Patents

Literature

58 results about "Semiconductor factory" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

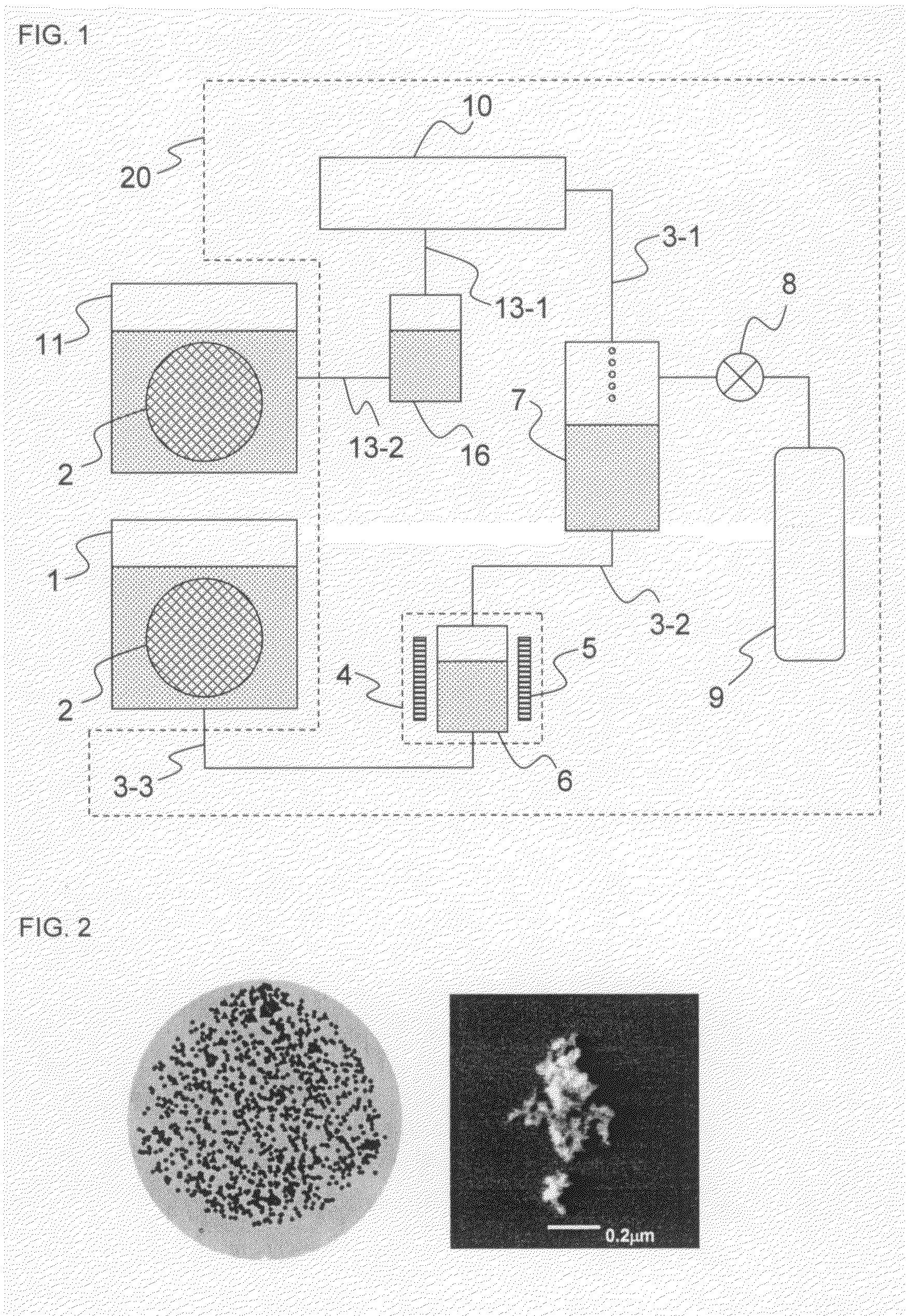

Cleansing agent for chemical absorbing hydrid gas and method for cleansing noxious gas

InactiveCN1565706AImprove adsorption capacityLow weight percentageOther chemical processesDispersed particle separationArsineCompound (substance)

The invention relates to a cleaning agent for chemical adsorption of hydride gas, specially a cleaning agent with titanium dioxide as carrier. The cleaning agent is made by coprecipitation process and BET specific surface area is no less than 60m#+[2] / g. The cleaning agent can remove harmful hydride component from the semiconductor factory and the photoelectricity factory by chemical adsorption.

Owner:IND TECH RES INST

Method for evaluating the quality of data collection in a manufacturing environment

ActiveUS7529642B2Improve the level ofGood reproducibilitySampled-variable control systemsTesting/monitoring control systemsTimestampSemiconductor fab

Owner:PDF SOLUTIONS SA

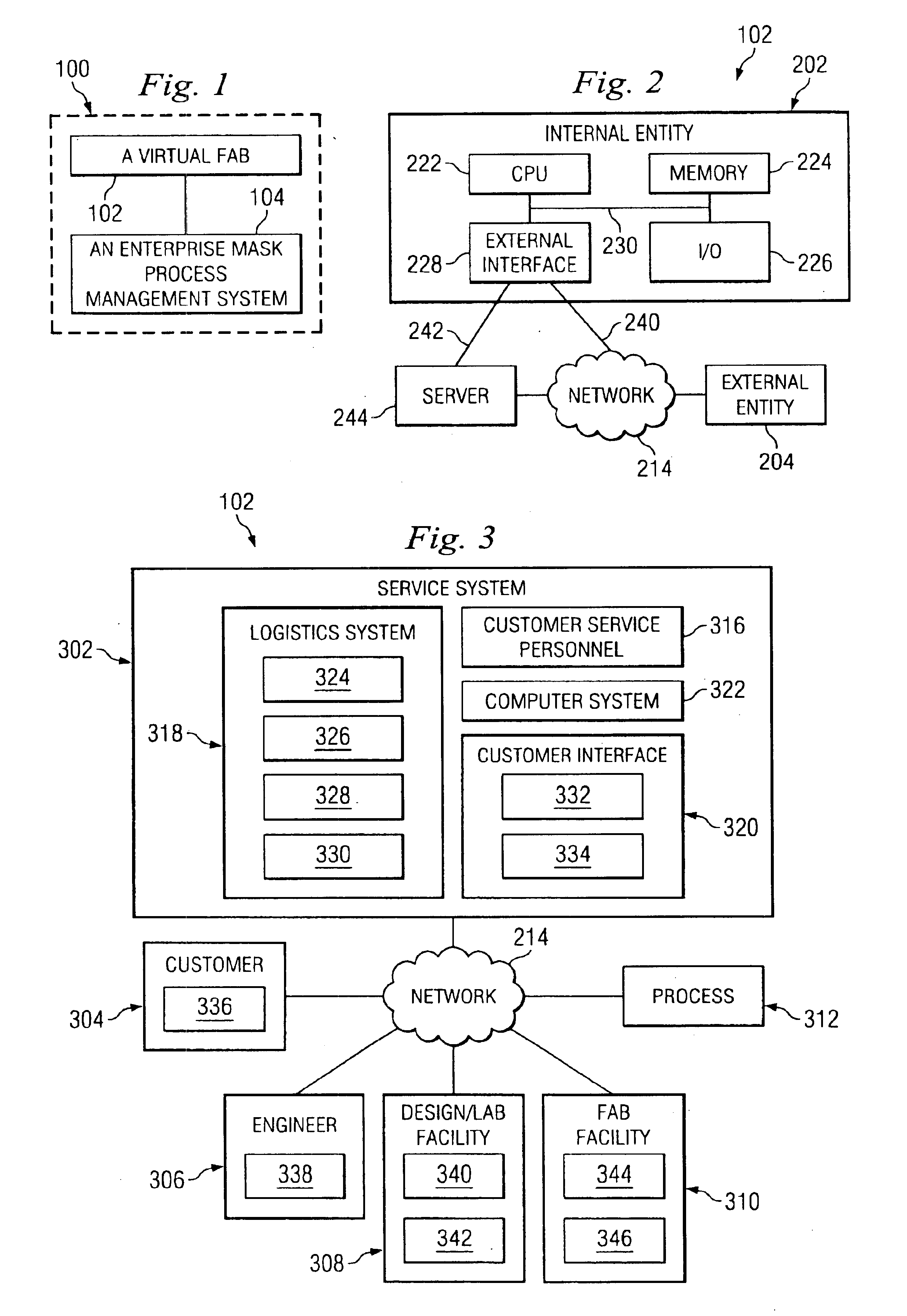

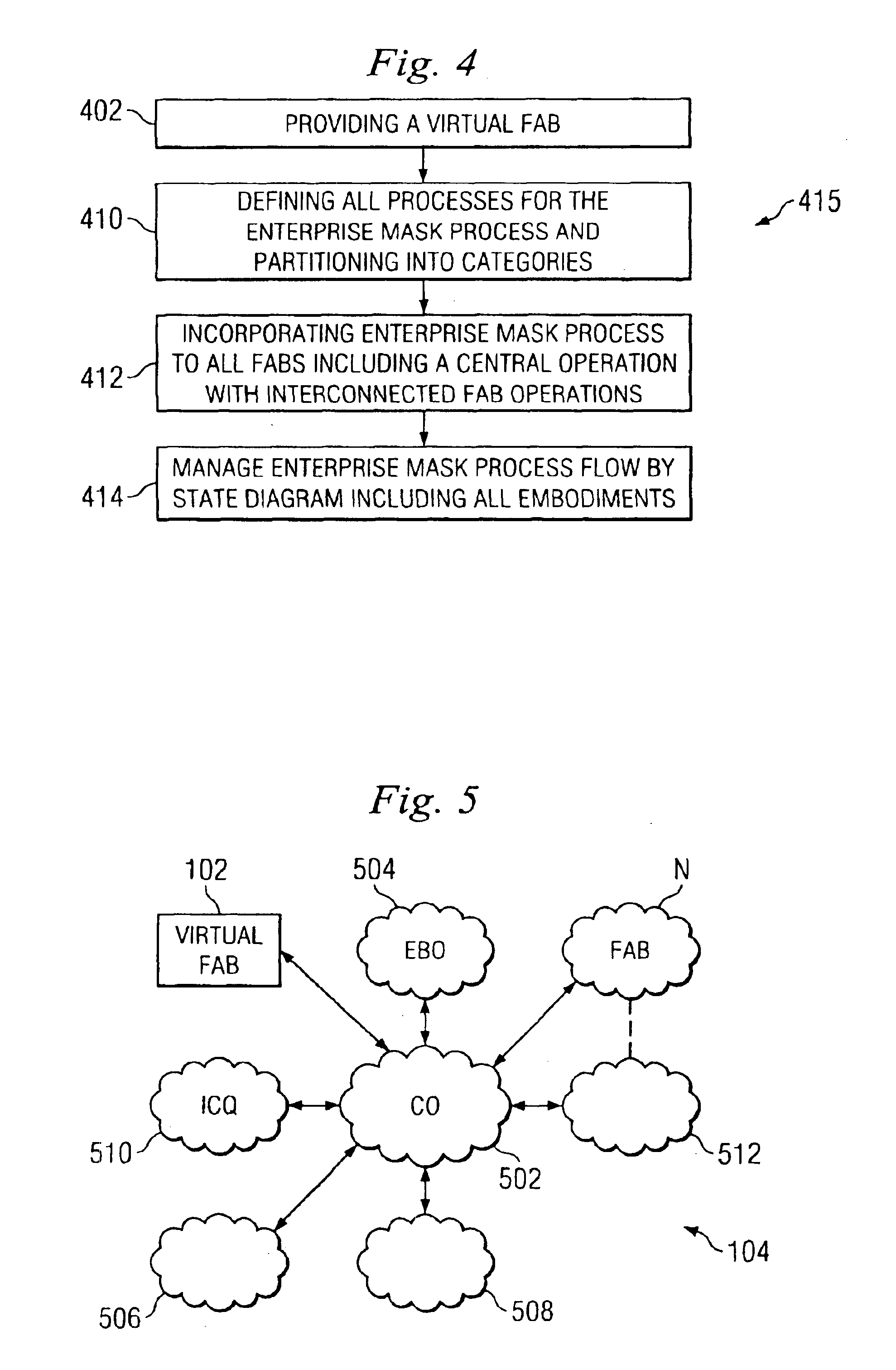

Mechanism for inter-fab mask process management

InactiveUS6928334B2Semiconductor/solid-state device manufacturingSpecial data processing applicationsVirtual plantSemiconductor fab

Owner:TAIWAN SEMICON MFG CO LTD

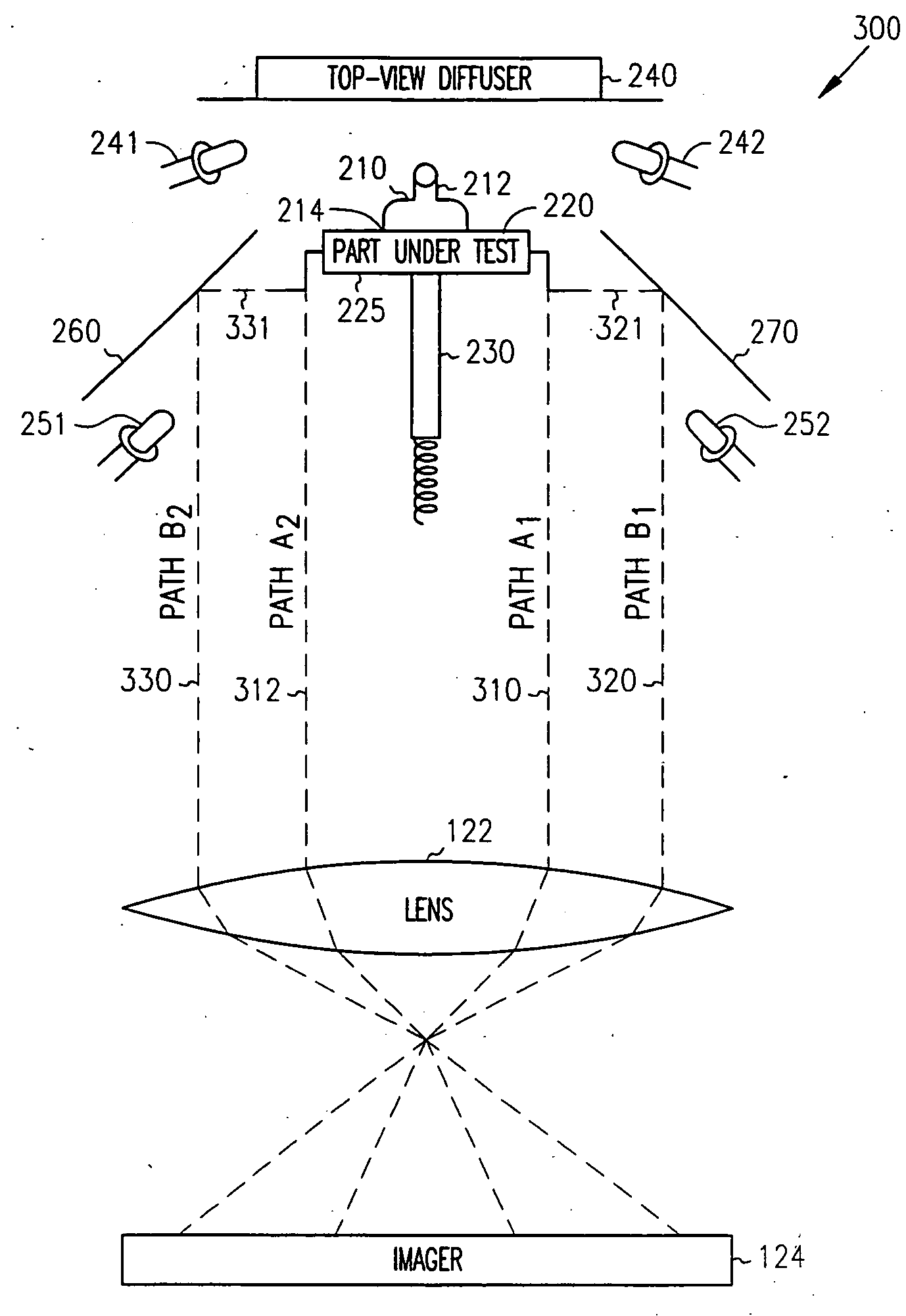

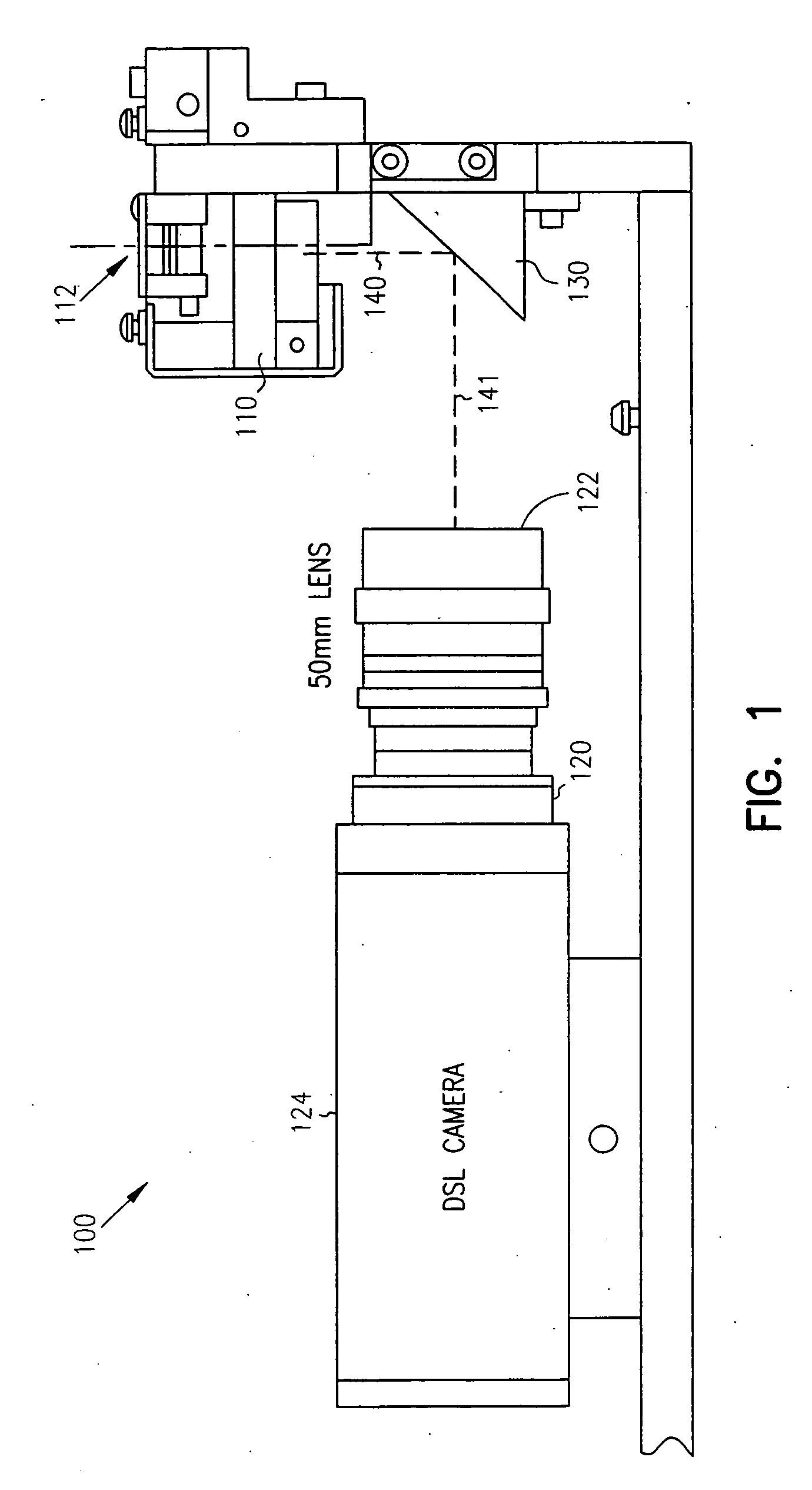

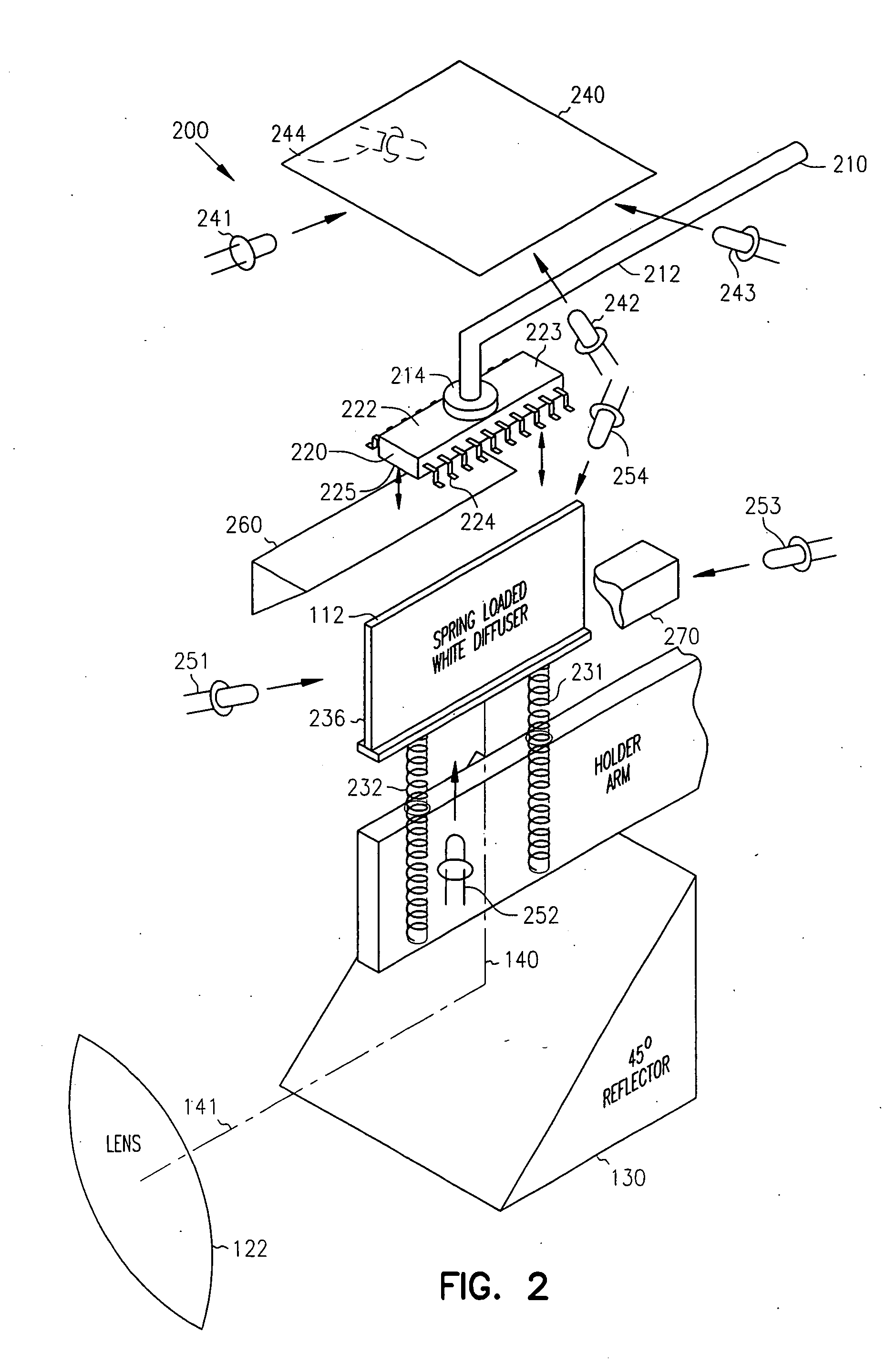

Method and apparatus for backlighting and imaging multiple views of isolated features of an object

InactiveUS20060152741A1Minimize and substantially eliminate problemAccurate measurementMaterial analysis by optical meansUsing optical meansDevice materialEngineering

Owner:LEMAIRE CHARLES A

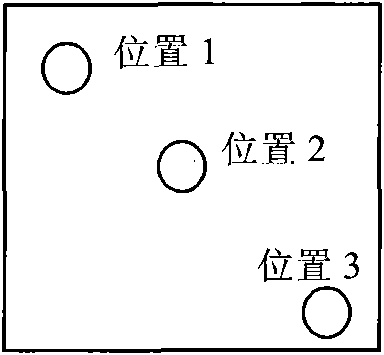

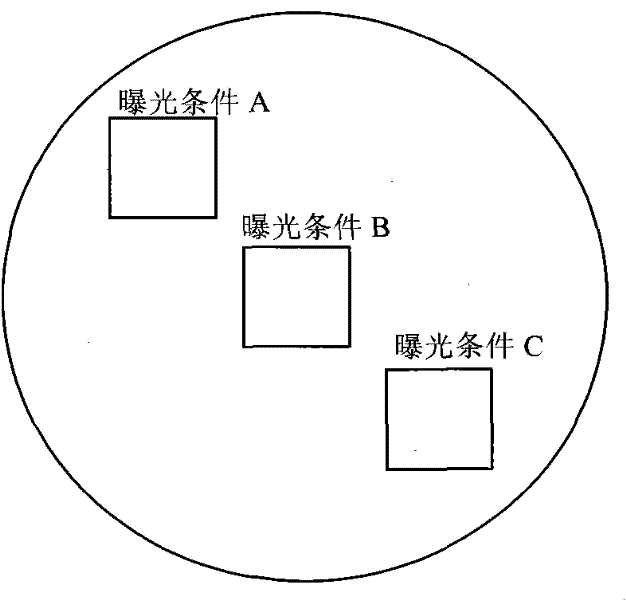

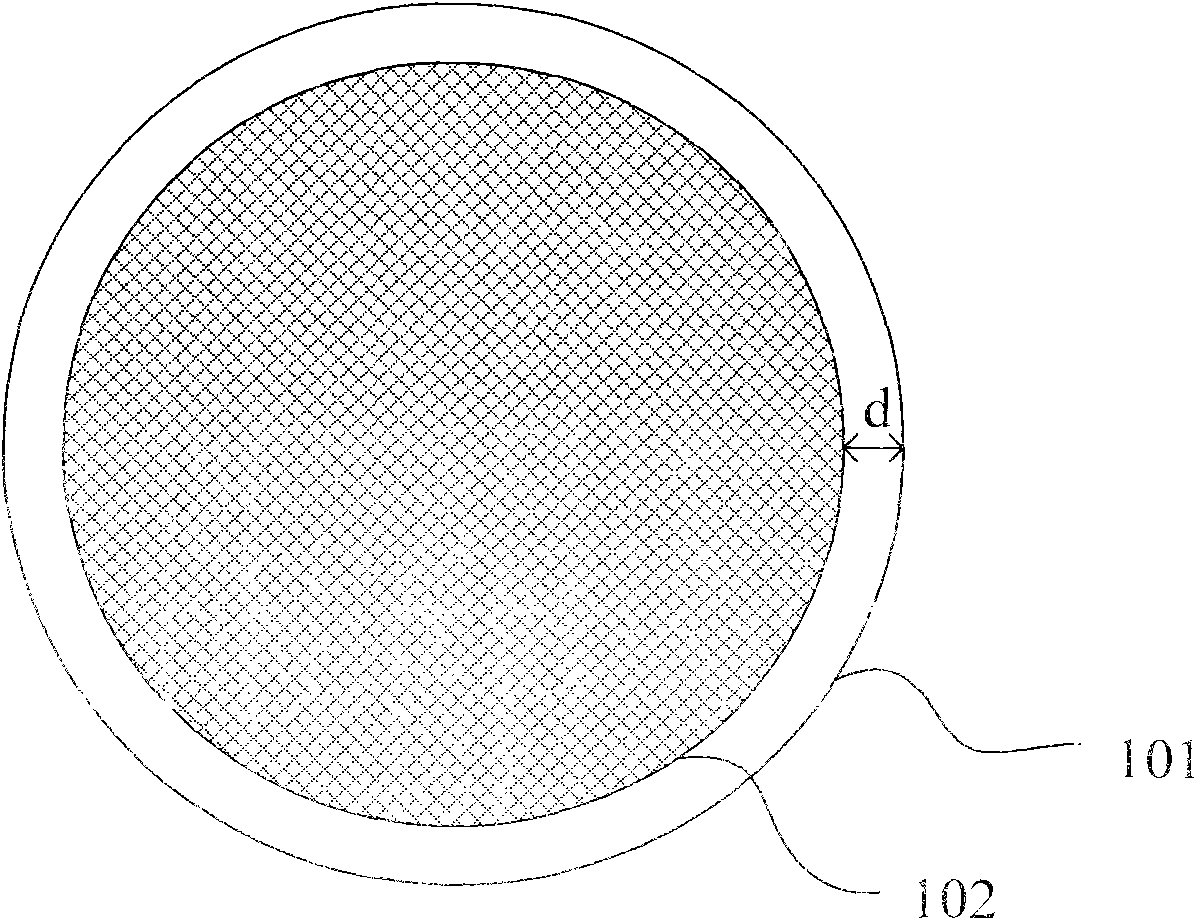

Method for preparing calibration standard sheet and method for calibrating with the standard sheet

ActiveCN102279516ALow costHigh measurement accuracyPhotomechanical apparatusSemiconductor factorySilicon chip

The invention discloses a preparation method of calibration standards, the calibration standards are used for calibrating a measure device with nanometer size, the invention is characterized in that the preparation method comprises the following steps: 1) preparing a photolithographic masking plate, placing the testing figures on more than two different positions of the photolithographic masking plate; 2) employing different exposure conditions, using the photolithographic masking plate for expositing at different positions of one silicon chip, and then developing and etching to obtain the calibration standards. According to the invention, a series of measured measure figures are taken as the calibration standards which are greatly raised the measure precision of equipments. Simultaneously, the difference for measuring the figures is generated through different illumination conditions, production can be realized in a common semiconductor factory, so that the cost of the calibration standards can be greatly reduced.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

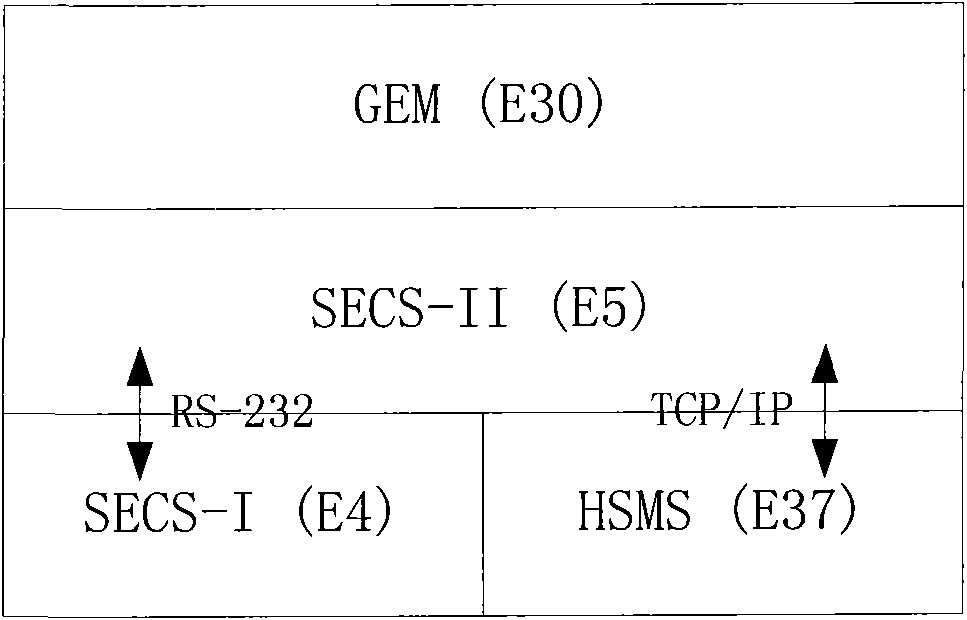

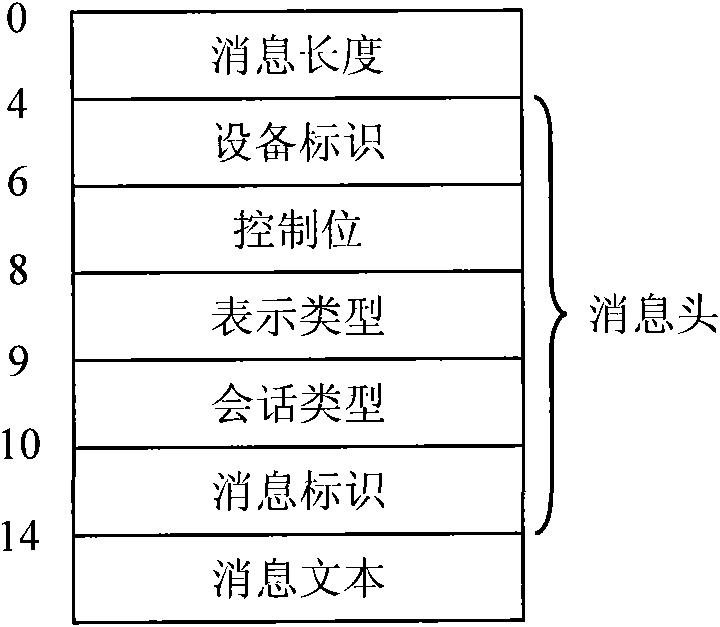

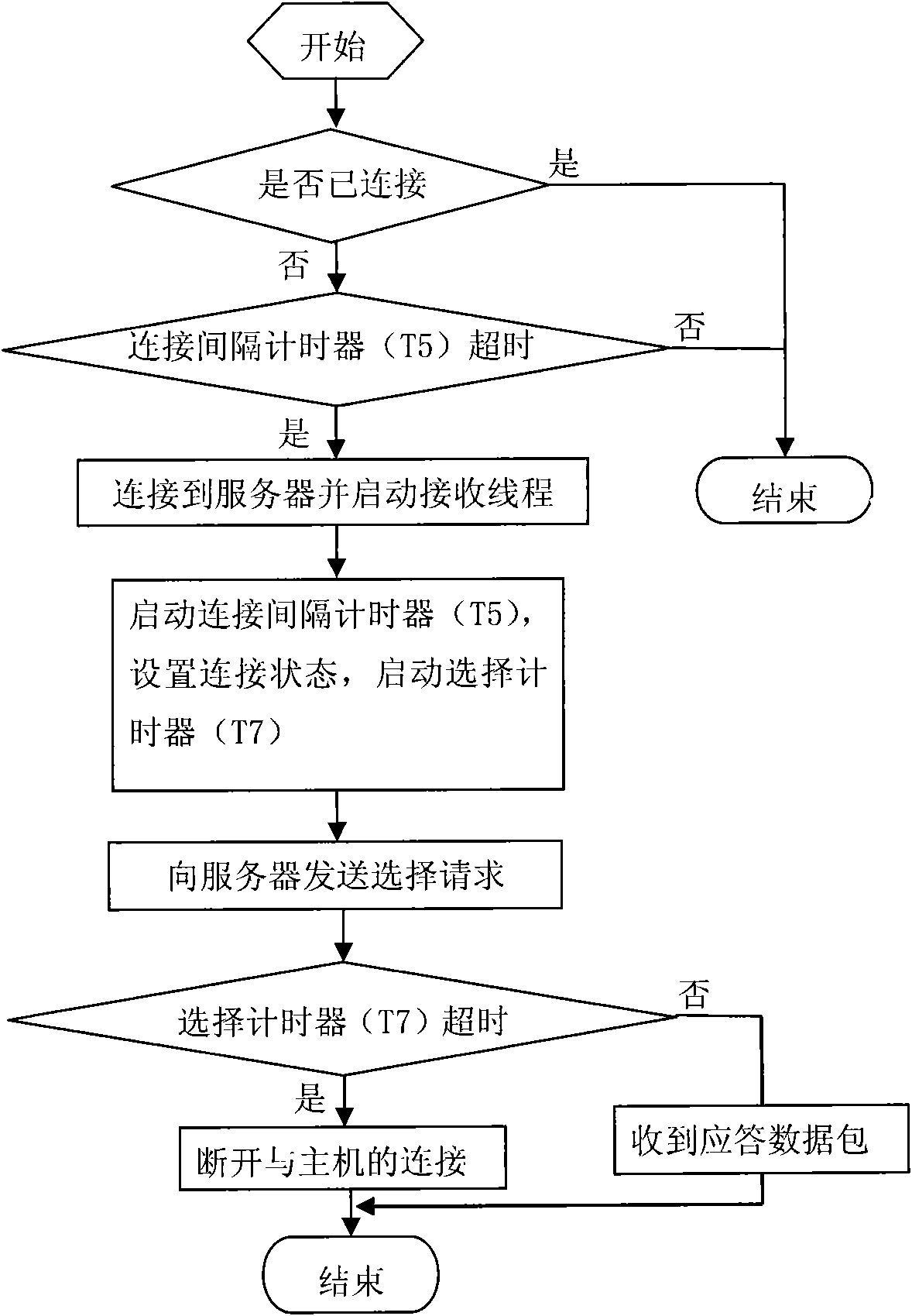

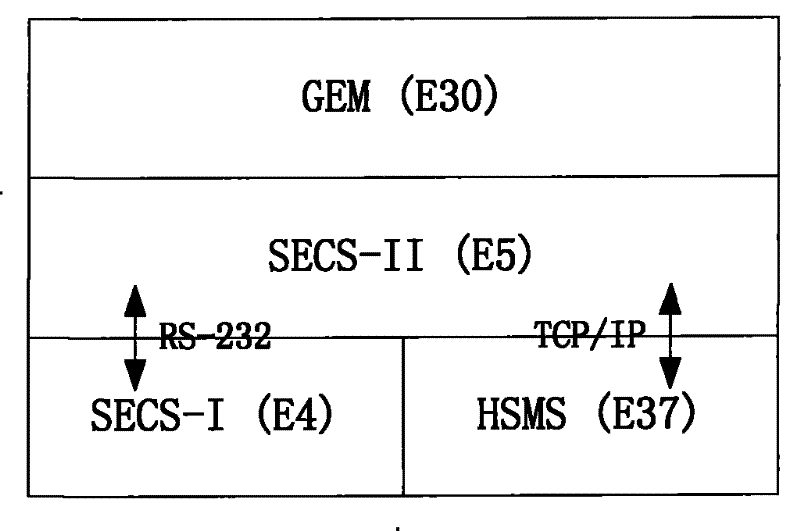

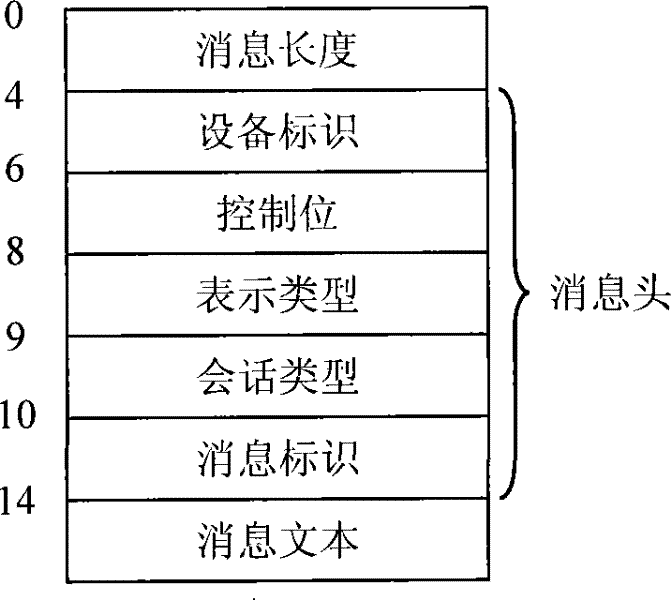

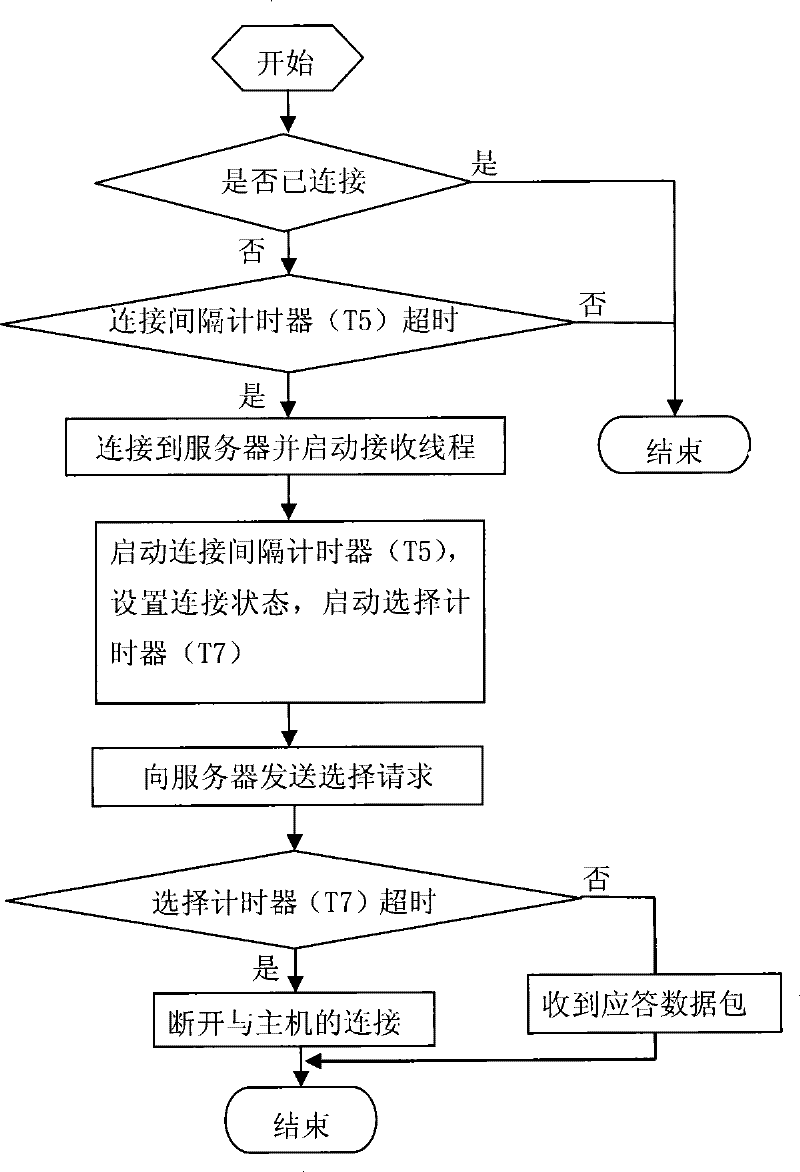

SECS communicating method based on SEMI standard

InactiveCN101552794AImprove cluster control capabilitiesIncrease the level of automationStore-and-forward switching systemsControl systemNetwork communication

The invention belongs to the network communication technology, in particular to a SECS communicating method based on SEMI standard. The method comprises the following steps of: realizing the connection of equipment to a host by an HSMS communication module and carrying out data transmission by a network; carrying out SECS II coding and decoding by an SECS protocol module and realizing data collection, equipment control and exception handling. The communicating method adopted can realize automatic management of a semiconductor factory, can meet characteristic requirements of high vacuum, high cleanness, high dustless, and the like in the manufacturing process of semiconductors, can standardize different equipment control systems, improve production efficiency and reduce production cost.

Owner:MICROCYBER CORP +1

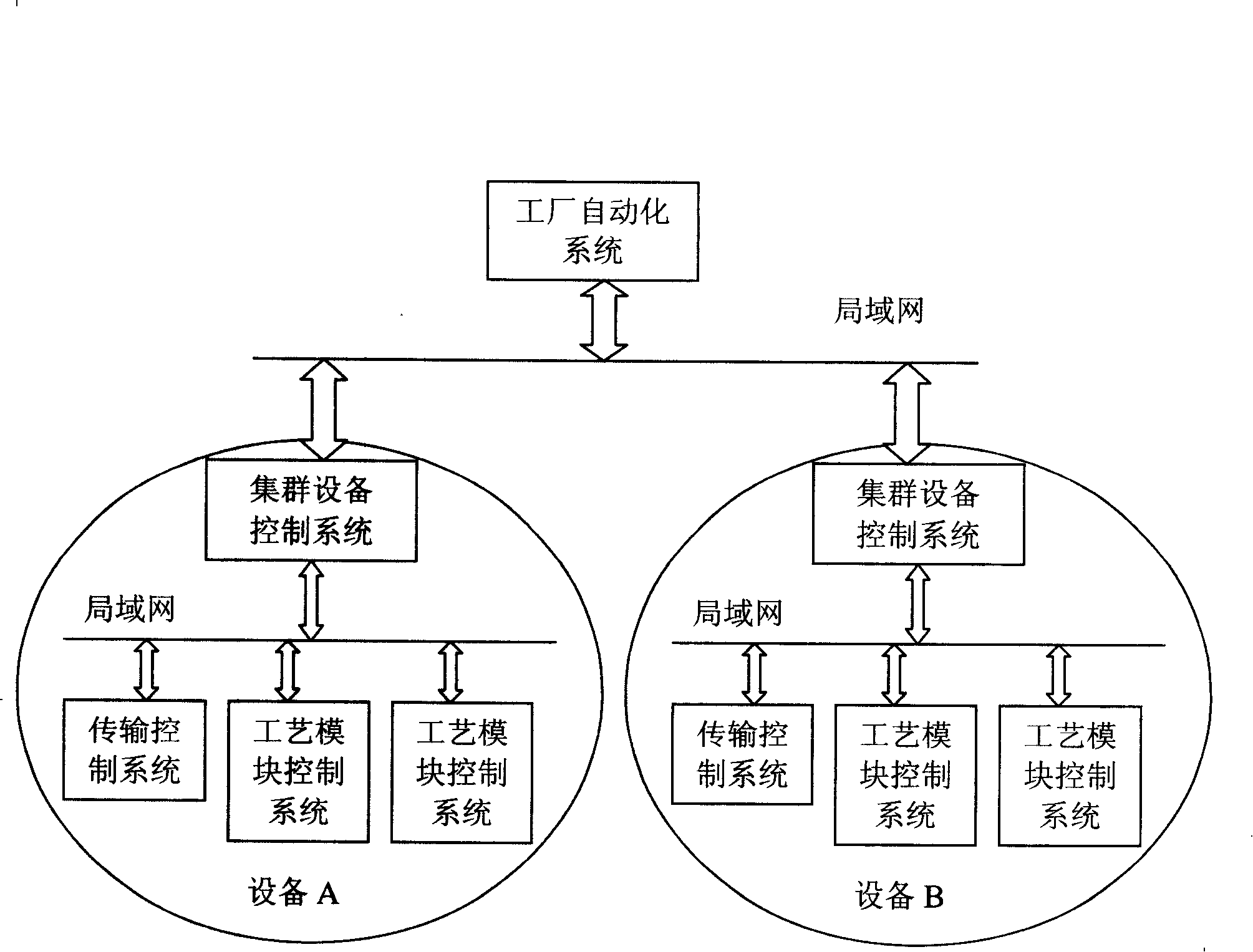

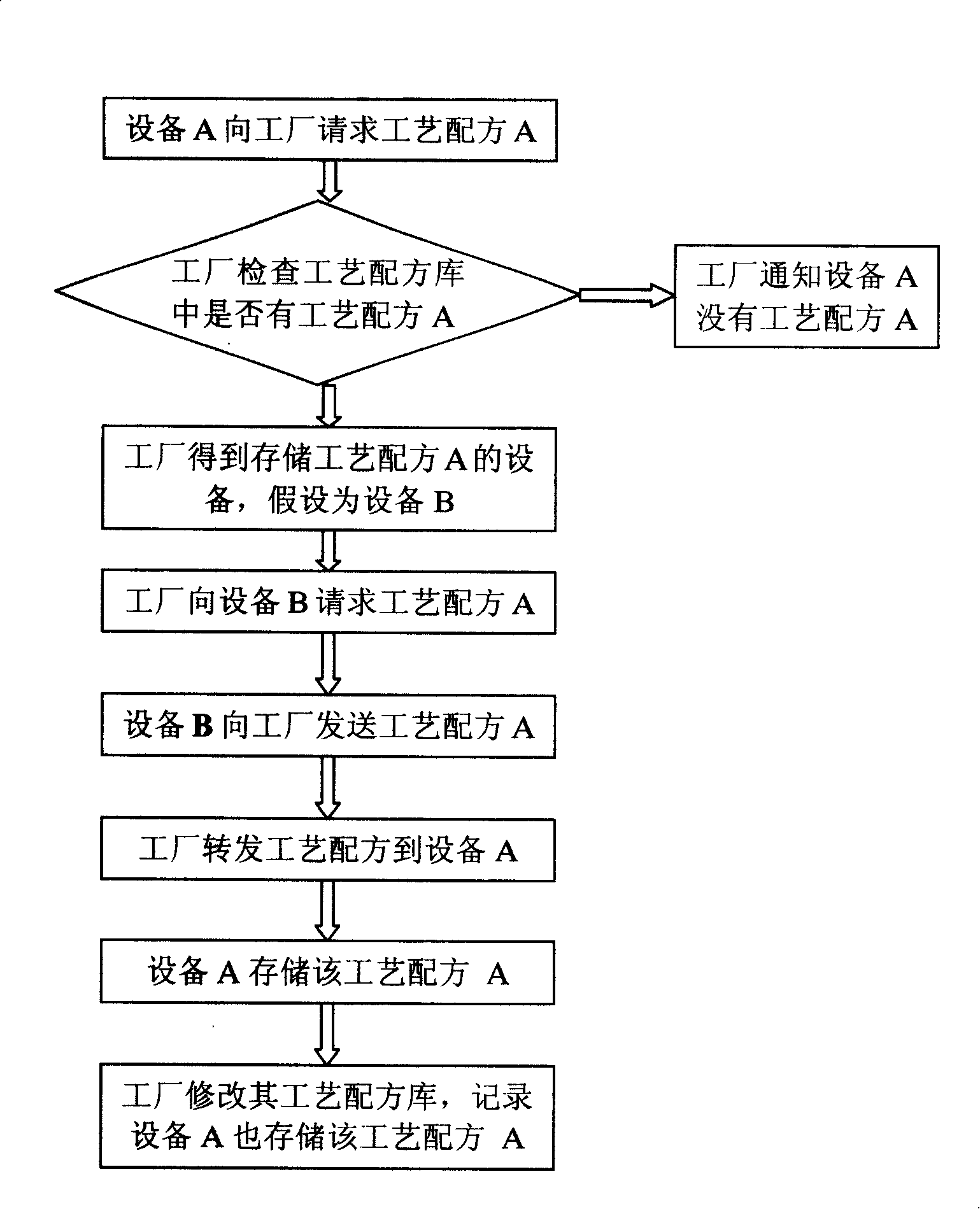

Semiconductor fabrication process formula management process

InactiveCN101216698AResolve synchronizationRealize automatic disseminationSemiconductor/solid-state device manufacturingProgramme control in sequence/logic controllersManagement processSemiconductor factory

The invention relates to the automation technical field of a semiconductor factory, in particular to a management method for semiconductor manufacturing process formulation. On the basis of dividing specific functional roles between a factory automation system and a device, the management method for the semiconductor manufacturing process formulation provided by the invention realizes the management on the process formulation in accordance with a plurality of strategies between the system and the device such as connection, disconnection and management. Through specifically dividing roles between the factory automation system and the device, two systems manage the process formulation coordinately, thereby decreasing the complexity of management and improving the efficiency of management.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

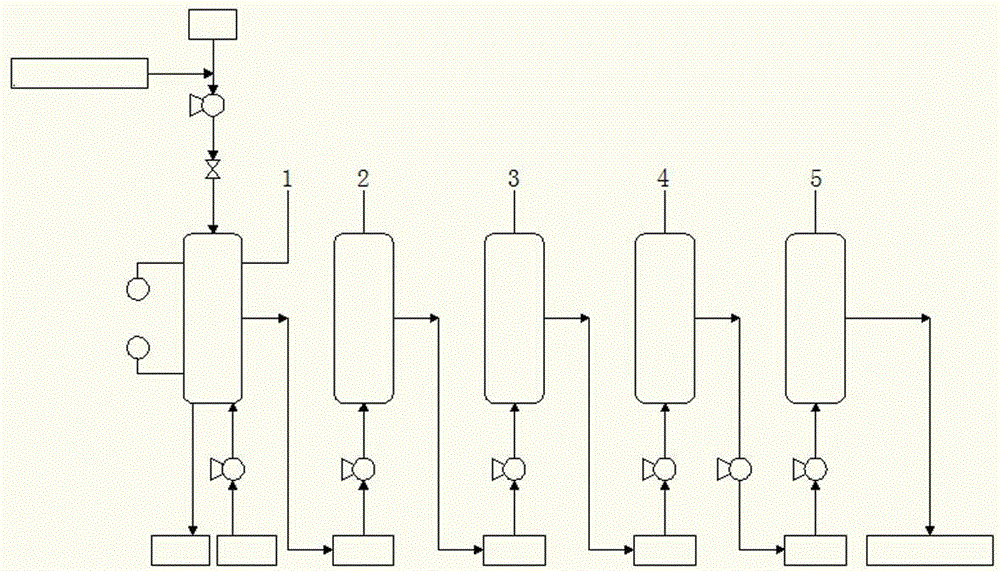

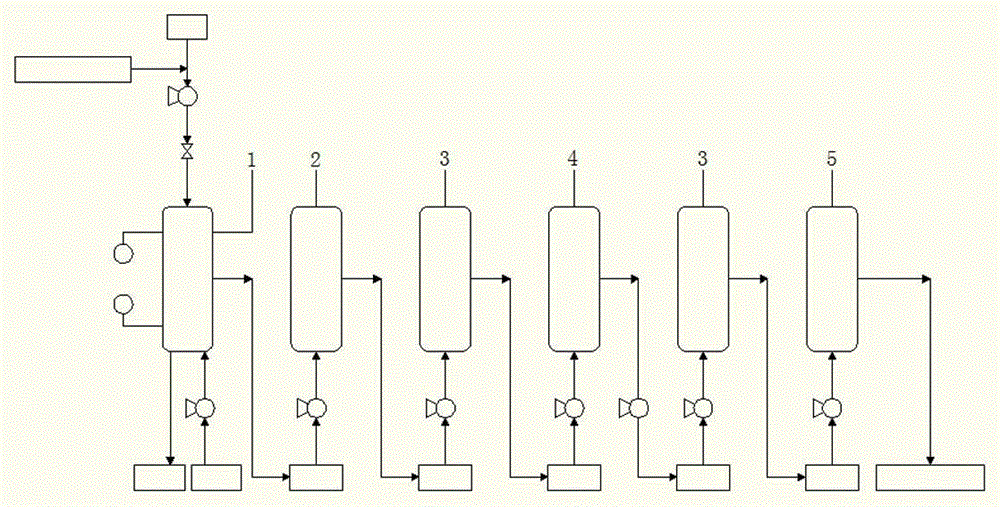

Regeneration system and method of tetramethyl ammonium hydroxide developing waste liquid

ActiveCN105314770ARelieve pressureEfficient recyclingMultistage water/sewage treatmentPhotosensitive material processingTetramethylammonium hydroxideProcess engineering

The invention relates to a regeneration system and method of a tetramethyl ammonium hydroxide developing waste liquid. The regeneration system comprises a plurality of feeding pumps, at least one group of neutralization separation device, at least one group of adsorption device, at least one group of cation exchange device, at least one group of anion exchange device and at least one group of purification processing device, wherein the neutralization separation device, the adsorption device, the cation exchange device, the anion exchange device and the purification processing device are sequentially connected by material tubes with control valves. According to the regeneration system, high-purity tetramethyl ammonium hydroxide developing liquid can be stably and circularly regenerated for a long time, so that the purposes of energy conservation and environment protection are achieved; meanwhile, the wastewater discharge pressure of a semiconductor factory is reduced, and the wastewater treatment cost of the factory is saved, so that the effective cyclic utilization of resources is realized.

Owner:HANGZHOU GREENDA CHEM

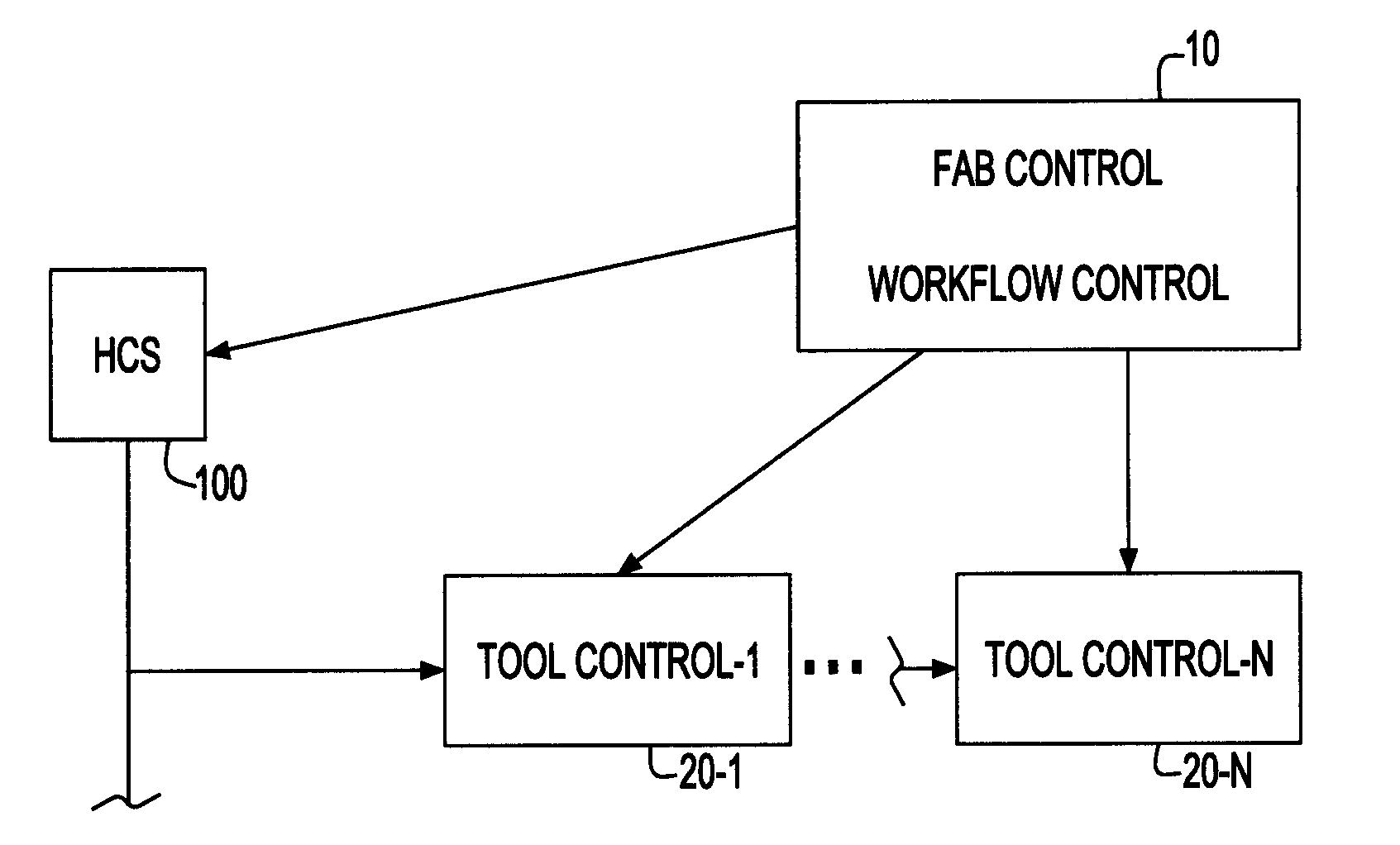

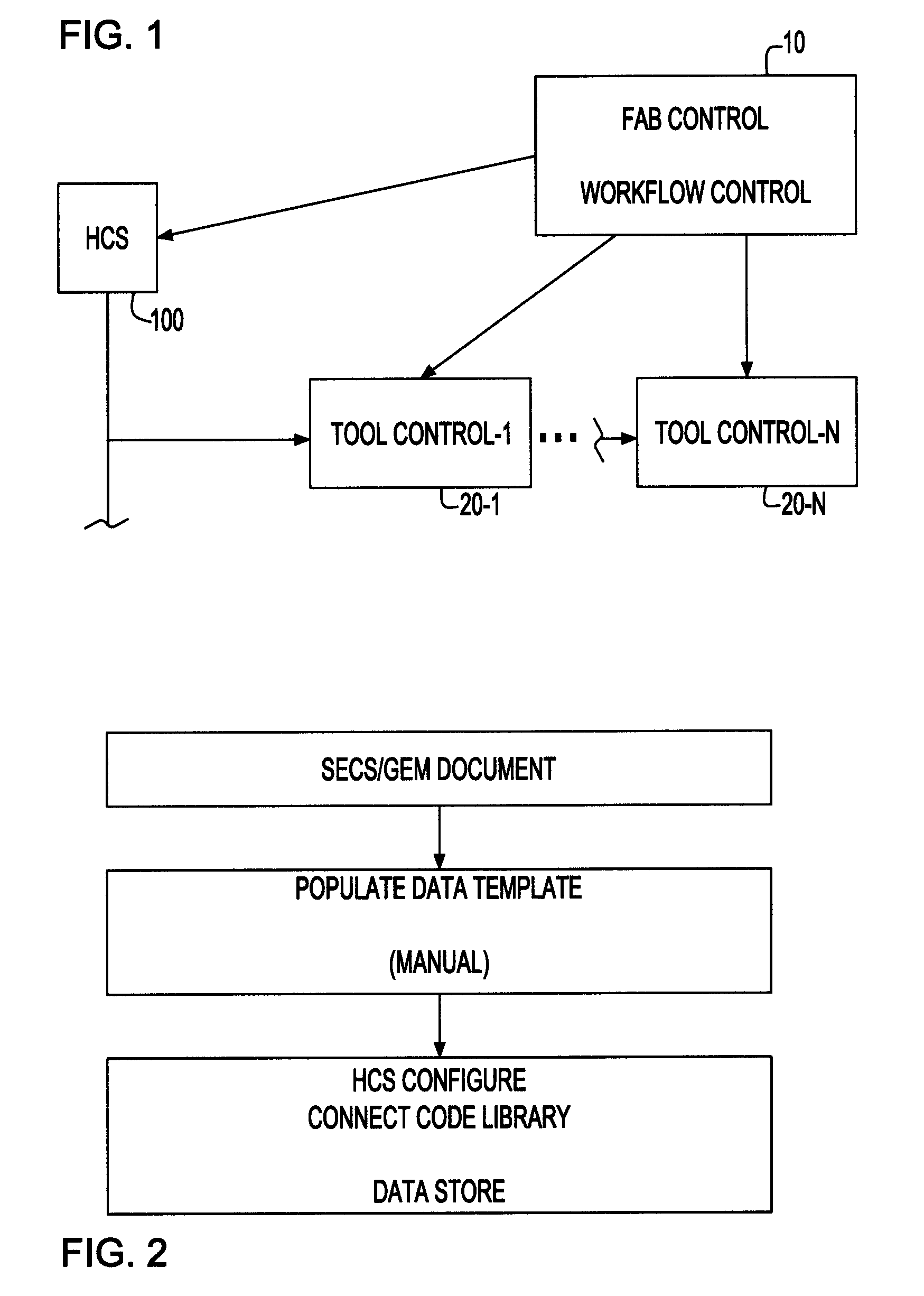

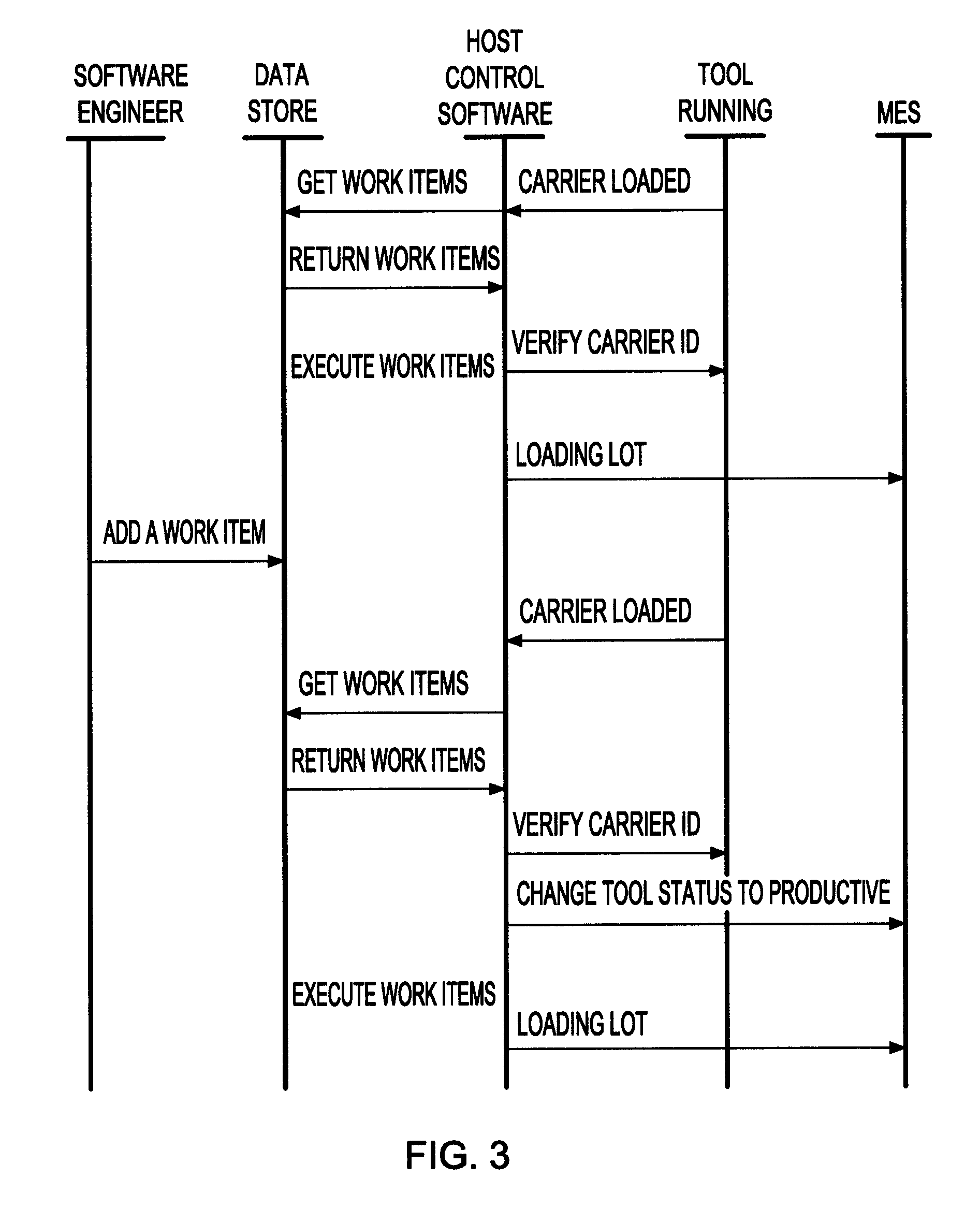

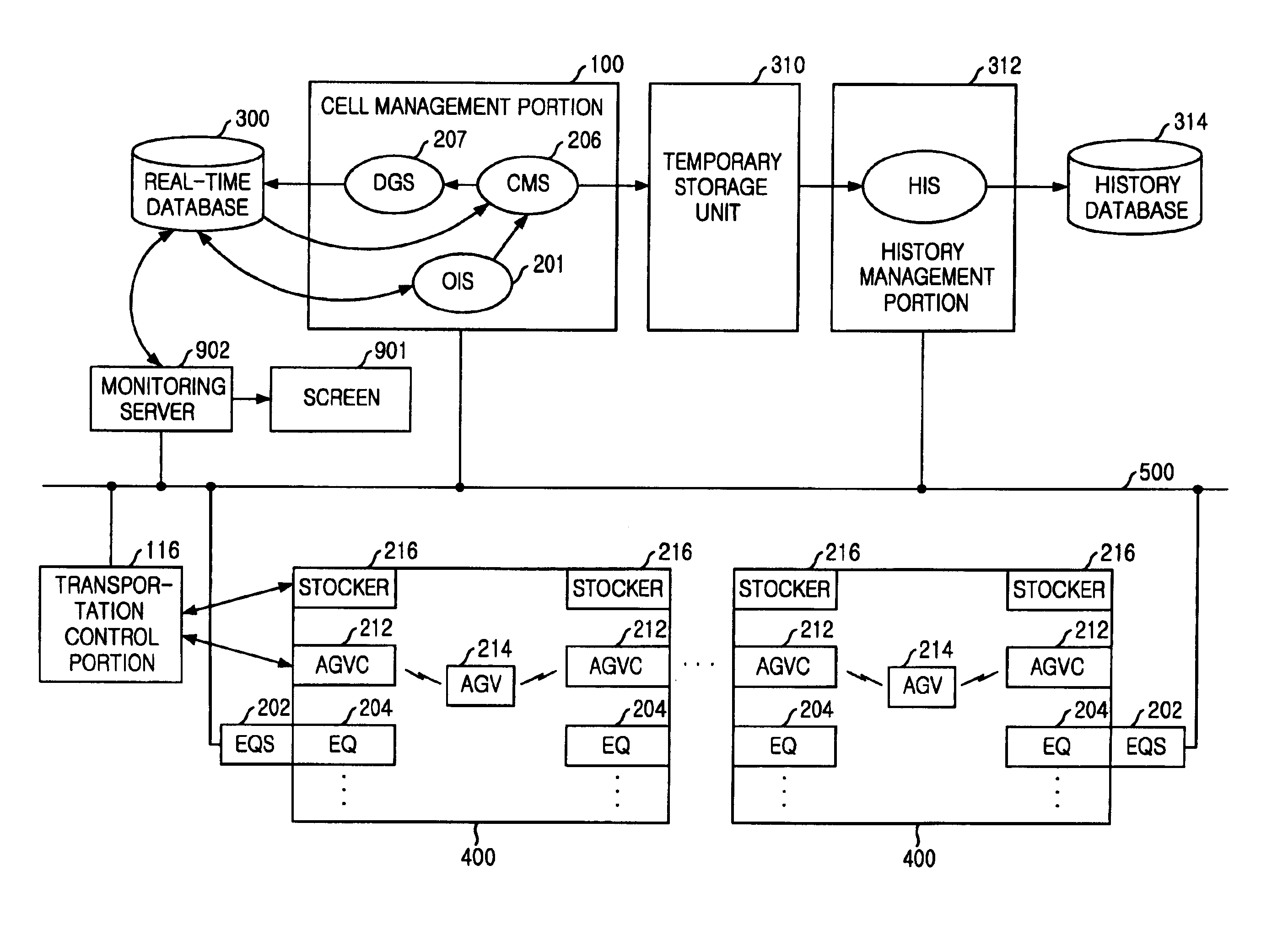

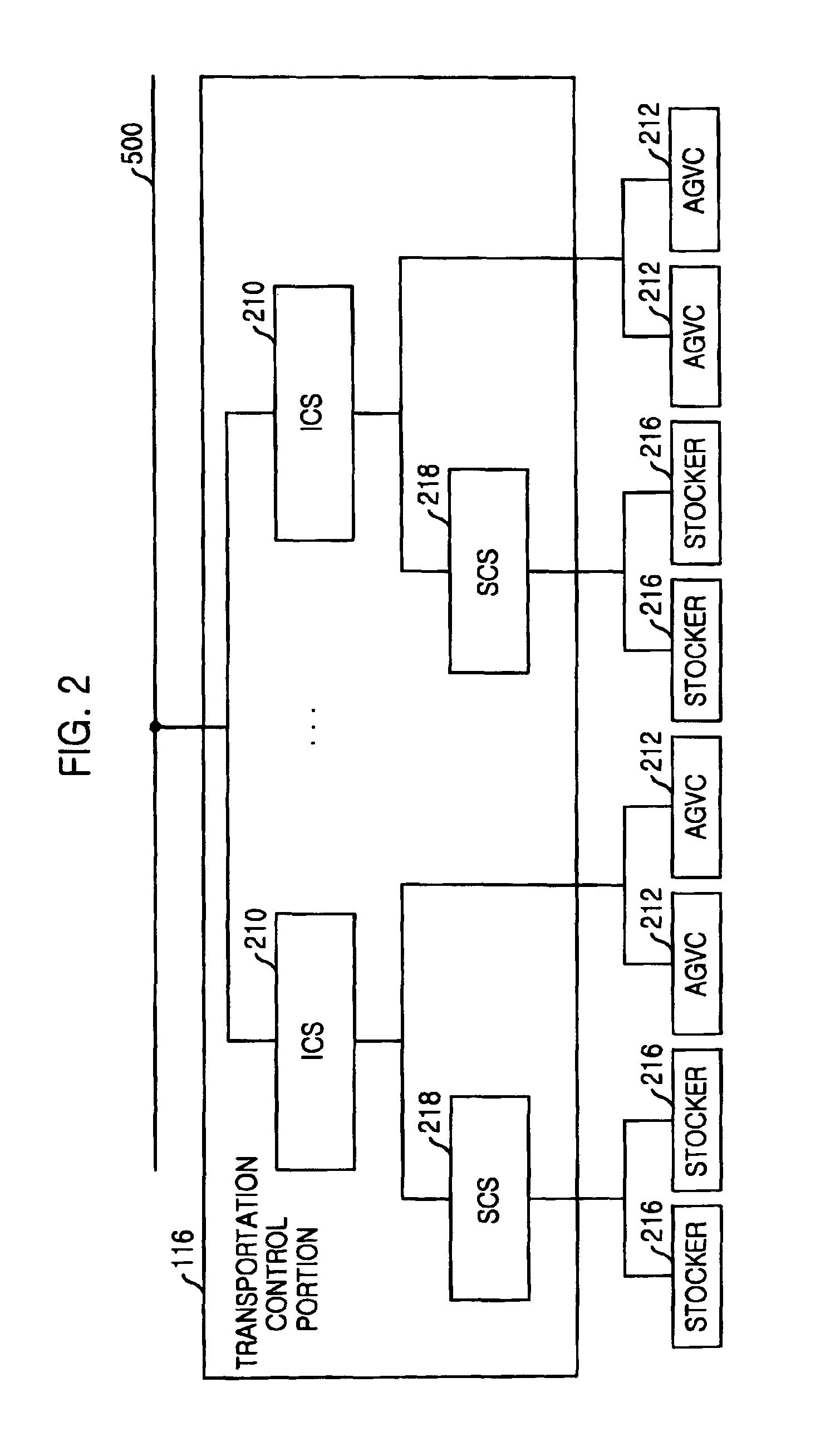

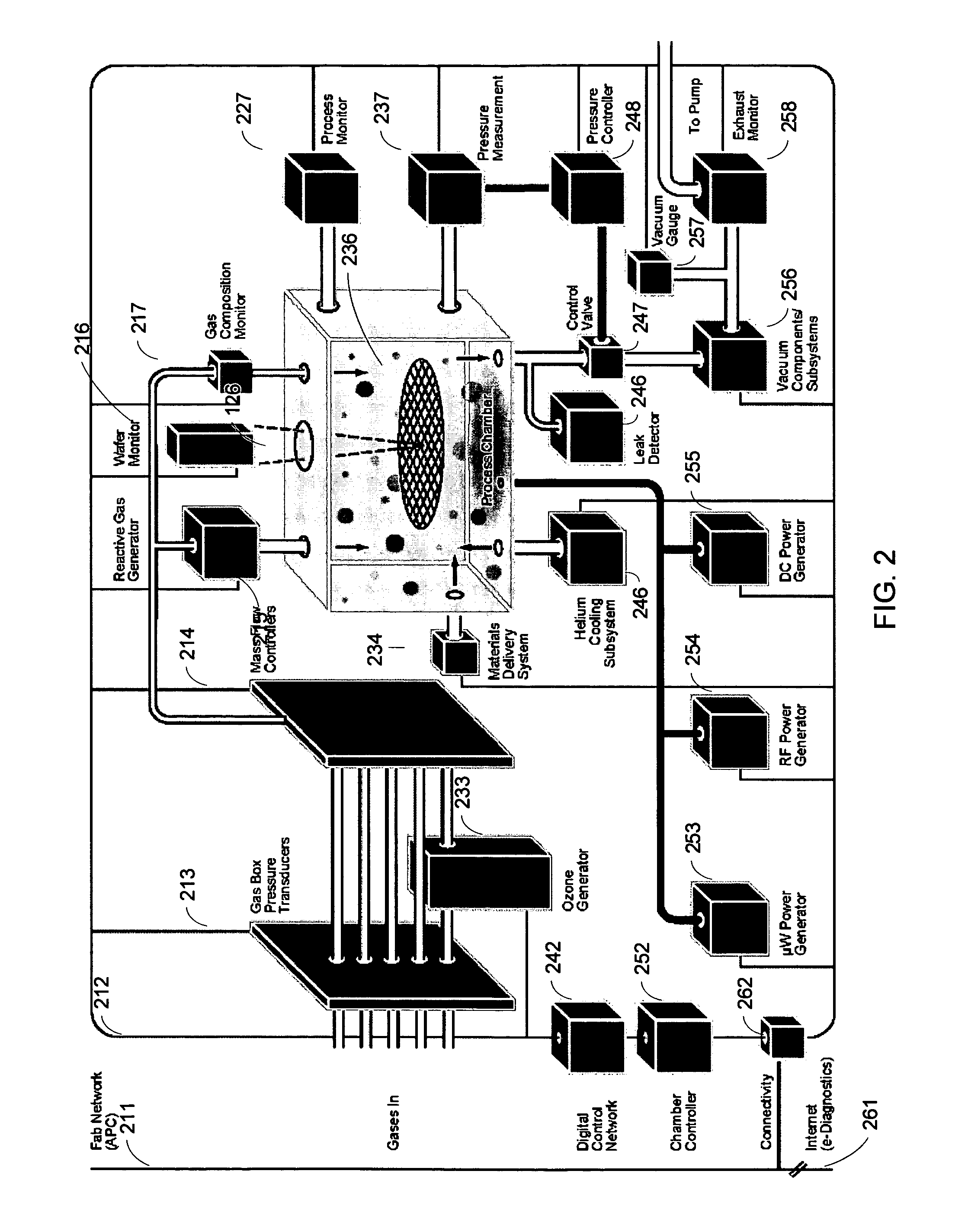

Host control for a variety of tools in semiconductor fabs

InactiveUS20060025880A1Programme controlTotal factory controlSemiconductor factoryIntegrated circuit fabrication

A software module for use within an integrated circuit fabrication facility sends commands to a tool according to a method that operates with any tool that satisfies SEMI standards to add or subtract steps in a process without reprogramming or recompiling. The program operates autonomously to change parameters of commands that it sends to the tool to improve performance of the fab.

Owner:GLOBALFOUNDRIES INC

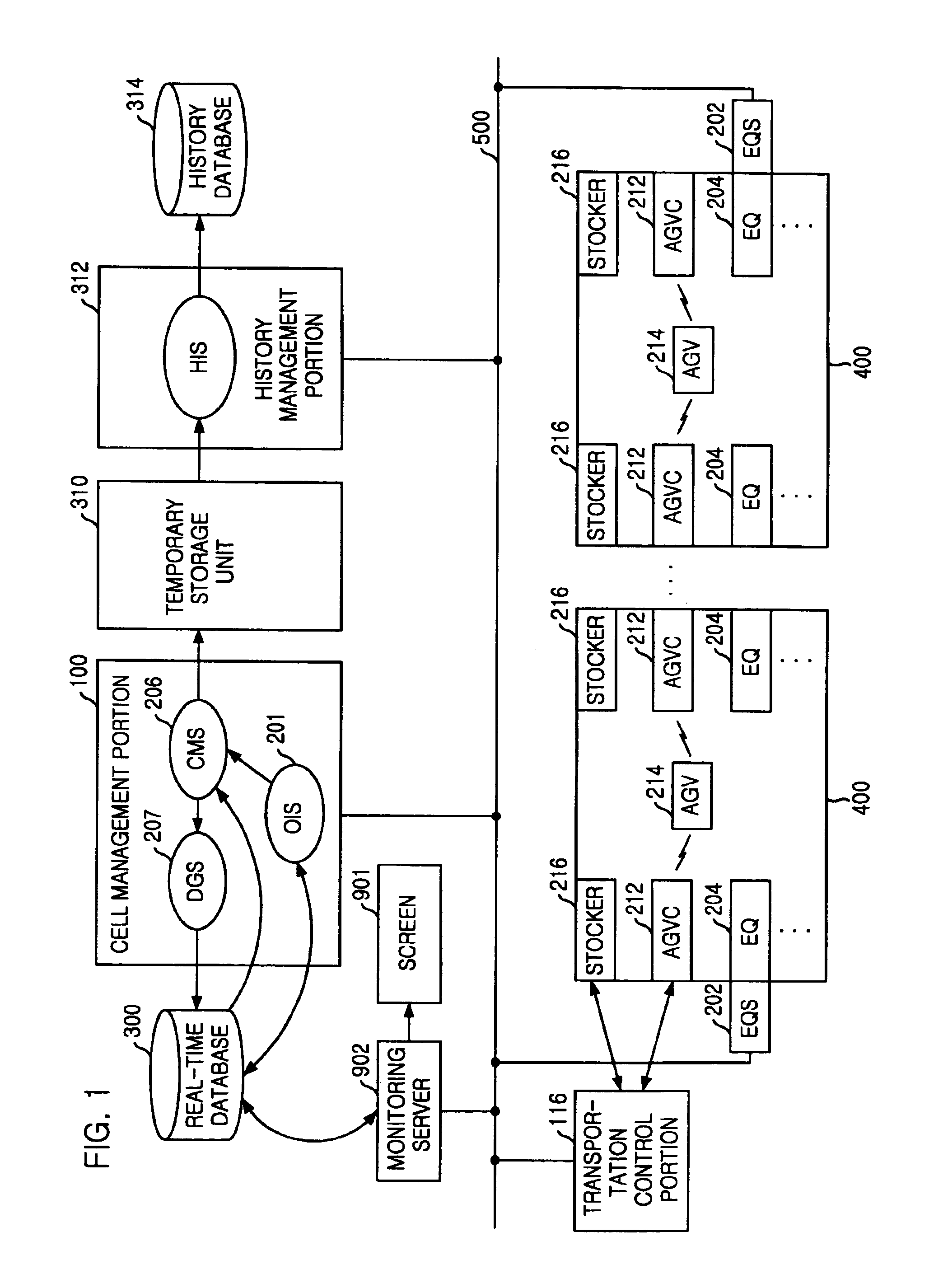

Semiconductor factory automation system and method for monitoring at least one server in real time

InactiveUS6859675B1Precise positioningComputer controlSimulator controlSemiconductor factorySemiconductor

A method for monitoring at least one server in a semiconductor factory automation (FA) system, includes the steps of: a) providing server state information from at least one server to a real-time database, wherein the server state information includes an availability of a central processing unit, an availability of a disk and a state of a program process related to the server; b) storing the processor state information in the real-time database; c) retrieving the server state information to monitor the server; and d) displaying the server state information retrieved. Therefore, the method monitors at least one server in a real time so that an operator can easily locate a failure of at least one-server.

Owner:HYUNDAI ELECTRONICS IND CO LTD

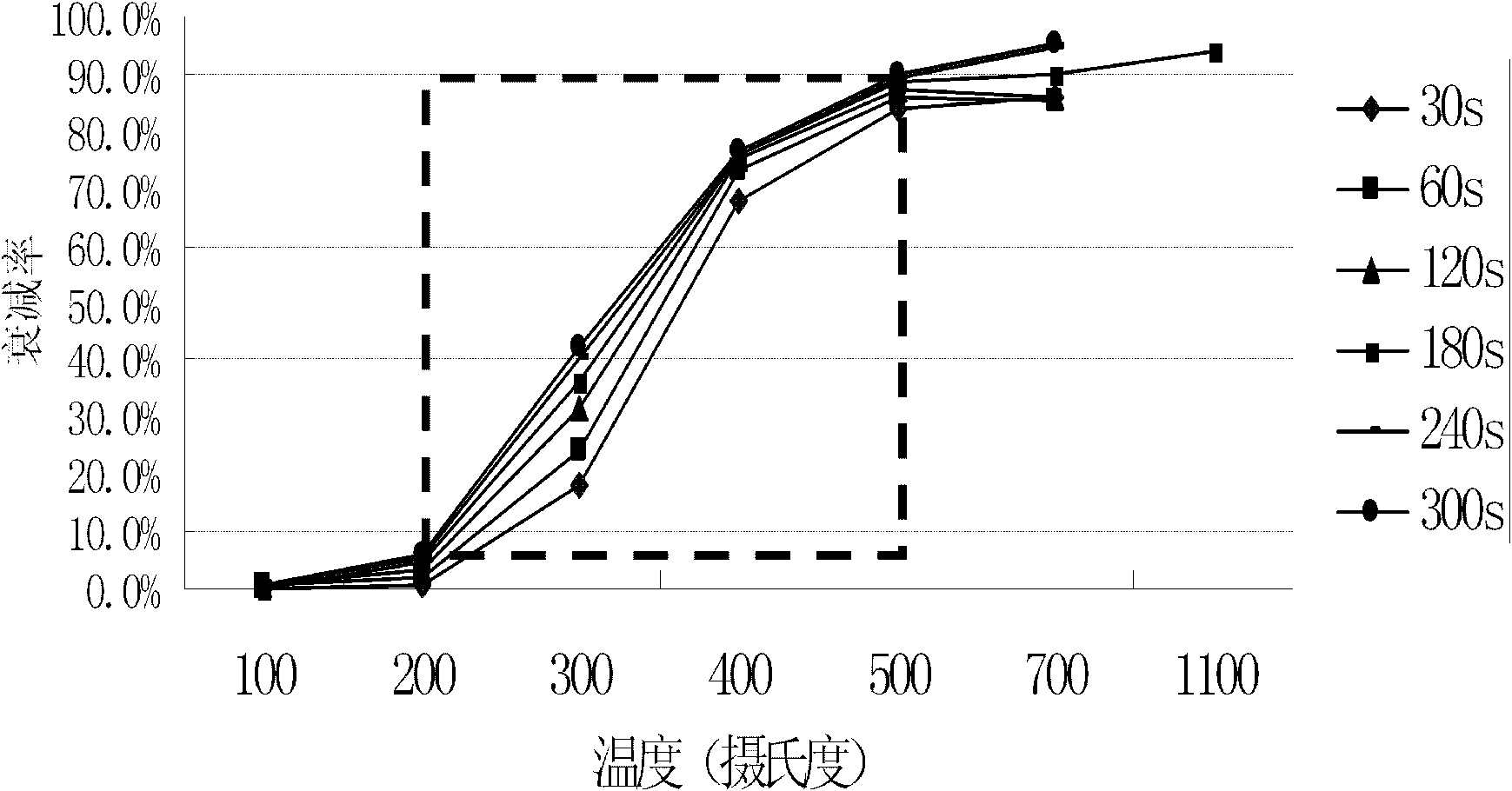

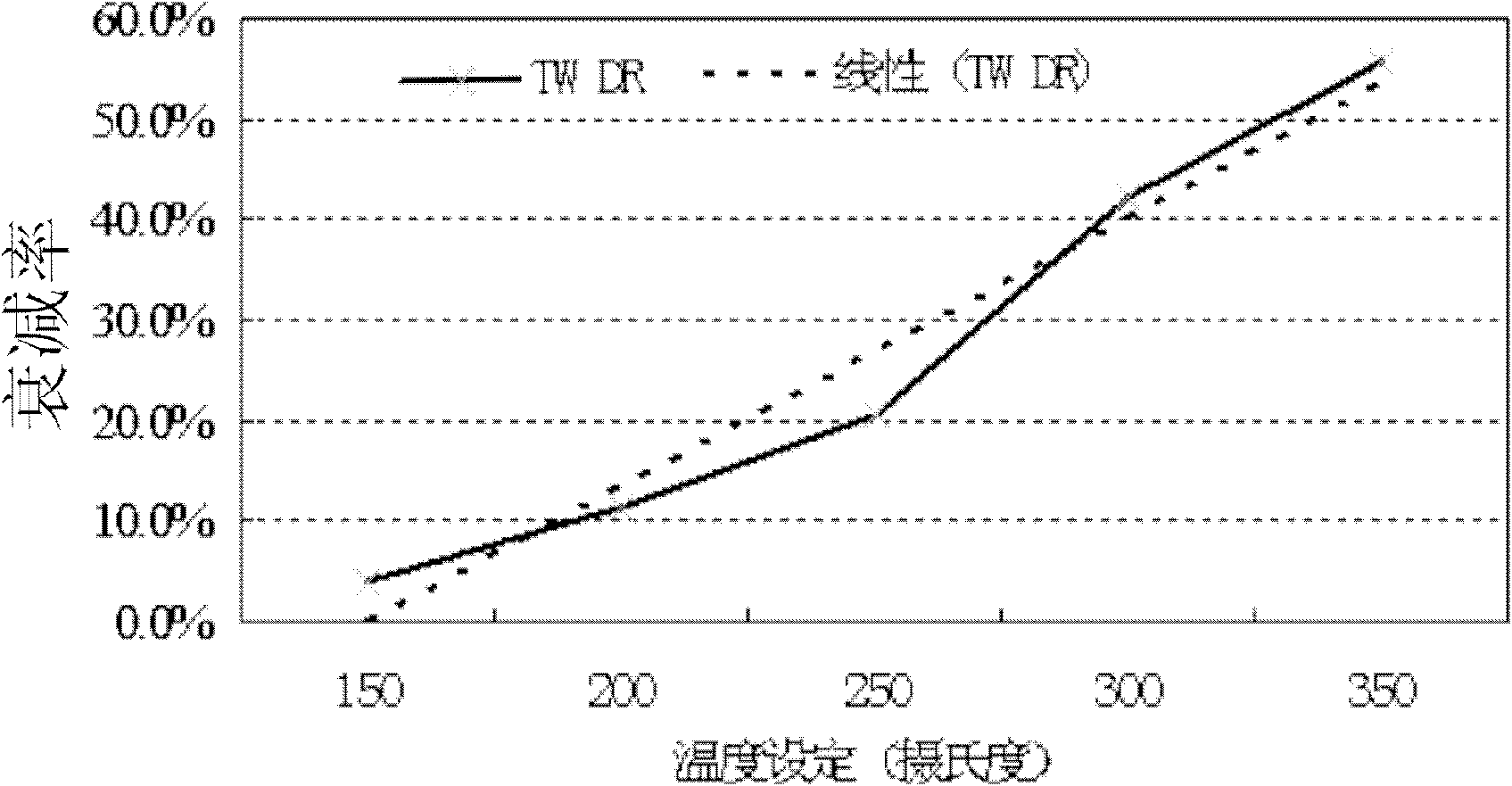

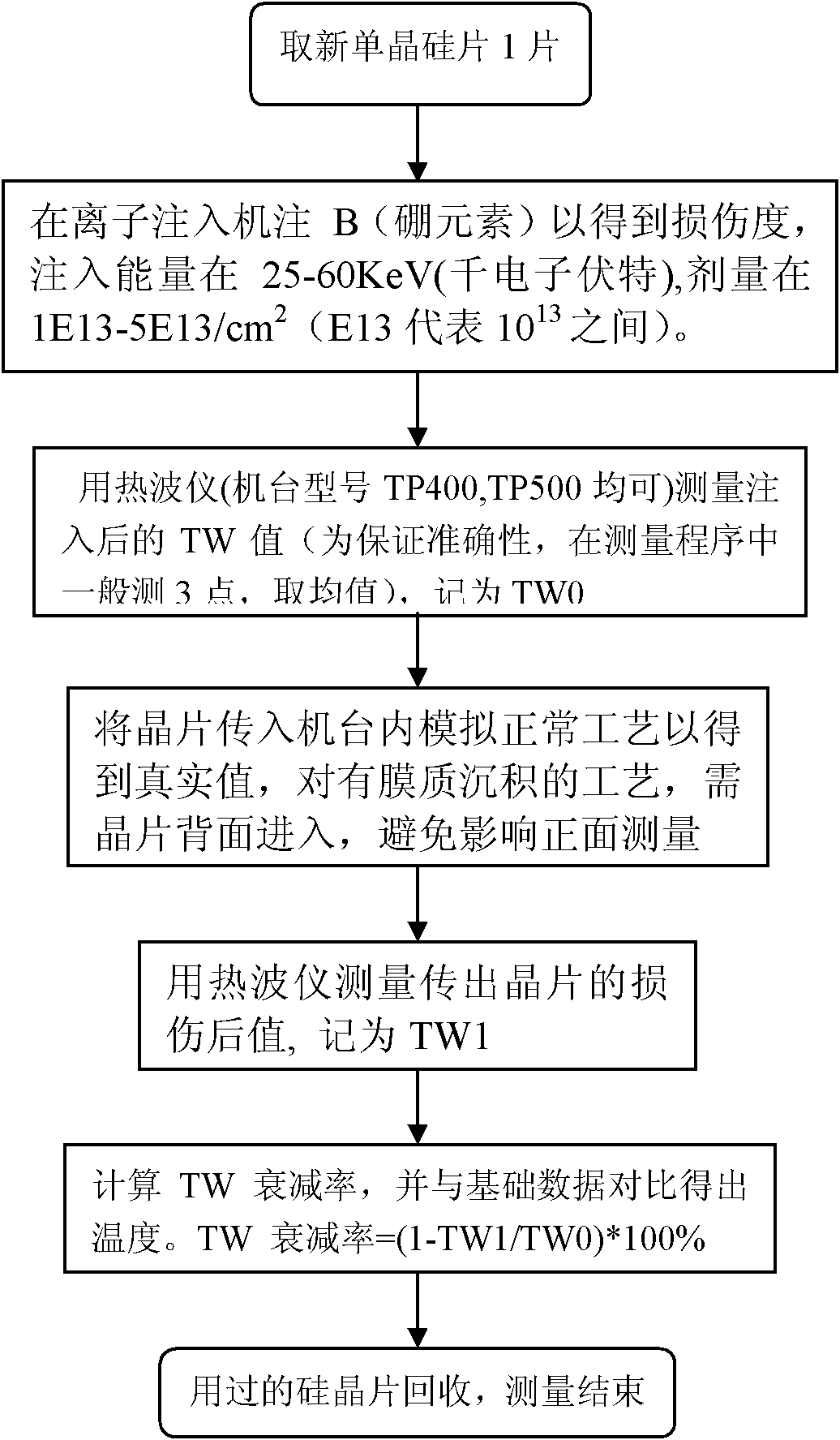

Method for measuring temperature by using thermal wave meter

InactiveCN102184877ALow costSimulate actual working conditionsSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingAlloySemiconductor factory

The invention discloses a method for measuring temperature by using a thermal wave meter. In a semiconductor manufacturing process, a lattice structure of a monocrystalline silicon wafer is damaged by ion injection, and the damage threshold, called as TW (Thermal Wave) value, can be measured through the thermal wave meter. The damage of a lattice can be repaired after annealing at a certain temperature and then the TW value is reduced. More importantly, the degree of the reduction is directly related to the temperature. According to the relation, the injected monocrystalline silicon wafer is respectively measured before and after the monocrystalline silicon wafer enters a machine platform of which the temperature is to be measured, the prior valve is called as TW0 and the later valve is called as TW1; the decay rate is calculated according to the formula that: TW decay rate is equal to (1-TW1 / TW0)*100%; the decay rate corresponds to a fixed temperature; and the temperature of wafer-accessed machine platform is obtained by comparing the fixed temperature and base data. The method has the advantages that: the operation is simple; the time is saved; the cost is low; the process imitativeness is high; the environment of the machine platform is not damaged; the adaptability is high; a film in a semiconductor factory can be etched; and the temperature of the alloy furnace tube machine platform can be measured.

Owner:NO 771 INST OF NO 9 RES INST CHINA AEROSPACE SCI & TECH

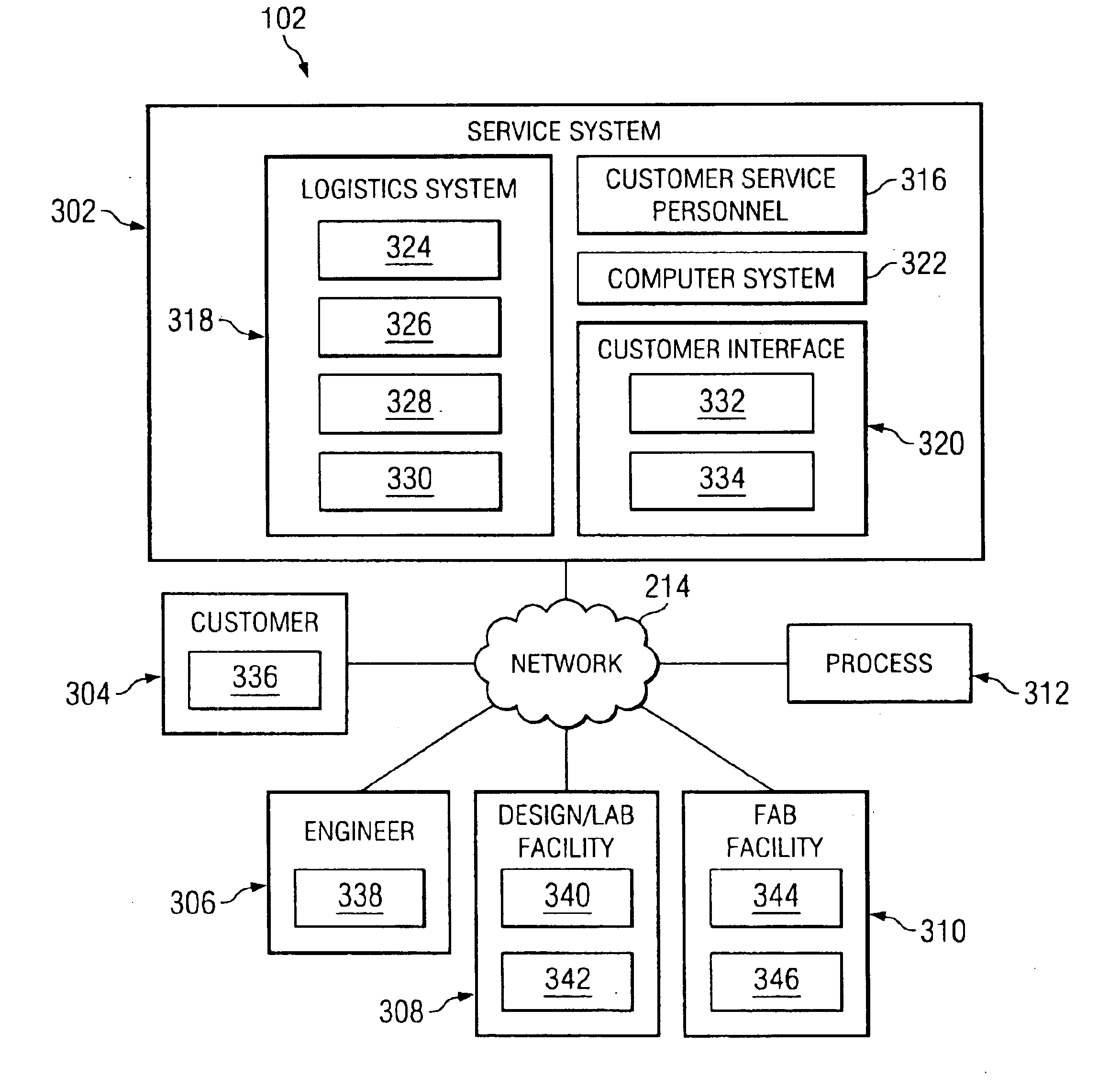

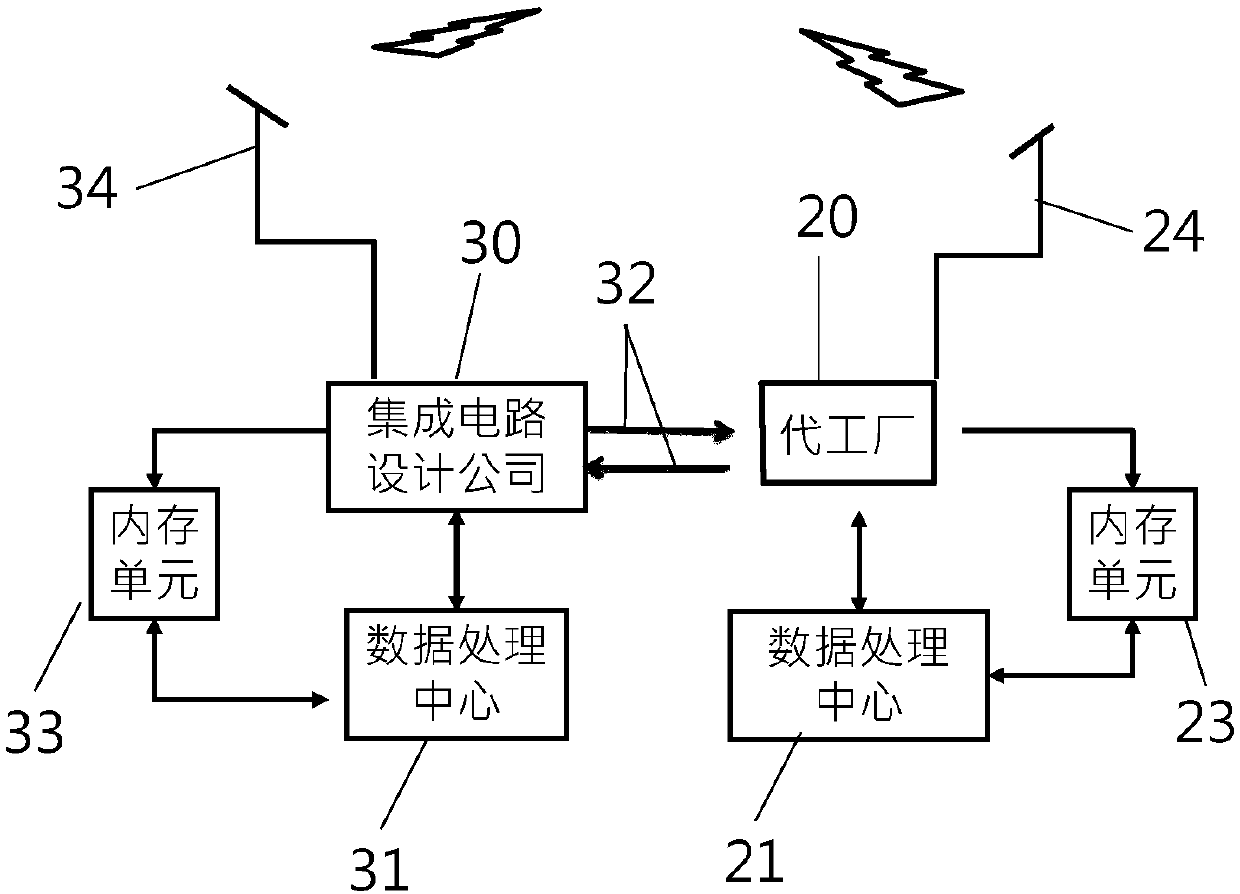

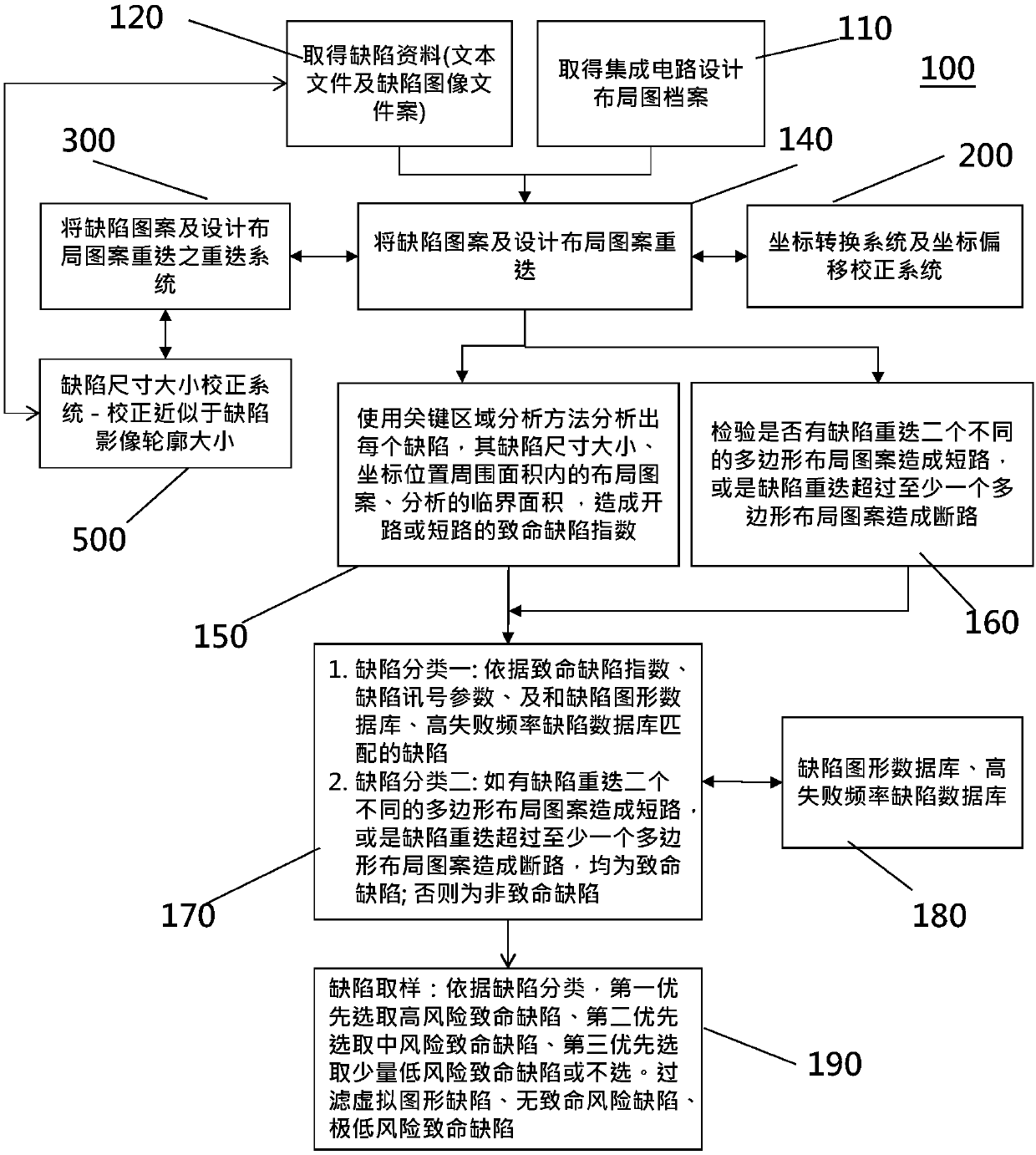

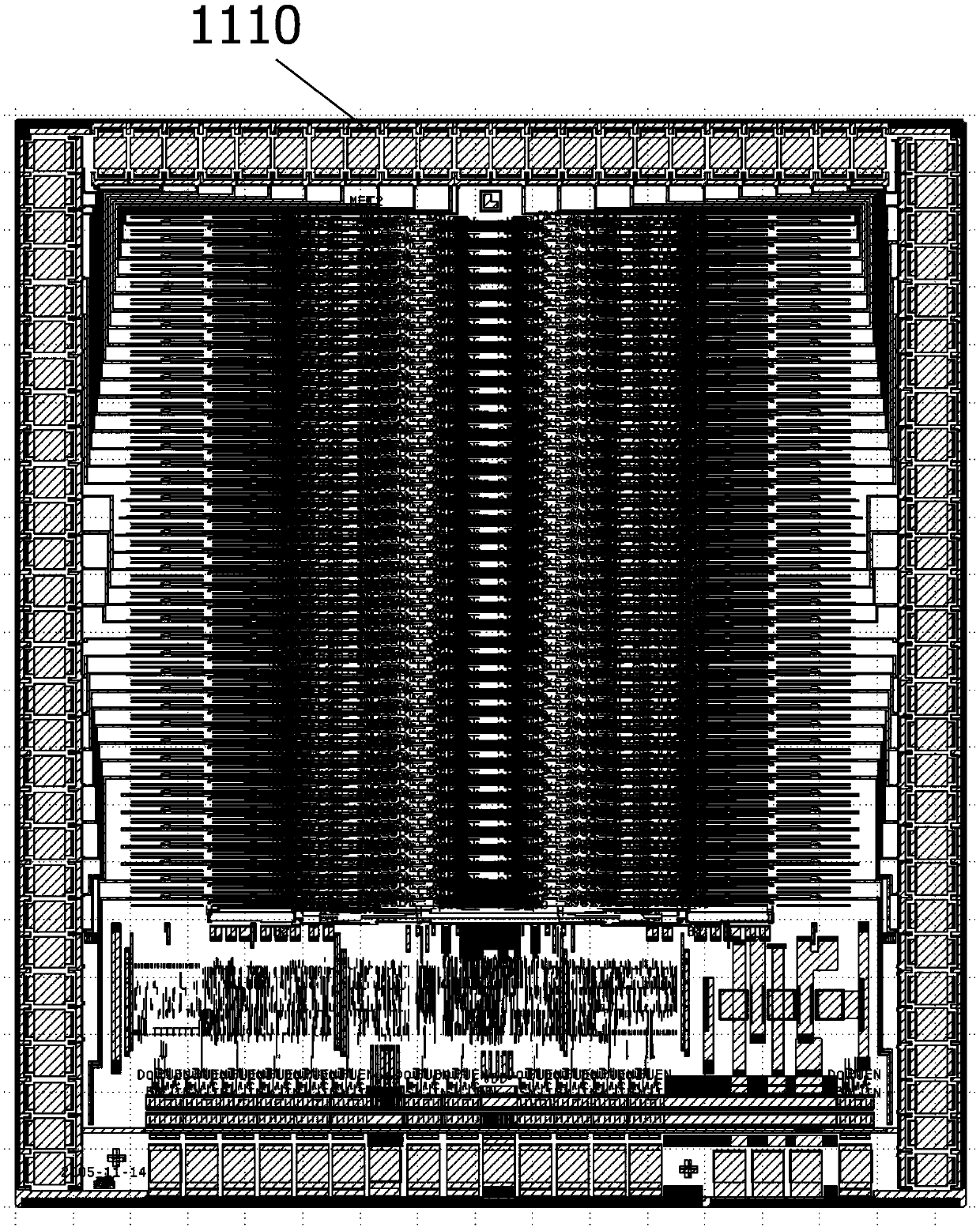

Defect operating system and device of semiconductor factory

ActiveCN110727247ASemiconductor/solid-state device manufacturingTotal factory controlSemiconductor factoryIntegrated circuit

The invention discloses a defect operating system of a semiconductor factory. The defect operating system of the semiconductor factory is used for immediately processing a plurality of defect data; then, coordinate correction, defect size correction and analysis by using critical area analysis are carried out to generate a fatal defect data file; then, an integrated circuit design company carriesout fault analysis and generates failure fatal defect data to generate new design layout data; and finally, the new design layout data and the failure fatal defect data are transmitted back to the semiconductor factory through a network. The defect operating system of the semiconductor factory is used for mutually paying and feeding back defect data and solving the root cause of the defect by theintegrated circuit design company and the semiconductor factory so as to achieve the purpose of improving the yield.

Owner:ELITETECH TECH

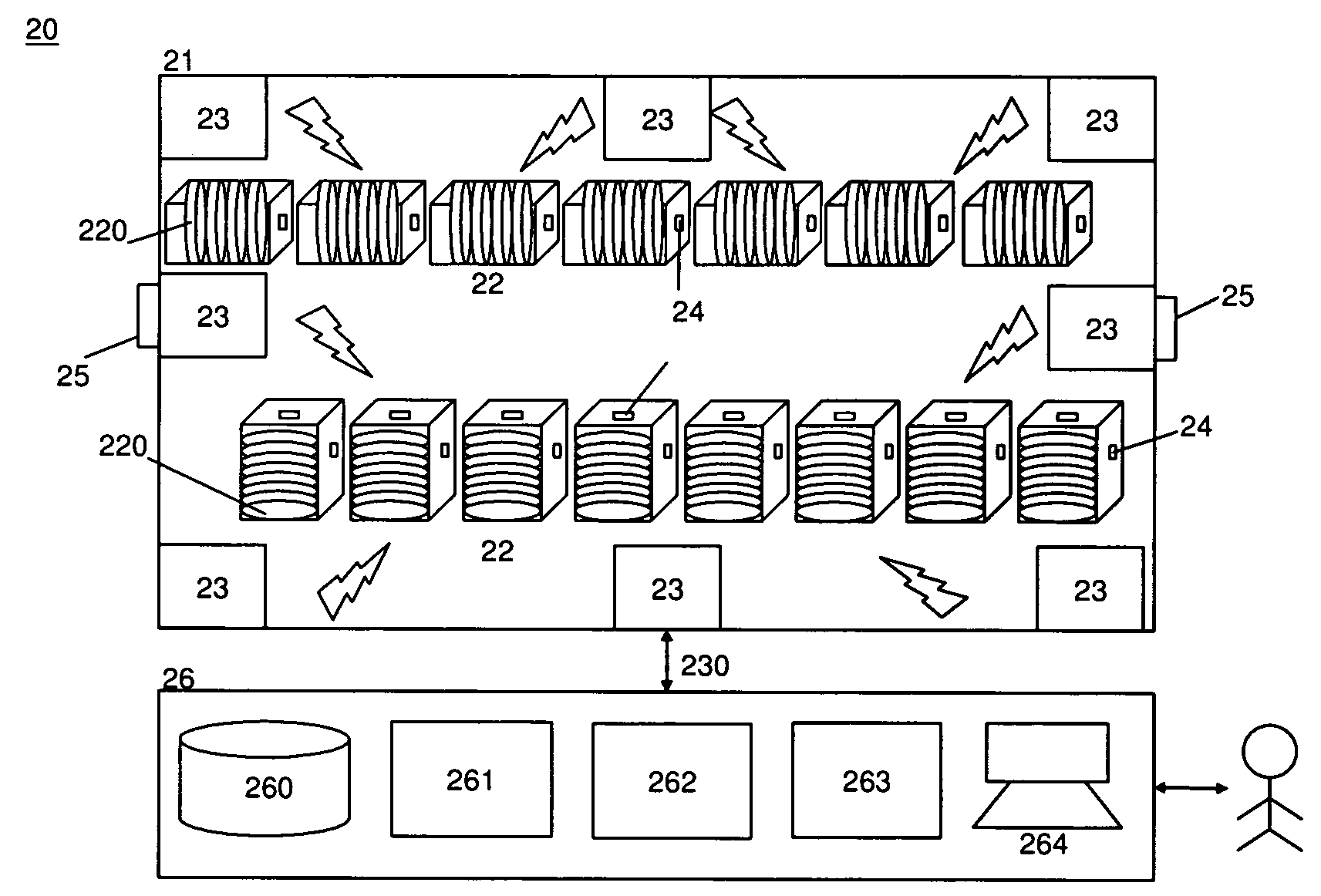

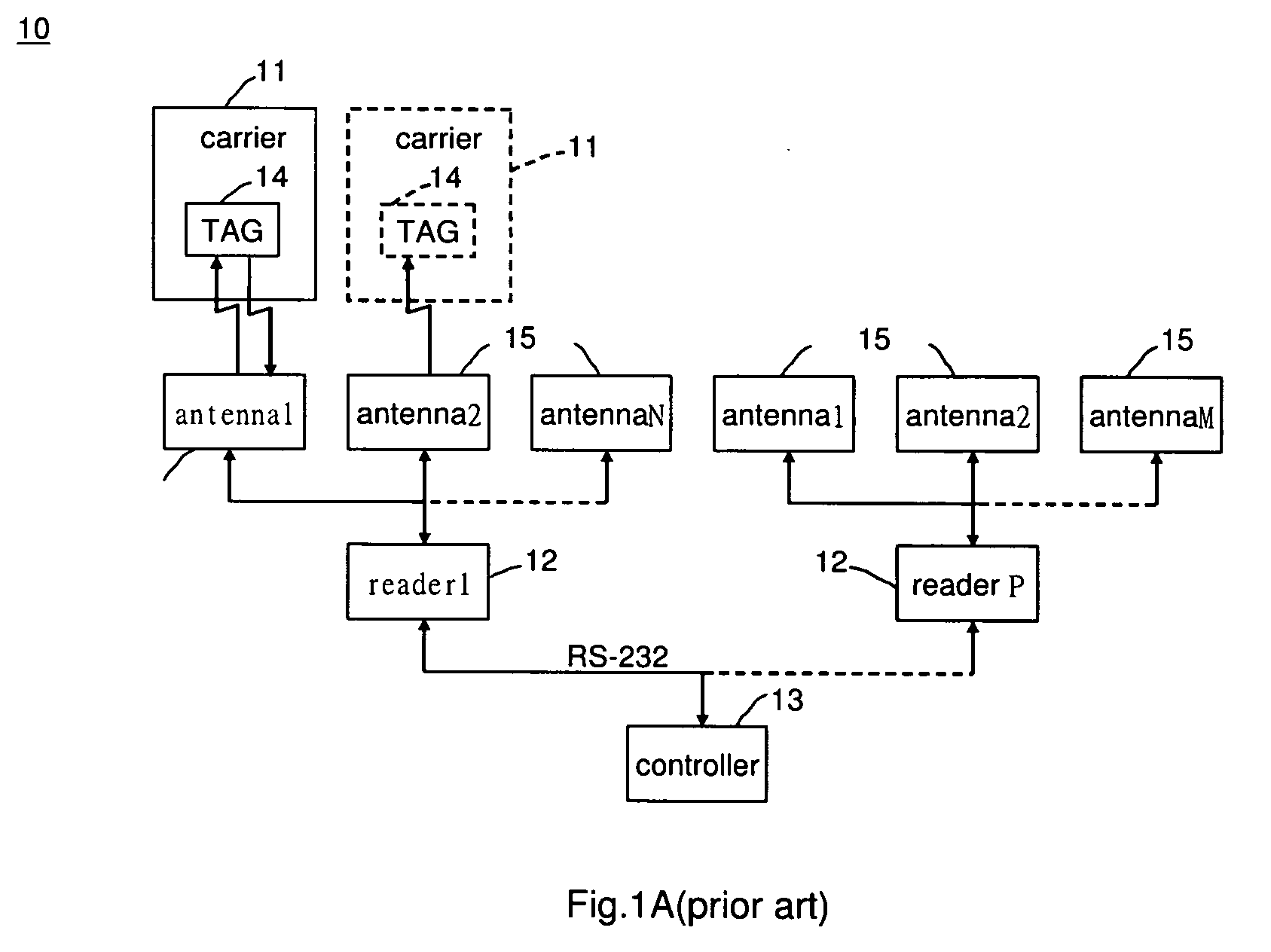

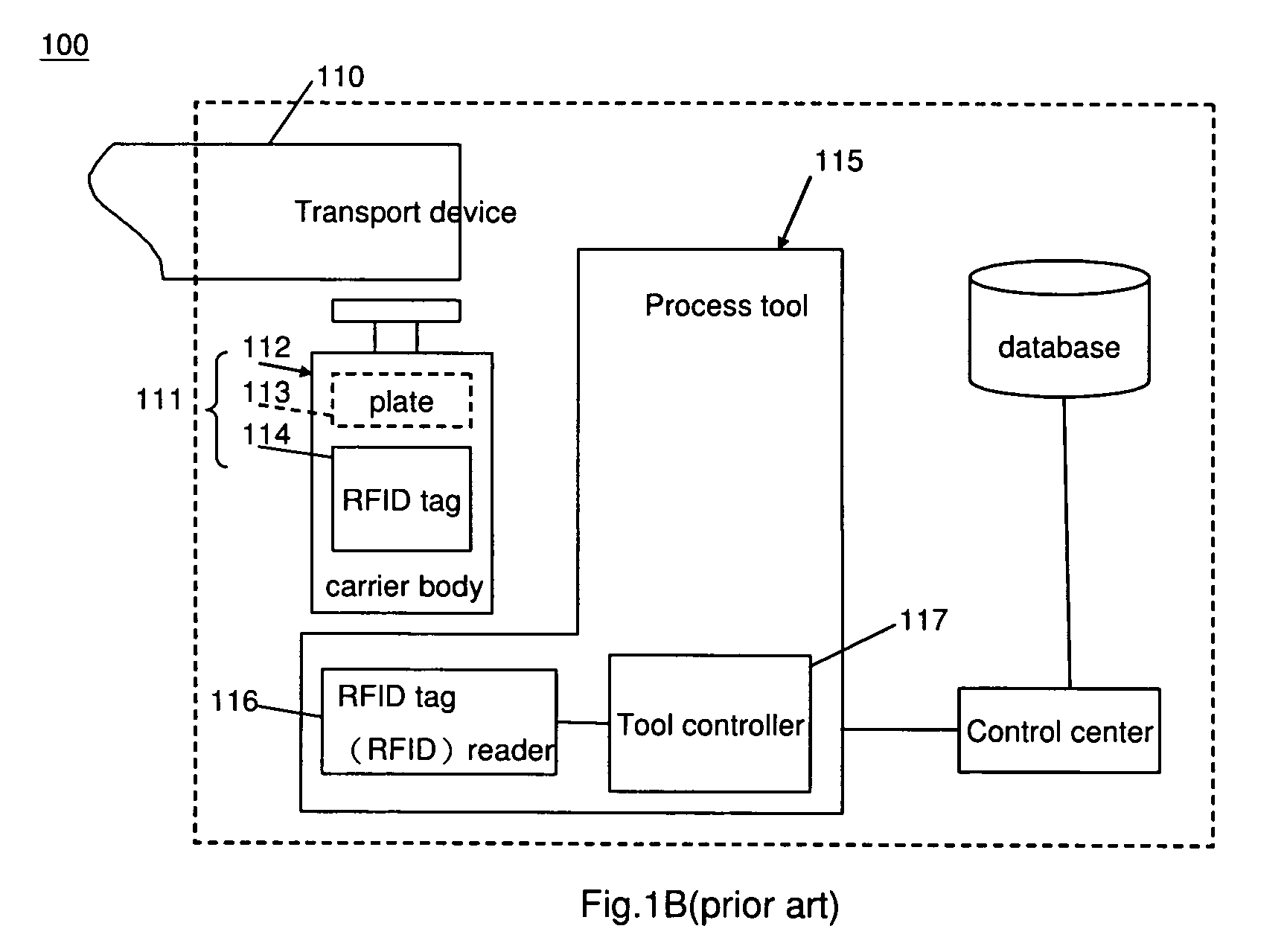

Depository monitoring system in semiconductor storage warehouse

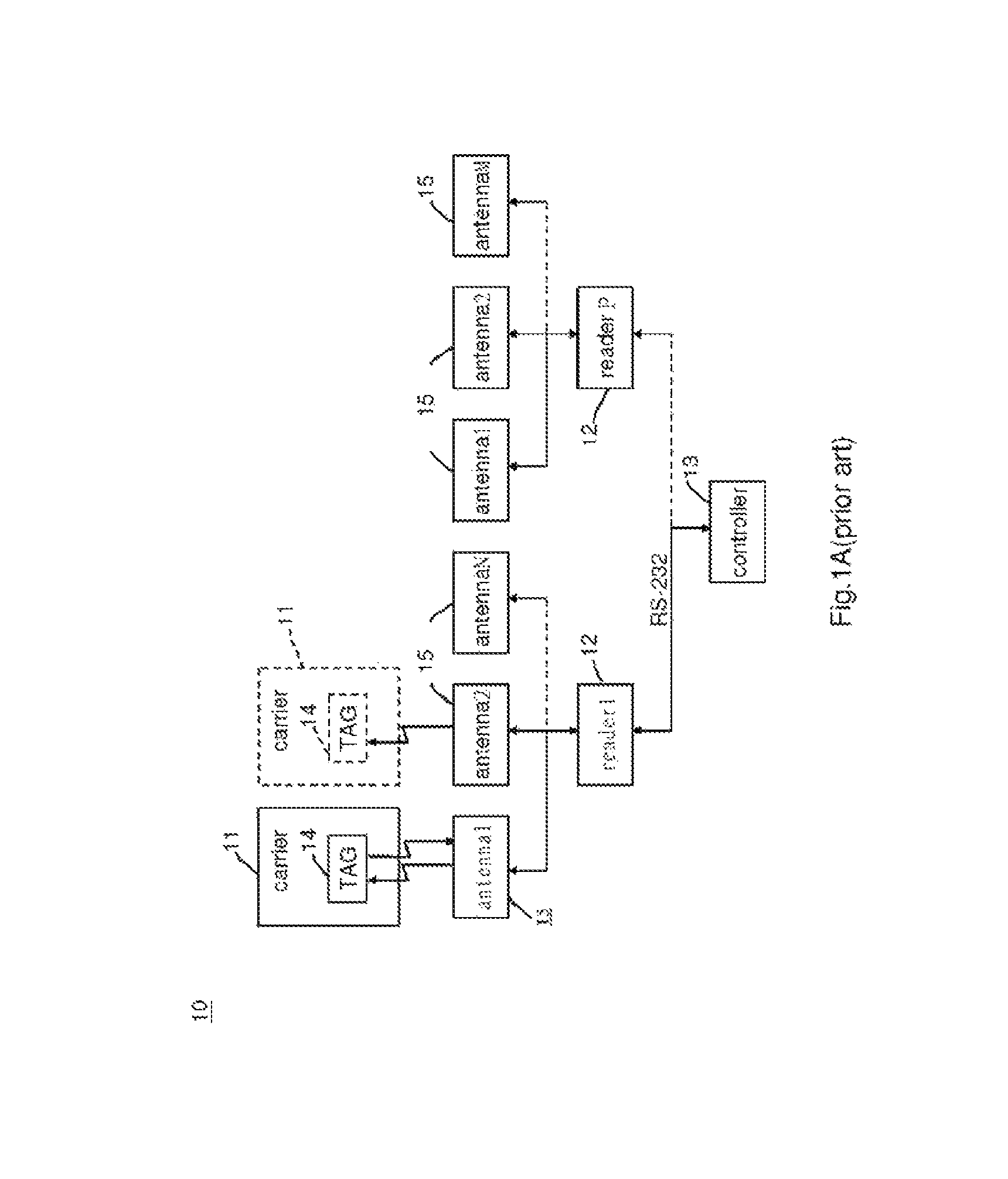

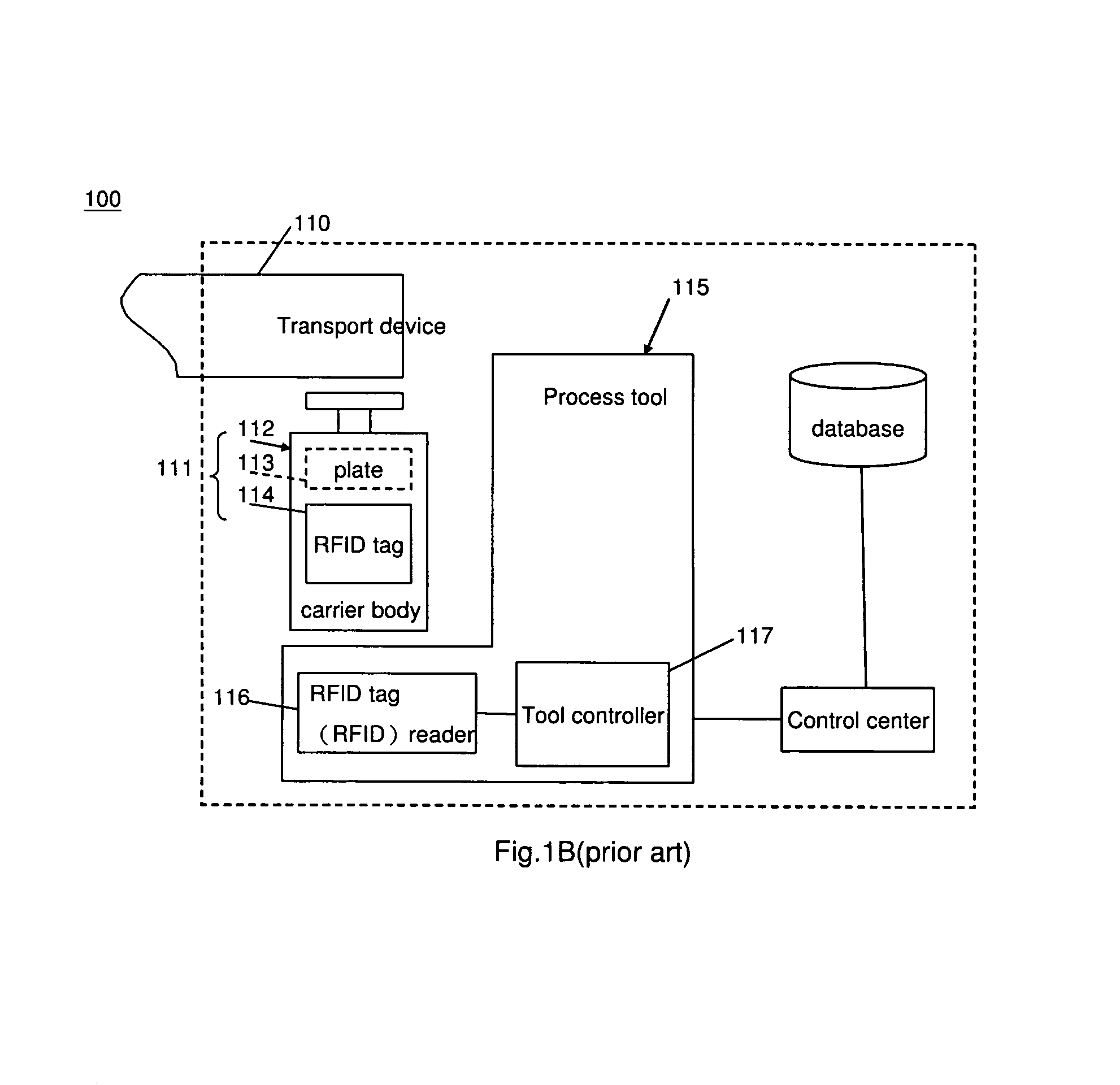

A depository monitoring system for use in a semiconductor factory comprises a plurality of carriers, each holding at least one semiconductor object; a depository monitoring host for monitoring a depository of each carrier; and a plurality of RFID tags and a plurality of RFID readers. It is characterized in that the RFID tags are disposed on the carriers and / or semiconductor objects, respectively, wherein each RFID tag has a tag information; the RFID readers read / write the tag information from / to the RFID tags; and the depository monitoring host comprises: a legacy database to store information related to the depository monitoring system; an RFID middleware for processing operations between the RFID readers and the RFID tags; a web interface for processing commands and query results through a B2B internet; an input / output interface for processing commands and query results through an intranet; and a depository controller for performing a sequence of processes in depository monitoring.

Owner:CHIPMOS TECH INC

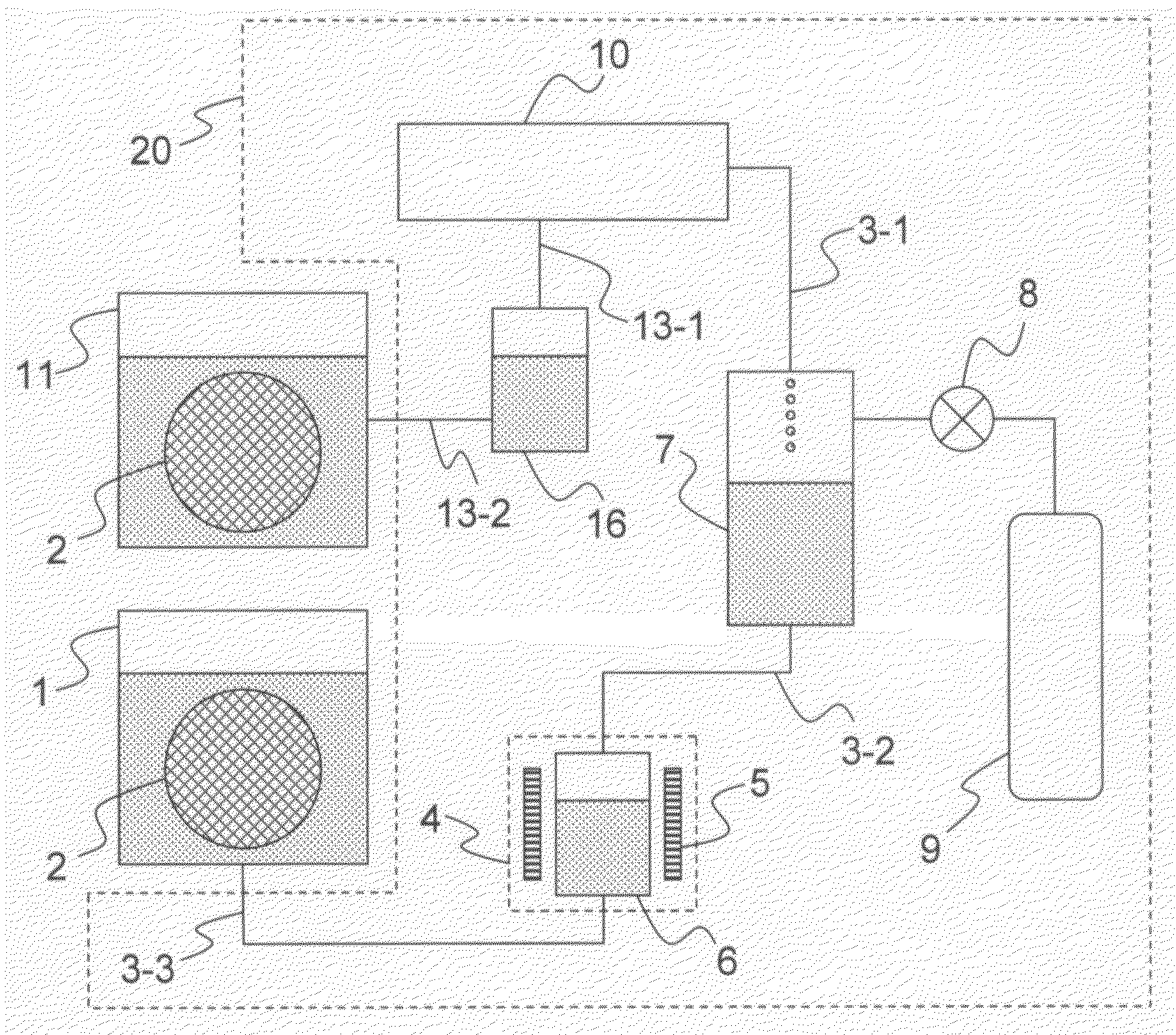

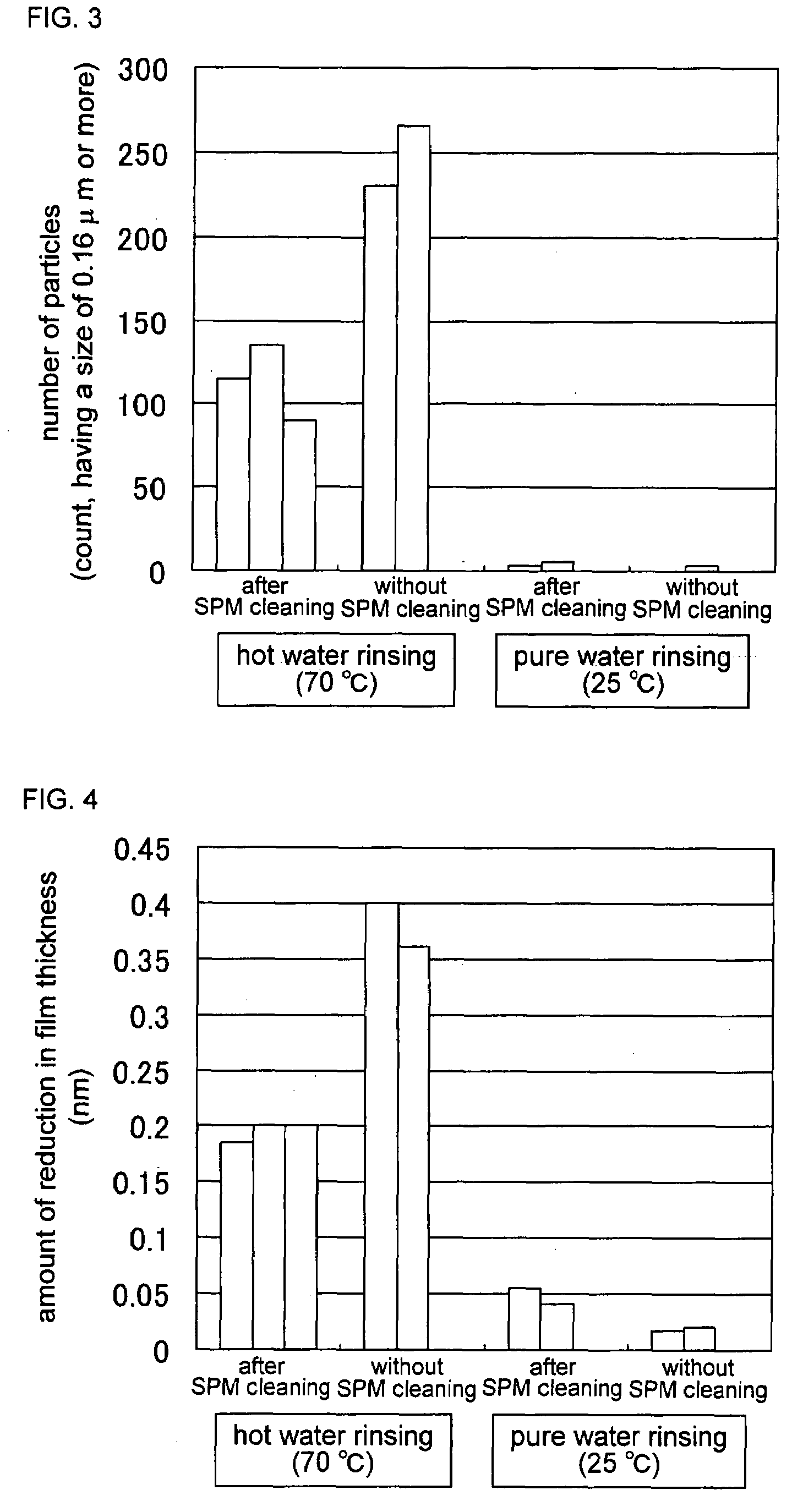

Pure water supply system, and cleaning system and cleaning method using pure water

InactiveUS20070186960A1Reduce the amount of solutionSpecific water treatment objectivesElectrostatic cleaningCouplingProduct gas

There is provided a system capable of supplying pure water containing almost no dissolved gas and pure water containing dissolved gas without increasing the amount of pure water manufactured in a volume production semiconductor factory. In the present invention, pure water is supplied using a pure water supply system, which includes: a pure water manufacturing means for manufacturing pure water having a dissolved gas concentration of 0.4 ppm or lower; a first pure water supply means capable of supplying the pure water from the pure water manufacturing means; a dissolving means that is coupled to the pure water manufacturing means via a coupling portion and dissolves gas in the pure water transferred from the pure water manufacturing means via the coupling portion; and a second pure water supply means capable of supplying the pure water in which the gas has been dissolved by the dissolving means.

Owner:ELPIDA MEMORY INC

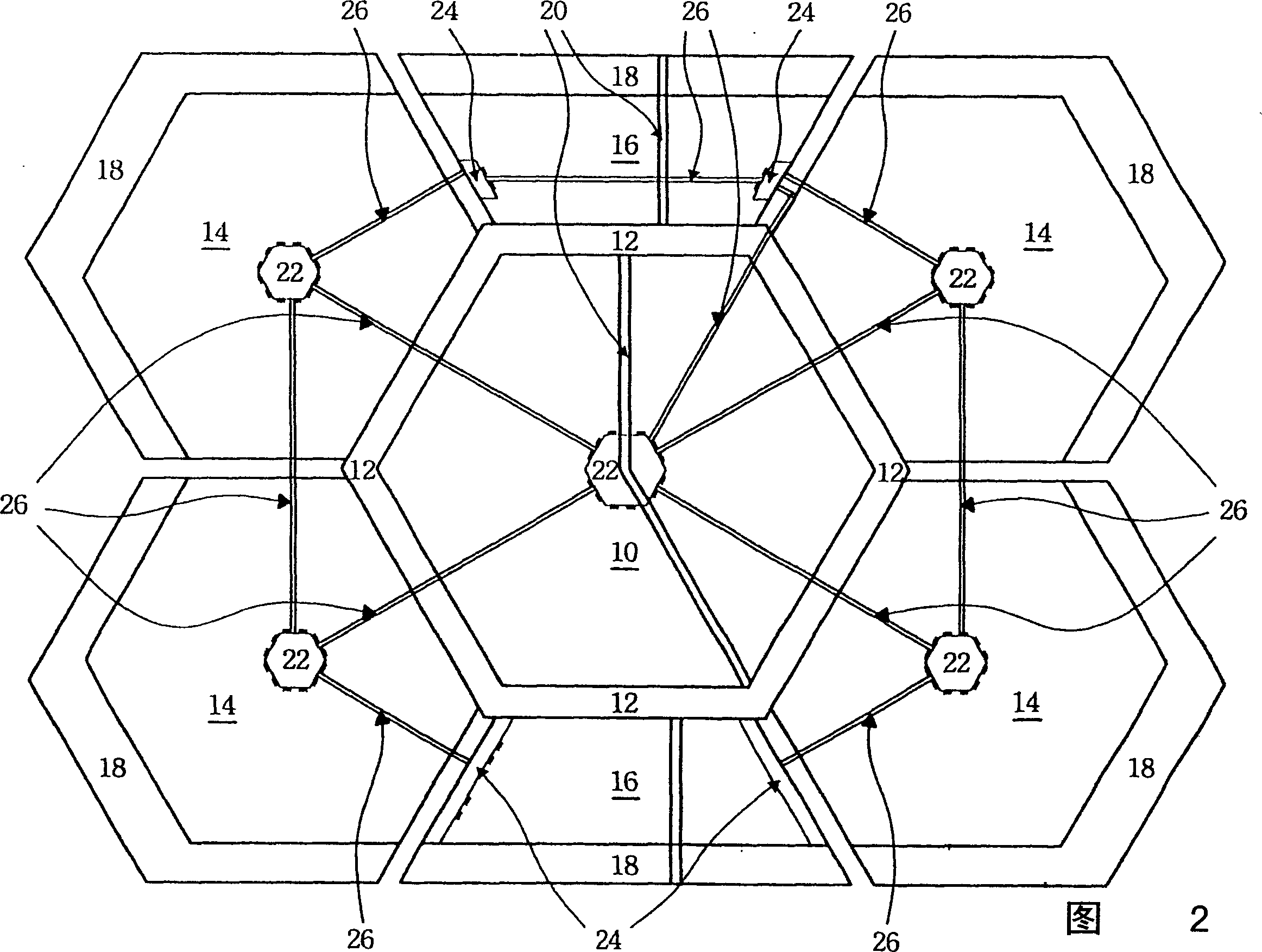

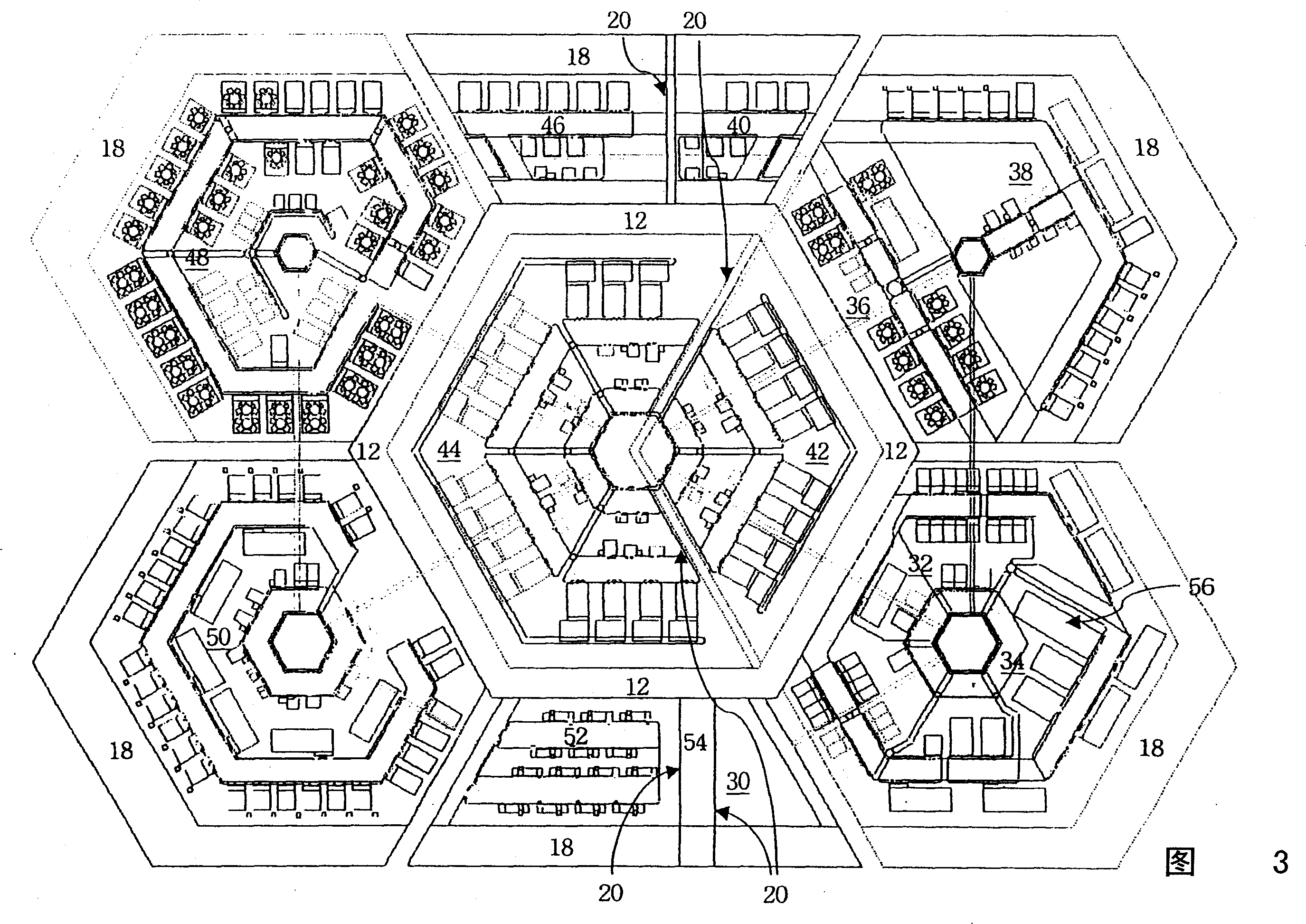

Semi-conductor manufacturing factory layout

InactiveCN1464157AEasy to implementImprove stabilityIndustrial buildingsSemiconductor factorySemiconductor

The configuration mode for semiconductor factory workshops includes seven main areas including one central hexagonal area, four peripheral hexagonal areas to the right and left sides and two peripheral trapeziform areas in the other two sides. The manufacture workshop most closely relative to material circulation is set in the central area for the automatic material circulation in shortest path and highest efficiency. The configuration may be planned flexibly according to the required areas, environment and numbers of equipment in different workshops to raise the overall utilization of the factory area. The configuration is beneficial to concentrated management and control, simplified building construction, etc.

Owner:李珩铭

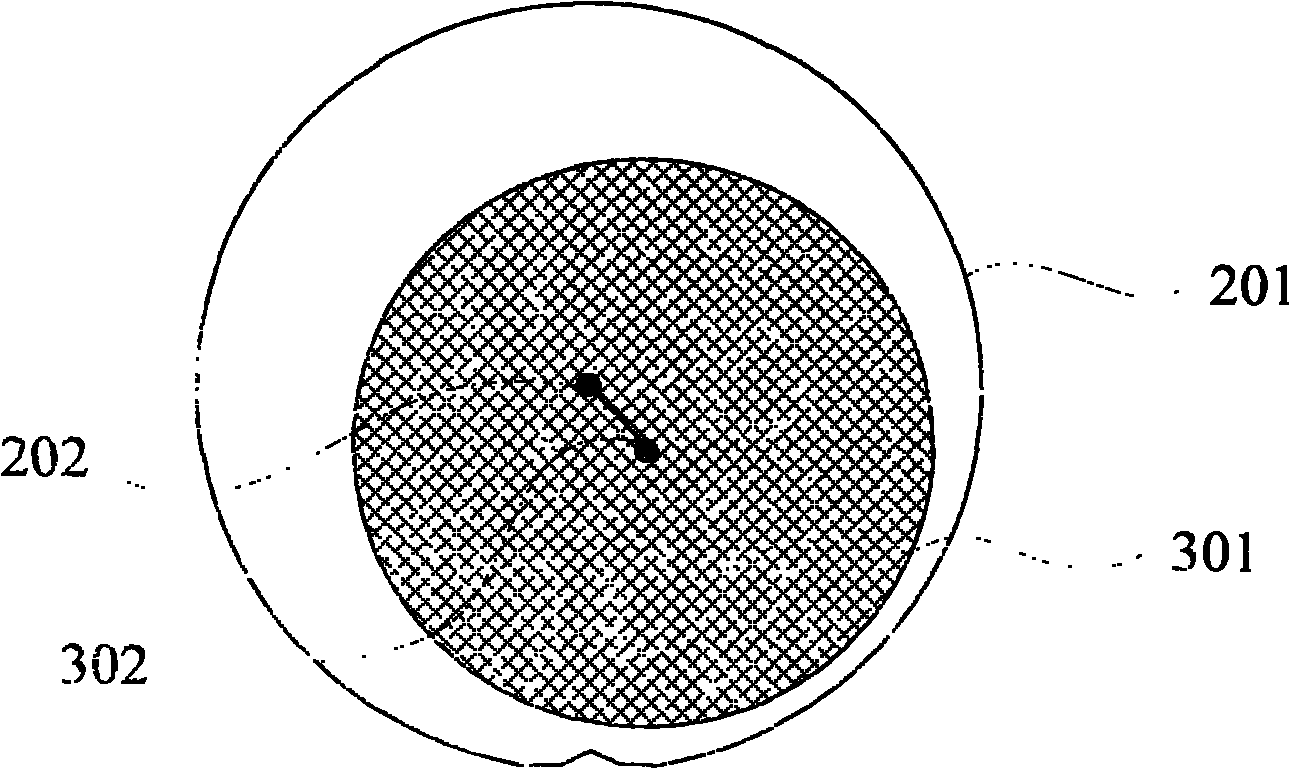

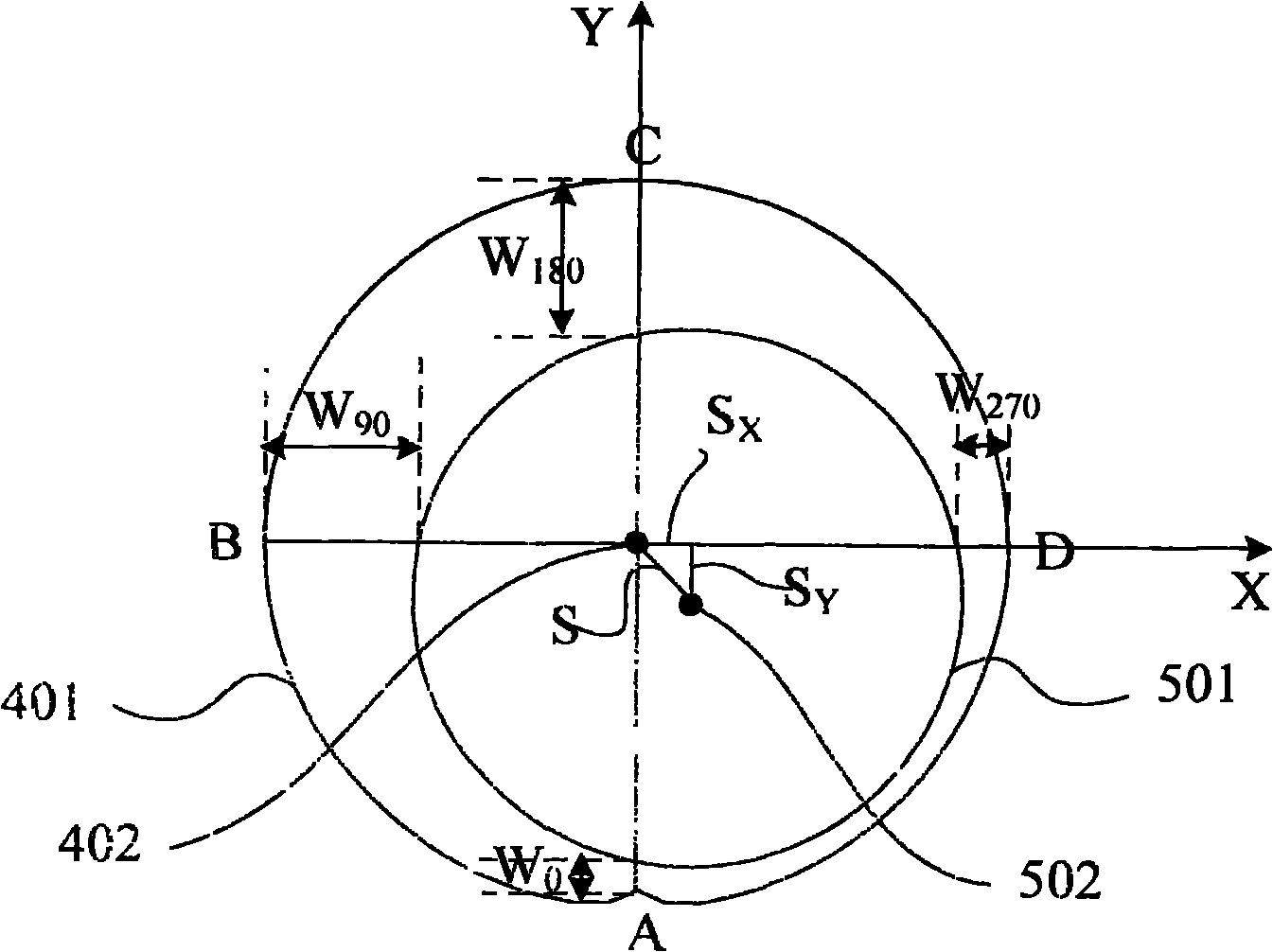

Photoresist edge edge-wash data measuring system and measurement monitoring method

InactiveCN102466979AAvoid process impactTimely detection of deviationsPhotomechanical exposure apparatusMicrolithography exposure apparatusMonitoring systemSemiconductor factory

The invention discloses a photoresist edge edge-wash data measuring system. The system comprises a developing post-measuring machine, a wafer edge position sensor, an edge-wash line position sensor, a logic operation unit and a pre-warning unit. The system can be used for carrying out developing post-measuring on the wafer and simultaneously calculating the edge-wash width of the photoresist edge and the offset of the edge-wash line, thus the photoresist edge edge-wash data can be obtained in time. The invention further discloses a measurement monitoring method of the photoresist edge edge-wash data, comprising the following steps: measuring and calculating the photoresist edge edge-wash data by using the system; automatically collecting the data, and sending the data to an automatic monitoring system of a semiconductor factory; judging whether the edge-wash width exceeds the maximum allowable width and whether the offset of the edge-wash line exceeds the maximum allowable offset, when exceeds, raising an alarm, and sending the edge-wash width and the offset to workers for measurement. According to the method, the real-time monitoring of the photoresist edge edge-wash data can be realized, and the offset of the edge-wash line can be discovered in time.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP +1

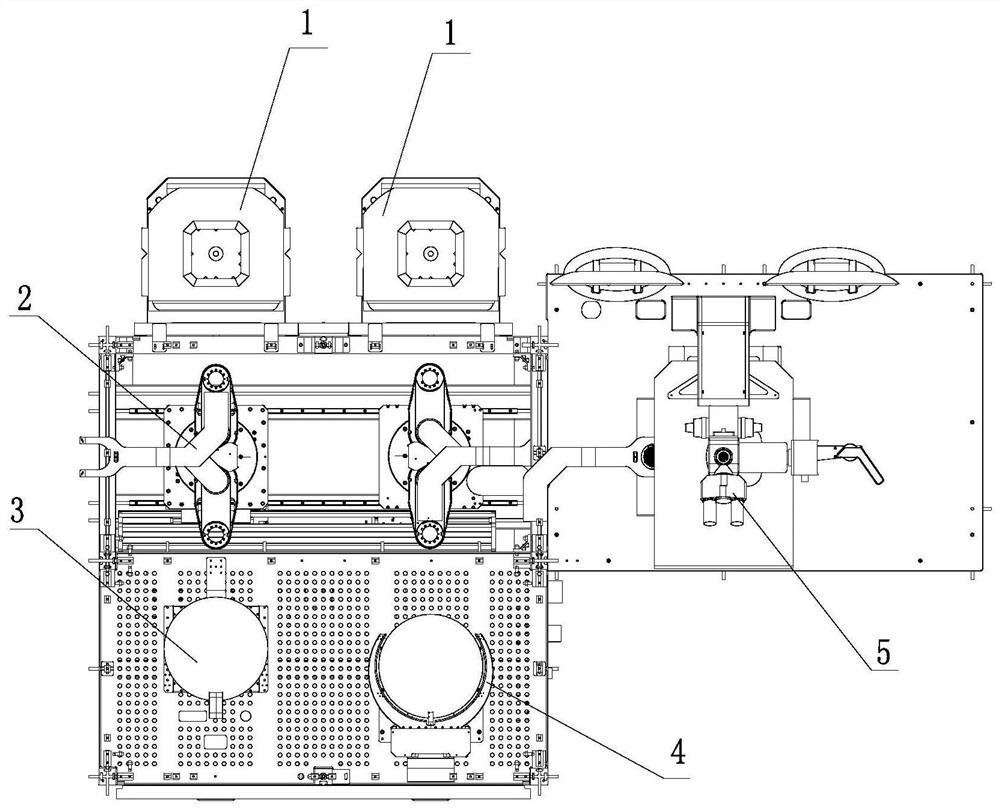

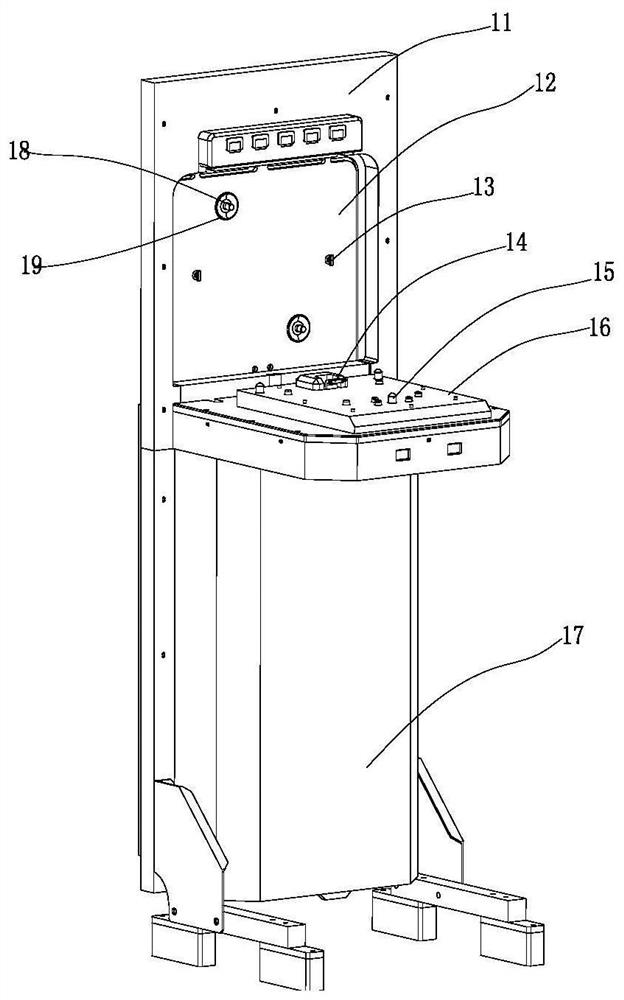

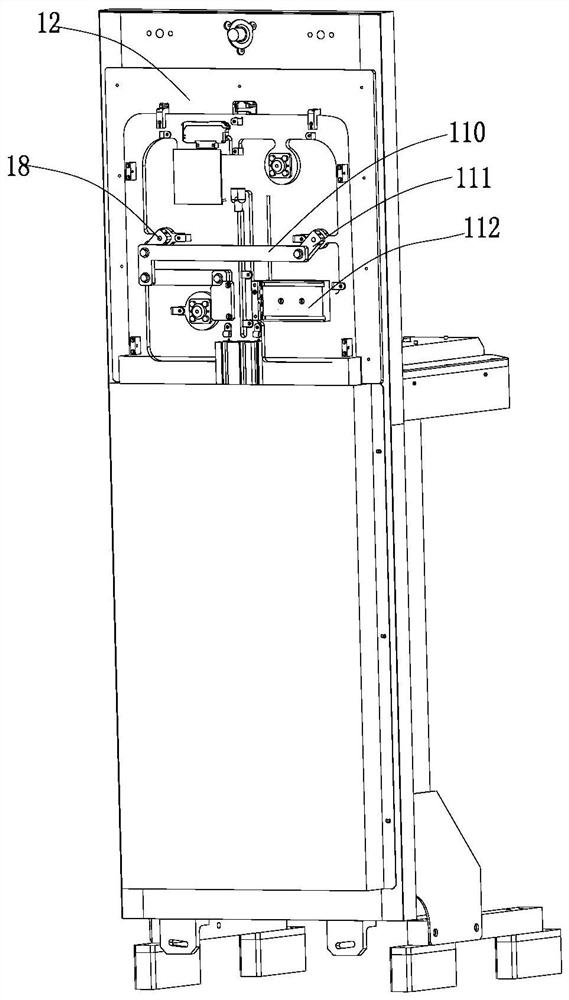

Full-automatic wafer appearance inspection system

PendingCN112820660AQuick judgment of tilt and bendRelieve fatigueSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingMicroscopic observationEngineering

The present invention relates to a full-automatic wafer appearance inspection system which comprises a wafer box opening carrier, a wafer taking and placing manipulator, a wafer position calibration mechanism, a wafer turnover mechanism and a microscope detection mechanism, the wafer box opening carrier is used for opening a wafer conveying box, the wafer taking and placing manipulator is used for carrying wafers, and the wafer position calibration mechanism is used for determining the circle center position of the wafer and rotating the wafer to a specified angle; and the wafer turnover mechanism is used for turnovering a wafer so as to inspect the back surface of the wafer, and the microscope detection mechanism inspects the surface of the wafer. The wafer can be automatically transmitted to the microscope for observation, so that damage caused by manual carrying is avoided; the surface and the back surface of the wafer can be visually inspected; and linear motion is adopted in the transmission process, and the wafers are prevented from being thrown out. The system is suitable for being used in semiconductor factories and wafer test factories.

Owner:无锡奇众电子科技有限公司

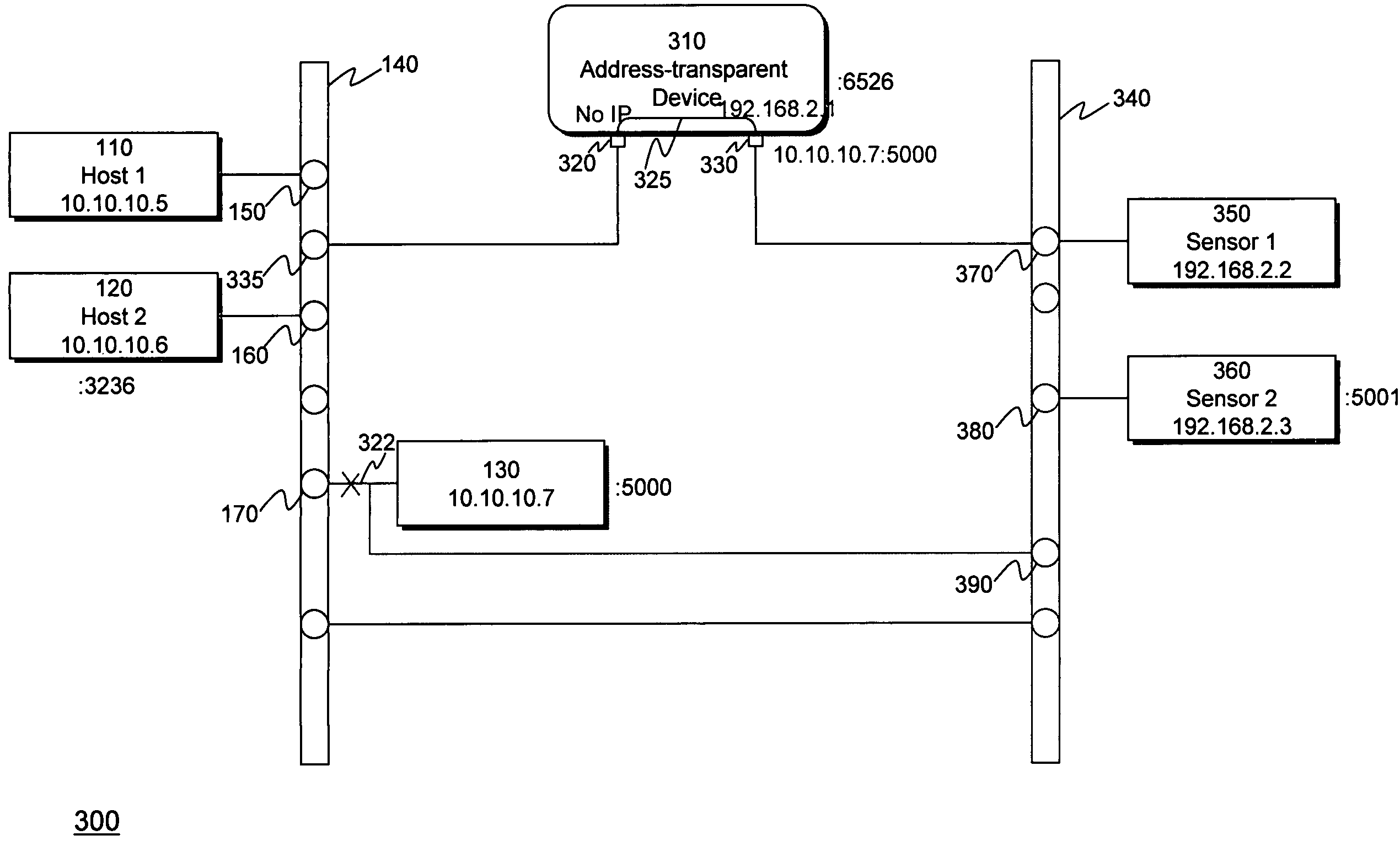

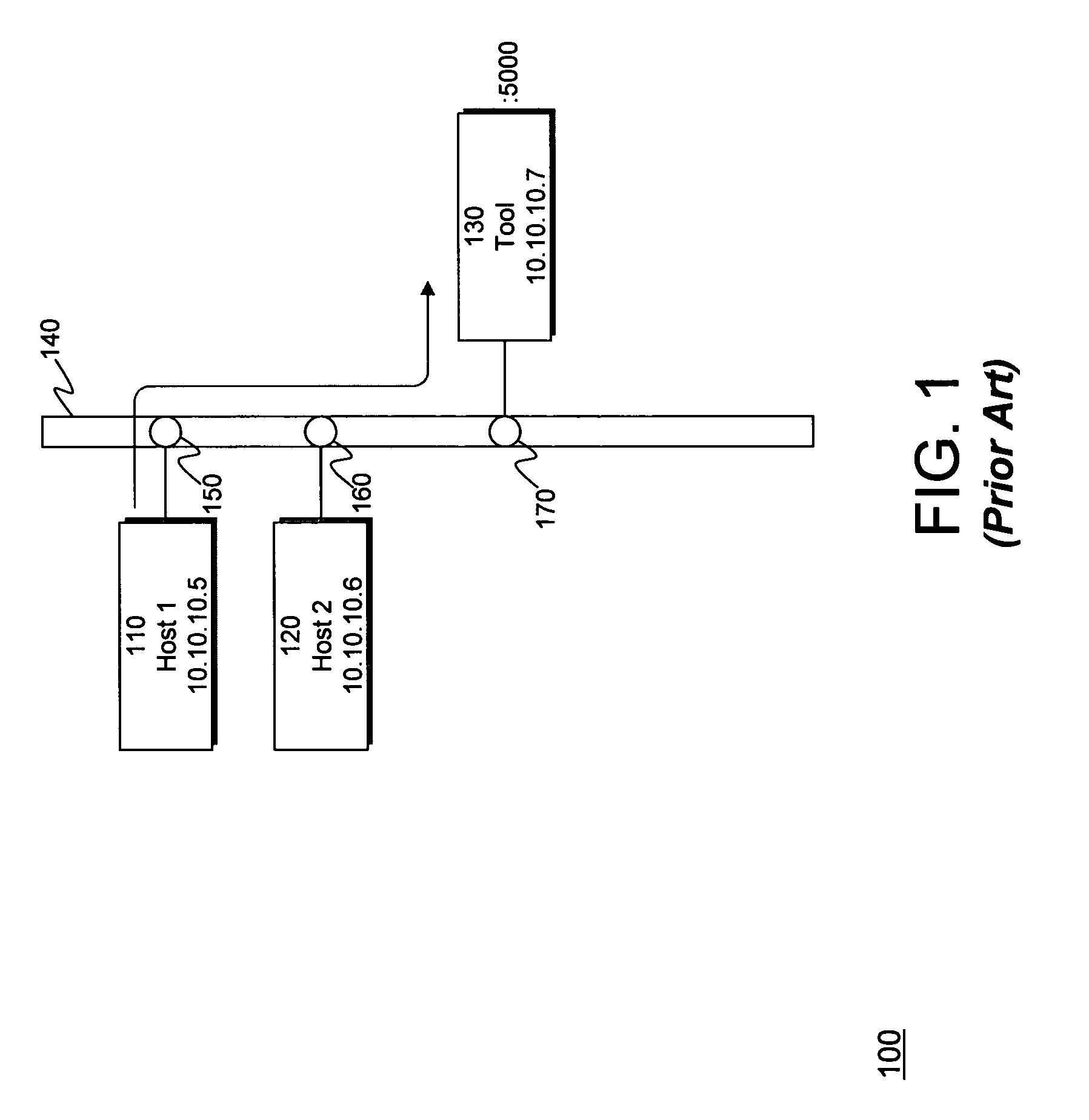

Address-transparent device and method

ActiveUS7787477B2Without significant delay and feeCost-effectiveError preventionFrequency-division multiplex detailsComputer networkData stream

An address-transparent device is disclosed that couples two networks in a semiconductor fab and communicates packets between a host on a first network and a tool on a second network. Optionally, the address-transparent device intercepts packets for local use by a data consumer that resides within or outside of the address-transparent device. The address-transparent device can intercept all or a portion of data streams. As another option, the address-transparent device reroutes packet to another destination by changing the header of the received packet.

Owner:MKS INSTR INC

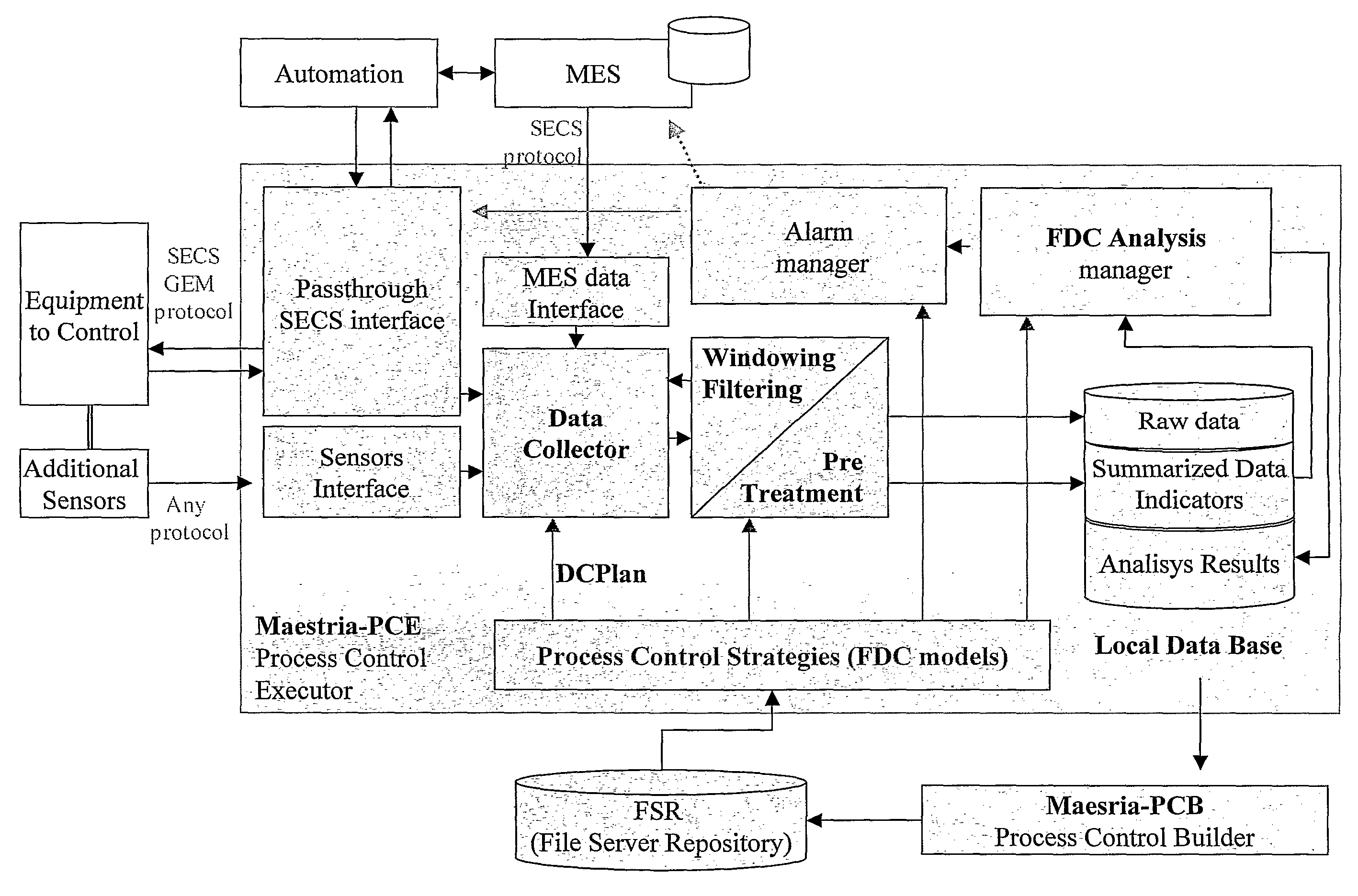

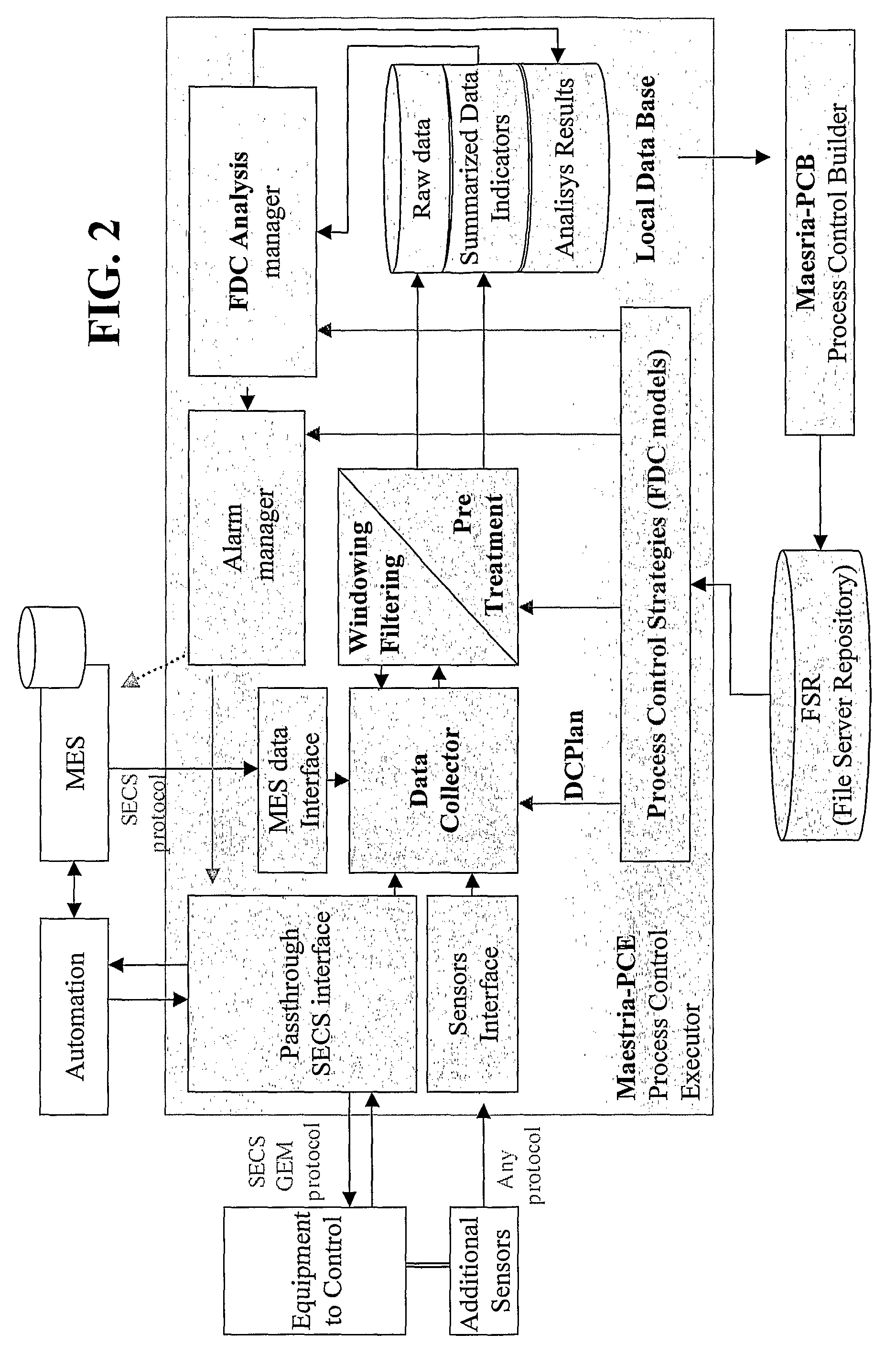

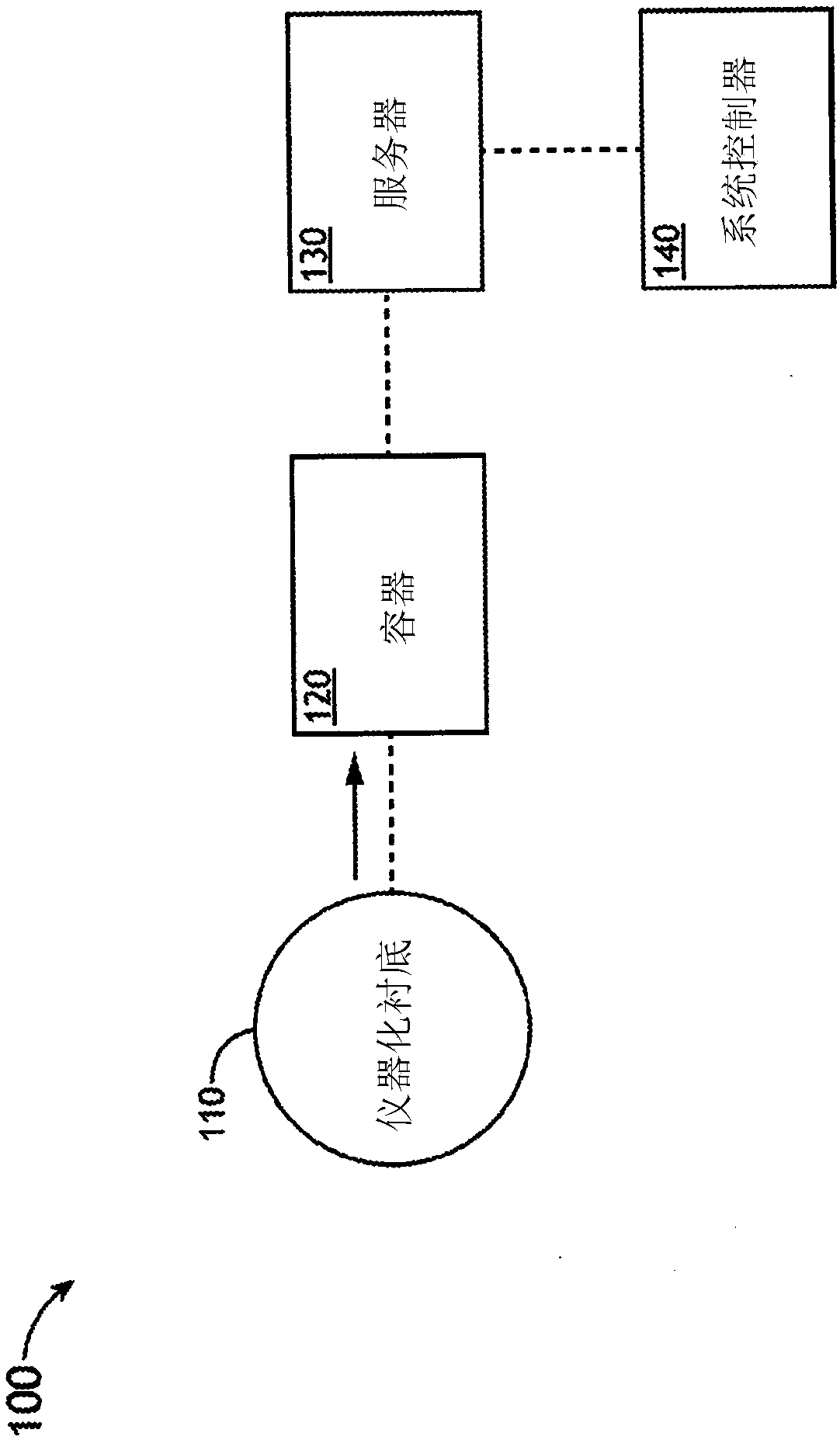

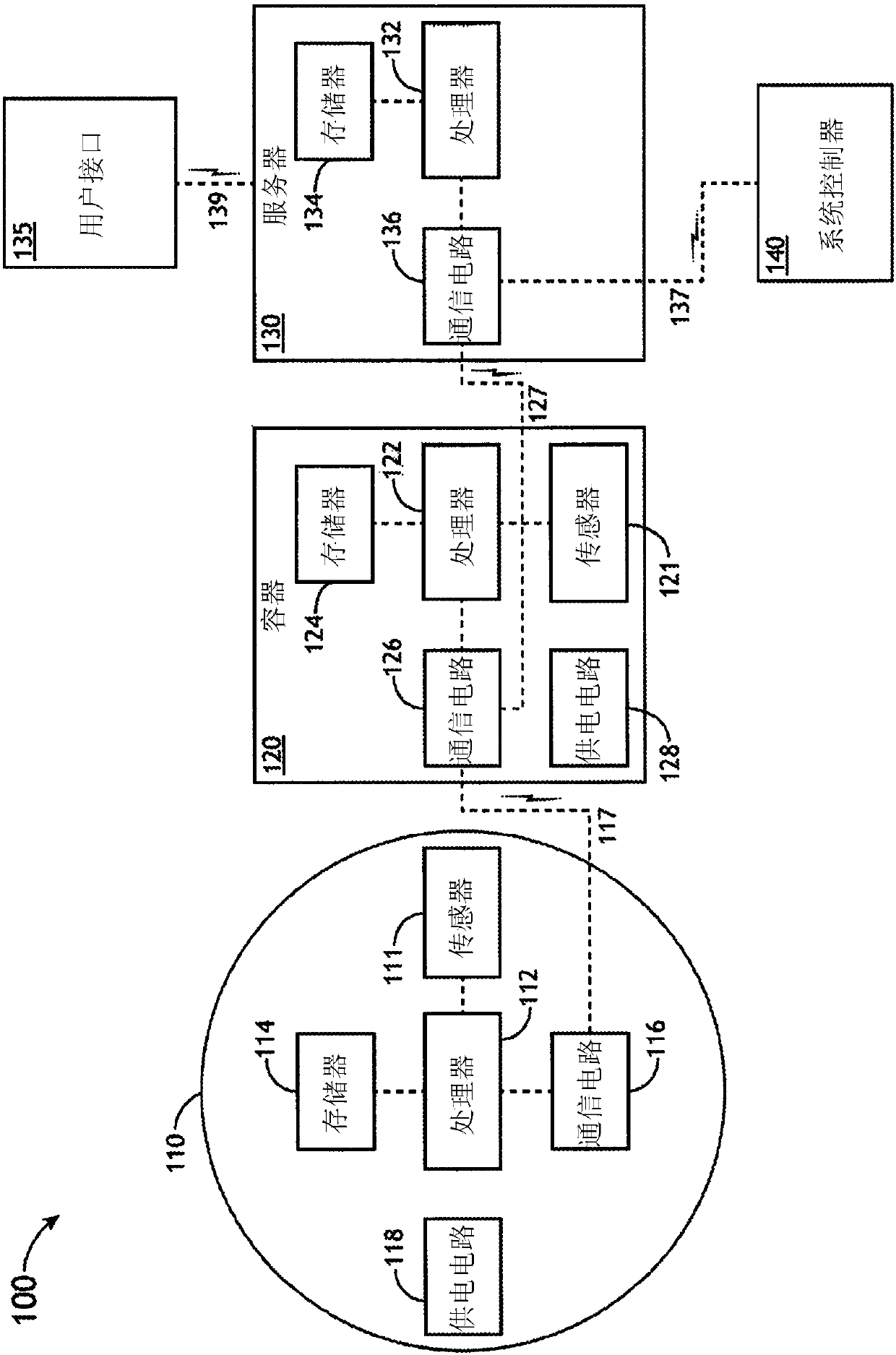

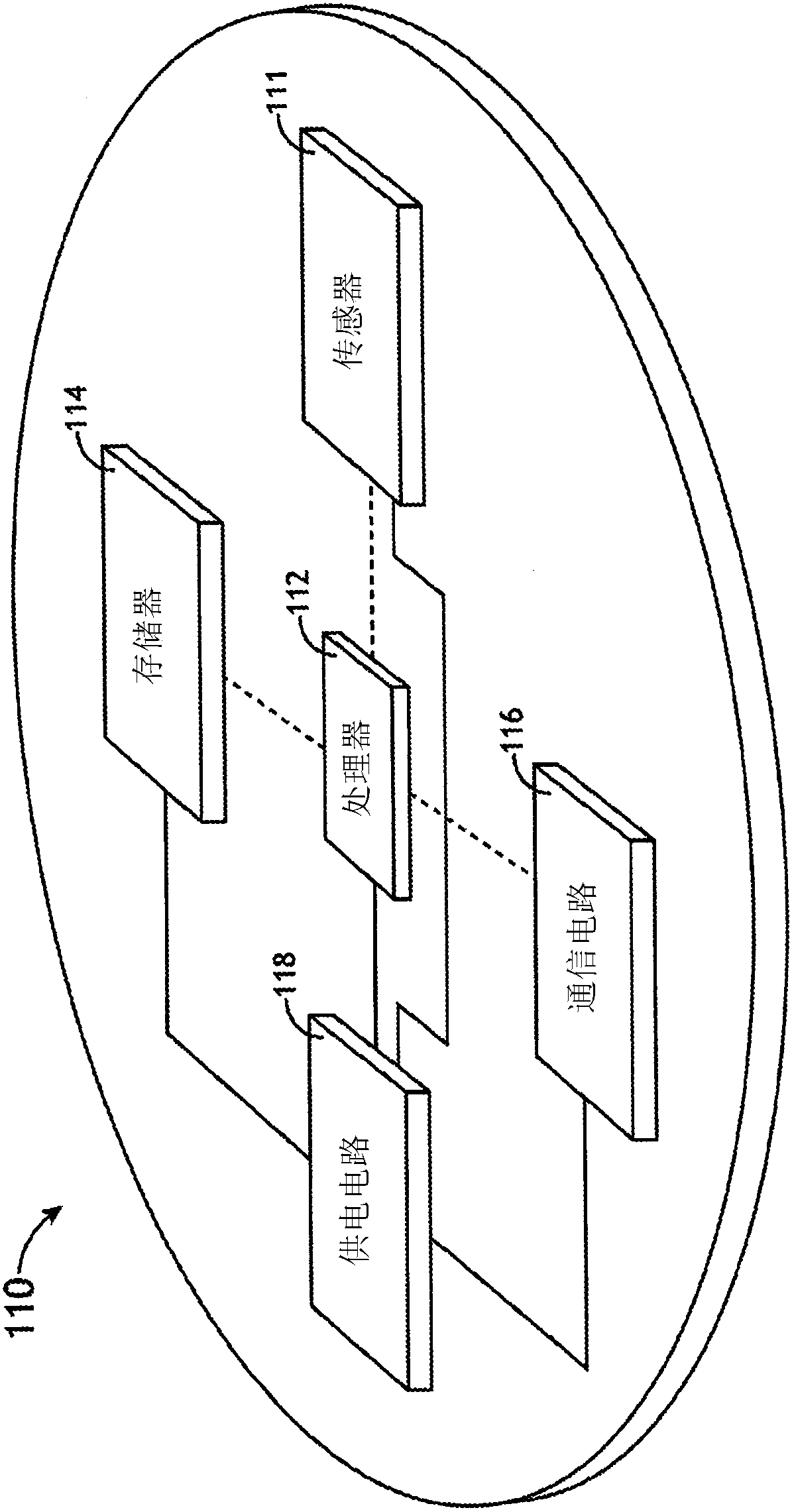

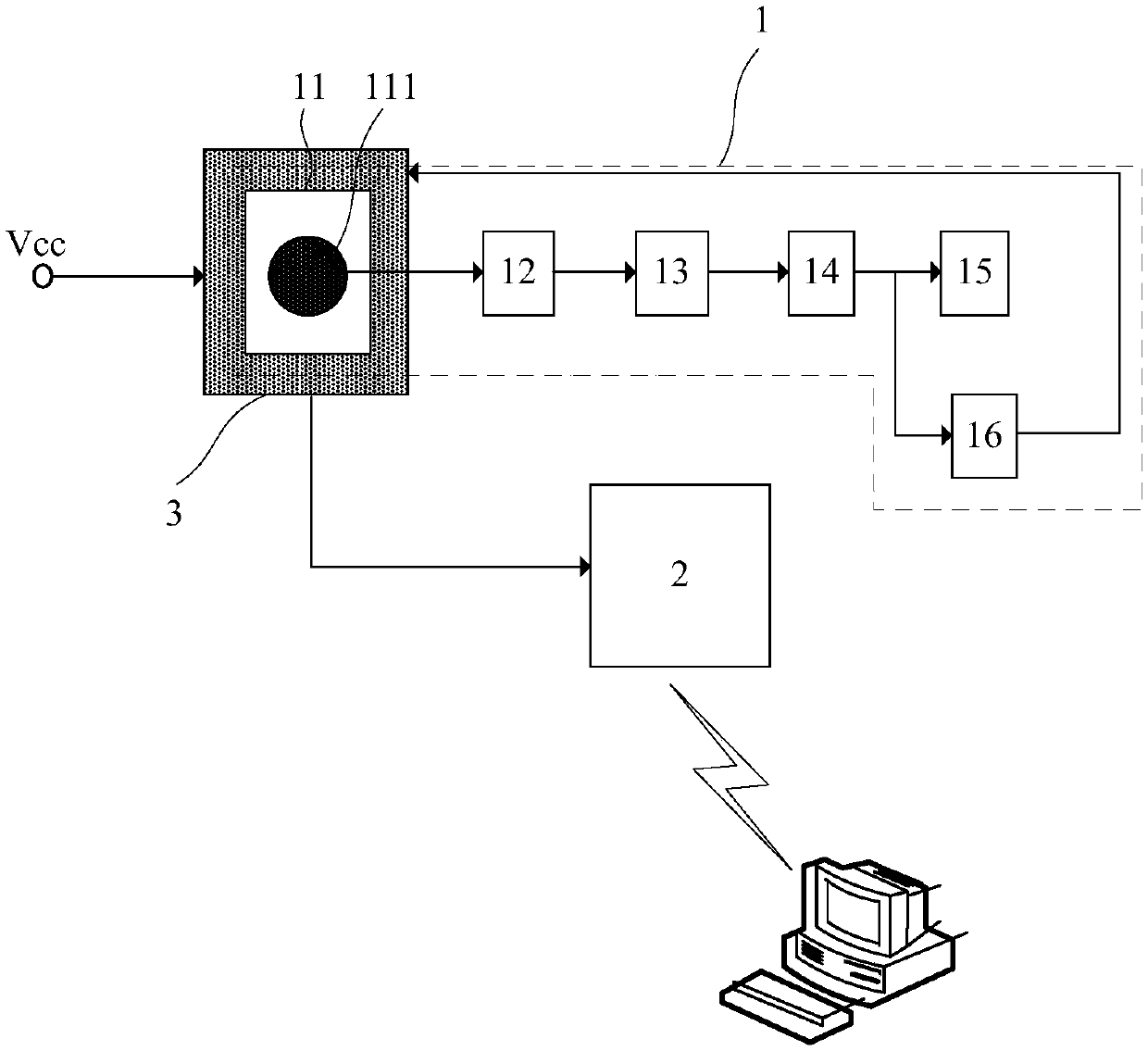

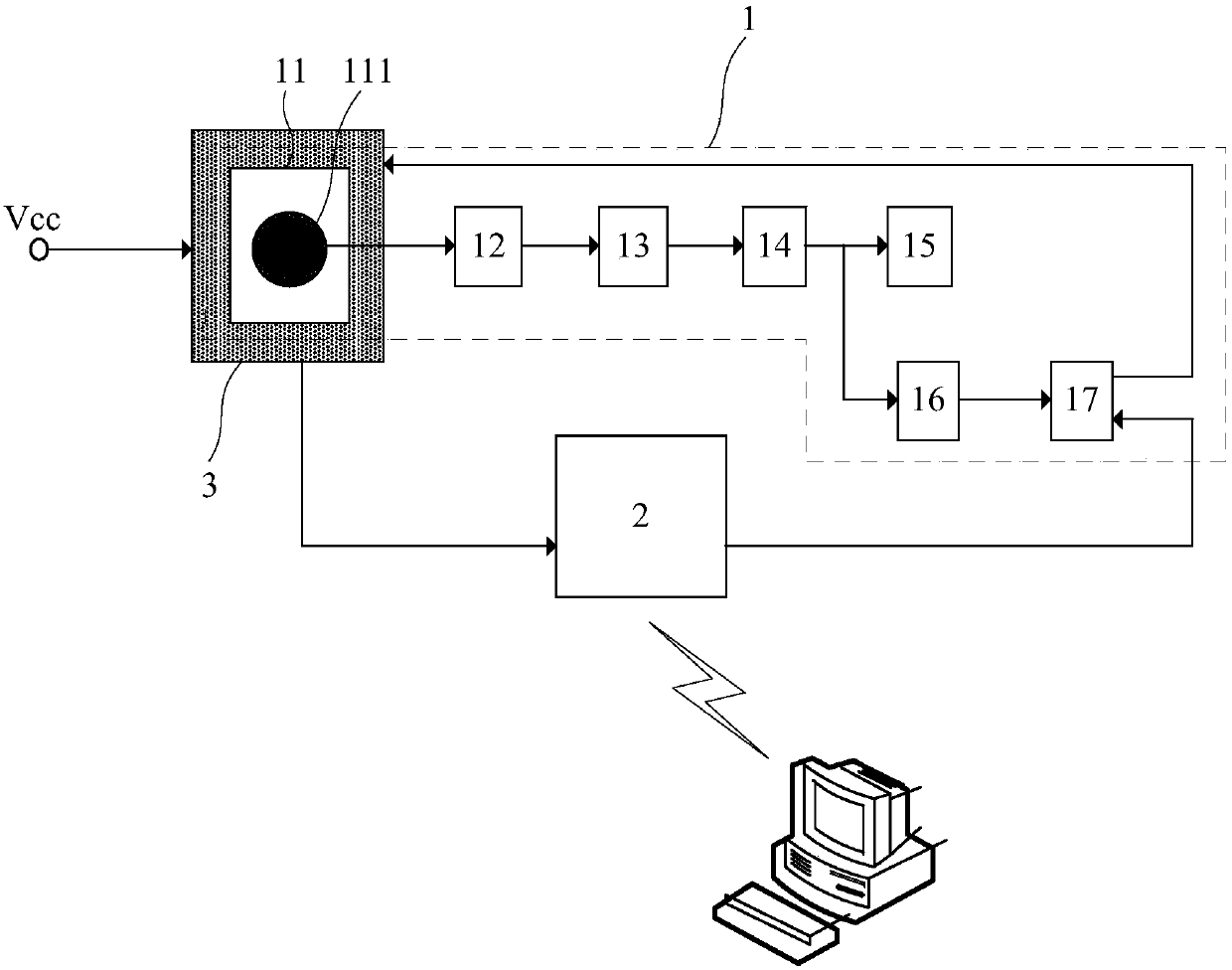

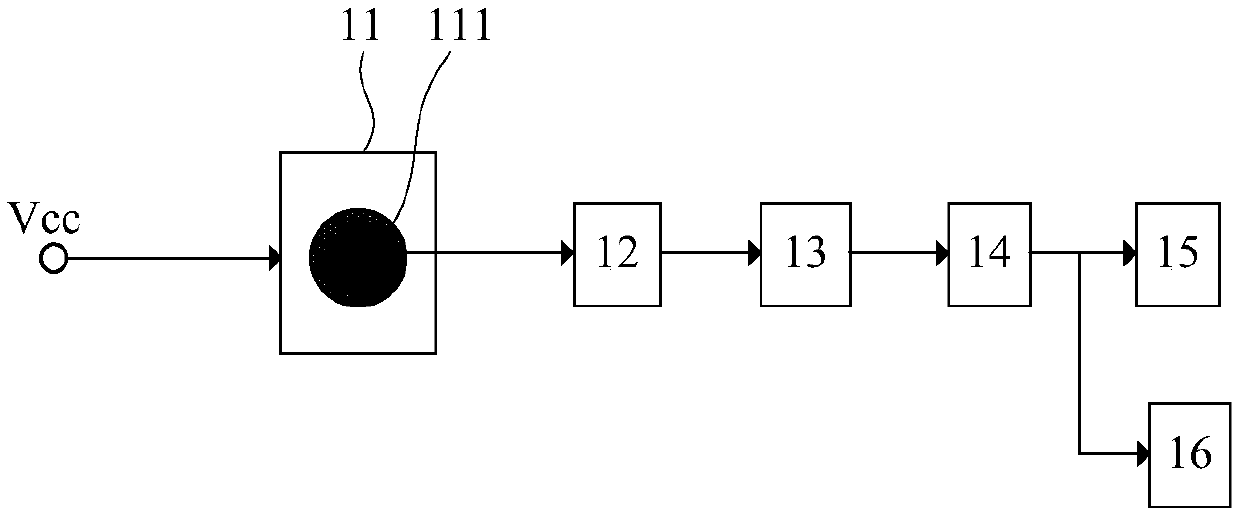

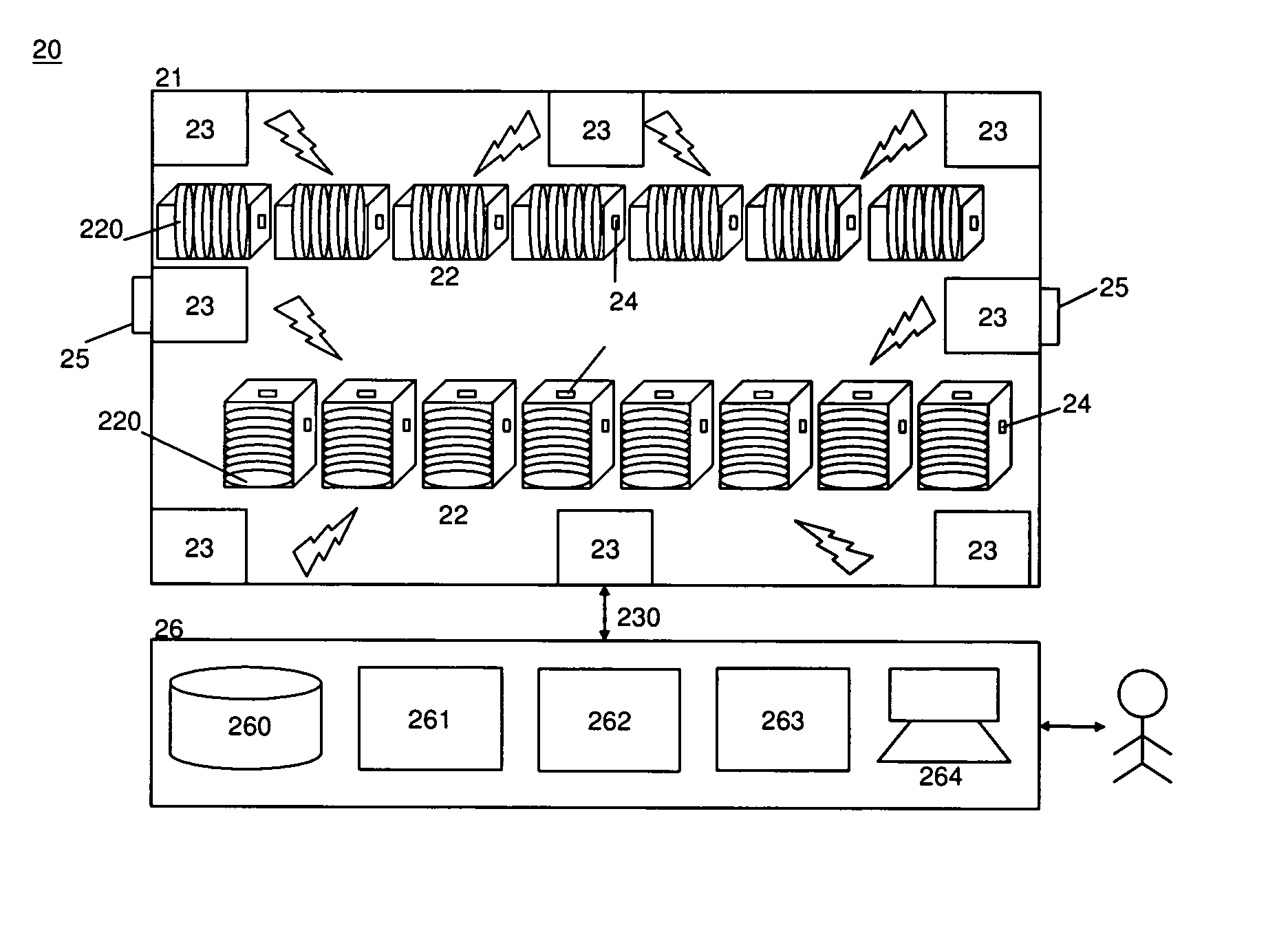

System and method for monitoring parameters of a semiconductor factory automation system

ActiveCN107690604ASemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingProcess engineeringSemiconductor factory

A system for monitoring one or more conditions of an automation system of a semiconductor factory includes one or more instrumented substrates, one or more sealable containers and one or more system servers. The one or more instrumented substrates include one or more sensors. The one or more sensors measure one or more conditions of the one or more instrumented substrates as the one or more sealable containers transport the one or more instrumented substrates through the semiconductor factory. The one or more sealable containers also receive sensor data from the one or more sensors included onthe one or more instrumented substrates. The one or more system servers are configured to receive the sensor data from the one or more sealable containers. The one or more servers are configured to identify one or more deviations in the measured one or more conditions.

Owner:KLA TENCOR TECH CORP

Heat dissipation device, semiconductor production system and fault monitoring method of heat dissipation fan

ActiveCN110345096ASimple structureThe fault monitoring method is simple and easySemiconductor/solid-state device manufacturingPump controlElectric machineComputer module

The invention provides a heat dissipation device. The device comprises a heat dissipation fan and a current monitoring module, wherein the heat dissipation fan comprises a motor, the current monitoring module is provided with an input end and an output end, wherein the input end of the current monitoring module is connected with the motor and used for monitoring the induction current of the motor.The invention further provides a semiconductor production system. The system involves semiconductor production equipment, a power supply device and the heat dissipation device, wherein the power supply device is connected with the semiconductor production equipment, the heat dissipation device comprises the heat dissipation fan and the current monitoring module, the heat dissipation fan is located in the power supply device and used for dissipating heat for the power supply device, the heat dissipation fan comprises the motor, the current monitoring module is provided with the input end and the output end, and the input end of the current monitoring module is connected with the motor and used for monitoring the induction current of the motor. According to the device and the system, the structure is simple, the use is convenient, the cost is low, and a guarantee can be provided for the safe production of a semiconductor factory; and the fault monitoring method of the heat dissipation fan is simple and feasible, and has great popularization value.

Owner:CHANGXIN MEMORY TECH INC

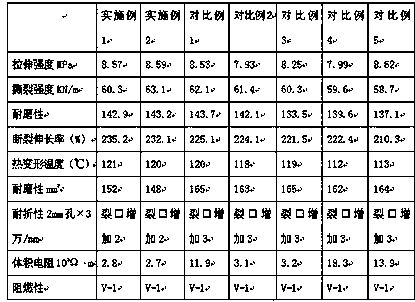

Method for preparing plastic granules for antistatic flame-retardant shoes

The invention belongs to the technical field of plastics processing and particularly relates to a method for preparing plastic granules for antistatic flame-retardant shoes. Prepared antistatic flame-retardant shoes are lightweight, portable, soft, comfortable and convenient and are convenient in washing and high in drying speed; white shoe soles are free of traces to floors and are applicable toassembly and checkout areas of electronic and semiconductor factories; and the antistatic shoes can effectively eliminate harm to human bodies caused by static charges. A working principle is as follows: static charges of a human body are conducted to the ground from the human body through wearing the antistatic shoes, an antistatic ground, and the like, and thus, the static charges of the human body are eliminated; and surface resistance of a shoe sole is low in release under the influence of wear and pollution, so that the antistatic flame-retardant shoes have the properties of acid resistance, alkali resistance, oil resistance and the like and the advantages of durability, good antislipping and antistatic properties, and the like. The antistatic flame-retardant shoes are applied to sites: any purification room or antistatic place of electronics, semiconductors, biomedicines, foods, optics and the like.

Owner:界首市鸿鑫塑业有限公司

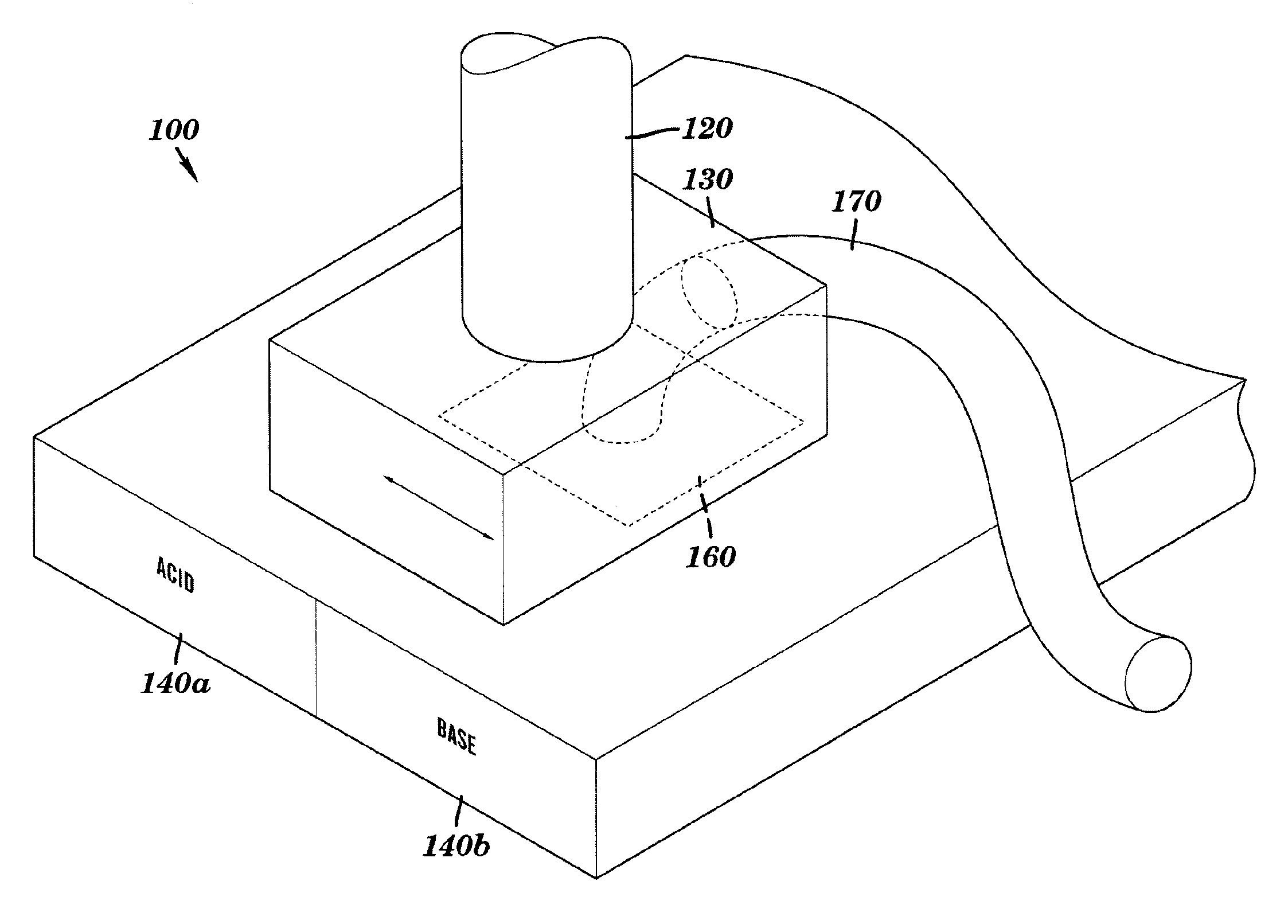

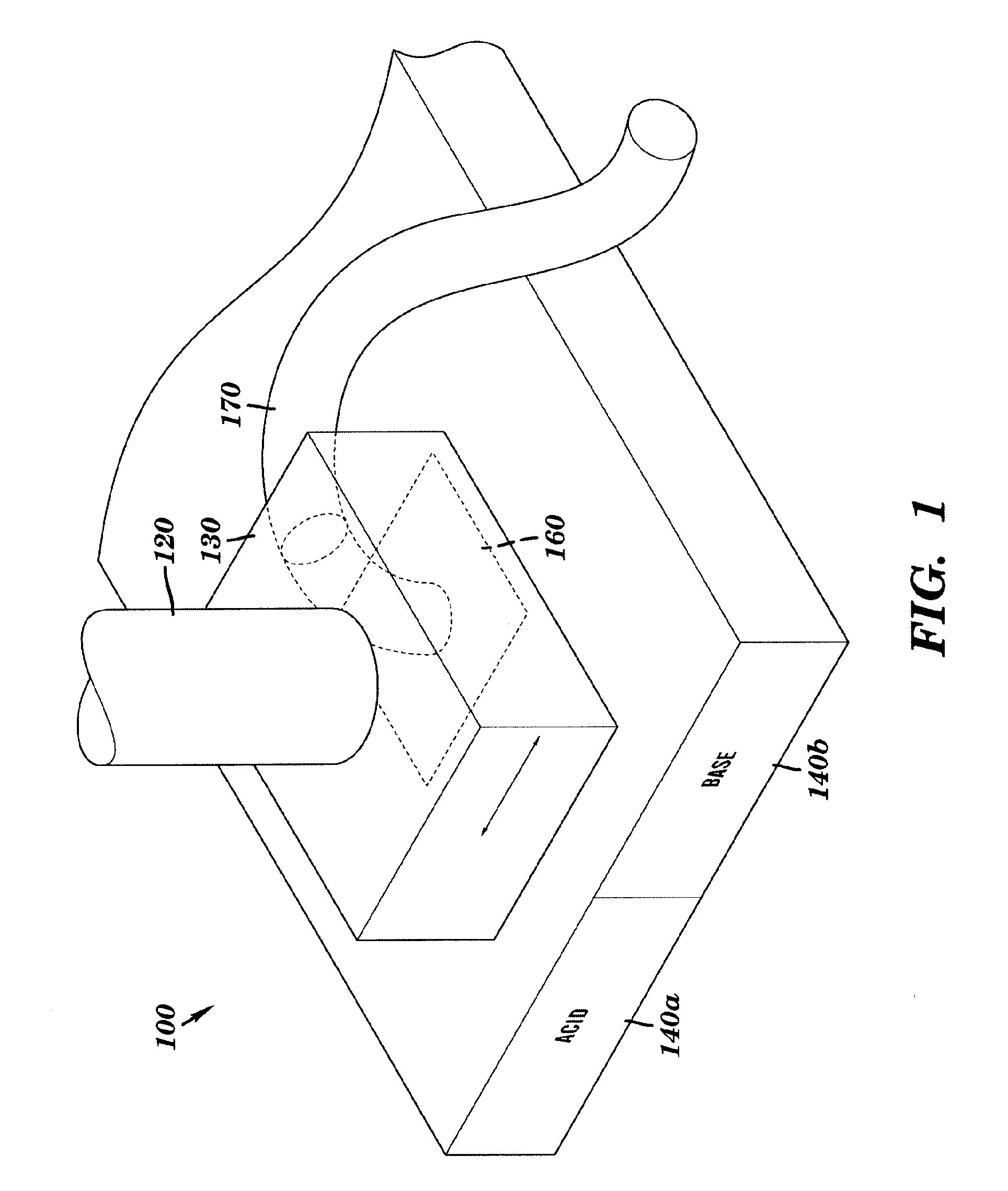

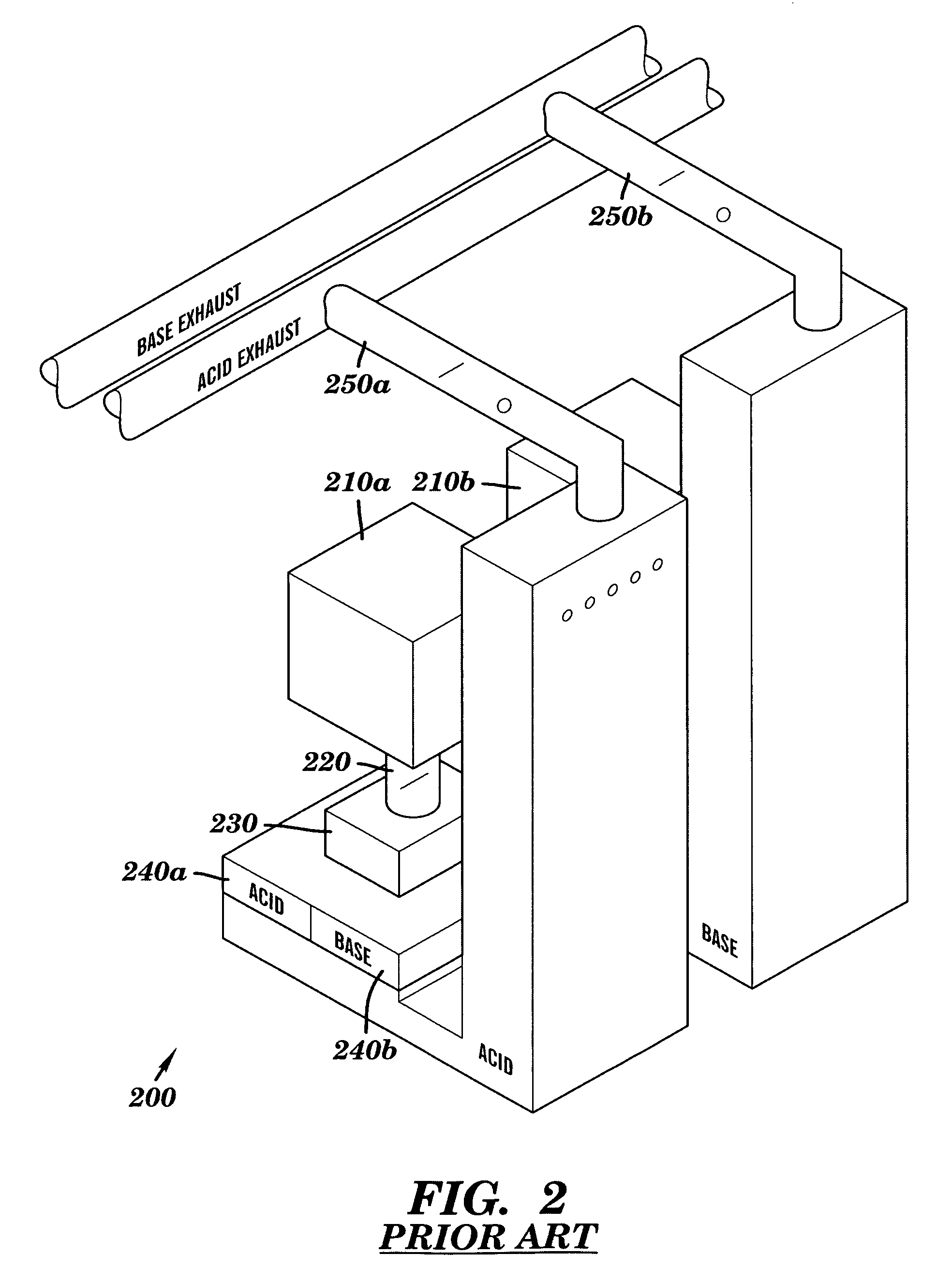

Variable exhaust static pressure management apparatus

InactiveUS7354874B2Eliminate pressureCombination devicesGas treatmentWaste streamSemiconductor factory

The present invention is directed to a semiconductor apparatus that enables in situ wet processing of semiconductor wafers, and prevents creation of a static pressure within the in situ wet processing system. The apparatus comprises multiple exhaust receptacles. Each exhaust receptacle is operable in an open and closed position and receives an associated toxic wet processing byproduct only in the open position. An exhaust is connected to each exhaust receptacle and suctions the contents of said exhaust receptacle in both the open and closed positions. An intake is connected to said exhaust receptacle only when the exhaust receptacle is in a closed position. The intake introduces a gas chemically compatible to the toxic wet processing byproduct associated with the exhaust receptacle. The exhaust releases the toxic wet processing byproduct and the chemically compatible gas to the same waste stream at the semiconductor factory.

Owner:GOOGLE LLC

Depository monitoring system in semiconductor storage warehouse

InactiveUS7864056B2LogisticsBurglar alarm by hand-portable articles removalControl storeMonitoring system

Owner:CHIPMOS TECH INC

SECS communication method based on semi standard

InactiveCN101552794BImprove cluster control capabilitiesIncrease the level of automationStore-and-forward switching systemsControl systemComputer module

Owner:MICROCYBER CORP +1

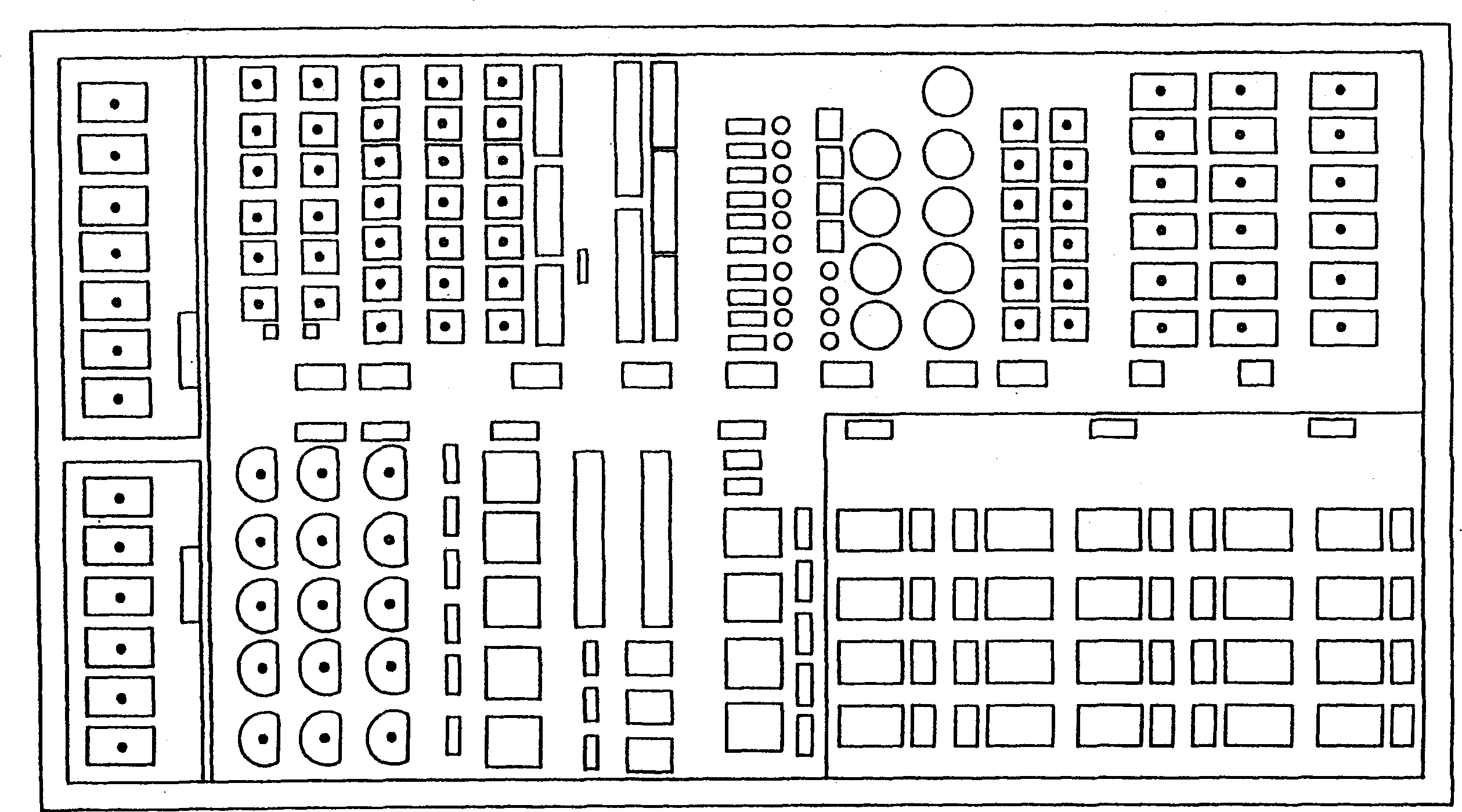

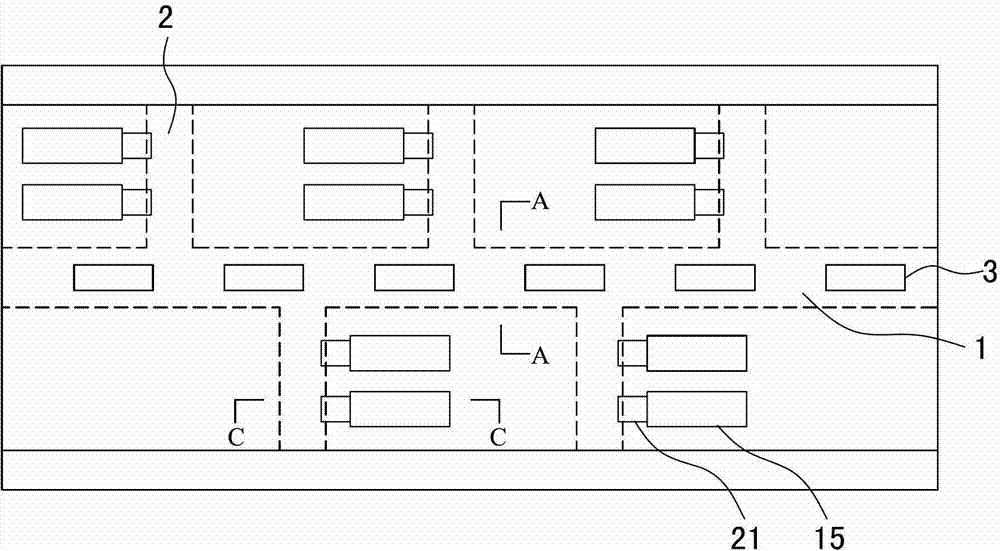

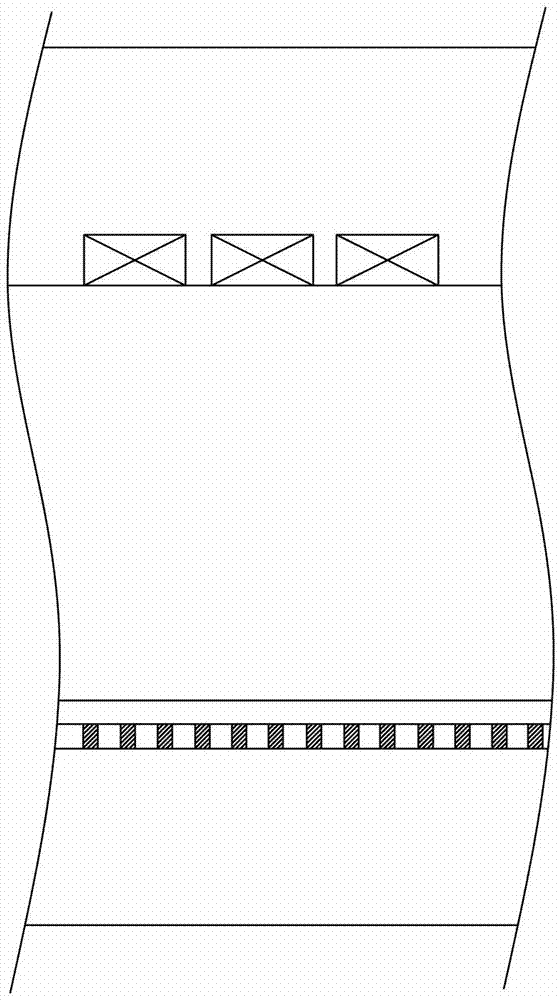

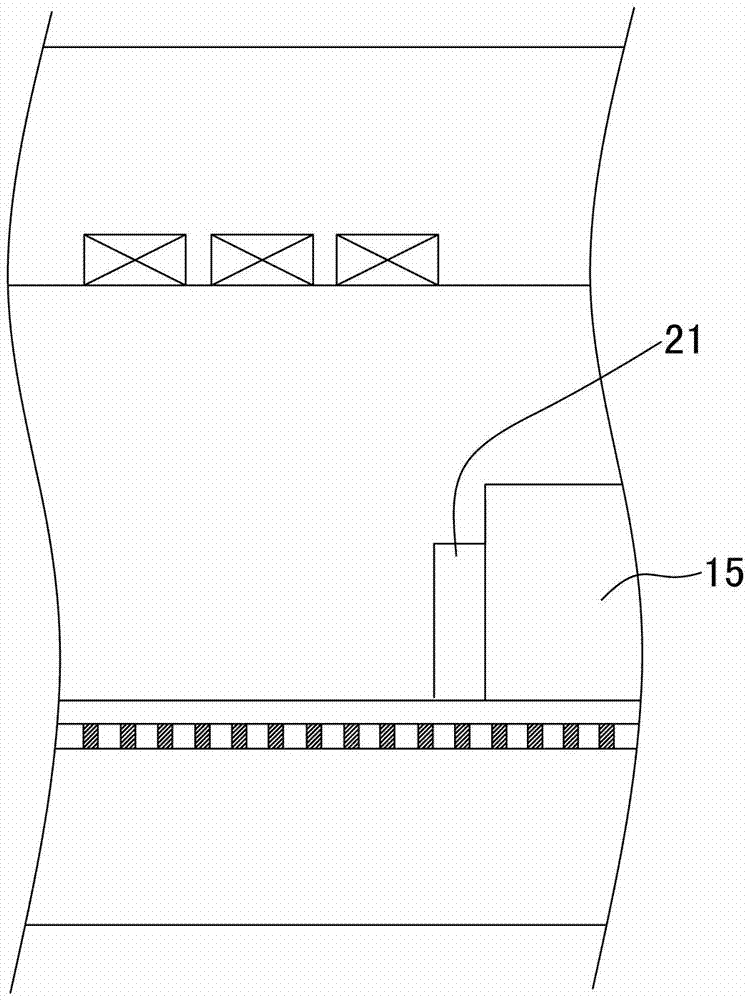

A clean room for semiconductor plant

ActiveCN103046776BTake advantage ofReduce consumptionSmall buildingsIndustrial buildingsSemiconductor factoryEngineering

The invention discloses a clean room for a semiconductor plant. The room comprises a fresh air conveying system, an exhaust system and a large clean space, wherein a central pavement and at least one production pavement are arranged in the large clean space, peripheries of the central pavement and the production pavements are provided with baffles, at least one part of frame space, clean space and space of a raised floor form an independent clean micro-environment structure, second baffles are arranged in the central pavement, the second baffles are arranged inside the baffles, the ceiling between the baffles and the second baffles are hollow, and the frame space and the clean space between the baffles and the second baffles form air returning channels. Peripheries of the central pavement and the production pavements are provided with baffles, the independent clean micro-environment structure is formed, and corrosive gas cannot affect storage bins and products in the central pavement and the production pavements.

Owner:L&K ENG SUZHOU

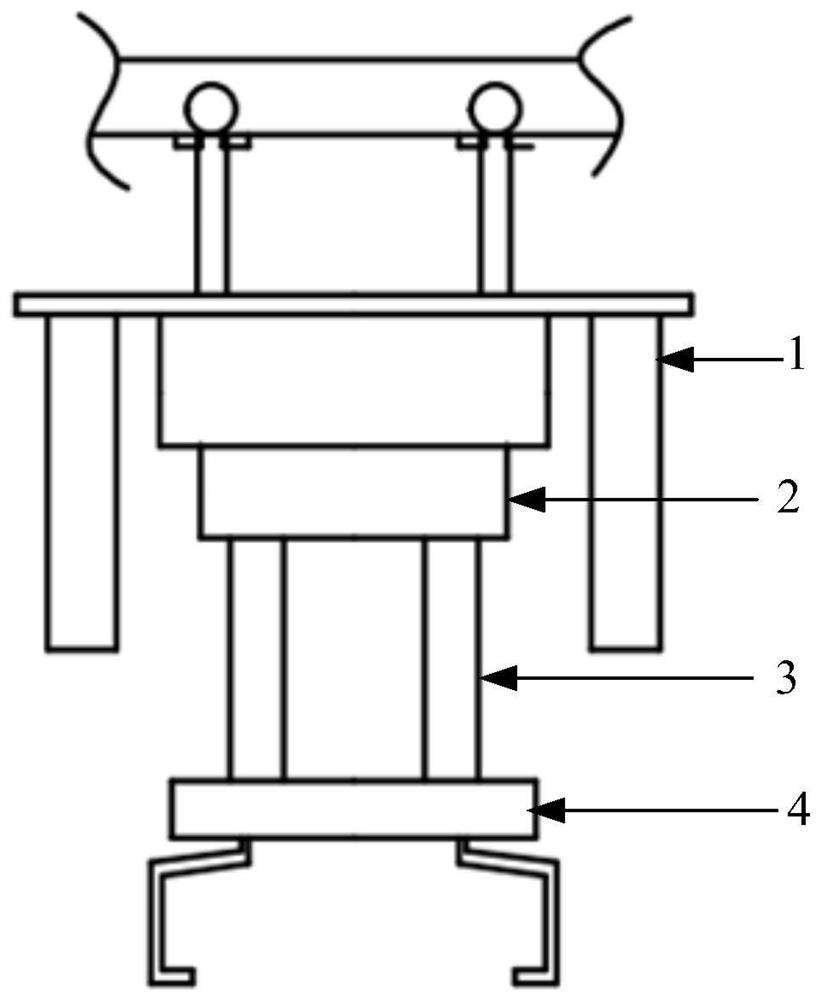

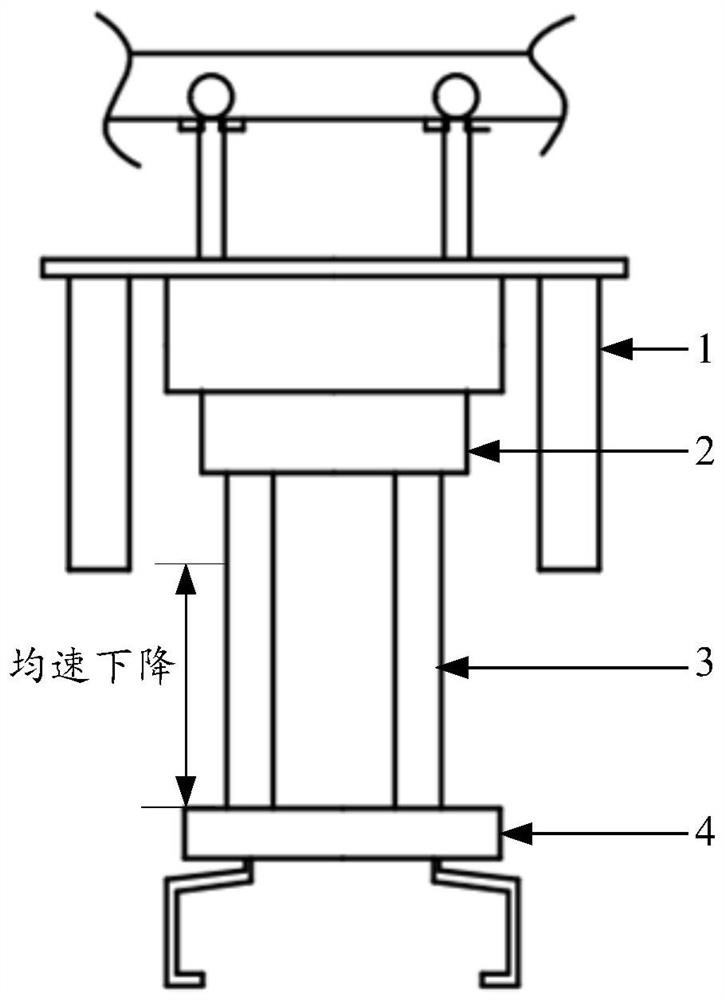

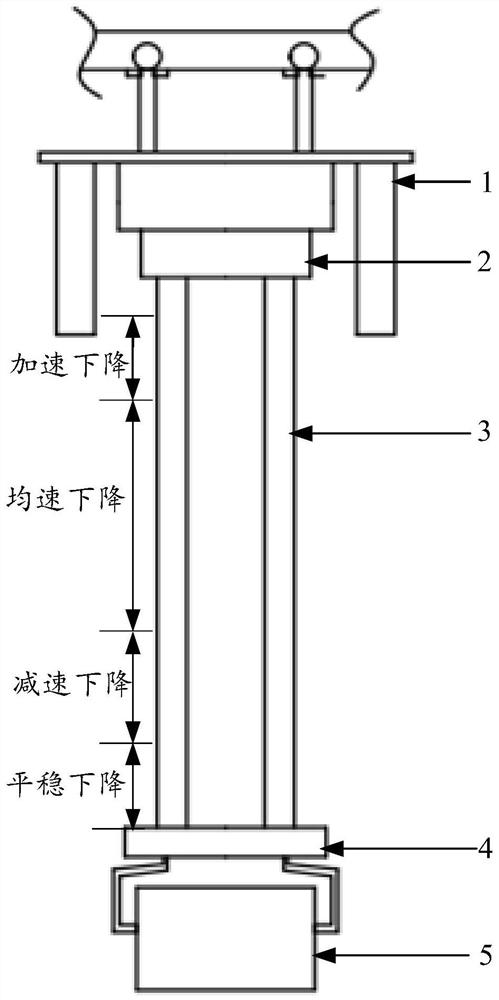

Method and system for controlling lifting mechanism of air transport vehicle

ActiveCN114455454AShort rise and fall timesShorten the action cycleSemiconductor/solid-state device manufacturingLoad-engaging elementsSemiconductor factoryControl theory

The invention provides a method and system for controlling a lifting mechanism of an air transport vehicle, which are applied to the technical field of semiconductor wafer manufacturing equipment.The method for controlling the lifting mechanism of the air transport vehicle comprises the steps that when the air transport vehicle runs to a preset position in a track, the lifting mechanism is started to drive a clamping mechanism; therefore, the clamping mechanism does lifting motion; and acquiring a speed value of the lifting motion, and performing segmented control on the lifting motion of the clamping mechanism according to the speed value of the lifting motion. The speed of the lifting motion is acquired in real time, and the lifting motion is subjected to stable and rapid segmentation control according to the real-time speed, so that the whole lifting motion runs stably, the running stroke perimeter is obviously optimized, the wafer carrying efficiency in automatic application of a semiconductor factory is greatly improved, and the wafer production efficiency is improved.

Owner:MEETFUTURE TECH (SHANGHAI) CO LTD

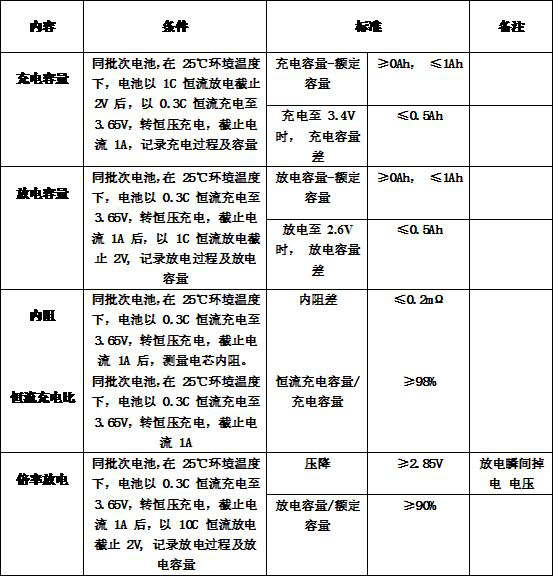

Battery cell consistency sorting method applied to energy storage lithium batteries of semi-conductor factories

The invention relates to a battery cell consistency sorting method applied to energy storage lithium batteries of semiconductor factories. The method comprises the following steps that charging capacity, discharging capacity, internal resistance, constant-current charging ratio and multiplying power screening is carried out, the batteries in the same batch are discharged and then charged, and the batteries of which the difference value between the charging capacity and rated capacity meets the requirement are screened out; the screened batteries are discharged and then charged, and the batteries of which the difference value between the discharge capacity and the rated capacity and the discharge capacity meet the requirements are screened out; and the screened batteries are charged, the batteries with the internal resistance difference less than or equal to 0.2 milliohm are screened out, and the ratio of the constant-current charging capacity to the charging capacity is greater than or equal to 98%. The screened batteries are charged and then discharged, and the batteries with the voltage drop larger than or equal to 2.85 V and the ratio of the discharging capacity to the rated capacity larger than or equal to 90% are screened out. The method has the advantages that the screened lithium ion batteries can keep good battery consistency in the aspects of charging capacity, rate discharge and the like, and in addition, the lithium ion batteries screened by the screening standards related to charging capacity, rate discharge and the like are more suitable for the semiconductor factories.

Owner:芜湖楚睿智能科技有限公司

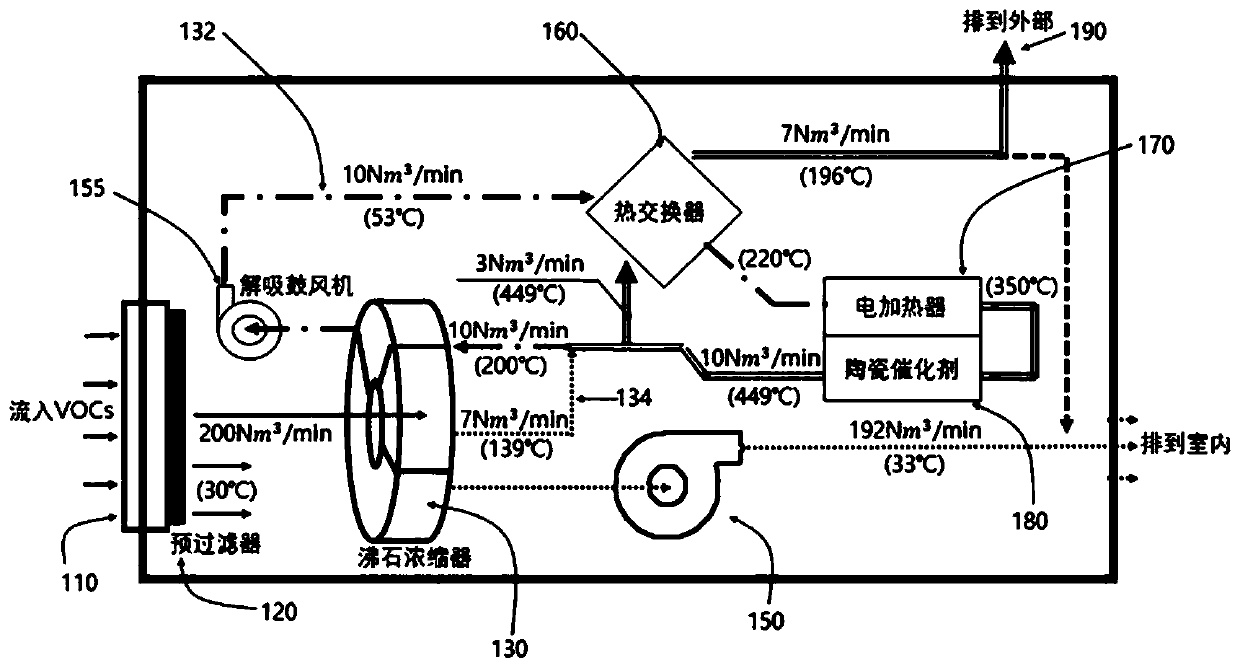

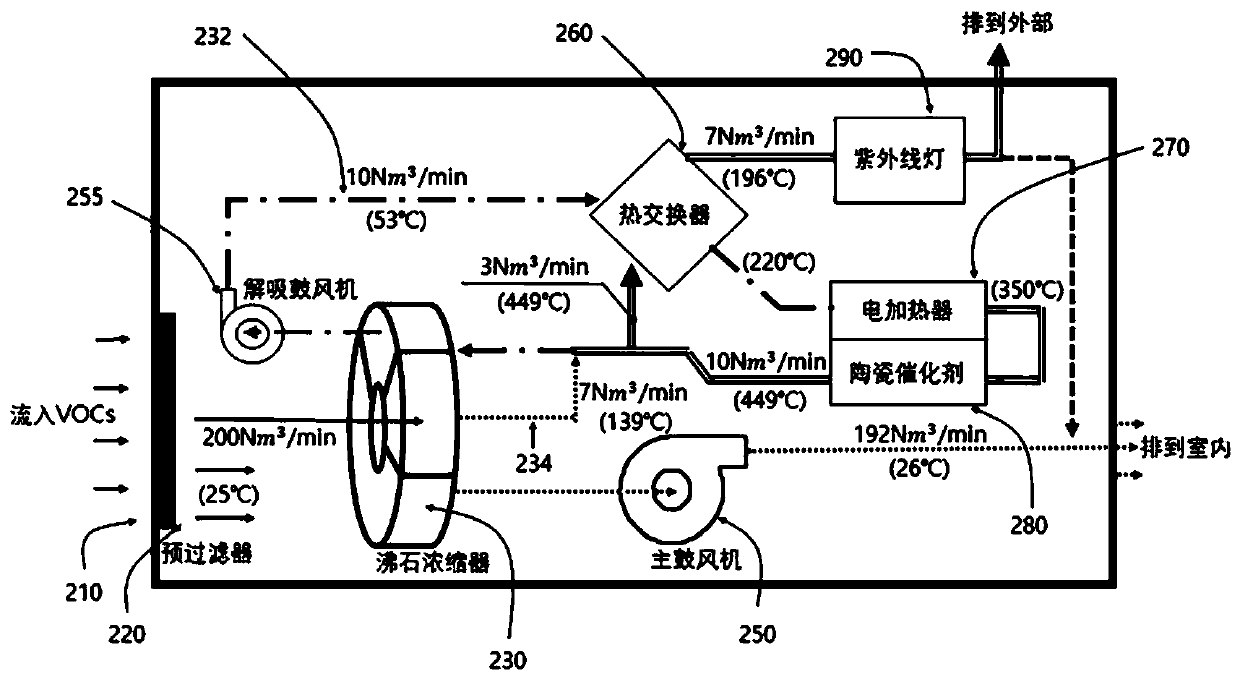

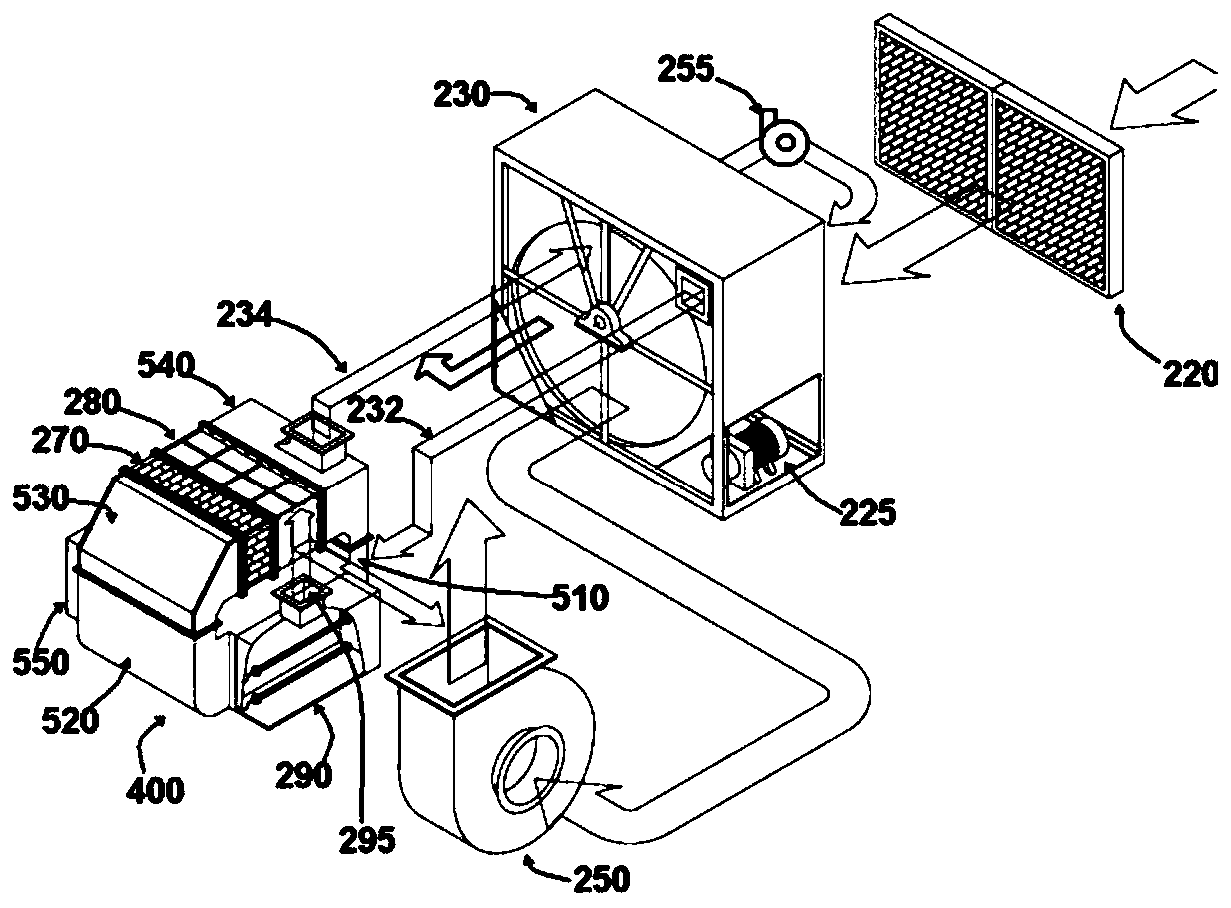

Indoor concentrated and combustion system of VOCs with catalytic poison oxidation device

InactiveCN109999632AEasy to handleHigh activityGas treatmentDispersed particle filtrationCombustion systemPaint thinner

The present invention relates to an indoor concentration combustion system having a catalytic poison oxidizer. The system comprises: a VOCs gas collecting unit (210), which is installed on the front surface of a square-box shaped zeolite concentrator unit and is capable of efficiently collecting a volatile material at a room temperature; a pre-filter (220), which is coupled to a rear portion of the VOCs gas collecting unit and is used to remove granular substances in the captured VOCs such as dust; and a zeolite concentrator (230) unit, which adsorb volatile substances such as benzene, paint thinner, odor, and the like, to filter VOCs in the pre-filter (220). The provided system is installed in a semiconductor factory or a display production factory and is capable of processing VOCs effectively.

Owner:K PLANT CO LTD

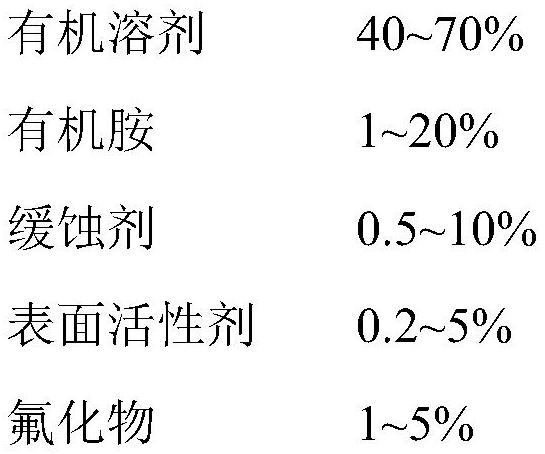

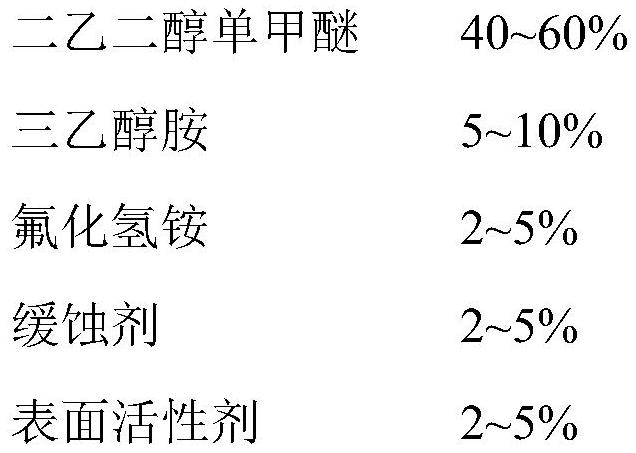

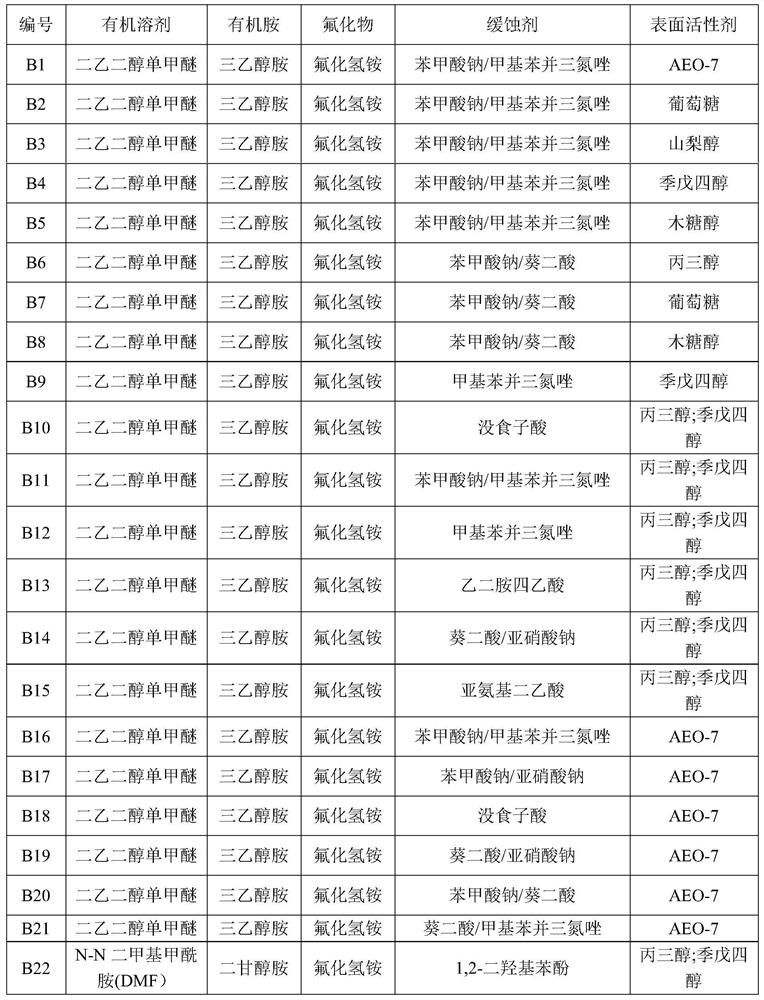

Polyvinyl alcohol cinnamate type KPR photoresist etching residue stripping agent composition

PendingCN114326333AQuick washImprove protectionPhotosensitive material processingPolyvinyl alcoholActive agent

The invention discloses a polyvinyl alcohol cinnamate type KPR photoresist etching residue stripping agent composition, which comprises 40-70% of an organic solvent, 1-20% of organic amine, 0.5-10% of a corrosion inhibitor, 0.2-5% of a surfactant, 1-5% of fluoride and the balance of ultrapure water, the surfactant is one or a mixture of more of ethylene glycol, glycerol, glucose, sorbitol, pentaerythritol, xylitol and AEO-7; the organic amine is one or a mixture of more of monoethanolamine, triethanolamine and isopropanolamine; the corrosion inhibitor is one or a mixture of more of phenols, carboxylic acids and benzotriazoles. The stripping agent has higher cleaning efficiency, the cleaning time is remarkably shortened compared with that of similar products, the cleaning effect and the protection effect on a wafer base material are better, and the operation cost of a semiconductor factory can be remarkably reduced.

Owner:深圳迪道微电子科技有限公司

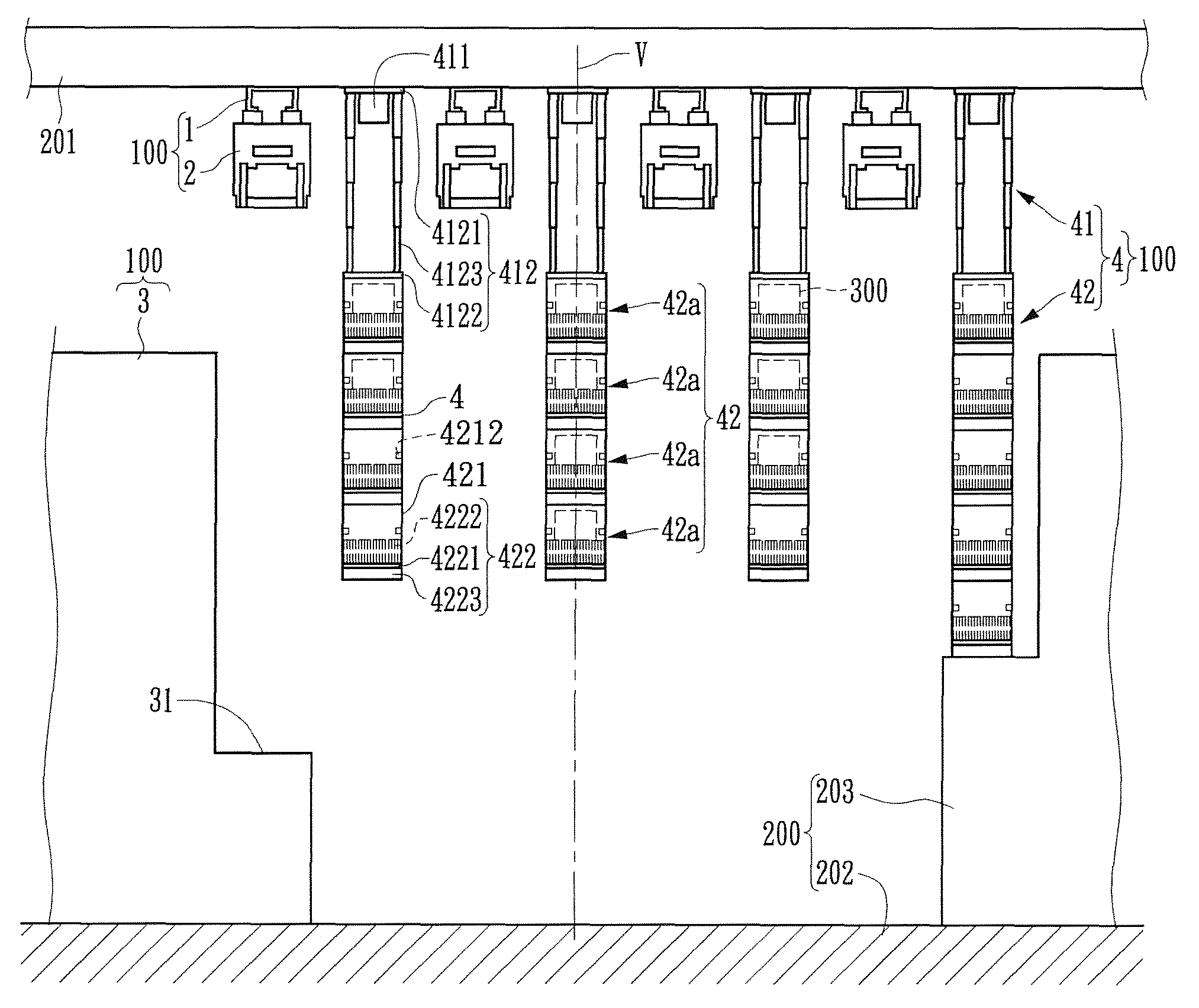

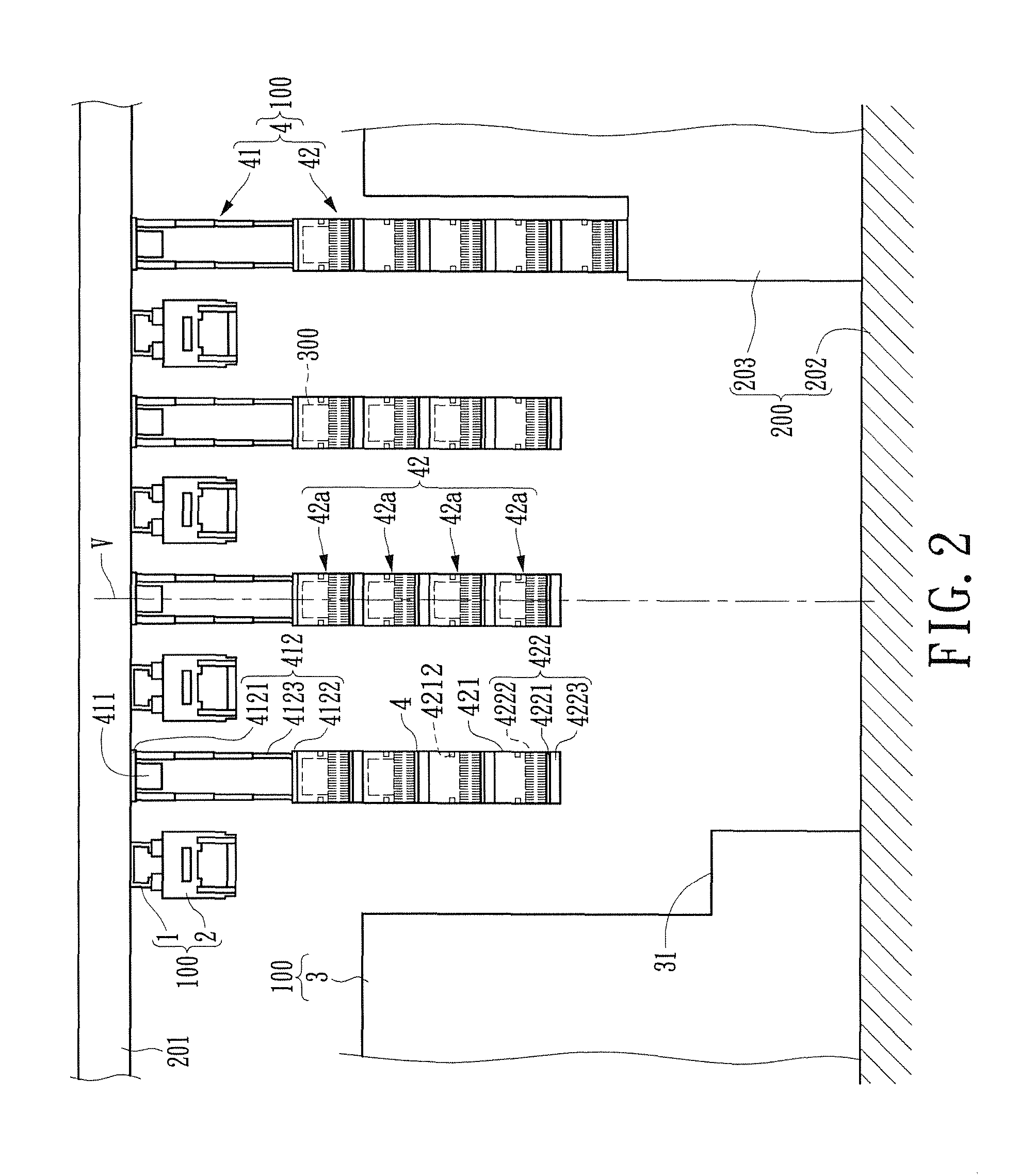

Overhead buffer device and wafer transport system

ActiveUS9209056B2Reduced production cycle timeIncrease ratingsSemiconductor/solid-state device manufacturingCharge manipulationTransport systemComputer module

An overhead buffer device used for disposing in a semi-conductor factory includes a strut module and a plurality of buffer modules. The strut module disposed on the top wall of the factory has a horizontal beam and a plurality of overhead strut. The overhead strut is set on the horizontal beam and spaced arranged along the horizontal beam. The buffer modules are installed on the overhead strut respectively. Each buffer module has a plurality of buffers arranged in sequence and along a vertical direction. Each buffer is used for receiving one front opening unified pod (FOUP). Thus, the instant disclosure can be used for using the space of the factory efficiently. Besides, the instant disclosure also provides a wafer transport system having the overhead buffer device.

Owner:MICRON TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com