Patents

Literature

208 results about "Plant automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

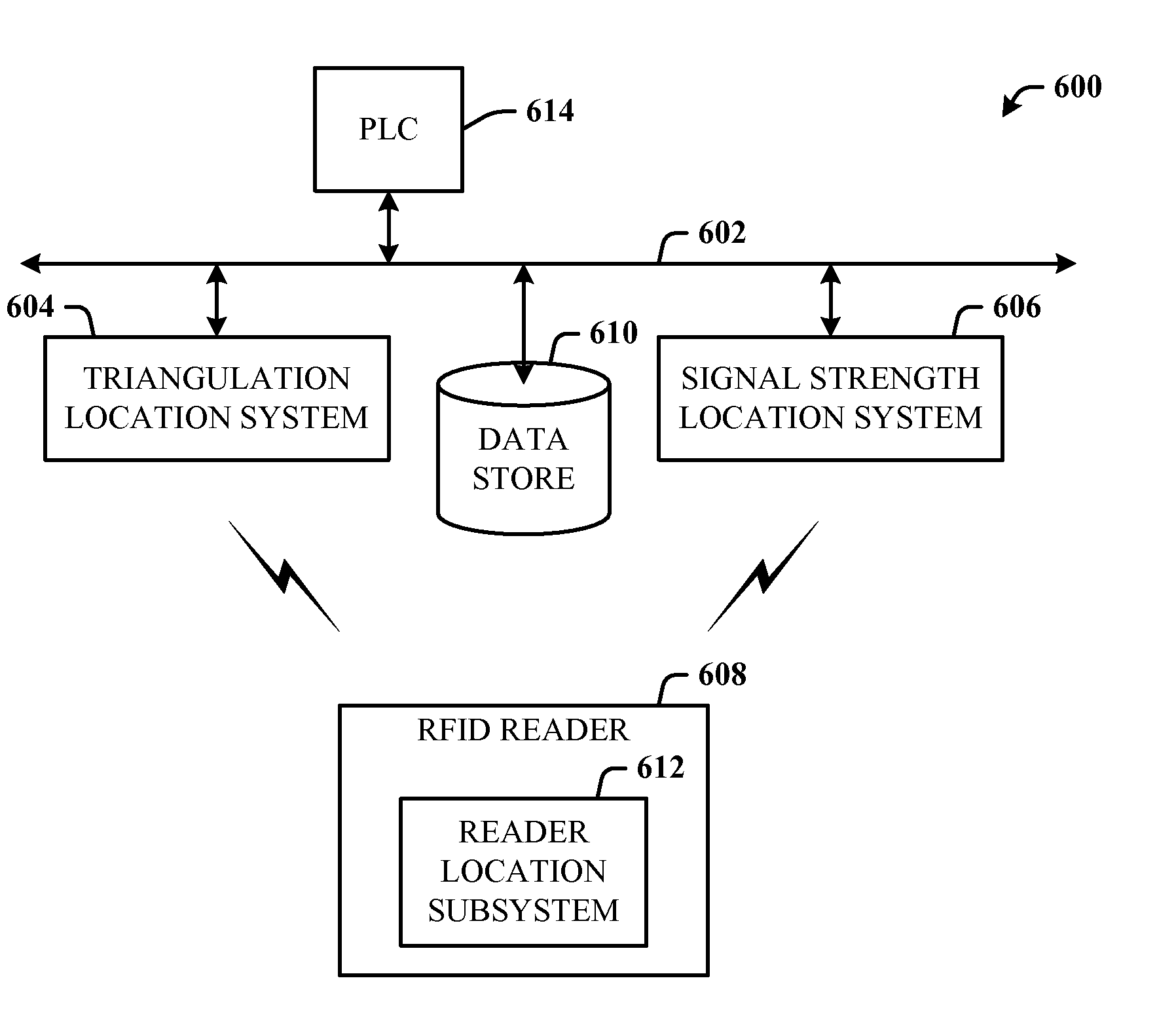

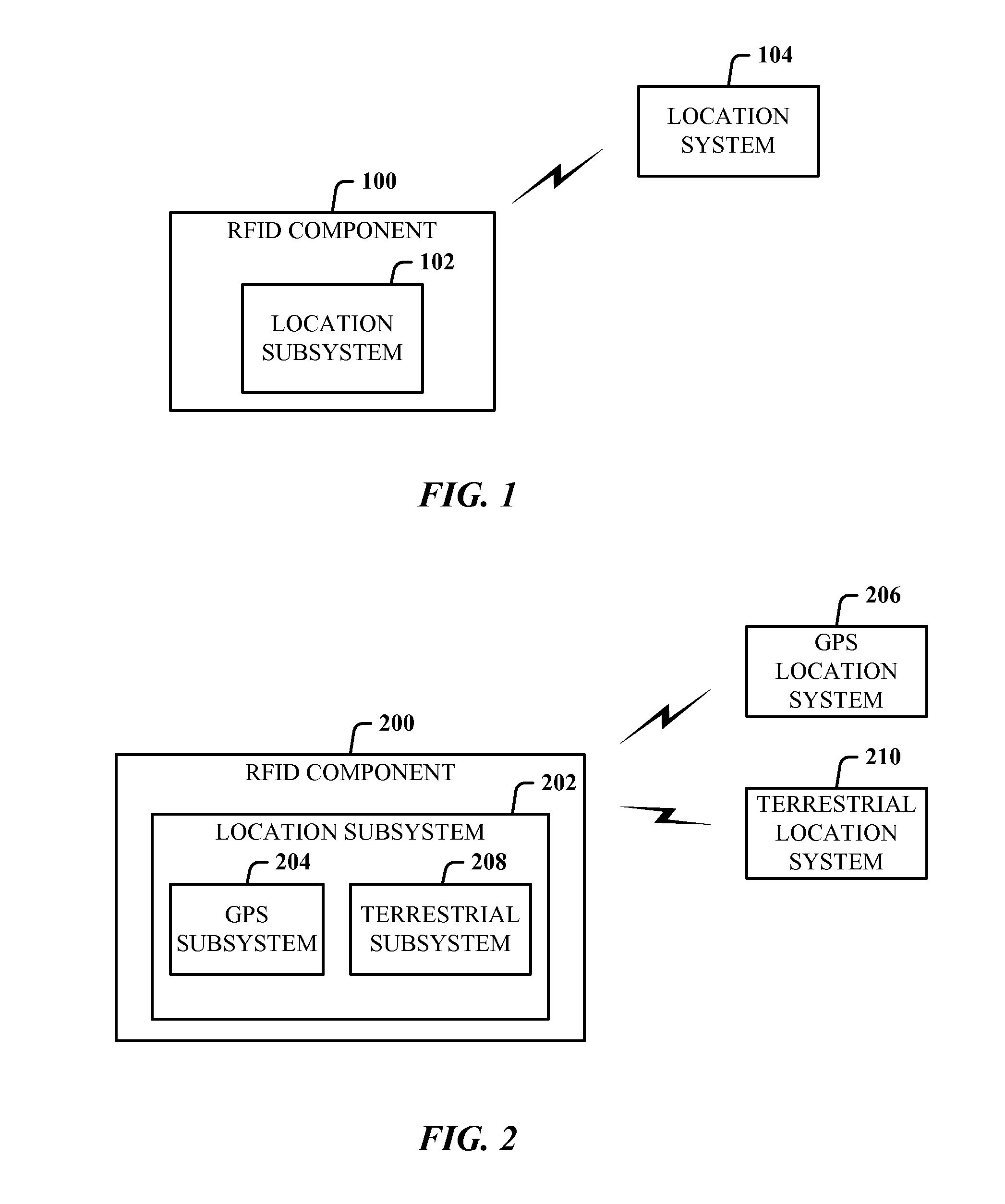

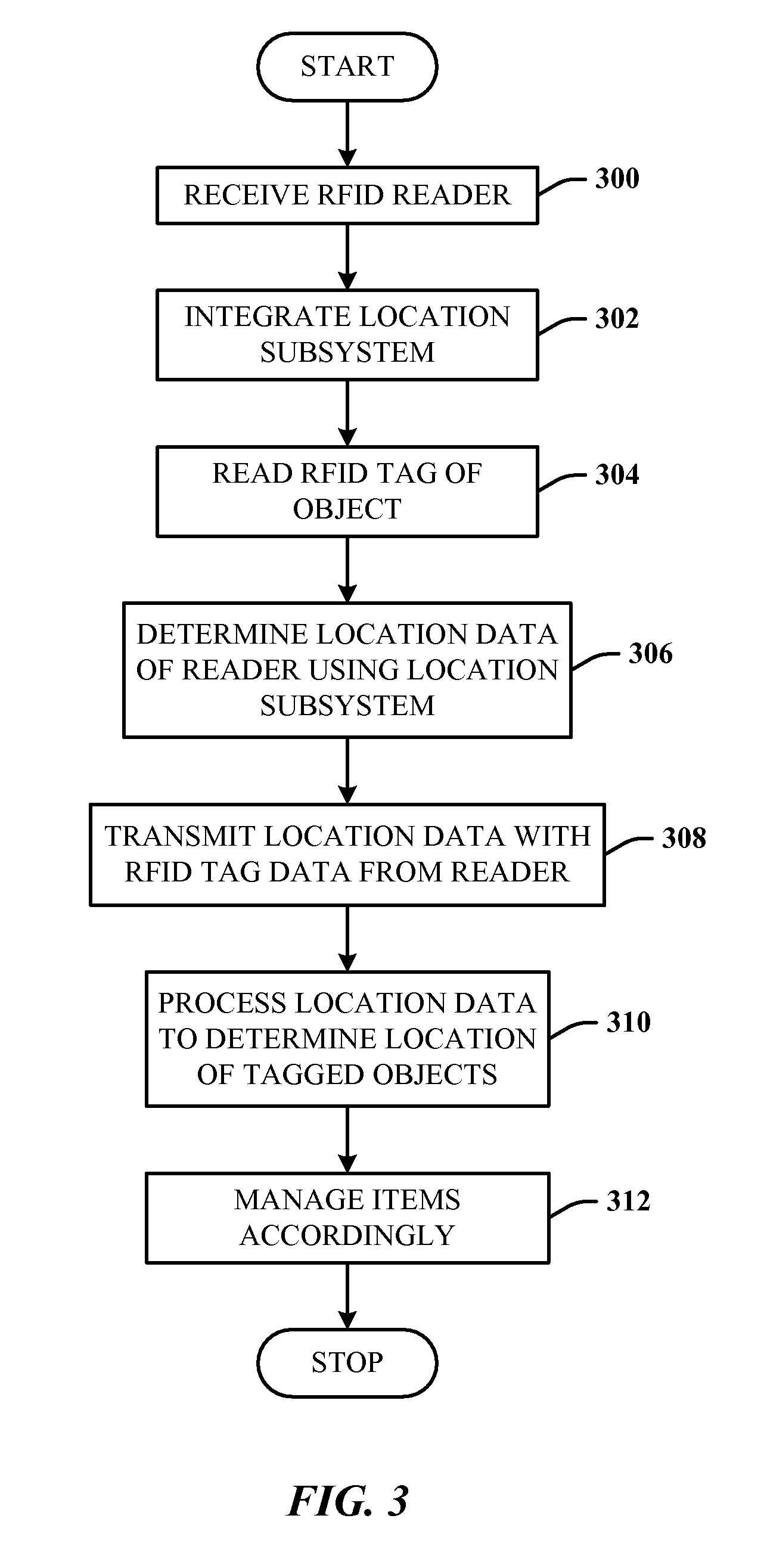

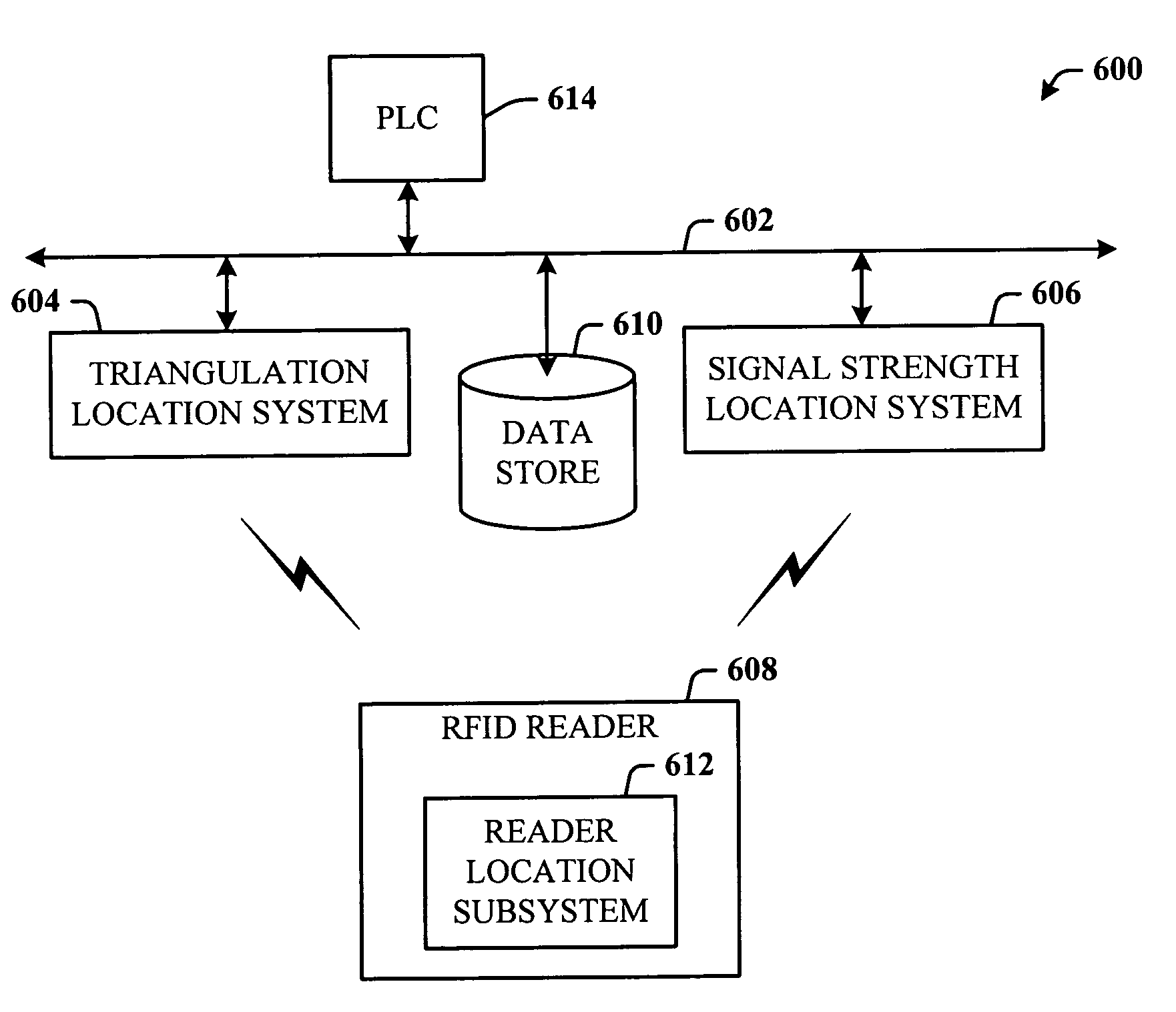

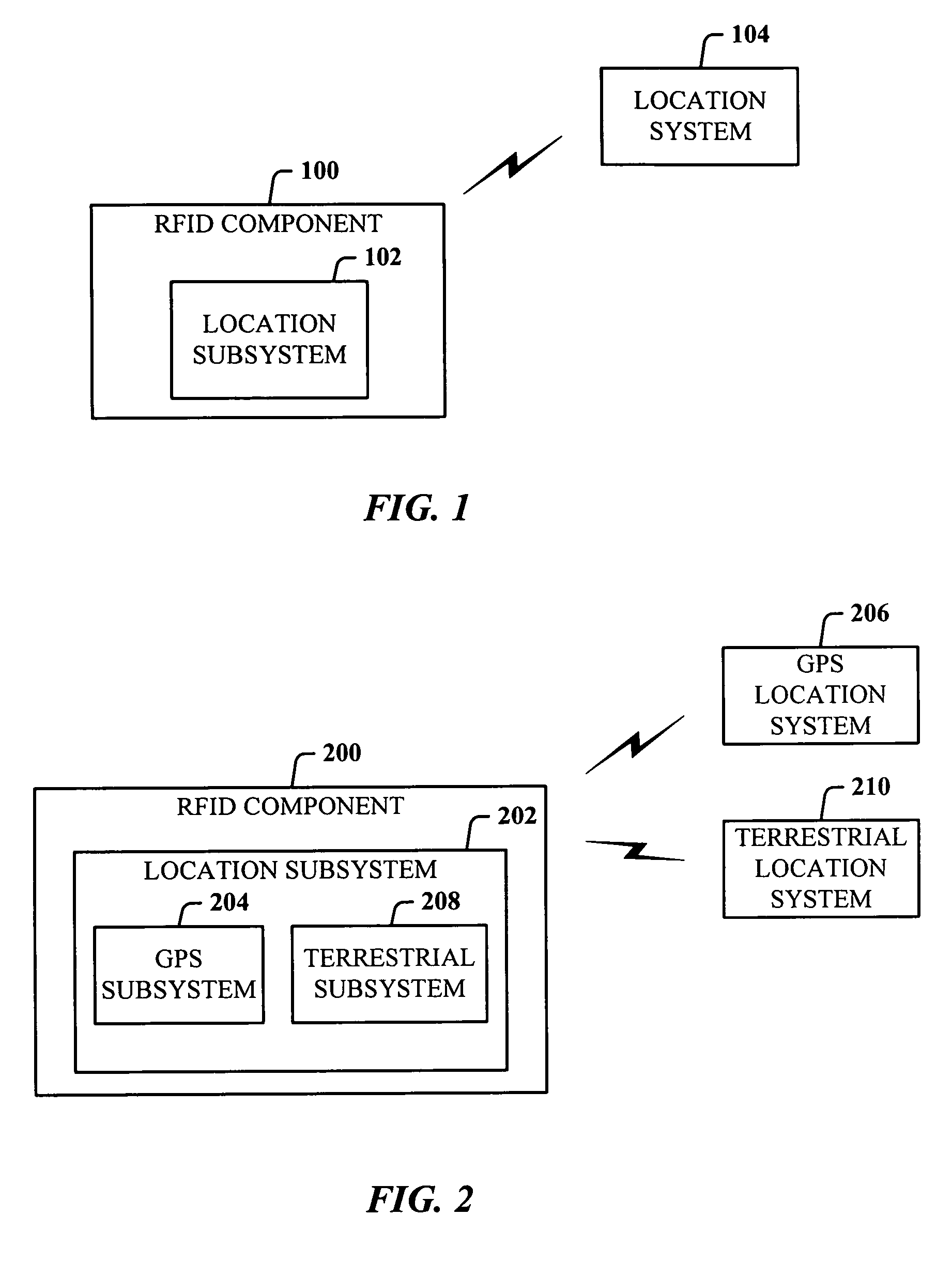

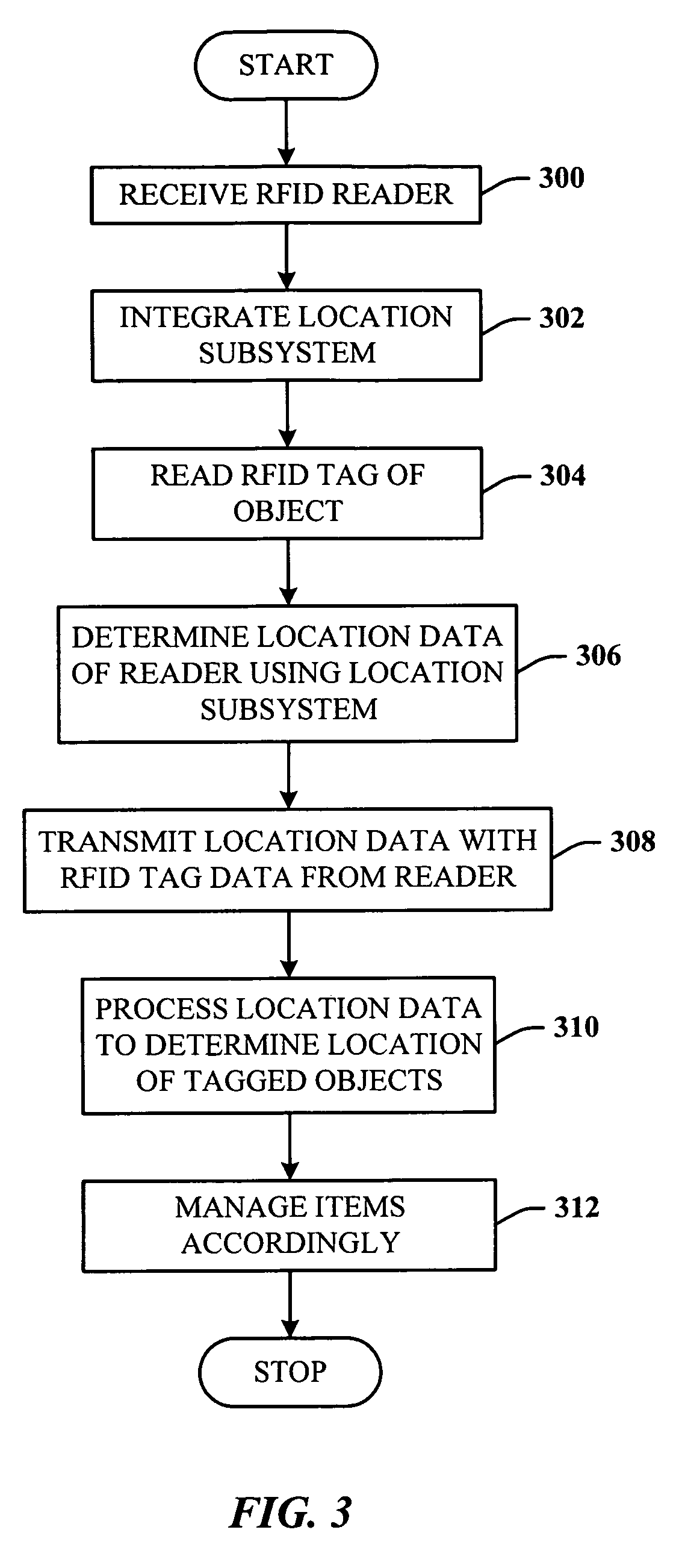

Mobile RFID reader with integrated location awareness for material tracking and management

ActiveUS20070018820A1Accurately determineMemory record carrier reading problemsNavigation instrumentsLocation awarenessGlobal Positioning System

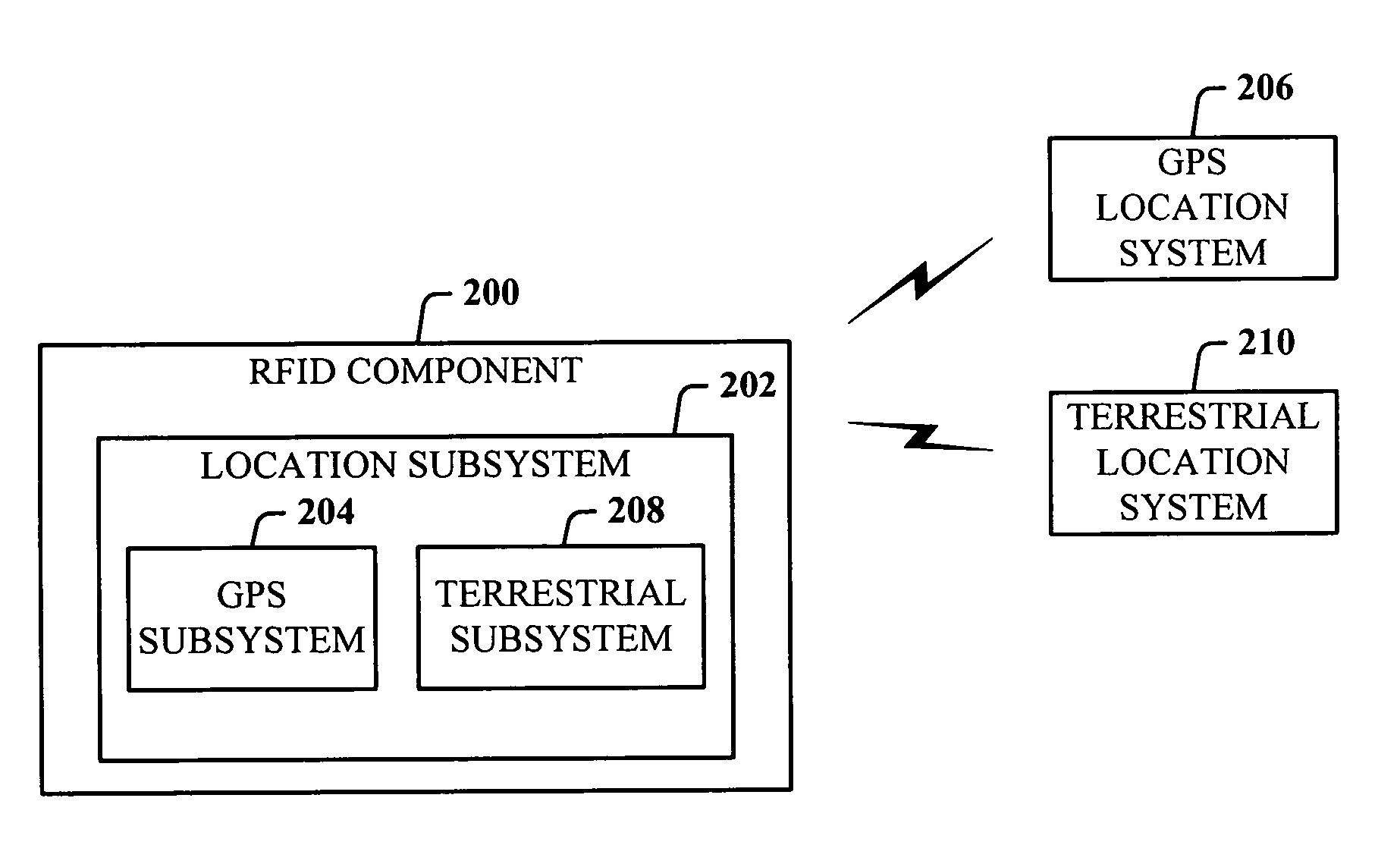

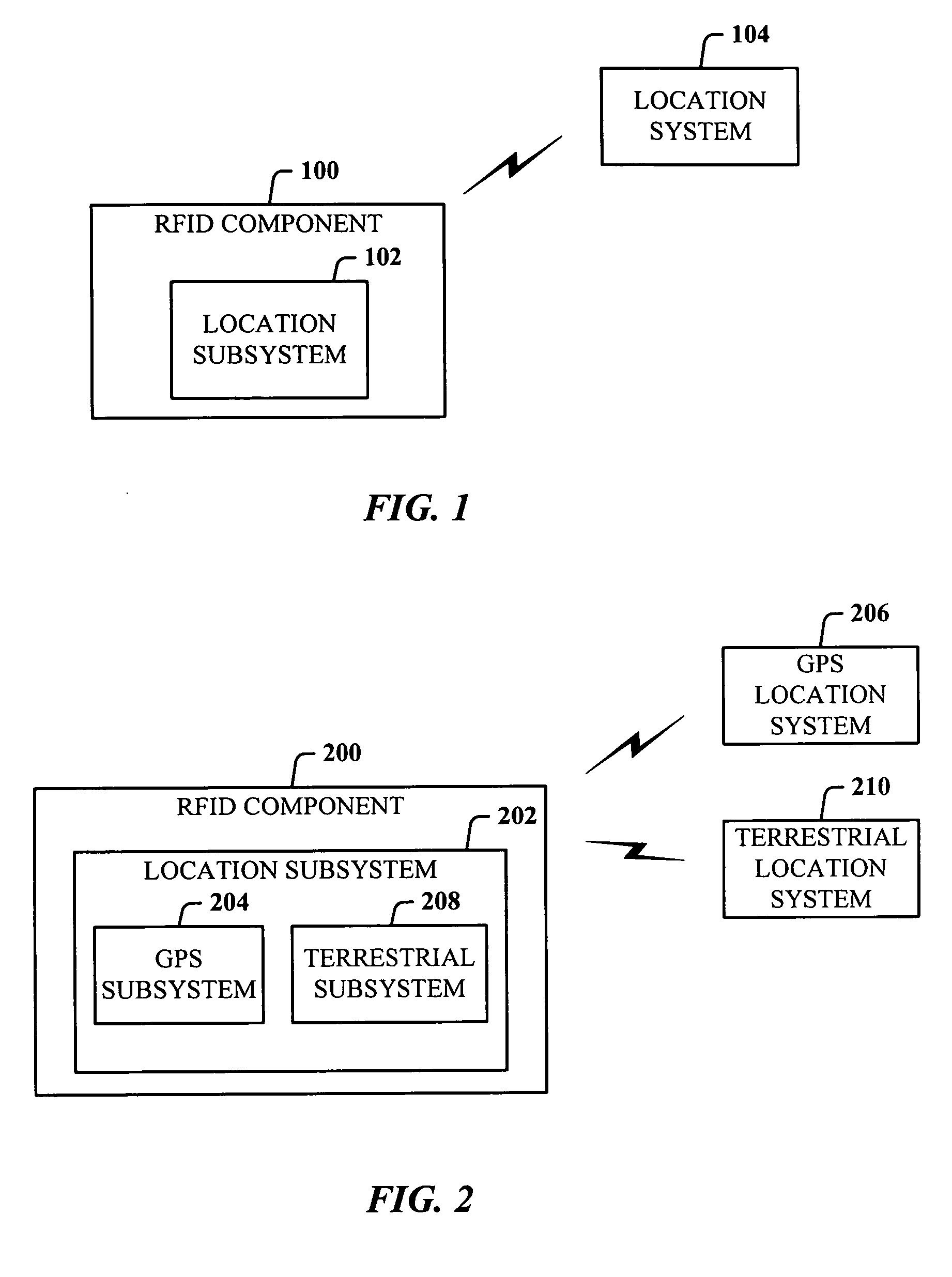

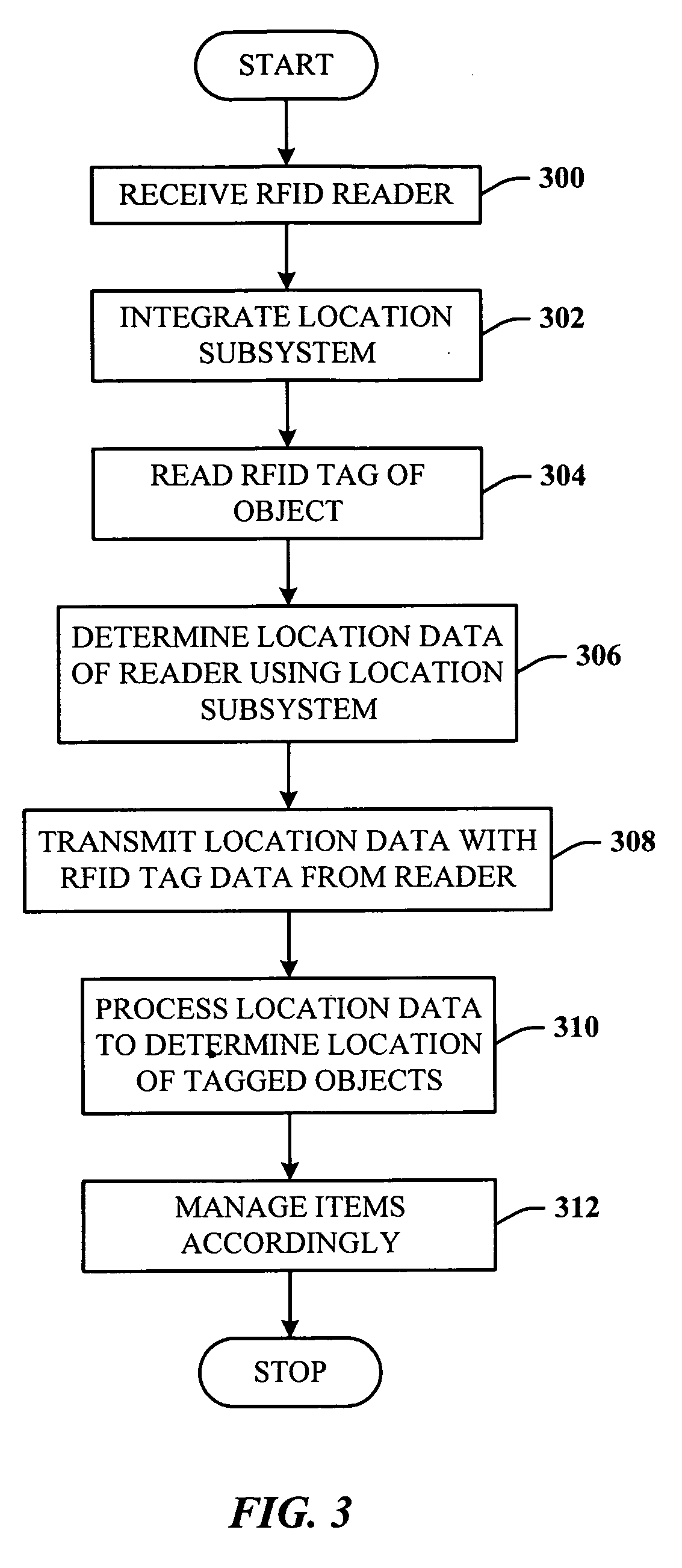

A portable RFID reader (or reader / writer) that also employs a location determination subsystem that facilitates determination of the reader (or reader / writer) location. The location subsystem can employ a satellite-based GPS (Global Positioning System) location technology where such signals are unimpeded by structures. Additionally, the location subsystem can employ other terrestrial location technologies that operate inside structures such as warehouses and the factory automation environment.

Owner:ROCKWELL AUTOMATION TECH

Computer integrated manufacturing techniques

InactiveUS7069101B1Process Control OptimizationQuality improvementData processing applicationsSemiconductor/solid-state device manufacturingConsequence analysisManufacturing technology

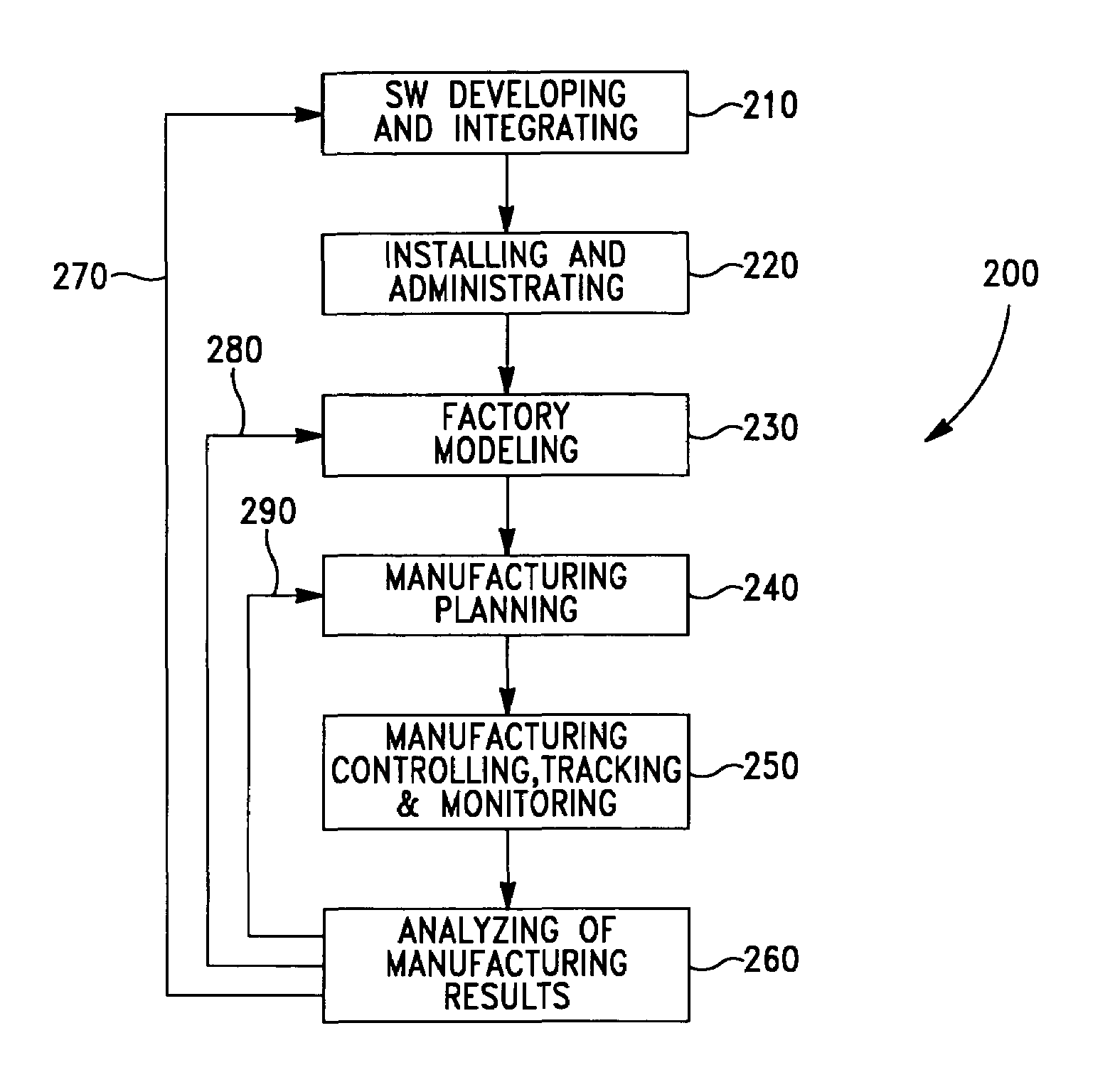

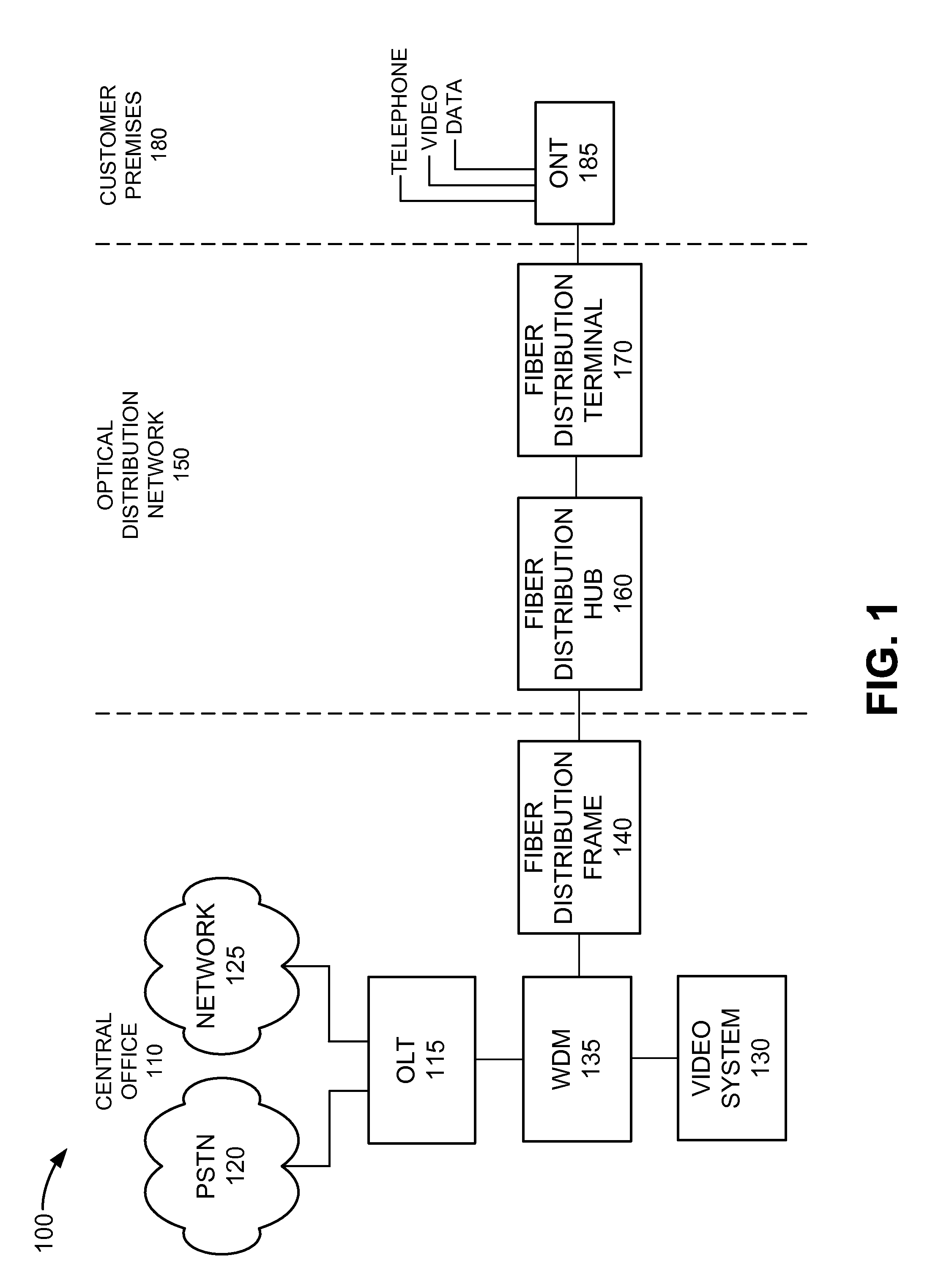

The present invention provides a novel distributed factory system framework including a novel factory automation lifecycle (200) having lifecycle activities for SW developing and integrating (210), installing and administrating (220), factory modeling (230), manufacturing planning (240), manufacturing controlling, monitoring and tracking (250) and analyzing of manufacturing results (260). The factory lifecycle comprises framework components. The distributed factory system framework also includes application components and software building blocks. The framework components are adapted for managing the application components, while the application components are utilized to provide instructions for managing a process such as a wafer fab. The building blocks are adapted for forming or modifying framework and application components. The distributed factory system framework provides computer implemented methods for integrating processing systems and facilitates process and equipment changes.

Owner:APPLIED MATERIALS INC

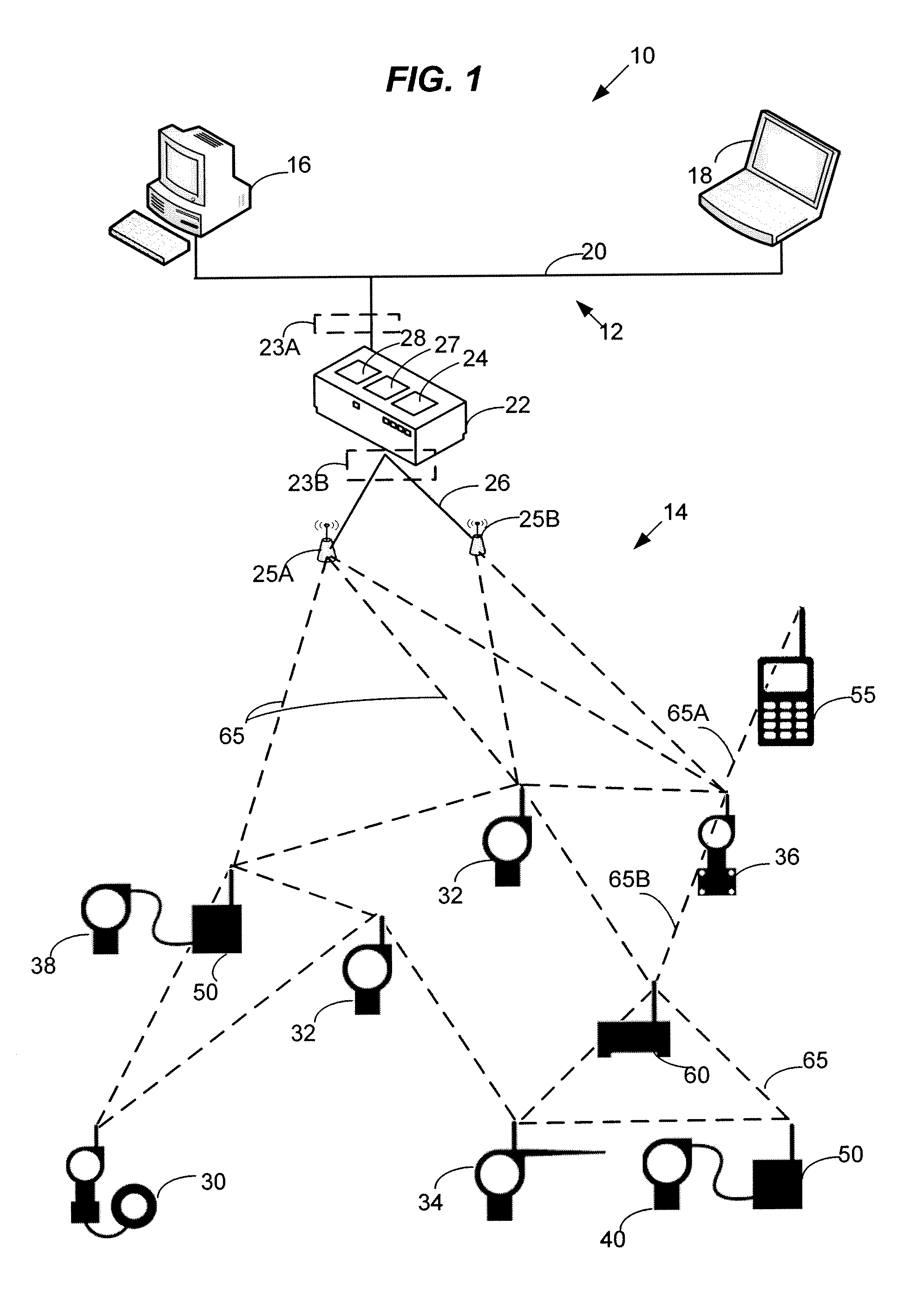

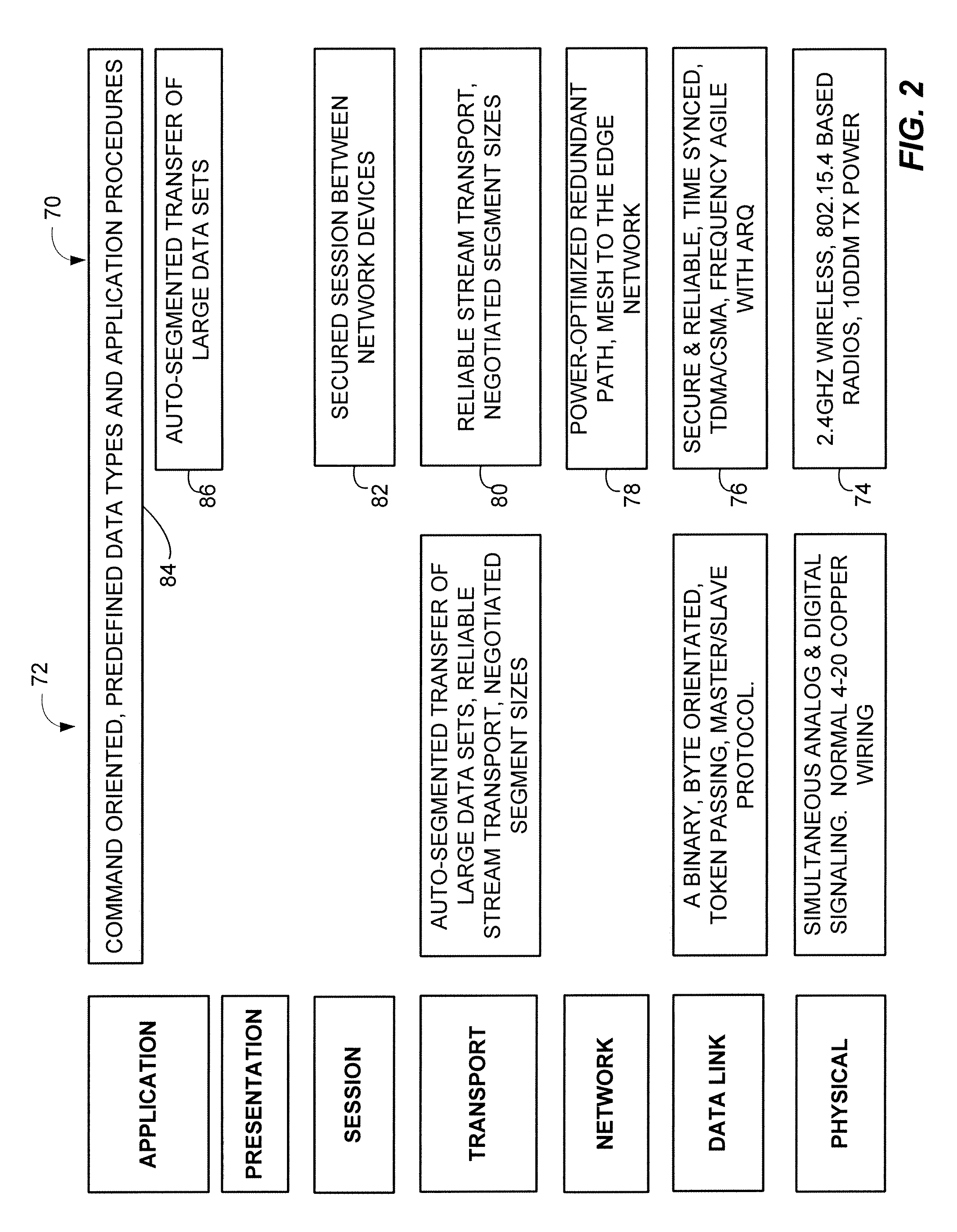

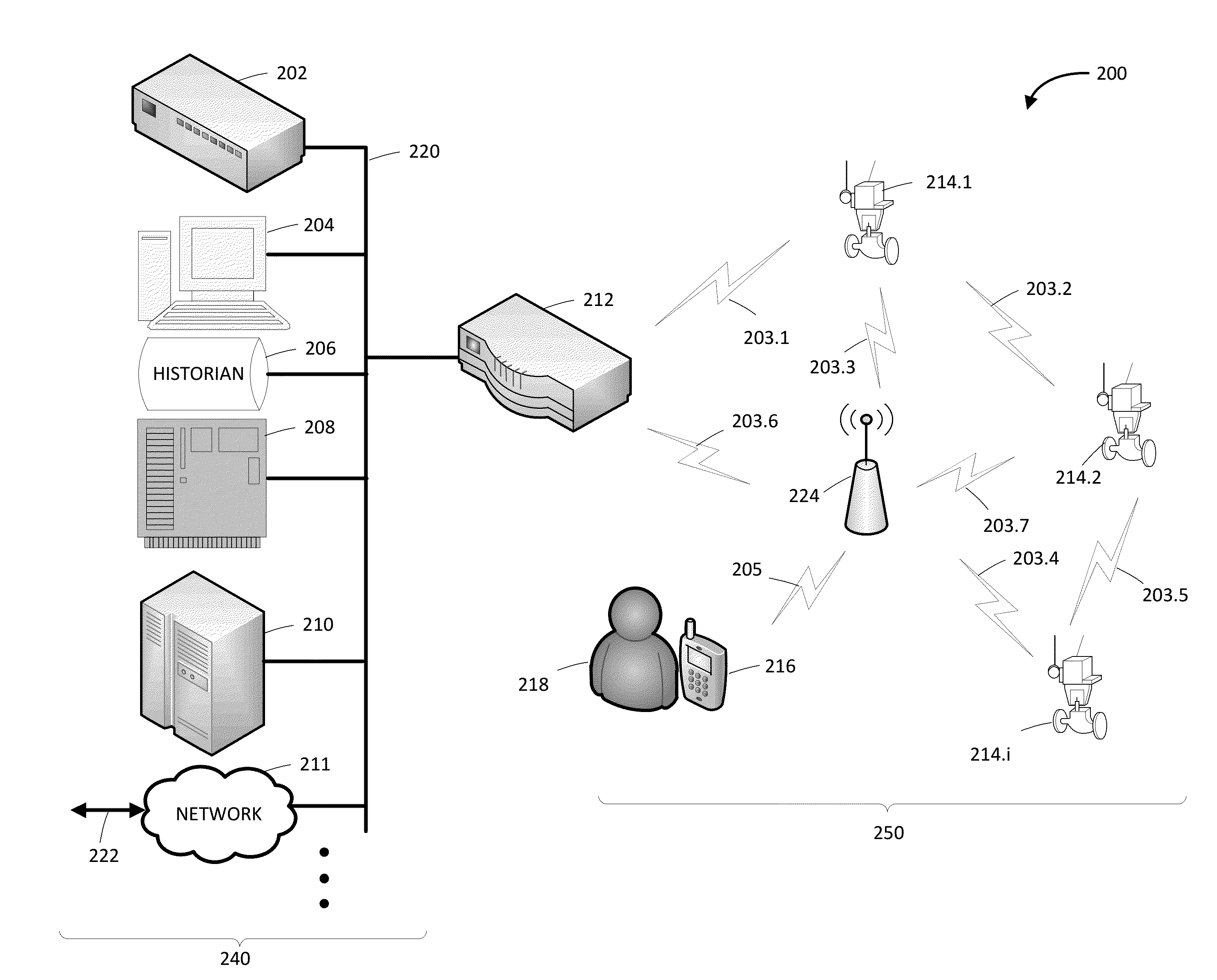

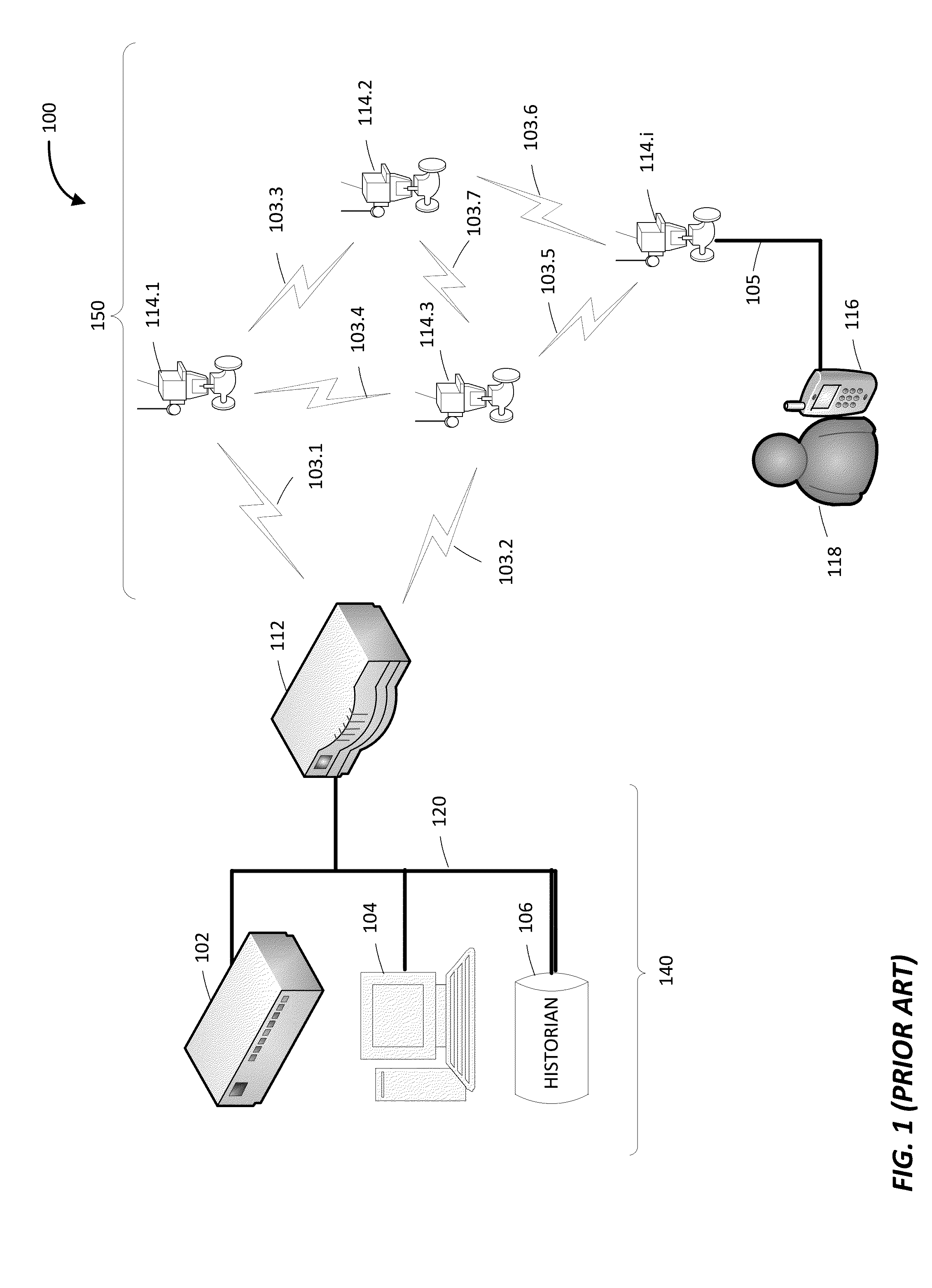

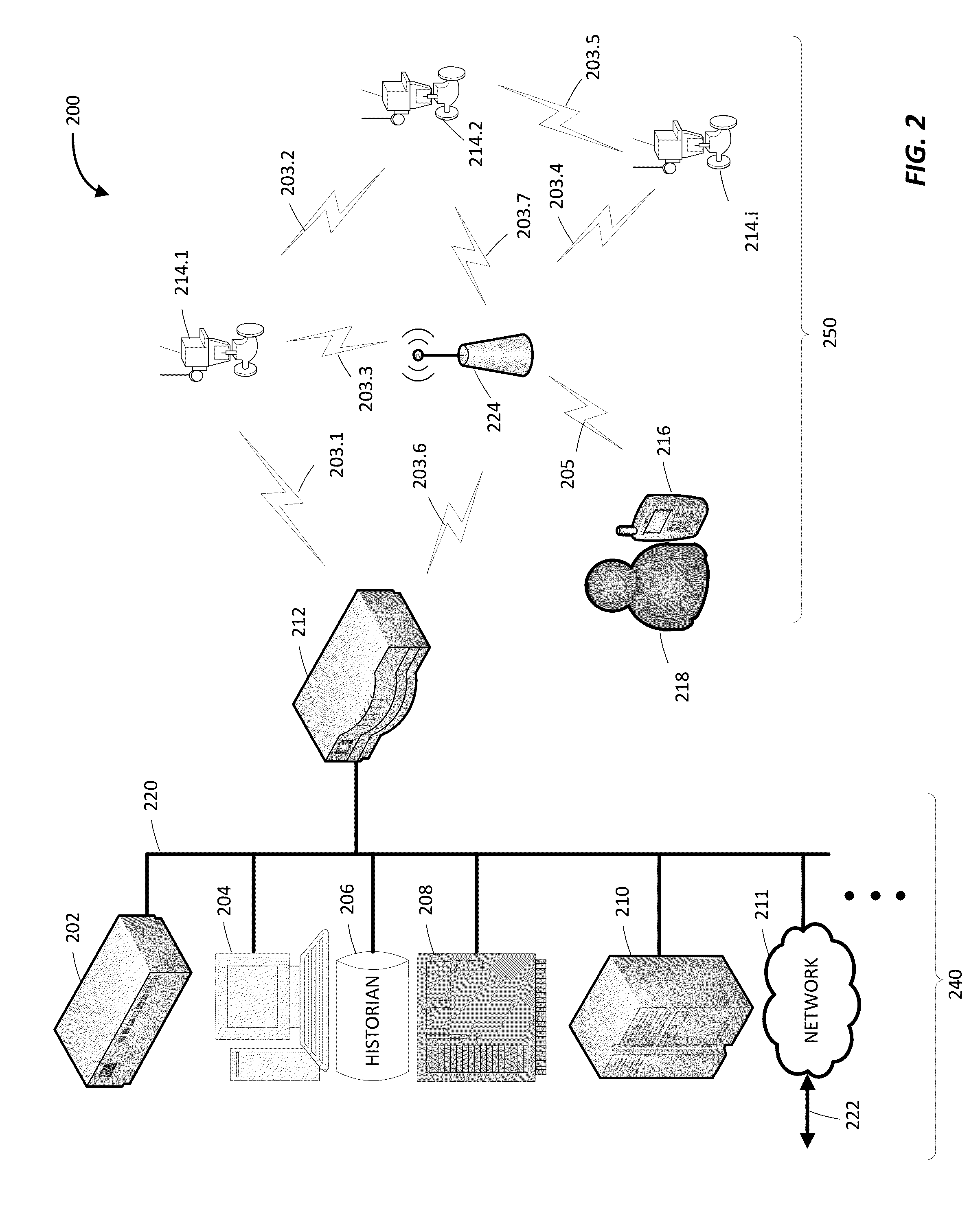

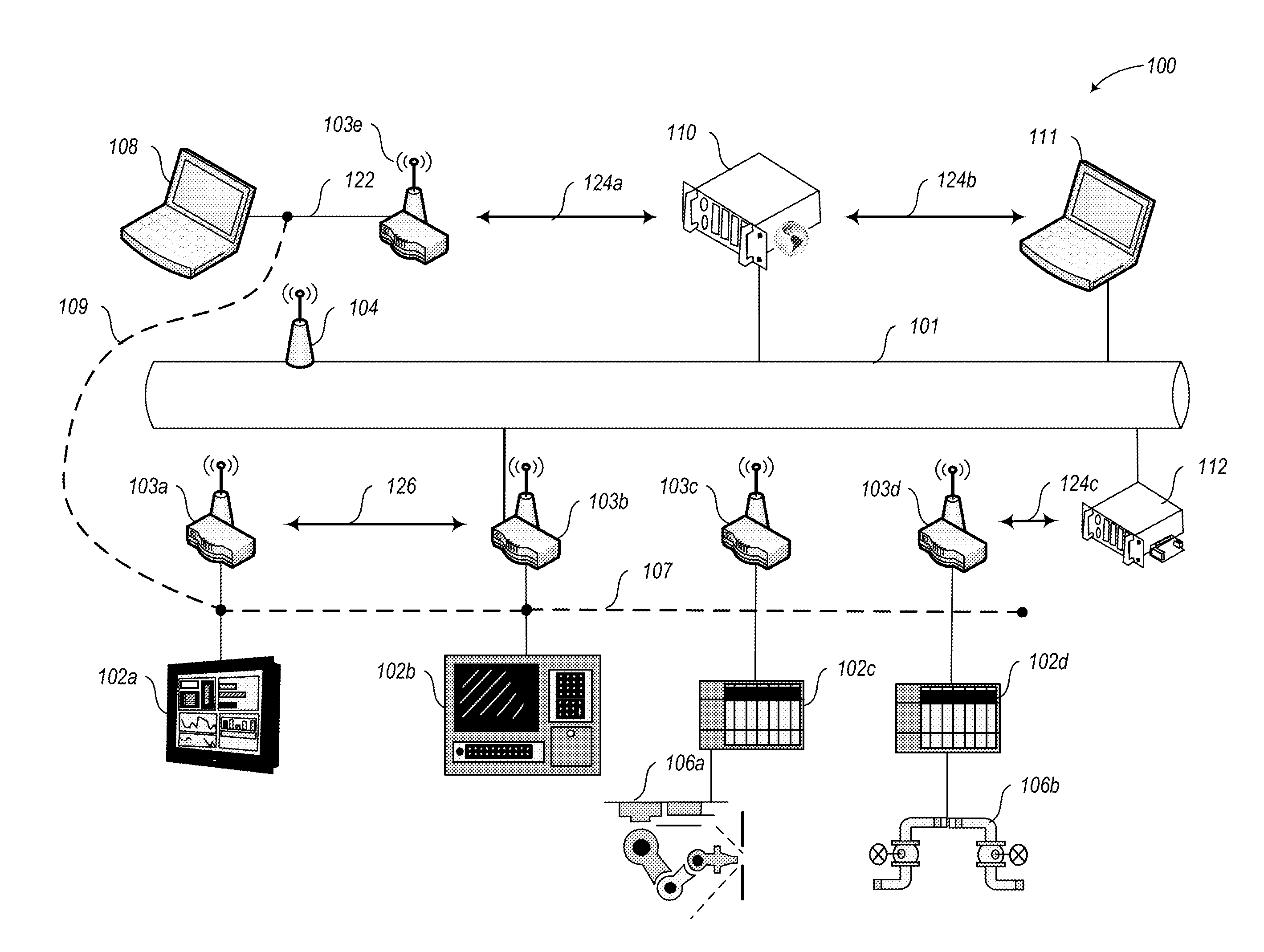

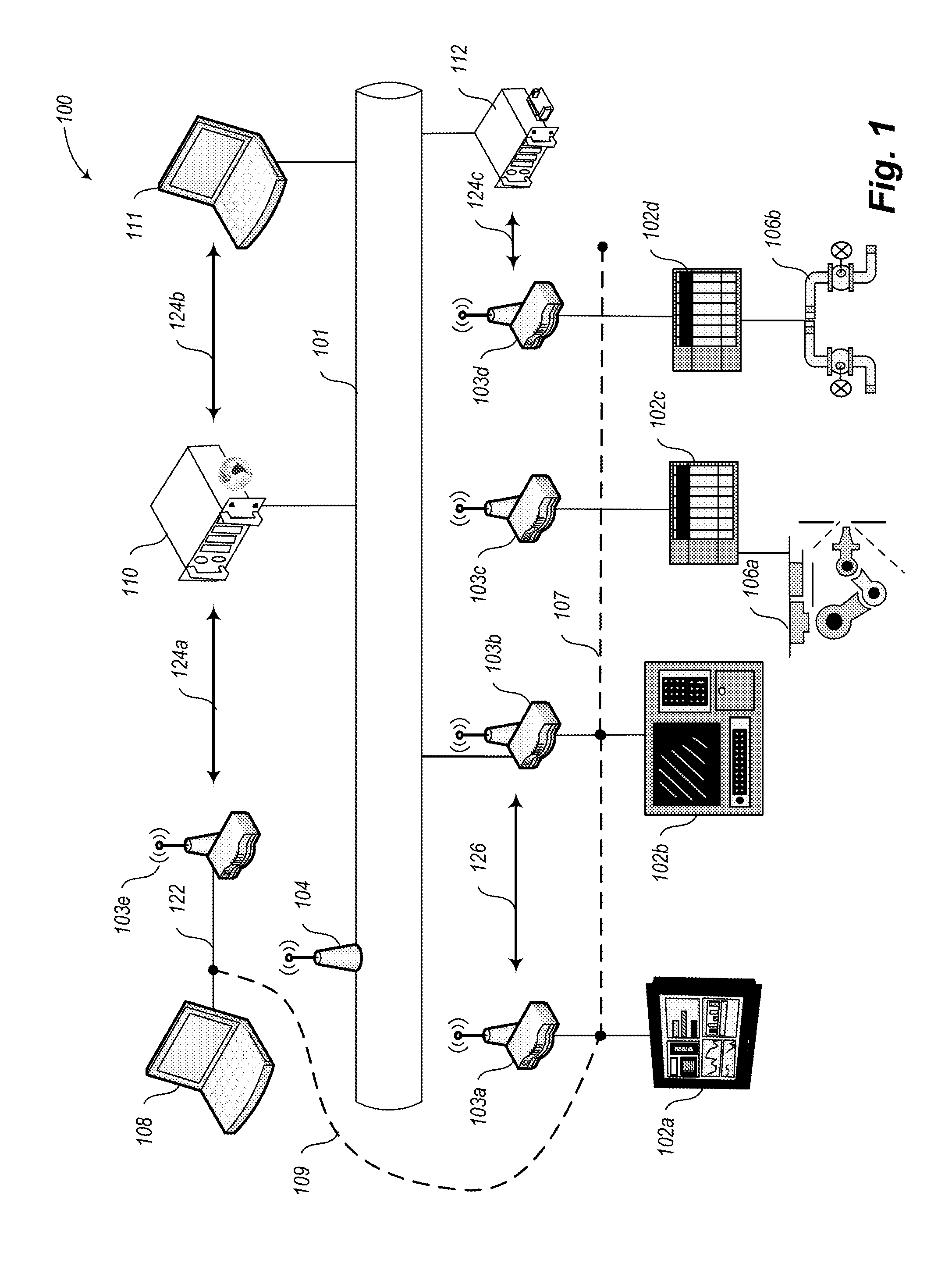

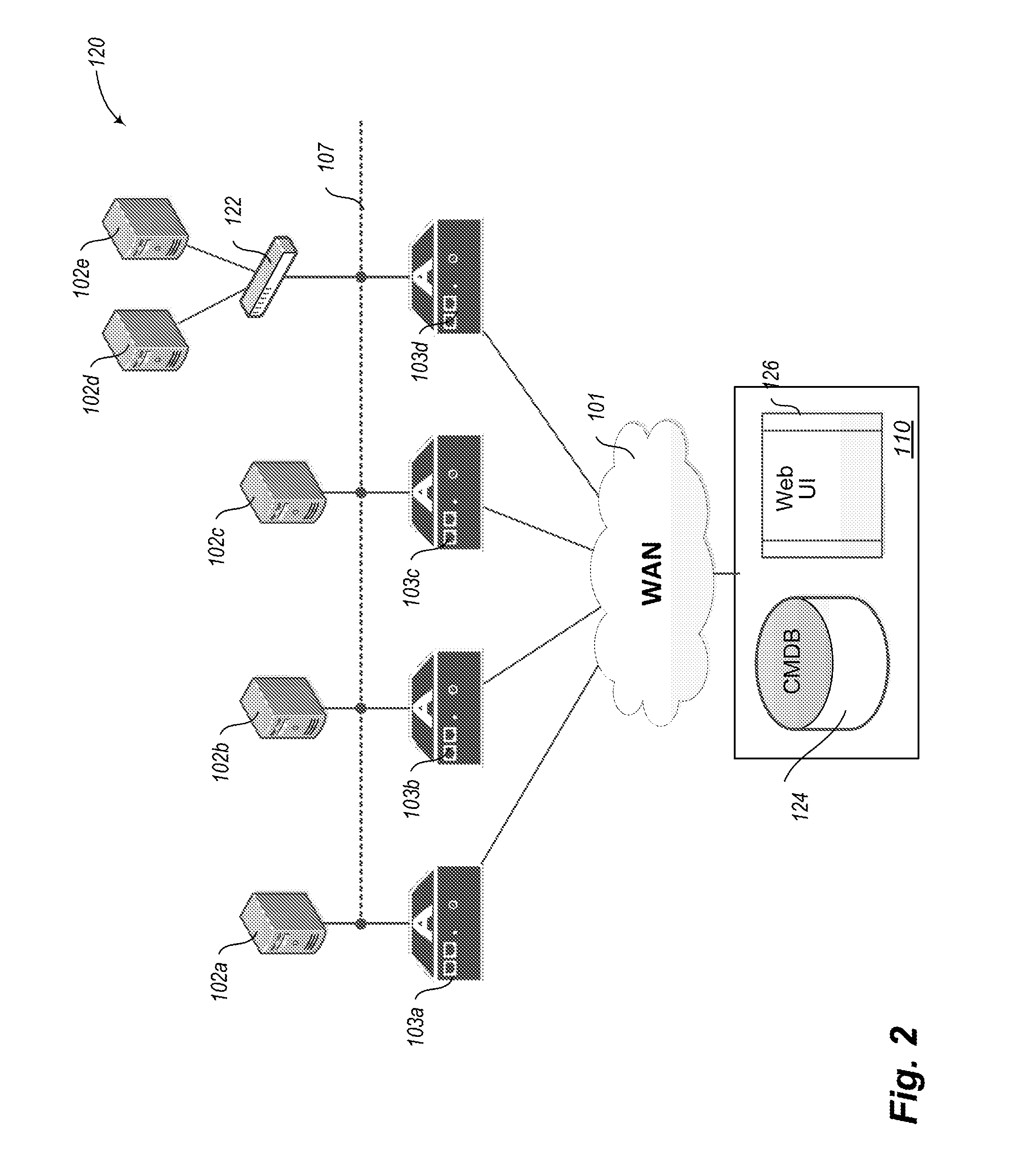

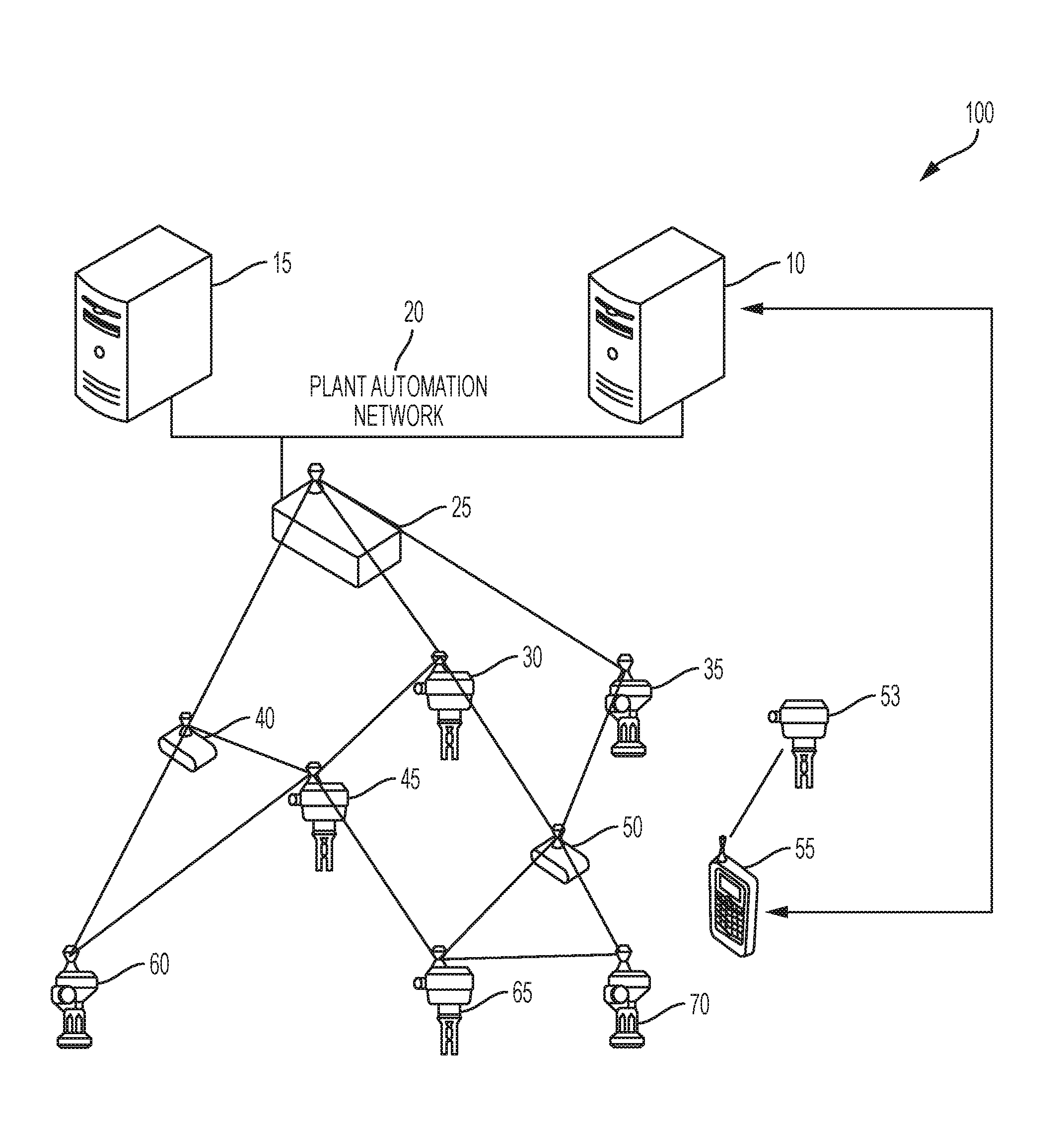

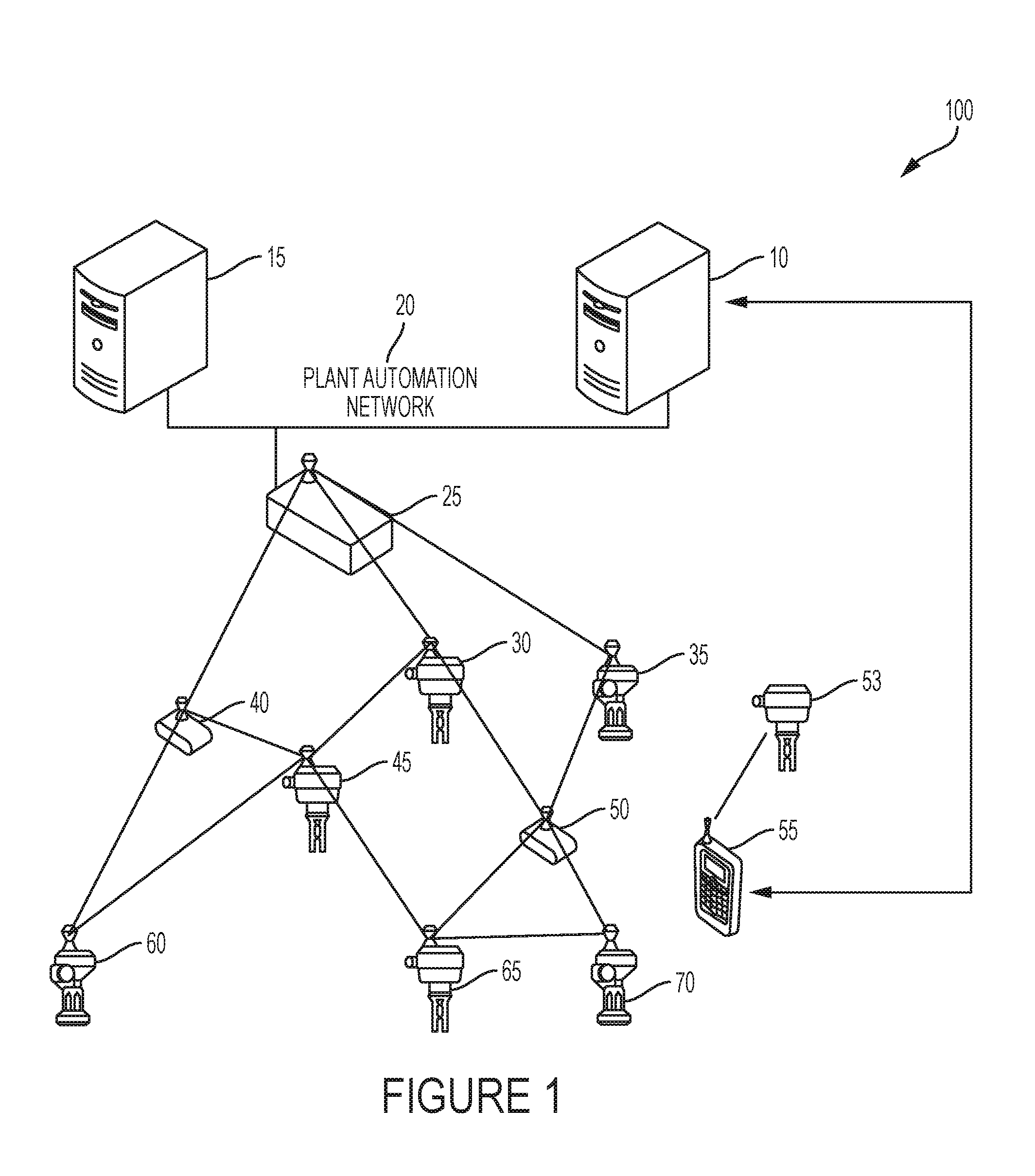

Combined Wired and Wireless Communications with Field Devices in a Process Control Environment

A method of providing a wireless extension to a plant automation network connected to a plurality of wired devices, each wired device performing a process control function, includes connecting a plurality of wireless devices to the plant automation network, each of the plurality of wireless devices adapted to communicate with at least another one of the plurality of wireless devices via at least one respective wireless connection; and providing access to each of the plurality of wireless devices from a host disposed in the plant automation network, such that the host accesses the plurality of wired devices and the plurality of wireless devices using a common communication scheme.

Owner:FIELDCOMM GRP INC

Mobile RFID reader with integrated location awareness for material tracking and management

ActiveUS20080278328A1Accurately determineMemory record carrier reading problemsNavigation instrumentsLocation awarenessGlobal Positioning System

Owner:ROCKWELL AUTOMATION TECH

Mobile RFID reader with integrated location awareness for material tracking and management

ActiveUS7388491B2Accurately determineMemory record carrier reading problemsNavigation instrumentsLocation awarenessGlobal Positioning System

A portable RFID reader (or reader / writer) that also employs a location determination subsystem that facilitates determination of the reader (or reader / writer) location. The location subsystem can employ a satellite-based GPS (Global Positioning System) location technology where such signals are unimpeded by structures. Additionally, the location subsystem can employ other terrestrial location technologies that operate inside structures such as warehouses and the factory automation environment.

Owner:ROCKWELL AUTOMATION TECH

Computer integrated manufacturing techniques

InactiveUS7174230B2Data processing applicationsSemiconductor/solid-state device manufacturingConsequence analysisManufacturing technology

The present invention provides a novel distributed factory system framework including a novel factory automation lifecycle (200) having lifecycle activities for SW developing and integrating (210), installing and administrating (220), factory modeling (230), manufacturing planning (240), manufacturing controlling, monitoring and tracking (250) and analyzing of manufacturing results (260). The factory lifecycle comprises framework components. The distributed factory system framework also includes application components and building blocks. The framework components are adapted to for managing the application components, while the application components are utilized to provide instructions for managing a process such as a wafer fab. The building blocks are adapted for forming or modifying framework and application components. The distributed factory system framework provides computer implemented methods for integrating processing systems and facilitates process and equipment changes.

Owner:APPLIED MATERIALS INC

Multi-protocol device supporting wireless plant protocols

ActiveUS20160100437A1Easy to optimizeReceivers monitoringError preventionWireless Application ProtocolThe Internet

A plant wireless access point (PWAP) is disclosed that bridges communications between a field communicator and a plant automation network. The PWAP may facilitate provisioning of new plant devices into a plant automation wireless network using the field communicator, and may also facilitate the field communicator performing various functions regarding one or more plant devices connected to the plant automation network. The PWAP may allow a field communicator to access information from the plant automation network and / or from other sources via the plant automation network such as the Internet. In addition, the PWAP may determine a location of one or more field communicators relative to the PWAP and / or other devices connected to the plant automation network.

Owner:FISHER-ROSEMOUNT SYST INC

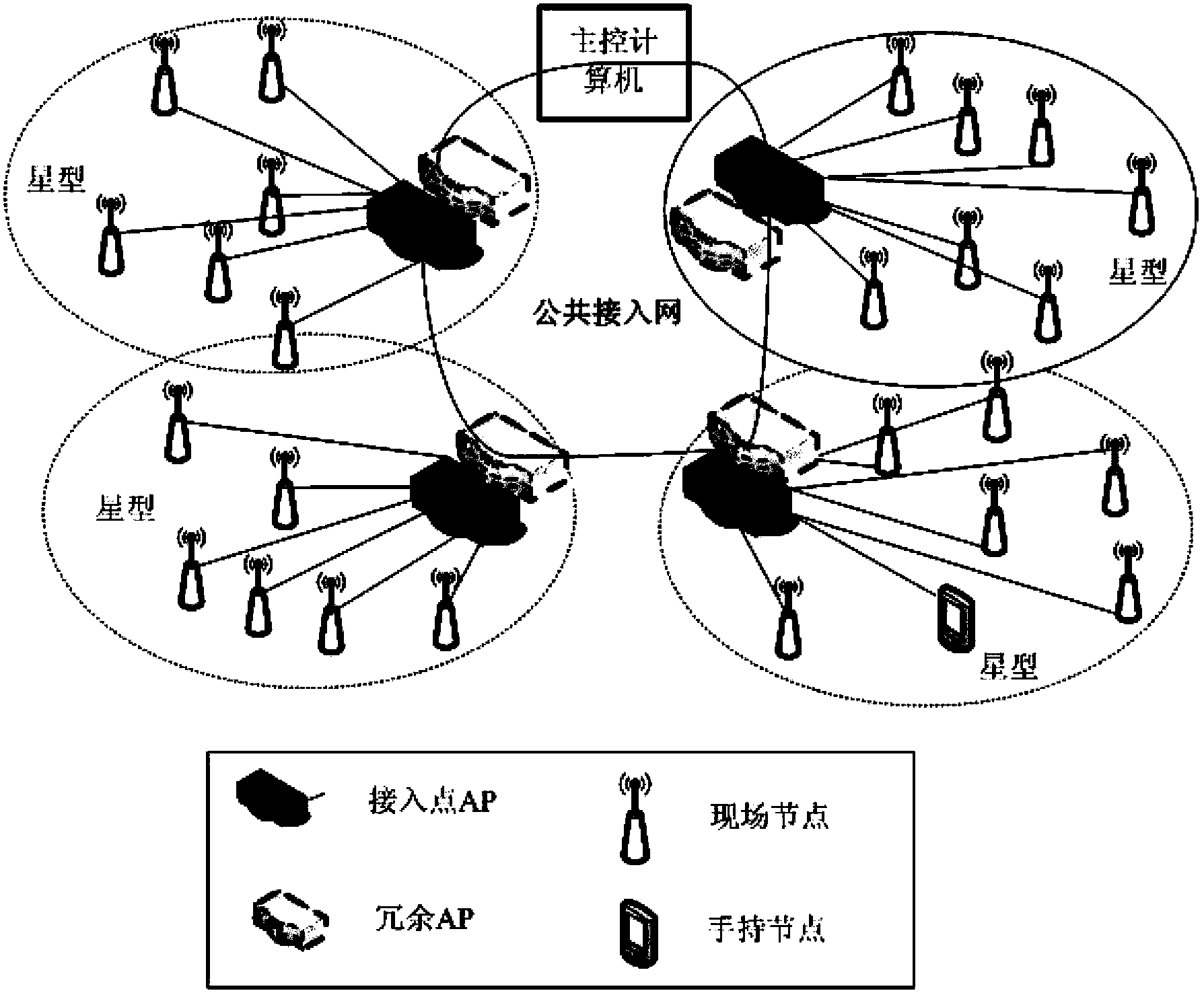

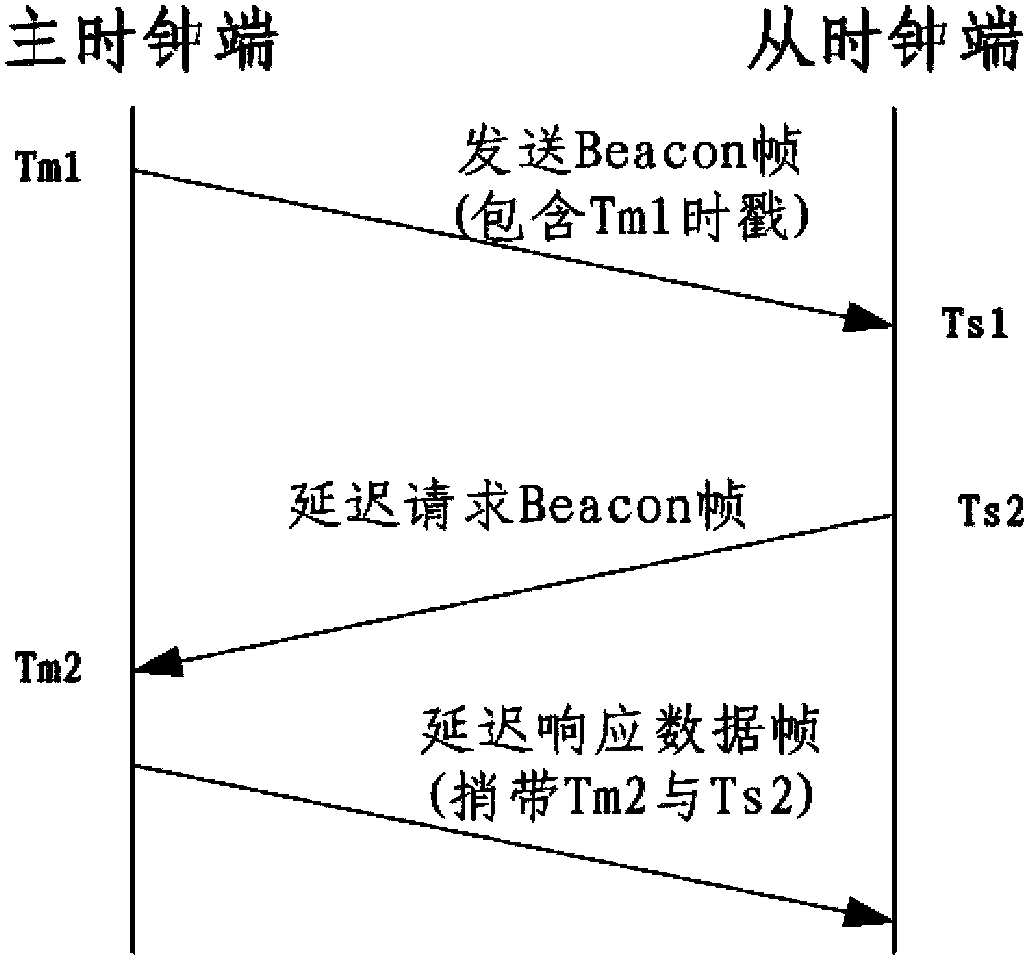

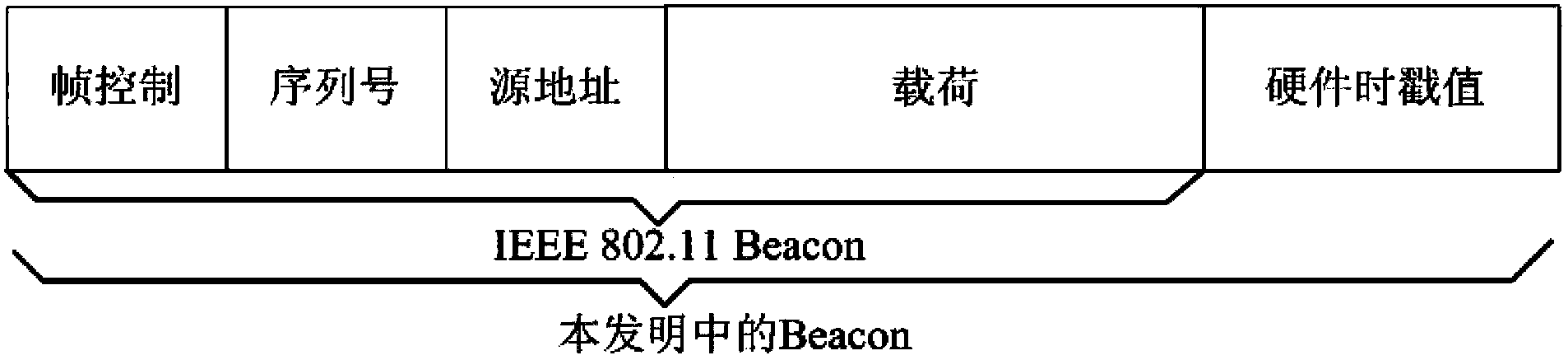

Method for precisely synchronizing time of industrial wireless network on basis of prediction and compensation

The invention relates to technologies for industrial wireless networks, in particular to a method for precisely synchronizing time of an industrial wireless network on the basis of prediction and compensation. The method includes constructing the factory-automation-oriented industrial wireless network into a star network on the basis of an IEEE (institute of electrical and electronics engineers) 802.11 single-hop basic service set (BBS) structure; setting a master clock and slave clocks according to types and functions of nodes in the industrial wireless network; enabling a master clock side and slave clock sides to interact with one another via two-way timestamp information and computing a time deviation value of a current synchronizing cycle; predicting a time deviation value of a next synchronizing cycle by the aid of the time deviation value of the current synchronizing cycle; compensating clock drift by the aid of the predicted time deviation value of the next synchronizing cycle and correcting the clocks. The method has the advantages that the method is implemented on the premise that application requirements of factory automation are sufficiently considered, so that high time synchronization precision can be realized by the aid of few wireless communication resources, and purposes of high precision, high efficiency, low expenditure and easiness in implementation can be achieved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

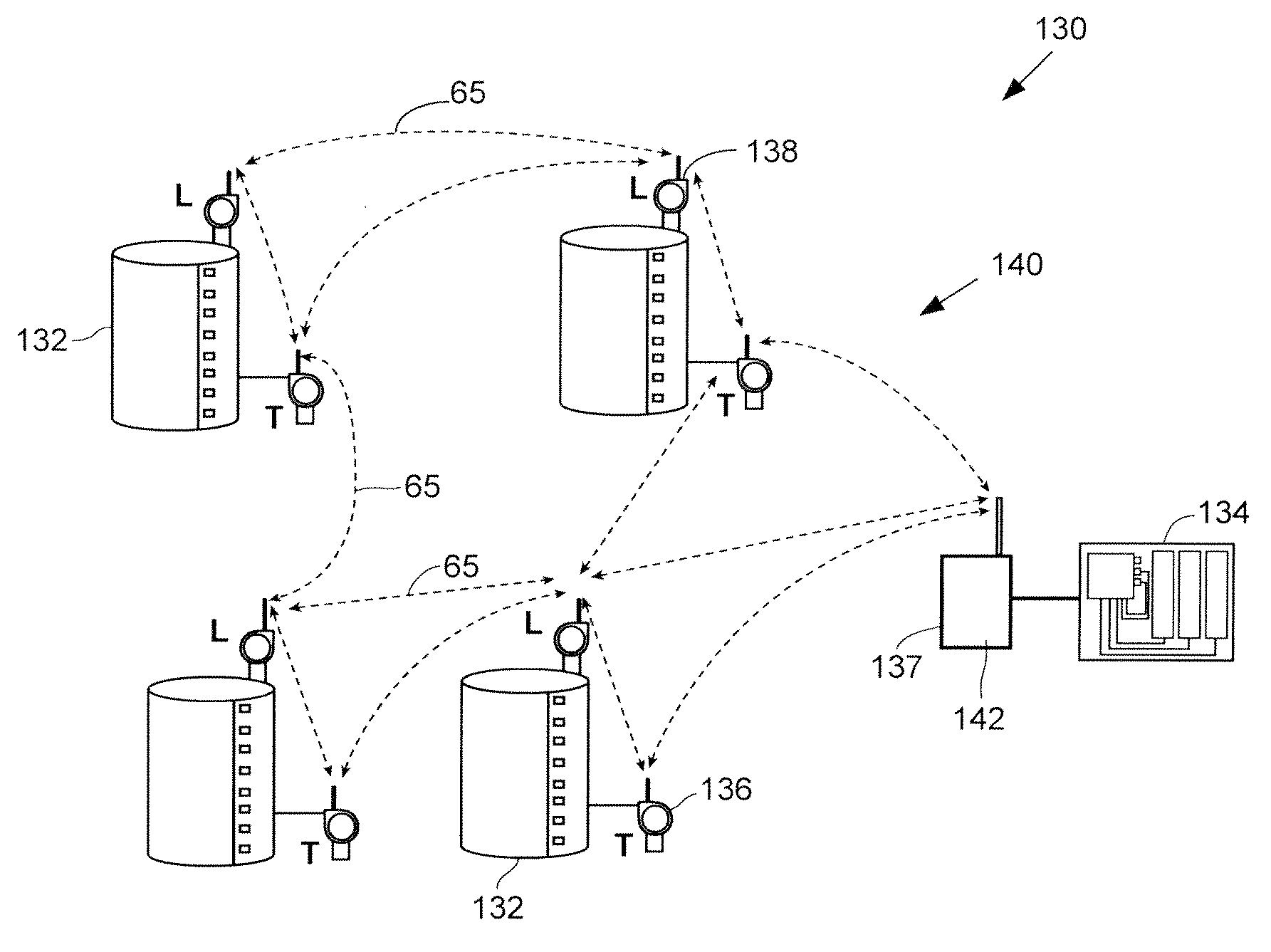

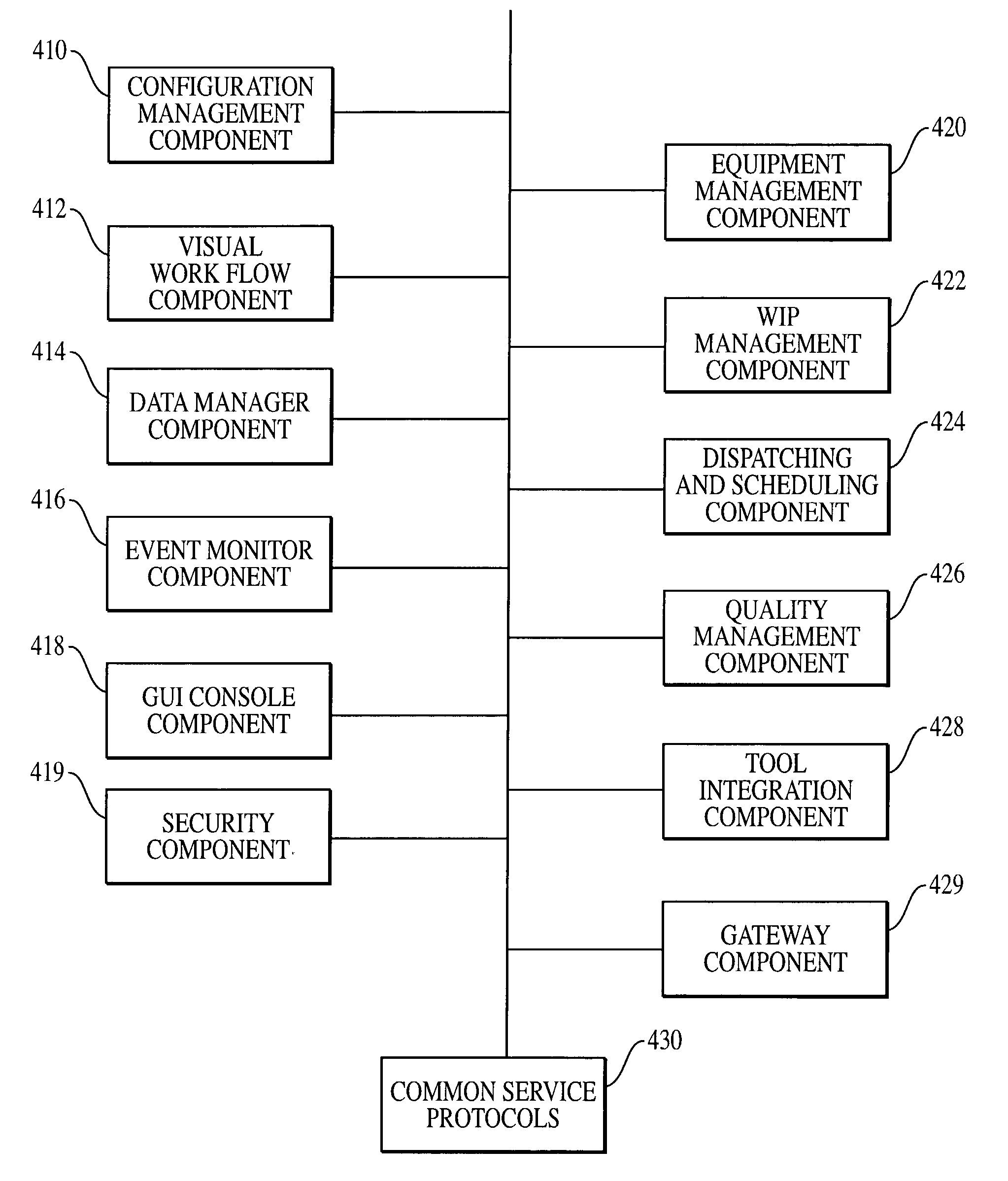

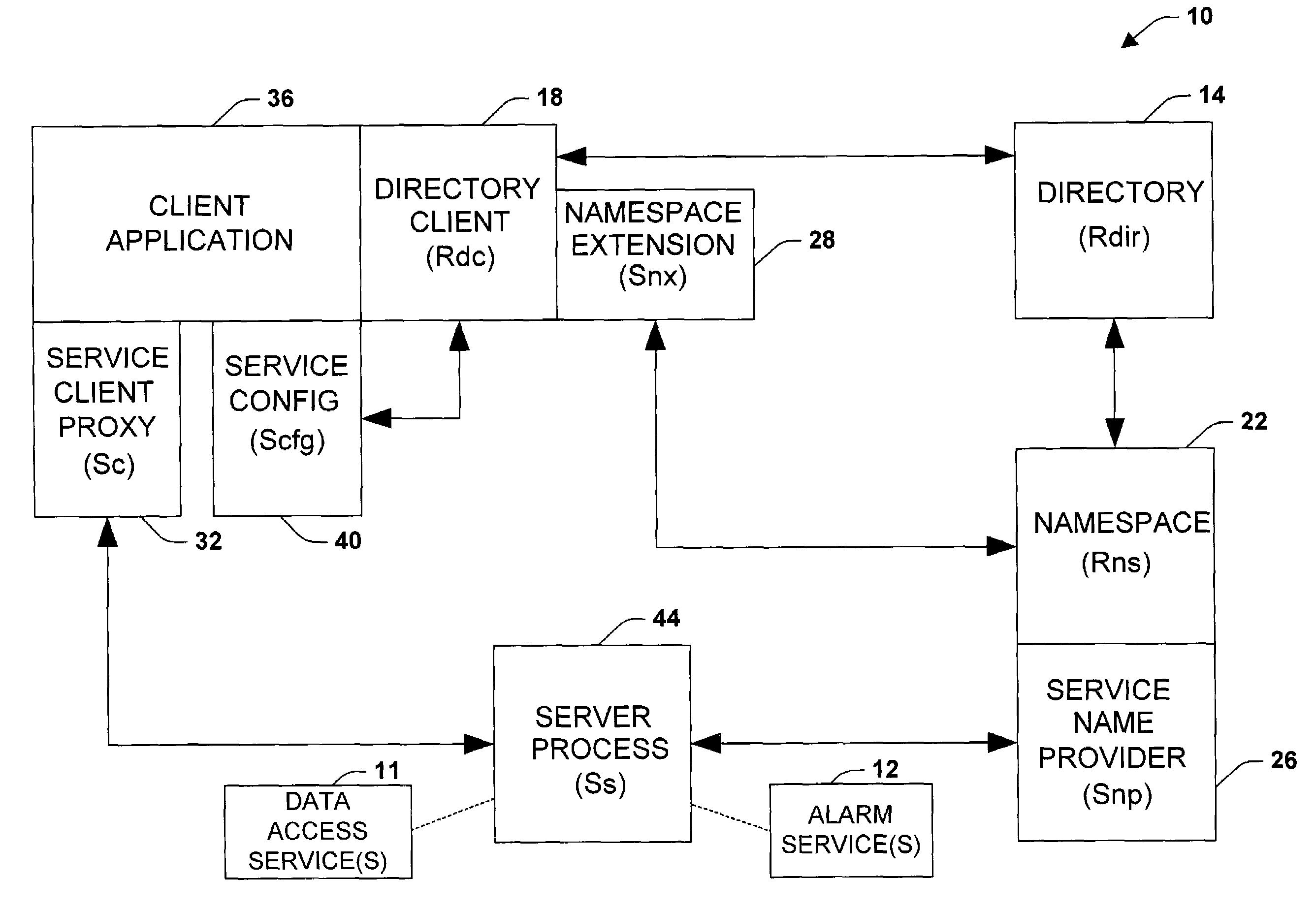

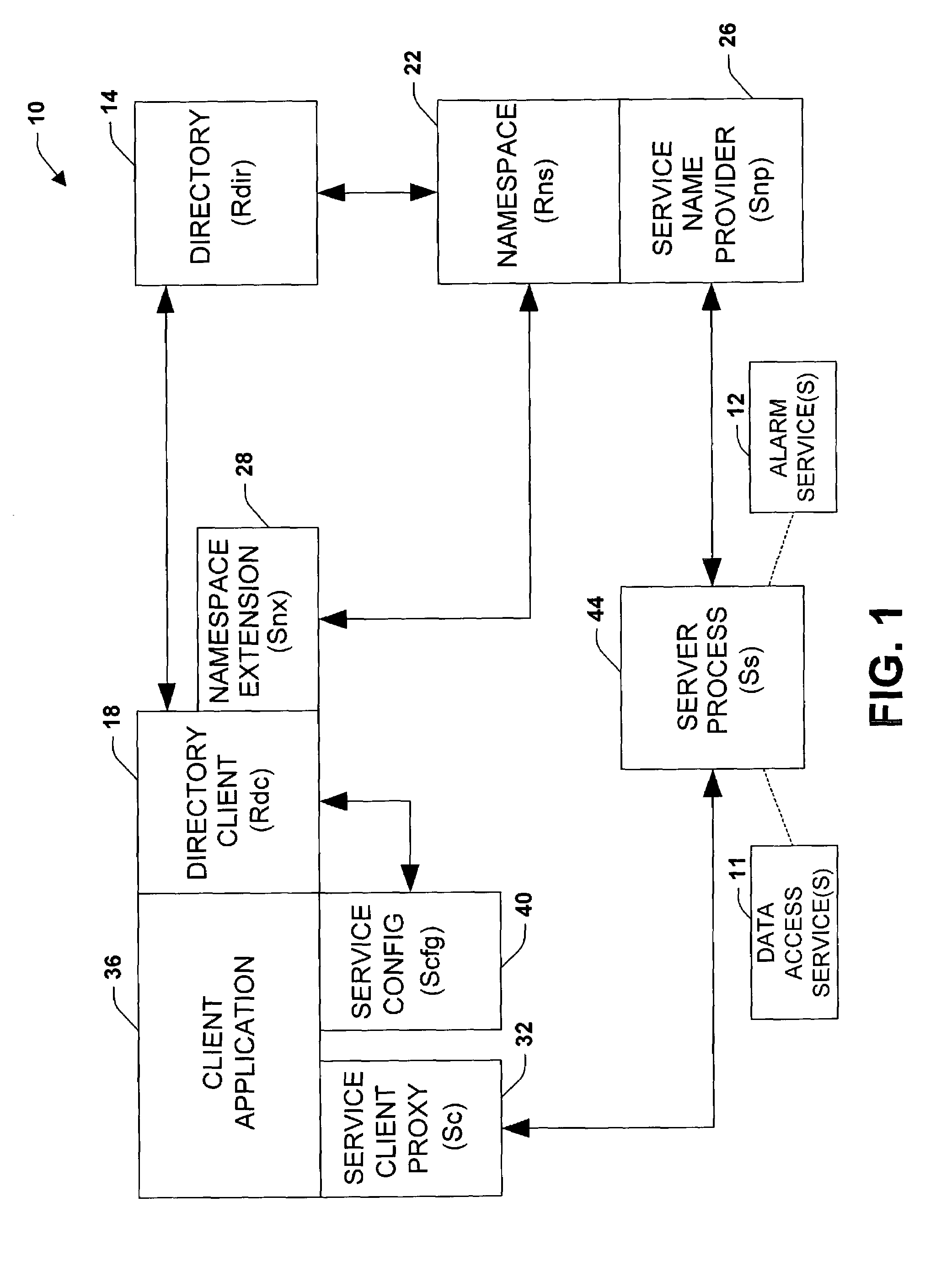

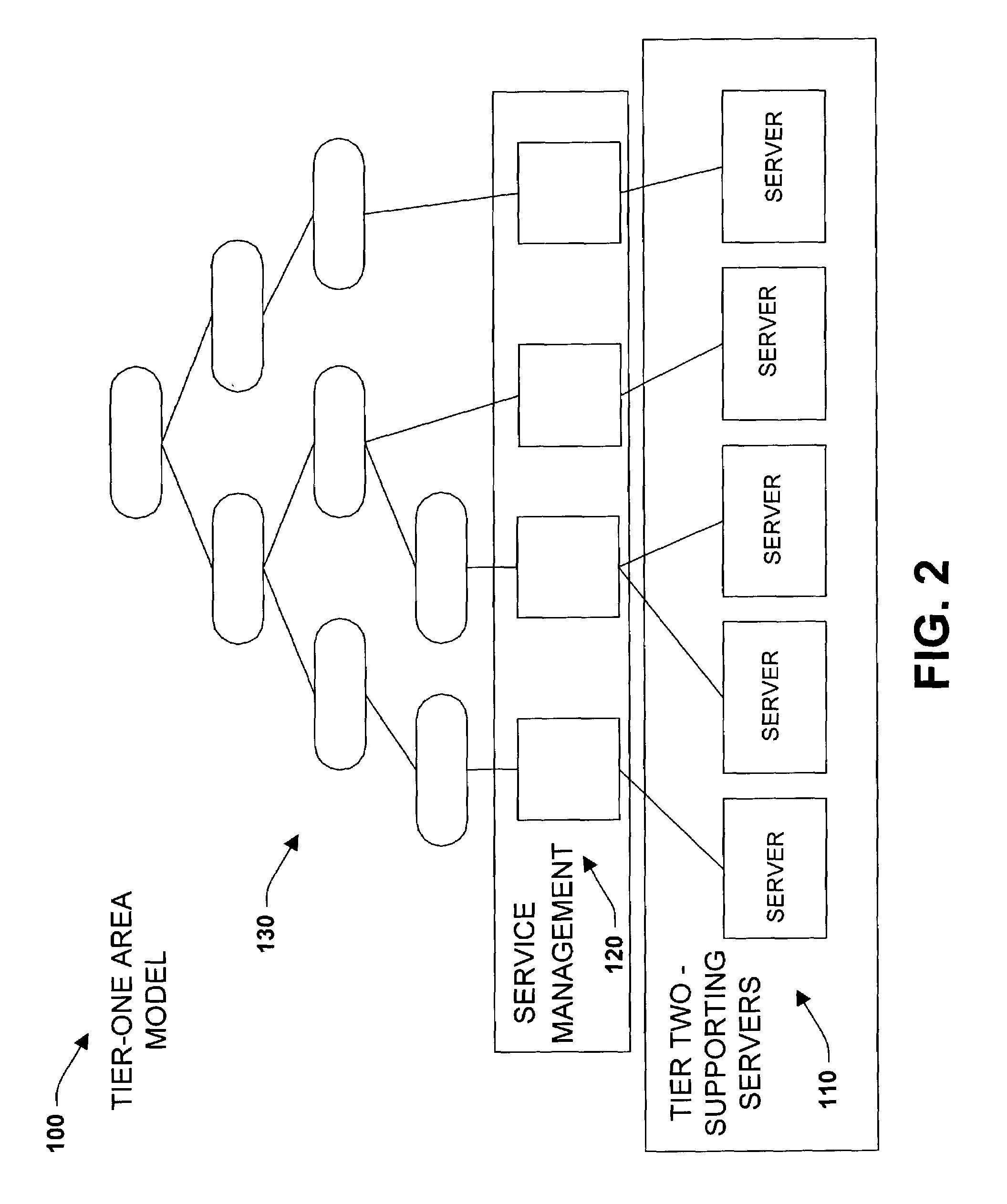

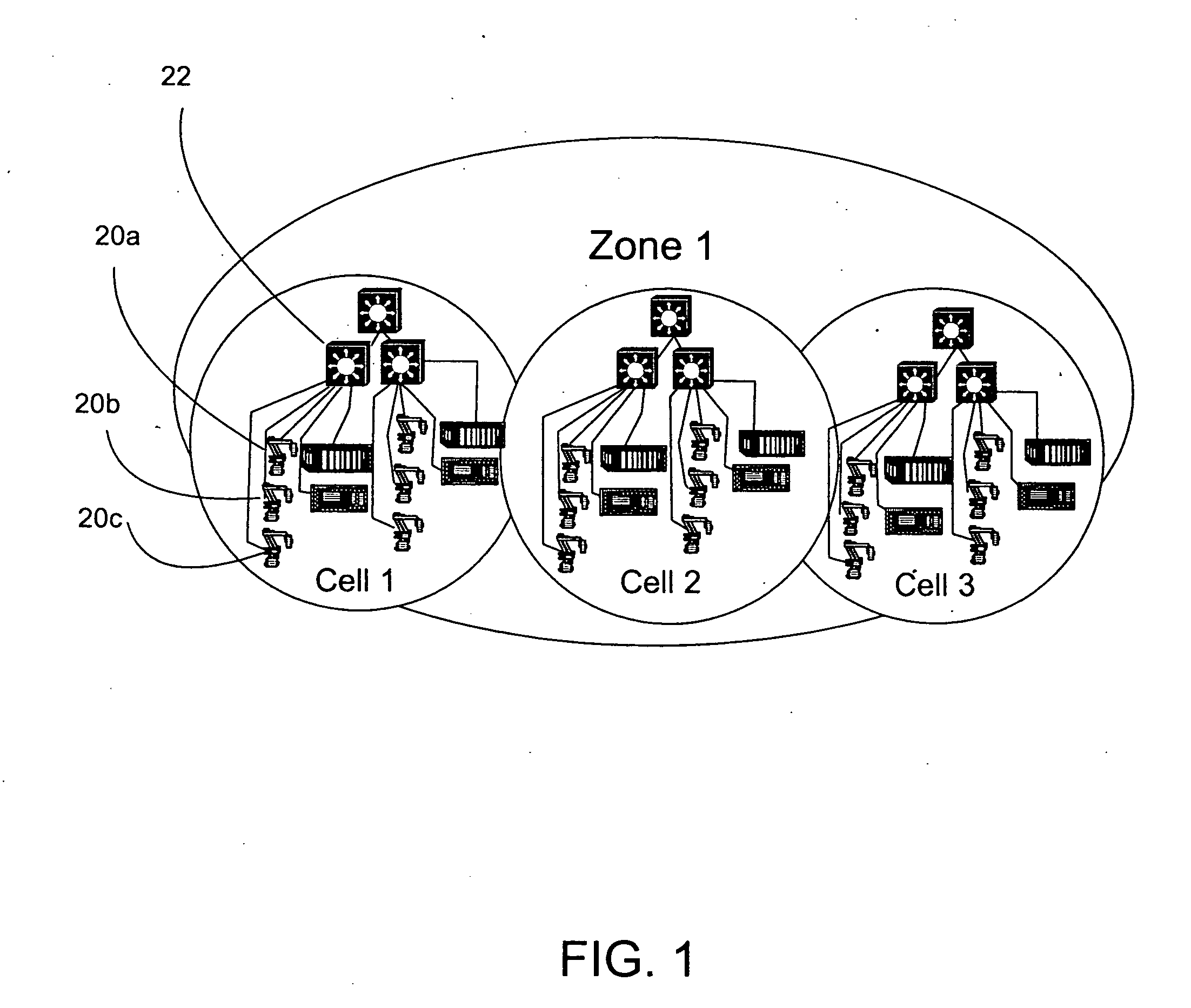

System and methodology that facilitate factory automation services in a distributed industrial automation environment

The present invention relates to a system and methodology providing automation services in a distributed industrial controller environment. In one aspect of the present invention, a data access service is provided that includes, sending and receiving data to and from a data access service namespace operative in the distributed controller environment. In another aspect of the present invention, an alarming service is provided wherein data values are monitored in a server component according to predetermined conditions configured by a user or other entity. If the data values are determined to be outside of boundaries as defined by the predetermined conditions, an alarm can be communicated to a plurality of other components cooperating in the distributed environment.

Owner:ROCKWELL SOFTWARE

Industrial network security

ActiveUS20140282850A1Facilitate communicationImprove network securityTransmissionSpecial data processing applicationsIndustrial safety systemNetwork link

A private overlay network is introduced into an existing core network infrastructure to control information flow between private secure environments. Such a scheme can be used to connect a factory automation network linking operations devices to a corporate network linking various business units, with enhanced network security. Such a connection can be facilitated by introducing into the existing infrastructure a set of industrial security appliances (ISAs) that work together to create an encrypted tunnel between the two networks. The set of ISAs can be scalable to overlay differently sized core networks, to create the private overlay network. Connections to the private overlay network can be managed by the ISAs in a distributed fashion, implementing a peer-to-peer dynamic mesh policy. The industrial security system disclosed may be particularly advantageous in environments such as public utility systems, medical facilities, and energy delivery systems.

Owner:TEMPERED NETWORKS

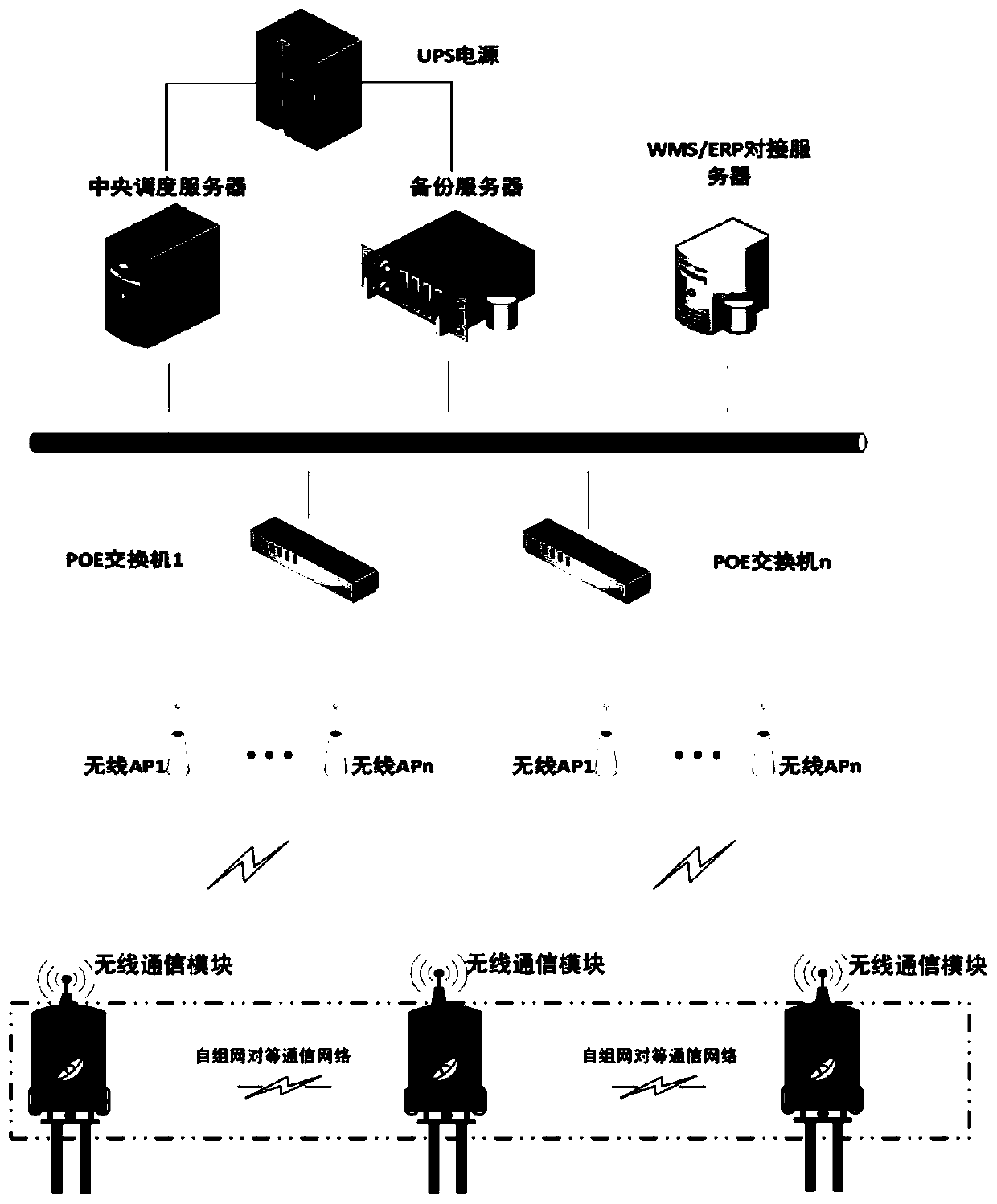

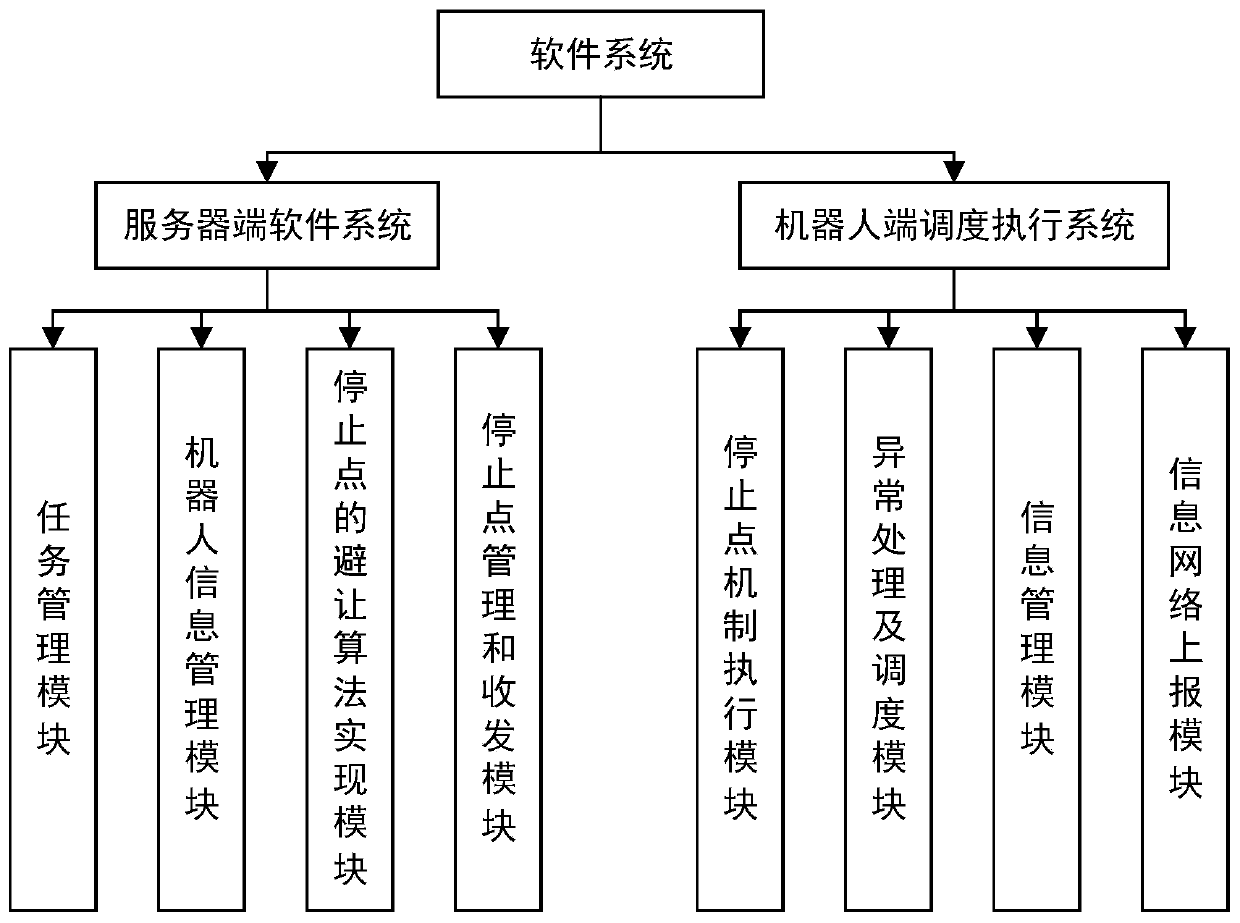

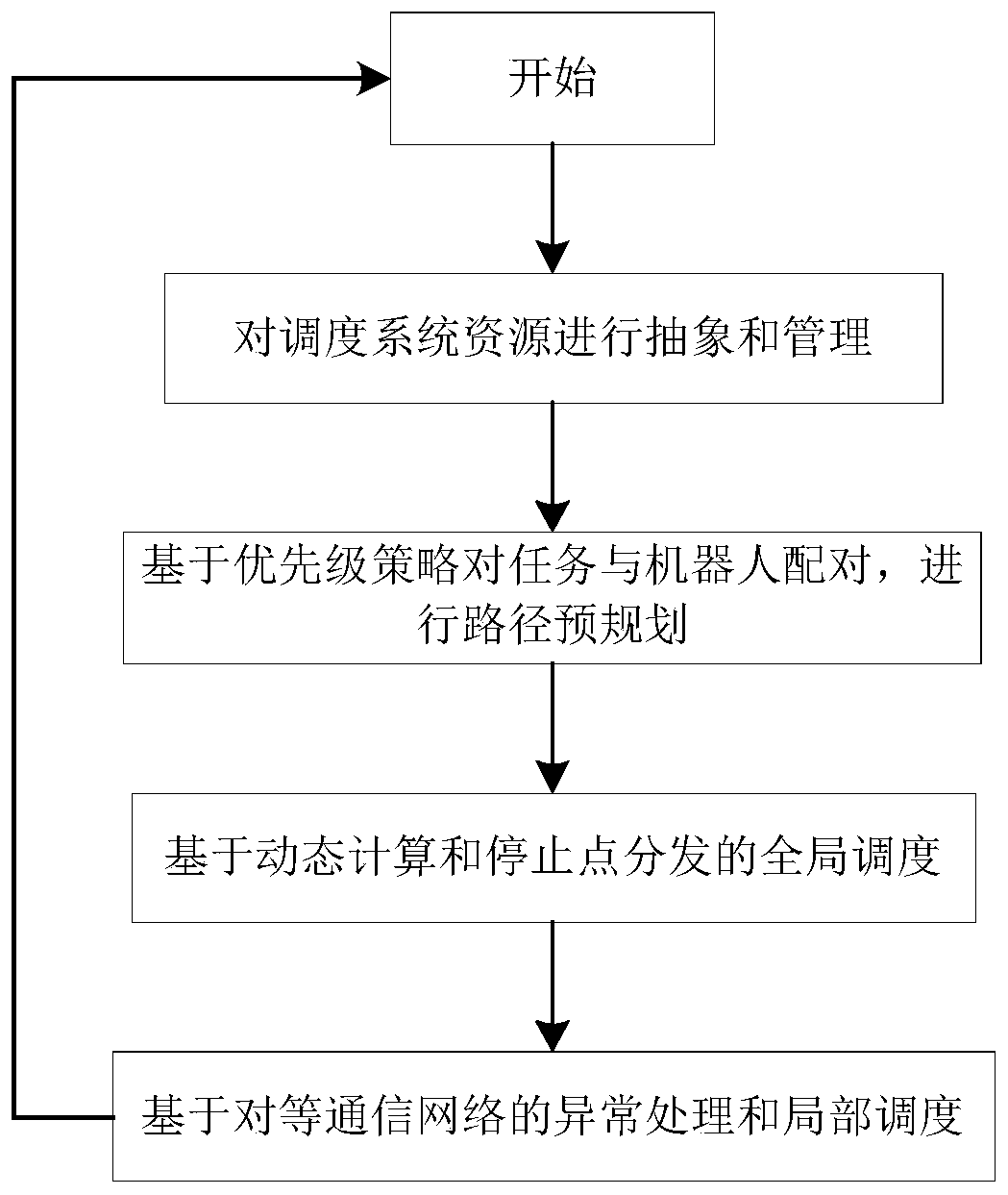

Dynamic avoidance method for multiple robots in collaborative operation

ActiveCN110209485AReduce the avoidance areaReliable designProgram initiation/switchingResource allocationSimulationPlant automation

The invention discloses a dynamic avoidance method for multiple robots in collaborative operation. The method comprises the steps: carrying out the path pre-planning of all tasks in a task pool according to the priorities, and reducing the conflict intervention between robots from a planning layer; monitoring the current operation states of all the robots, dynamically pre-judging the safety distance, generating different types of stop points, coordinating the operation of the robots, and solving the technical problems of collision, delay, interlocking and the like during the cooperative operation of the robots. Overall scheduling is carried out to optimize resource distribution, traffic control and coordinated avoidance are achieved, local peer-to-peer communication solves the overall operation problem after the robot individual is abnormal, and therefore the robustness of the whole scheduling system is guaranteed. The method is suitable for multi-robot scheduling avoidance scenes suchas factory automation and storage commodity transfer.

Owner:青岛海通胜行智能科技有限公司

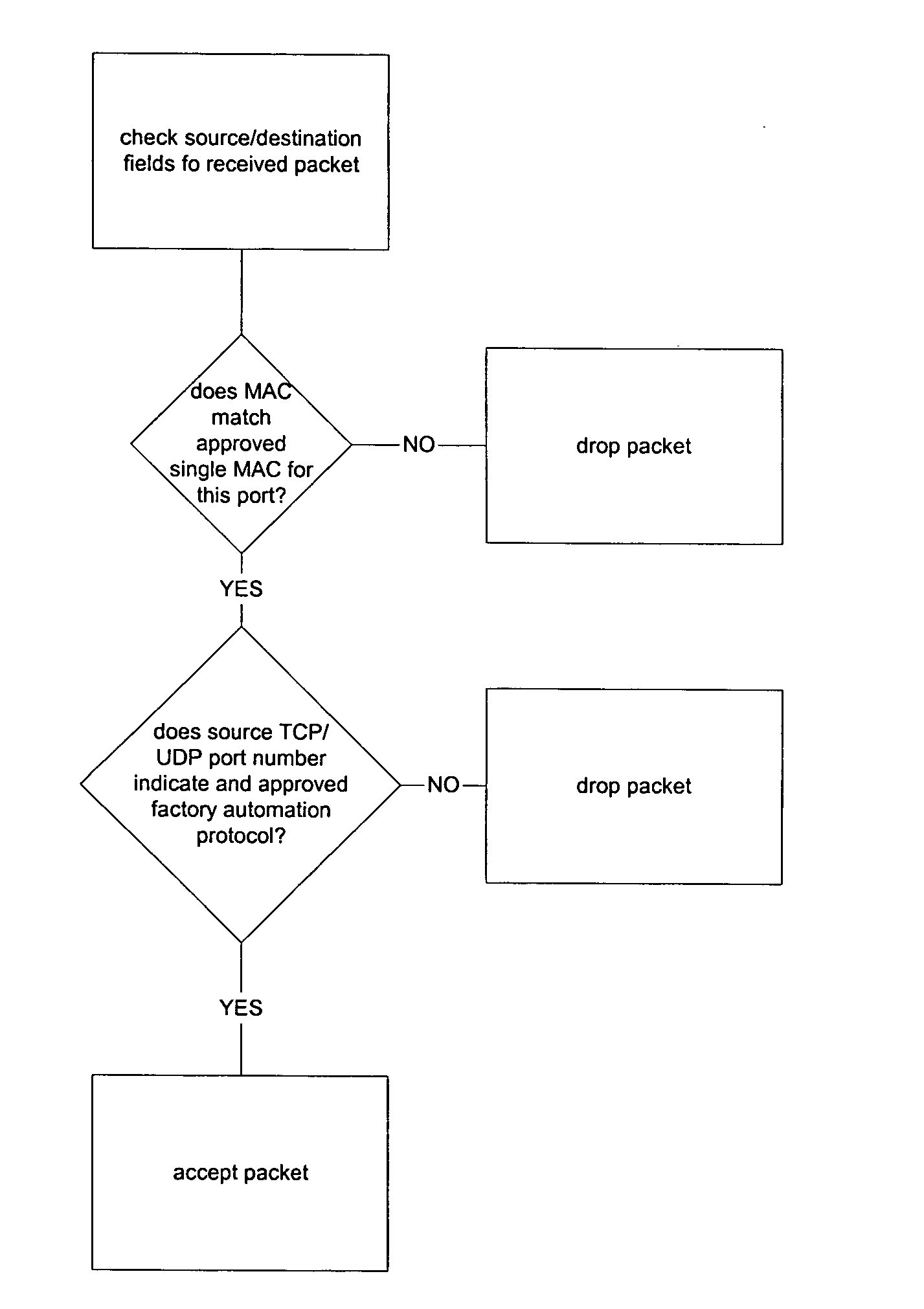

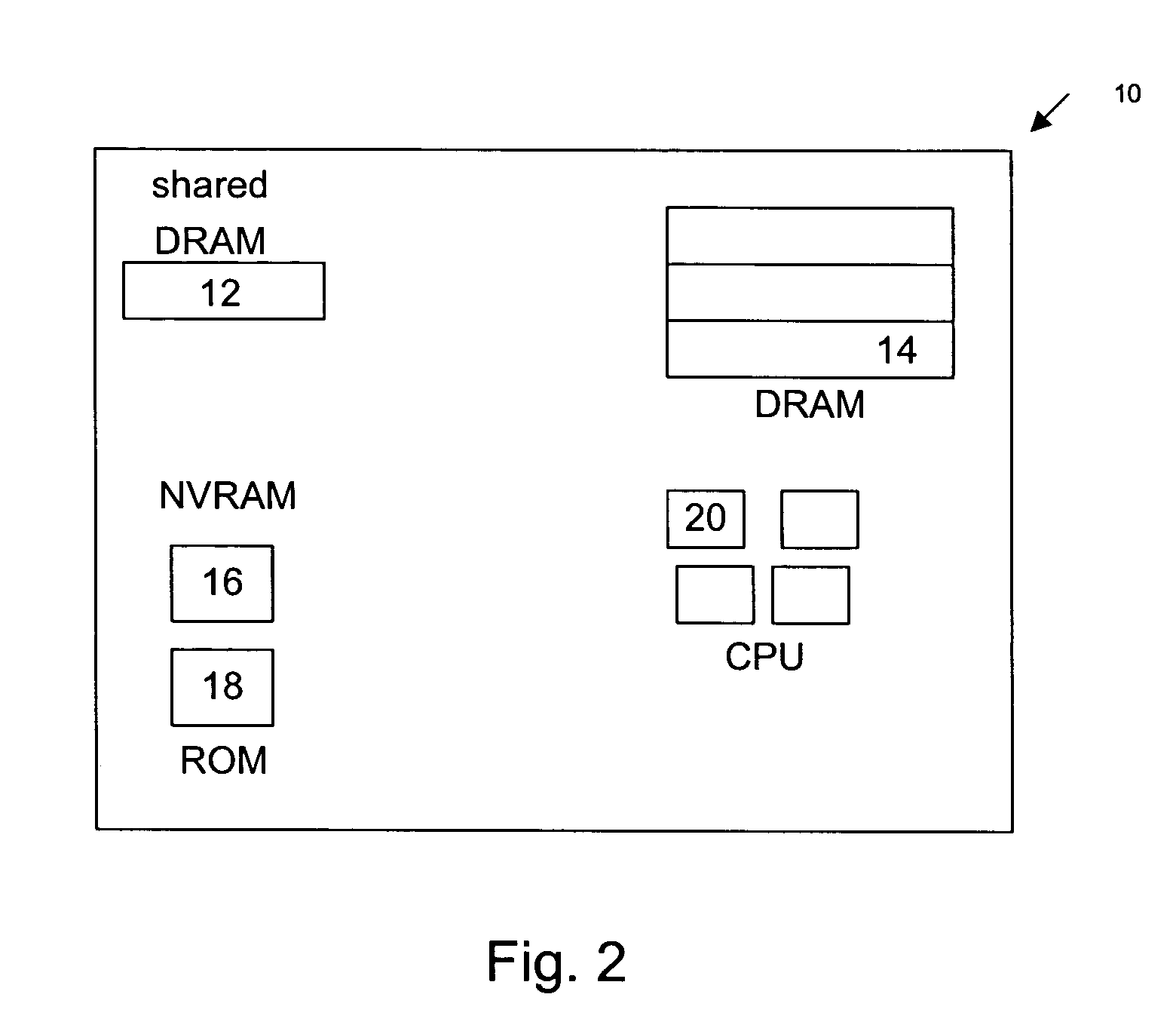

Secure manufacturing devices in a switched Ethernet network

ActiveUS20060010318A1Digital data processing detailsMultiple digital computer combinationsTraffic capacityNetwork packet

A method and apparatus for providing security to factory automation devices in a switched Ethernet network. Traffic between factory automation devices and an Ethernet switch is limited to packets including approved TCP / UDP port numbers and to selected data rates.

Owner:CISCO TECH INC

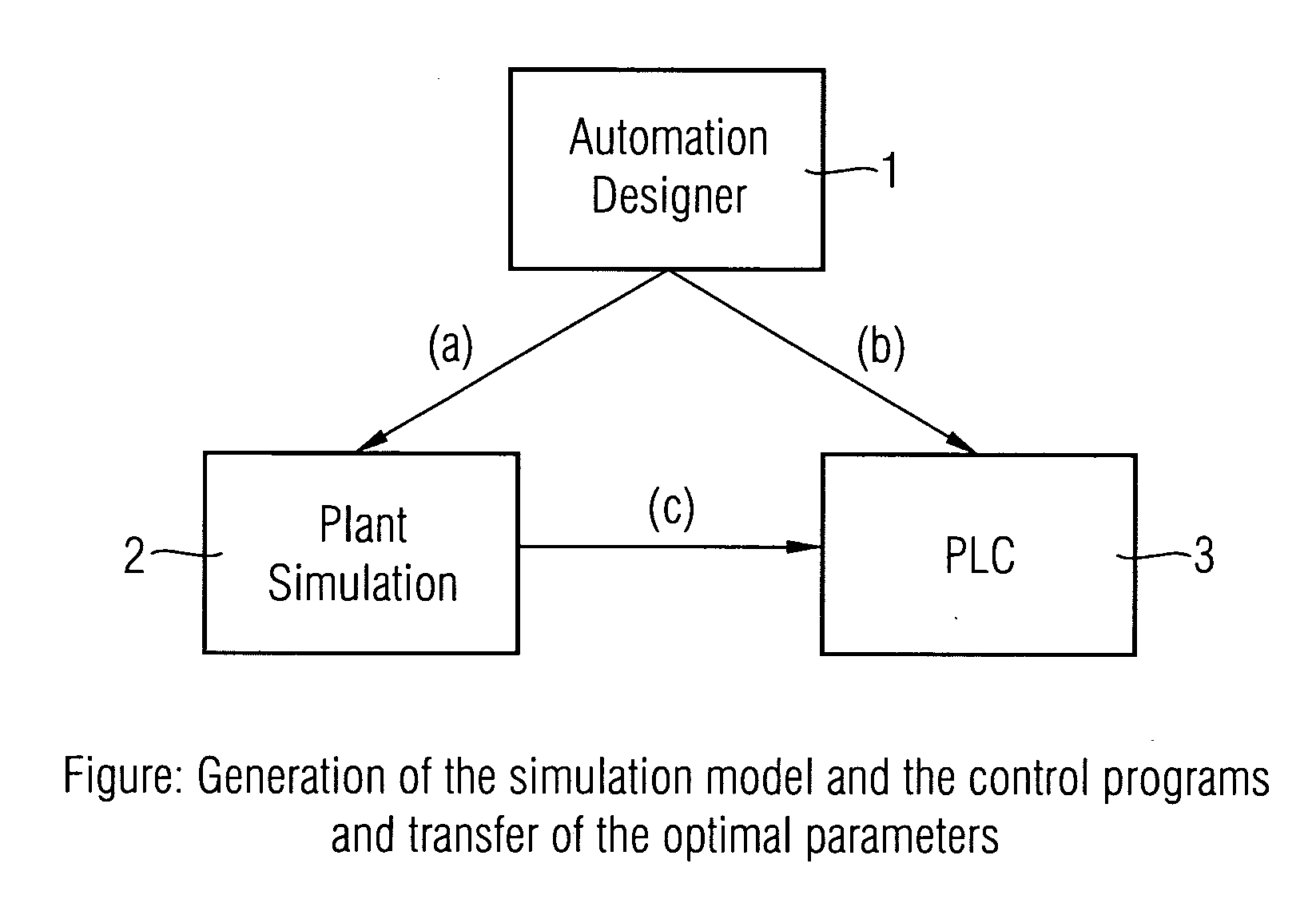

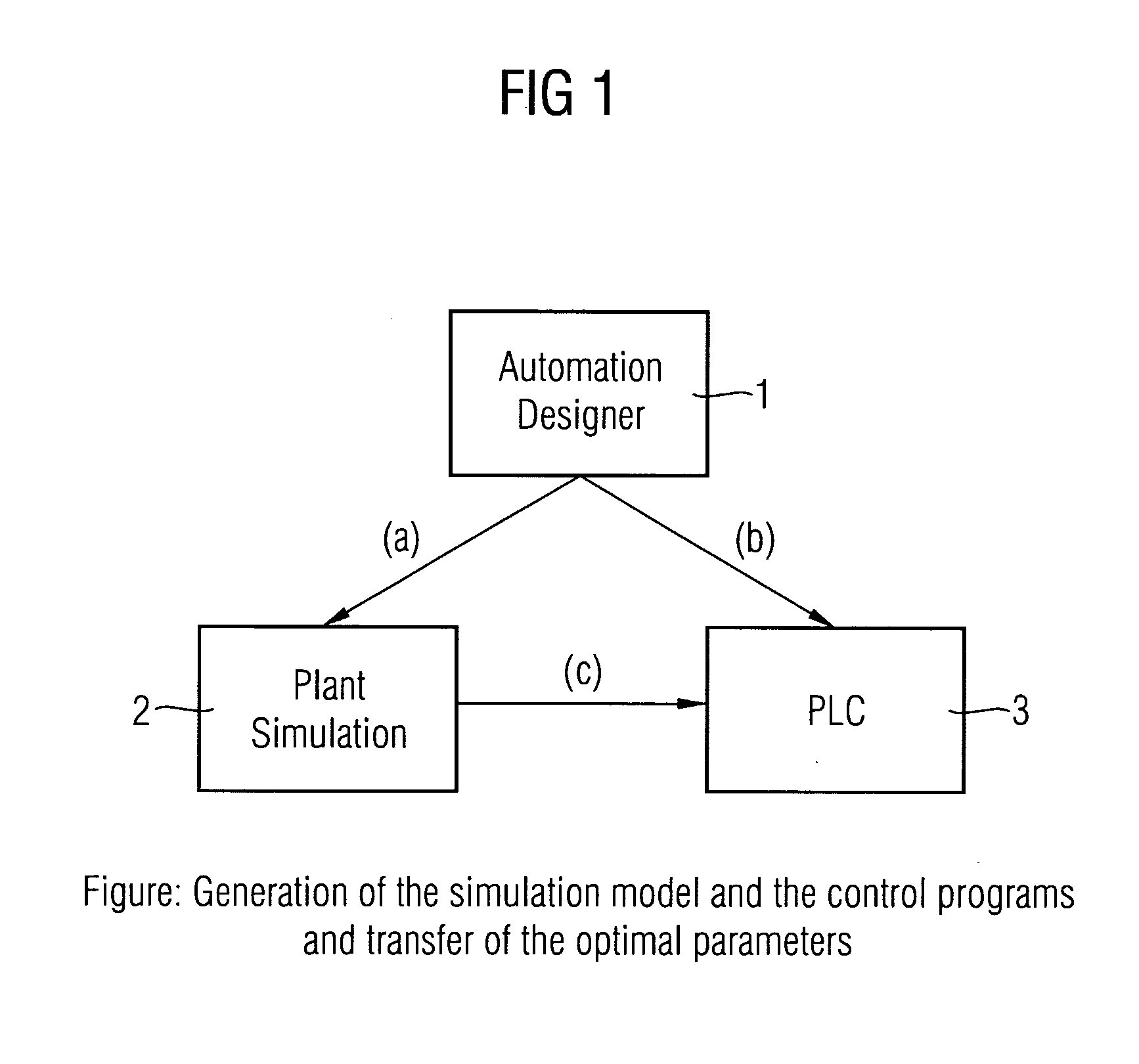

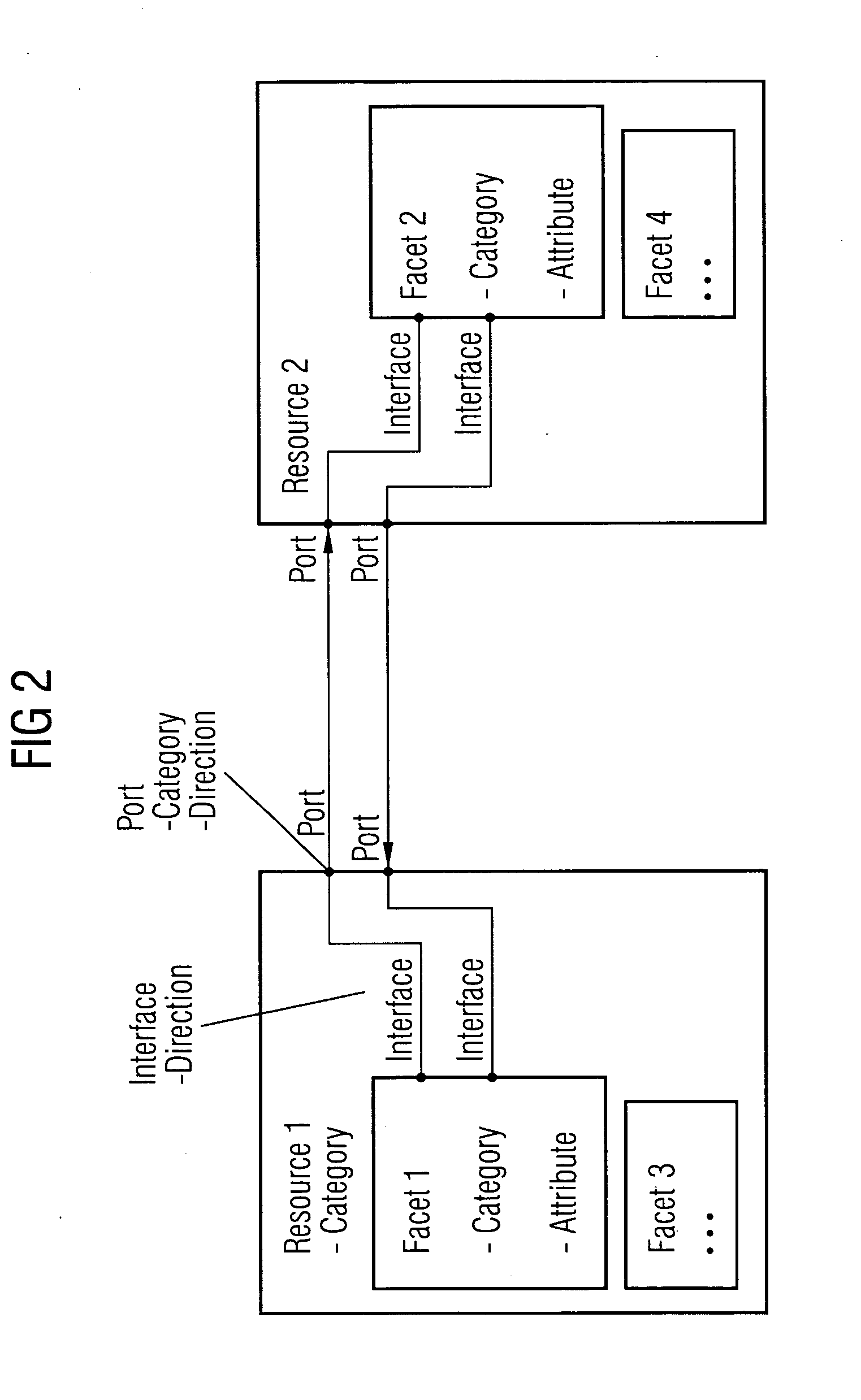

System for simulating automated industrial plants

ActiveUS20090265157A1Improve throughputAvoid damageTotal factory controlProgramme control in sequence/logic controllersParallel computingConveyor belt

Automation technology facilities are used for automating industrial processes such as the control of conveyor belts. A high-level control device with a logical model of the plant stored in the control device is disclosed. Simulation models and control programs are generated by the control device. The generated control programs have special data blocks which contain the parameters that are to be optimized by the simulation. The generated simulation models generate the parameters as result values of the simulation evaluation algorithms and supply the values in an automated manner to the special data blocks of the generated control programs.

Owner:SIEMENS AG +1

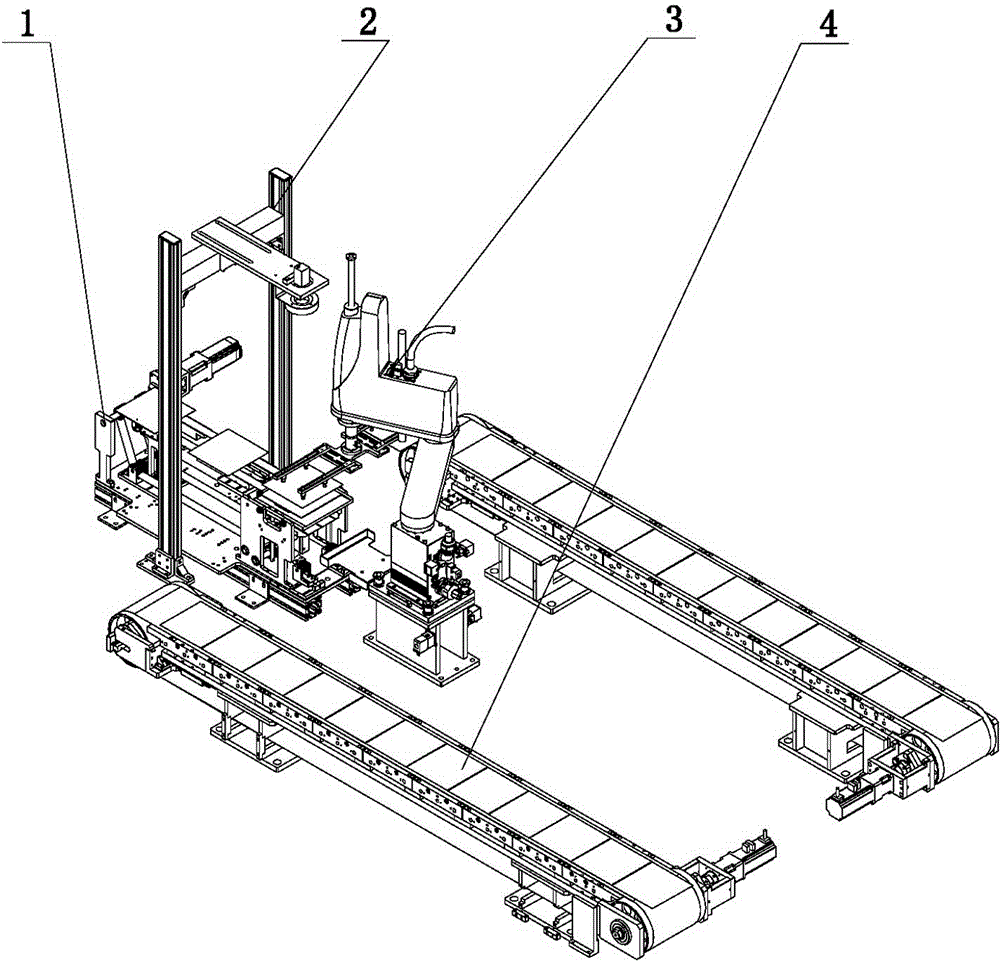

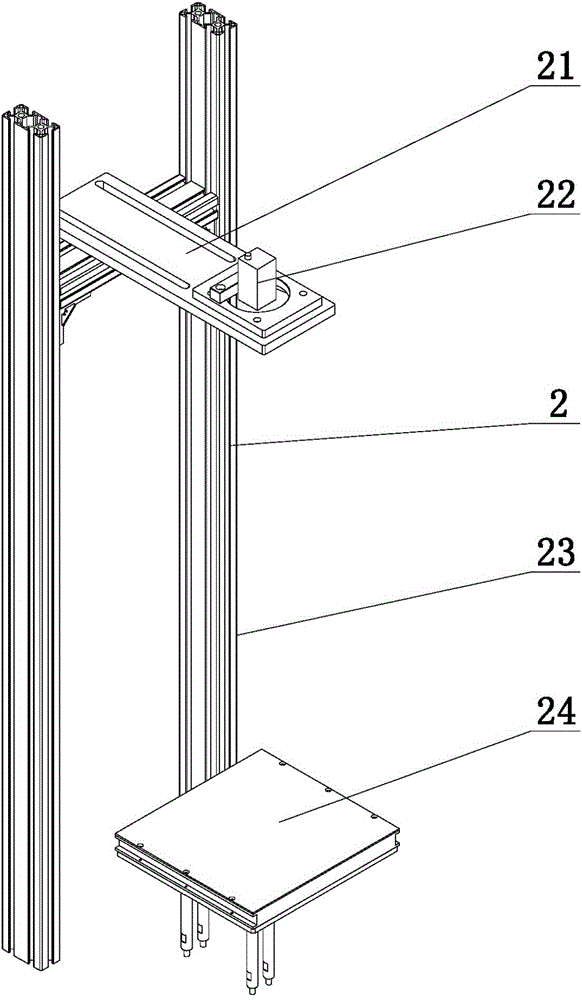

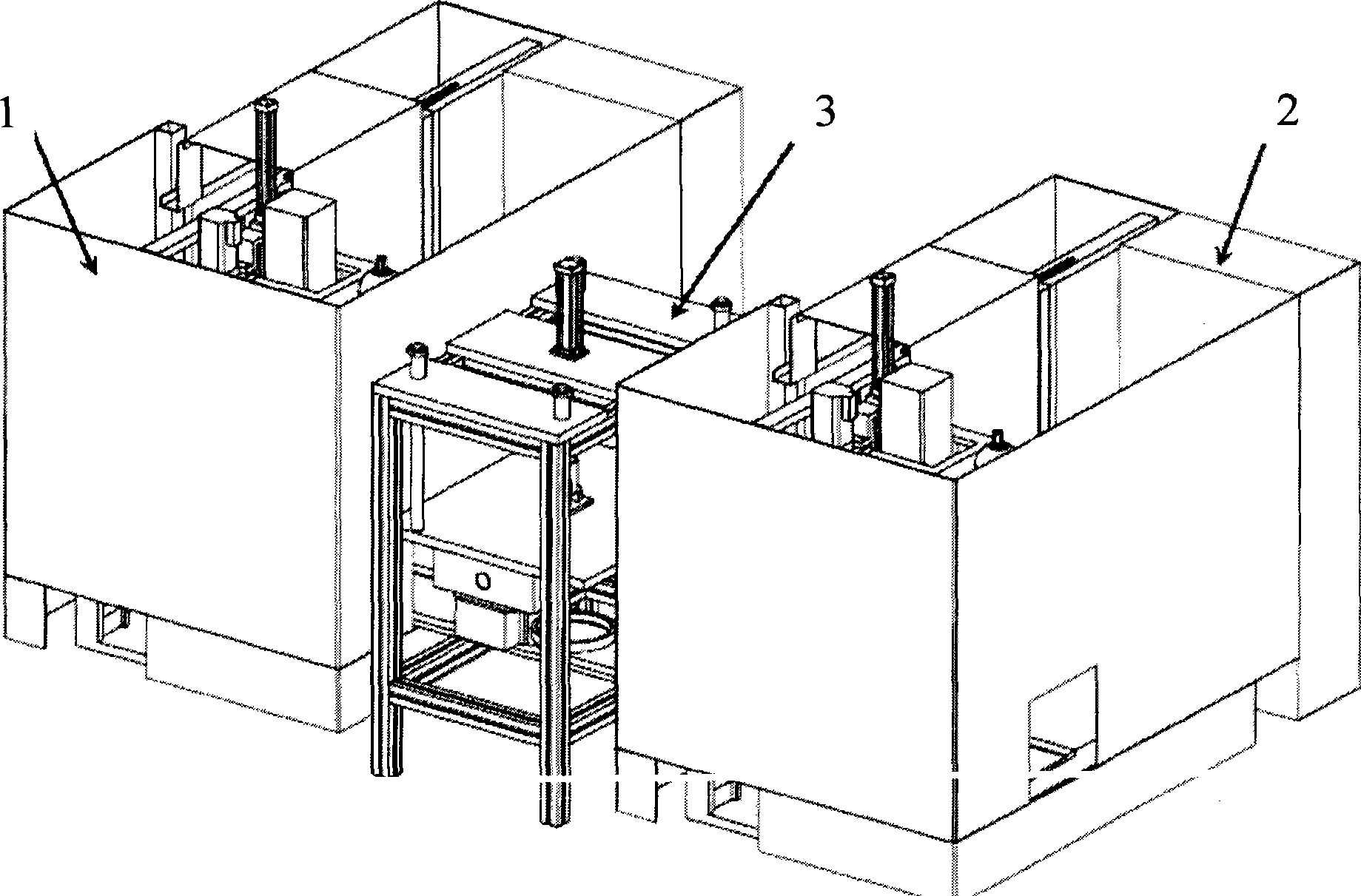

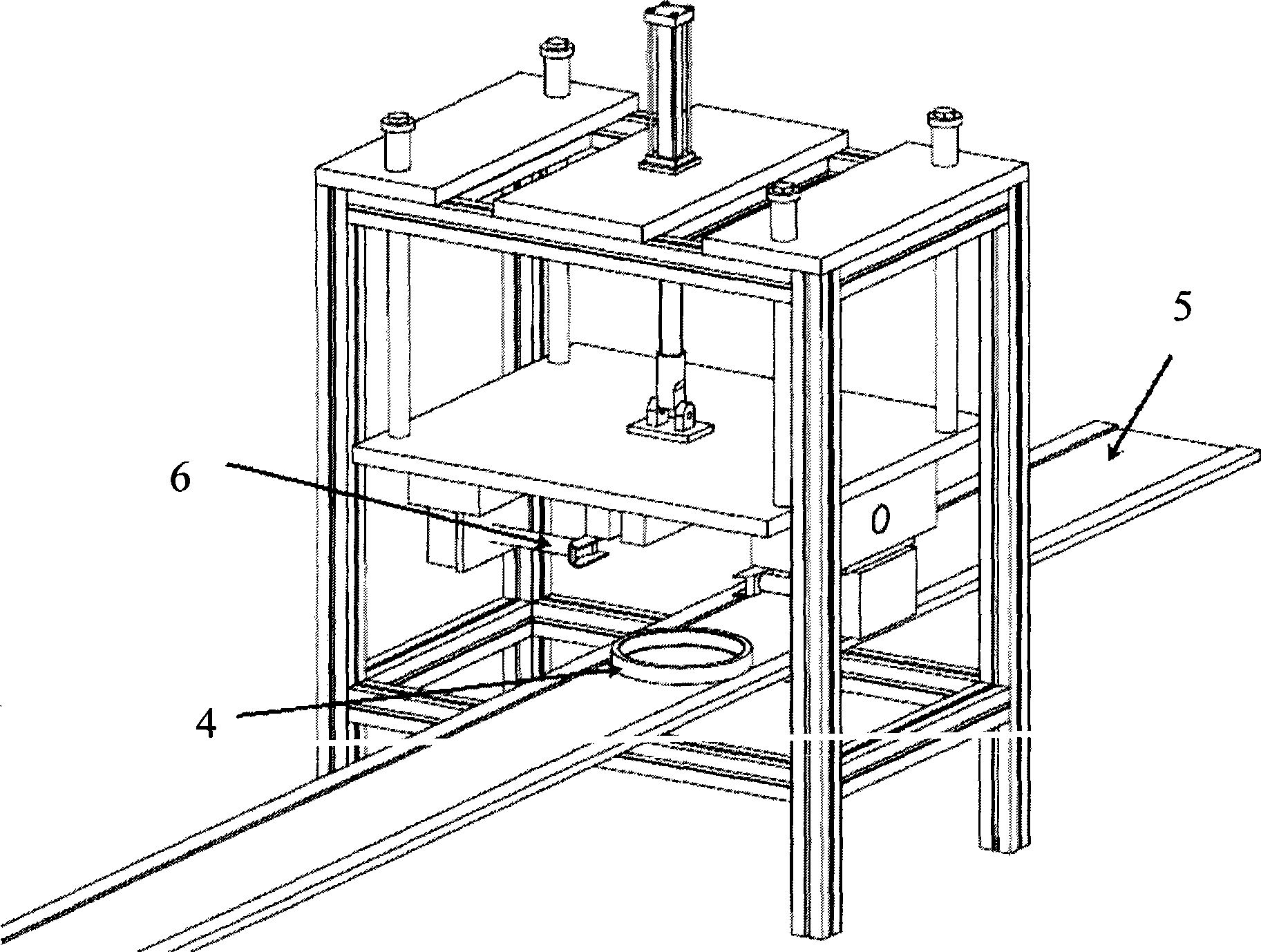

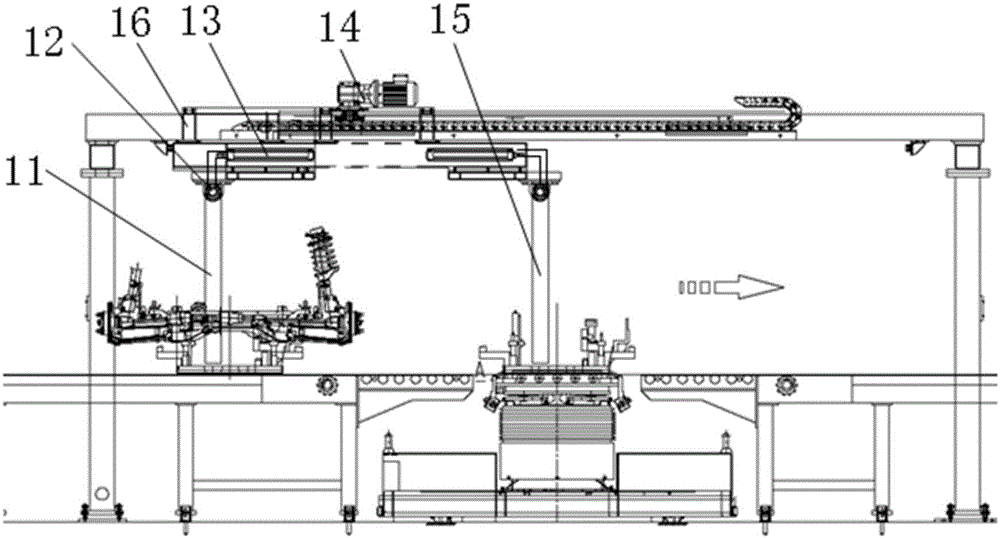

Multi-axis manipulator carrying mechanism

InactiveCN105858187AImprove work efficiencyReduce upgrade costsProgramme-controlled manipulatorConveyor partsVisual monitoringMulti axis

The invention belongs to the technical field of automatic production equipment in factories, and particularly relates to a multi-axis manipulator carrying mechanism. The multi-axis manipulator carrying mechanism is high in efficiency, stable and high in cost performance. The multi-axis manipulator carrying mechanism comprises a feeding mechanism and a carrying manipulator mechanism. The multi-axis manipulator carrying mechanism is characterized in that the feeding mechanism comprises a feeding conveying belt connected with a servo driving module; the carrying manipulator mechanism comprises a base, and a multi-axis manipulator corresponding to the tail end of the feeding conveying belt is arranged on the base; a rotary connecting frame is arranged on the multi-axis manipulator; mounting frames are arranged on the two sides of the rotary connecting frame correspondingly; suction cup devices are arranged on the two mounting frames correspondingly; a CCD visual monitoring system is arranged at the tail end of the feeding conveying belt and correspondingly located above the feeding mechanism; and a backlight source is arranged below the tail end of the feeding conveying belt.

Owner:YINGKOU JINCHEN AUTOMATION CO LTD

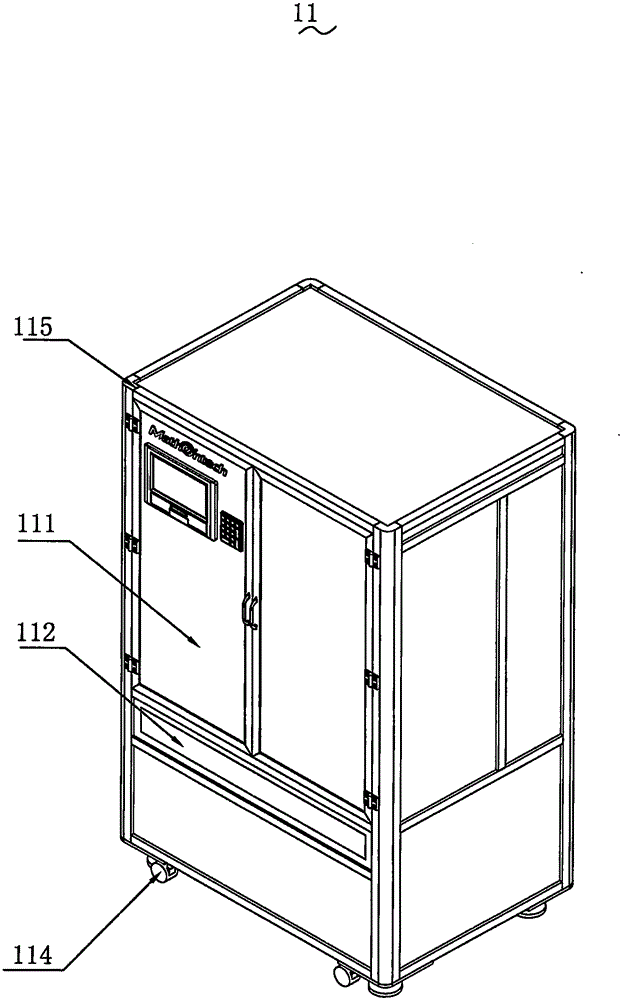

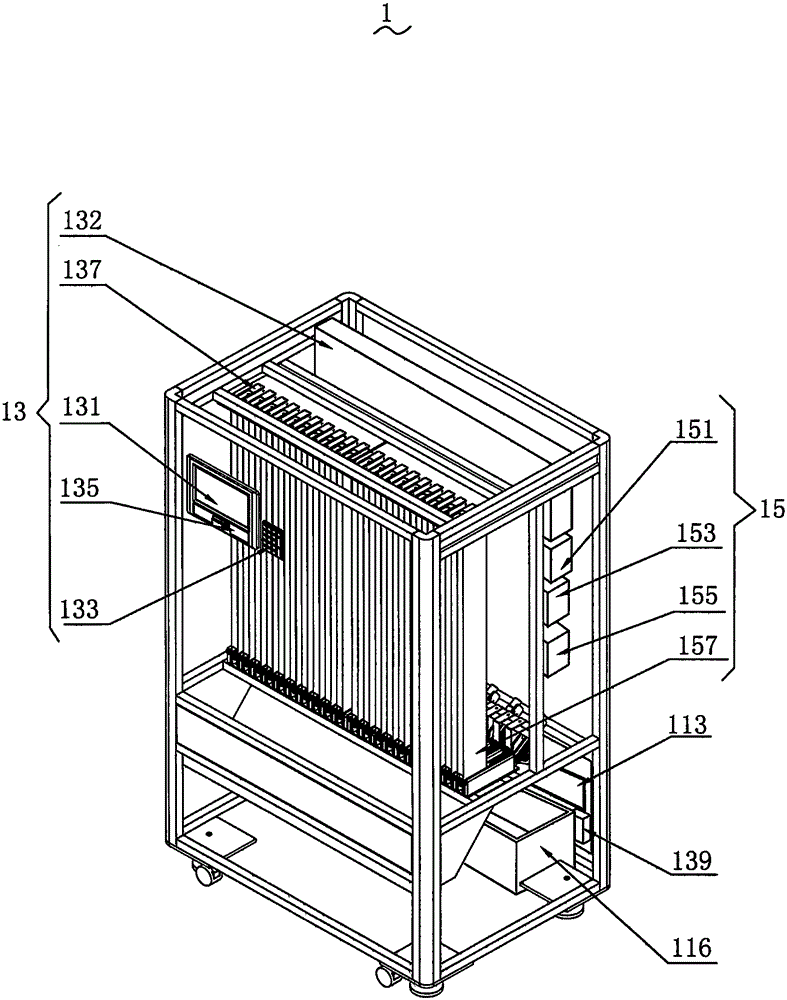

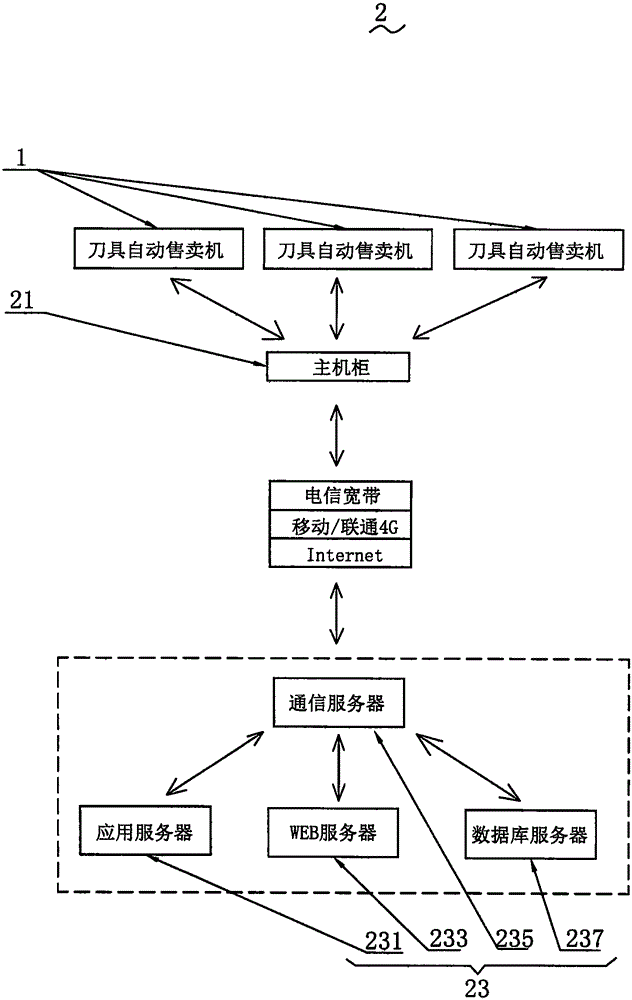

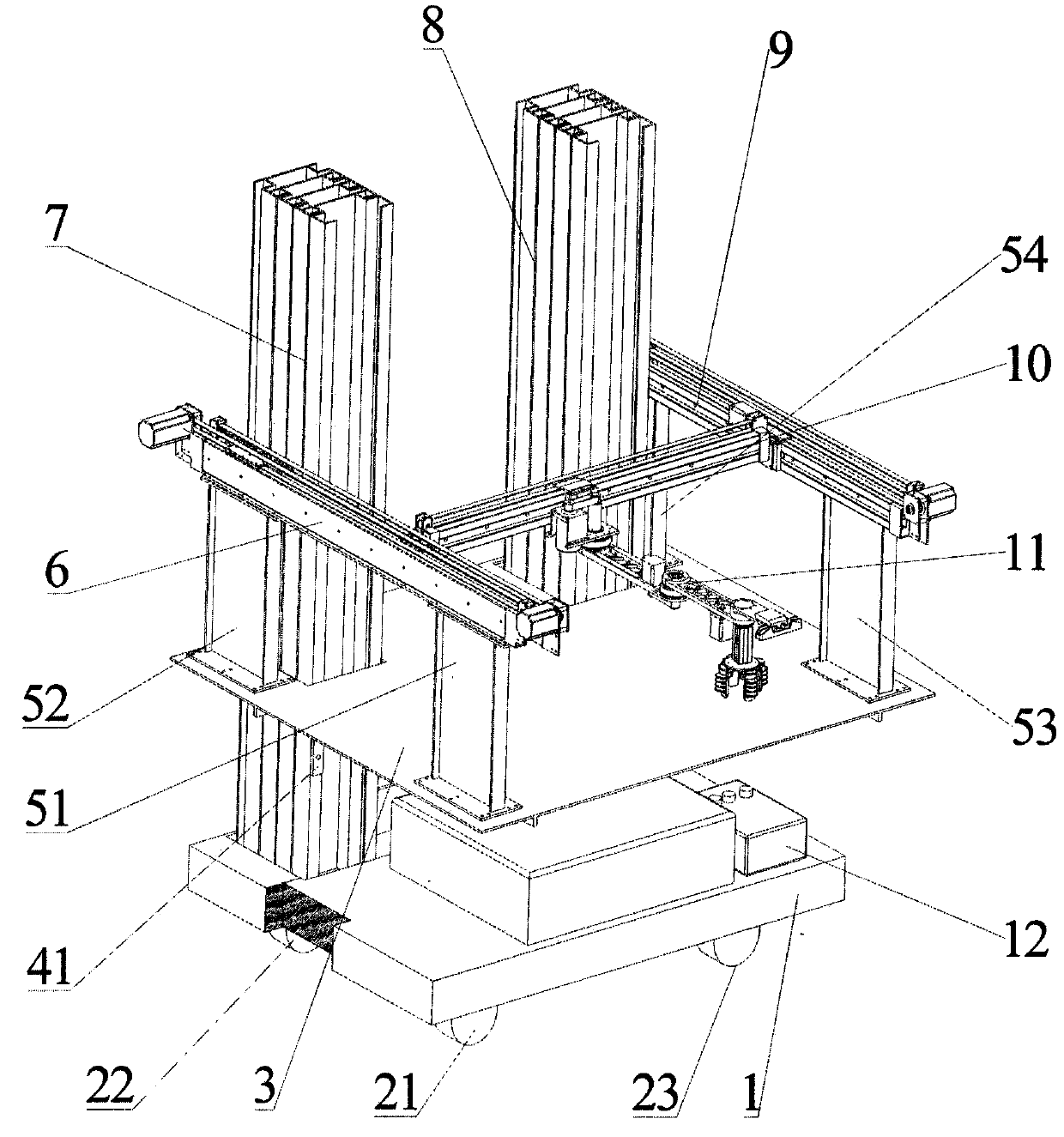

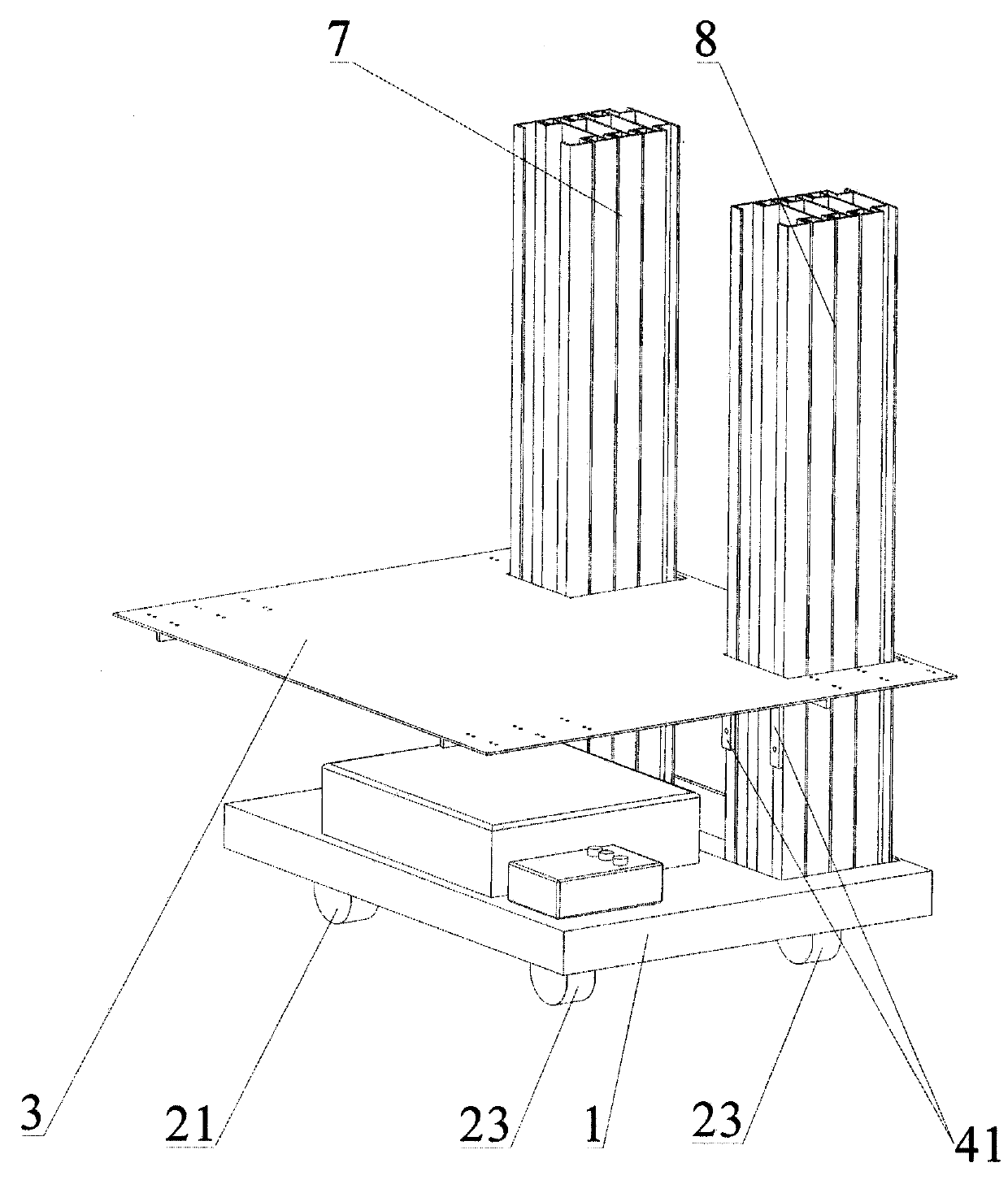

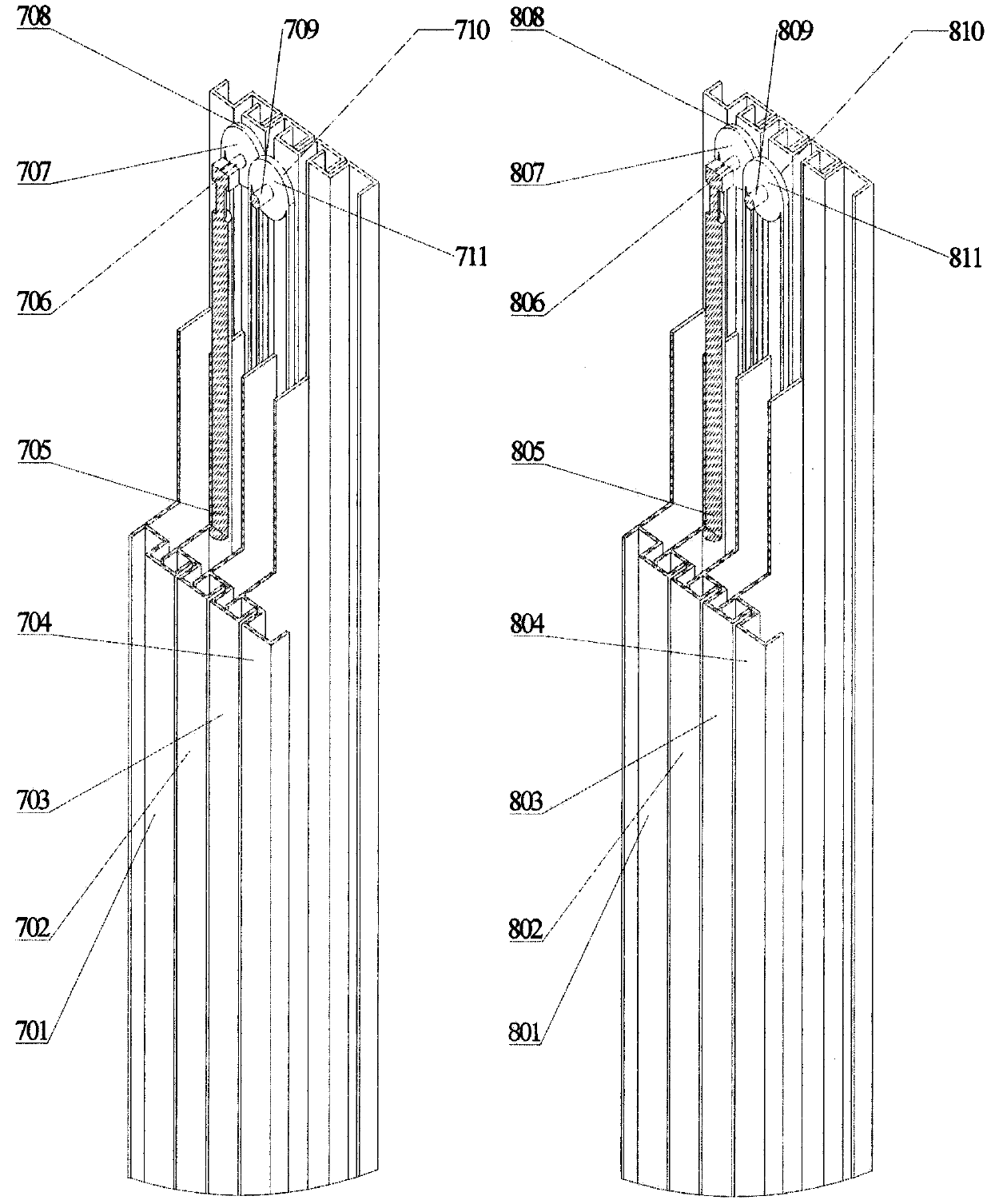

Automatic tool vending machine and system

InactiveCN105069912AImprove automationEasy to manageCoin-freed apparatus detailsBuying/selling/leasing transactionsPersonal computerHuman–robot interaction

The invention relates to an automatic tool vending machine and system. The automatic tool vending machine comprises a machine cabinet, an industrial control system and a mechanism execution system. An RFID induction zone, an RFID induction antenna and an internal industrial personal computer are arranged in the industrial control system, the RFID induction antenna conducts automatic data recognition on materials inside the automatic tool vending machine, and the internal industrial personal computer achieves the human-computer interaction function of the system; a taking mechanism is arranged in the mechanism execution system and comprises a plurality of independent pushing mechanisms arranged side by side, and materials selected by a user are pushed out of the automatic tool vending machine through the pushing mechanisms. According to the automatic tool vending machine, the whole processes of production, usage, recycling and management are efficiently managed and controlled, and the greater promoting effect is achieved for improving the processing efficiency of a factory and improving the whole automation concept of the factory.

Owner:SHENZHEN MATHENTECH INTELLIGENT TECH

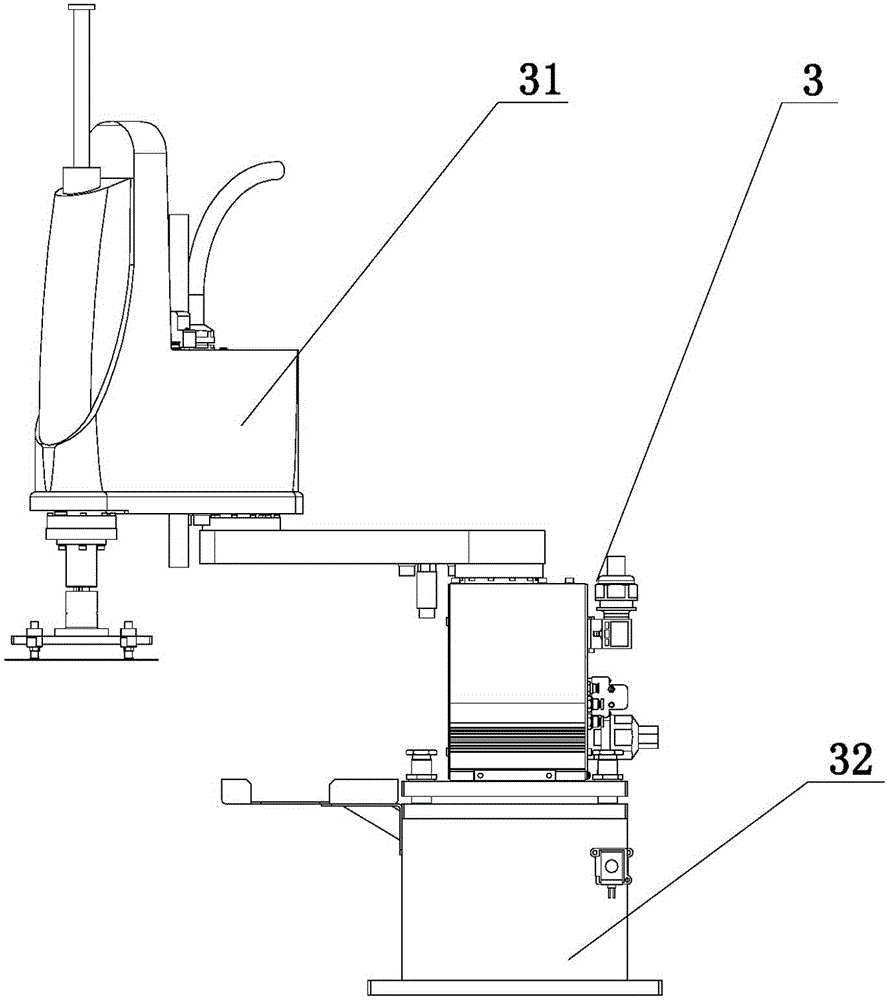

Mushroom picking robot applicable to multilayer mushroom bed operation

ActiveCN110073904ACompact structureFlexible moving processCultivating equipmentsMushroom cultivationModular designEngineering

The invention discloses a mushroom picking robot applicable to multilayer mushroom bed operation. The mushroom picking robot comprises a movable lifting platform, a telescopic guide rail extending platform and a picking mechanical arm, and is characterized in that the self structure is compact; the automatic lifting can be performed according to picking requirements; an arm installing mechanism performs telescopic operation; the mushroom picking robot can be applicable to a multilayer mushroom bed operation mode in industrialized mushroom cultivation. The mushroom picking robot has the advantages that the picking requirement on multilayer parallel arrangement industrialized planted portobello mushrooms is met; the functions of effective lifting, contraction and extending and flexible advancing in a passage can be realized; the structure uses a modular design; the replaceability is high; the picking requirements under the portobello mushroom industrialized planting condition can be effectively met; the problems of low factory automation degree, high work cost and the like are solved.

Owner:NANJING AGRICULTURAL UNIVERSITY

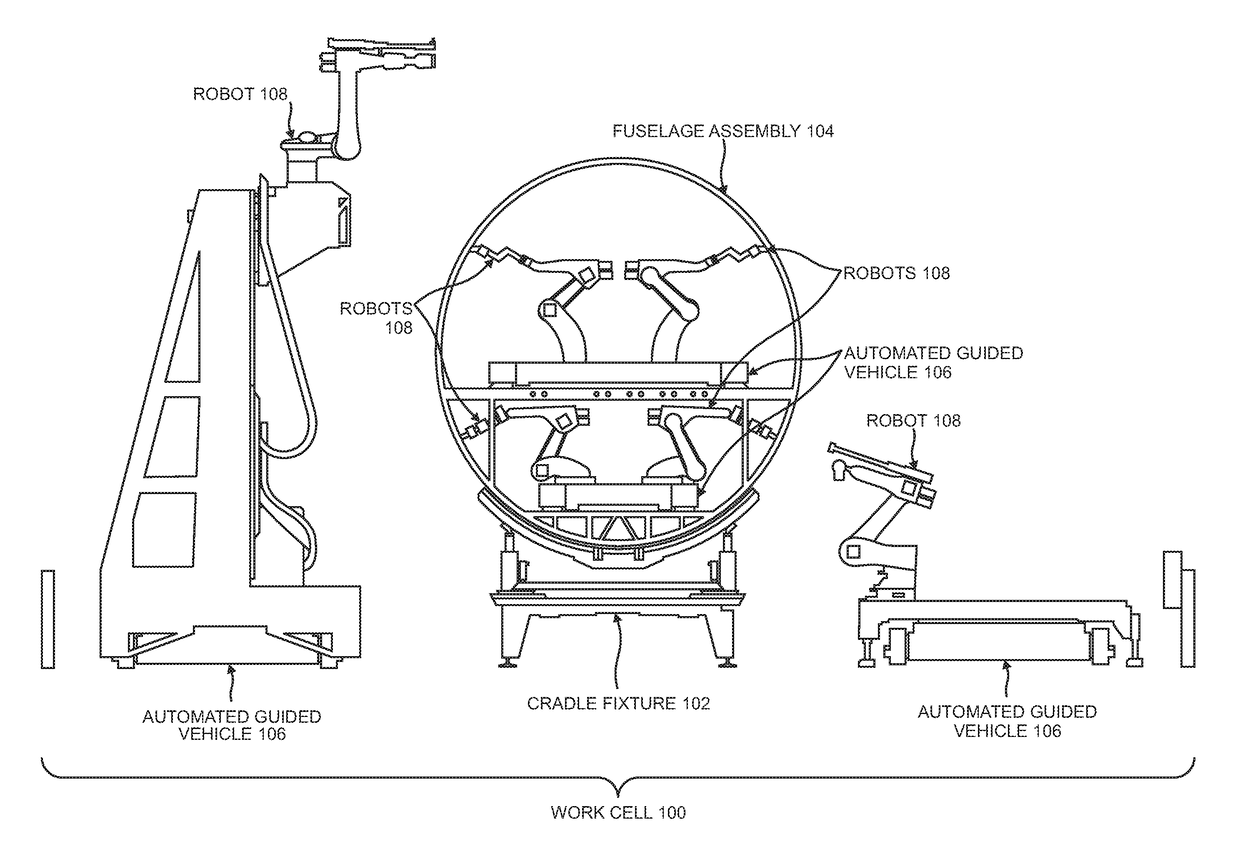

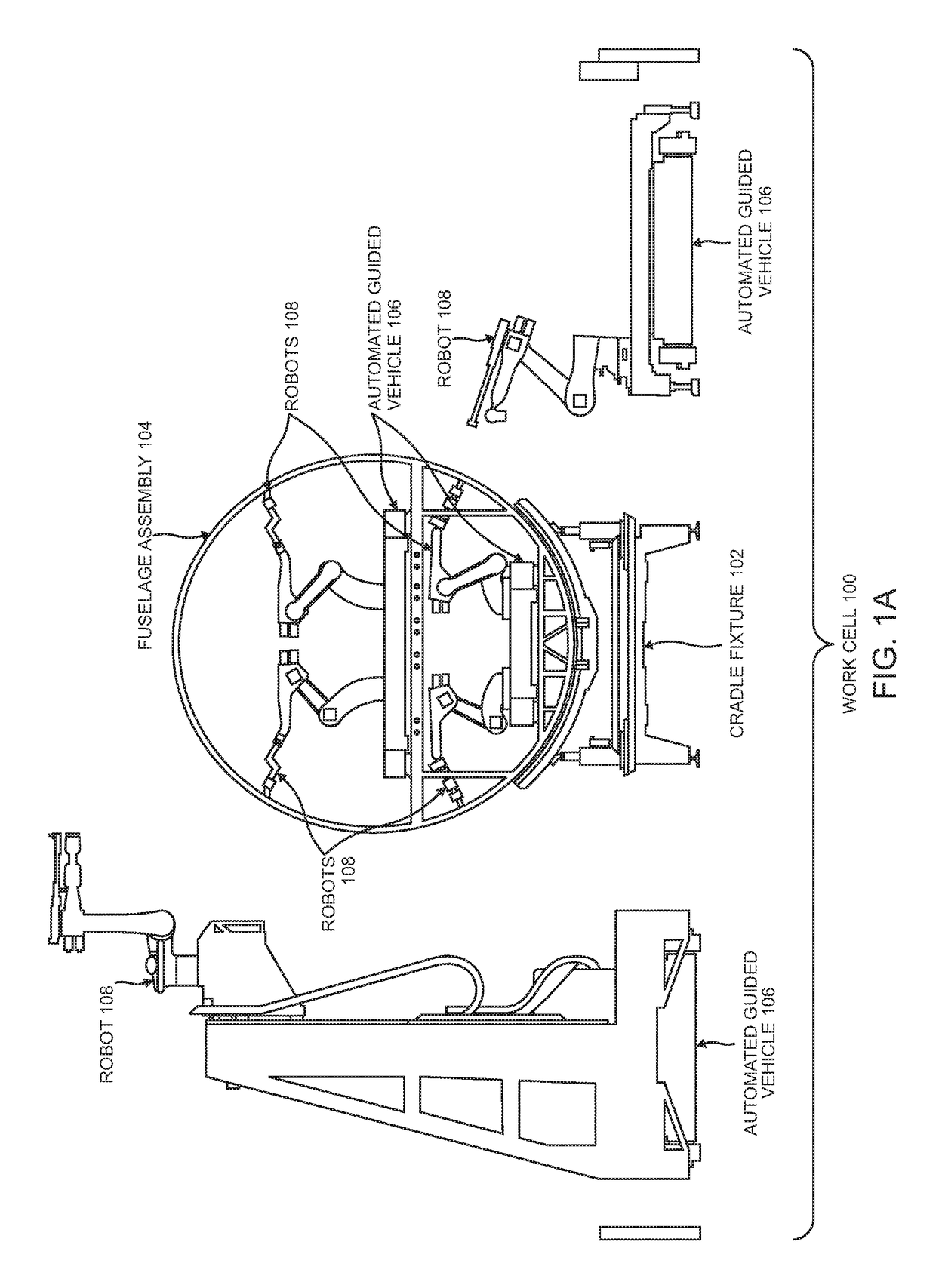

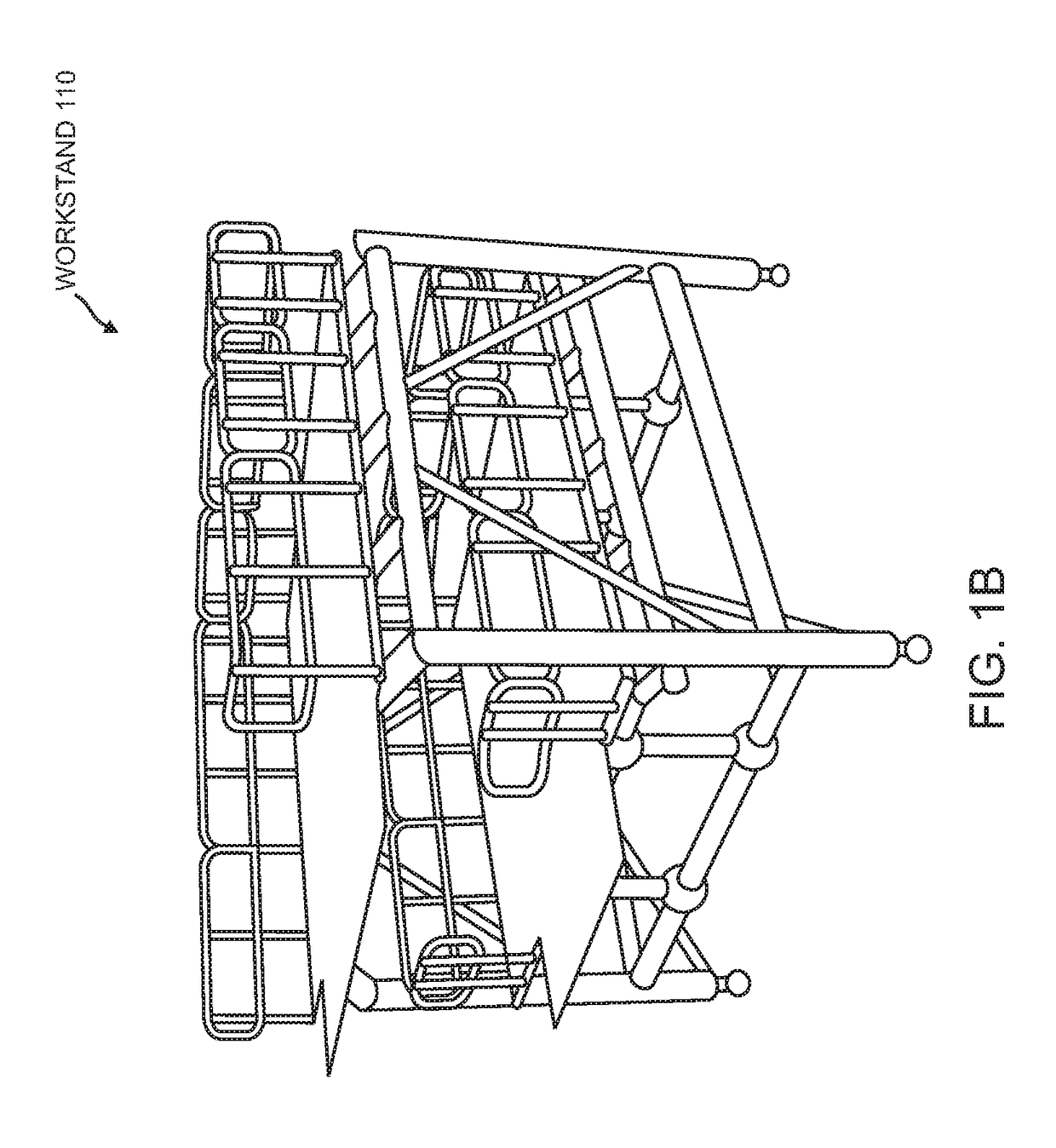

Application of factory automation for an airline assembly and build process

Work cell and factory level automation require that an Automated Guided Vehicle (AGV) achieve demanding positional accuracy and repeatability relative to a cradle fixture or workstand within a work cell. The AGV makes distance measurements of objects within the work cell using laser scanner sensors. The distance measurements are filtered of objects that are not target features on the cradle fixture or workstand. Systematic or bias errors of the laser scanner sensor are removed from the filtered distance measurements, and a mathematical filter or estimator is applied to the filtered distance measurements using random errors of the laser scanner sensor to generate estimated distance measurements. A map of the target features is then constructed using the estimated distance measurements, wherein the map is used for path planning and navigation control of the AGV relative to the cradle fixture or workstand within the work cell.

Owner:THE BOEING CO

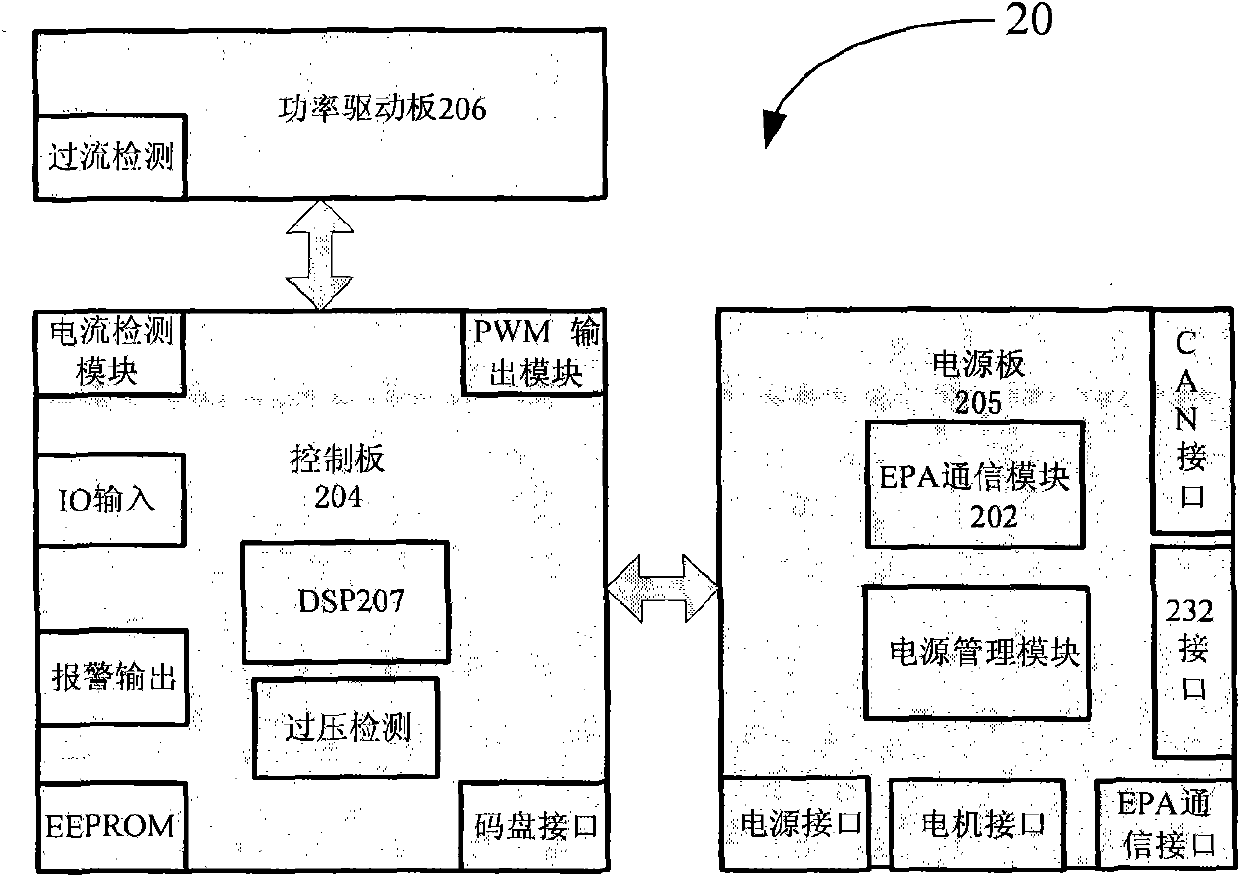

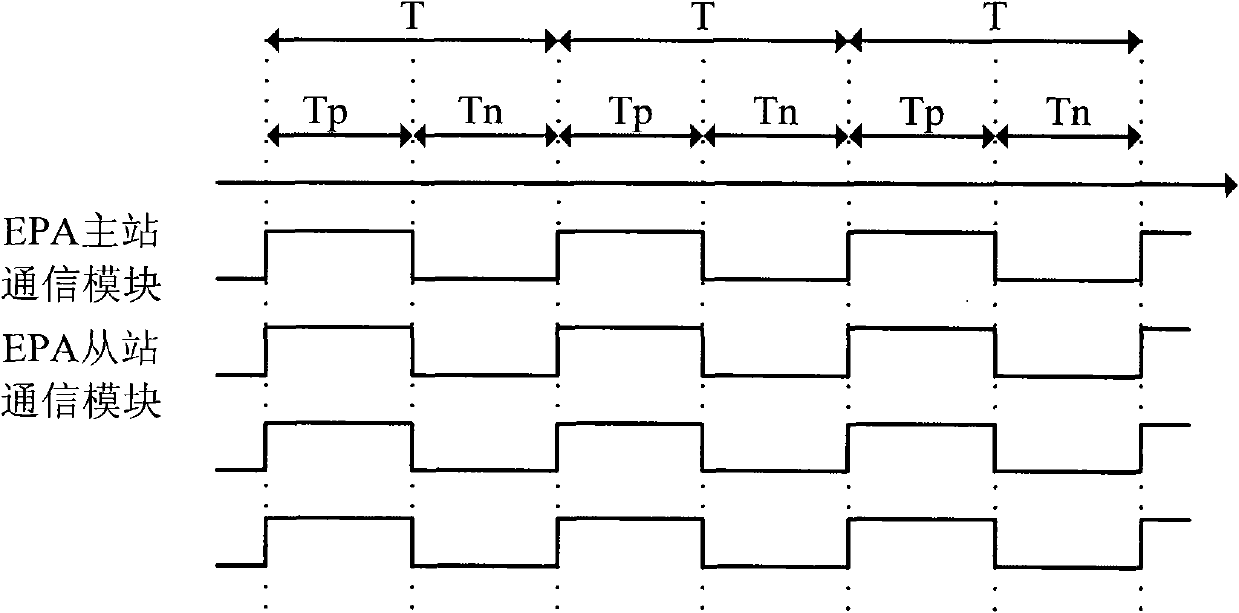

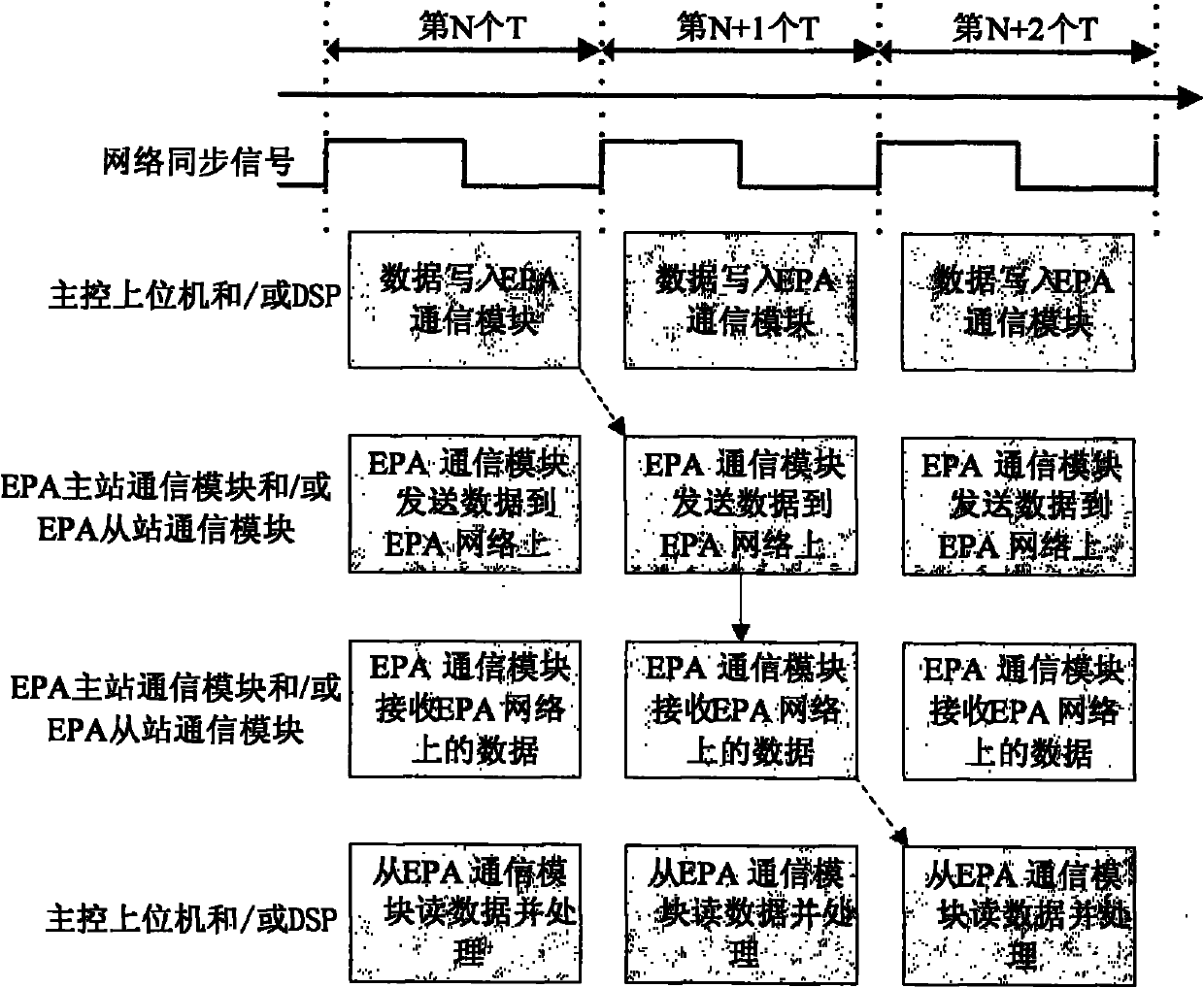

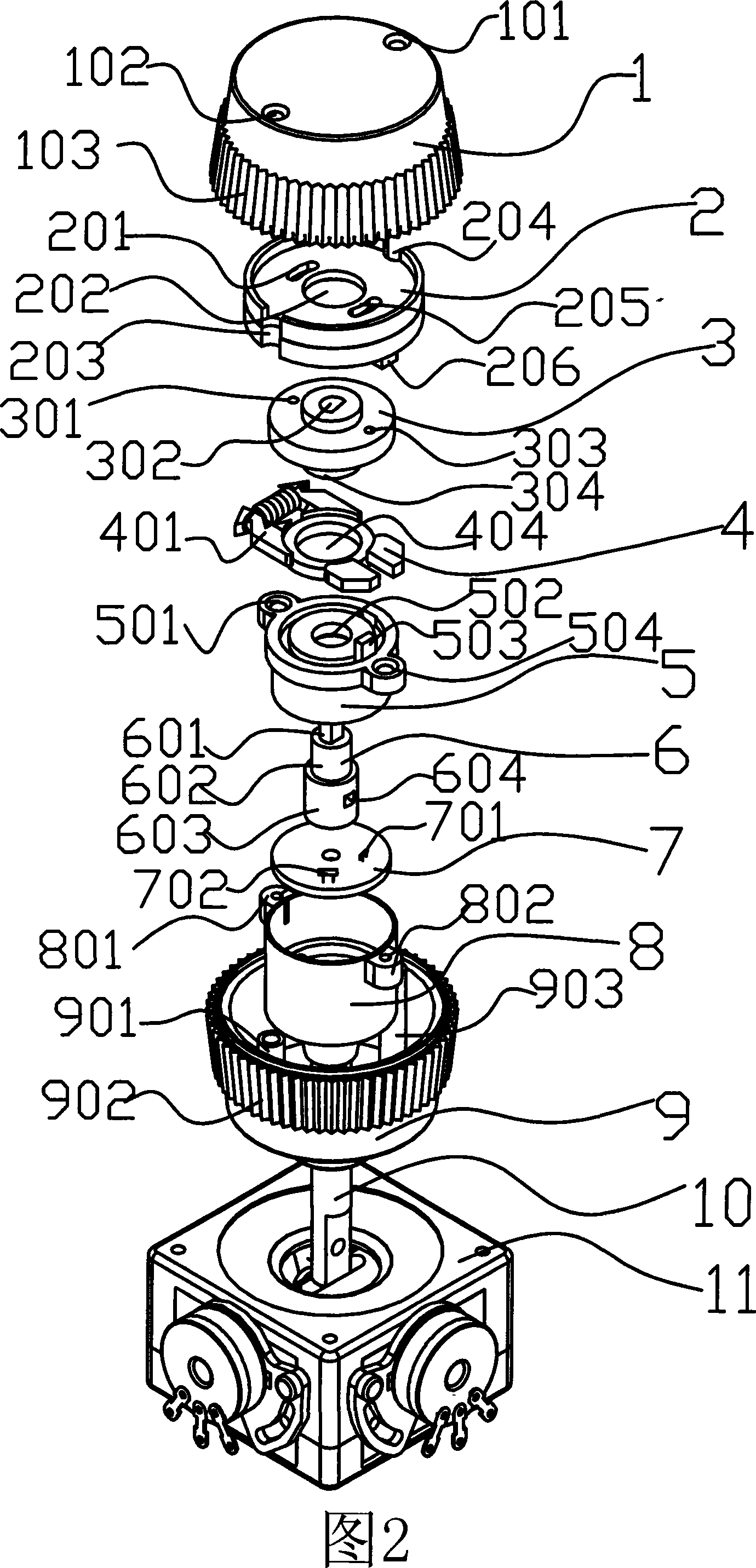

Multi-shaft DC servo motor control system and method based on EPA (Ethernet for Plant Automation) field bus

InactiveCN101907882AThe synchronization accuracy is smallGuaranteed certaintyElectric signal transmission systemsTotal factory controlPrimary stationEngineering

The invention relates to a multi-shaft DC servo motor control system and a method based on an EPA (Ethernet for Plant Automation) field bus. The system comprises a main control upper computer and a plurality of DC servo drivers, wherein the main control upper computer is connected with the DC servo drivers through an EPA communication network and comprises an EPA main station communication module for data exchange with the DC servo drivers; the EPA main station communication module further comprises a plurality of first data sending areas and a plurality of first data receiving areas; and each DC servo driver comprises an EPA slave station communication module for data exchange with the EPA main station communication module, and the EPA slave station communication module further comprises a second data sending area and a second data second receiving area. The invention realizes high speed communication and high precision synchronization and high reliability communication, and has good expansibility.

Owner:ZHEJIANG SUPCON ELECTRICAL +1

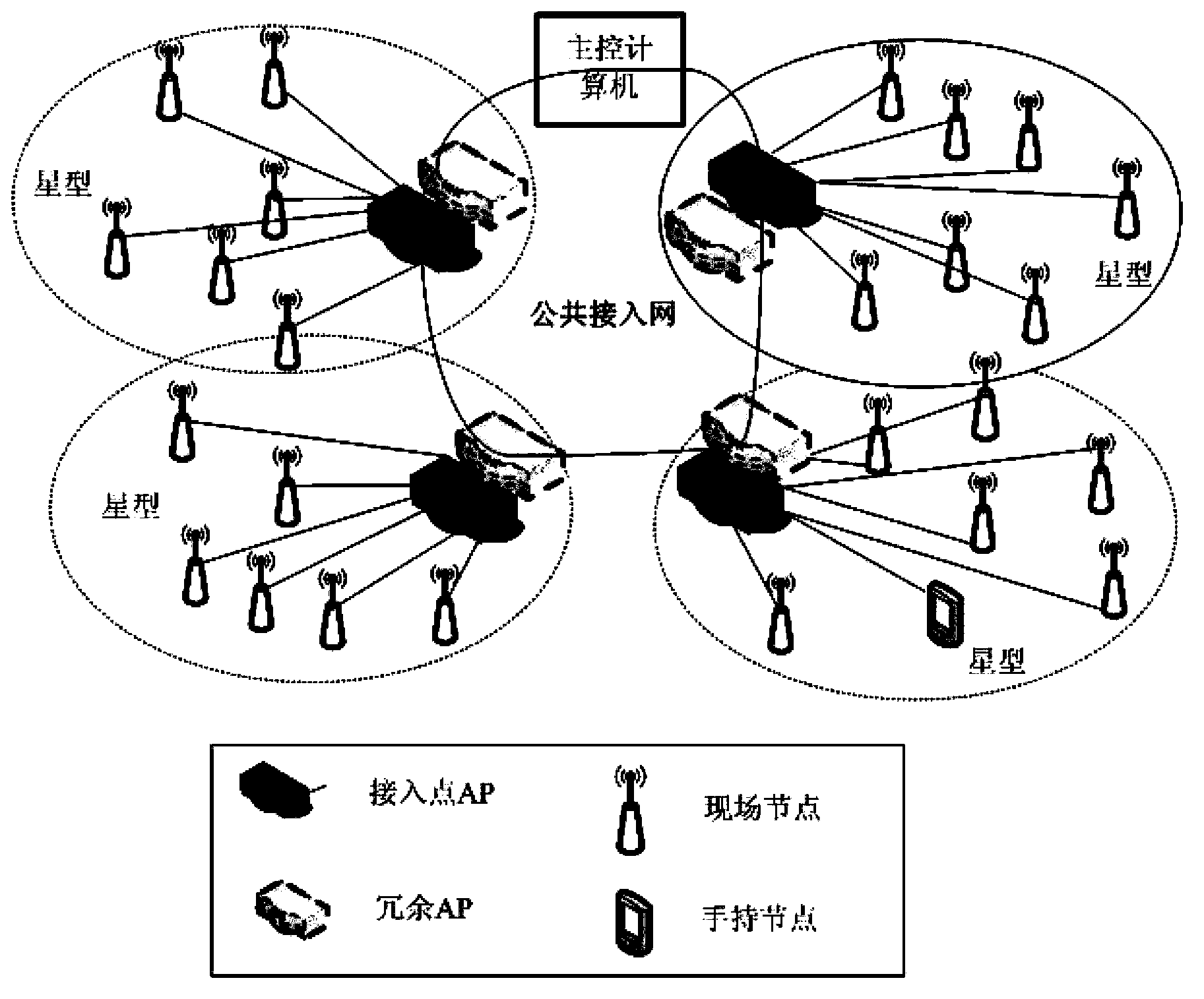

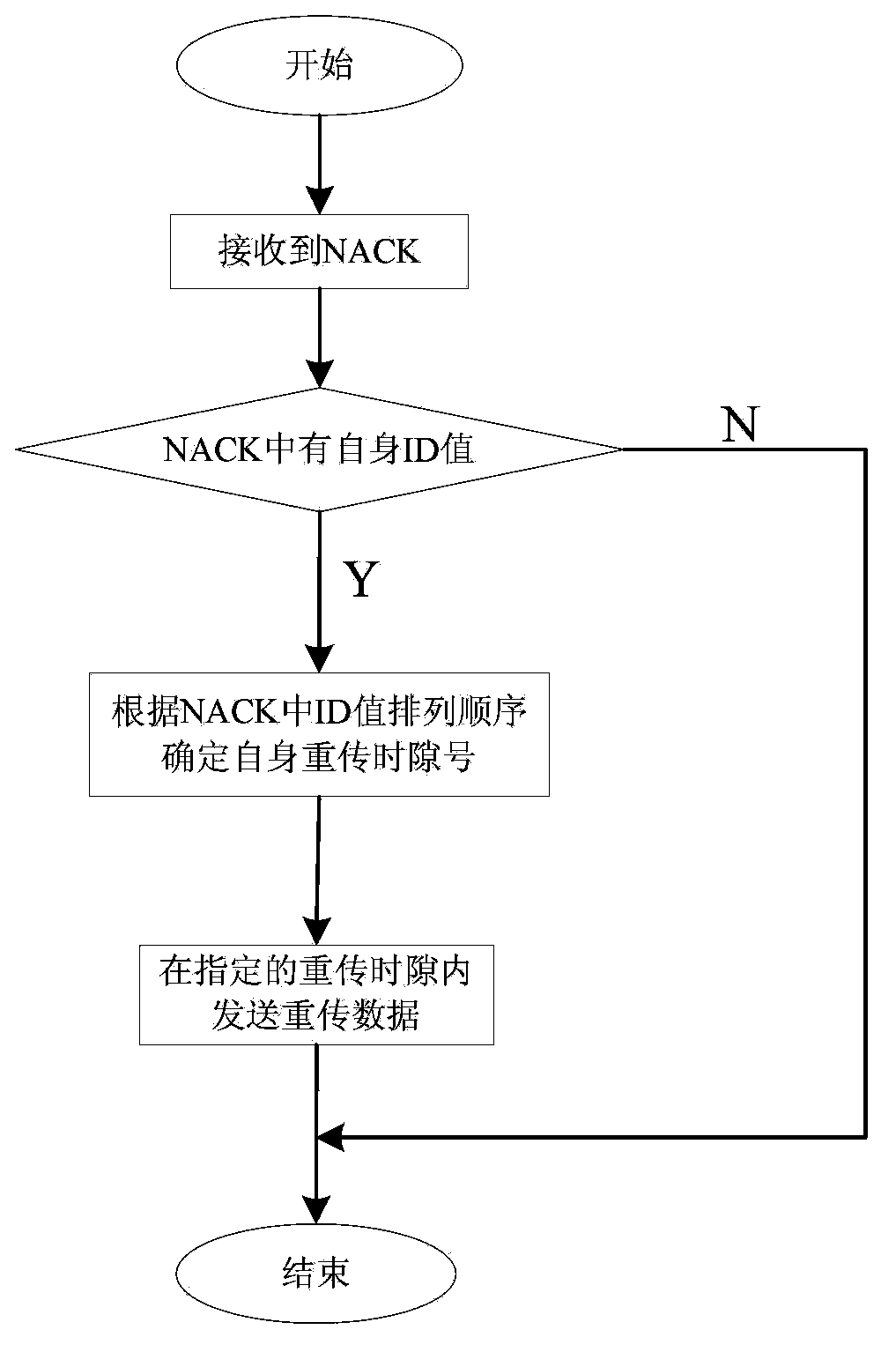

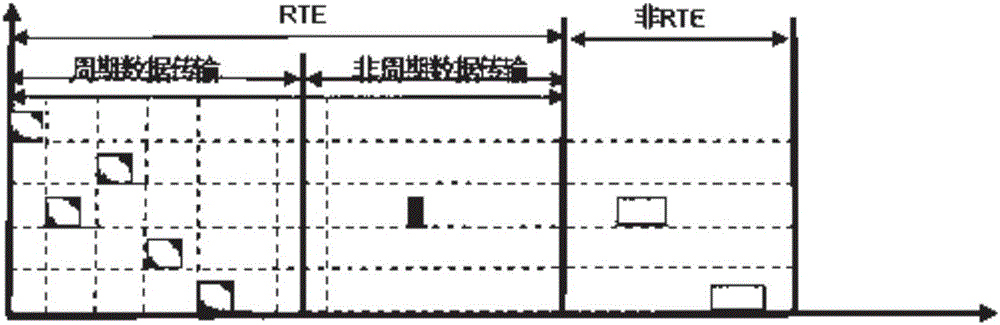

Channel model based factory automation wireless network ARQ retransmitting method

ActiveCN103684711ASatisfy real-timeFulfil requirementsError prevention/detection by using return channelResource utilizationStructure of Management Information

The invention relates to the industrial wireless network technology, in particular to a channel model based factory automation wireless network ARQ retransmitting method. The method is oriented to a star network of an IEEE 802.11 single-hop BSS structure, reduces difficulty for maintenance and management, improves the system flexibility, and meets the network real-time and reliable requirements as the method adopts a TDMA mechanism to support ordered transmission for retransmission data of large-scale network nodes in each TDMA time slot. The dynamic retransmission time slot reserving method based on a link layer channel model is adopted to ensure the reliability index, reduce the time and message overhead due to distribution of the retransmission communication resource and improve the communication resource utilization rate. Aggregated NACK and a resource distribution method based on ID value are utilized to obviously reduce the overhead due to ACK transmission and resource distribution information, and achieve high efficiency, low overhead, high possibility of implementing and the like.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

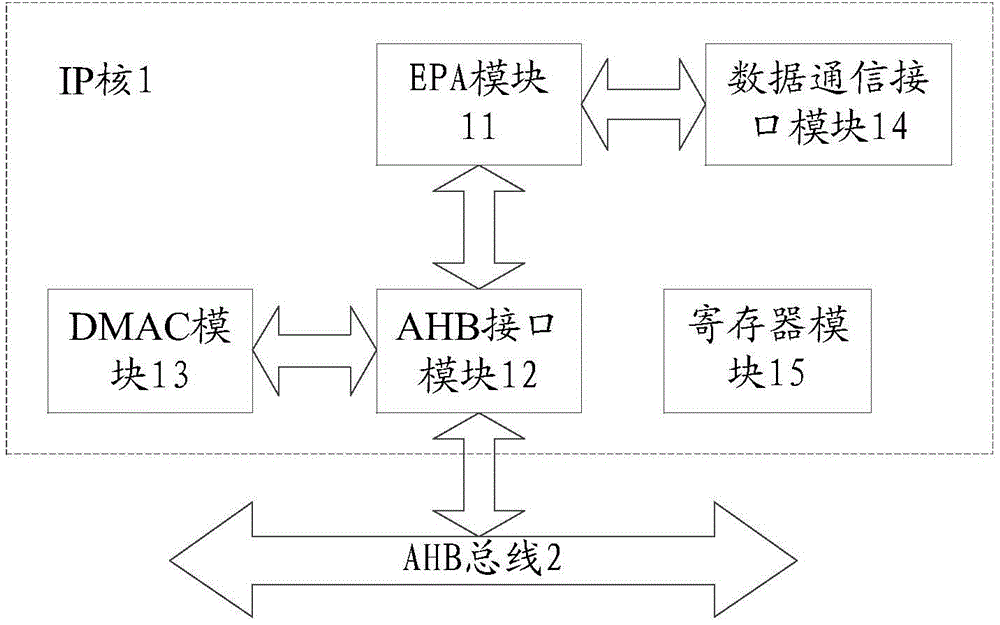

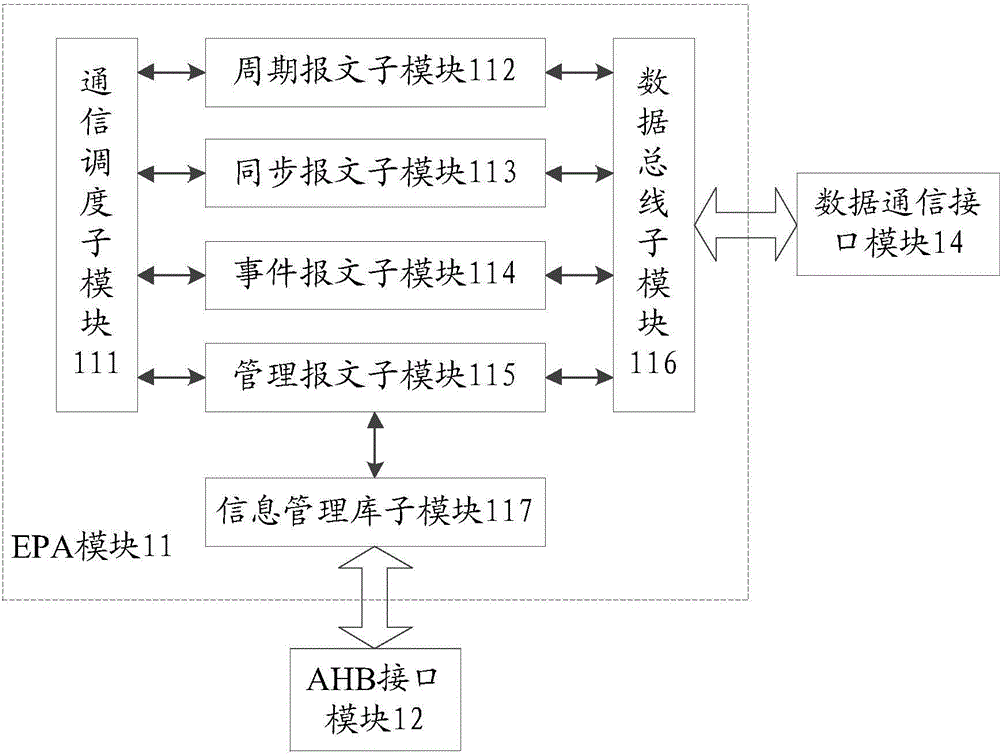

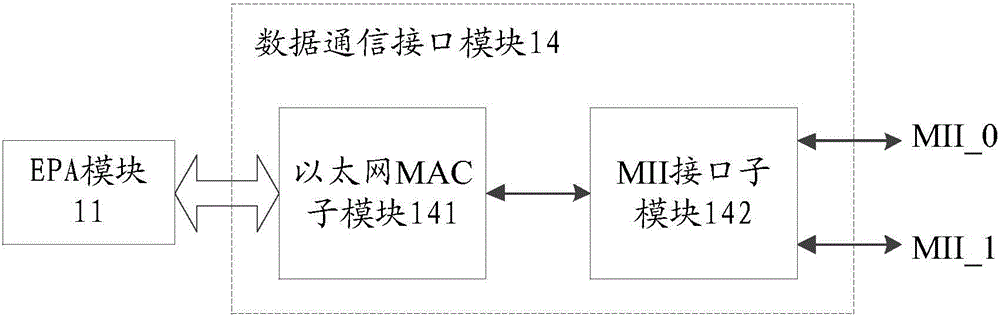

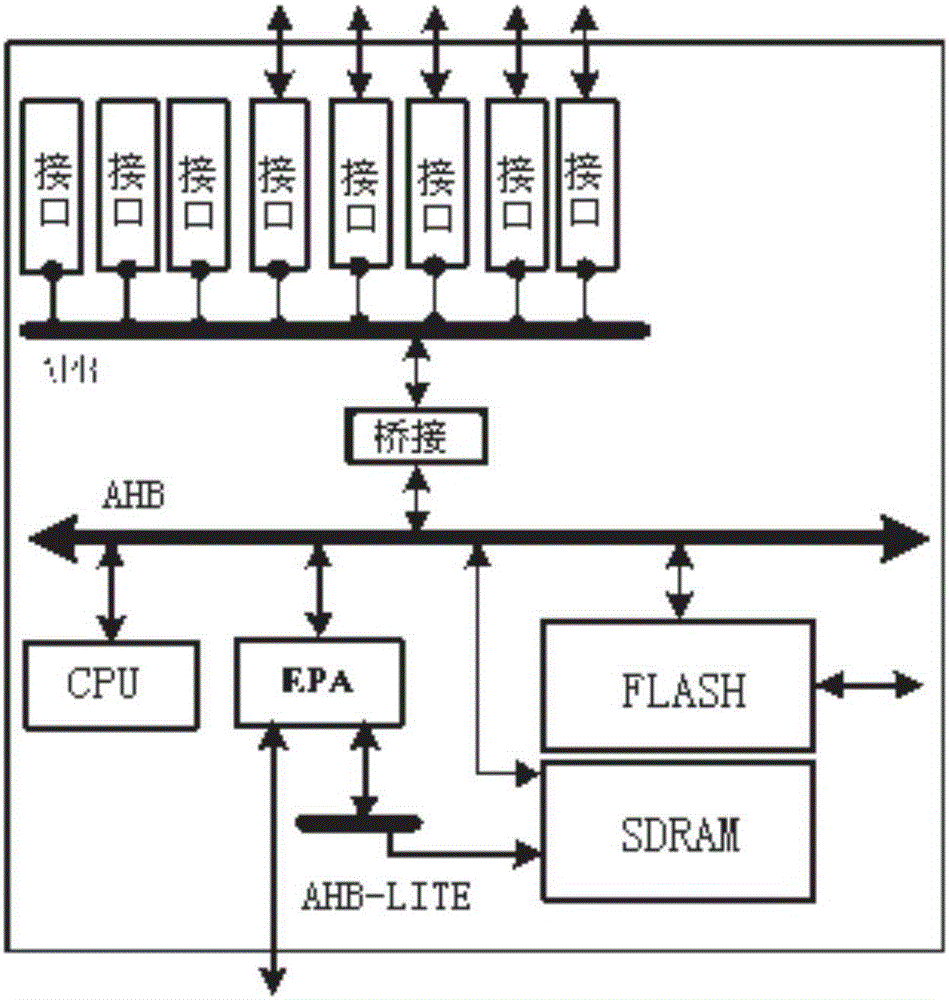

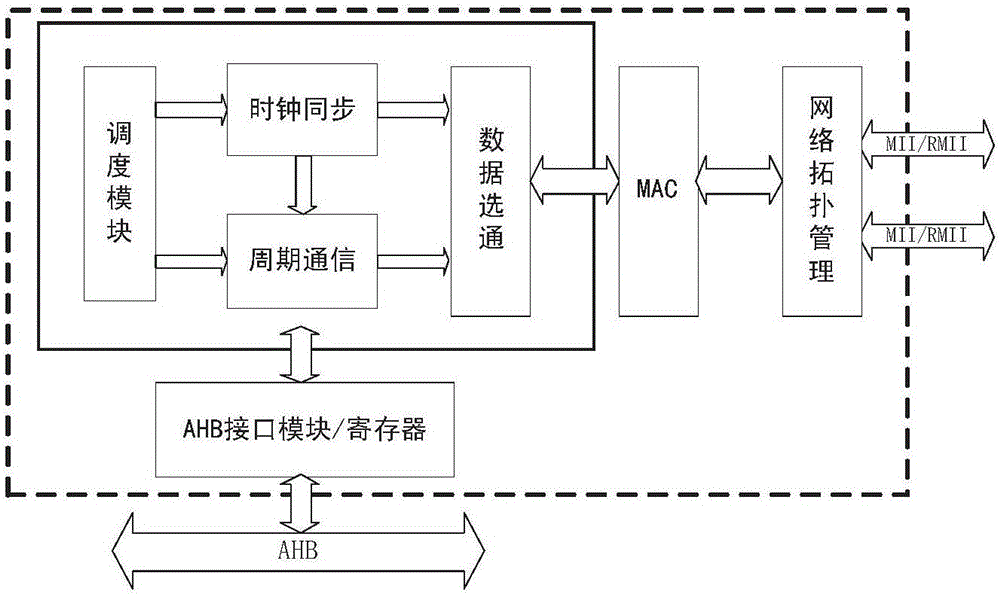

EPA (Ethernet for Plant Automation) communication IP (Intellectual Property) core and system on chip (SOC) based on AMBA (Advanced Microcontroller Bus Architecture) bus structure

InactiveCN104135410ASolve the costSolve the shortcomings of core technology that is easy to be crackedArchitecture with single central processing unitElectric digital data processingStatic random-access memoryAdvanced Microcontroller Bus Architecture

The invention discloses an EPA (Ethernet for Plant Automation) communication IP (Intellectual Property) core and a system on chip (SOC) based on an AMBA (Advanced Microcontroller Bus Architecture) bus structure. An EPA protocol stack is encapsulated into an IP hard core, and the IP core comprises an EPA module, an AHB (Advanced High-performance Bus) interface module, a DMAC (Direct Memory Access Controller) module, a data communication interface module and a register module. The EPA protocol stack is hooked on an AMBA bus, and constructs the SOC together with units such as a CPU (Central Processing Unit), an SRAM (Static Random Access Memory) and a FLASH. The EPA communication IP core and the system on chip have the beneficial effects that the technical advantages of an ARM (Advanced RISC Machine)+FPGA (Field Programmable Gate Array) platform are realized, and the defects of high cost, easiness in cracking a core technology and the like in the platform are successfully overcome; based on the implemented efficient interface-open SOC, a communication system based on EPA is more stable and reliable; and by adopting the IP core provided by the invention, an EPA communication function is realized, and a redundant function and an accurate clock synchronizing function are supported.

Owner:浙江杰芯科技有限公司

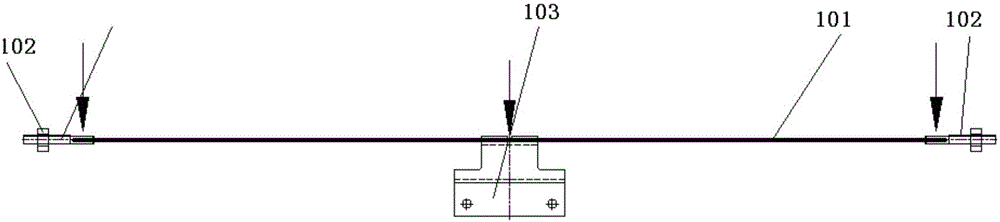

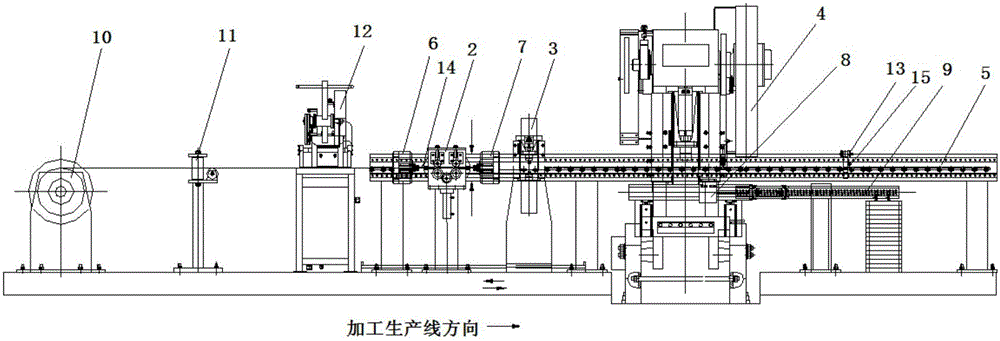

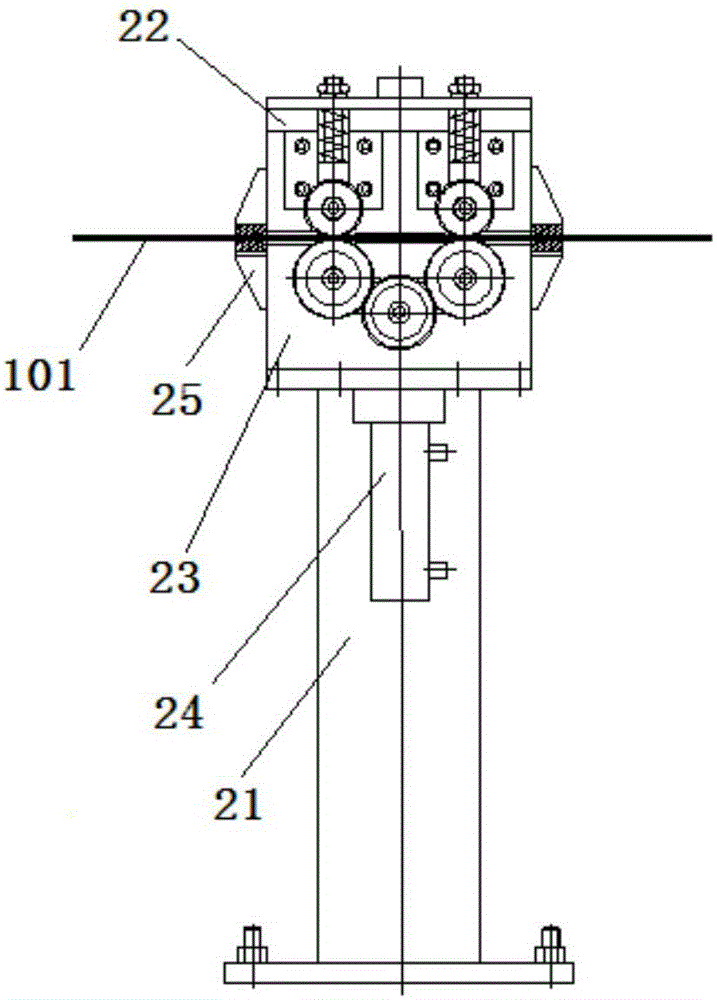

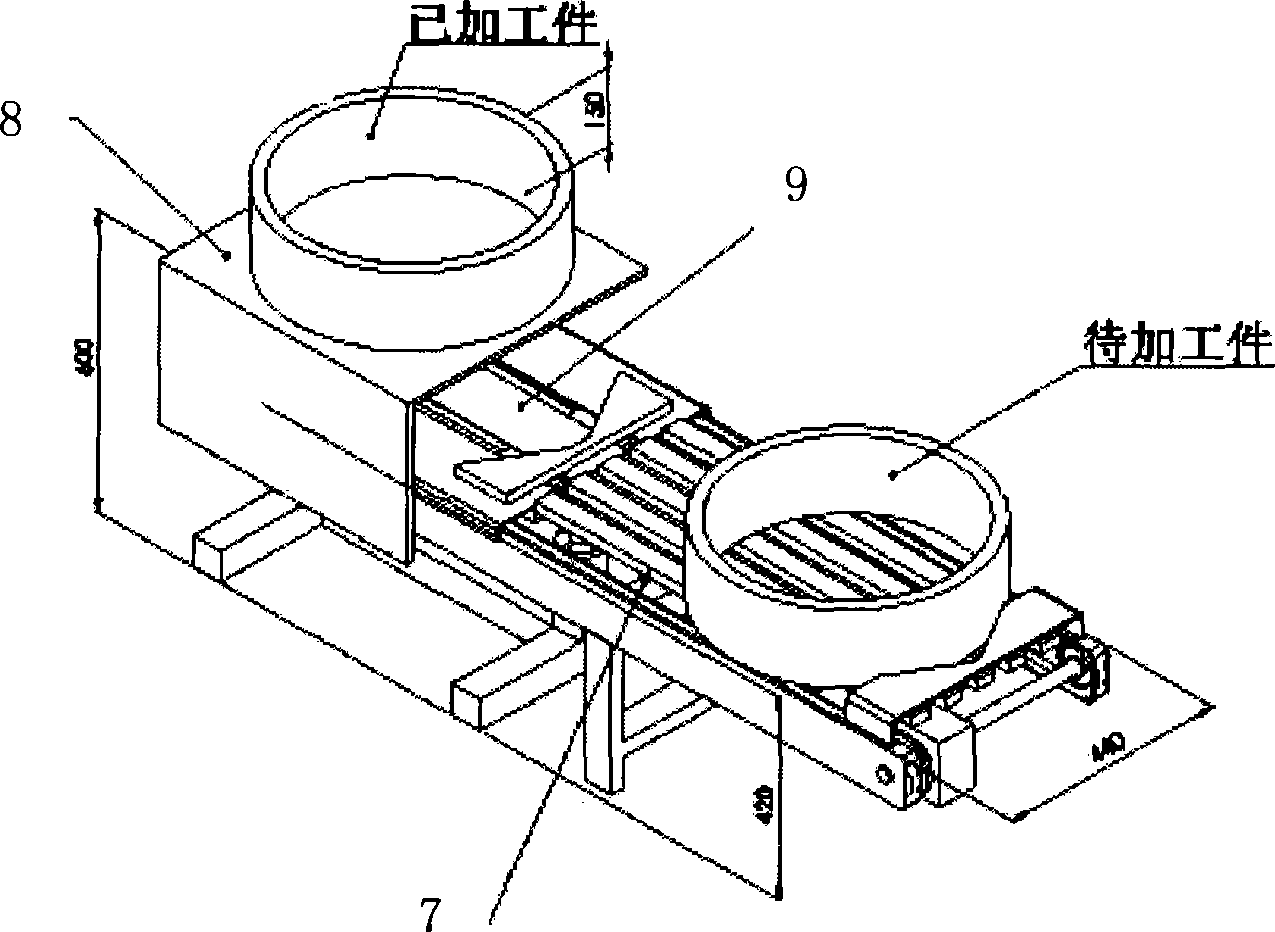

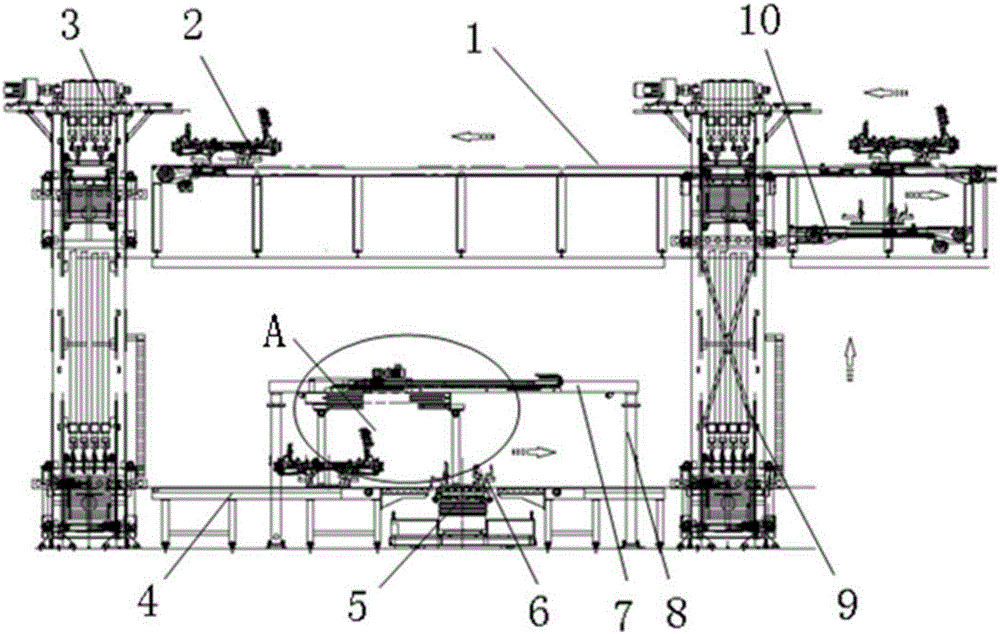

Steel wire rope assembly machining system and method

ActiveCN105033122AEasy to produceBuild craftMaterial strength using tensile/compressive forcesEngineeringMachining system

The invention discloses a steel wire rope assembly machining system and method and belongs to the technical field of factory automatic machining. A steel wire rope assembly comprises a steel wire rope, screws arranged at the two ends of the steel wire rope, and a connecting plate arranged in the middle of the steel wire rope. The machining system comprises a feeding device, a first riveting machine, a second riveting machine and a production guide rail, wherein the feeding device, the first riveting machine and the second riveting machine are arranged in sequence, and the production guide rail is used for connecting the feeding device, the first riveting machine and the second riveting machine. The feeding device and the first riveting machine are arranged on the same side of the second riveting machine. The machining system further comprises a first clamp, a second clamp and a third clamp. The first clamp and the second clamp are arranged on the production guide rail in a sliding manner and arranged on the two sides of the feeding device, and the third clamping device is arranged on the second riveting machine in a sliding manner. The machining system fills up the blank of domestic elevator production enterprises in the automatic machining industry of steel wire rope assemblies, formation of standardized production can be facilitated, and a systematic machining technology and a production system can be established.

Owner:CMCU ENG

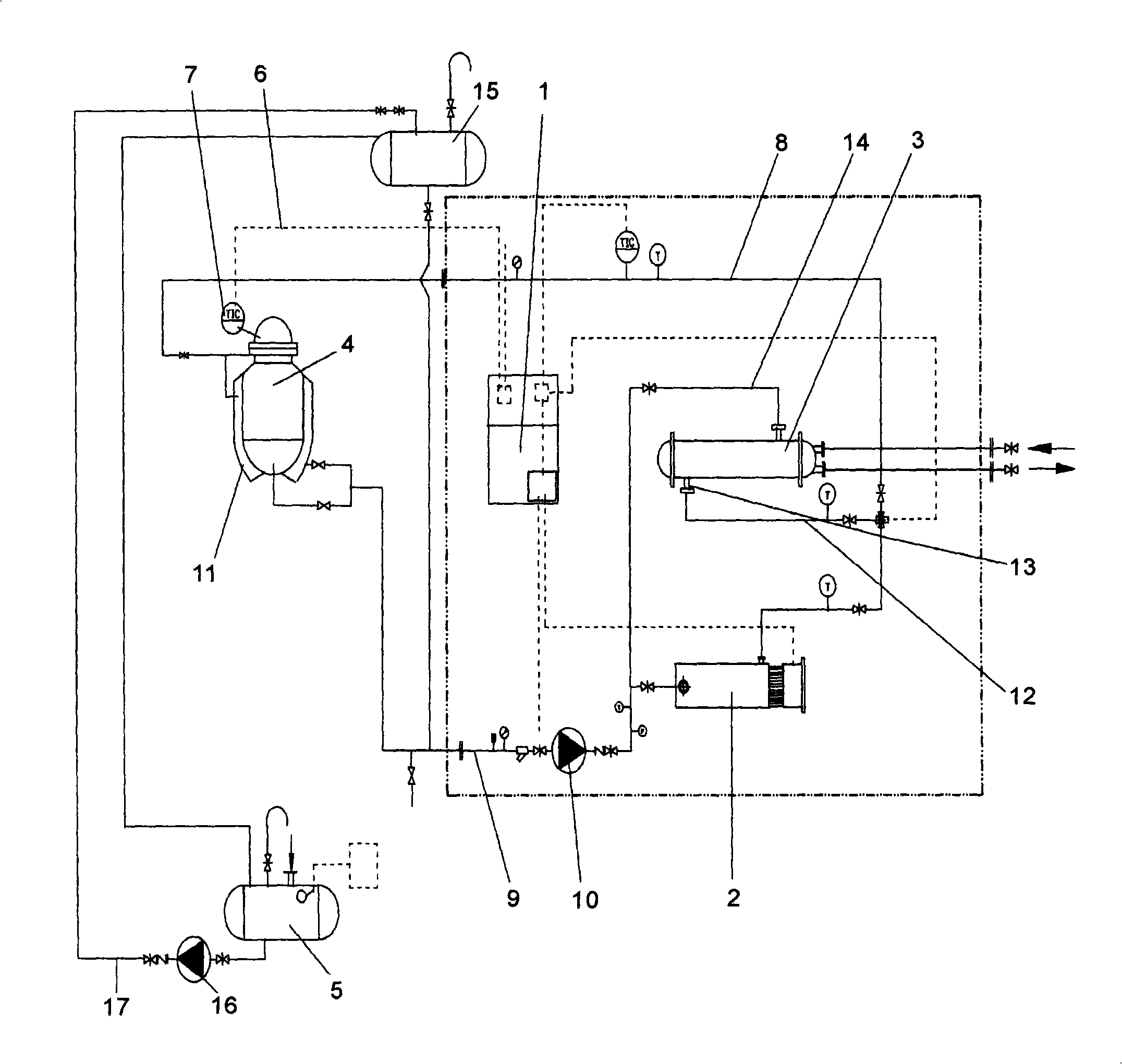

Temperature device for controlling heating or cooling of reaction kettle

InactiveCN101537335ASatisfy process needsTemperature control without auxillary powerChemical/physical/physico-chemical processesElectrical controlProcedural approach

The invention relates to a temperature device for controlling the heating or the cooling of a reaction kettle, which is characterized in that a signal conducting wire of an electrical control cabinet is connected with a temperature sensor of a reaction kettle body, a switch cabinet and a three-way valve of a heating system and oil pumps of an oil delivery pipe and an oil return pipe; the electrical control cabinet is connected with a power supply; the oil delivery pipe output by the heating system is connected with an oil pipe output by a cooler through the three-way valve; an outlet of the three-way converging valve is connected with an oil inlet pipe of the reaction kettle through a pipeline; a circulating oil pump is arranged on the oil return pipe; and a slippage pump of the circulating oil pump is arranged on an oil supplementing pipeline positioned between an oil storage tank and an expanding oil tank. When materials inside the reaction kettle are heated to certain temperature by oil which flows to a clamping sleeve of the reaction kettle, the temperature sensor which is embedded into the reaction kettle body sends signals back to the electrical control cabinet, and the electrical control cabinet sends a command to the heating system to adjust heating power or stop heating or partly start a cooling loop of the three-way valve so as to enable the reaction kettle to internally keep preset temperature. The whole temperature device is controlled by procedures, thereby meeting a requirement for automated management of factories.

Owner:王颖

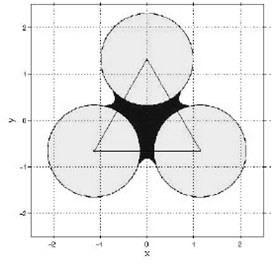

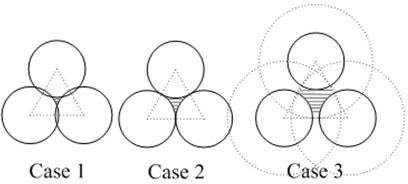

Detection-information-fusion-based wireless sensor network deterministic deployment method

InactiveCN102256269AExpand the range of perceptionReduce in quantityEnergy efficient ICTNetwork topologiesInformation processingTarget signal

The invention discloses a detection-information-fusion-based wireless sensor network deterministic deployment method, which comprises the following steps of: detecting the signal strength x of a target by utilizing sensor devices, wherein the target can be detected by a plurality of sensor devices; computing an estimation value of a target characteristic parameter Theta and a parameter estimation error according to the detected signal strength and characteristic parameter expression of the target by adopting a best linear unbiased estimation method; and computing a maximum spacing distance dmax between adjacent sensor nodes; and computing the number of the sensor nodes required to be deployed and specific arrangement positions according to the dmax. In the method, the number of the sensor nodes for detection can be greatly reduced based on a parameter estimation theory under the condition of given detection probability, detection efficiency can be improved and the cost of implementing effective monitoring by a wireless sensor network can be reduced by utilizing the cooperative information processing capability of the sensor nodes; and the method is applied in the fields of factory automatic equipment state monitoring and fault diagnosis, urban traffic safety monitoring and the like.

Owner:SUZHOU UNIV

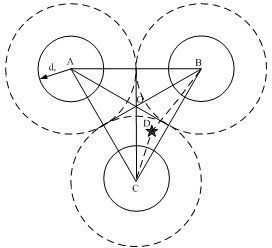

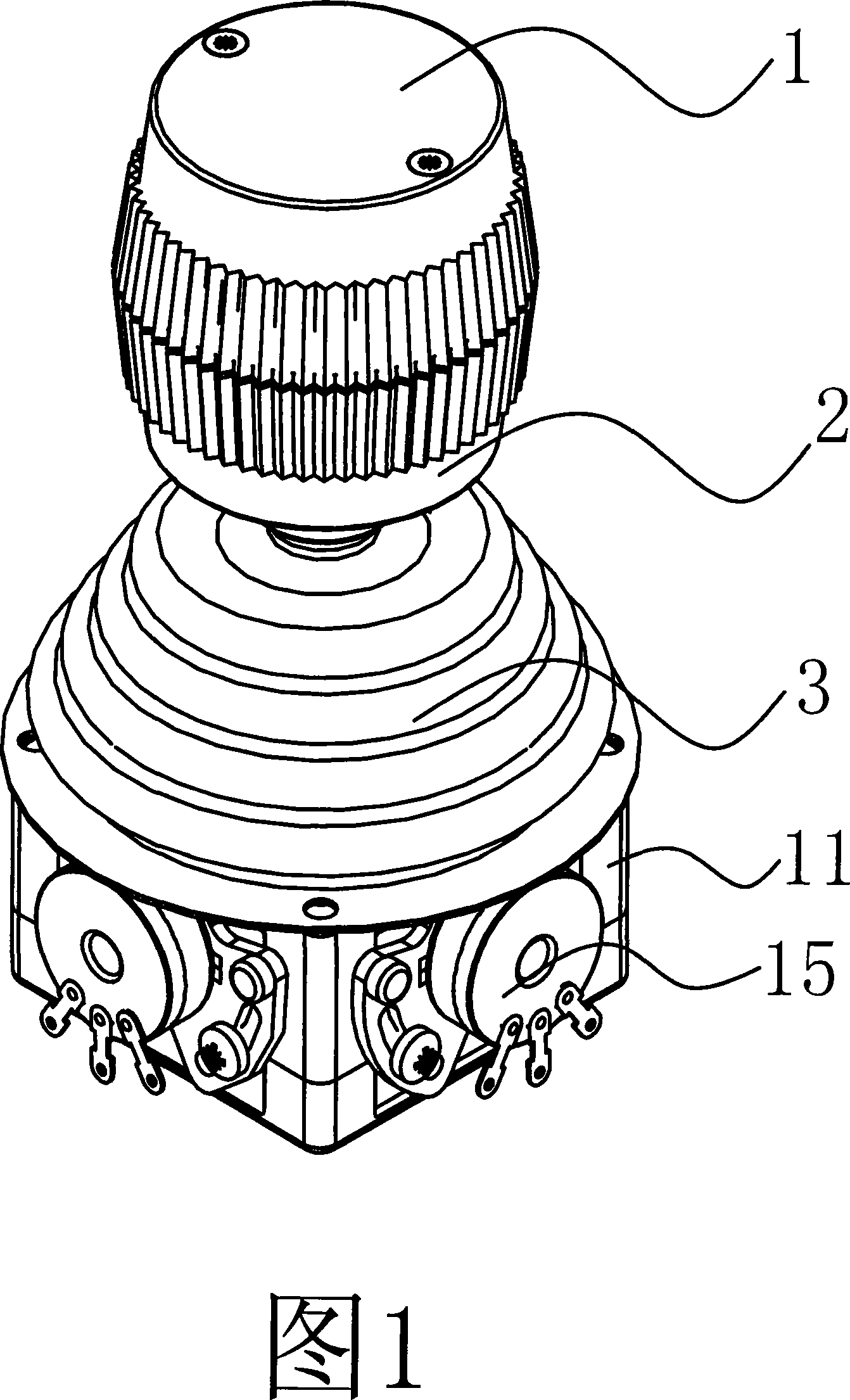

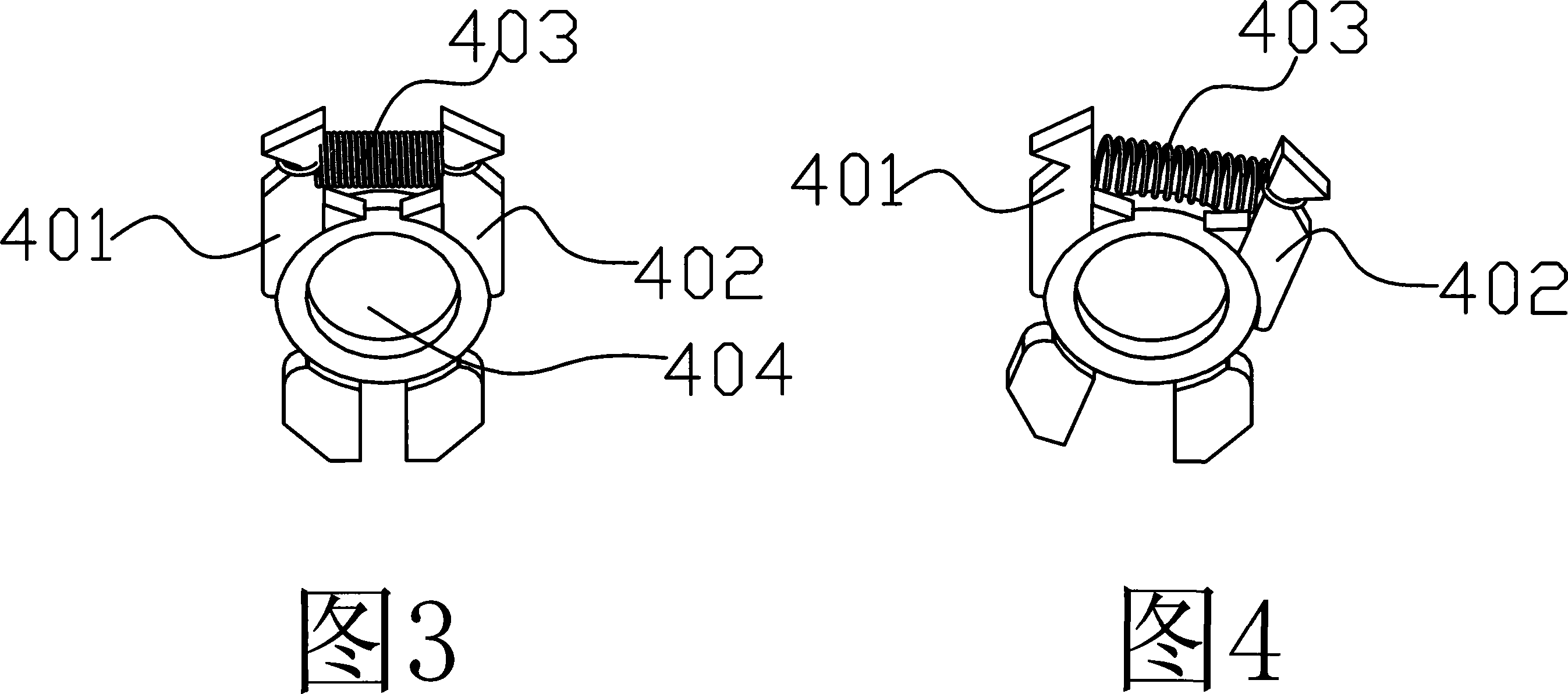

High accuracy three-dimensional rocker

InactiveCN101034296ASensitive controlEasy to assembleControlling membersMedical imagingPlant automation

The invention relates to a high-precision 3-D rocker, including the dock, connecting rod wearing located on the dock, the first, second direction of movement devices being linked together with the connecting rod activities with setting on the base ,installed in the external base moves with the direction of the first device, the second direction of movement devices connected Potentiometers, located at the other end of the connecting rod handle Rocker, located at the stated rocker a third direction handle internal moves device, the third direction of movement installations include reduction devices, Shaft, Hall sensor circuit boards. The beneficial effect of this invention: the invention of the technology program that is to achieve a three-dimensional control on the condition of not increasing the volume of rocker, and this third direction of movement installation moves easily,with structure strong, stable performance, control sensitive, high precision, and can be widely used in urban security, road monitoring, factory automation, electric power, finance, instruments, chemicals, metallurgy, medical imaging, and other mechanical and electrical equipments.

Owner:ZHE JIANG PEARMAIN ELECTRONICS

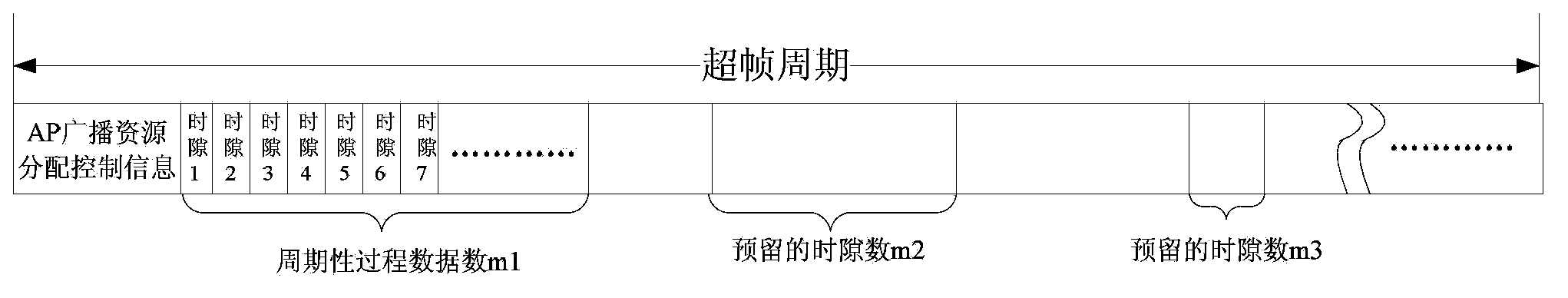

EPA (ethemet for plant automation) on-chip system, EPA communication system and EPA communication method

The invention provides an EPA (ethemet for plant automation) on-chip system, an EPA communication system and an EPA communication method in order to solve technical problems. A third non-real-time phase is added to EPA data communication on the basis of previous periodic and non-periodic communications, non-EPA messages can be supportively and compatibly dispatched and processed apart from EPA periodic messages and non-periodic messages, the on-chip system is supportive to not only EPA configuration software of an upper computer to be pre-configured but also to common EPA message dispatch to be pre-configured, and limitation of the EPA configuration software is broken through; meanwhile, parameters of macro period, module communication time slots, periodic time and the like can be determined on the on-chip system according to situations of scale and data size of entire network, and singular distribution of EPA modules by users is avoided.

Owner:浙江杰芯科技有限公司

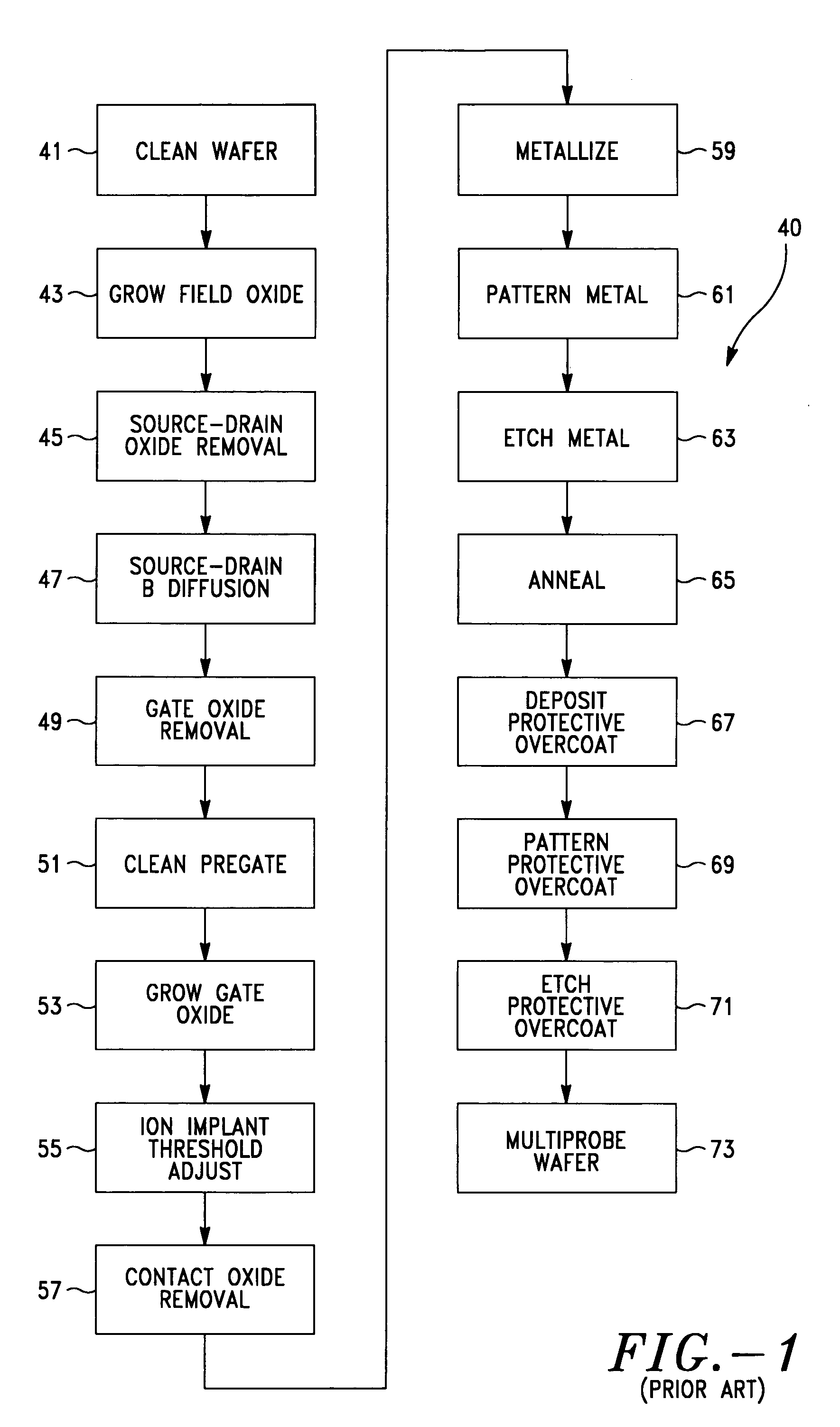

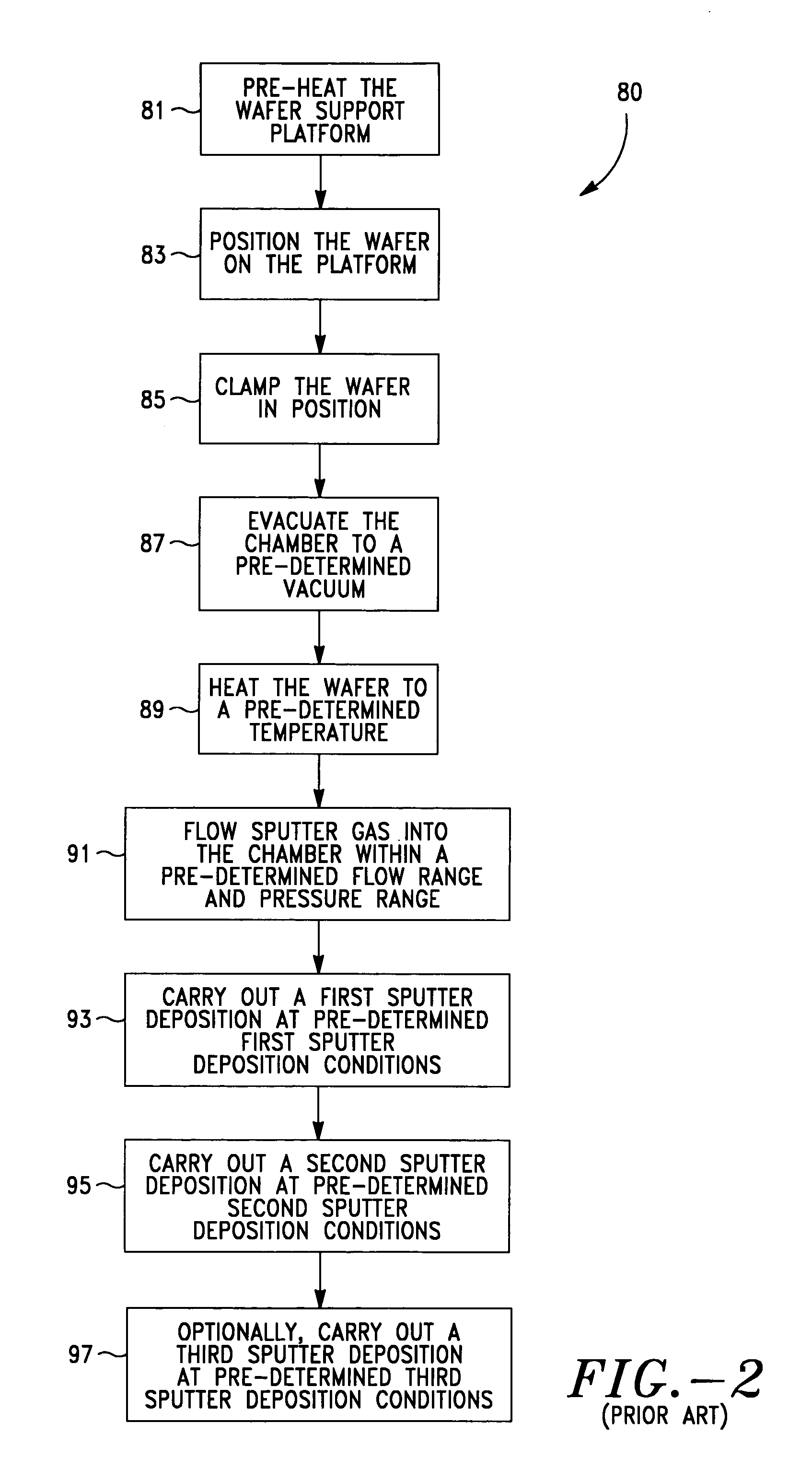

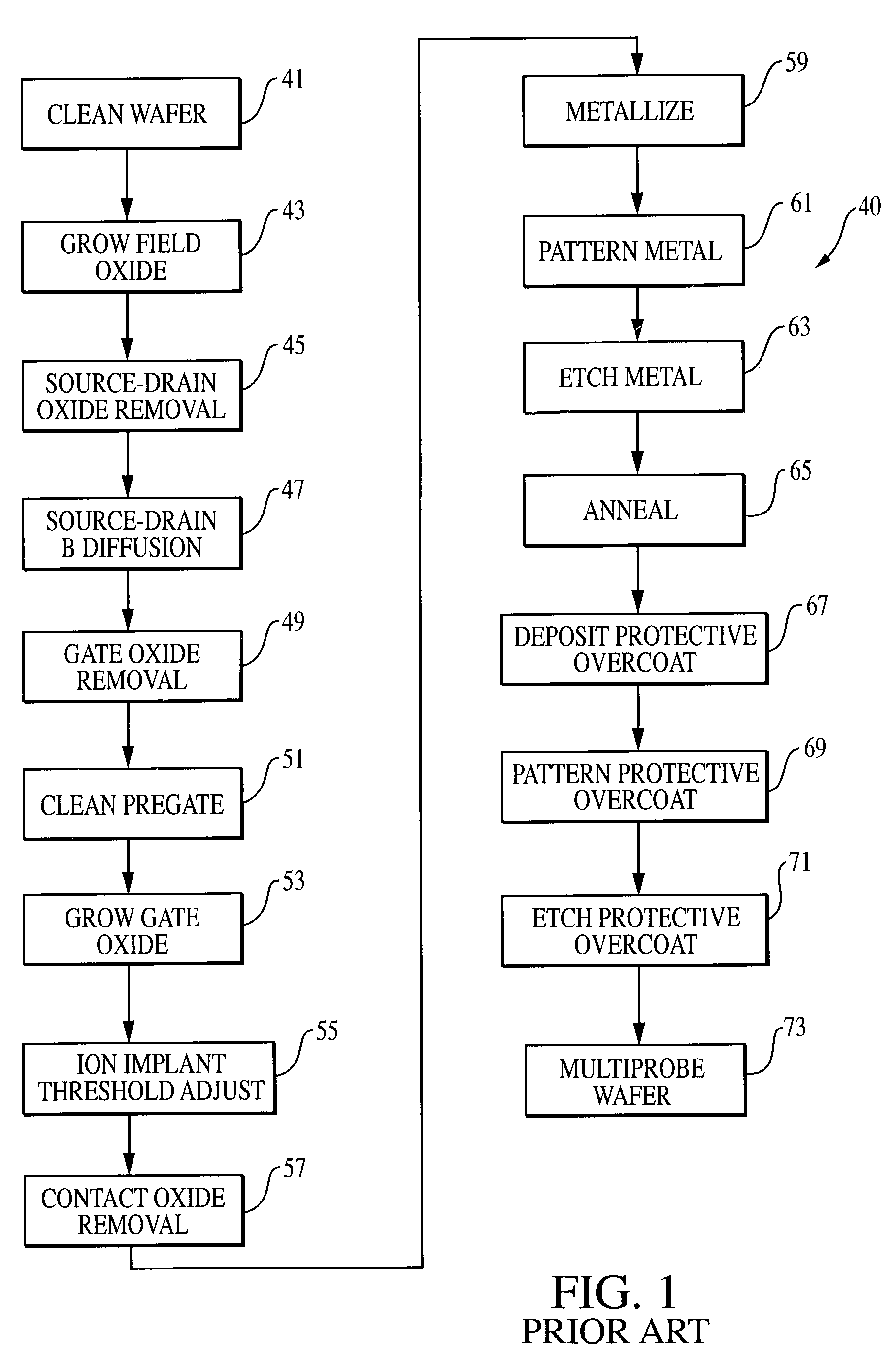

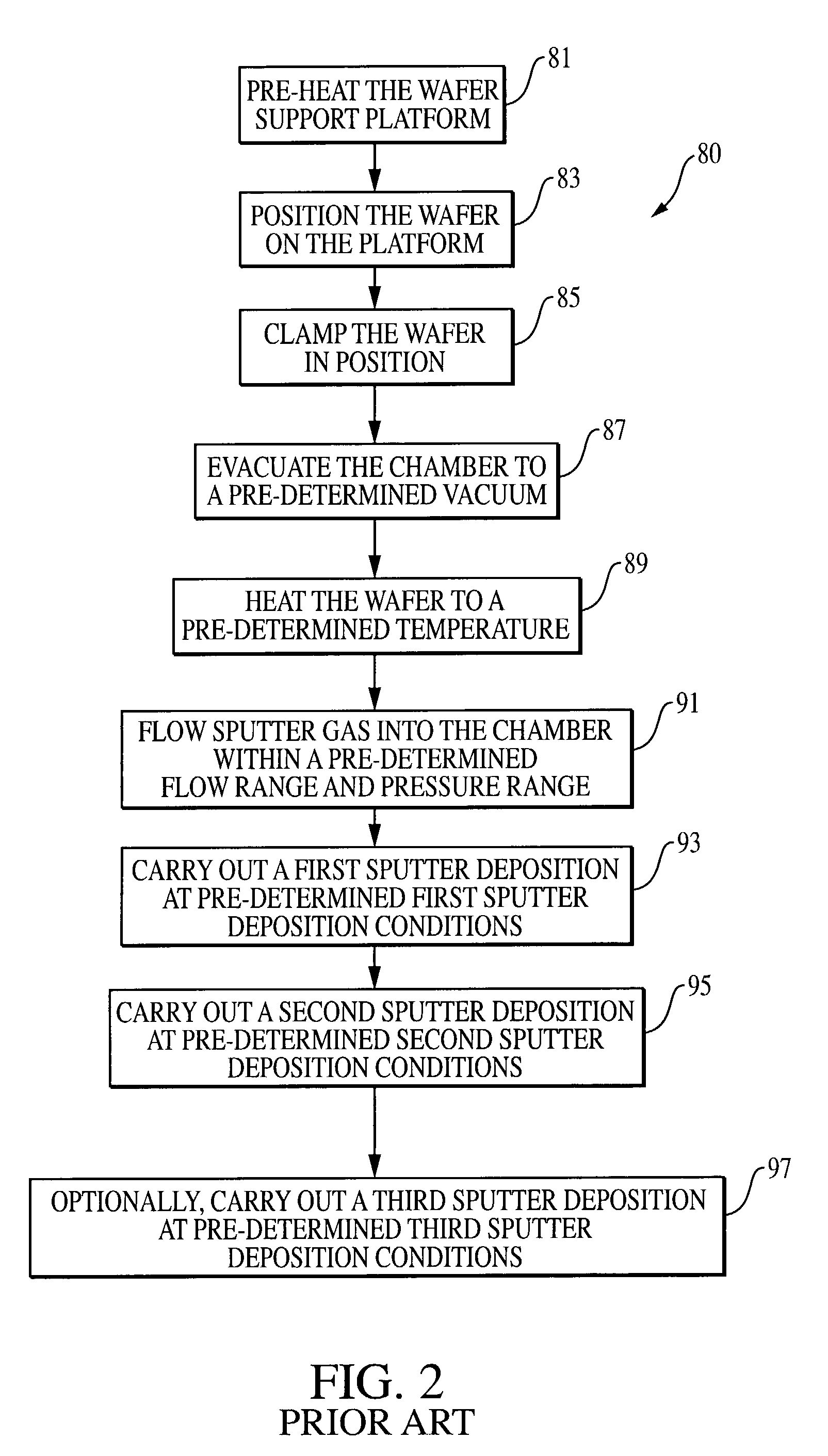

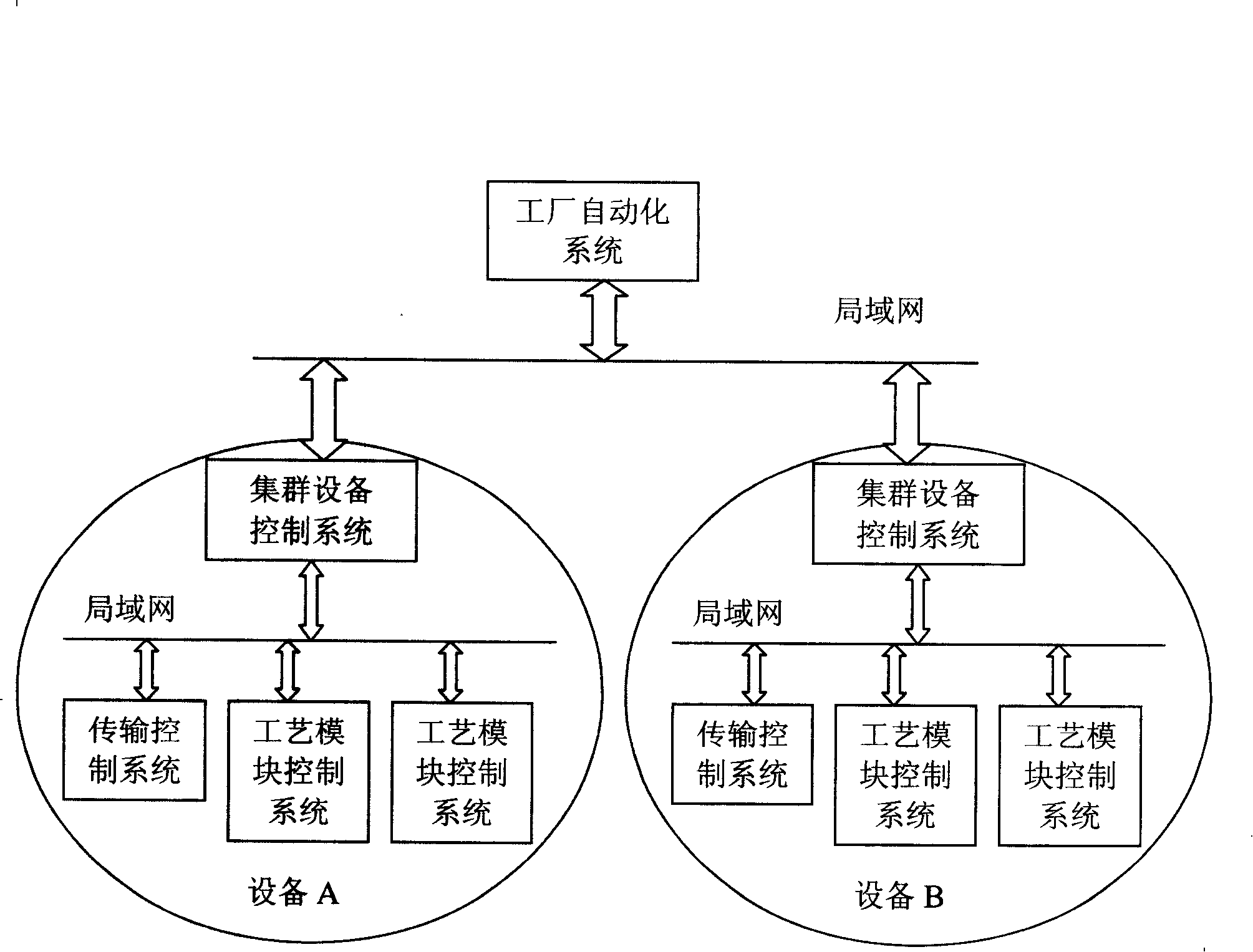

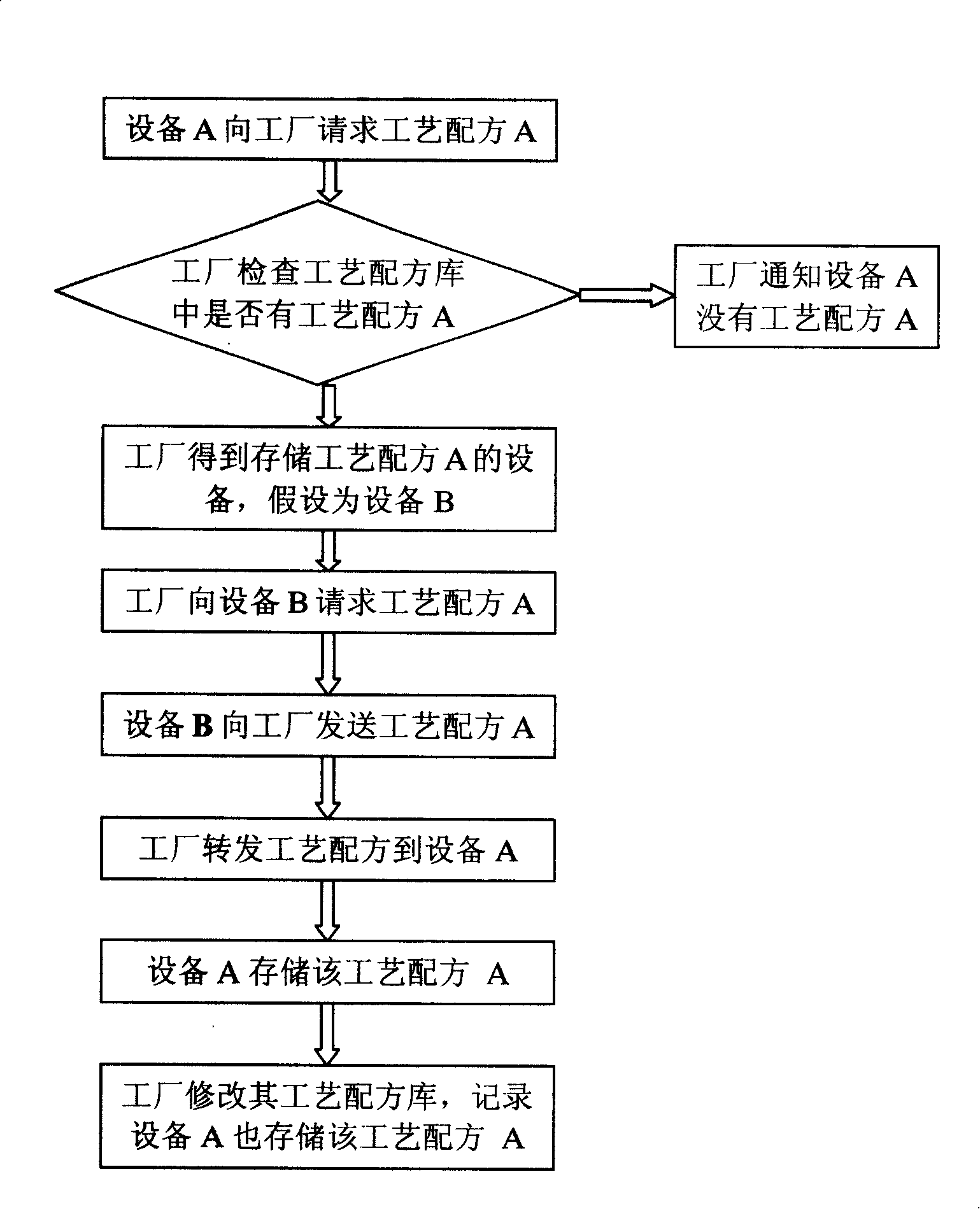

Semiconductor fabrication process formula management process

InactiveCN101216698AResolve synchronizationRealize automatic disseminationSemiconductor/solid-state device manufacturingProgramme control in sequence/logic controllersManagement processSemiconductor factory

The invention relates to the automation technical field of a semiconductor factory, in particular to a management method for semiconductor manufacturing process formulation. On the basis of dividing specific functional roles between a factory automation system and a device, the management method for the semiconductor manufacturing process formulation provided by the invention realizes the management on the process formulation in accordance with a plurality of strategies between the system and the device such as connection, disconnection and management. Through specifically dividing roles between the factory automation system and the device, two systems manage the process formulation coordinately, thereby decreasing the complexity of management and improving the efficiency of management.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Automatic charging and discharging and transmitting device for handstand type numerical controlled lathe

ActiveCN101417345ARealize automatic flow operationRealize automated productionAutomatic conveying/guiding stockNumerical controlReciprocating motion

The invention discloses an automatic feeding and discharging and transmission device used for an inverted numerically controlled lathe, comprising a feeding and discharging platform, a conveying guide rail and a workpiece turnover mechanism. The feeding and discharging platform is arranged at one side of the lathe bed of the lathe, the back of the lathe bed is provided with a feed hole, the conveying guide rail is distributed and arranged on the feeding and discharging platform from the feed hole and is connected with the subsequent inverted numerically controlled lathes mutually, and the workpiece turnover mechanism is arranged on the conveying guide rail among the lathes, wherein, the feeding and discharging platform comprises a conveying table, a discharging platform and an automatic aligning mechanism; the conveying table has fixed structure which is driven by a chain and connected with the conveying guide rail, the discharging platform is driven by the chain at the bottom to carry out reciprocating motion, and the automatic aligning mechanism is arranged between the conveying table and the discharging platform. In the invention, the workpiece feeding and discharging is realized by the automatic feeding and discharging and transmission device, thus effectively reducing the labor intensity of workers; and the workpiece machining process and the workpiece feeding and discharging can be finished on one machine, thus realizing the factory automated production.

Owner:CSC BEARING

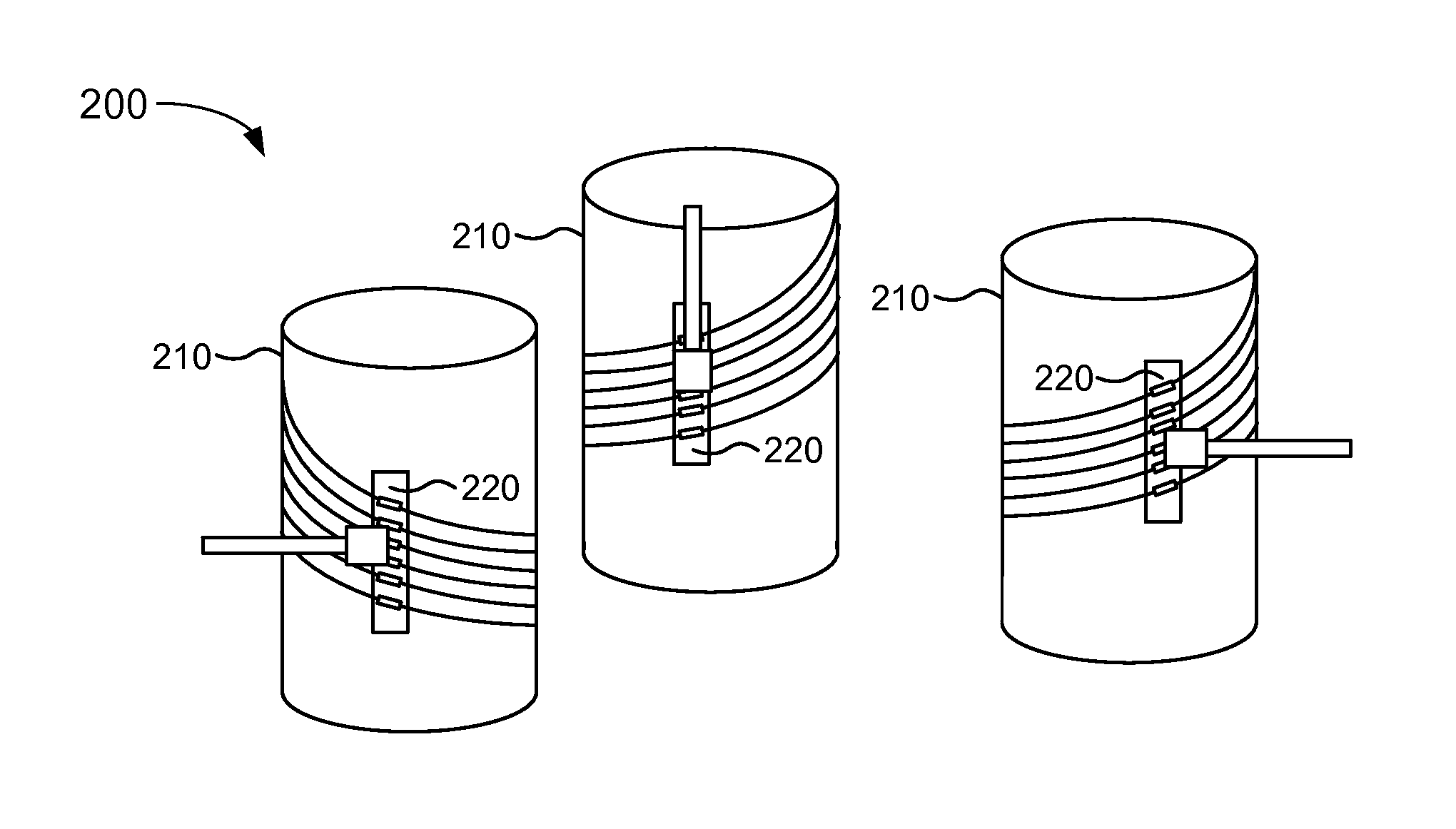

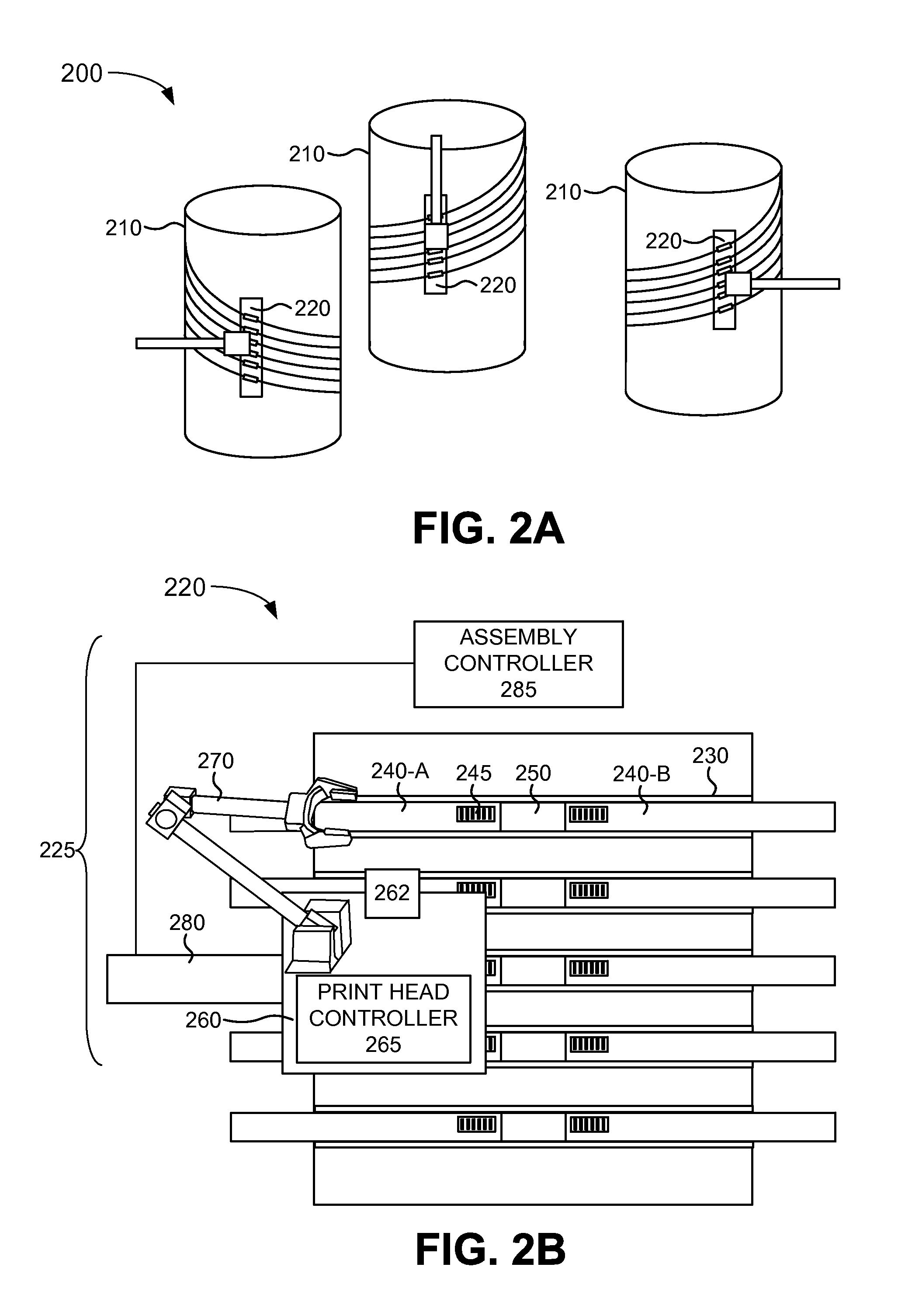

Machine-to-machine plant automation using 3D printed fiber splicing

A system may include a fiber distribution hub including a plurality of fiber-optic cables, wherein a particular one of the plurality of fiber-optic cables includes a machine-readable identifier; and a robotic device configured to access particular ones of the plurality of fiber-optic cables. The robotic device may include a print head configured to splice together the particular ones of the plurality of fiber-optic cables by three-dimensional printing of a silane material. A hand-held unit may also include a print head configured to splice together fiber-optic cables by three-dimensional printing of a silane material.

Owner:VERIZON PATENT & LICENSING INC

Automatic pallet transfer device and conveying system

ActiveCN106315158ARequirements for realizing automated transshipmentReduce the risk of fallingMechanical conveyorsPlant automationDelivery system

The invention relates to an automatic pallet transfer device and a conveying system. The automatic pallet transfer device comprises a first aerial conveying line, a second aerial conveying line, a pallet with a workpiece, a ground conveying line, an automatic conveying trolley, a first lifter, a second lifter and a transfer device assembly, one end of the first aerial conveying line is connected with the upper portion of the first lifter, the upper portion of the second lifter is connected with an upper station of the workpiece, the lower portion of the first lifter is connected with one end of the ground conveying line, the other end of the ground conveying line is connected with the lower portion of the second lifter, the transfer device assembly crosses over the ground conveying line, and the automatic conveying trolley is respectively connected with the ground conveying line and the transfer device assembly in a matched manner. The automatic pallet transfer device meets requirements of automatic transfer of the workpiece, safety of an assembly shop is improved, drop risks of the workpiece in the lifting process are effectively reduced, and the automation degree of a factory is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

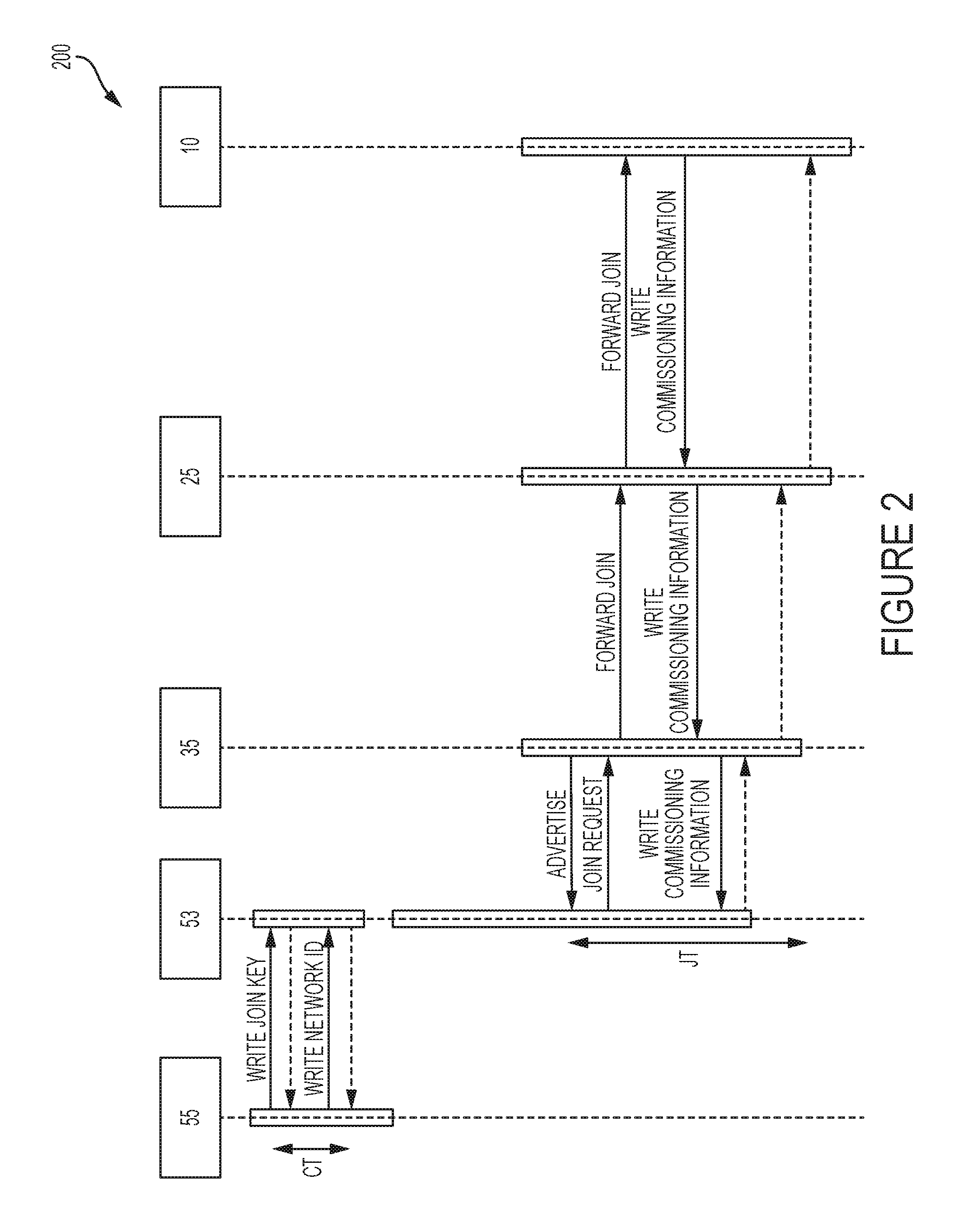

Method for commissioning and joining of a field device to a network

ActiveUS20170034308A1Particular environment based servicesWireless commuication servicesLine sensorNetwork key

The invention relates to a method for joining of a first field device to a wireless sensor actuator network using a configuration tool. The wireless sensor actuator network comprises a plurality of interconnected field devices and gateway for connecting the interconnected field devices to a plant automation network comprising controllers and network manager. The method comprises receiving device information associated with the first field device, transmitting a commissioning request for the first field device, the commissioning request comprising device information and geographical location information of the first field device, receiving commissioning information comprising a session key, a network key and routing information, and commissioning the first field device using the received commissioning information for joining the said field device to the wireless sensor actuator network.

Owner:ABB (SCHWEIZ) AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com