Polyvinyl alcohol cinnamate type KPR photoresist etching residue stripping agent composition

A polyvinyl alcohol cinnamate and photoresist technology, which is applied in the processing of photosensitive materials and other directions, can solve the problem of high occupancy rate of cleaning equipment, and achieve the effect of good protection effect, shortening cleaning time and reducing operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~39

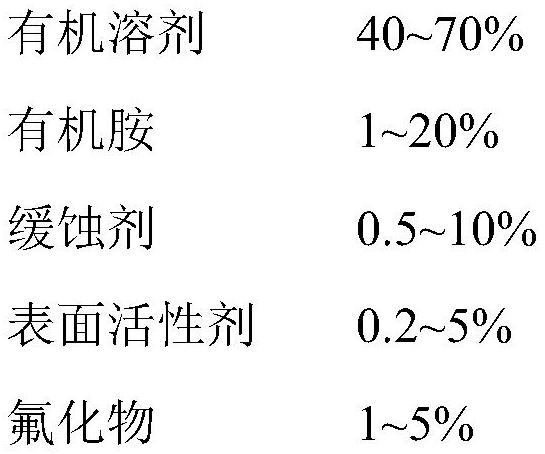

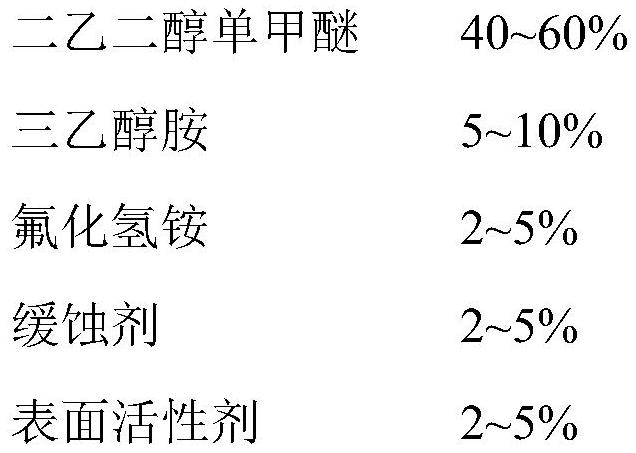

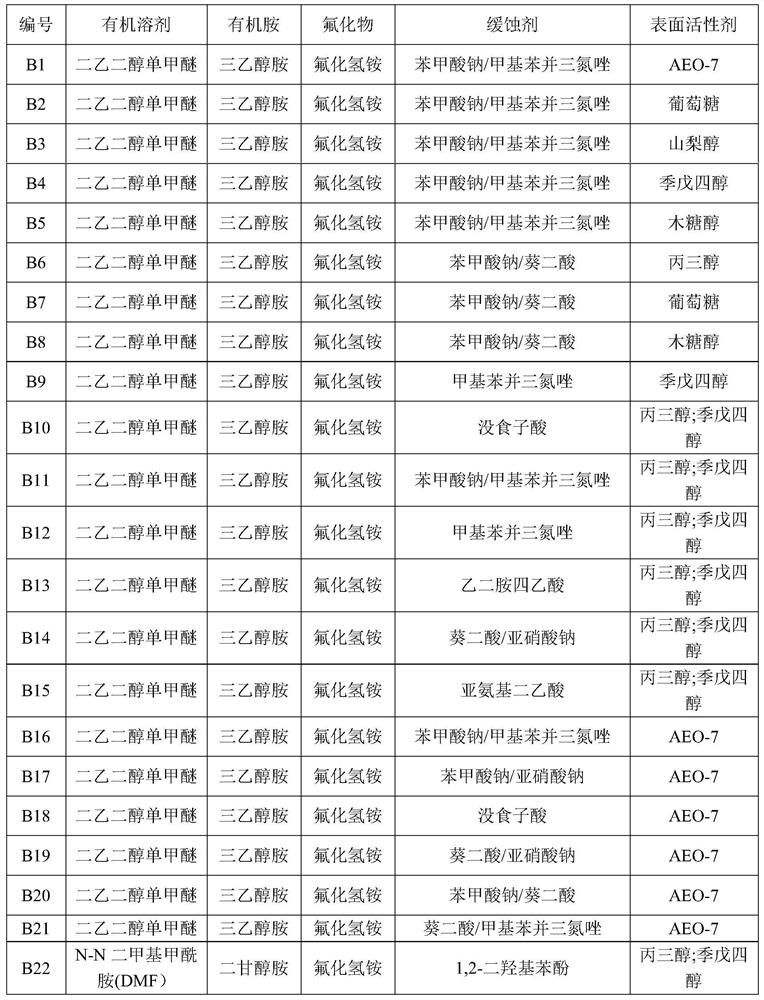

[0030] The KPR photoresist etching residue stripping agents described in Examples 1 to 39 of the present invention are mixed and prepared according to the components and ratios shown in Tables 1 and 2. Wherein embodiment 1~10 tests the influence of different surfactants on cleaning effect; Embodiment 11~21 tests the impact of different corrosion inhibitor combinations on cleaning effect and test piece corrosion situation; Influence of photoresist residue cleaning effect.

[0031] Table 1 is the component material of the stripping agent of described embodiment 1~33

[0032]

[0033]

[0034] Table 2 Mass percentage content and cleaning time of each component in Examples 1-33.

[0035]

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com