Full-automatic wafer appearance inspection system

A visual inspection, fully automatic technology, applied in the direction of conveyor objects, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problem that the inspection system cannot meet the inspection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

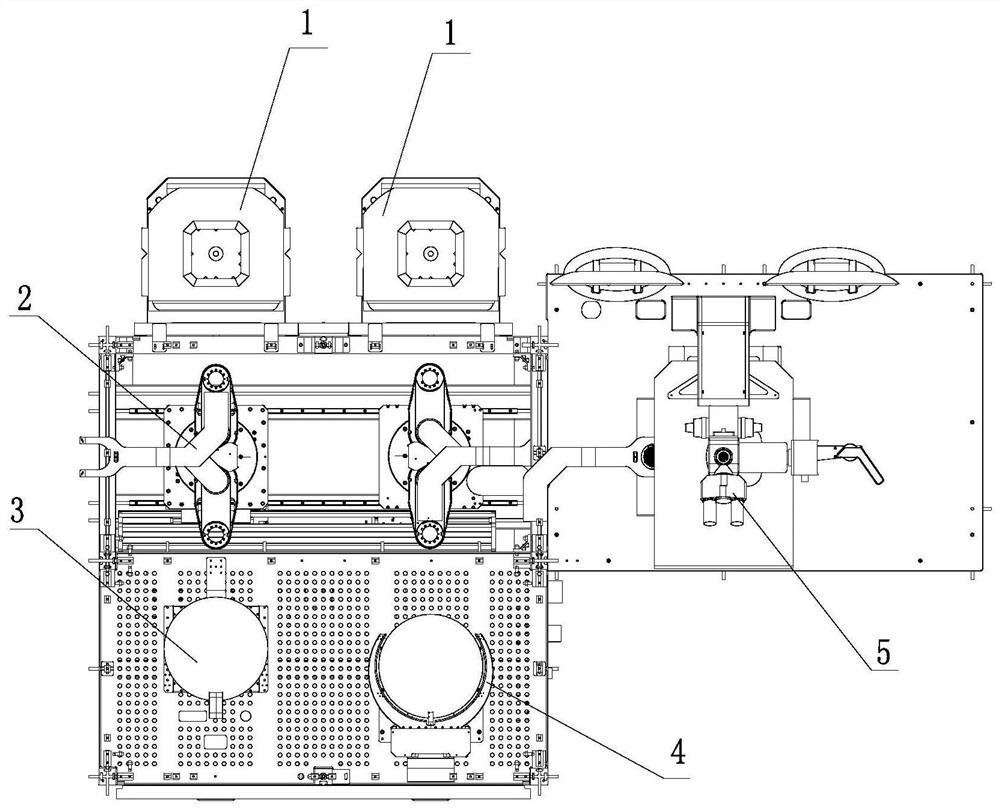

[0022] like figure 1 As shown, the fully automatic wafer appearance inspection system of the present invention includes a wafer box unpacking carrier 1, a wafer pick-and-place manipulator 2, a wafer position calibration mechanism 3, a wafer turning mechanism 4, and a microscope detection mechanism; The wafer box unpacking carrier is used to open the wafer transfer box, the wafer pick-and-place manipulator is used to carry the wafer, and the wafer position calibration mechanism is used to determine the position of the center of the wafer and rotate it to An angle is specified; the wafer turning mechanism is used to turn over the wafer so as to inspect the back side thereof, and the microscope inspection mechanism checks the wafer surface.

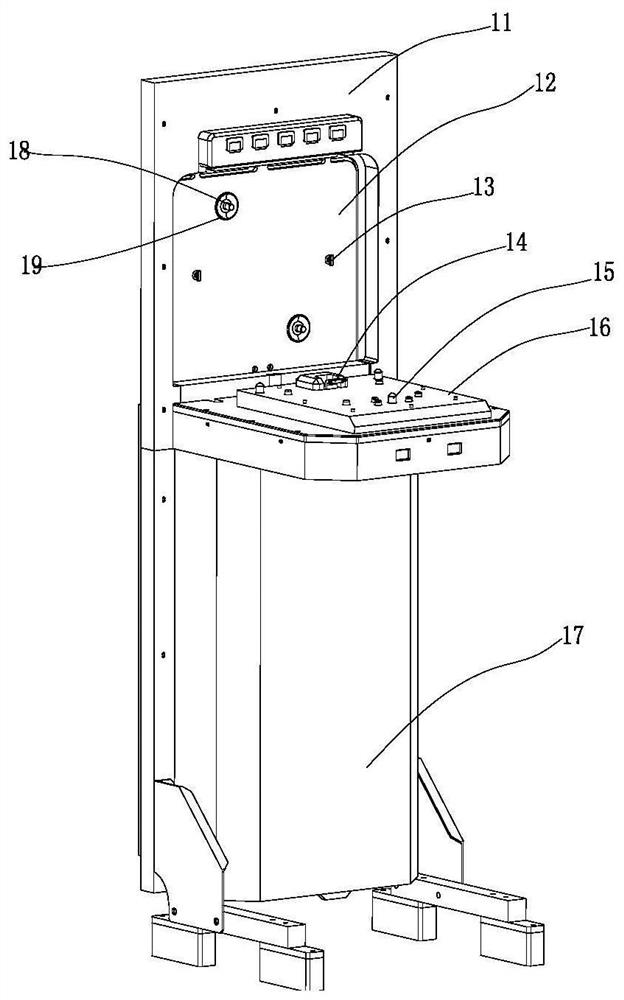

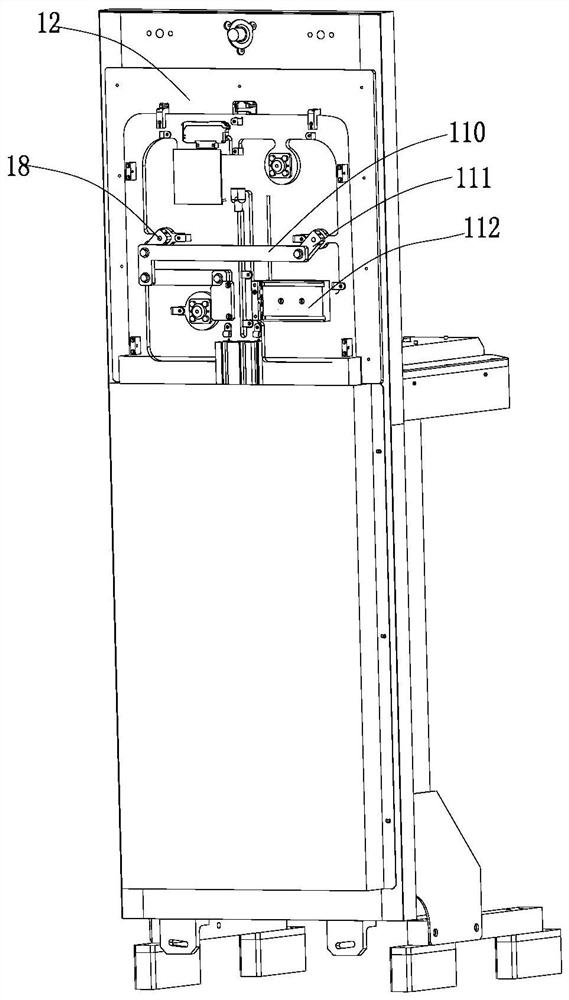

[0023] Wherein the specific structure of the wafer box unpacking carrier 1 is as follows: figure 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com