Lithium ion battery for automotive startup power supply

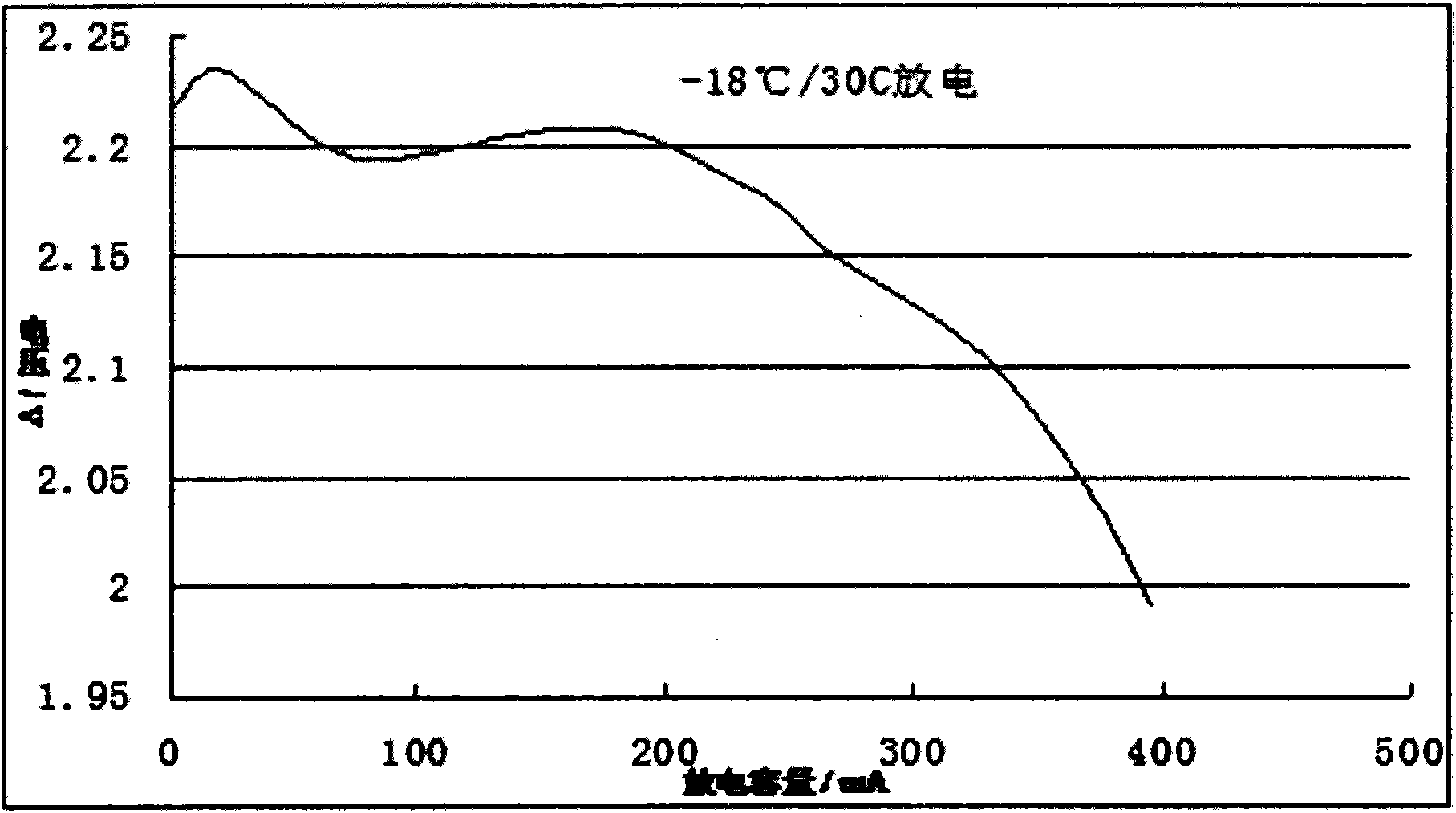

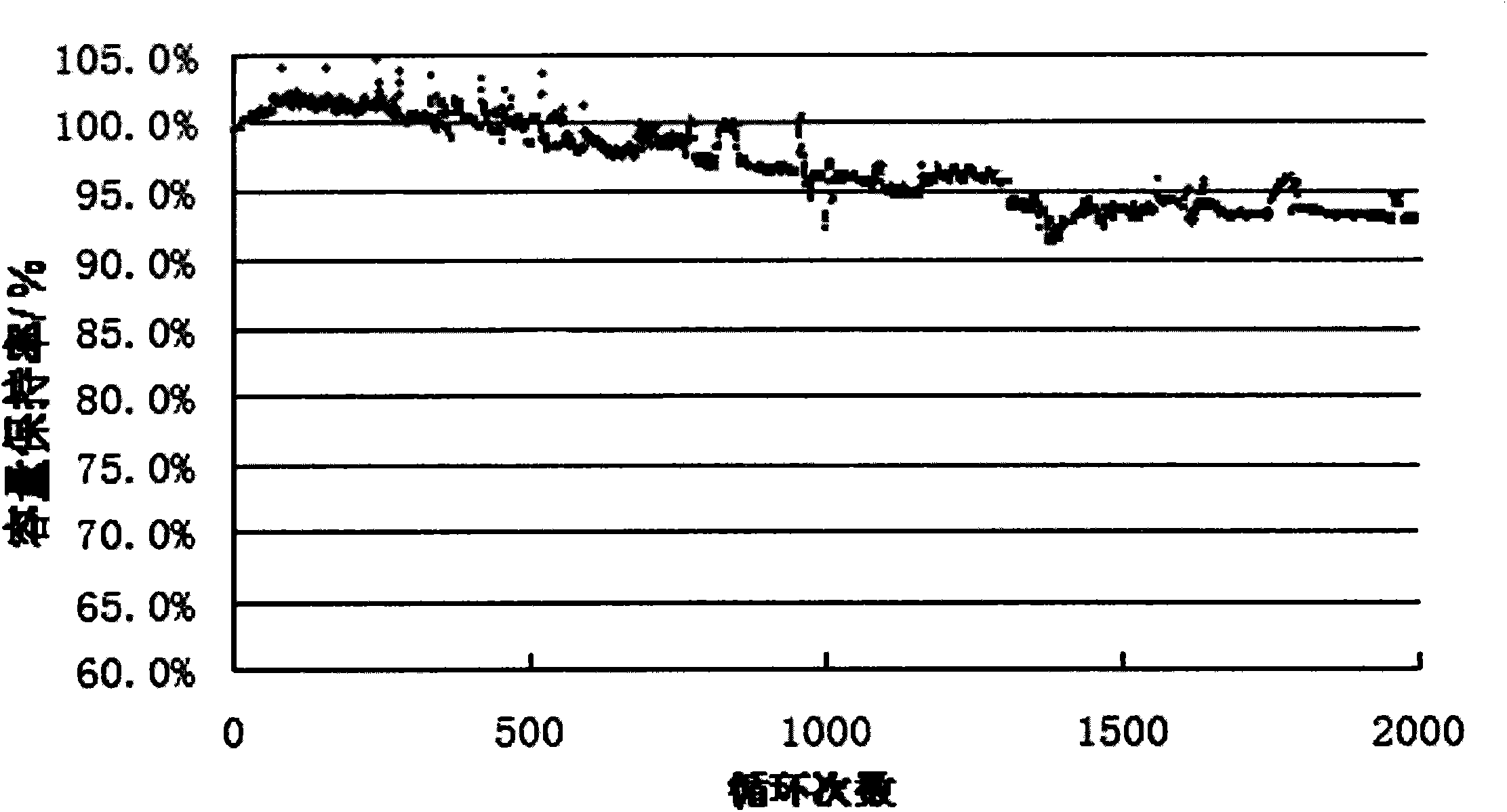

A technology for starting lithium-ion batteries and automobiles, which is applied in the direction of battery electrodes, secondary batteries, battery pack components, etc. It can solve the problem that automobiles cannot be started at low temperature, and the high-temperature cycle performance of lithium-ion batteries is not enough to meet the requirements of the automobile starting power supply environment. needs, environmental pollution and other issues, to achieve the effect of ensuring cycle life and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0026] The invention provides a lithium ion battery for starting a power supply of an automobile, comprising a positive electrode material, a negative electrode material, a separator and an electrolyte;

[0027] Described anode material comprises by accounting for total weight percentage:

[0028] 45% to 53% of lithium iron phosphate, 1% to 2% of conductive graphite, 1% to 2% of conductive carbon nanotubes, 3% to 4% of polyvinylidene fluoride (PVDF), and N-methylpyrrolidone (NMP ) to complete.

[0029] The starting power supply for automobiles first requires high safety performance and good high-temperature cycle performance. With its stable olivine structure, lithium iron phosphate material has high safety and stability, which is beneficial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice spacing | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com