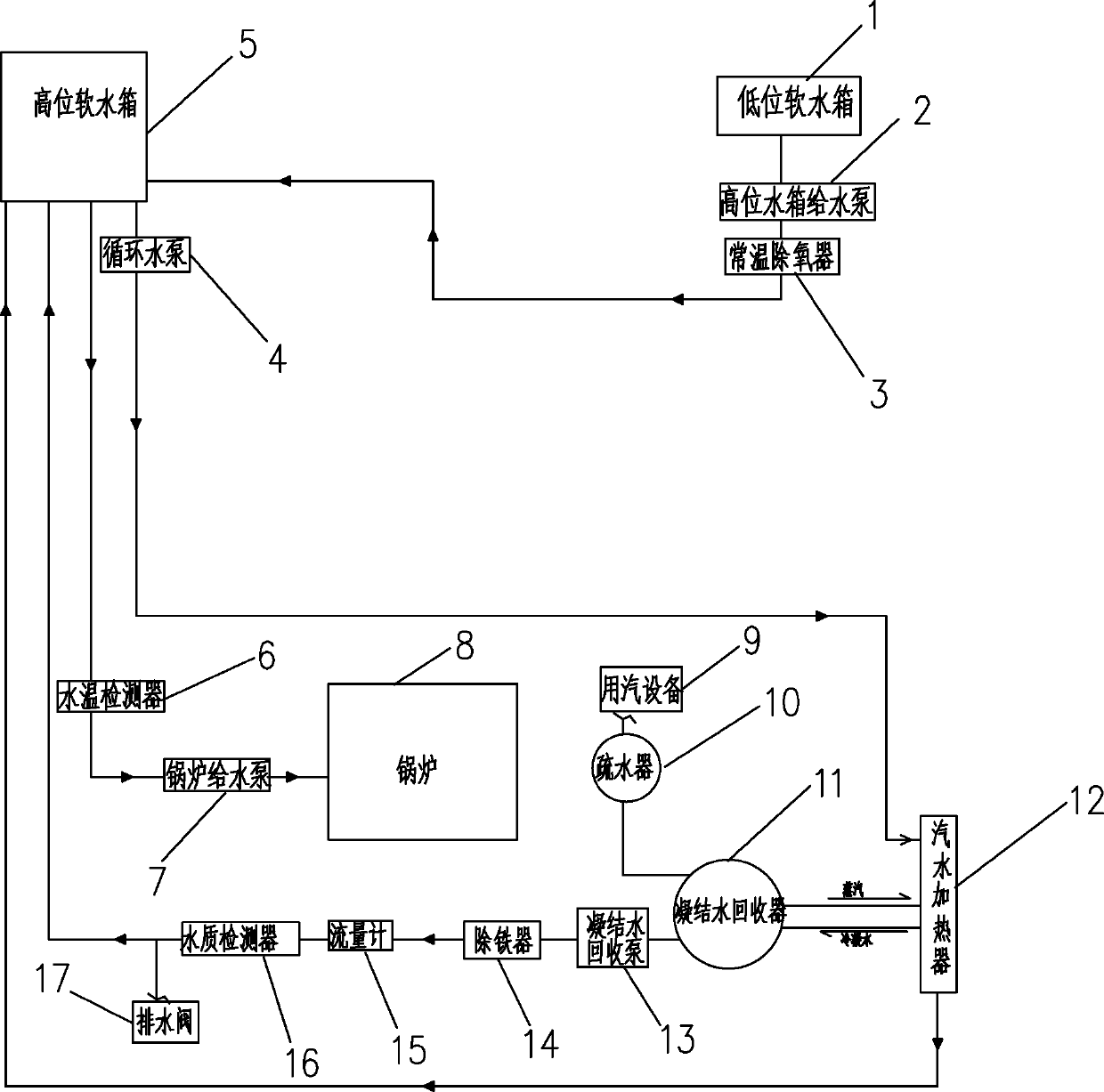

Boiler water replenishing system capable of collecting waste heat and condensed water

ActiveCN102607014AHydration does not affectReduce consumptionFeed water supplyExpansion tankBoiler blowdown

The invention discloses a boiler water replenishing system capable of collecting waste heat and condensed water. A boiler blowdown pipe of a boiler is connected with a blowdown expansion tank, a steam outlet of the blowdown expansion tank is connected into a hot water tank through a blowdown flash steam pipe, a blowdown water pipe of the blowdown expansion tank is connected into a continuous-discharge heat exchanger which is further connected with a softened water feeding pipe, the softened water feeding pipe is connected with a water softening station through a water supply pump, the softened water feeding pipe for the continuous-discharge heat exchanger is connected with a boiler secondary energy saver prior to being connected into the hot water tank, and the hot water tank is connected with a hot water outlet pipe which is sequentially connected with a circulating pump, a heat deaerator and a boiler water feeding pump prior to being connected into a boiler water inlet. The boiler water replenishing system has the advantages that centralized use of the waste heat and the condensed water is achieved, steam consumption of the deaerator is reduced, waste heat absorption effect is enhanced, connection of the deaerator is simplified, pollution of the heat and the condensed water to the environment is reduced, and water replenishing for the boiler is unaffected when heat exchange equipment fails.

Owner:CHINA TOBACCO HENAN IND

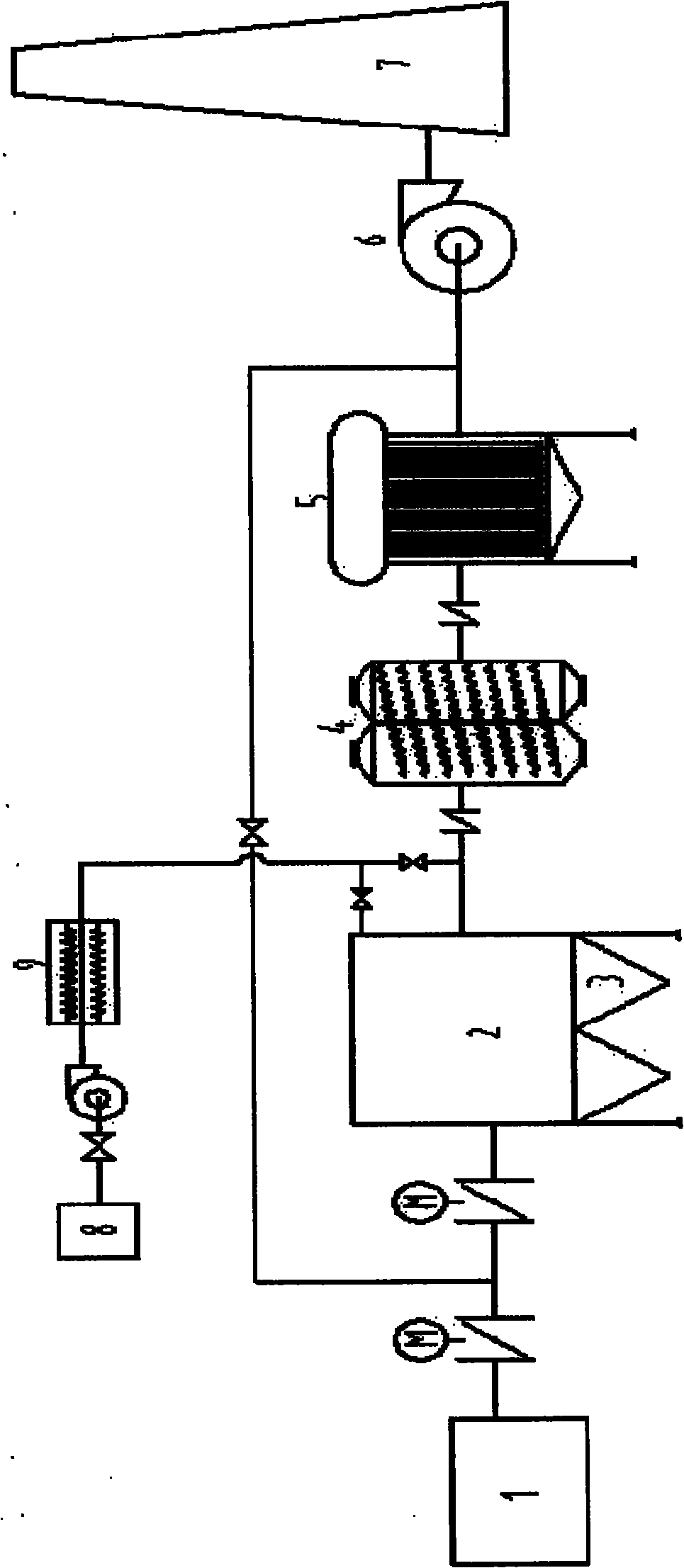

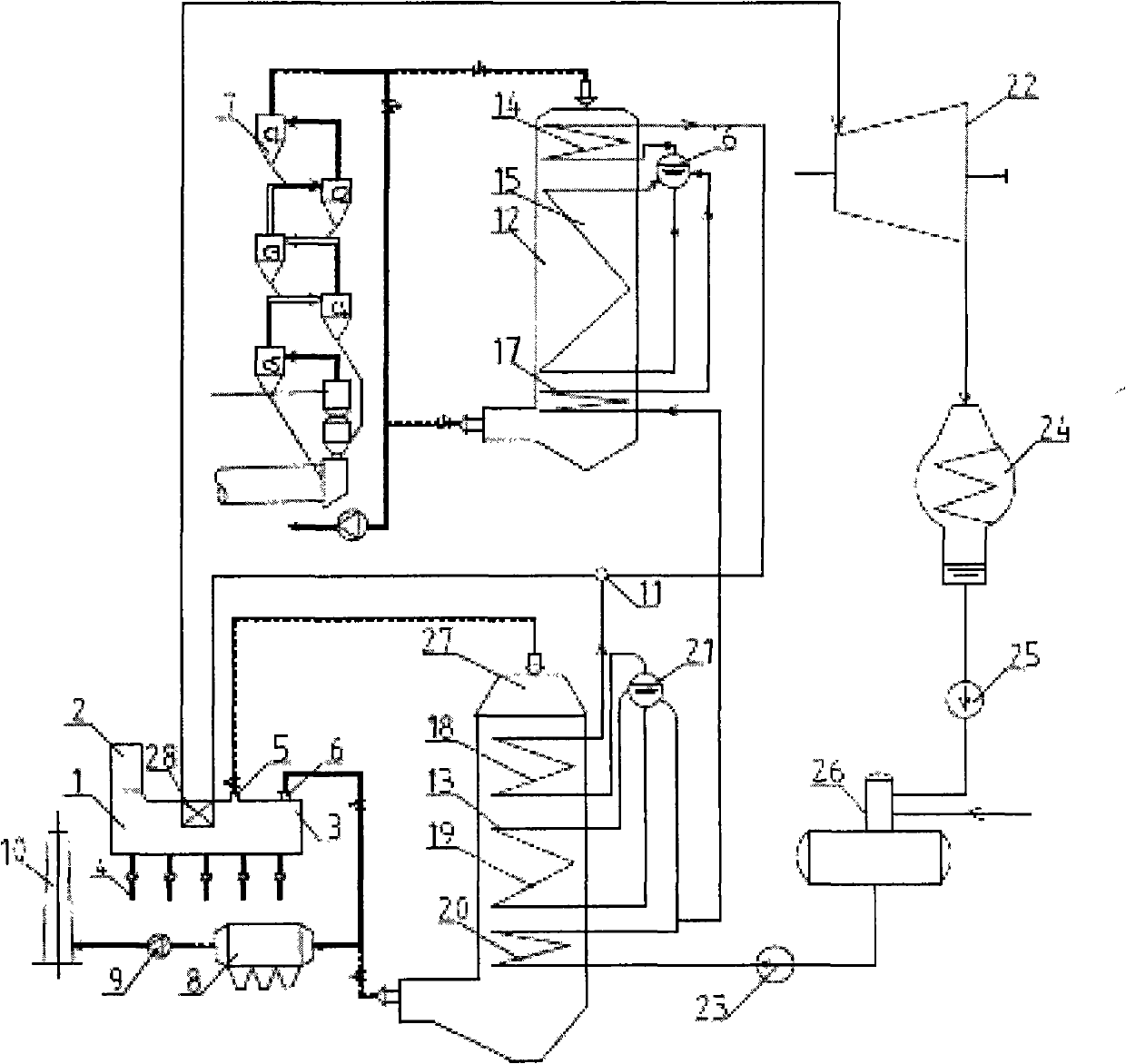

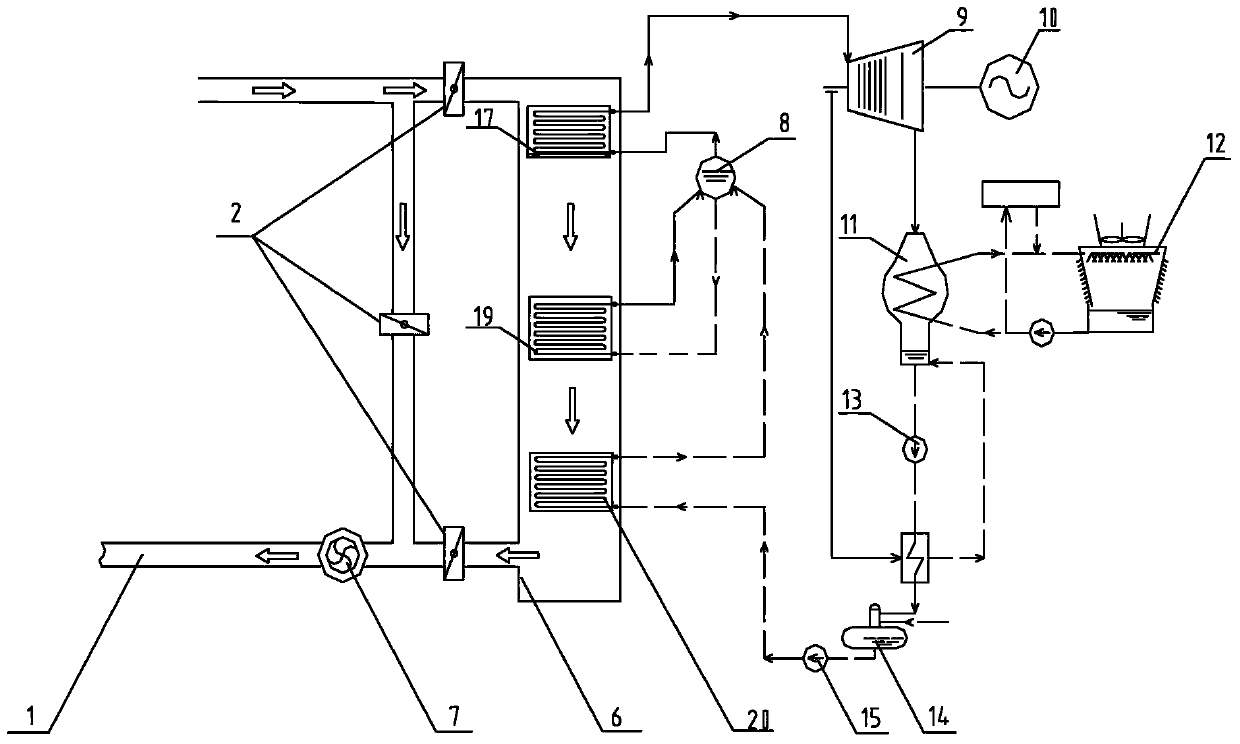

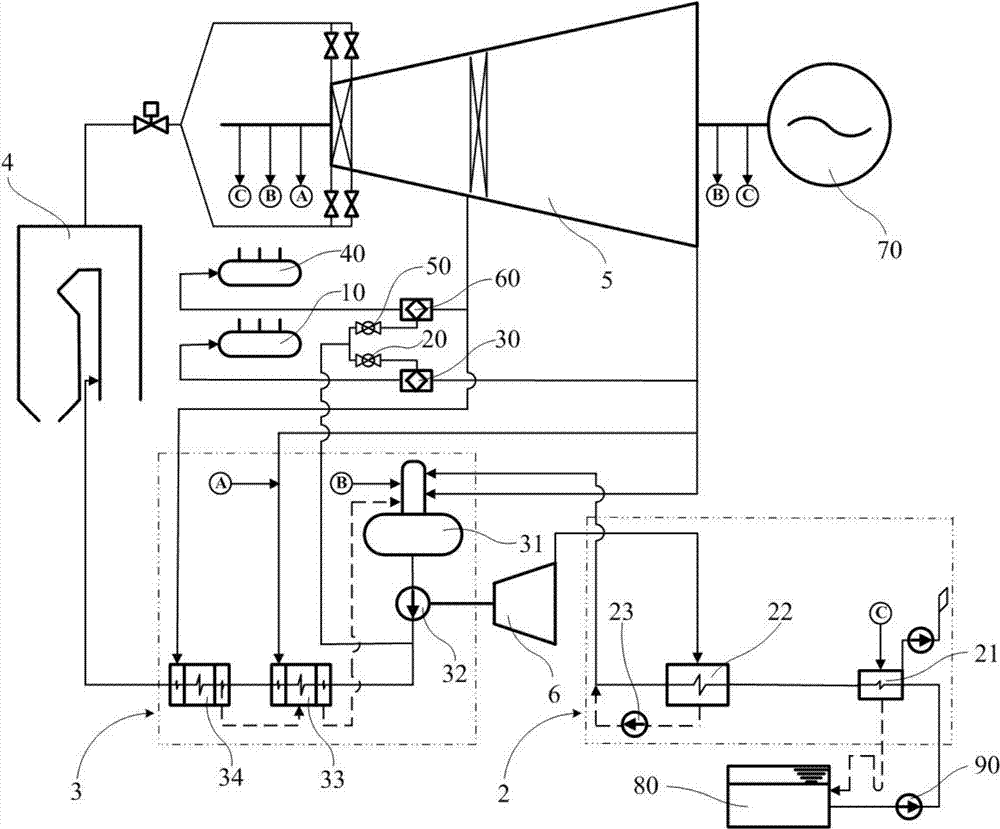

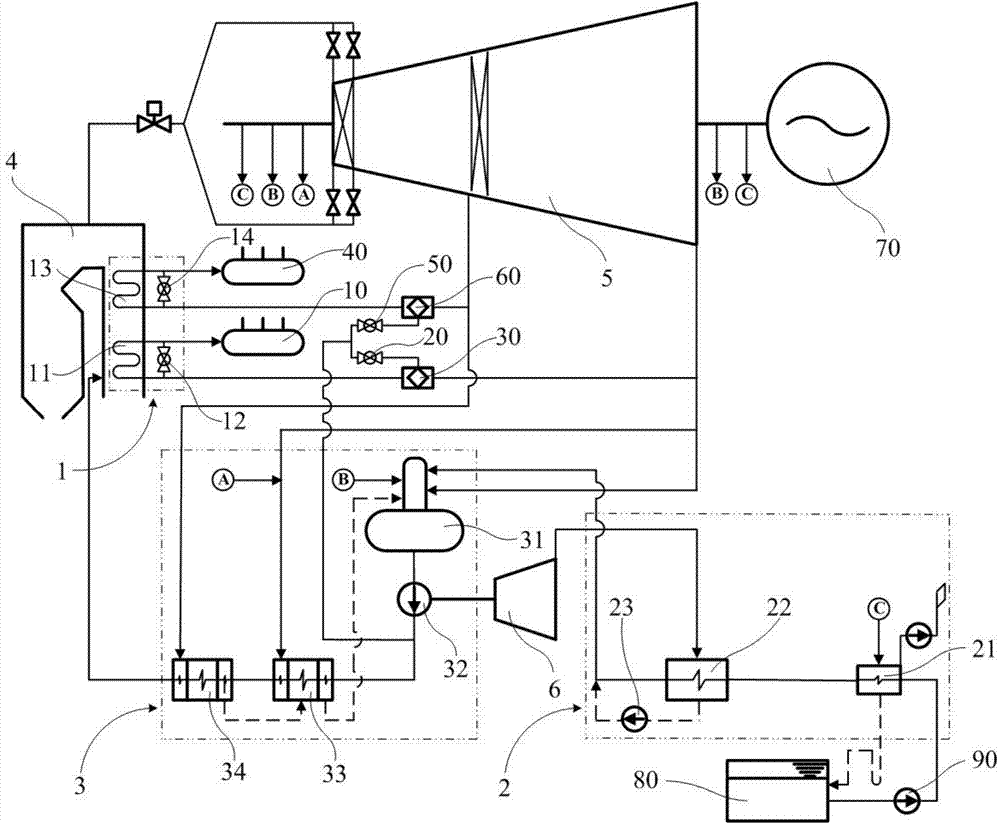

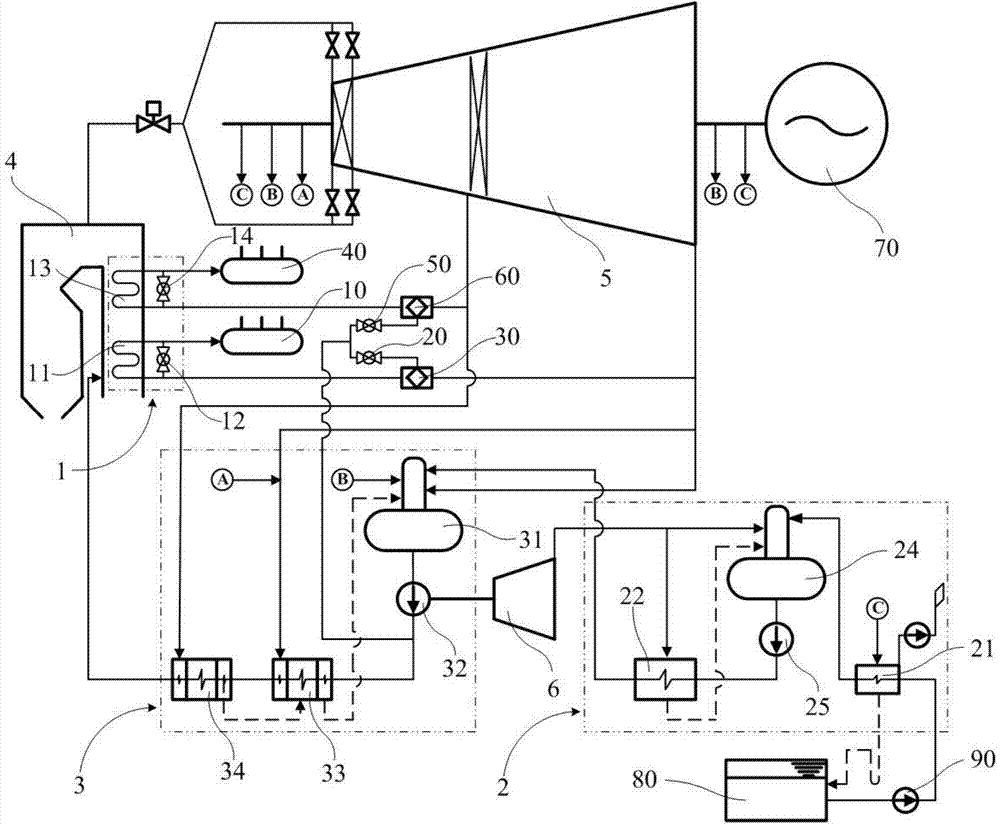

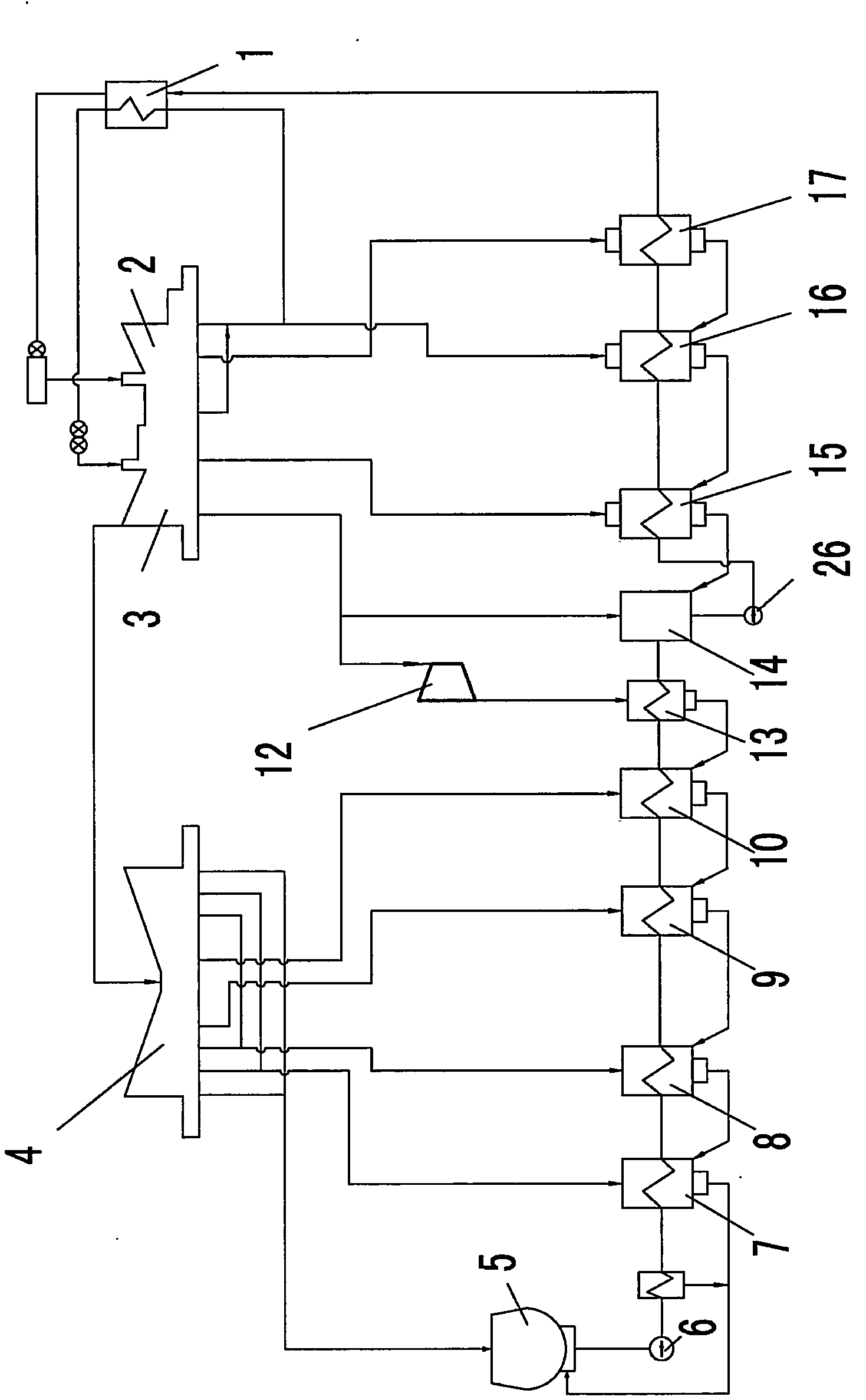

Pure medium-low temperature waste heat generating system in cement kiln

InactiveCN101793467AIncrease temperatureIncrease enthalpyFeed water supplyIncreasing energy efficiencySuperheaterDeaerator

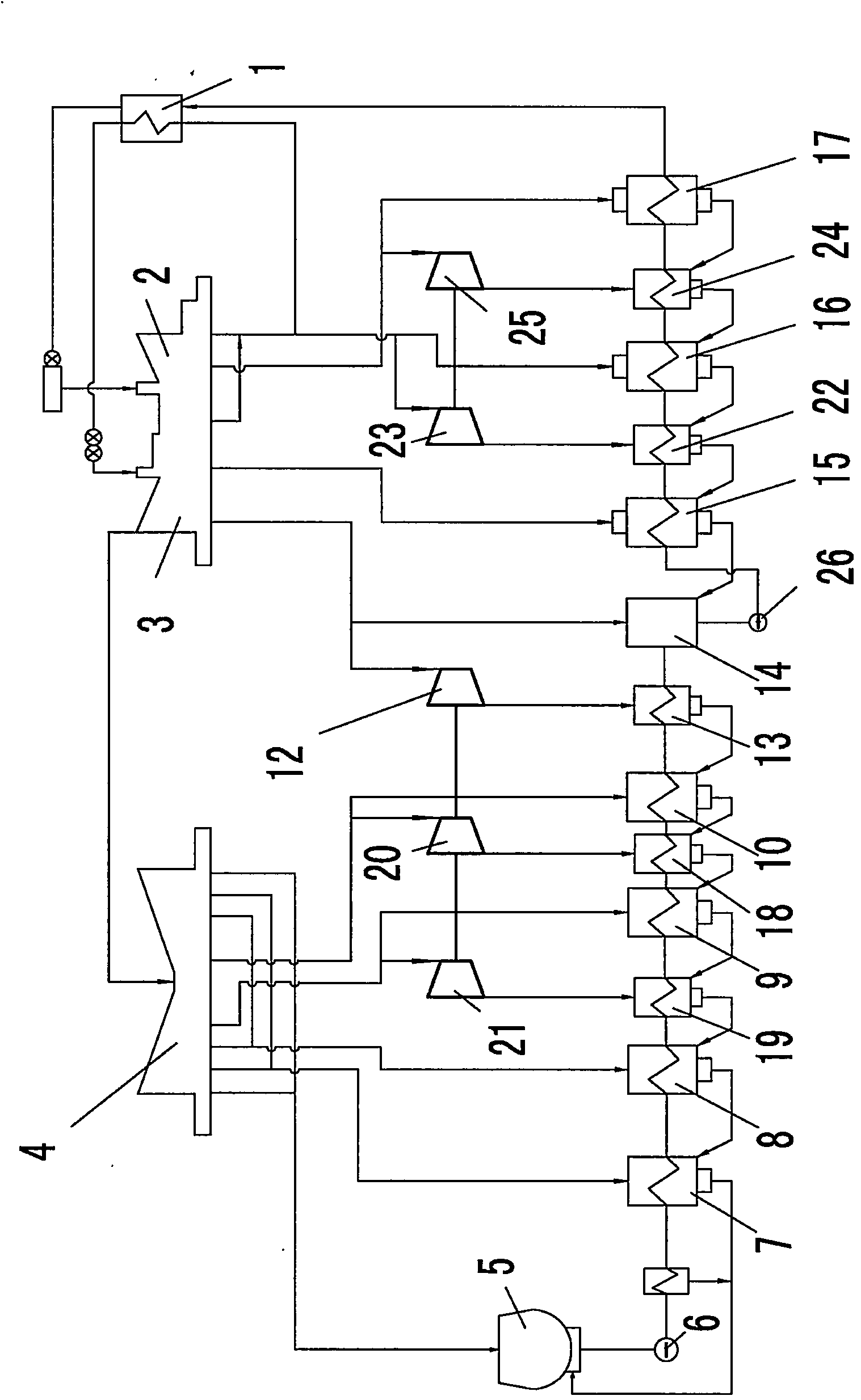

The invention relates to a pure medium-low temperature waste heat generating system in a cement kiln. The invention is characterized in that an AQC boiler is arranged at the kiln head to generate low-temperature low-pressure steam; an SP boiler is arranged at the kiln tail to generate low-temperature low-pressure steam; the low-temperature low-pressure steam generated by the two waste heat boilers are mixed by a steam distributor and then goes into a common high-temperature superheater arranged in the front end of a grate cooler at the kiln head, the low-temperature low-pressure steam generated by the AQC boiler and the SP boiler is superheated into high-temperature high-pressure steam and then goes into a condensing steam turbine, the dead steam after the action of the steam turbine goes into a condenser, condensation water goes into a vacuum deaerator through a condensation water pump and a pipeline to deoxidize, and the deoxidized water goes into the AQC boiler and the SP boiler through a boiler feed pump. By reasonably using the waste steam temperature in the cement kiln and carrying out the cascading use of the waste steam heat based on the temperature, the invention reduces or avoids the entropy phenomena, and enables the temperature of the superheated steam at the inlet of the steam turbine to be raised, thereby realizing the pure medium-low temperature waste heat generating system in the cement kiln, of which the generating capacity is improved.

Owner:LUOYANG CEMENT ENG DESIGN & RES INST

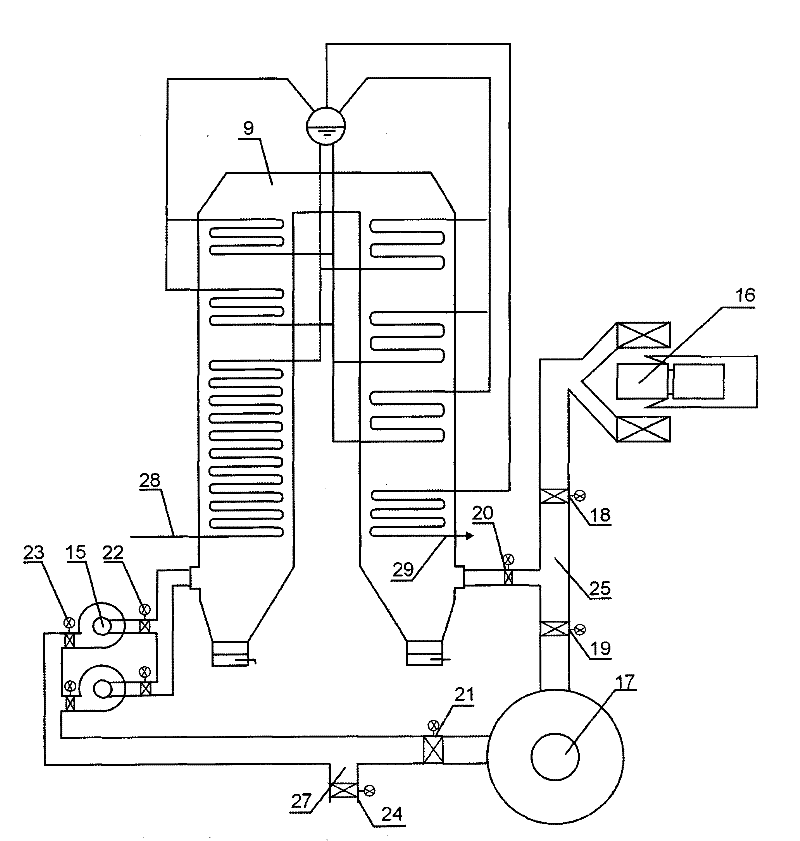

Glass kiln denitration generating system

ActiveCN101947413AMeet the requirements of denitrification processLow investment costDispersed particle separationIncreasing energy efficiencyEngineeringSuperheater

The invention relates to a glass kiln denitration generating device. The system comprises an ammonia spraying device, a reactor, a boiler evaporimeter, a superheater and a boiler economizer, wherein the ammonia spraying device comprises an ammonia storing tank, a heater, an ammonia spraying fence, a fan and a heat exchanger; the reactor is arranged inside a denitration exhaust-heat boiler and on the upper part of the heat exchanger; the boiler evaporimeter is arranged inside the denitration exhaust-heat boiler and is connected with a turbine outside the denitration exhaust-heat boiler through a pipeline, and the turbine is successively connected with a generator, a condenser, a condensate pump, a deaerator, a boiler feed pump outside the denitration exhaust-heat boiler through the pipeline; the superheater is arranged inside the denitration exhaust-heat boiler and at the bottom of the ammonia spraying fence and on the upper part of a smoke inlet, wherein one end of the superheater is connected to the evaporimeter through the pipeline, and the other end thereof is connected to the turbine through the pipeline; and the boiler economizer is arranged inside the denitration exhaust-heat boiler and at the bottom of the boiler evaporimeter.

Owner:SINOMA ENERGY CONSERVATION

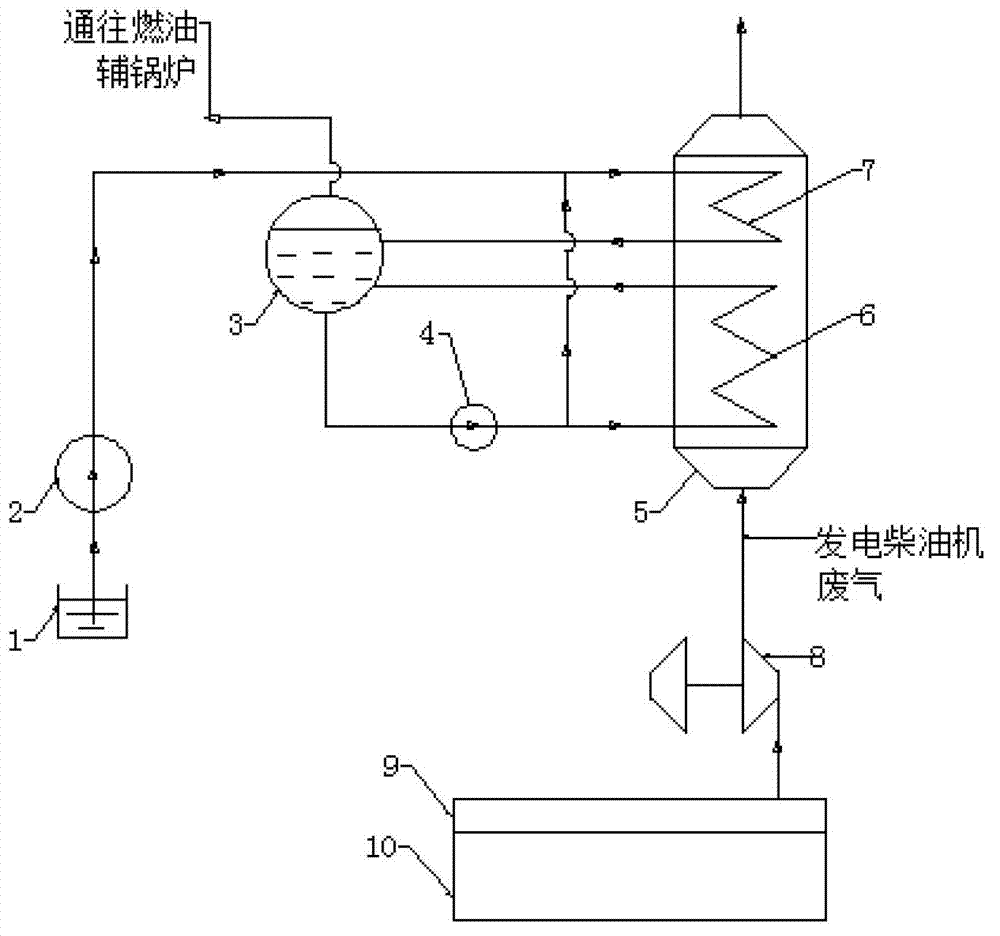

Exhaust gas waste heat steam producing system of marine diesel generating set

InactiveCN102777876AReduce fuel consumptionLower fuel costsSteam generation using hot heat carriersBoiler feedwater pumpExhaust fumes

The invention discloses an exhaust gas waste heat steam producing system of a marine diesel generating set. The exhaust gas waste heat steam producing system comprises a hot well, a boiler water-feeding pump, a steam pocket, an exhaust boiler, an evaporator and a preheater, wherein the evaporator and the preheater are installed in the exhaust boiler, and the hot well is sequentially connected with the boiler water-feeding pump, the preheater, a steam pocket first inlet, a steam pocket first outlet, the evaporator, a steam pocket second inlet, a steam pocket second outlet and a fuel auxiliary boiler. Exhaust gas produced by the marine diesel generating set is led into the exhaust boiler. The exhaust gas waste heat steam producing system can effectively recover exhaust gas waste heat of the marine diesel generating set, save fuel cost and improve ship environment friendliness.

Owner:JIANGSU UNIV OF SCI & TECH

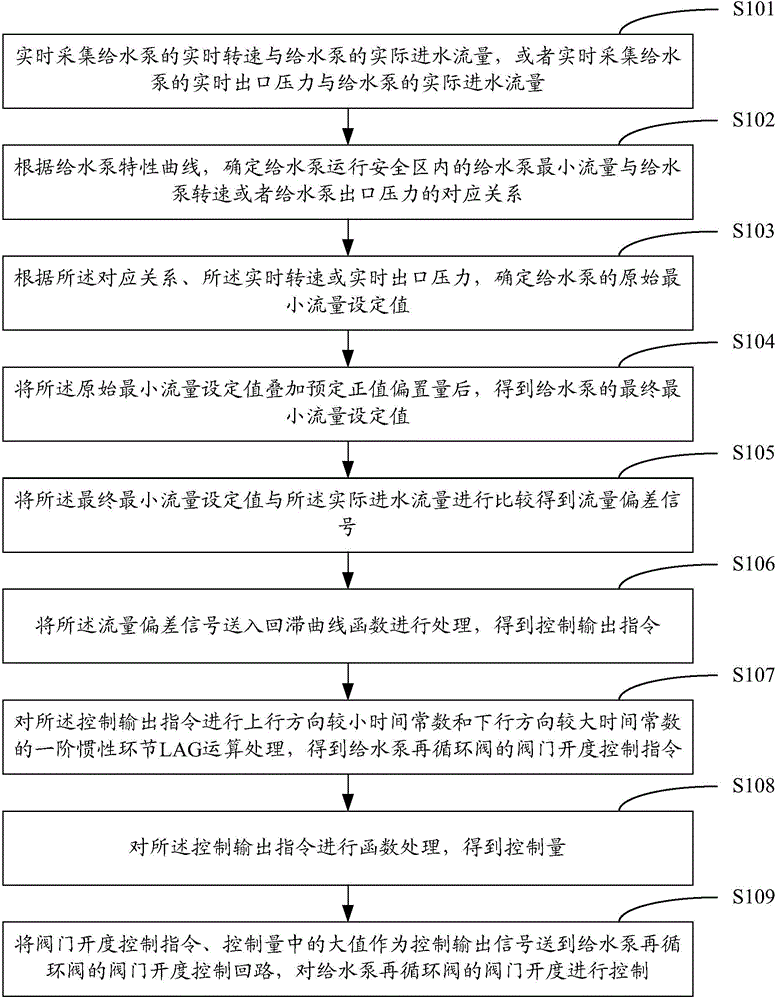

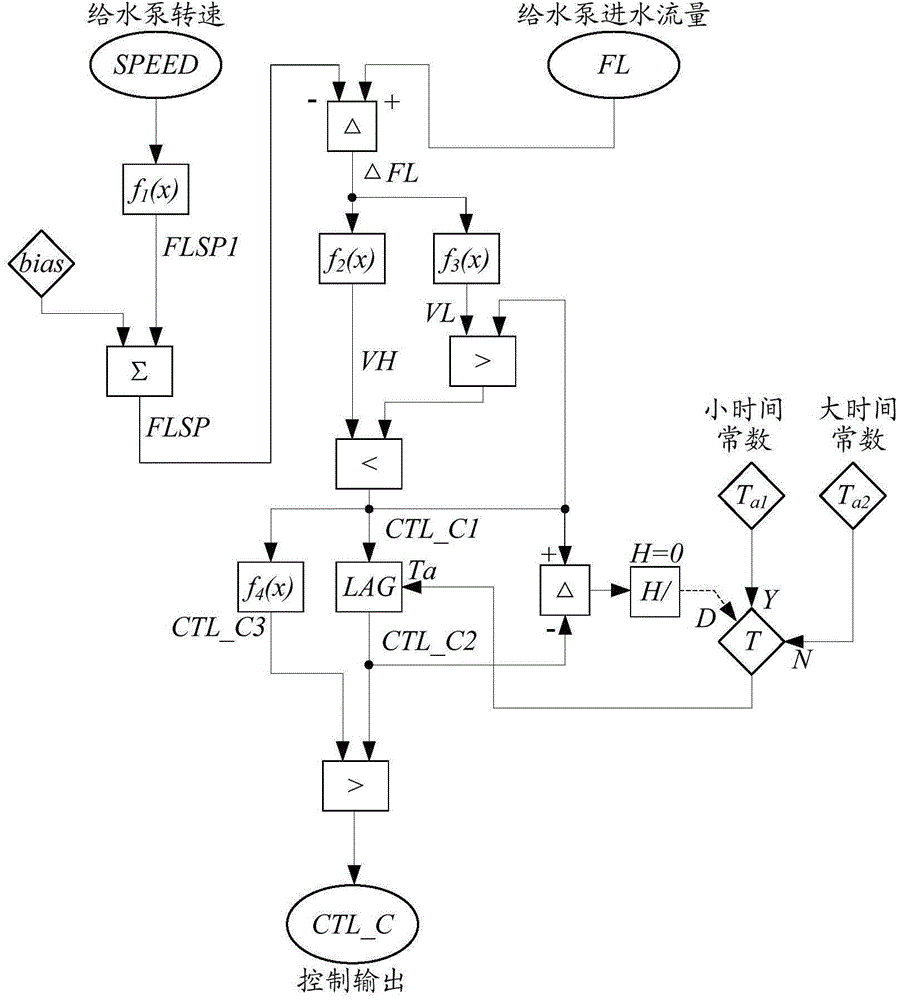

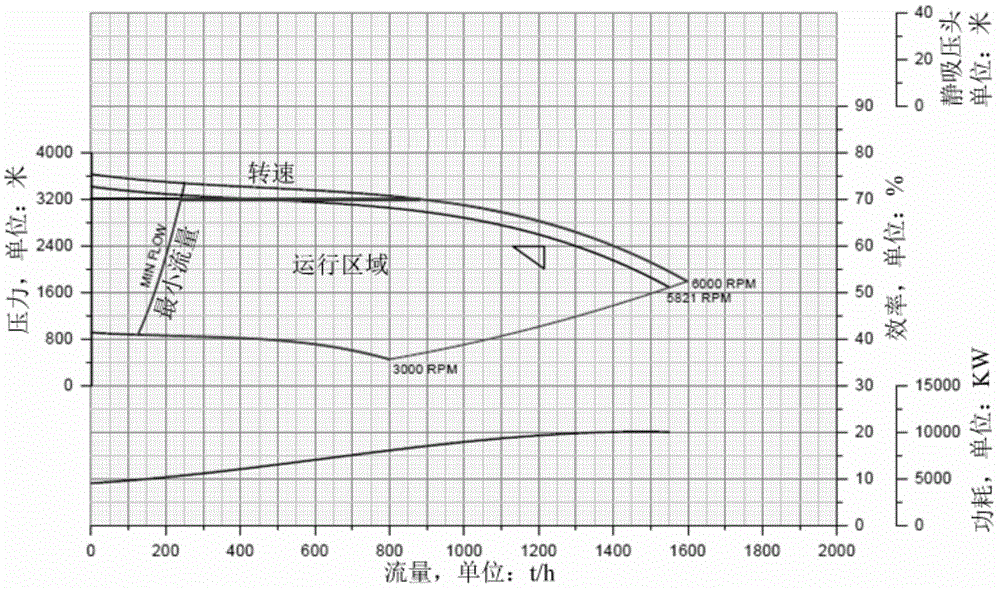

Control method of minimum-flow recirculation valve of water supply pump of power station boiler

The invention discloses a control method of a minimum-flow recirculation valve of a water supply pump of a power station boiler. The control method comprises the following steps: collecting real-time rotation rate (or outlet pressure) and actual water inlet flow of the water supply pump in real time; determining the minimum flow according to a corresponding relationship between minimum flow in a safe running area of the water supply pump and the rotation rate (or outlet pressure) of the water supply pump, real-time rotation rate (or outlet pressure) and positive value offset; comparing the minimum flow with the actual water inlet flow to obtain flow deviation signals; feeding the flow deviation signals into a hysteresis curve function and processing to obtain a control output instruction; carrying out first-order inertial element LAG calculation processing on the control output instruction with different time constants in uplink and downlink directions to obtain a valve opening control instruction; carrying out function processing on the control output instruction to obtain a control quantity; by taking the valve opening control instruction and a large value in the control quantity as output signals, controlling the valve opening of the recirculation valve of the water supply pump. The control method can be used for quickly responding and stably and reliably controlling the recirculation valve of the water supply pump.

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

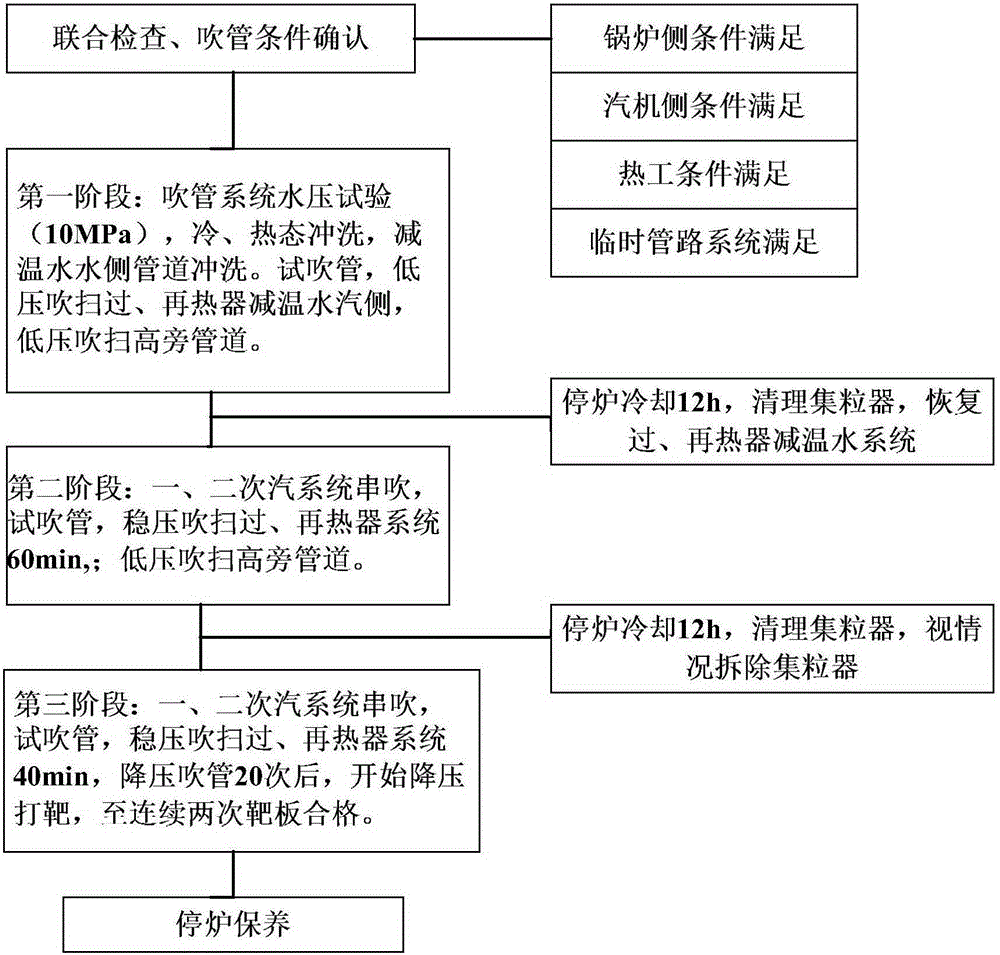

Steam pipe blowing method for ultra-supercritical once-through boiler with no boiler water pump

ActiveCN105352361AAlleviate the problem of high water consumptionShorten the timeFlush cleaningWork periodBoiler feedwater pump

The invention discloses a steam pipe blowing method for an ultra-supercritical once-through boiler with no boiler water pump. The steam pipe blowing method comprises a first stage of trial pipe blowing and purging of attemperation water pipelines and high-pressure bypass pipelines of a superheater and a reheater, a second stage of serial-connection pressure stabilization purging of the superheater, the reheater and a connecting pipeline of the boiler, and a third stage of serial-connection pressure stabilization and reduction purging of the superheater, the reheater and the connecting pipeline of the boiler; and after target practice is qualified, the boiler is shut down for maintenance, and the pipe blowing work is finished. According to the steam pipe blowing method, on one hand, the problems that under the condition that the ultra-supercritical once-through boiler is provided with no boiler water pump, water and heat in the starting stage and the low-load wet running stage are hard to recycle, and water and heat consumption is large can be effectively relieved, and the water and heat consumption in the starting stage and the pipe blowing stage of a unit is greatly reduced; and on the other hand, the beneficial effects of the pressure stabilization pipe blowing method can be given into full play, impacts on a temporary system in the pipe blowing process are greatly reduced, the work period of steam pipe blowing of the boiler is shortened, and it is guaranteed that steam pipe blowing of the ultra-supercritical once-through boiler with no boiler water pump is completed quickly and efficiently in a quality keeping manner.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

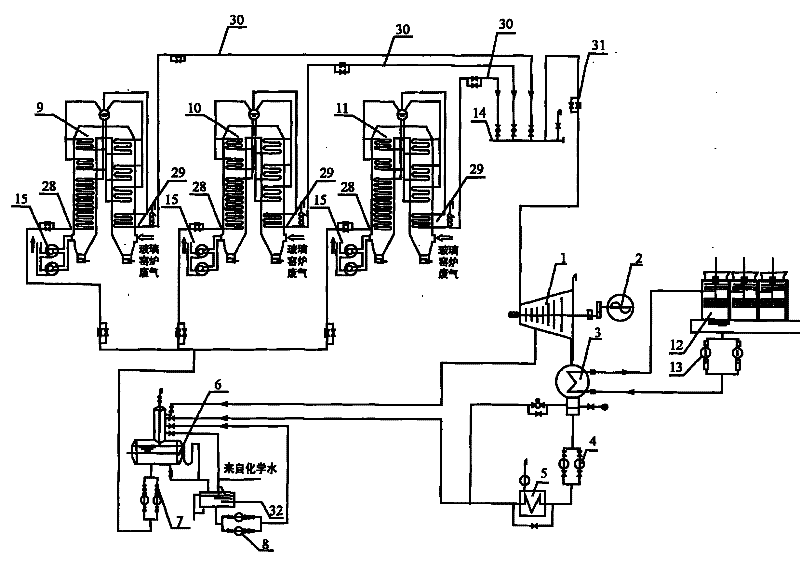

Waste heat power generation system of multiple glass kilns

InactiveCN102242647AReduce the impactImprove power generation qualityFeed water supplyBoiler controlEngineeringElectric generator

The invention relates to a waste heat power generation system of multiple glass kilns. The system solves the technical problems of low waste heat utilization efficiency, low power generation efficiency, poor system stability, high heat reclamation cost, large waste gas heat parameter fluctuation range, serious environmental pollution, high disposable investment cost and the like in the waste gas heat utilization of the traditional glass kilns. The smoke exhaust ports of the multiple glass kilns are communicated with the smoke inlets of multiple parallel waste heat boilers, and the smoke outlets of the waste heat boilers are communicated with a chimney; the water outlet end of a boiler water pump is communicated with the circulating water inlets of the multiple parallel waste heat boilers respectively, the steam outlets of the multiple parallel waste heat boilers are communicated with a steam collecting cylinder, the outlet of the steam collecting cylinder is communicated with the steam input port of a steam turbine, and the steam turbine is connected with a generator; and a steam discharge pipe of the steam turbine is connected with a condensed water system, and the condensed water system is communicated with the water inlet end of the boiler water pump through a deoxidation device. The system is suitable for waste heat power generation of two or more glass kilns.

Owner:南志远

Lime kiln waste gas waste heat electricity generating system with by-product coal gas afterburning function

InactiveCN103344124AIncrease temperatureImprove working abilityIncreasing energy efficiencyMachines/enginesCooling towerSuperheater

The invention discloses a lime kiln waste gas waste heat electricity generating system with a by-product coal gas afterburning function. The lime kiln waste gas waste heat electricity generating system comprises a smoke valve, a waste heat boiler, a steam pocket, a turbine, a boiler water feeding pump, a condenser, a condensate water pump, a cooling tower, a deaerator, an electricity generator, an induced draft fan, an air blower, and a chimney. A combustion hearth, a high temperature super-heater, a low temperature super-heater, an evaporator and a coal economizer are sequentially arranged in the waste heat boiler from top to bottom, an outlet of the high temperature super-heater is connected with a steam inlet of the turbine through a pipeline, the waste heat boiler is provided with a lime kiln waste gas inlet and a by-product coal gas inlet, and an air blowing opening is additionally formed in an air inlet smoke pipe so as to provide oxygen needed by coal gas burning. The lime kiln waste gas waste heat electricity generating system with the by-product coal gas afterburning function can greatly increase smoke temperature, so that the temperature and the pressure of superheated steam at the inlet of the turbine are increased, and electricity generating capacity is improved.

Owner:广州智光节能环保有限公司

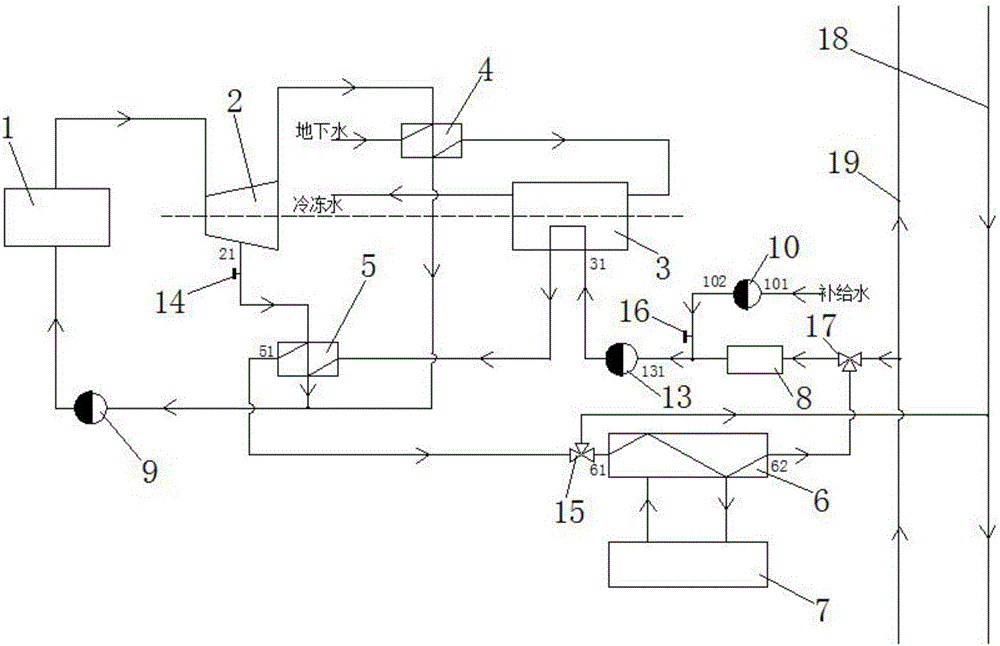

Water source heat pump-steam turbine and heat supply network complementary combined heating supply system

InactiveCN105972681AVarious formsEnvironmentally friendlyLighting and heating apparatusSustainable buildingsWater sourceEnergy conservation

The invention provides a water source heat pump-steam turbine and heat supply network complementary combined heating supply system. The heating supply system comprises a steam boiler, a steam turbine, a steam condenser, a peak heat supply network heater, a heat exchange station, a heat consumer, a dirt cleaner and a boiler water feed pump and further comprises a water source heat pump, a supply water pump, a network circulating water pump, a heat supply network water supply pipeline and a heat supply network water return pipeline. According to the water source heat pump-steam turbine and heat supply network complementary combined heating supply system provided by the invention, underground water renewable energy and exhaust-steam waste heat are fully used, the energy conversion link in the heat supply process of the water source heat pump is reduced, and thus the stability and heat efficiency of the heating supply system are improved. The heating supply system form suitable for the northeast severe cold area is improved, and economy, environmental protection, energy conservation and emission reduction of distributed type heat supply are achieved.

Owner:SHENYANG JIANZHU UNIVERSITY

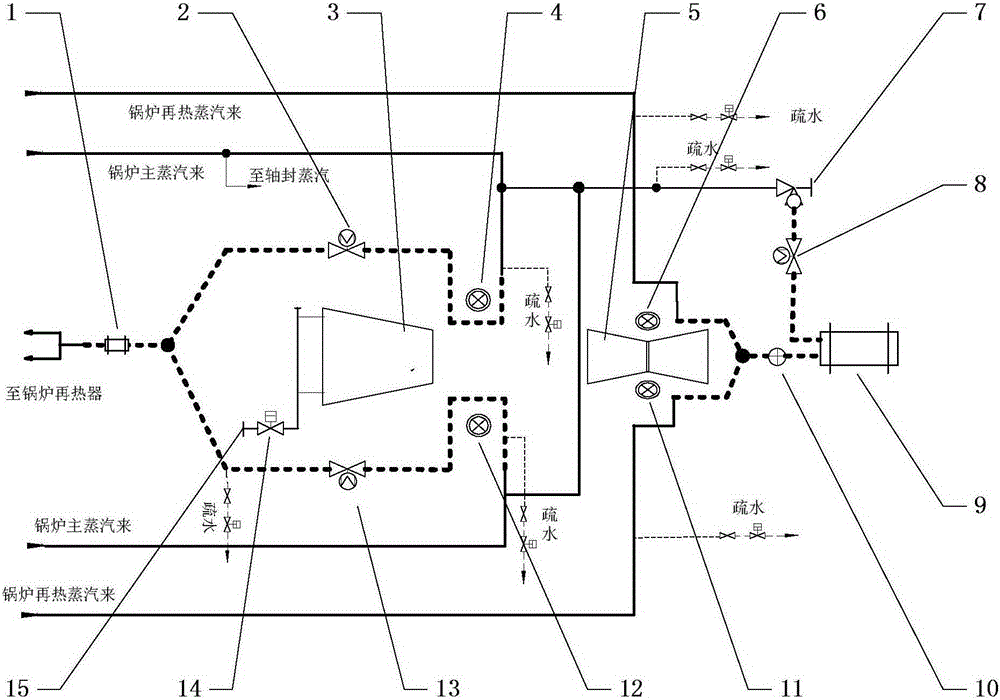

Thermodynamic system of concurrent heating ultra-high pressure/subcritical backpressure heat supply unit

ActiveCN104763485AIncrease main steam pressureImprove working abilitySteam engine plantsUltra high pressureSteam pressure

The invention discloses a thermodynamic system of a concurrent heating ultra-high pressure / subcritical backpressure heat supply unit. The thermodynamic system comprises a reheating system, a low pressure reheating system, a high pressure reheating system, a boiler, a turbine and / or a small steam turbine which drives a boiler feeding pump, wherein the low pressure reheating system and the high pressure reheating system are connected with the small steam turbine, the high pressure reheating system is connected with the boiler and the turbine, and the boiler is connected with the turbine and the reheating system; the main steam pressure of the turbine is higher than conventional pressure and reaches up to ultrahigh pressure, subcritical or supercritical grade; the reheating system comprises a re-heater, the exhaust steam or extracted steam of the turbine is supplemented and heated by the boiler gas heat by virtue of a re-heater, and then the turbine is used for heating externally after the temperature of the steam reaches the requirements; the re-heater is made from a tubular product of a conventional boiler economizer. According to the thermodynamic system provided by the invention, the steam power improvement capacity of a backpressure unit can be improved, the generating condition can be greatly improved under the condition of completing a certain heating task, and the economic benefit of a power station can be obviously improved.

Owner:南京博沃科技发展有限公司

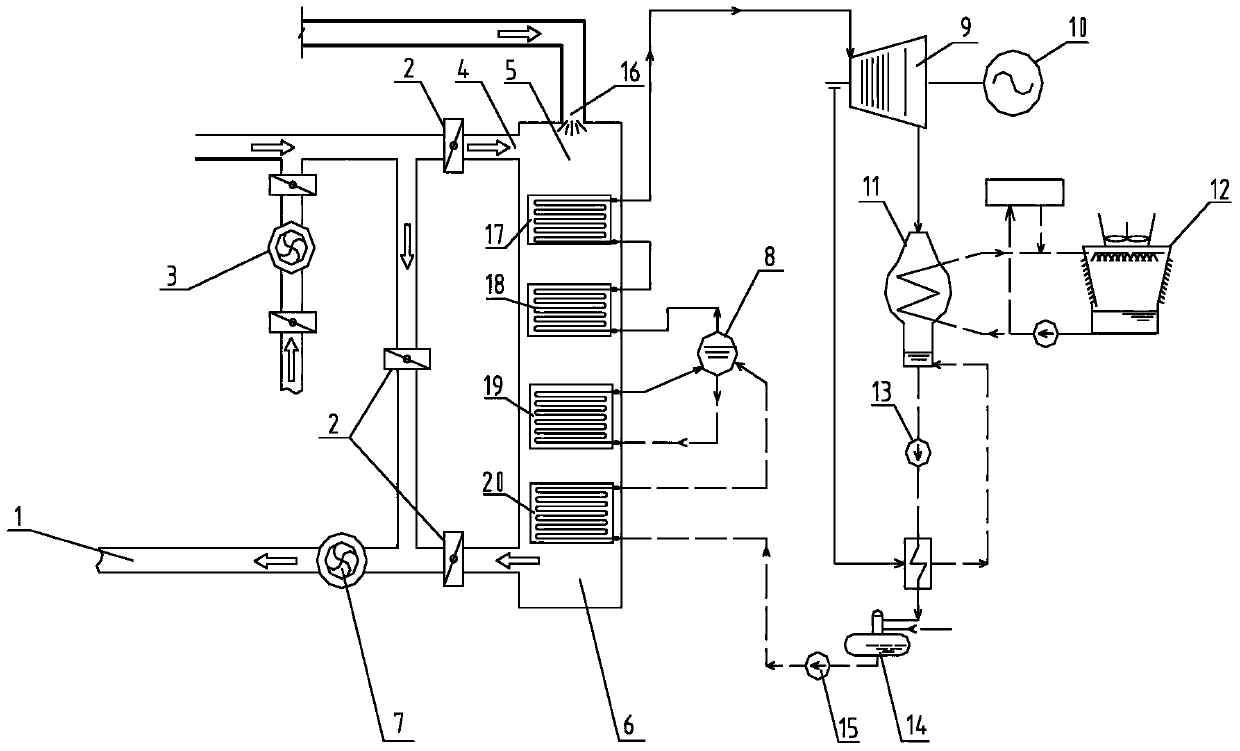

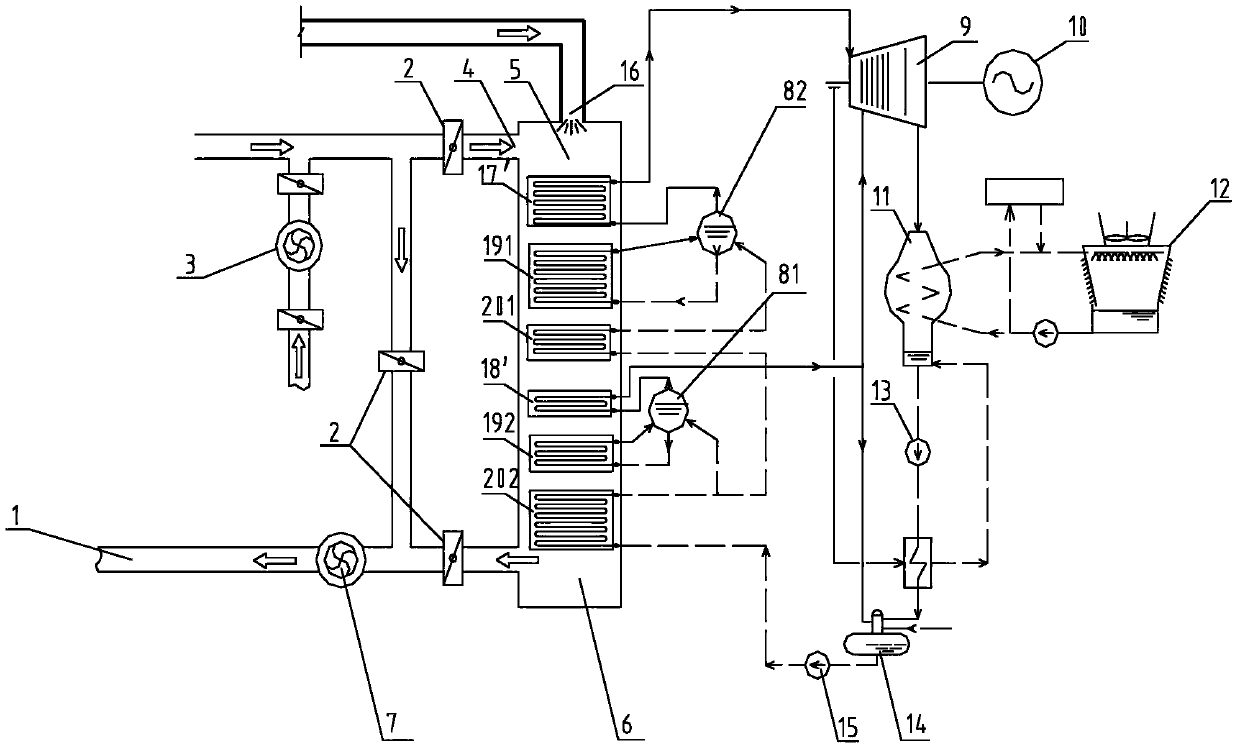

Step-by-step waste heat recovery system and method for electric furnace flue gas on whole temperature section

ActiveCN104061793AEfficient recyclingImprove utilization efficiencyIncreasing energy efficiencySteam superheatersRecuperatorDeaerator

The invention provides a step-by-step waste heat recovery system and method for electric furnace flue gas on the whole temperature section. The step-by-step waste heat recovery system provided by the invention comprises a flue gas subsystem and a steam-water subsystem, wherein the flue gas subsystem comprises an electric furnace, a vaporization flue duct, a low-pressure water supply heat exchanger, a settling chamber with a heat accumulation device, an evaporator, a coal economizer, a low-temperature coal economizer, a dust removal device and a flue gas extractor; the steam-water subsystem comprises a water pump, a deaerator, a boiler feed pump device a steam pocket; the water pump is connected with the low-pressure water supply heat exchanger; the low-pressure water supply heat exchanger is connected with the deaerator; the deaerator, the boiler feed pump, the low-temperature coal economizer, the coal economizer and the steam pocket are connected in sequence; the steam pocket is connected with the evaporator and the vaporization flue duct respectively. Compared with the prior art, owing to the arrangement of the vaporization flue duct between the electric furnace and the combustion settling chamber, the step-by-step waste heat recovery system effectively recovers part of heat of high-temperature flue gas between the electric furnace and the combustion settling chamber, and improves the waste heat recovery efficiency and the utilization efficiency of energy sources.

Owner:SHANGHAI BAOSTEEL ENERGY TECH

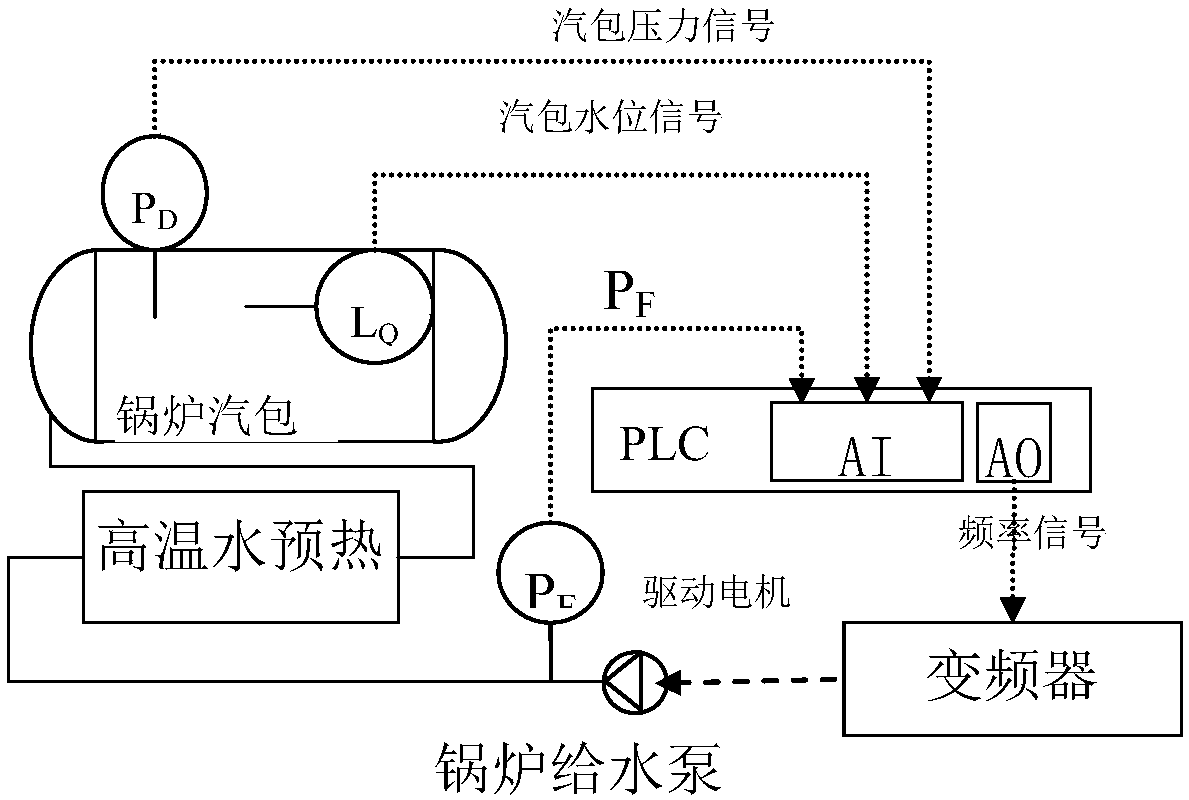

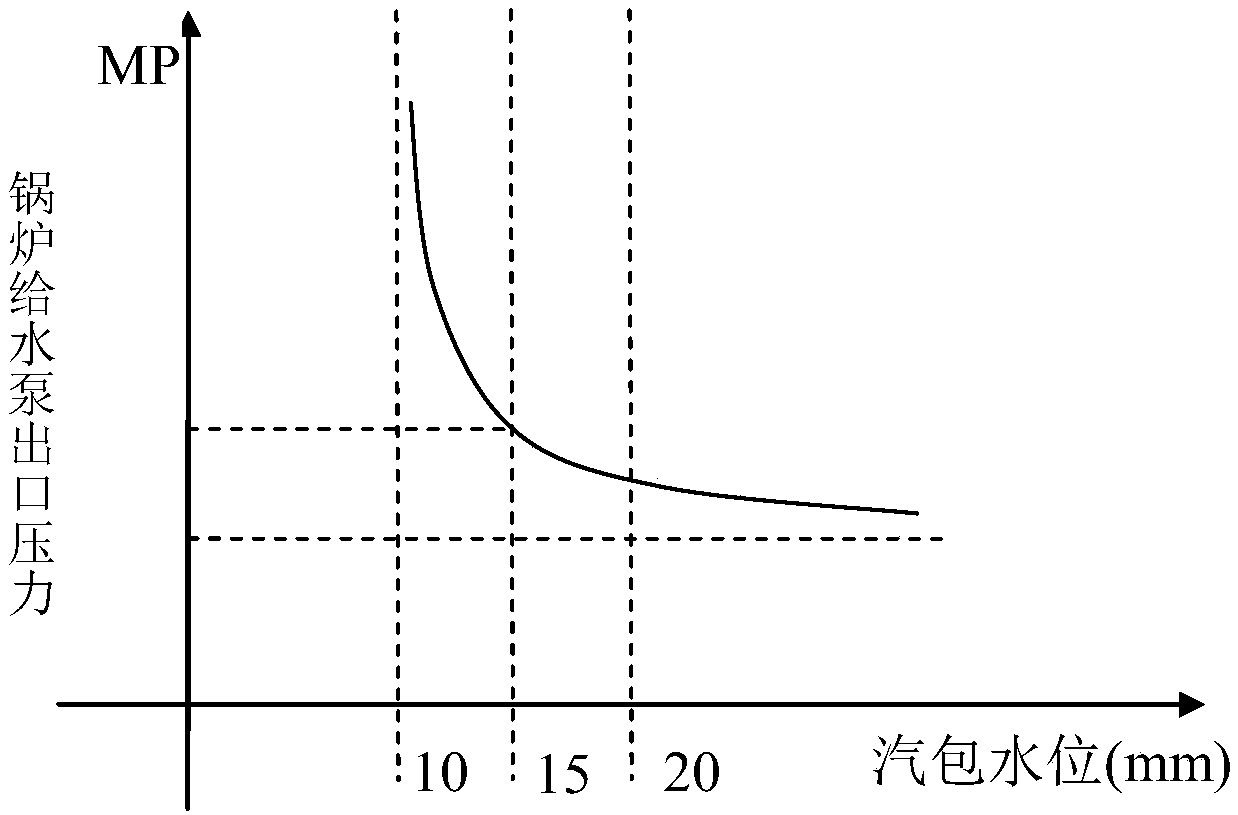

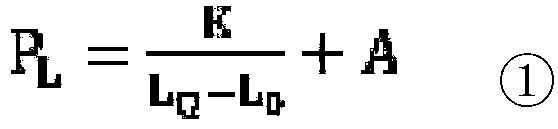

Boiler drum water level control system and control method thereof

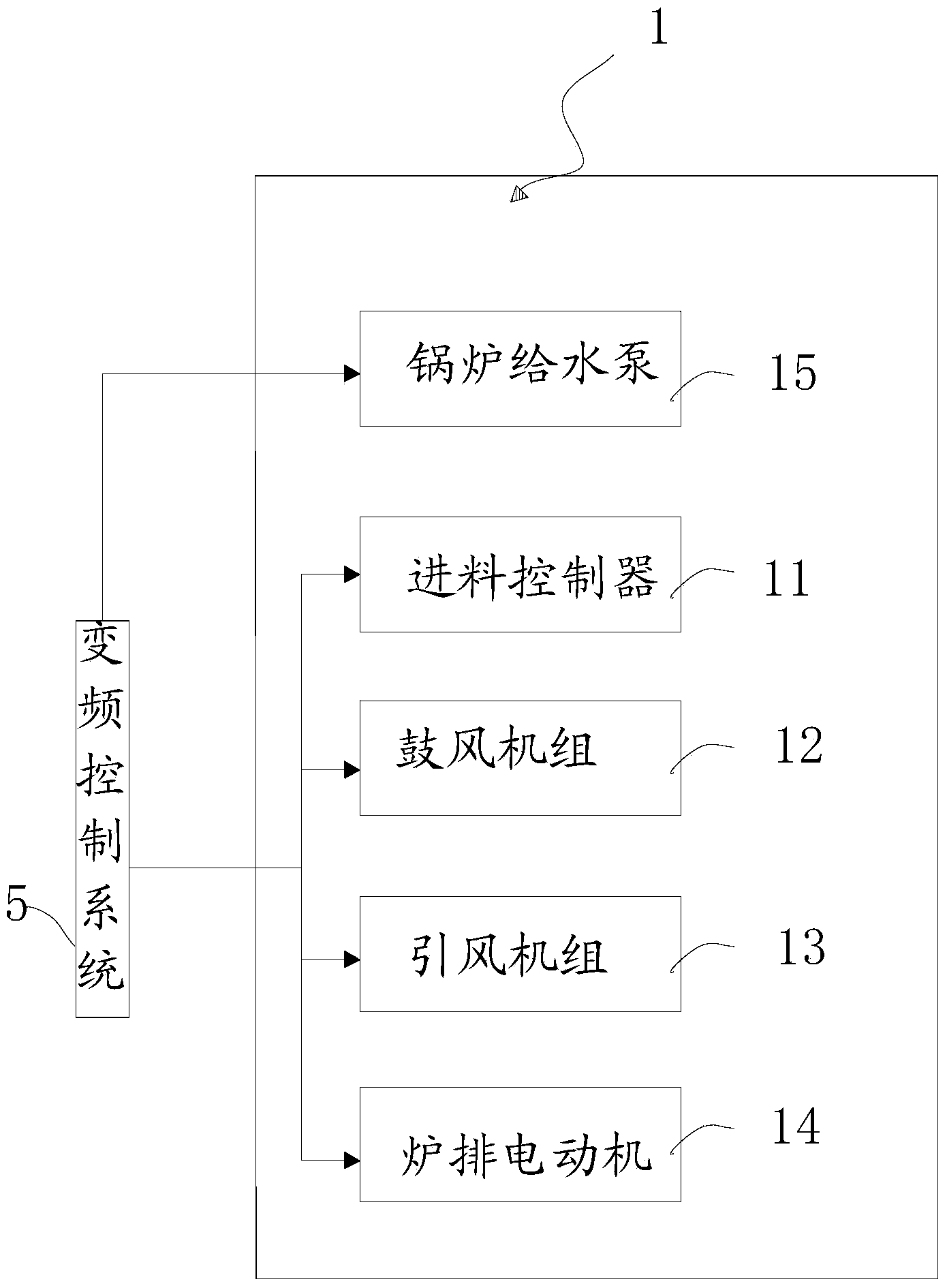

ActiveCN108224404AHigh thermal efficiencyGuaranteed uptimeWater feed controlFrequency changerBoiler feedwater pump

The invention discloses a boiler drum water level control system. The boiler drum water level control system comprises a boiler feed pump, a boiler drum, and a programmable logic controller PLC, wherein a frequency changer and a driving motor are installed on the boiler feed pump, and the analog input terminal of the frequency changer is connected with the analog output module of the PLC; a firstpressure sensor is installed on the outlet of the boiler feed pump, and the first pressure sensor is connected with an analog input module of the PLC; a second pressure sensor is installed on the upper portion of the boiler drum, and the second pressure sensor is connected with the analog input module of the PLC; a content gauge is installed in the middle portion of the boiler drum, and the content gauge is connected with the analog input module of the PLC; and the PLC is used for controlling the rotating speed of the driving motor. The invention further discloses a boiler drum water level control method, the occurrence of false water level is prevented, and the smooth running of the control system is kept.

Owner:INNER MONGOLIA NORTH HEAVY INDS GROUP

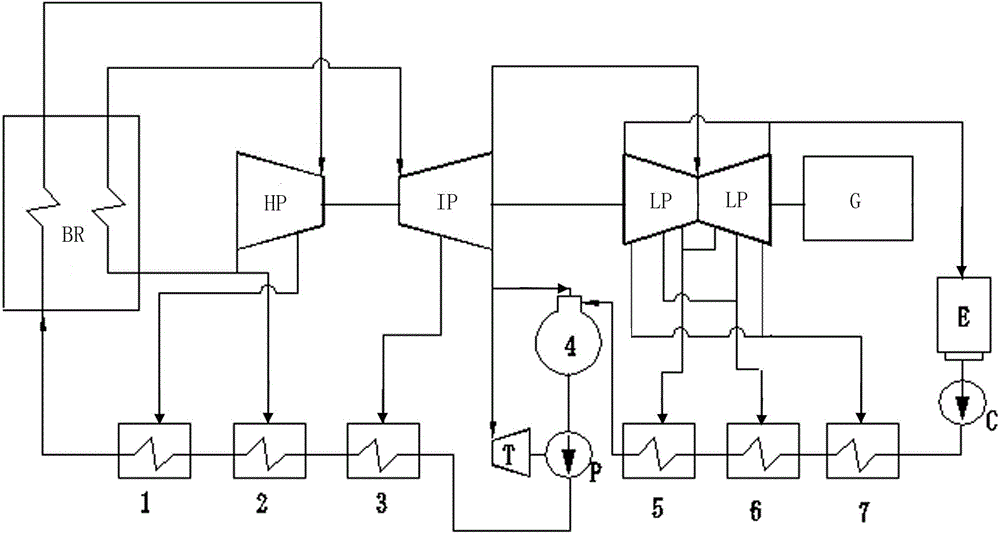

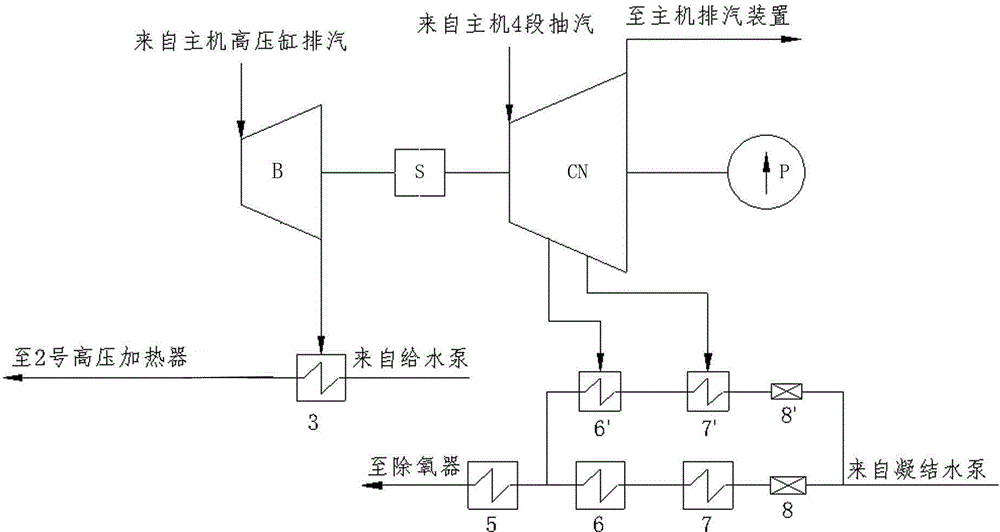

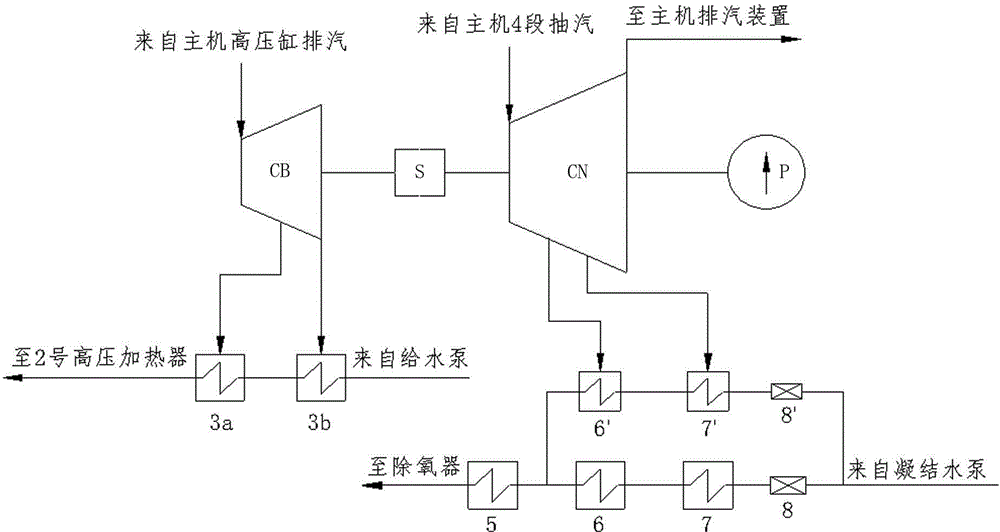

Compound feed pump turbine for thermal power plant and thermodynamic system

The invention relates to a compound feed pump turbine for a terminal power plant and a thermodynamic system, in particular to a feed pump compound turbine driving system used for the thermodynamic power plant. The feed pump compound turbine driving system comprises a steam extracting and condensing type small turbine, an extracting and condensing small machine low-pressure heater 6', an extracting and condensing small machine low-pressure heater 7' and a condensing water flow adjusting valve. The output end of the steam extracting and condensing type small turbine is connected with a boiler feed pump. The extracting and condensing small machine low-pressure heater 6' and the extracting and condensing small machine low-pressure heater 7' are connected with the steam extracting and condensing type small turbine through steam extracting pipelines. The extracting and condensing small machine low-pressure heater 6' is connected with the extracting and condensing small machine low-pressure heater 7' and the condensing water flow adjusting valve in series through a condensed water pipeline, and condensing pipelines formed through series connection are connected to a condensing pipeline which is formed through series connection of a main machine low-pressure heater 6, a main machine low-pressure heater 7 and a main machine condensed water flow adjusting valve in parallel. The problems of a feed pump configuration manner and slightly high energy consumption which trouble a direct air-cooling unit at present are solved.

Owner:山西漳电科学技术研究院(有限公司) +2

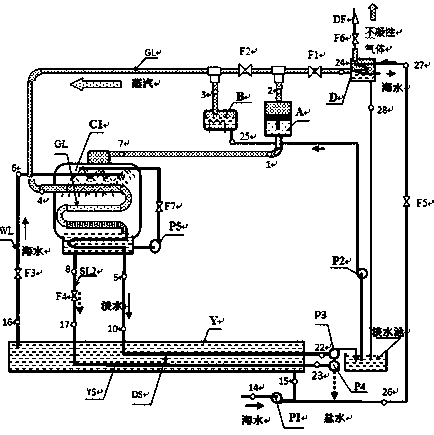

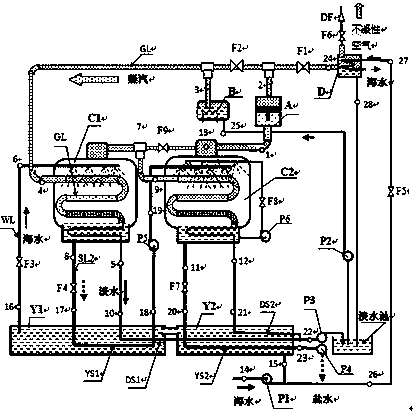

Seawater desalination method using heat supplied by steam heat pump, and system thereof

InactiveCN107804886ANo wasteIncrease the spray sea water flow rateWater treatment parameter controlGeneral water supply conservationDistillationEngineering

The invention provides a seawater desalination method using heat supplied by a steam heat pump, and a system thereof. A steam booster is used to compress seawater vaporization steam, and pressurized and heated hot steam is used to heat seawater, and then is condensed to form distilled water freshwater; and the heated seawater vaporization steam is compressed again and then is condensed to form thedistilled water freshwater, and above processes are cycled. The theory of the method is characterized in that electric energy consumed during the compression of the steam booster firstly increases the effective energy of the pressurized steam and then is used for offsetting the effective energy consumed in the seawater preheating and seawater evaporation heat transfer processes. The system includes the steam booster, a boiler, an evaporation-condensation heat exchanger, a seawater feed water preheater, a seawater cooler, a seawater booster pump, a brine pump, a freshwater pump, a boiler waterfeeding pump, a circulating pump, and a signal test and control systems; and initial hot steam in the initial running stage of the system is supplied by the boiler. The running cost is several timeslower than that of multi-effect distillation seawater desalination methods using a self-contained boiler to generate steam in the whole course.

Owner:陈则韶

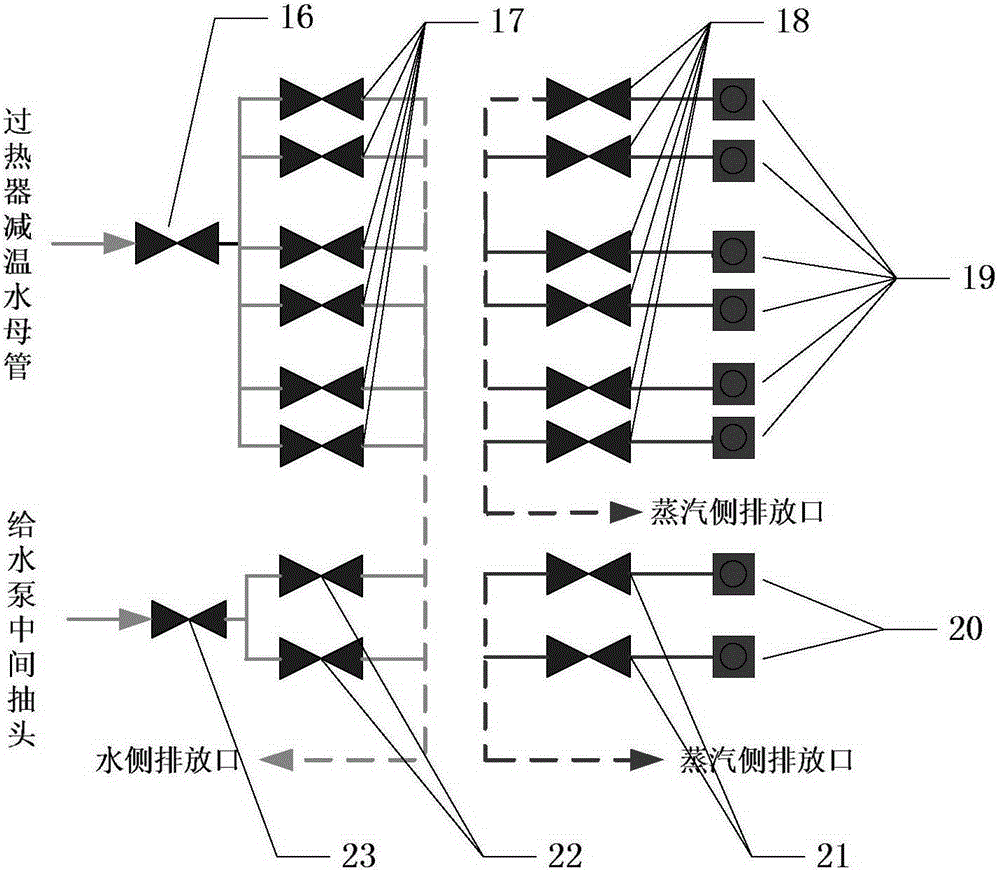

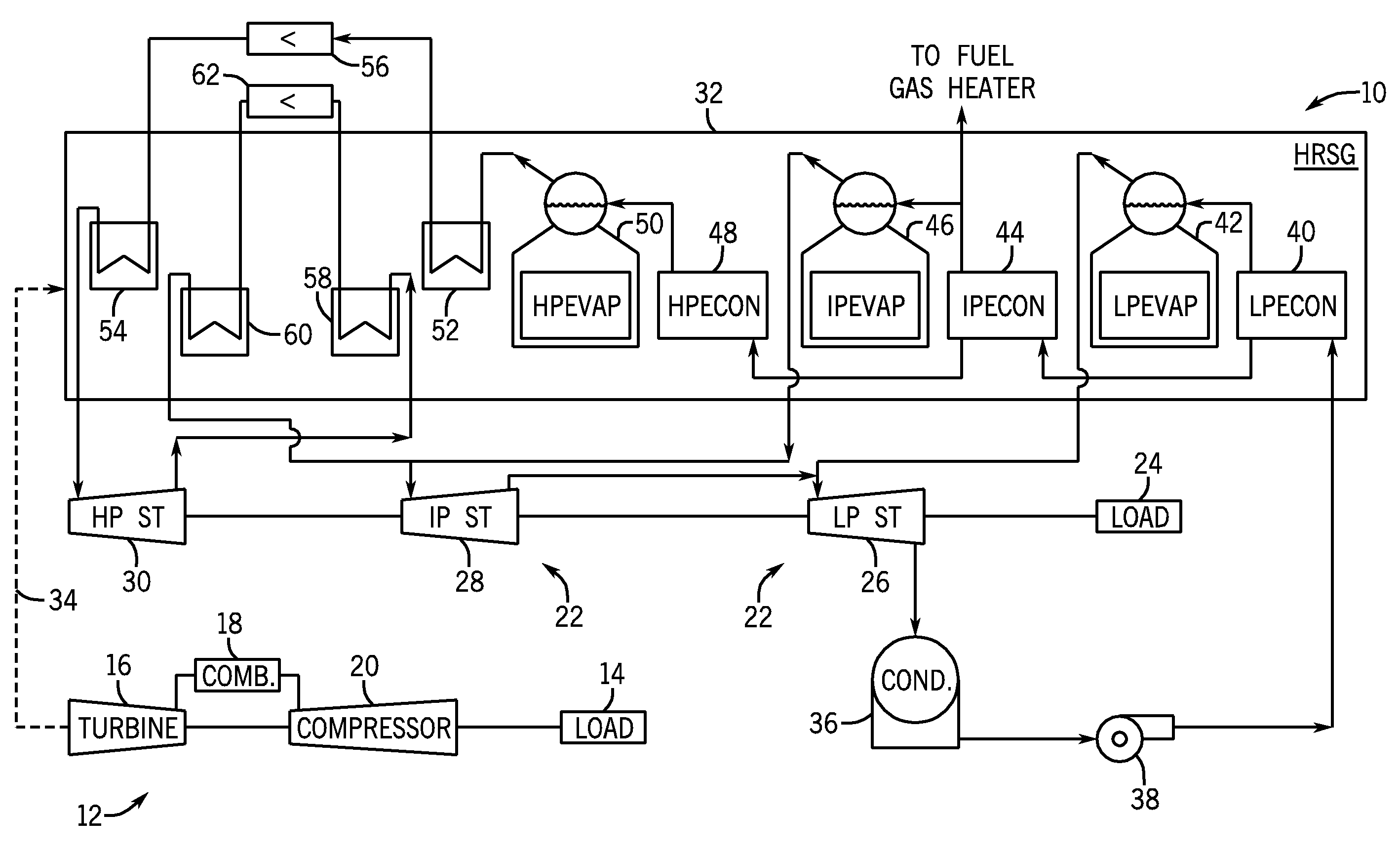

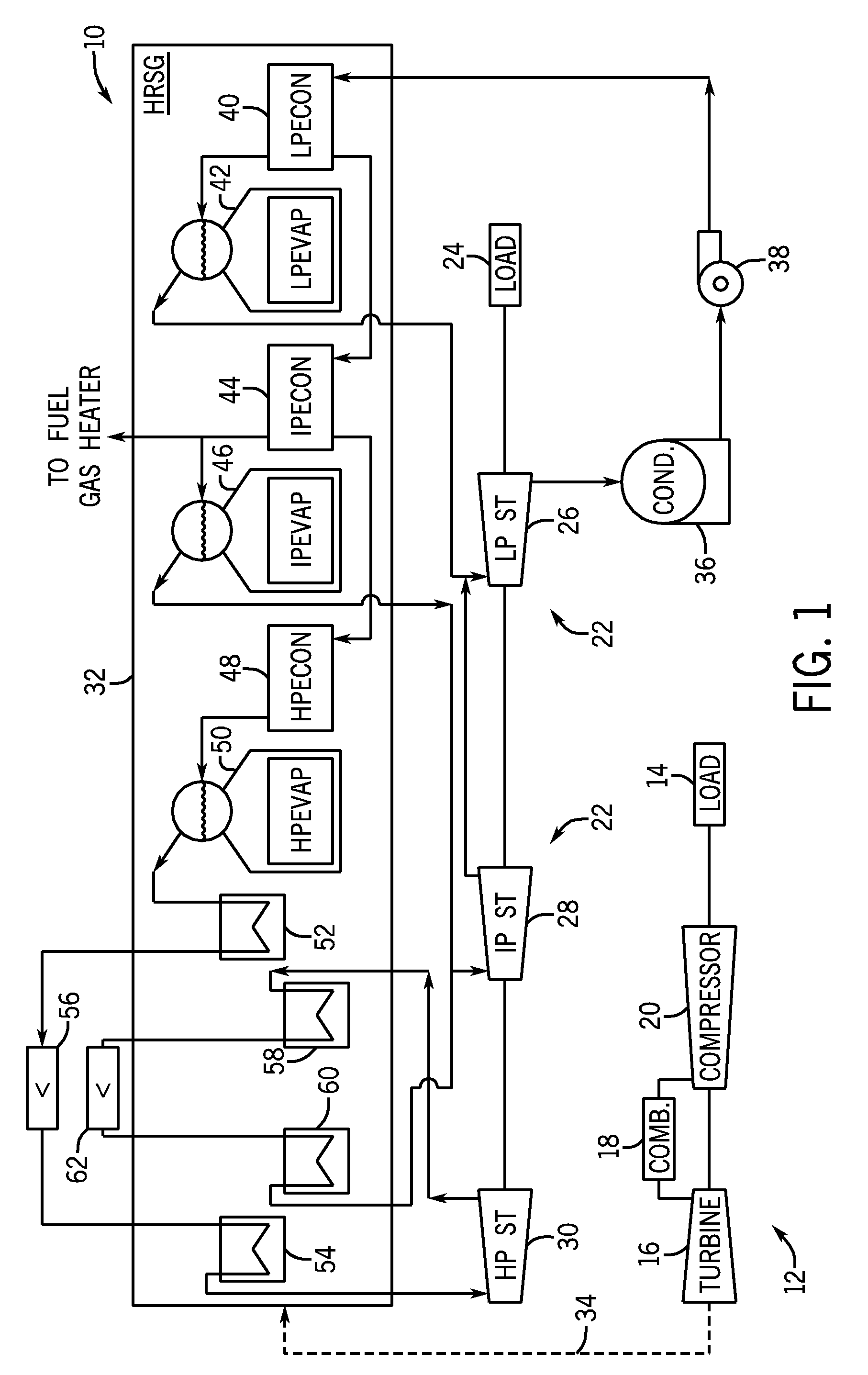

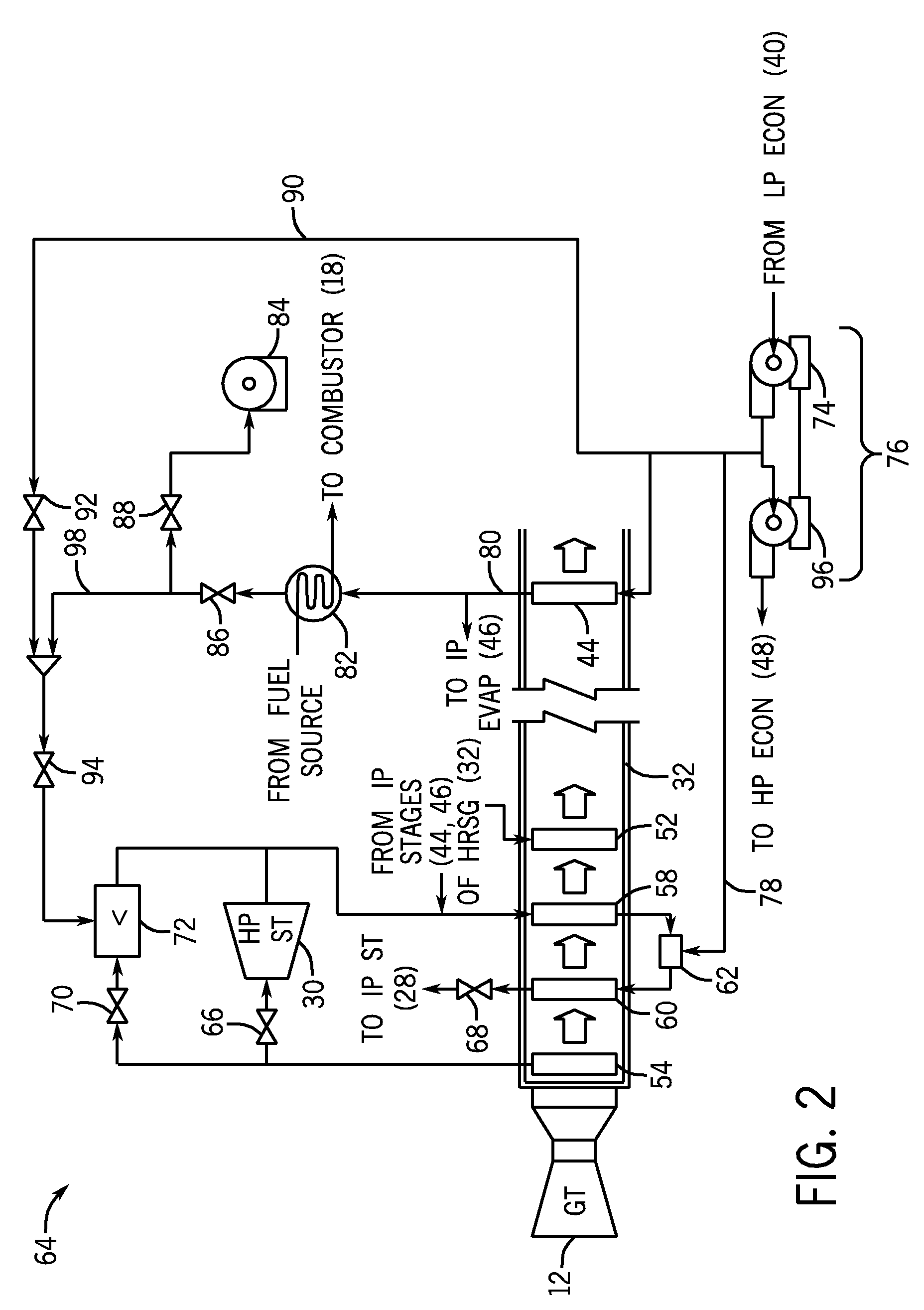

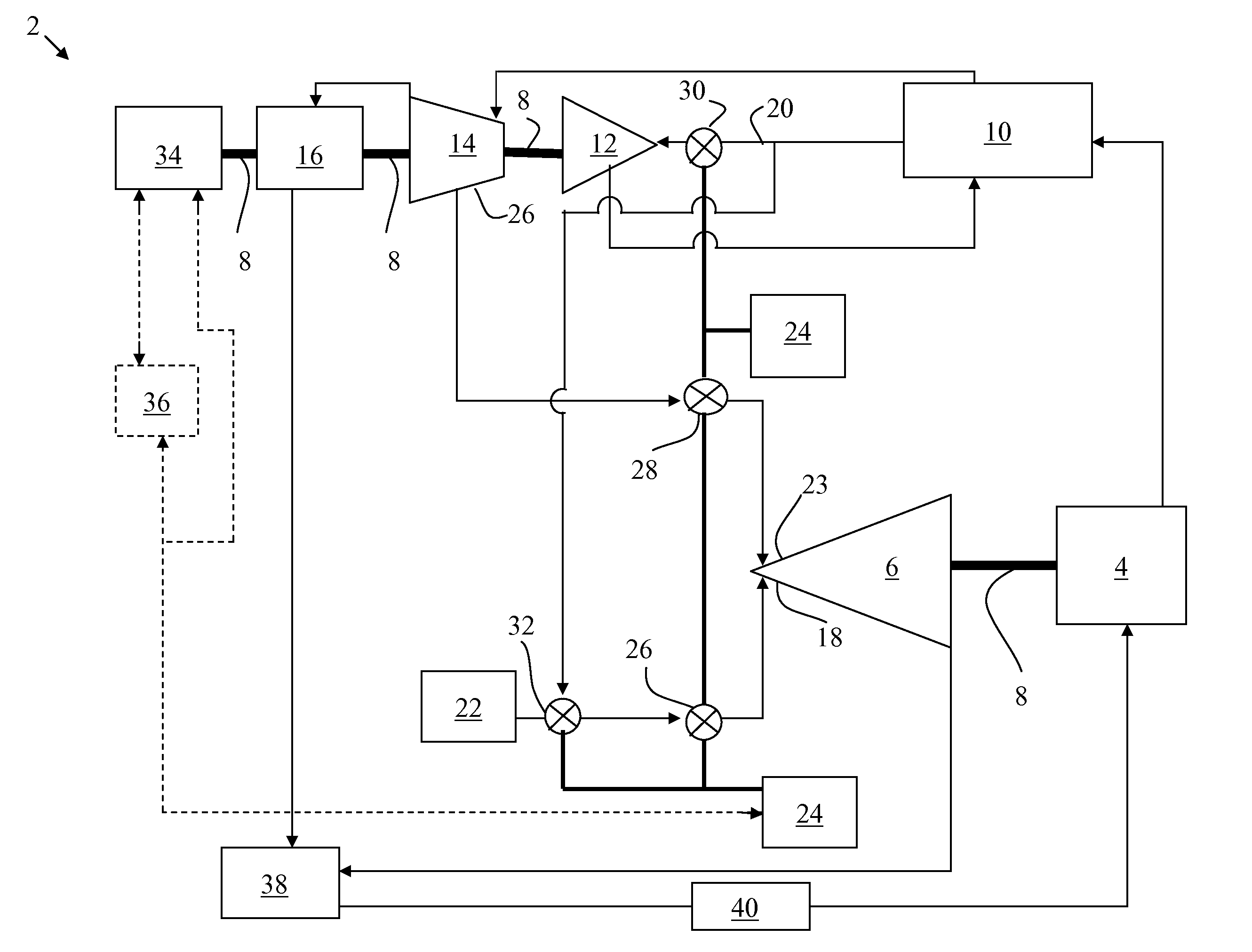

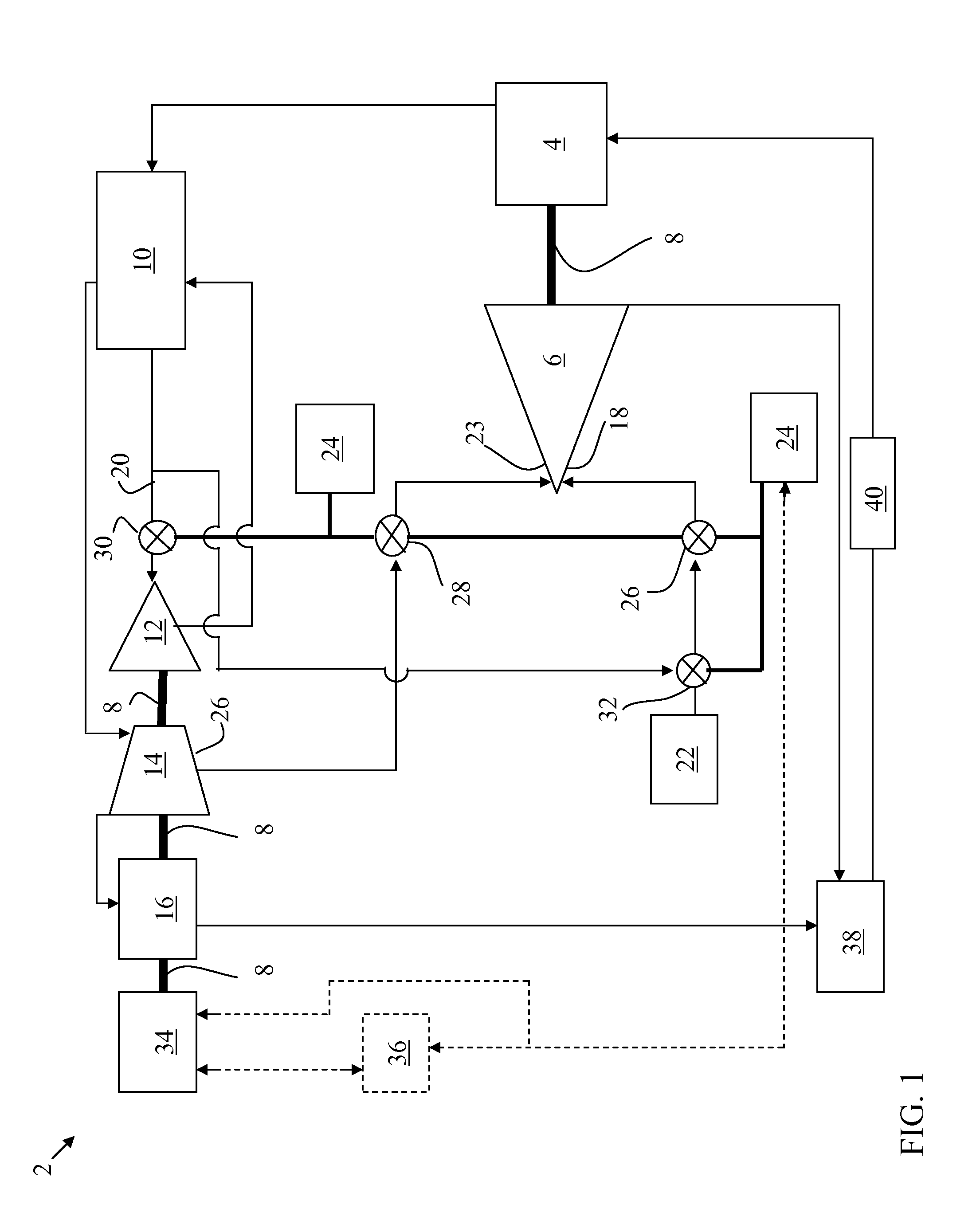

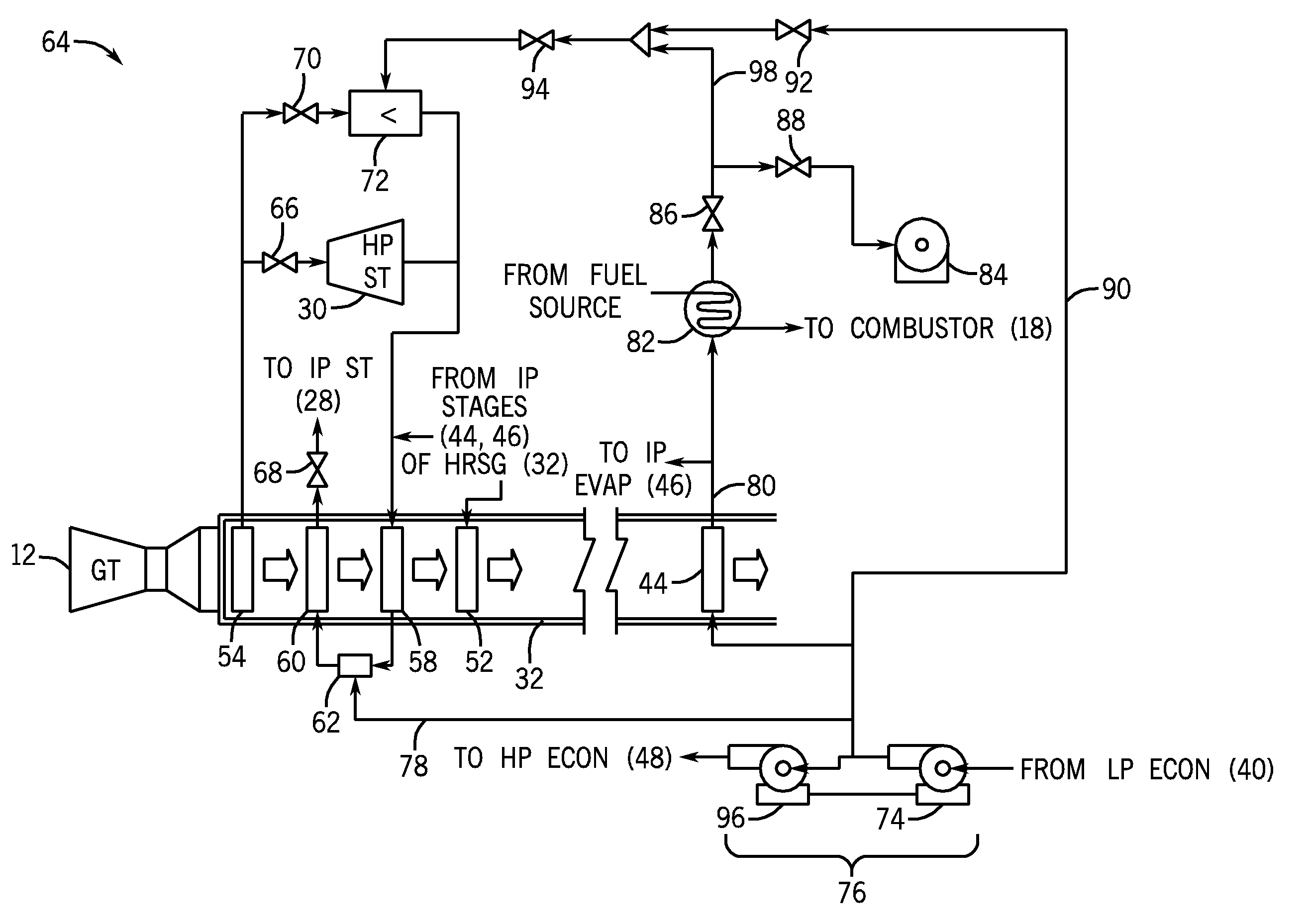

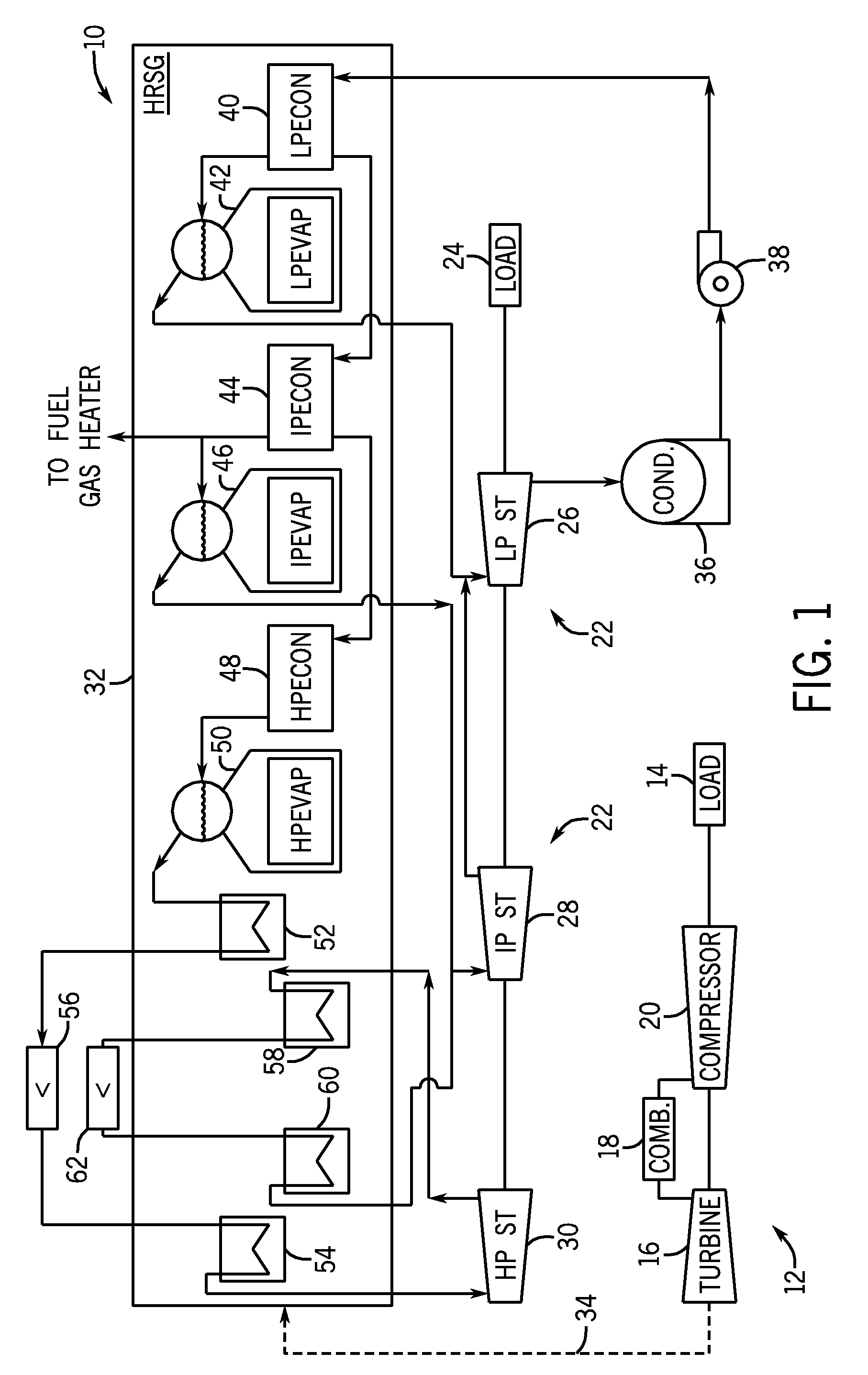

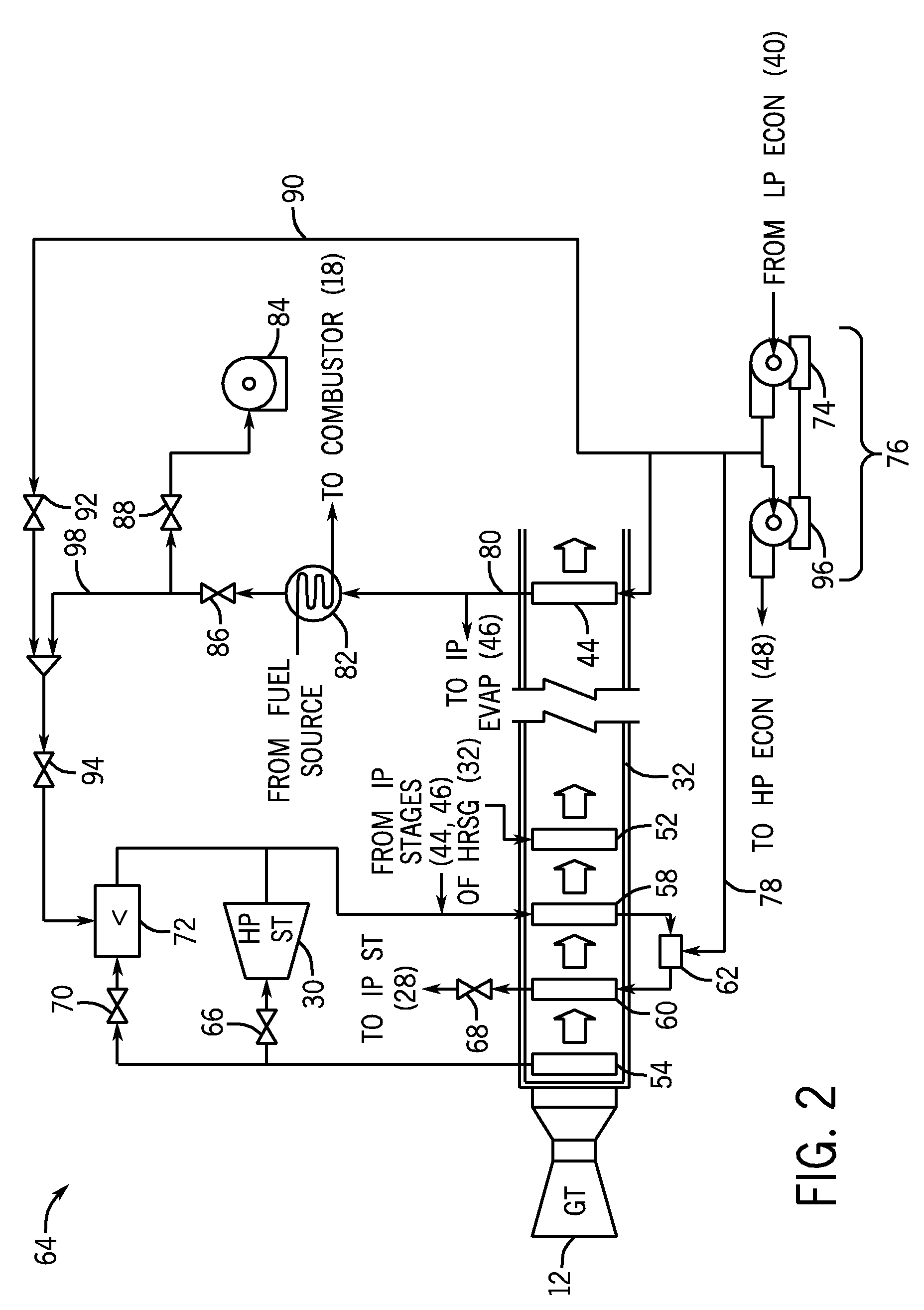

Apparatus for steam attemperation using fuel gas heater water discharge to reduce feedwater pump size

Attemperation systems and methods for cooling steam bypassed from a steam turbine during tripping of the steam turbine are provided in the disclosed embodiments. The systems may be configured to deliver water discharged from a fuel gas heater to a bypass attemperator, where the water discharged from the fuel gas heater may be used to cool the bypass steam. Before being used by the fuel gas heater, the water used to heat the fuel gas may be heated by an economizer. The water may be delivered to the economizer by an intermediate pressure stage of a boiler feedwater pump. In the disclosed embodiments, the intermediate pressure stage of the boiler feedwater pump may also be used to supply water to a re-heater attemperator, which may be used to further cool the steam after it has been delivered from the bypass attemperator to a re-heater. In addition, the intermediate pressure stage of the boiler feedwater pump may deliver water directly to the bypass attemperator as a supplemental water source.

Owner:GENERAL ELECTRIC CO

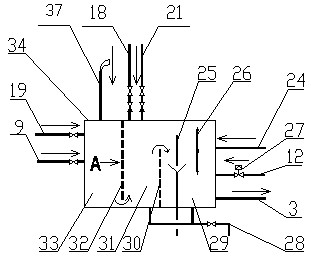

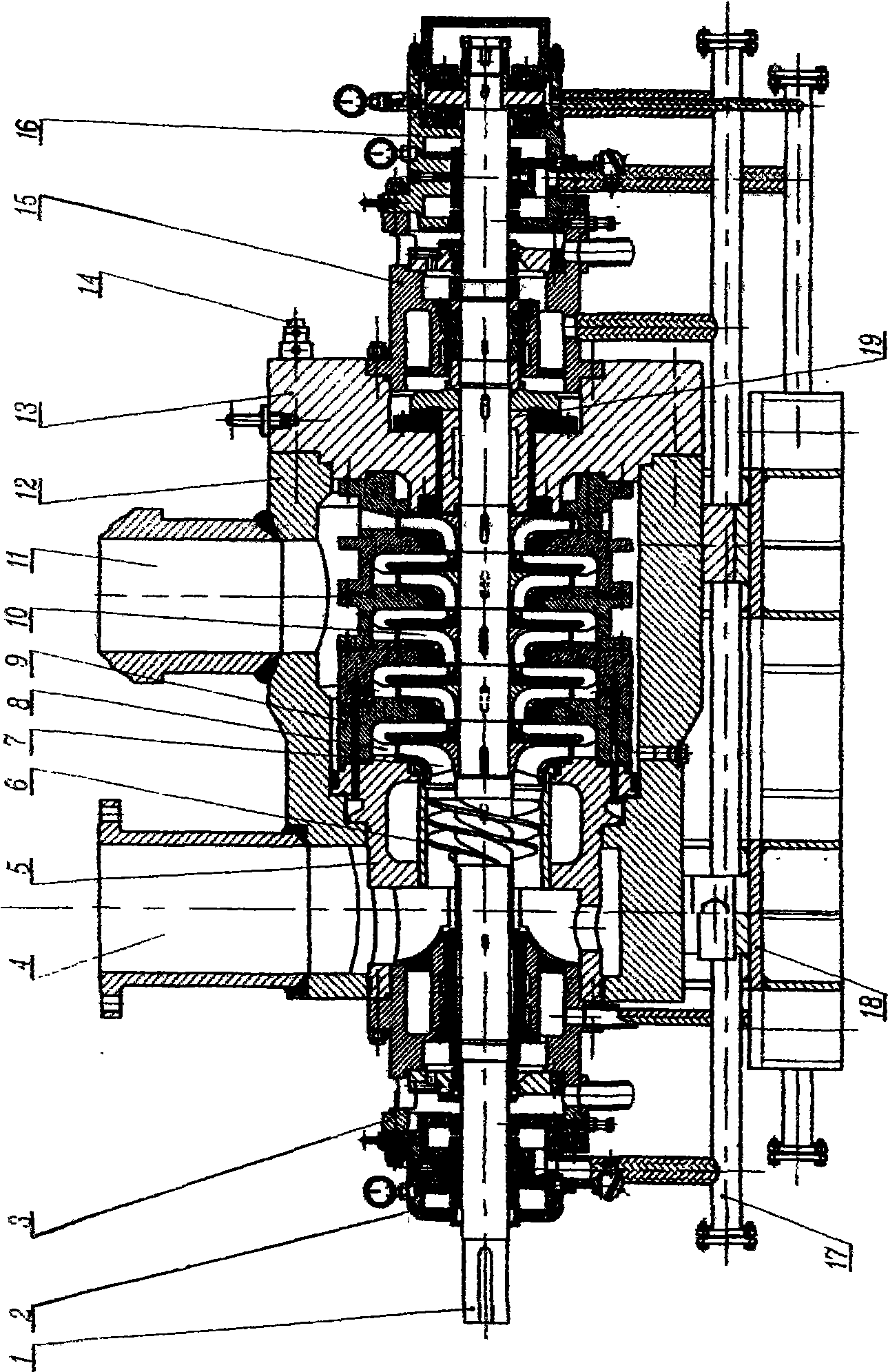

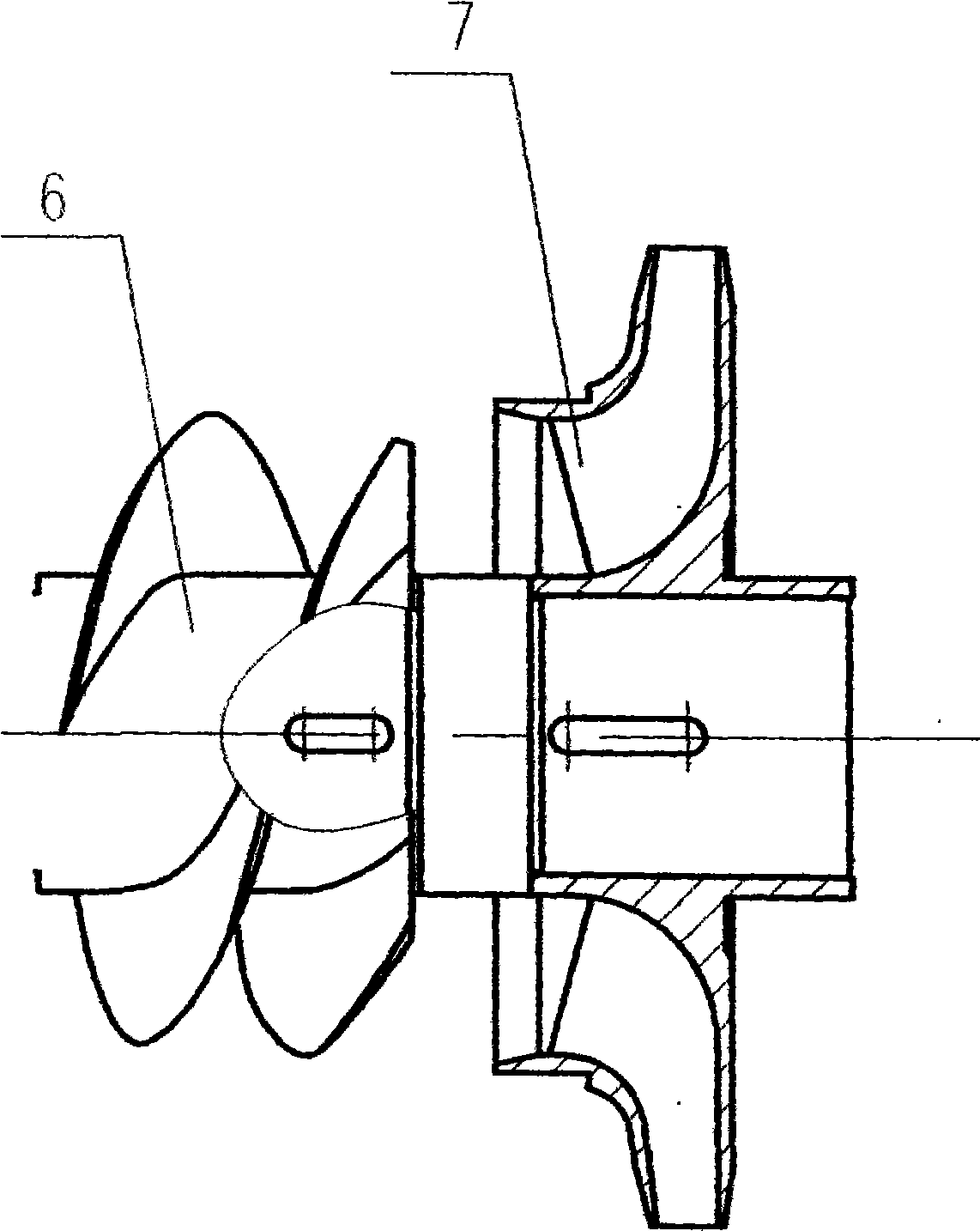

Boiler water-feeding pump

InactiveCN101545491AIncrease profitSmall footprintPump componentsRadial flow pumpsCavitationEngineering

The invention relates to the technical field of boiler water-feeding pump, in particular to a high-pressure boiler water-supplying pump matching with a thermal generator set, which is characterized in that a pump shaft in front of a first-stage impeller of a multi-stage impeller is provided with an inducer, and the inducer and the first-stage impeller form an inducer mechanism. The high-pressure boiler water-supplying pump has the following advantages that: the inducer mechanism solves the problem of cavitation, and by combining with dual-shell structure technology, the designed novel high-speed large-flow high-pressure boiler water-supplying pump is not provided with a fore pump and is not convenient to overhaul. Because the boiler water-feeding pump is not provided with the fore pump, the occupied space of a pump set is reduced, a system is simplified, the reliability and the safety of the system are improved, and the construction cost is reduced; and by using the dual-shell structure, water inlet and outlet pipelines, and a pump base and pump shell components are not necessary to be disconnected during overhaul so that the mounting, the debugging, the maintenance and the overhaul are convenient and quick, the overhauling time is reduced, the utilization rate of a boiler is improved, and the economic benefit of an electric power plant is increased.

Owner:SHANGHAI AOLI PUMP MFG

Power generating system

InactiveCN103835778ASmall temperature differenceImprove thermal cycle efficiencySteam useBoiler feedwater pumpEngineering

The invention relates to a power generating system which comprises a boiler, a main steam turbine, a steam extraction heater and a generator. A steam cylinder of the main steam turbine is provided with a steam extraction opening, and steam is extracted from the steam extraction opening. Supply water of a condensate pump and feed water of a boiler feed water pump are heated through the steam extraction heater. The steam extracted from the steam extraction opening is divided into two ways, one way is connected to the steam extraction heater and used for heating the condensation water or the boiler feed water, and the other way is connected to an auxiliary steam extraction heater through a back-pressure type expansion machine. In the auxiliary steam extraction heater, the heated water is connected with a water channel outlet of a later-stage steam extraction heater closest to the main steam turbine through a water channel inlet. The water channel outlet of the auxiliary steam extraction heater is connected with the water channel inlet of a same-stage steam extraction heater. According to the power generating system, by means of the back-pressure steam turbine, more heat is converted into power, more temperature gradients are obtained through the auxiliary steam extraction heater to lower the temperature difference between the two sides of the steam water of the steam extraction heater, and therefore the whole thermodynamic cycle efficiency is higher.

Owner:俞述茜

Method for triggering fault diagnosis at low-pressure alarming state of deaerator

InactiveCN103411204AImprove operational safetyLiquid degasificationFluid pressure measurementAlarm stateDeaerator

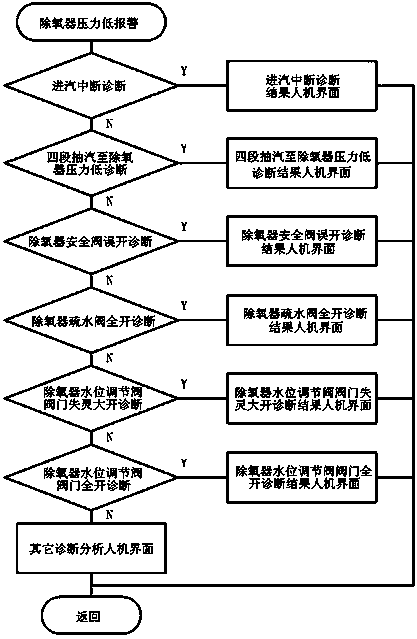

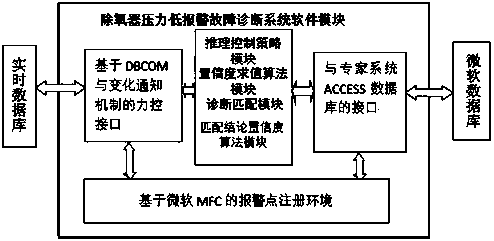

The invention relates to a method for triggering a fault diagnosis at a low-pressure alarming state of a deaerator. The method comprises the following steps: when actually-measured pressure of the deaerator is lower than a low limiting value after the pre-treatment, activating to trigger the fault diagnosis; firstly carrying out the diagnosis on an admission interrupting fault according to a fault priority; if a diagnosis result is tenable, turning to an admission interrupting diagnosis result human-computer interface for explaining that the admission interrupting fault is tenable as well as the confidence coefficient of the admission interrupting fault, reasons for causing the admission interrupting fault and operation guide information, and then finishing a whole diagnosis process; if the diagnosis result is not tenable, turning to a diagnosis for low pressure of a four-section steam extraction deaerator, a deaerator safety valve wrongly-opened diagnosis, a deaerator drain valve fully-opened diagnosis and a deaerator water-level adjusting valve failure ineffectively-opened diagnosis; and finally, carrying out a diagnosis on the valve full opening of the deaerator water-level adjusting valve. The method provided by the invention can be used for carrying out the real-time fault diagnosis on heat returning system equipment and operation conditions and the operation safety of the deaerator and a boiler water feed pump steam turbine are improved.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Condensate-recycling system

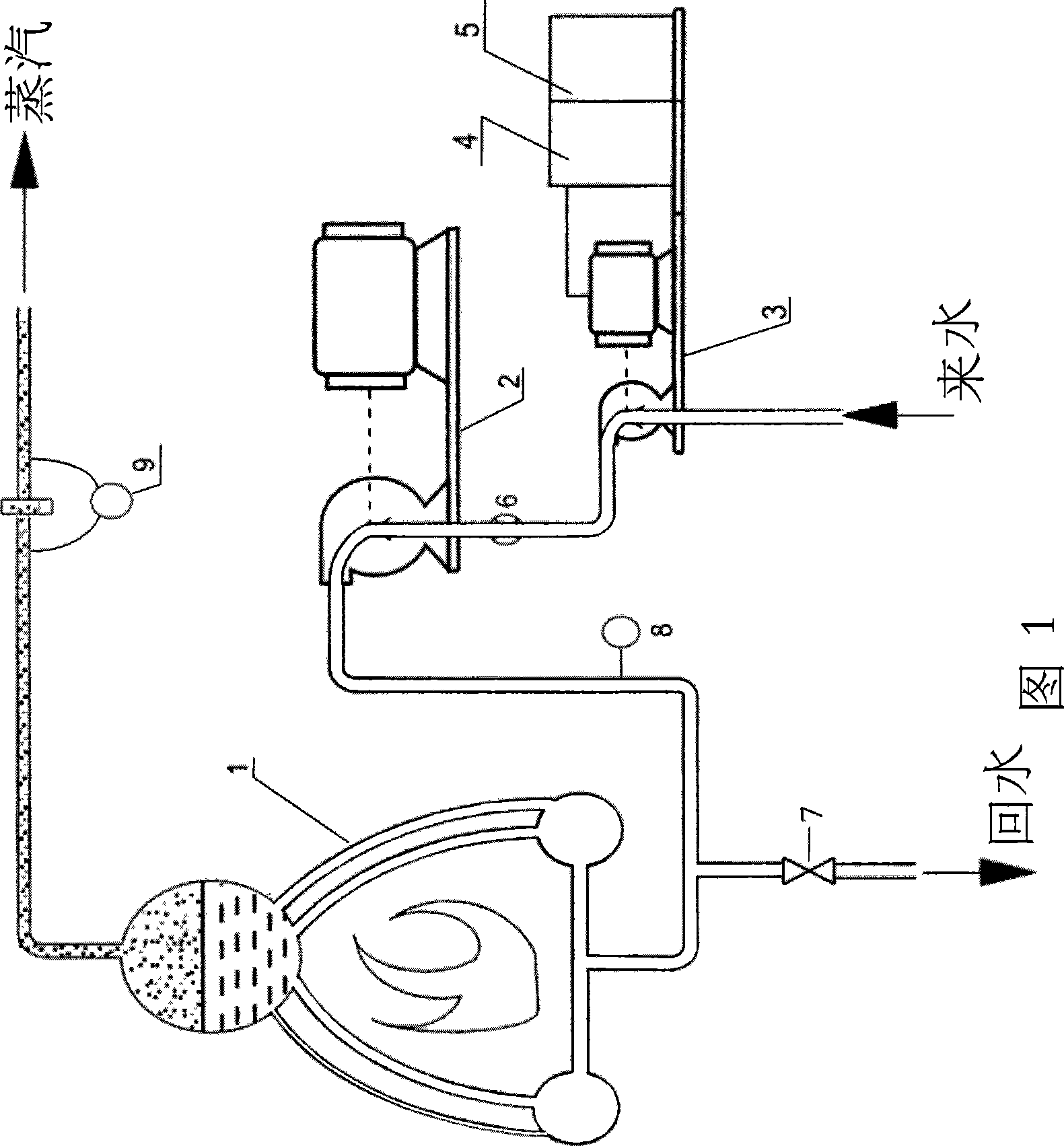

ActiveCN102563609ATake advantage ofEfficient use ofLiquid degasificationFeed water supplyBoiler feedwater pumpSoft water

The invention discloses a condensate-recycling system. A top soft water tank is connected with a boiler through a boiler feed pump, a condensate collector is connected with steam-consuming equipment through a steam trap, the top soft water tank is connected with the water inlet of a steam-water heater through a water-circulating pump, the water outlet of the steam-water heater is connected with the top soft water tank, the exhaust outlet of the condensate collector is connected with the steam inlet of the steam-water heater, the condensate discharge outlet of the steam-water heater is connected with the water inlet of the condensate collector, and the water outlet of the condensate collector is connected with the top soft water tank through a condensate-recovering pump. Consequently, the heat of flash steam and leaked steam can be sufficiently utilized, so that the waste of energy can be effectively prevented, meanwhile, the condensate which is produced after steam is cooled can flow into the top soft water tank and is recycled by the boiler, so that the water resource is also effectively utilized and the waste of the water resource is reduced, and therefore the condensate-recycling system can meet the requirement for energy saving and environment-friendliness.

Owner:CHINA TOBACCO GUIZHOU IND

Power generation apparatus

A power generation apparatus including a boiler feedwater pump turbine control system is disclosed. In one embodiment, a power generation apparatus is disclosed, including: a boiler feedwater pump turbine having a low pressure steam inlet and a high pressure steam inlet; a high pressure control valve for controlling admission of high pressure steam to the high pressure steam inlet; a low pressure control valve for controlling admission of low pressure steam to the low pressure steam inlet; and a control system operably coupled to the high pressure control valve and the low pressure control valve, the control system configured to close the low pressure control valve and prevent flow of the low pressure steam to the boiler feedwater pump turbine in response to a request for increased power output from a power grid.

Owner:GENERAL ELECTRIC CO

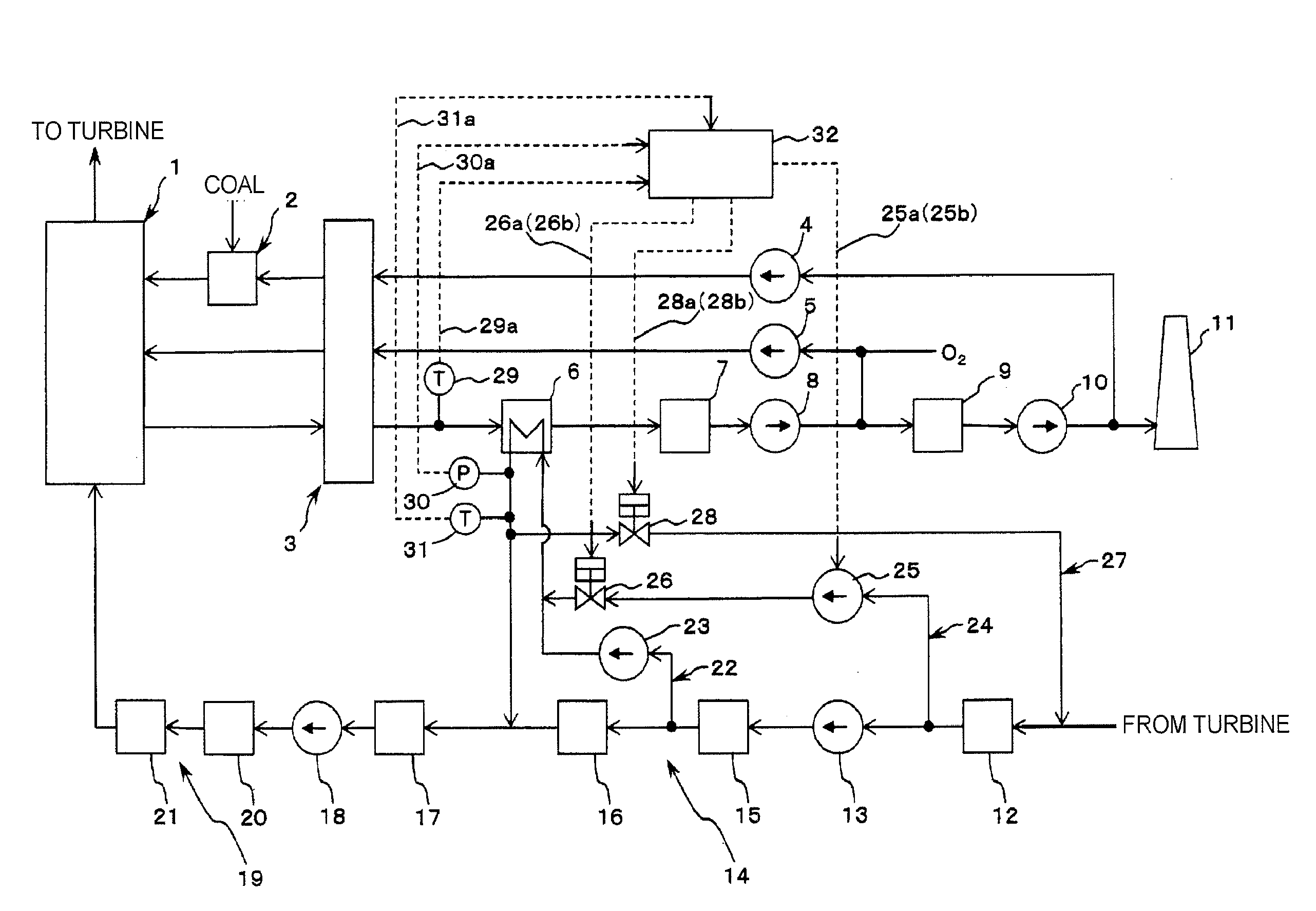

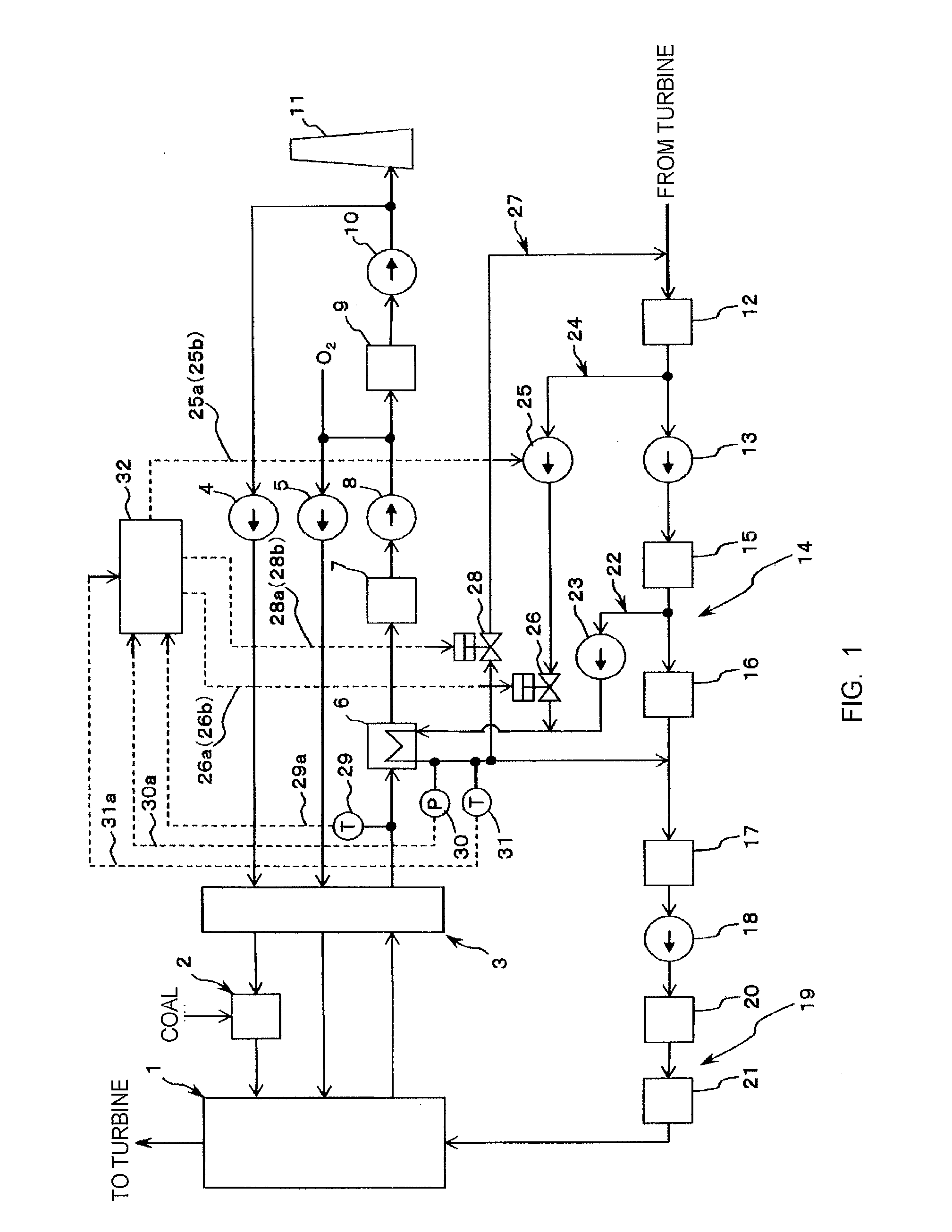

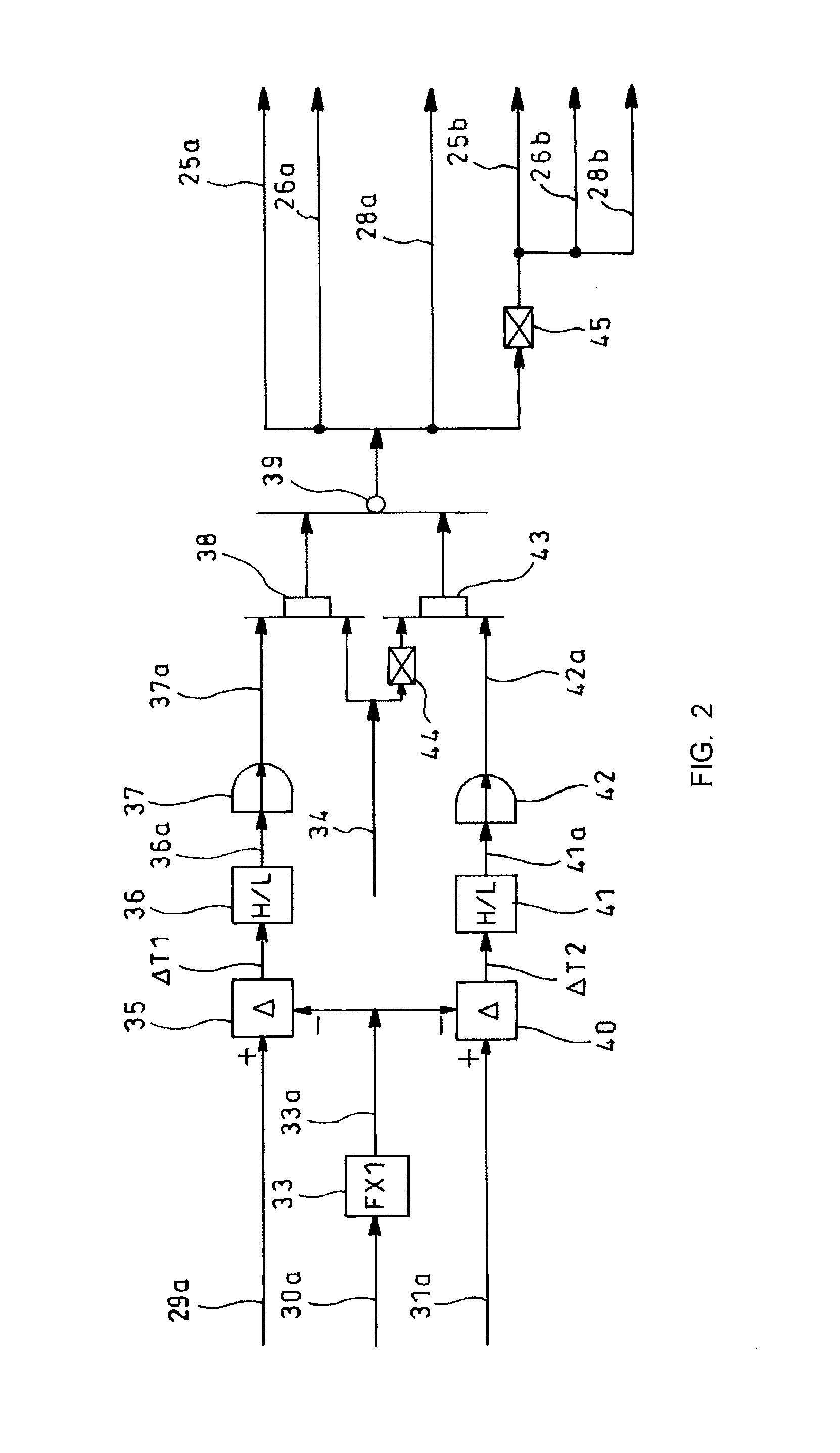

Device for preventing steam from being produced in flue gas cooler for oxyfuel combustion boiler

ActiveUS20160169504A1Good effectSolid fuel combustionIndirect carbon-dioxide mitigationBoiler feedwater pumpCombustion

A feed-water discharge side of a condenser is connected to a feed-water entry side of an flue gas cooler through a bypass line provided with a steam production preventive pump and with an inlet cutoff valve. A feed-water discharge side of the flue gas cooler is connected to the feed-water entry side of the condenser through a steam production preventive water circulation line provided with an outlet cutoff valve. When a boiler feed-water pump is stopped in boiler fuel cutoff, the inlet and outlet cutoff valves are opened and the steam production preventive pump is activated to cause water to flow through the bypass line into the flue gas cooler, is returned through the steam production preventive water circulation line to the condenser and is circulated.

Owner:IHI CORP

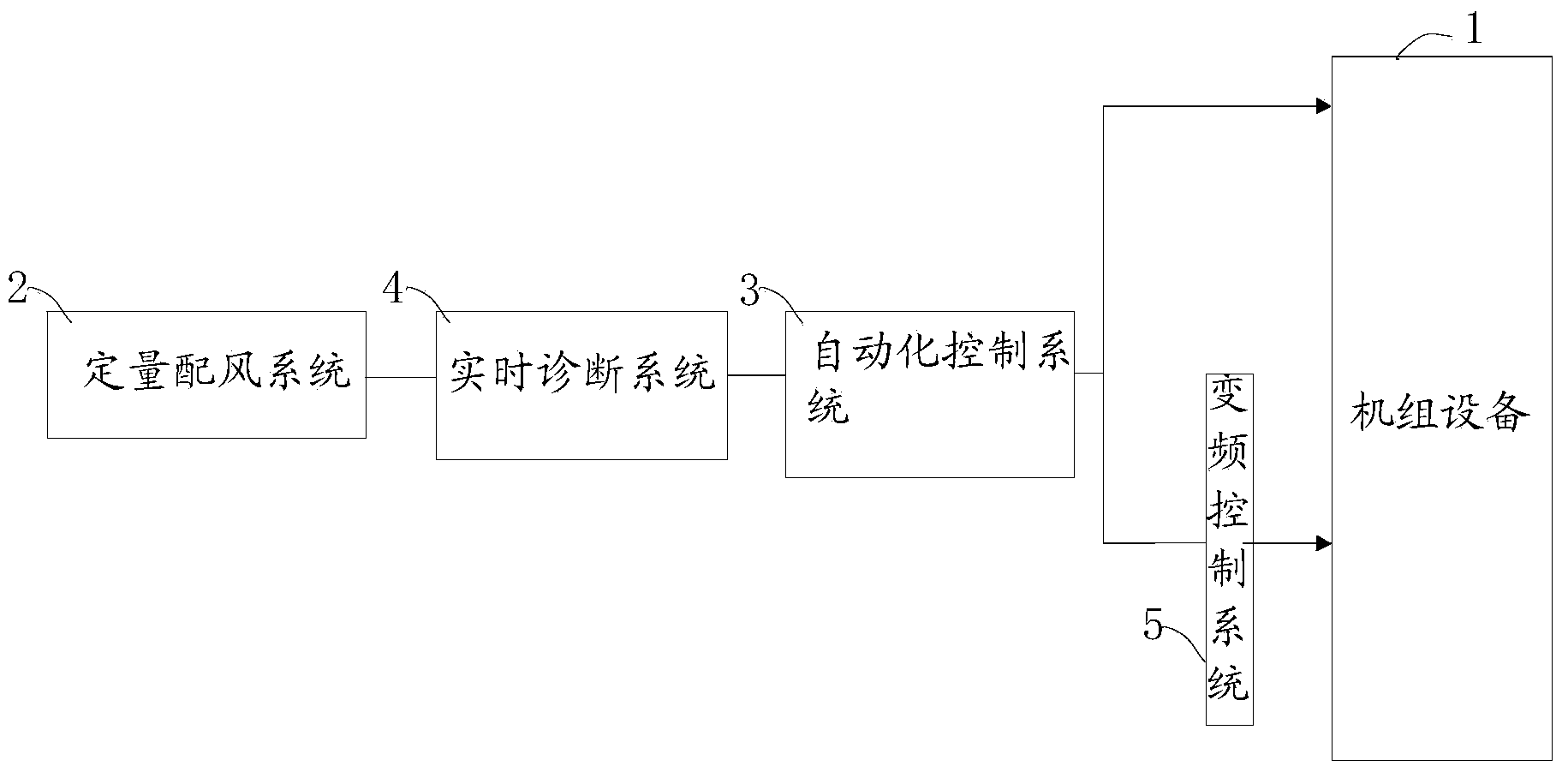

Quantitative air distribution economic combustion energy saving control system

InactiveCN103411234AImprove work efficiencyPlay the role of energy savingFuel supply regulationElectricityAutomatic control

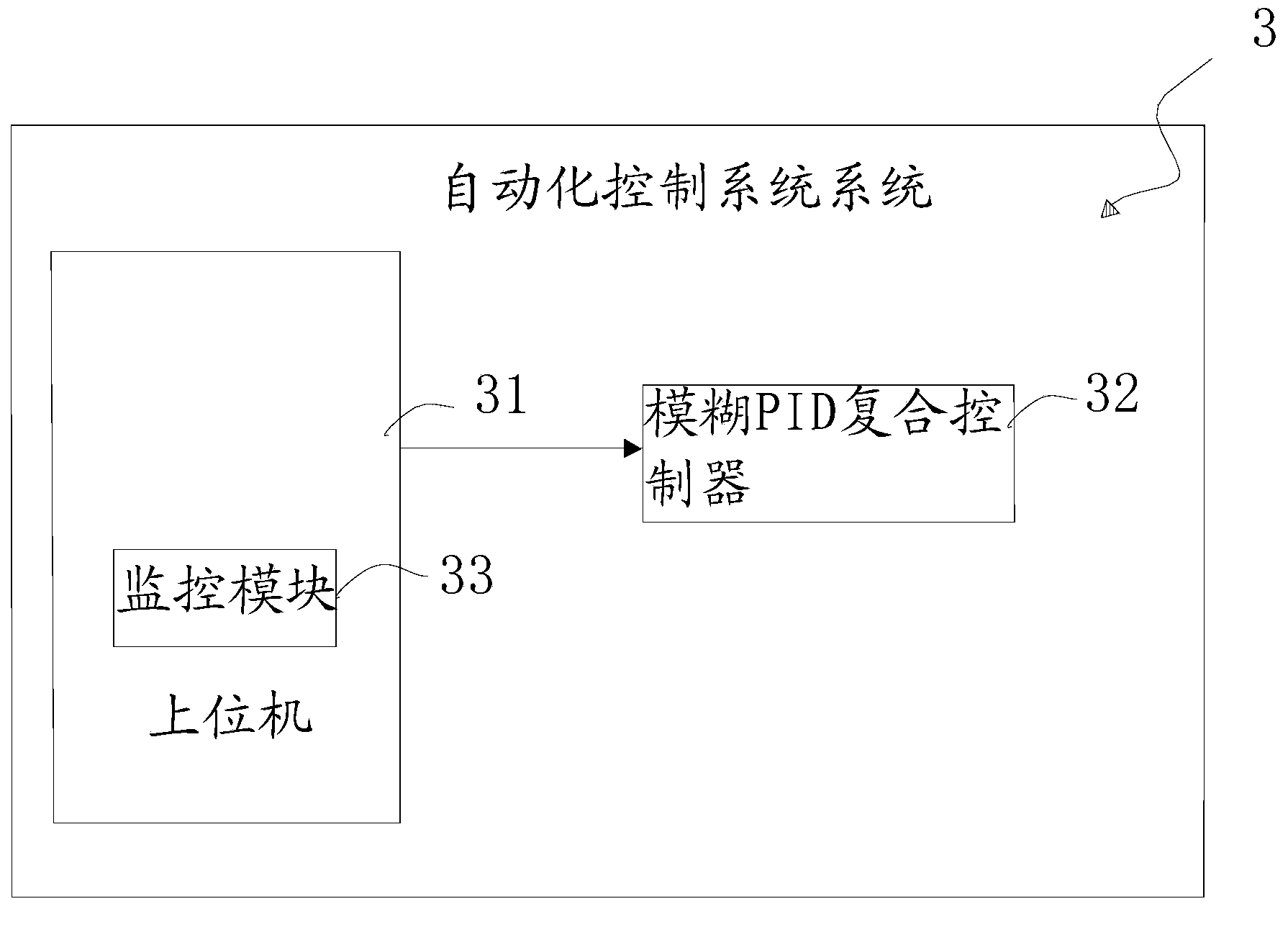

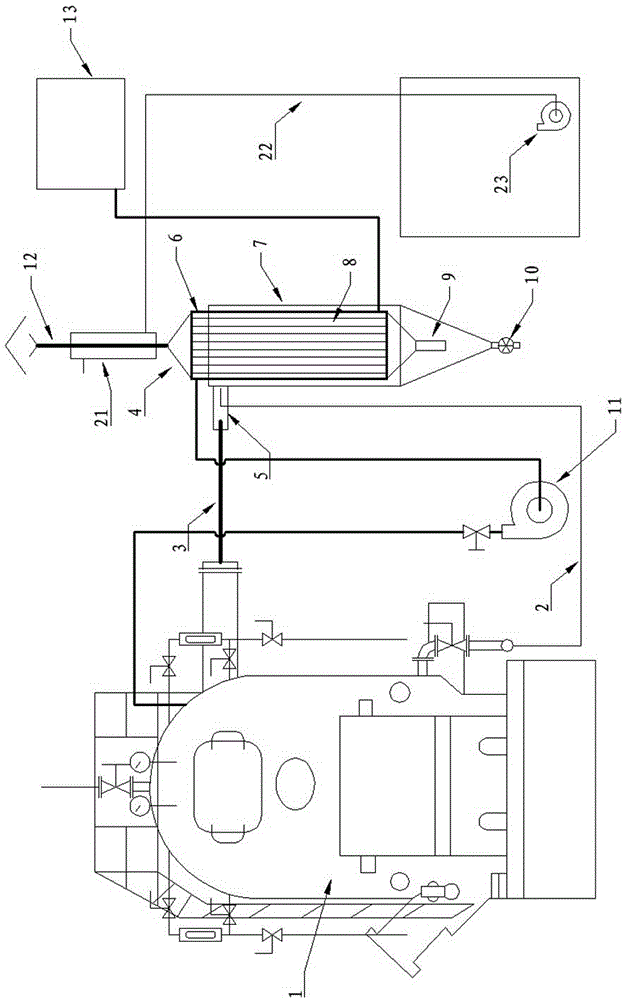

The invention discloses a quantitative air distribution economic combustion energy saving control system. The quantitative air distribution economic combustion energy saving control system comprises a machine set device which comprises a feeding controller, a blower assembly, an induced fan assembly, a grate motor and a boiler feed pump. The quantitative air distribution economic combustion energy saving control system also comprises a quantitative air distribution system, an automatic control system and a real-time diagnosis system which are electrically connected with the machine set device; the quantitative air distribution system is used for controlling the rotating speed of the blower assembly, the induced fan assembly and the grate motor of the machine set device to achieve a reasonable ratio; the real-time diagnosis system is used for receiving boiler performance parameters which is sent from the automatic control system, obtaining an optimal control scheme after analysis and calculation, generating into a regulation control command according to the optimal control scheme and sending the regulation control command; the automatic control system is used for monitoring the machine set device to obtain the boiler performance parameter, receiving the regulation control command and performing distributed logic control and process control on the machine set device. The quantitative air distribution economic combustion energy saving control system has the advantages of being efficient, energy saving and environmentally friendly, enabling the service life of the boiler and ancillary facilities of the boiler to be prolonged and being high in safety performance.

Owner:柳州市泰尔热能环保科技有限公司

Exhaust heat recovery and dust removal integrated type biomass boiler

InactiveCN104930531AReduce investmentImprove work efficiencyHeating arrangementFeed-water heatersVertical tubeCyclone

The invention discloses an exhaust heat recovery and dust removal integrated type biomass boiler which comprises a boiler body, a boiler exhaust pipe, a boiler blow-off pipe and a cyclone exhaust heat efficient recoverer, wherein the cyclone exhaust heat efficient recoverer is formed by stacking a tube type heat exchanger and a cyclone dust collector, the boiler exhaust pipe is tangential to the cyclone dust collector, dust is exhausted through a closed-air aspirator at the conic bottom after cyclone de-dusting, the exhaust gas is connected with a conic body through a cyclone rising pipe, penetrates through vertical tubes after scattered uniformly and is exhausted through an exhaust pipe after centralized by an upper hopper; a pure water pool is connected with the lower part of the shell side of the tube type heat exchanger, and the upper part of the shell side of the tube type heat exchanger is connected with the boiler body through a boiler water feed pump. According to the exhaust heat recovery and dust removal integrated type biomass boiler, synchronous processing of exhaust heat use and de-dusting of the biomass boiler is realized, the practicability is high, and the application prospect is wide.

Owner:杭州华政新能源科技有限公司

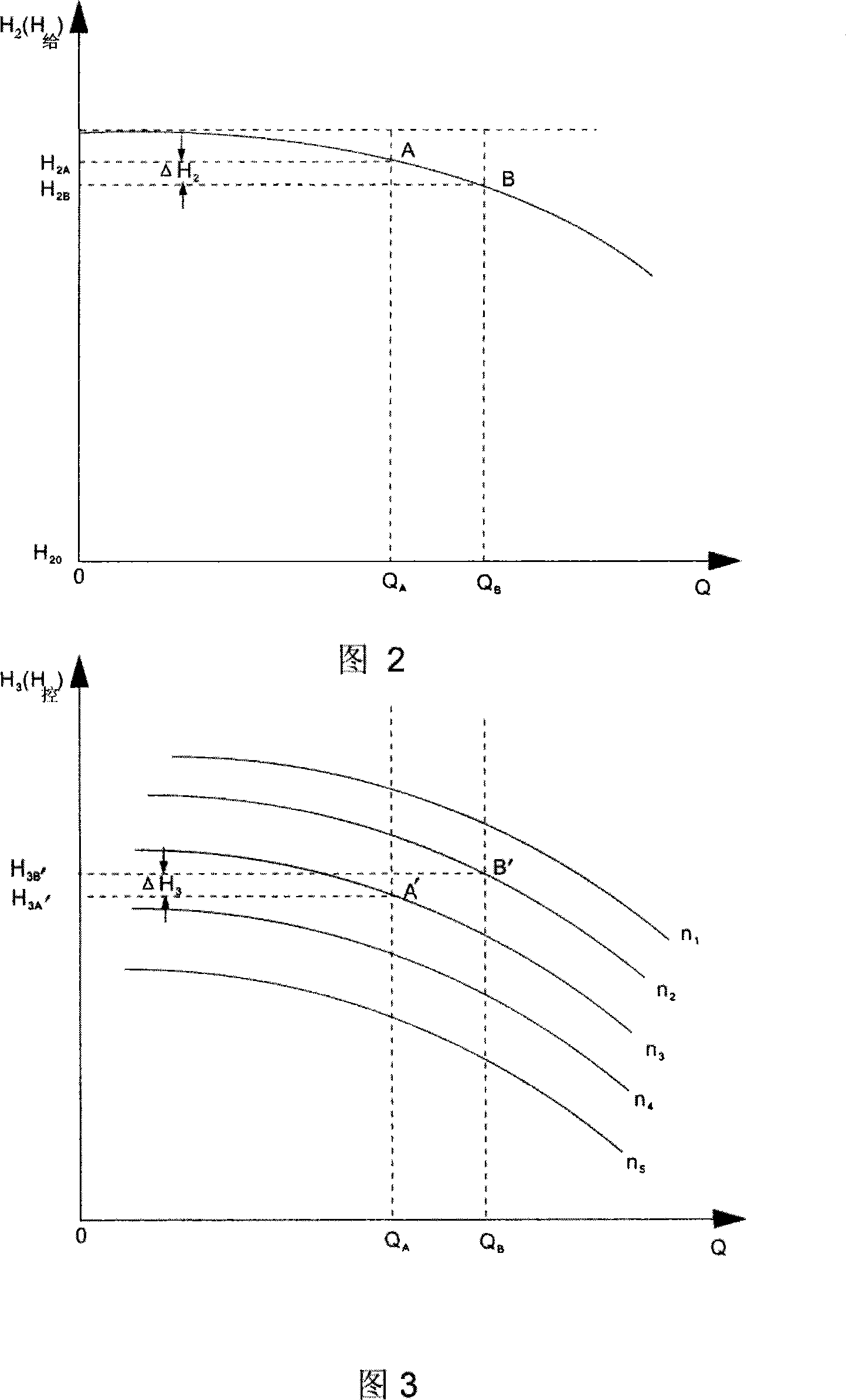

Water feed flow control and pressure compensating system of boiler

InactiveCN101435572AStable jobReduce energy consumptionWater feed controlBoiler feedwater pumpEngineering

The invention provides a system for controlling water supply flow for a boiler and compensating pressure, which comprises the boiler, a boiler water supply pump and a water supply pipe, and also comprises a prefix flow control pump, a revolution driver for flow control, and a flow control and pressure compensation adjuster. The revolution driver is electrically connected with a driving motor of the prefix flow control pump and the flow control and pressure compensation adjuster respectively. The flow control and pressure compensation adjuster monitors adjusting parameters of the boiler water supply pump, and changes the flow of the prefix flow control pump through changing the revolution of the revolution driver to further change pump lift variation of the prefix flow control pump, thereby achieving flow control and pressure compensation for the boiler water supply pump. A water injection pump in the prior art deviates from an efficient area, has reduced efficiency, pollutes electric network, only can be adjusted in a single direction, can not ensure stable water supply pressure, and has huge investment. The system can achieve infinitely variable adjustment for water supply amount, and has the advantages of stable water supply pressure, low power consumption, and improved efficiency.

Owner:陕西天程石化设备有限公司

Apparatus for steam attemperation using fuel gas heater water discharge to reduce feedwater pump size

Attemperation systems and methods for cooling steam bypassed from a steam turbine during tripping of the steam turbine are provided in the disclosed embodiments. The systems may be configured to deliver water discharged from a fuel gas heater to a bypass attemperator, where the water discharged from the fuel gas heater may be used to cool the bypass steam. Before being used by the fuel gas heater, the water used to heat the fuel gas may be heated by an economizer. The water may be delivered to the economizer by an intermediate pressure stage of a boiler feedwater pump. In the disclosed embodiments, the intermediate pressure stage of the boiler feedwater pump may also be used to supply water to a re-heater attemperator, which may be used to further cool the steam after it has been delivered from the bypass attemperator to a re-heater. In addition, the intermediate pressure stage of the boiler feedwater pump may deliver water directly to the bypass attemperator as a supplemental water source.

Owner:GENERAL ELECTRIC CO

Intelligent multi-mode PID (proportional integral differential) water-feeding control system for large generator unit

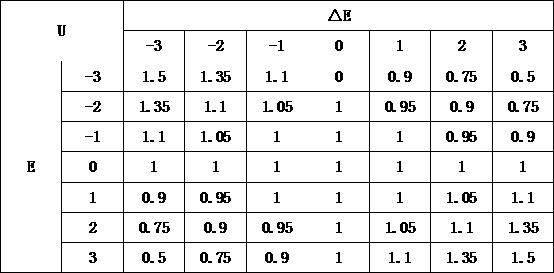

ActiveCN103225801AReal-time online adjustmentImprove economic indicatorsWater feed controlIntelligent lightingProportional integral differential

The invention discloses an intelligent multi-mode PID water-feeding control system for a large generator unit, and solves the problem that feedwater flow fluctuates substantially due to the fact that a conventional PID automatic control system with fixed parameters cannot adapt to a nonlinear characteristic of a controlled object. The water-feeding control system comprises a PID controller module in a generator water-feeding control system and a boiler water feeding pump; a function module, a differential module, a multiplication module, a division module, a subtraction module, a power module, a high value monitoring module and an analog quantity switching module in a distributed control system are adopted to construct a multi-mode fuzzy control real-time online optimizer; and the multi-mode fuzzy control real-time online optimizer accesses a PID closed-loop control system existing in a boiler to form an independent closed-loop control system of the water-feeding system, so that the stable control of the large boiler water-feeding system is realized, the stability of the main steam pressure and the main steam temperature of the boiler can be improved, and the accurate control of a unit load can be guaranteed.

Owner:STATE GRID CORP OF CHINA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com