Integrated waste heat generating and heating system and process flow thereof

A technology of waste heat power generation and process flow, which is applied in the direction of hot water central heating system, heating system, and process efficiency improvement, etc., can solve the problems of increasing the pollution coefficient, ineffective utilization, pollution, etc., and achieves a simple overall structure. , Conducive to environmental protection, the effect of reducing thermal pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

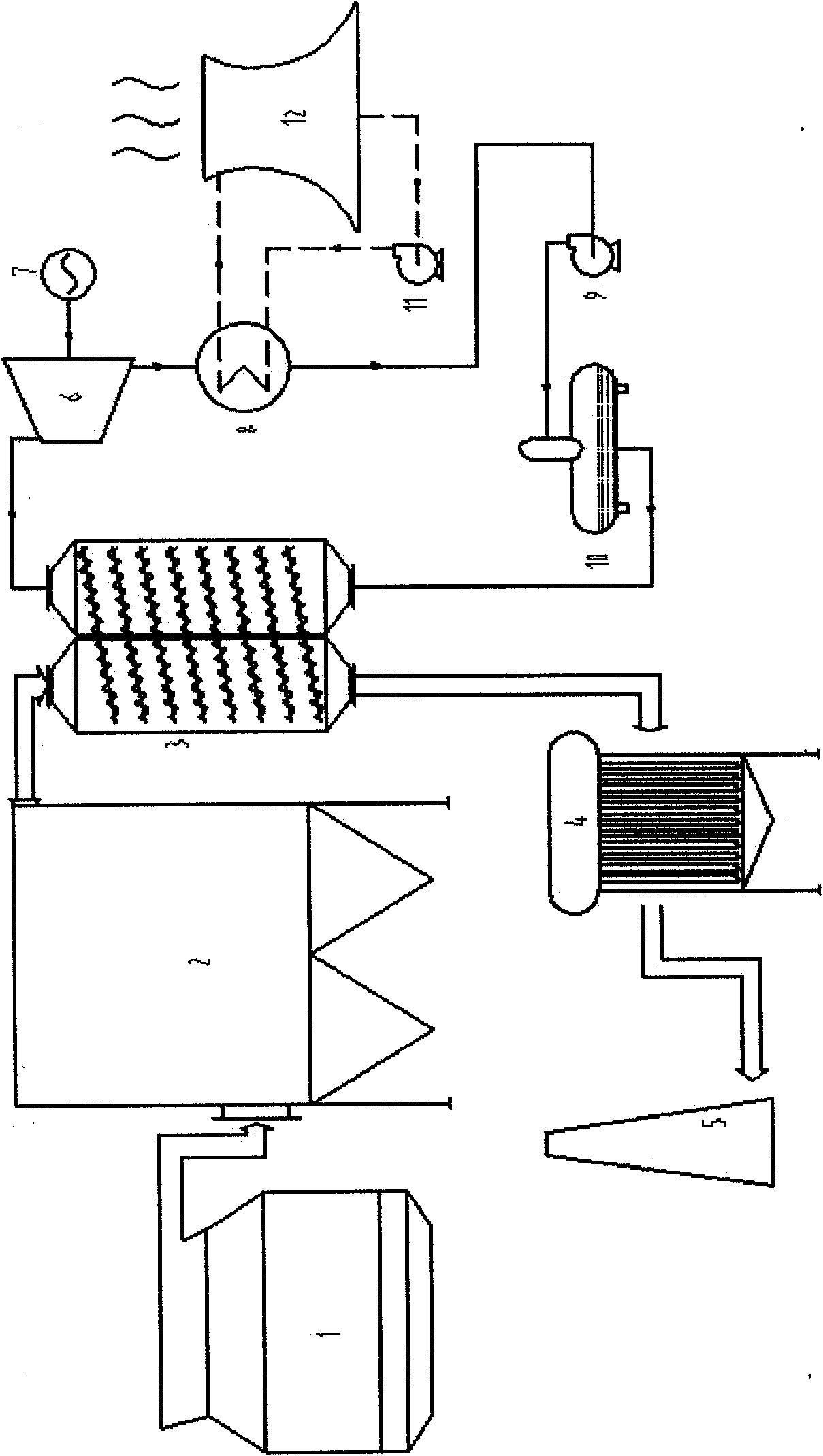

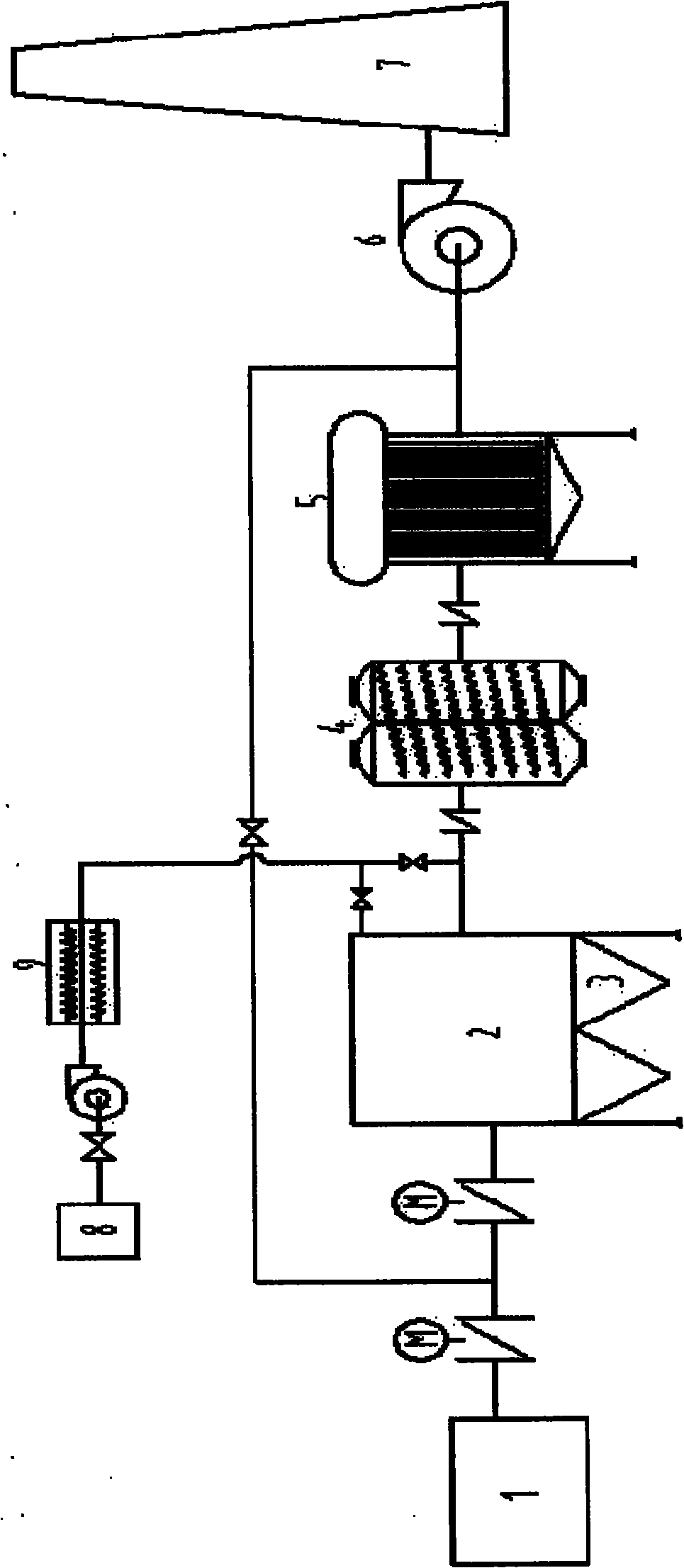

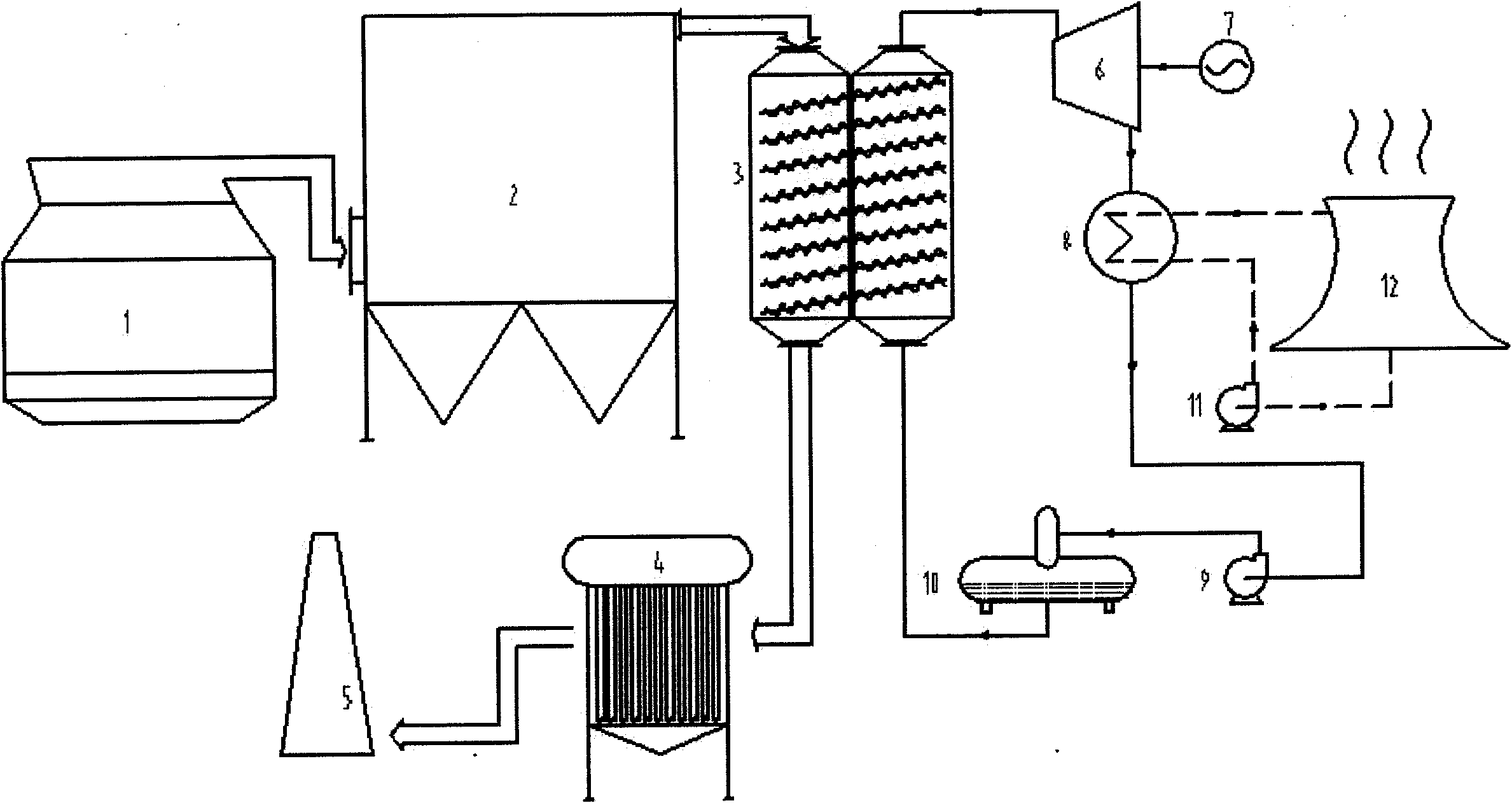

[0025] like figure 1 , 2 Shown in: waste heat power generation and heating integrated equipment system and process, with a heat pipe waste heat boiler (3) installed at the flue gas outlet to undertake all heating functions and generate medium and low pressure steam; the medium and low pressure main steam generated by the waste heat boiler is mixed Afterwards, it enters the supplementary steam condensing turbine (6) through the pipeline, and the low-pressure steam enters the steam turbine through the supplementary steam pipeline: the exhaust steam at the tail of the steam turbine enters the condenser (8), and the condensed water enters the vacuum deaeration through the condensate pump (9) and the pipeline The water after deoxygenation in the deaerator enters the boiler through the boiler feed water pump (9); the exhaust gas after heat exchange enters the waste heat heating device (4) through the pipeline, and is discharged through the chimney (5). In the inlet and outlet secti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com