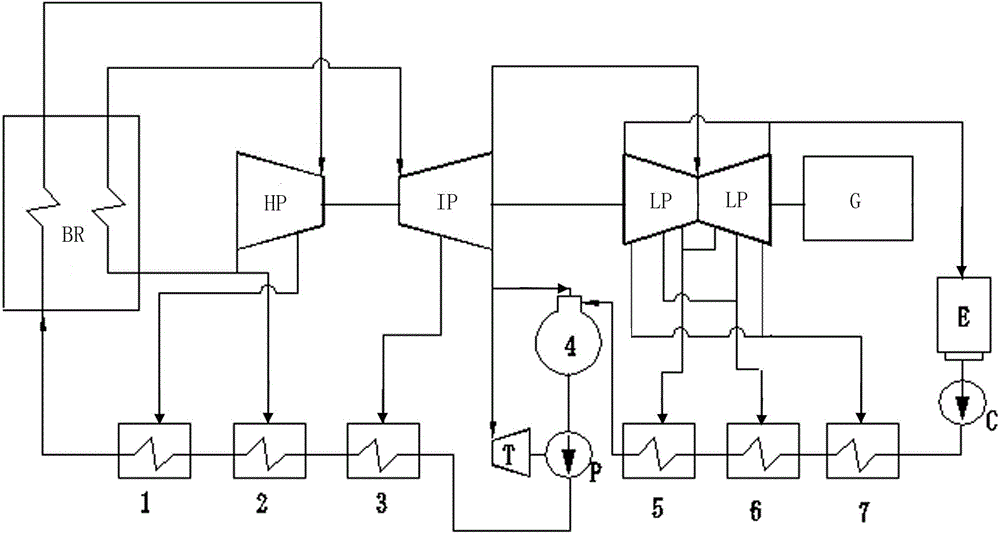

Compound feed pump turbine for thermal power plant and thermodynamic system

A technology for feedwater pump steam turbines and thermal power plants, which is applied in the direction of steam engine devices, machines/engines, mechanical equipment, etc., and can solve the problem of affecting the heat recovery cycle efficiency of the unit, the inability to use high-quality energy more reasonably, and the pure condensing machine Low operating efficiency and other issues, to achieve the effect of reducing land occupation, reducing project cost, and simplifying the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

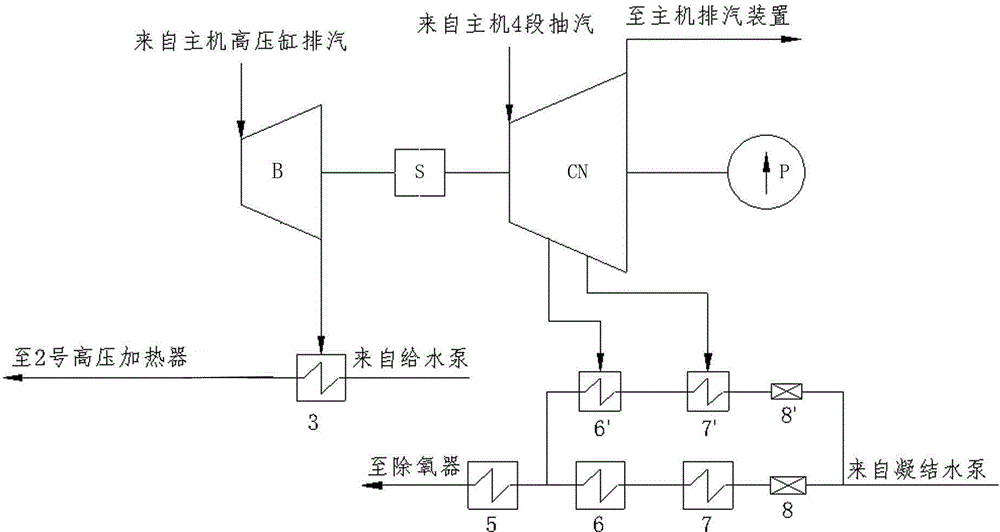

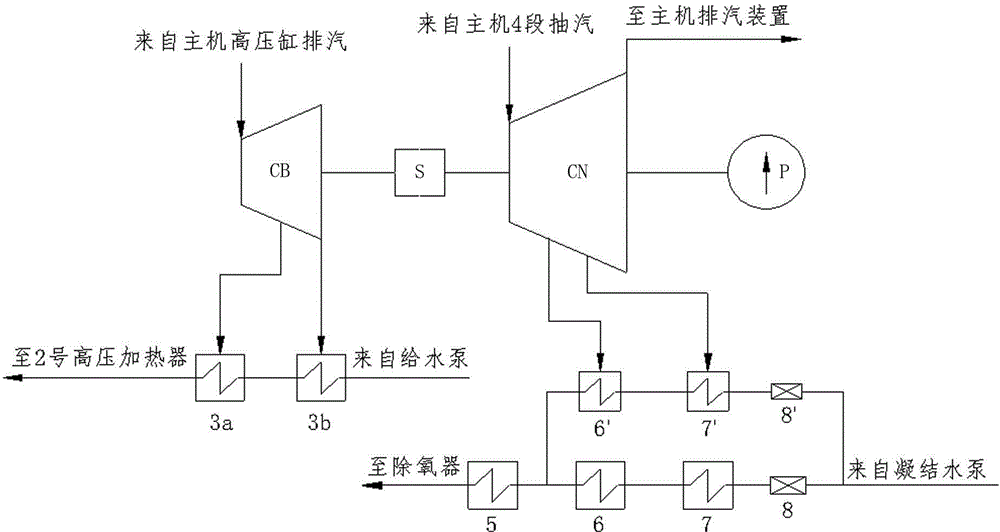

[0022] like figure 2 , image 3 As shown, a composite feedwater pump steam turbine and thermal system used in a thermal power plant, including steam extraction and condensing small steam turbine CN, small condensing machine No. 6' low-pressure heater 6', small condensing machine No. 7' The low-pressure heater 7' and the condensate flow regulating valve 8' of the extraction and condensing small machine, the output end of the steam extraction and condensing small steam turbine CN is connected to the boiler feed water pump P, the low-pressure heater 6' of the small extraction condensing machine 6' and the extraction The low-pressure heater 7' of the small condensing machine 7' is respectively connected to the steam extraction condensing small steam turbine CN through the steam extraction pipeline, and the low-pressure heater 6' of the small condensing machine 6' is connected to the small condensing machine 7 through the condensate pipe. 'No. low-pressure heater 7' and condensat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com