Semiconductor fabrication process formula management process

A technology of process formula and manufacturing process, which is applied in semiconductor/solid-state device manufacturing, electrical program control, program control in sequence/logic controller, etc., and can solve the problem that the process formulas in the two places are not synchronized, and there is no unified strategy and storage space Waste and other issues, to achieve the effect of reducing storage space requirements, improving efficiency, and solving synchronization problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

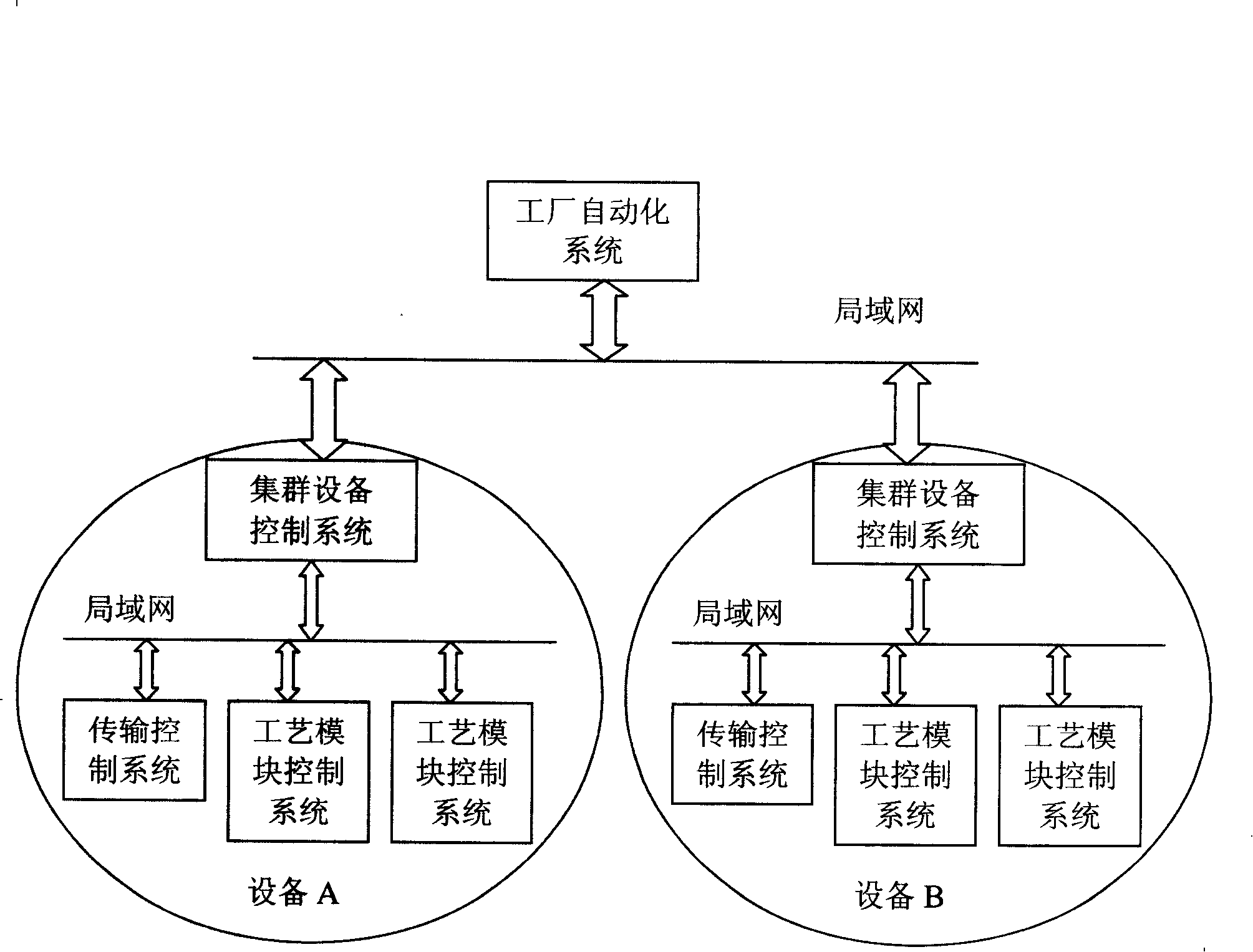

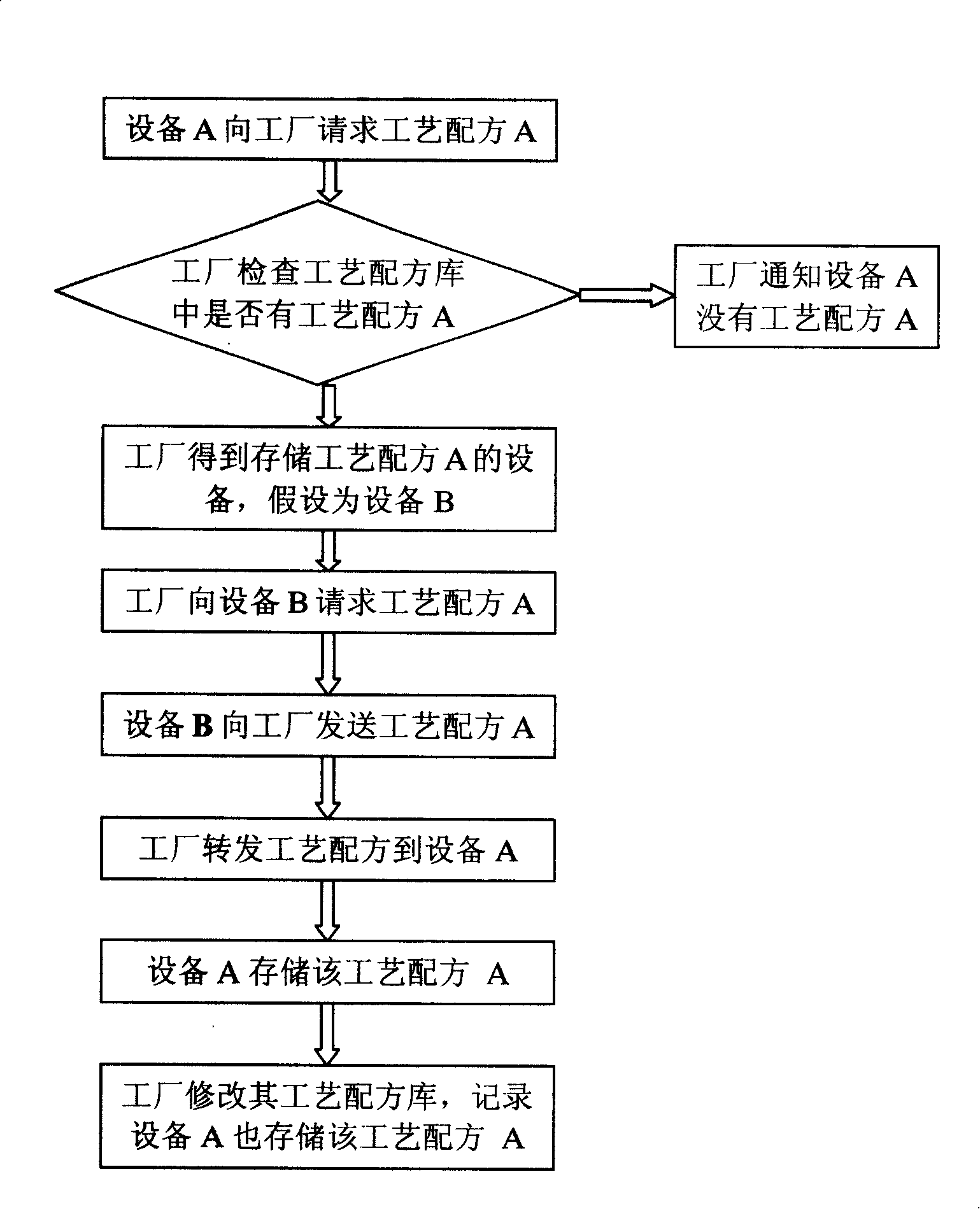

[0052] Currently there is a factory automation system (FA) and two devices (DA and DB respectively). Equipment A contains process recipes: RA1 (name), V1 (version number); RA2 (name), V1 (version number). Equipment B contains process recipes: RB1 (name), V1 (version number); RB2 (name), V1 (version number).

[0053] Initially, there is no connection between FA and DA, DB, and there is no record in its process recipe library.

[0054] After the connection between FA and DA is established, according to strategy 1, the process recipe library of FA will change, and it will record all the process recipes in device A, as shown in Table 1. Then FA establishes a connection with DB, and the contents of the final FA process formula library are shown in Table 2. During the above process, the process recipes stored in DA and DB have not been ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com