Method for precisely synchronizing time of industrial wireless network on basis of prediction and compensation

An industrial wireless network, time synchronization technology, applied in time division multiplexing systems, electrical components, multiplexing communications, etc., to achieve the effect of reducing time synchronization errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0065] The inventive method comprises the following steps:

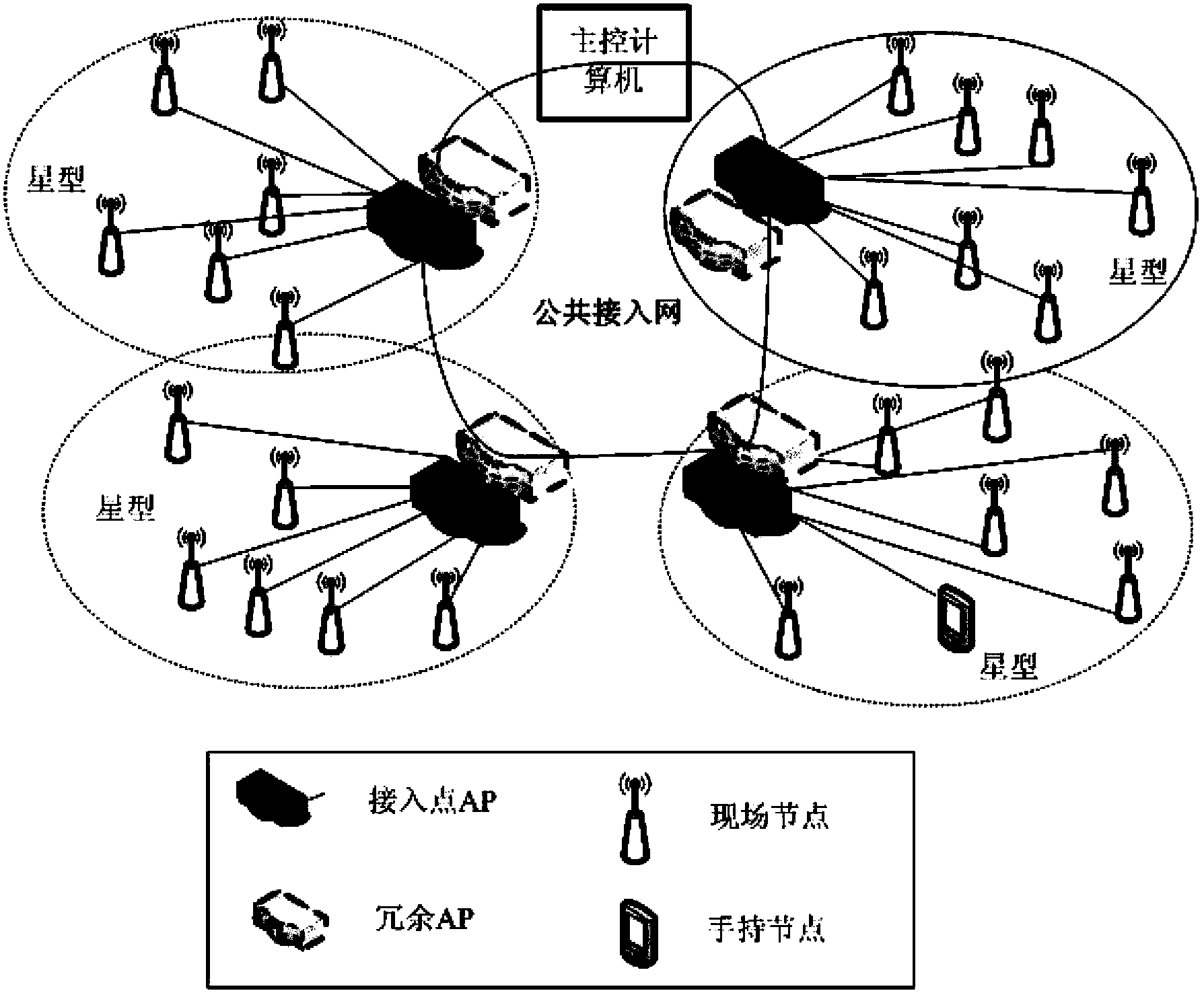

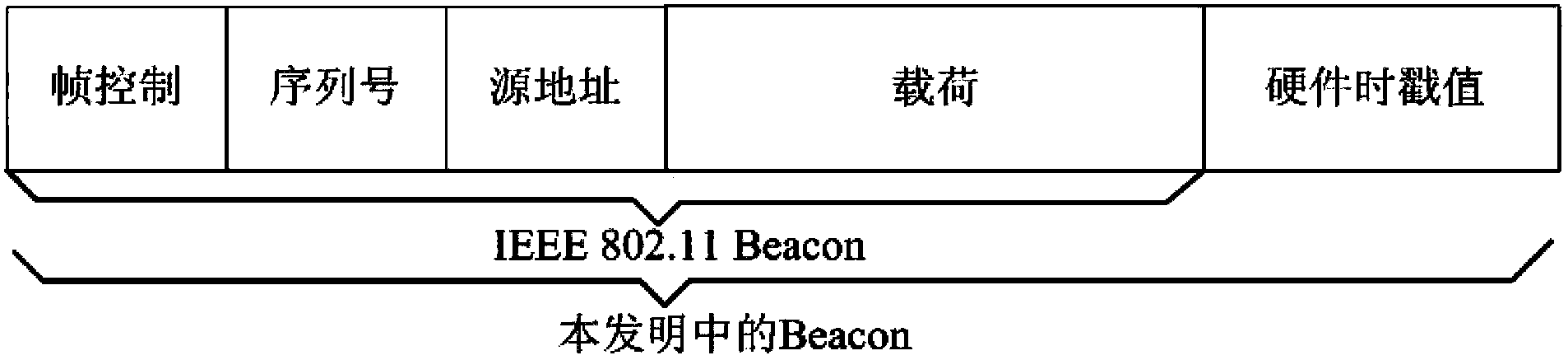

[0066] Establish the factory automation wireless network as a star network based on the IEEE 802.11 single-hop Basic Service Set (BSS, Basic Service Set) structure;

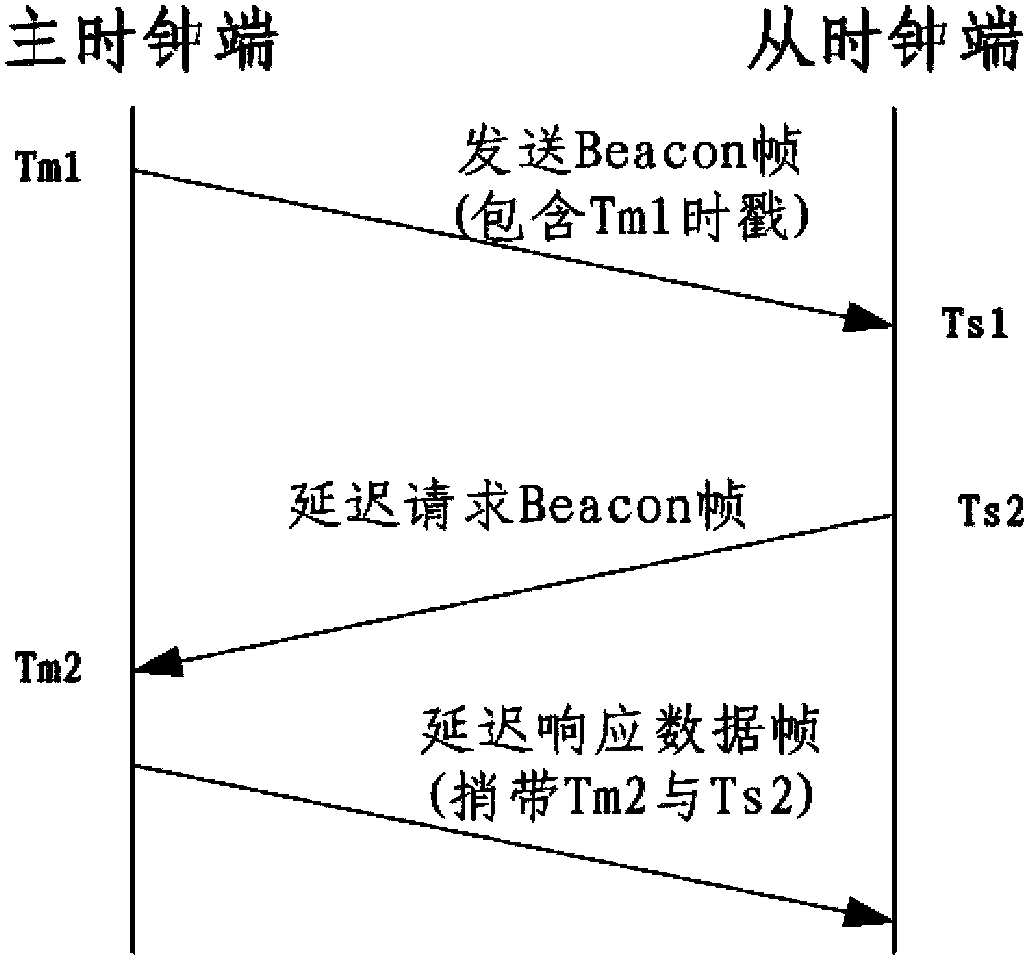

[0067] According to the type and function of the nodes in the network, set the master clock and slave clock;

[0068] The time offset value is calculated through two-way time stamp information interaction between the master clock end and the slave clock end;

[0069] Use the time offset value of the current synchronization cycle to predict the time offset value of the next synchronization cycle;

[0070] The clock drift is compensated by using the predicted time offset value of the next synchronization cycle, and the clock is calibrated.

[0071] Factory automation wireless network among the present invention adopts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com