Interval interactive microchannel liquid-cooled plate

An interactive micro- and liquid-cooling plate technology, applied in electrochemical generators, electrical components, circuits, etc., can solve the problems of reduced battery cycle life, efficiency, cooling effect, etc., to ensure battery cycle life and work efficiency. , the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

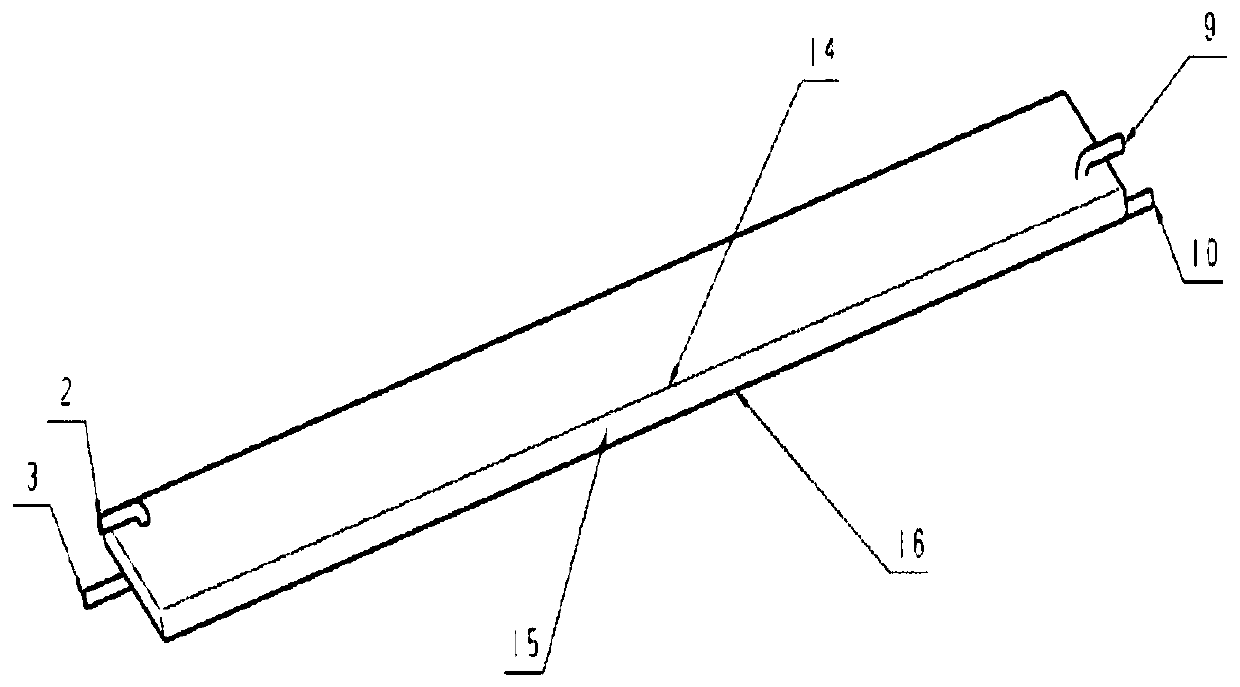

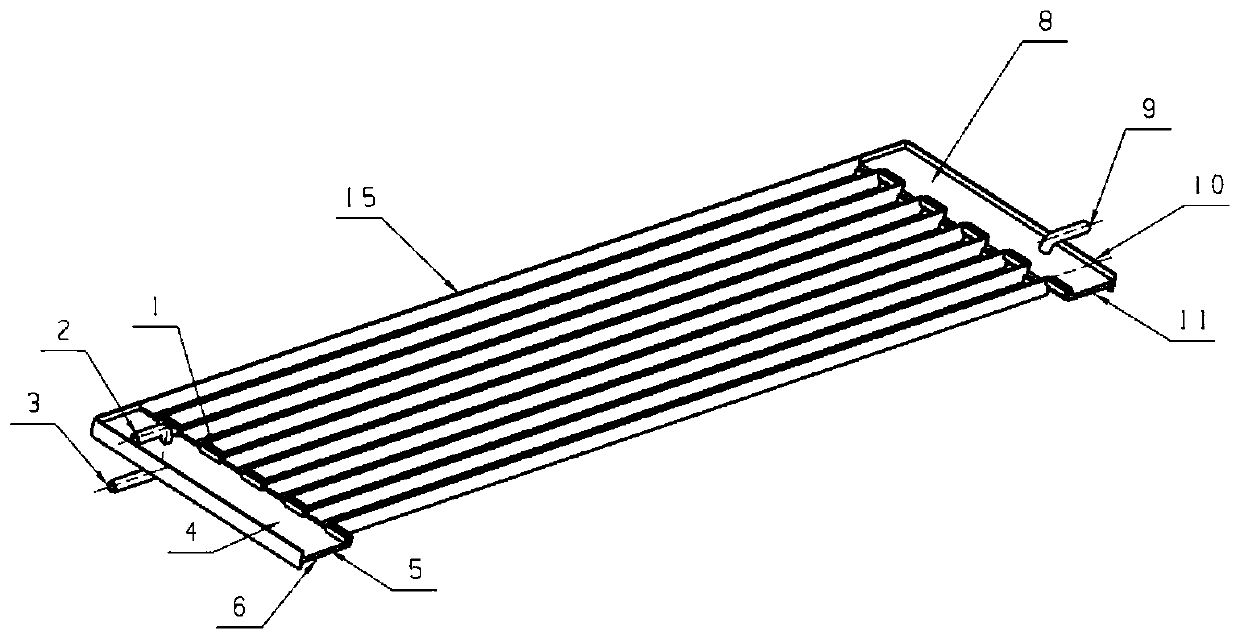

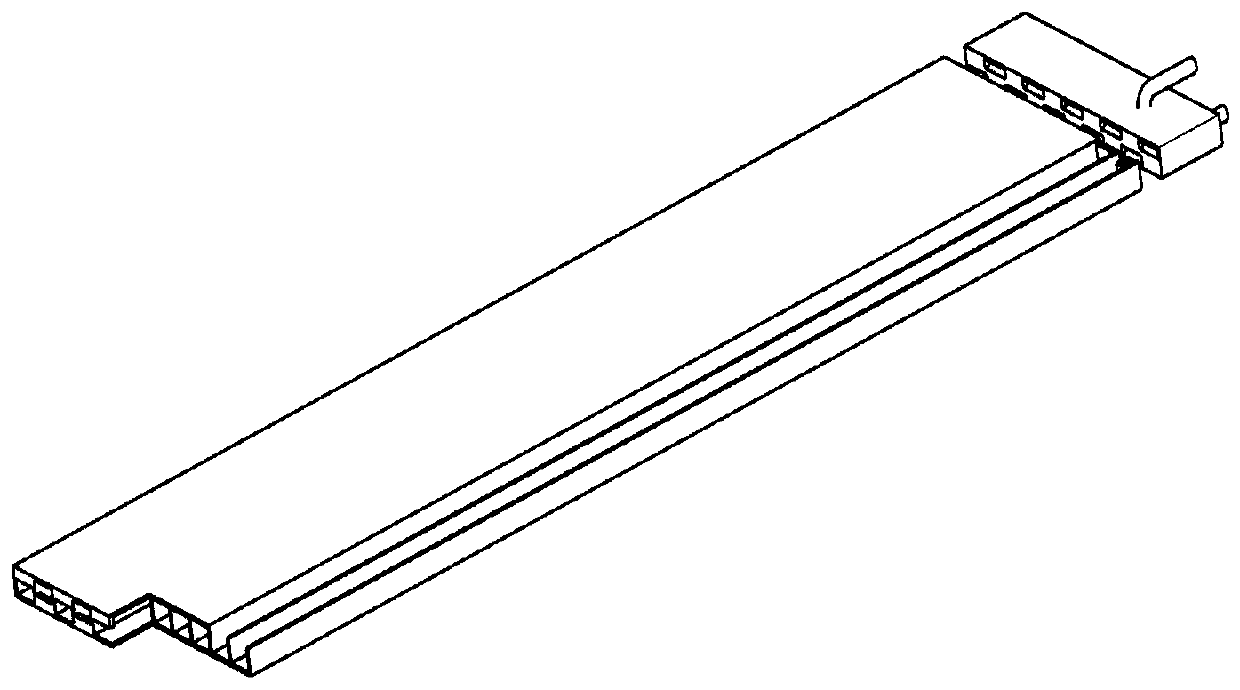

[0024] like Figure 1-Figure 5 As shown, a spaced interactive microchannel liquid cooling plate includes an upper plate 14, a lower plate 16 and a plate body 15, and a liquid cooling area is formed between the upper plate 14, the lower plate 16 and the plate body 15, and the liquid cooling area includes several The microchannel partition 7 is arranged between the plate bodies 15 to divide the liquid cooling area into several microchannels. In this embodiment, 8 microchannel partitions 7 divide the liquid cooling area into 10 microchannels. The height of the microchannel partitions 7 is 4 mm, and the thickness is 0.5 mm. The micro-channels are divided into two groups of even-numbered channels and odd-numbered channels from the back to the front, and the coolant flows in the opposite direction in the odd and even-numbered channels, and flows alternately at intervals.

[0025] Specifically, the left and right ends of the liquid cooling area in this embodiment are respectively pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com