Battery cell consistency sorting method applied to energy storage lithium batteries of semi-conductor factories

A lithium battery and semiconductor technology, applied in the field of cell sorting of energy storage lithium batteries in semiconductor factories, can solve problems such as low pertinence and inability to ensure that the battery is particularly suitable, and achieve the effect of ensuring service life and good battery consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

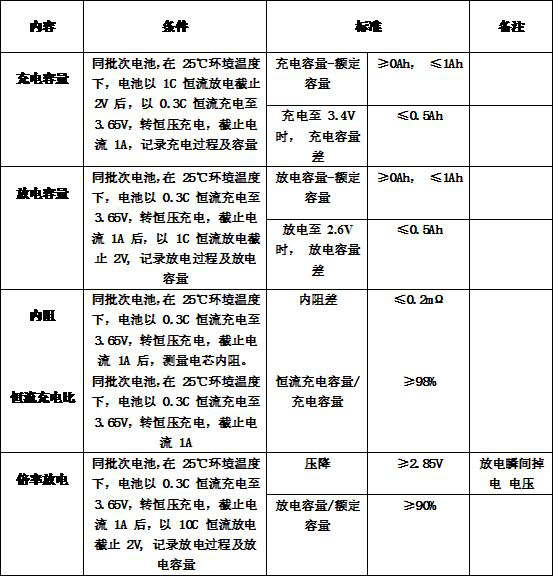

[0021] The steps of the battery cell consistency sorting method applied to the energy storage lithium battery in the semiconductor factory are as follows:

[0022] In semiconductor factory applications, it is necessary to keep the lithium battery in the floating state for a long time, so the floating charging voltage value during the charging process is very critical. After many experimental demonstrations, the single cell 3.4V floating charging voltage is the most suitable. By sorting the 3.4V charging capacity, it is more suitable for semiconductor factory applications. The following describes the implementation process of the present invention by taking the sorting of 3.4V charging capacity as an example

[0023] (1), charging capacity screening:

[0024] (1.1) For the same batch of batteries, at an ambient temperature of 25°C, the battery is discharged at a constant current of 1C to 2V, then charged at a constant current of 0.3C to 3.65V, transferred to a constant voltage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com