Patents

Literature

129results about How to "Quick scrape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

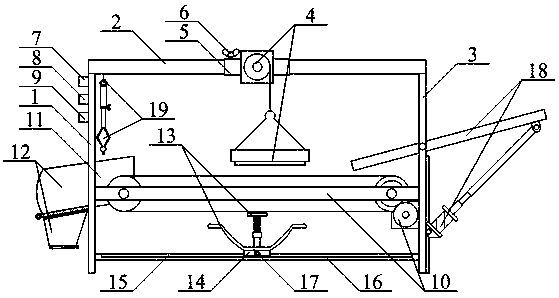

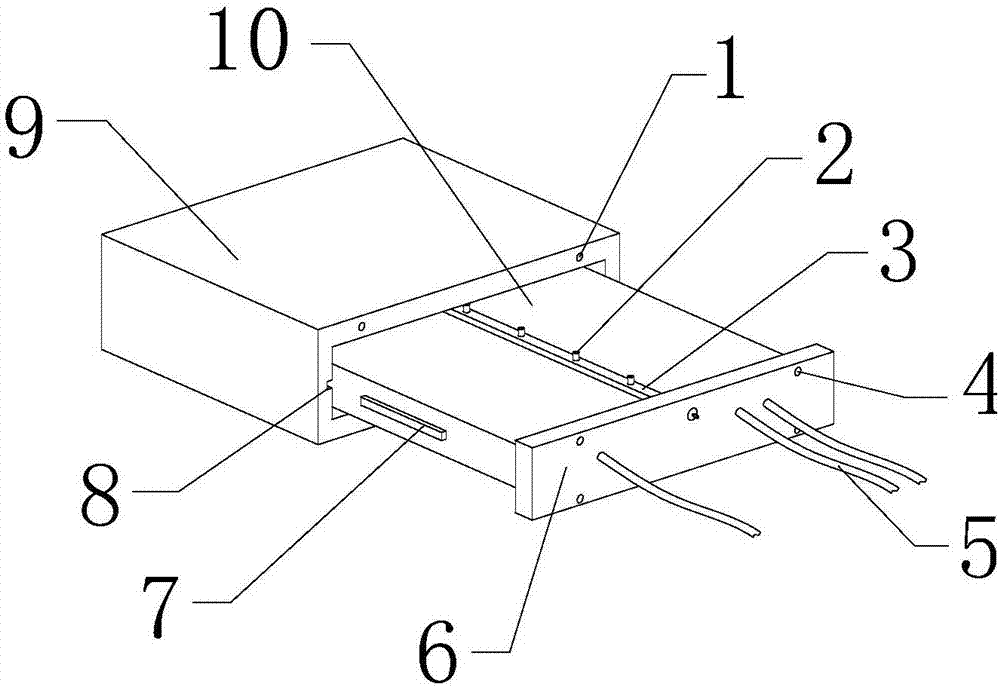

Petroleum pipeline inner wall processing machine with cleaning and drying functions

ActiveCN106238415AQuick scrapeQuick functionHollow article cleaningGrinding machinesHigh pressurePetroleum

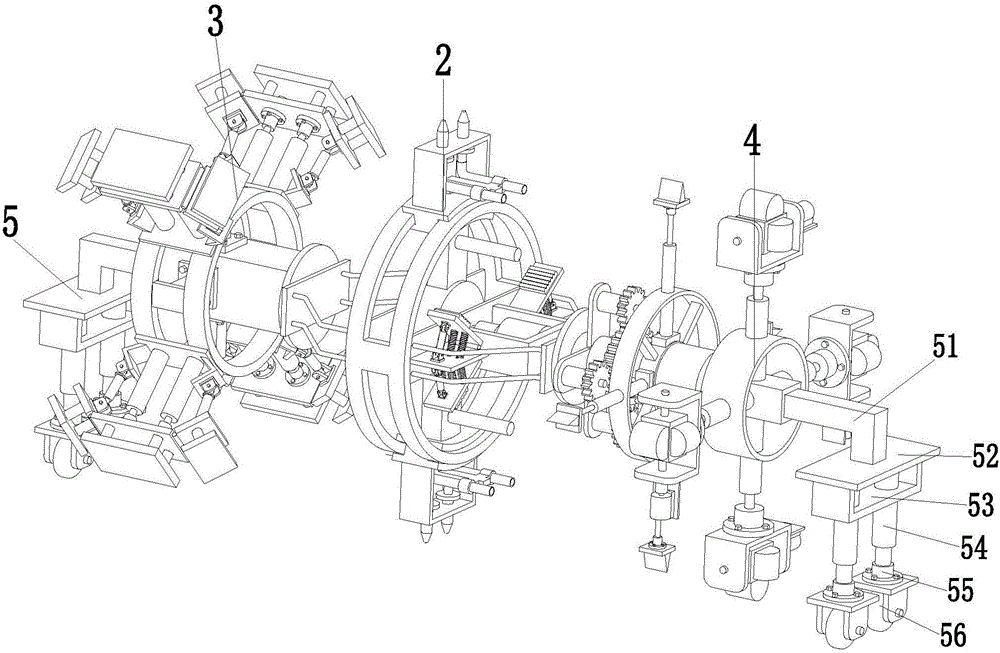

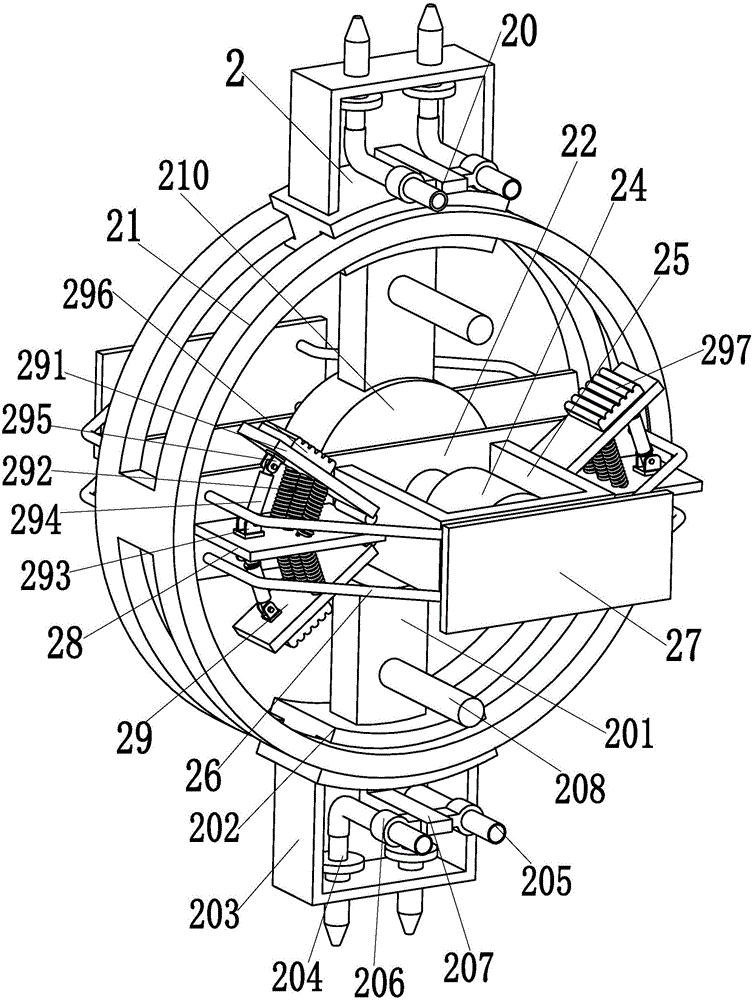

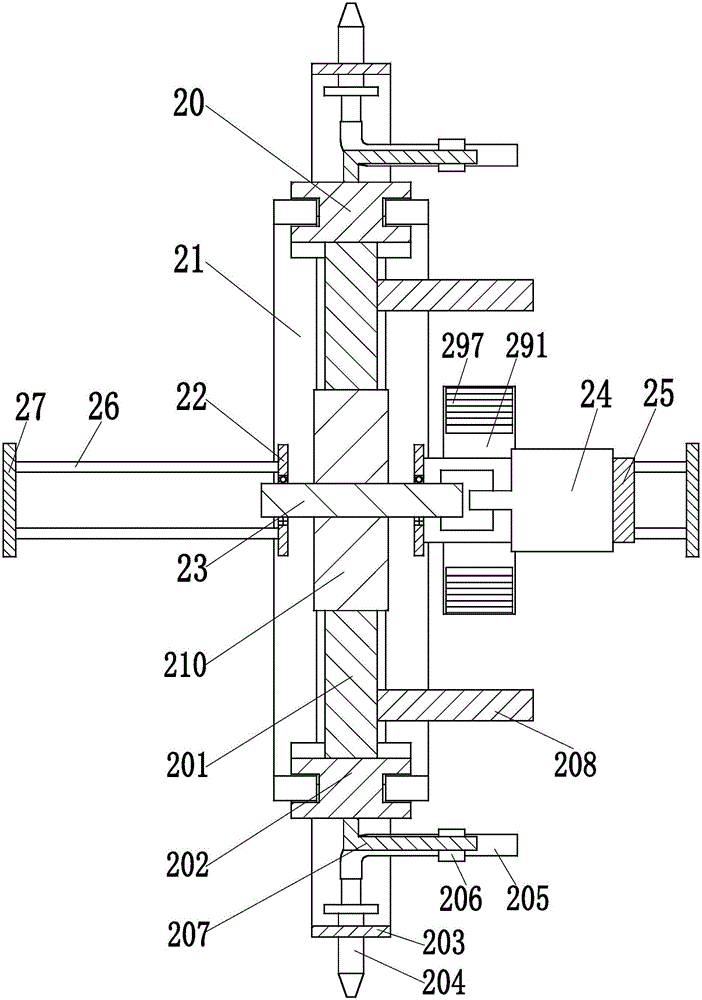

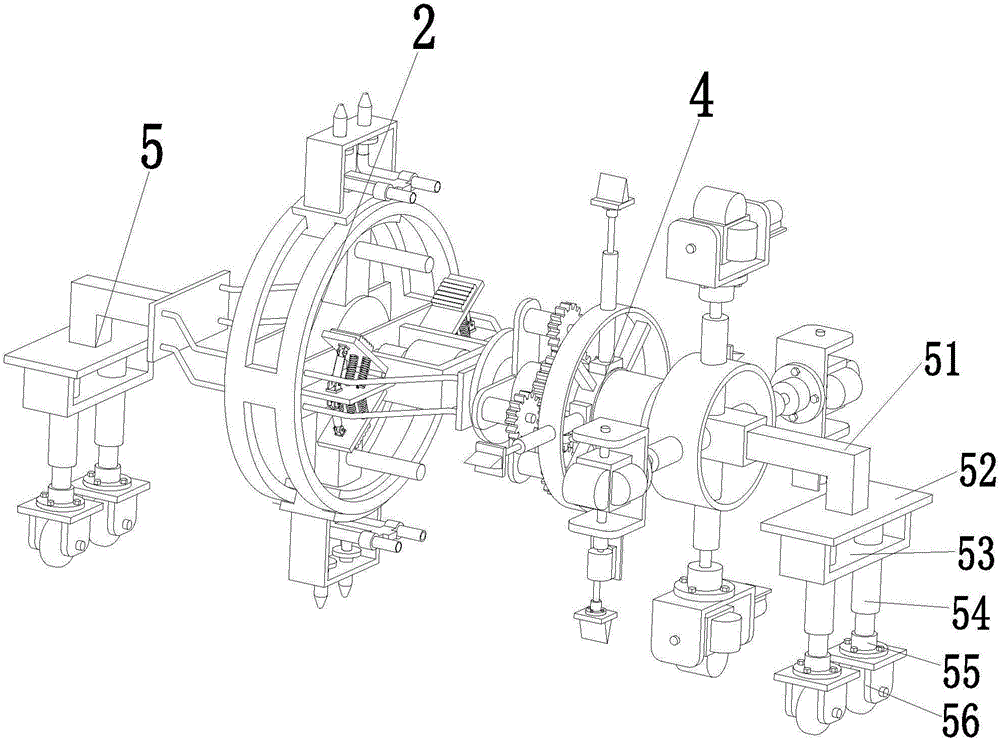

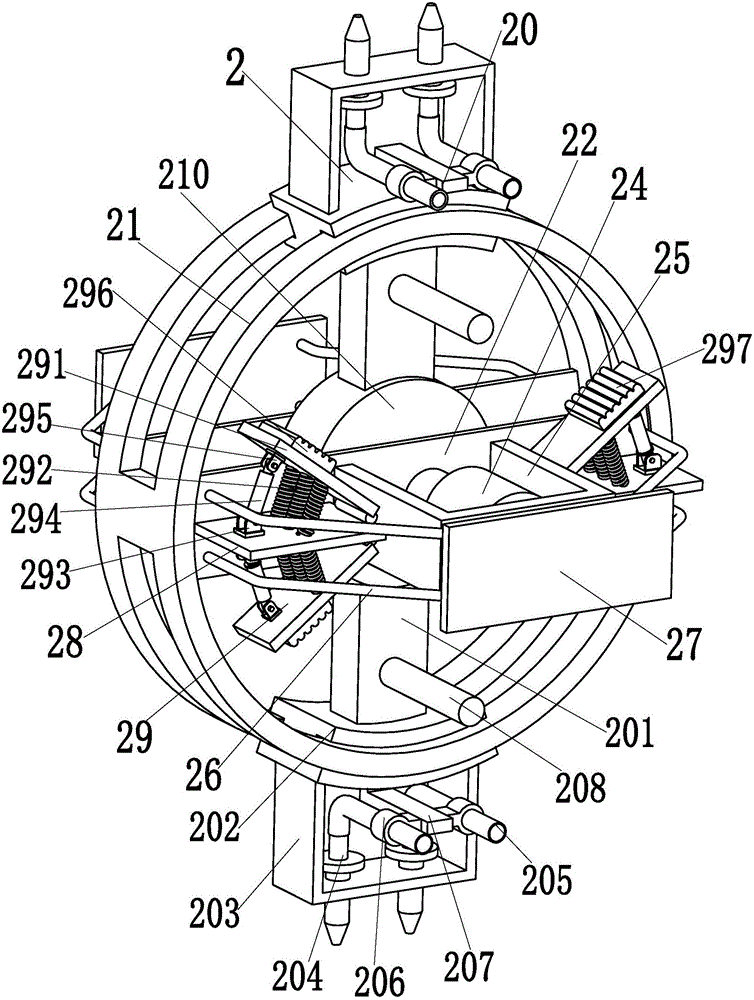

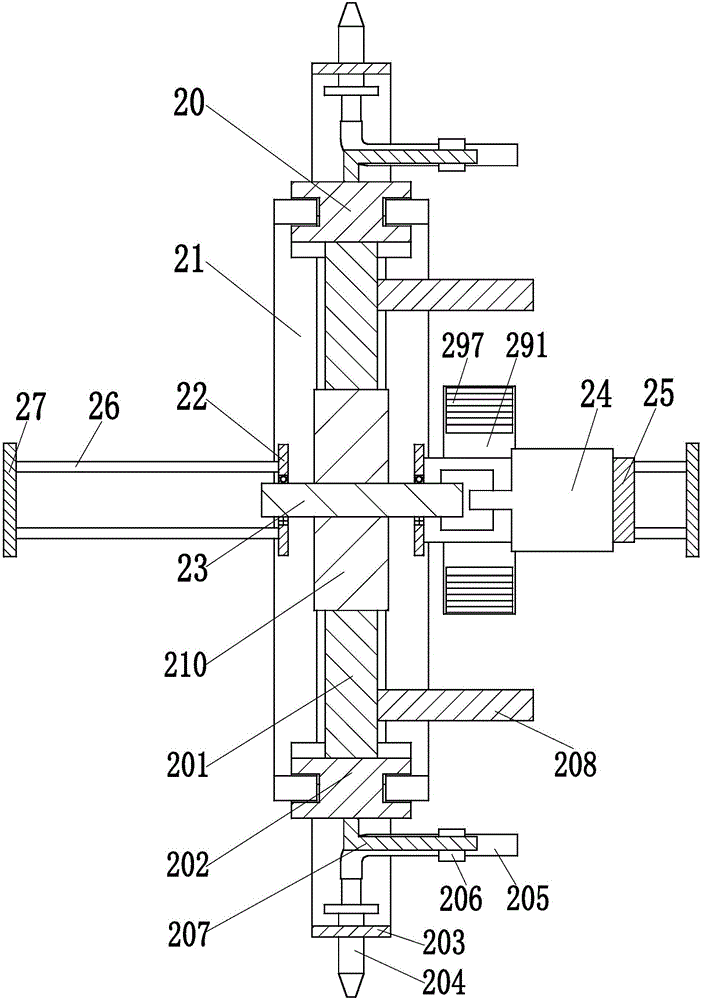

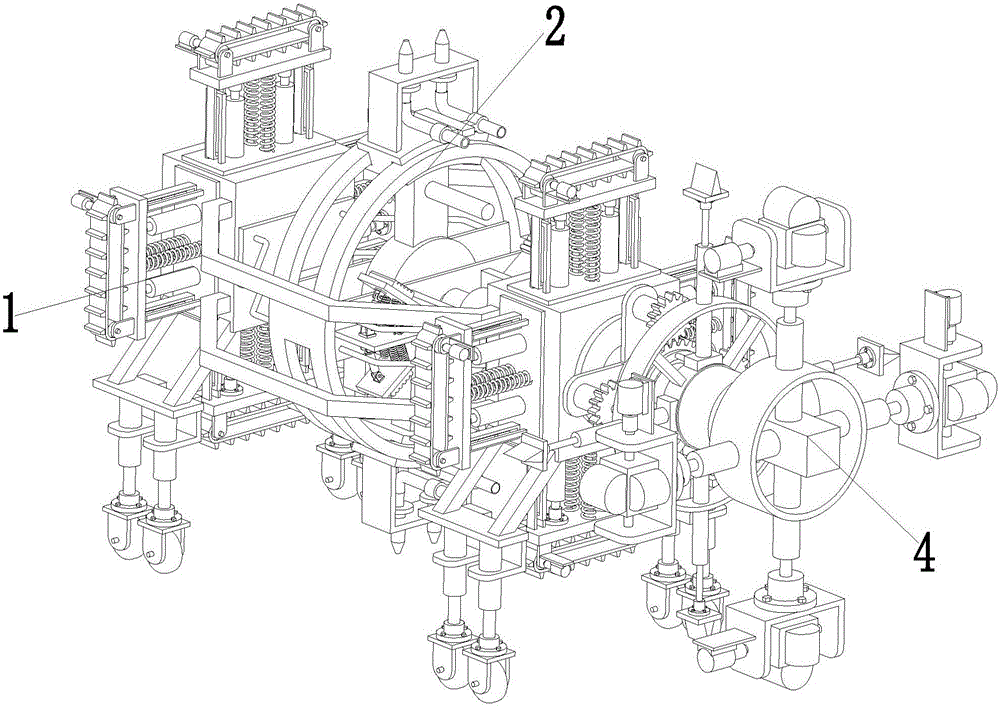

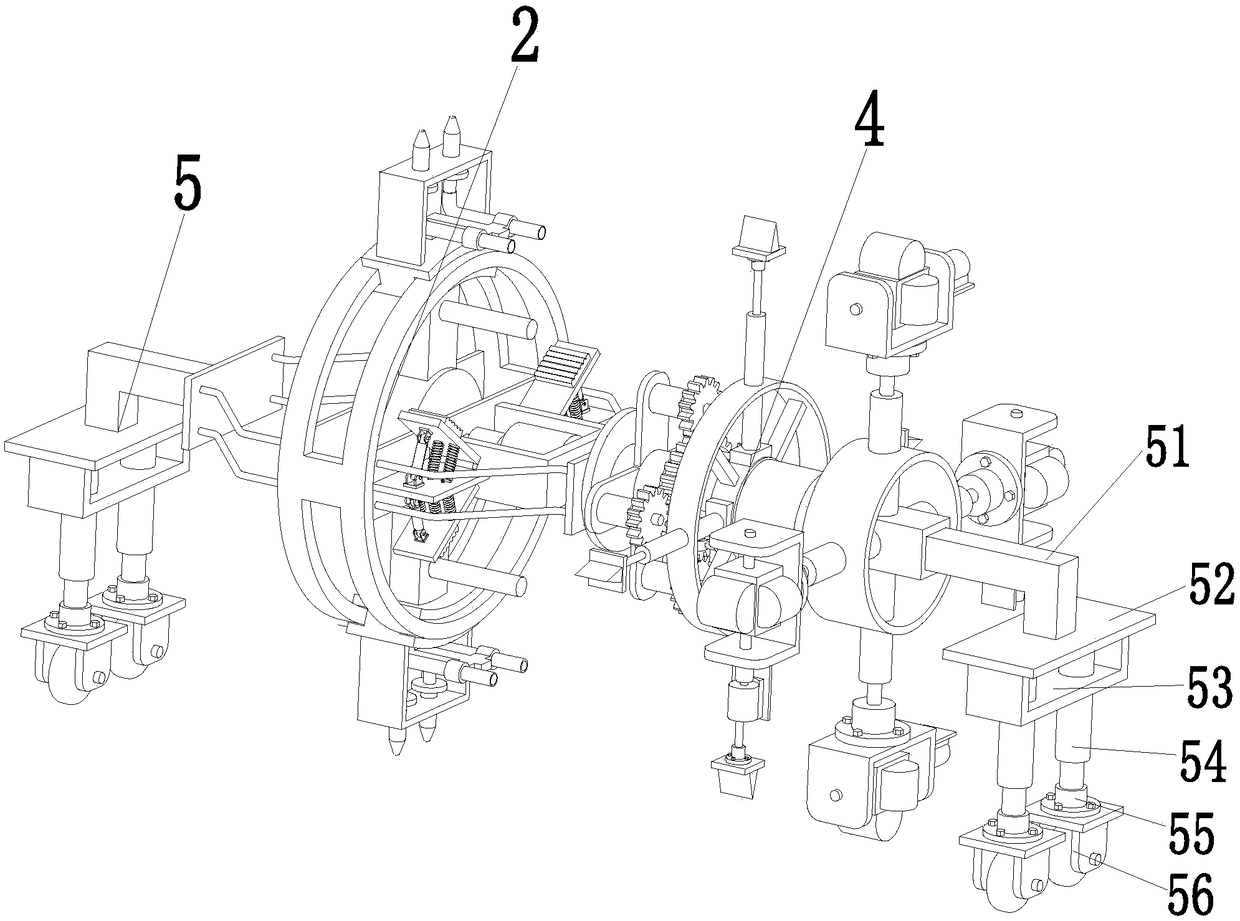

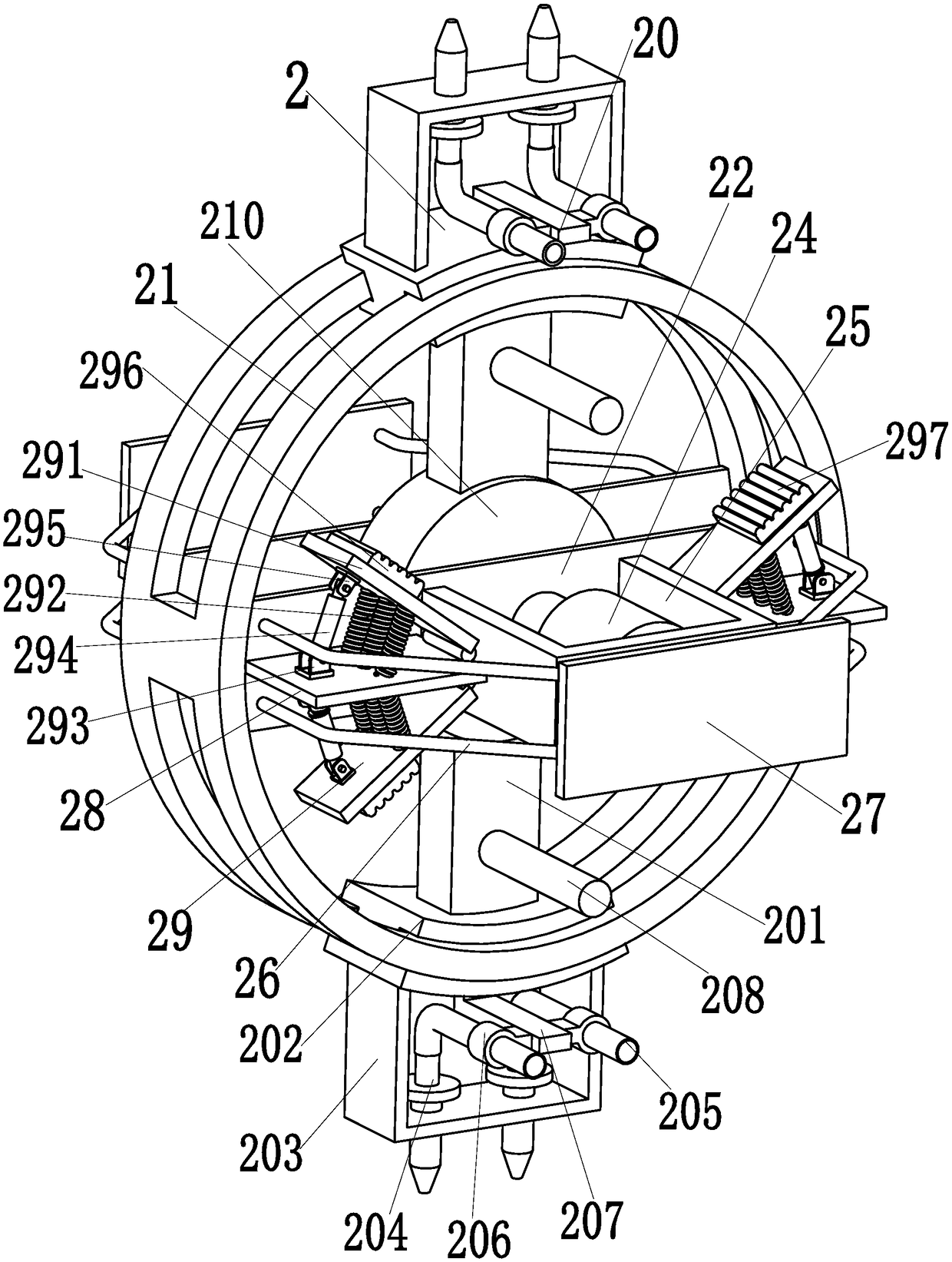

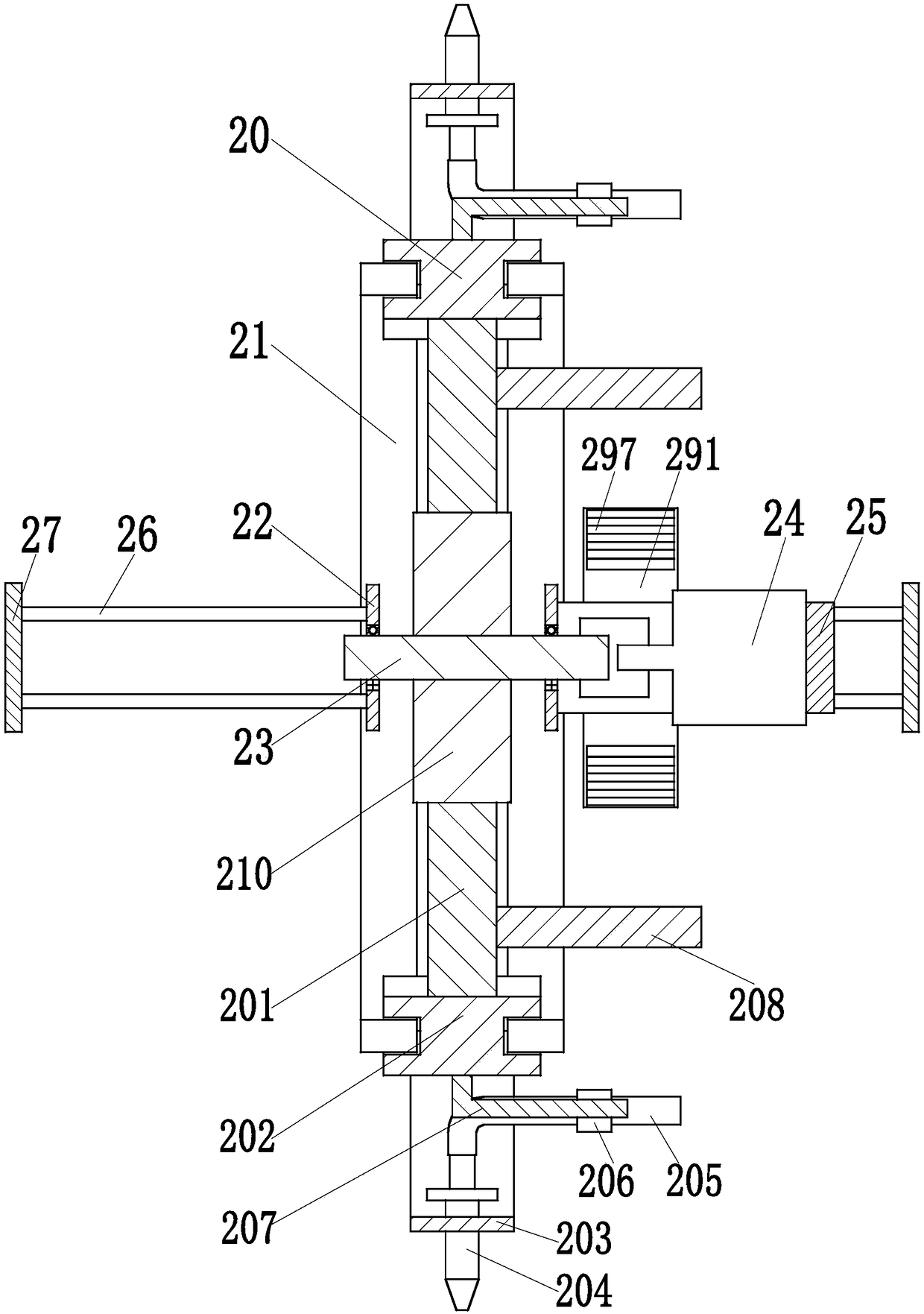

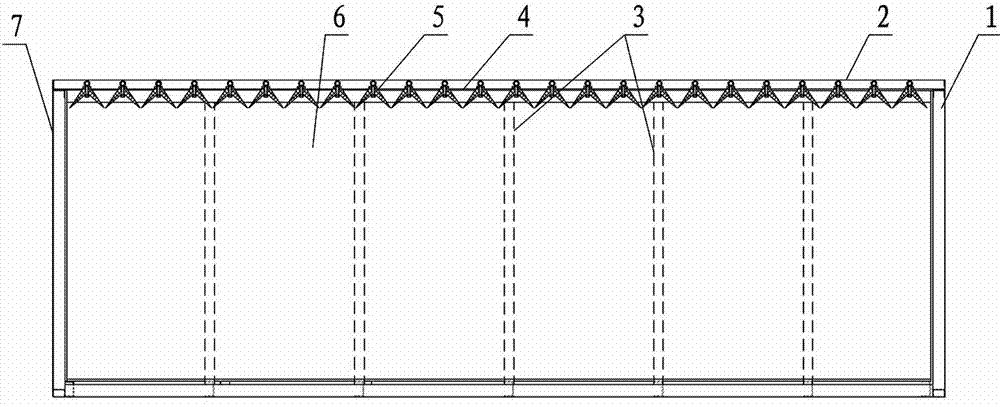

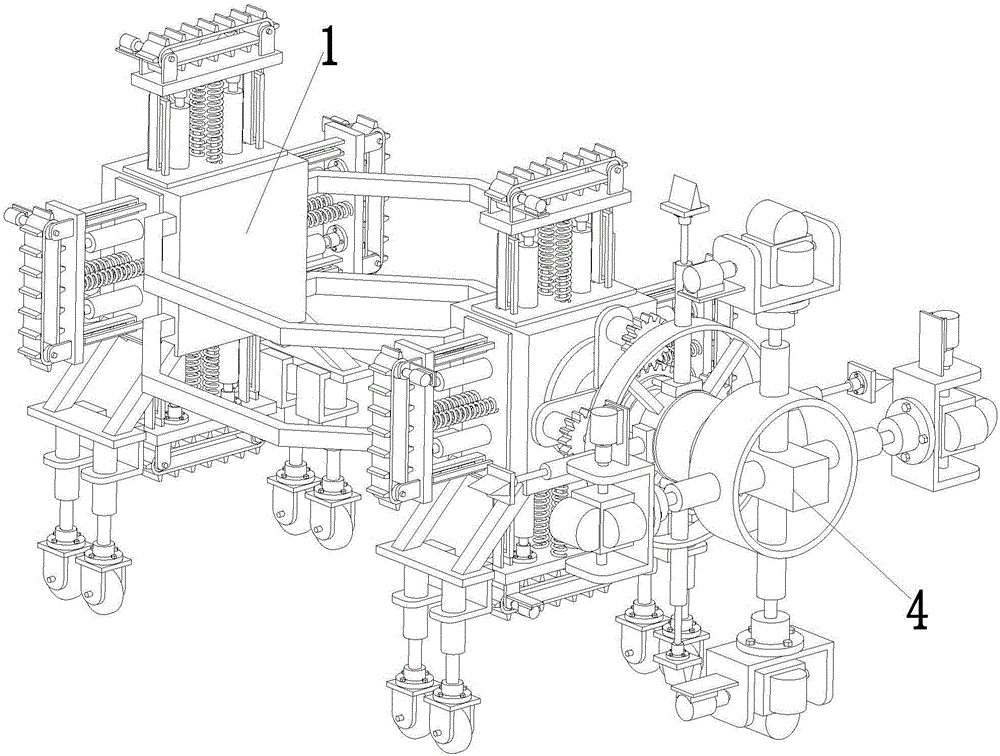

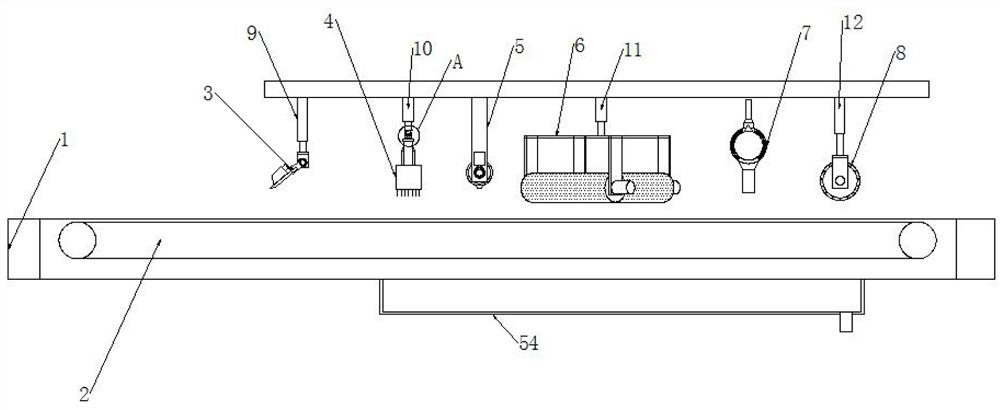

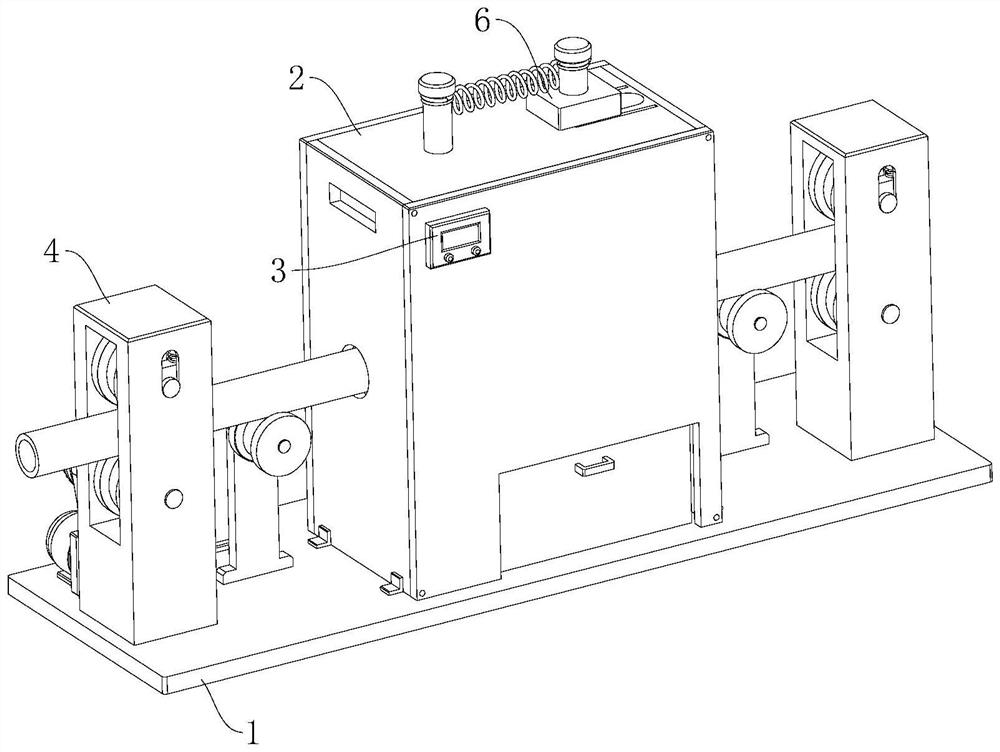

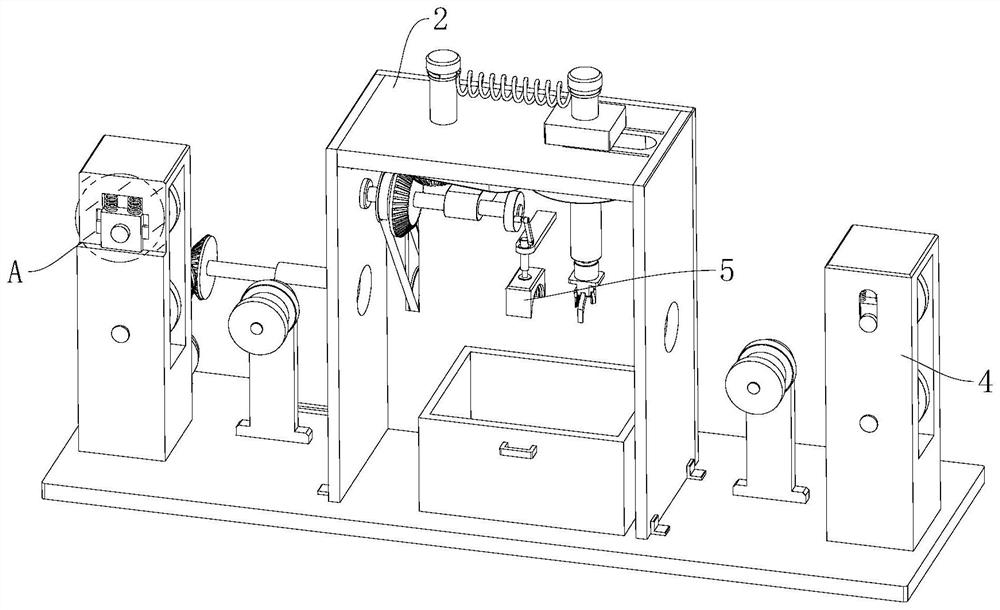

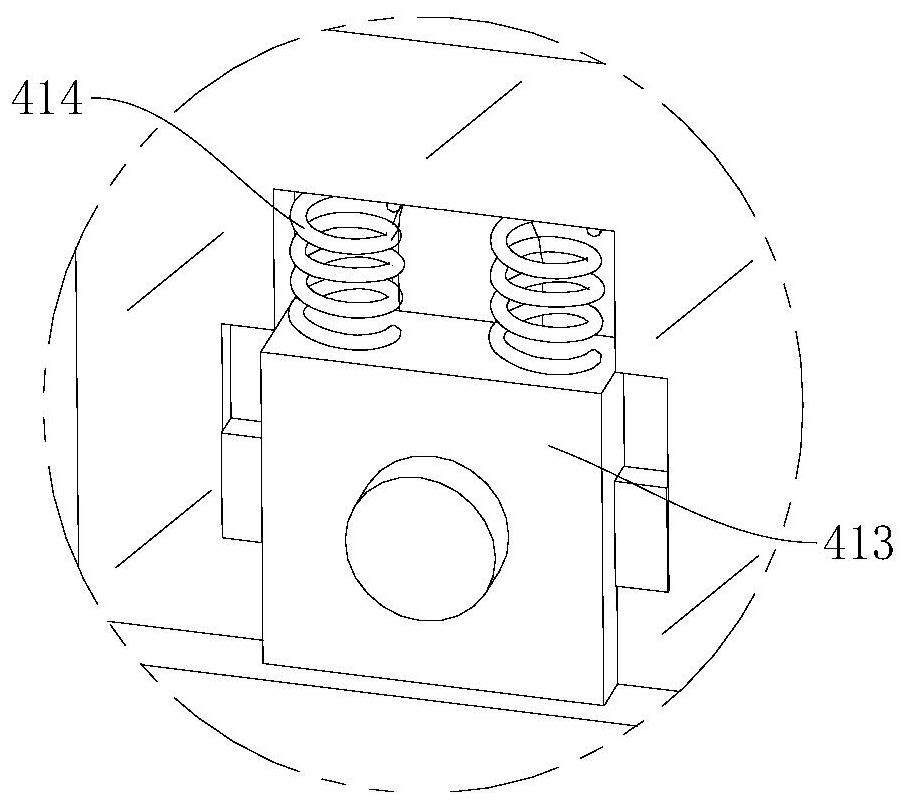

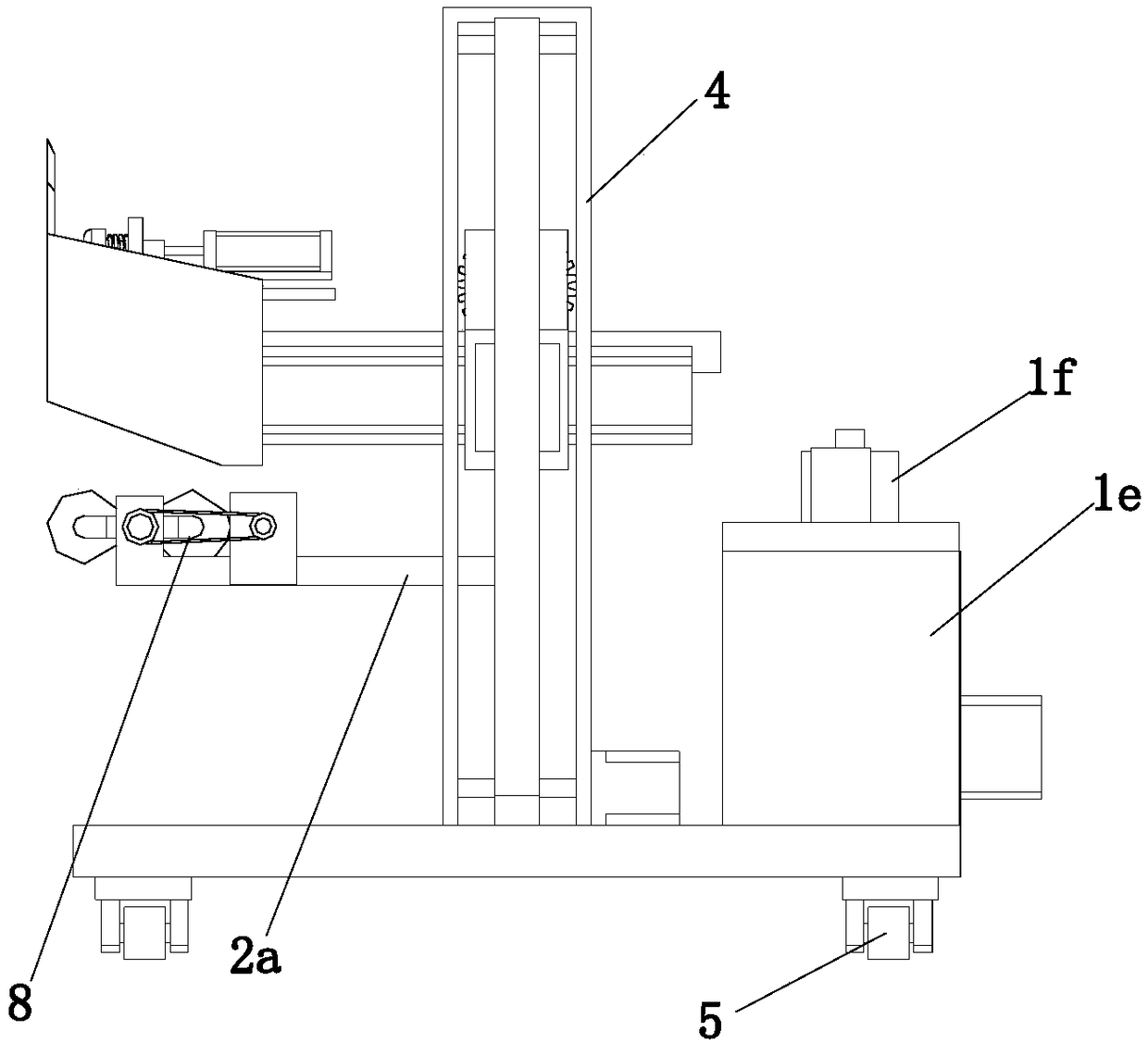

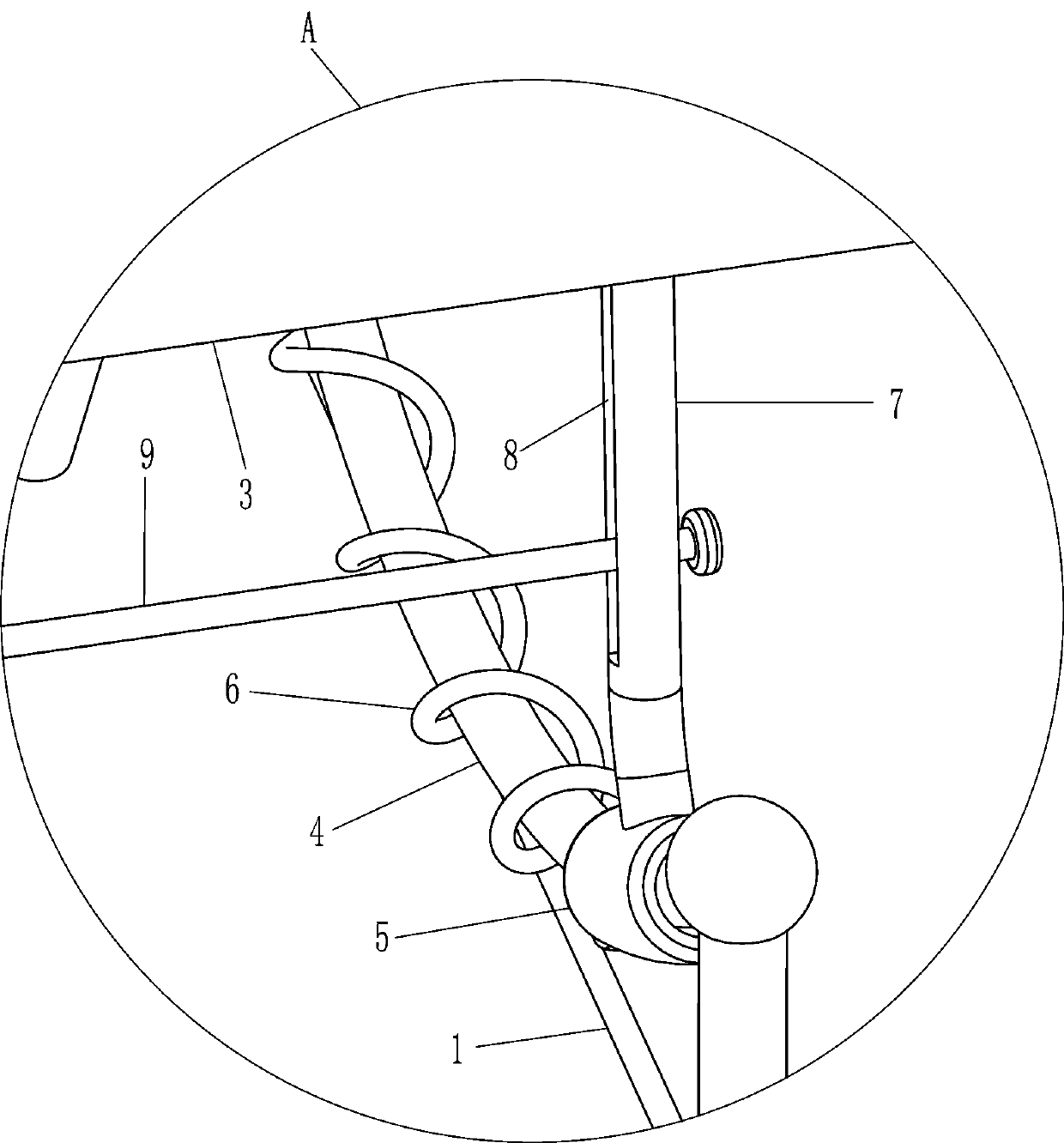

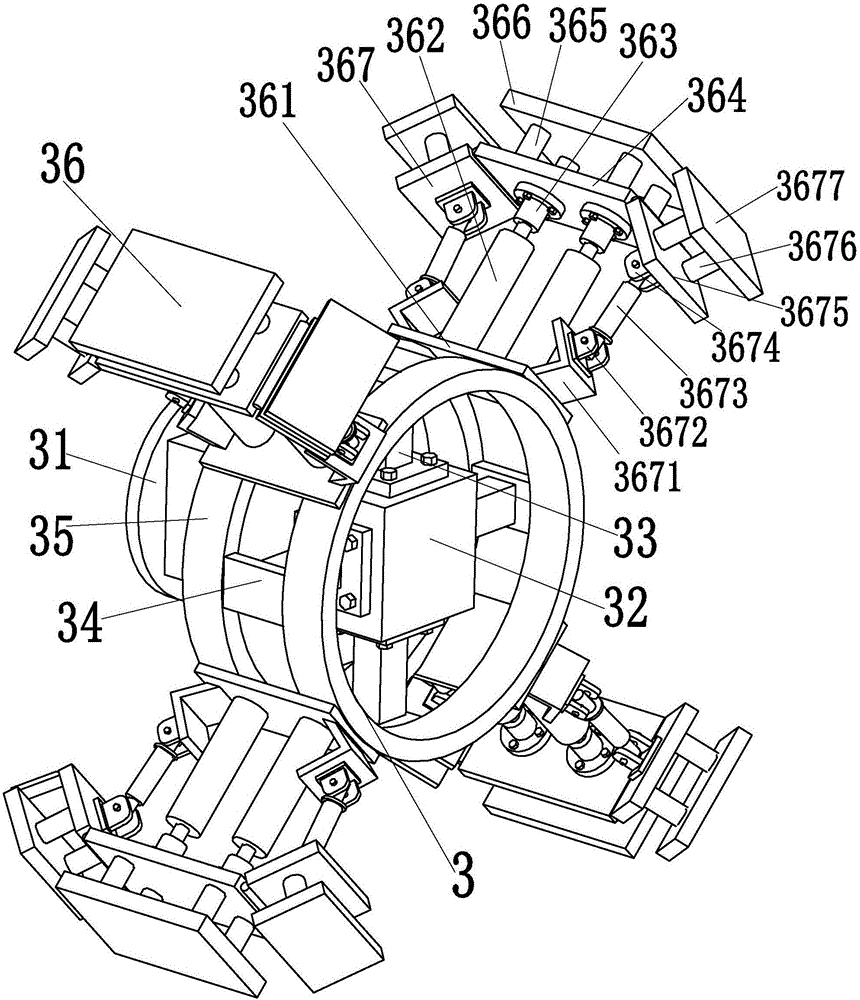

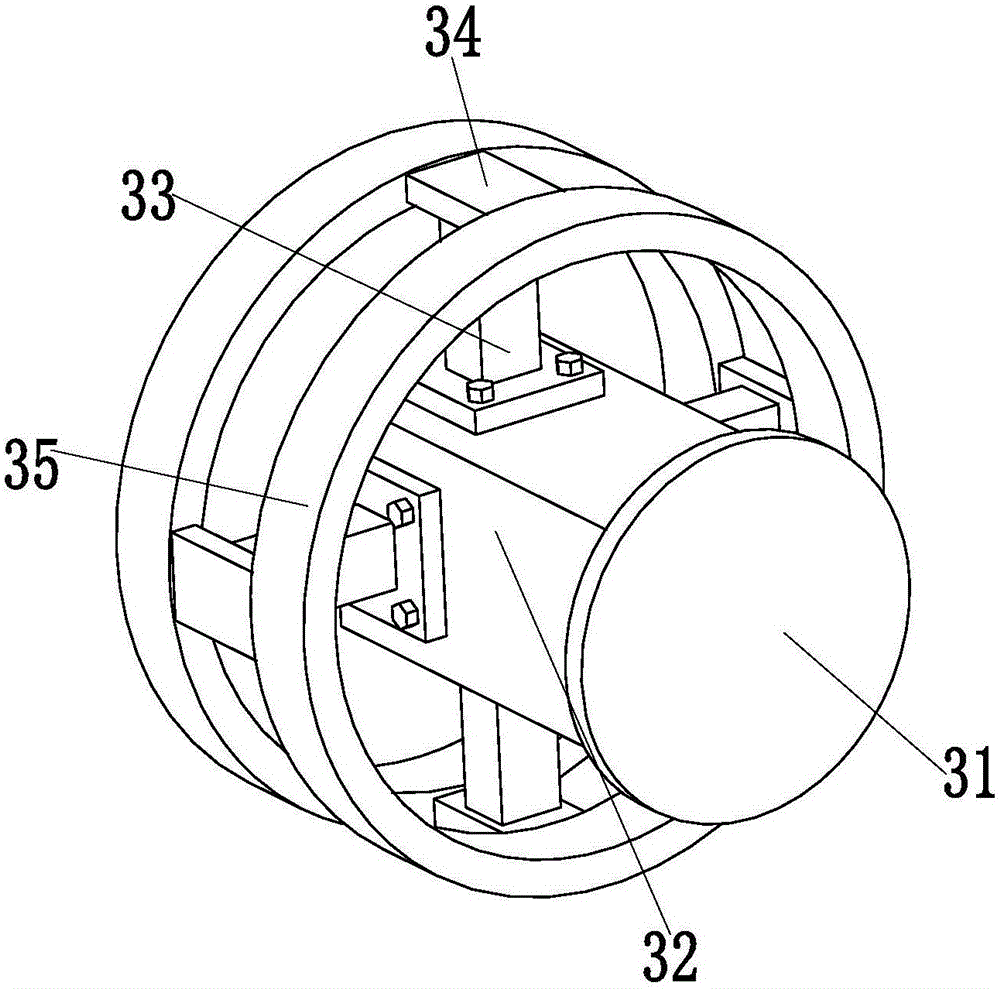

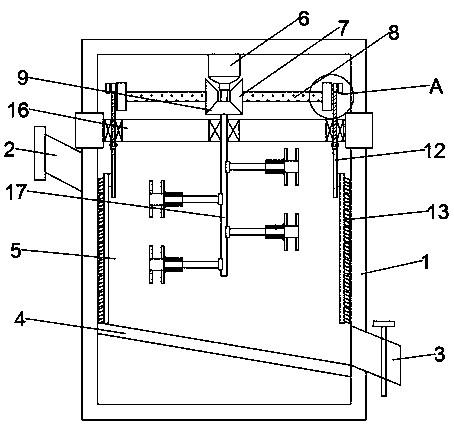

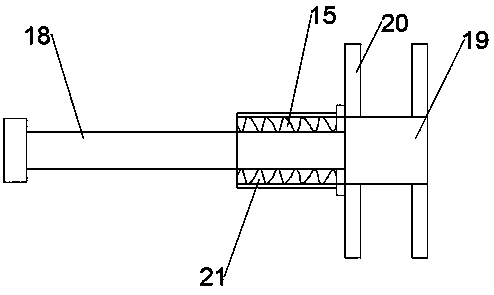

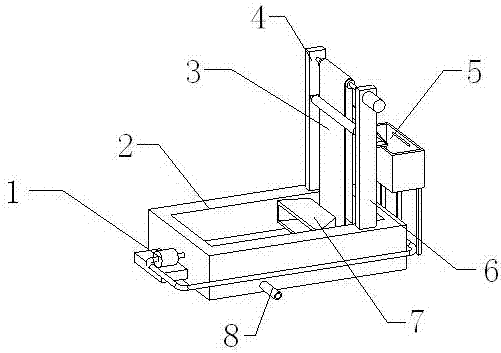

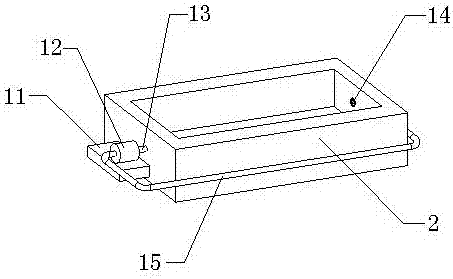

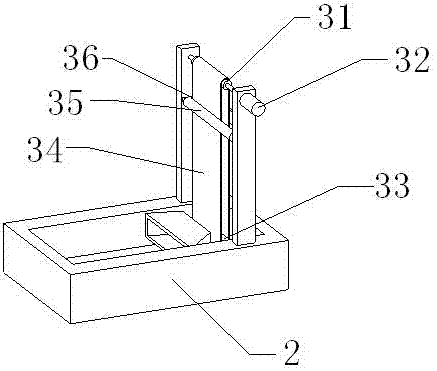

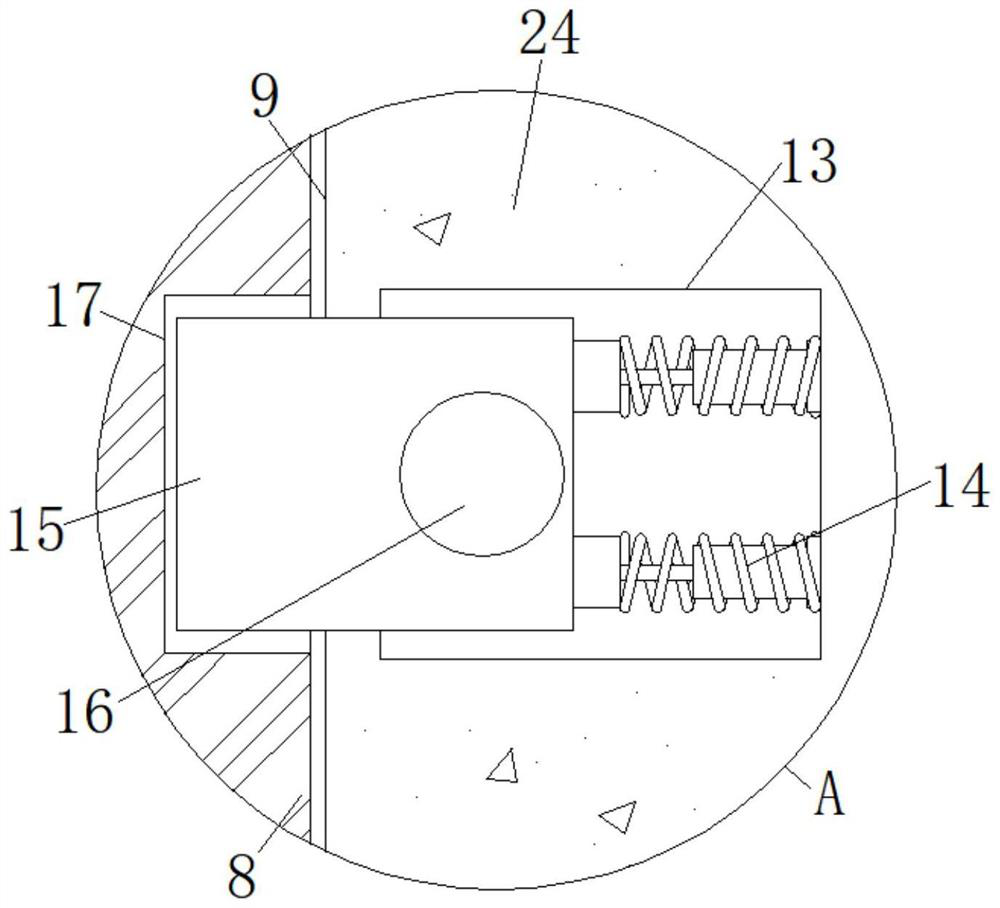

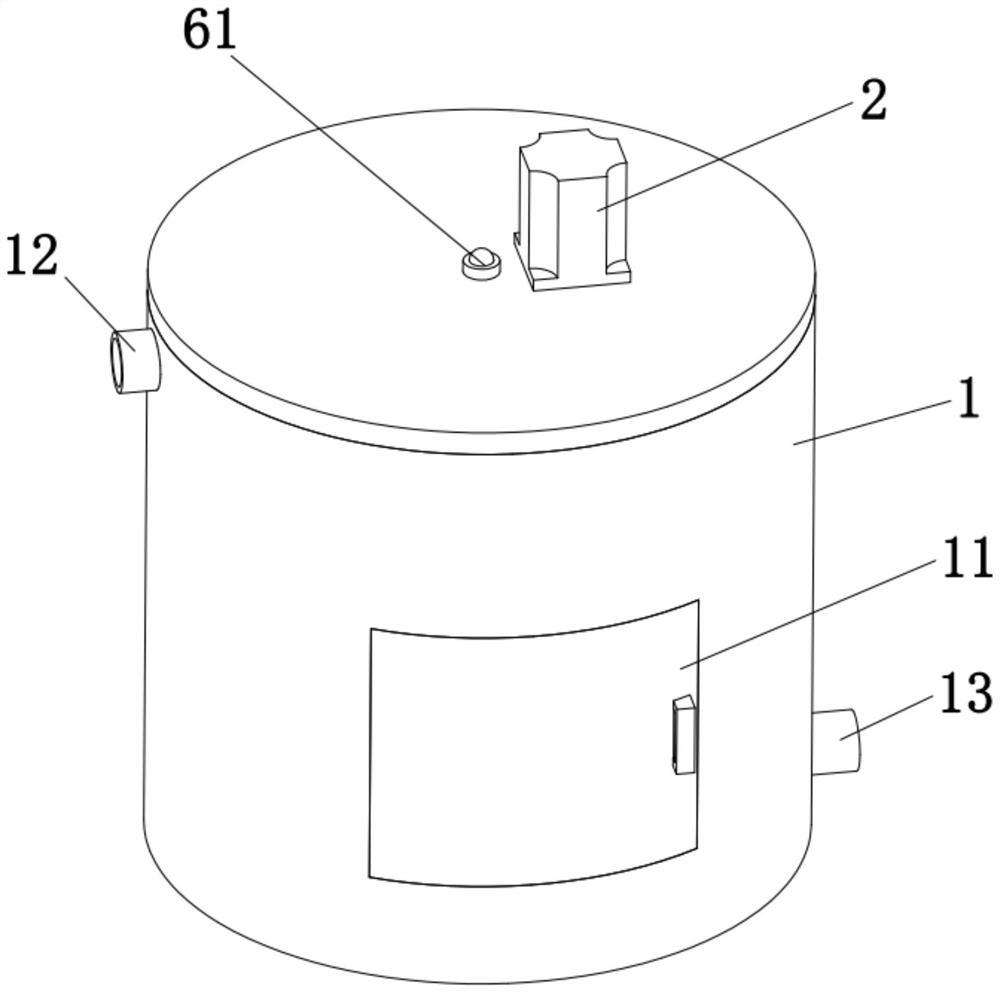

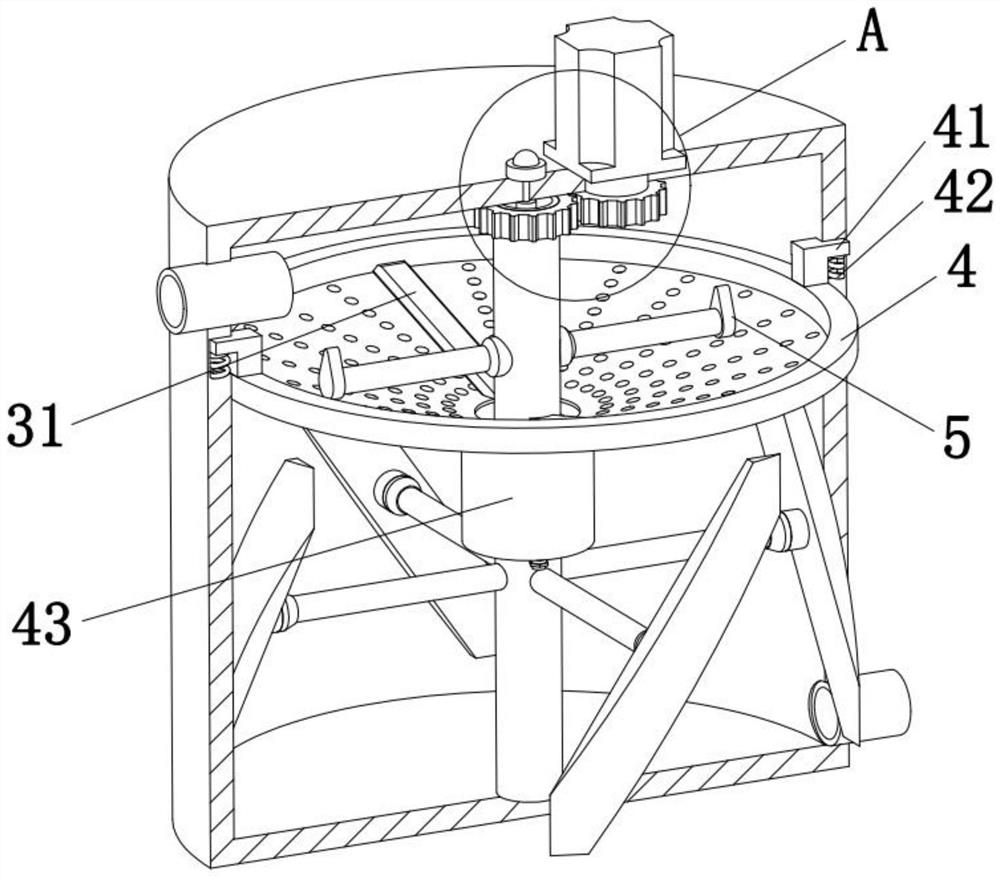

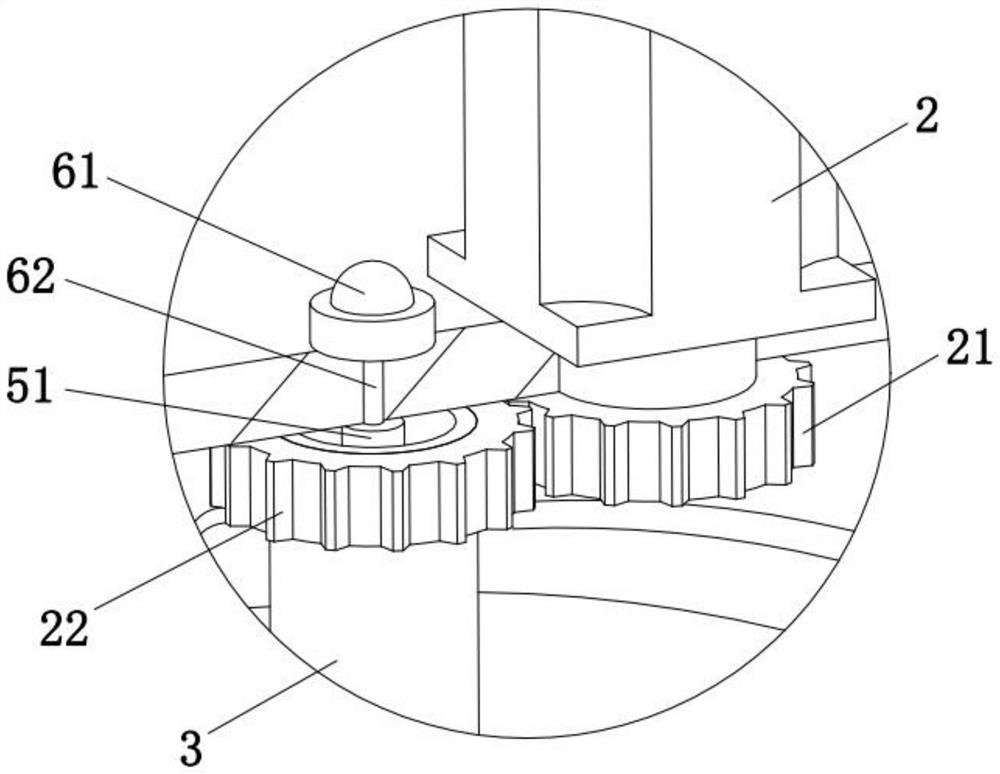

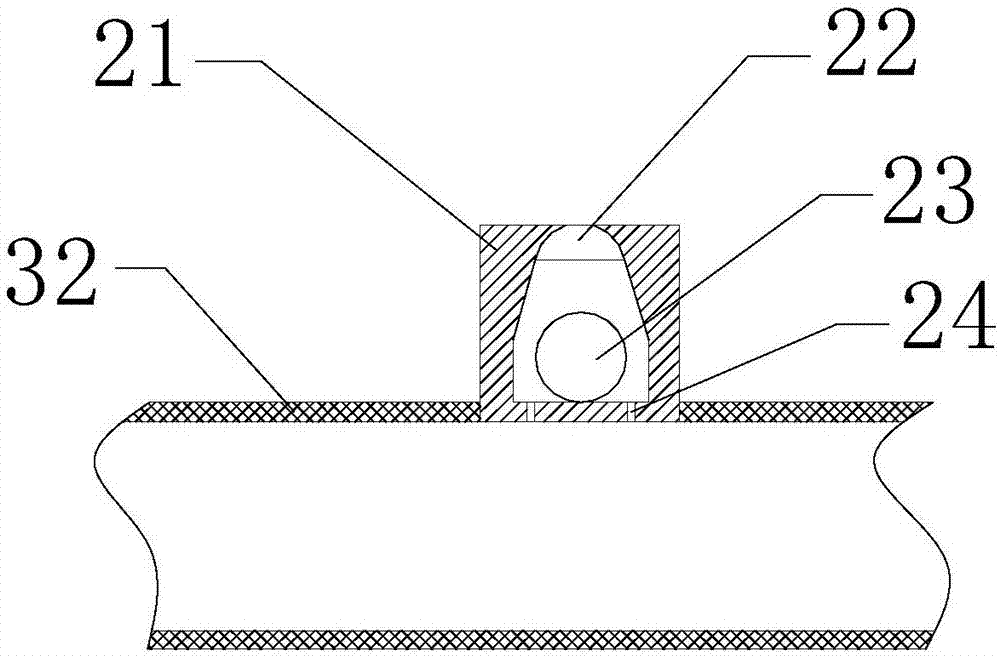

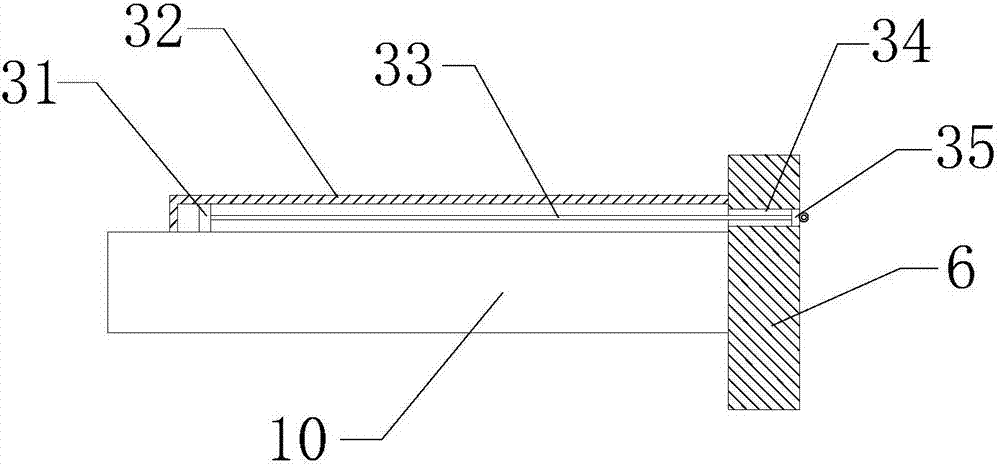

The invention relates to a petroleum pipeline inner wall processing machine with cleaning and drying functions. The petroleum pipeline inner wall processing machine comprises an inner wall rotary cleaning device which can achieve high-pressure cleaning of the inner wall of a pipeline, and local high-pressure cleaning can be carried out according to the requirement of the inner wall of the pipeline. An inner wall drying device is installed at the left end of the inner wall rotary cleaning device, can achieve fast drying of the inner wall of the pipeline and can carry out local fast drying according to the actual situation of the inner wall of the pipeline. An inner wall derusting device is installed on the right side of the inner wall rotary cleaning device and can achieve rapid impurity removal, derusting and grinding of the inner wall of the pipeline. Traveling branch chains are welded to the left end of the inner wall drying device and the right end of the inner wall derusting device. The petroleum pipeline inner wall processing machine travels on the inner wall of the pipeline through the two traveling branch chains. The petroleum pipeline inner wall processing machine can achieve continuous and stable derusting, cleaning and drying functions for the inner wall of the petroleum pipeline, and the speed and efficiency of processing on the inner wall of the pipeline are high.

Owner:徐州楚润重型机械制造有限公司

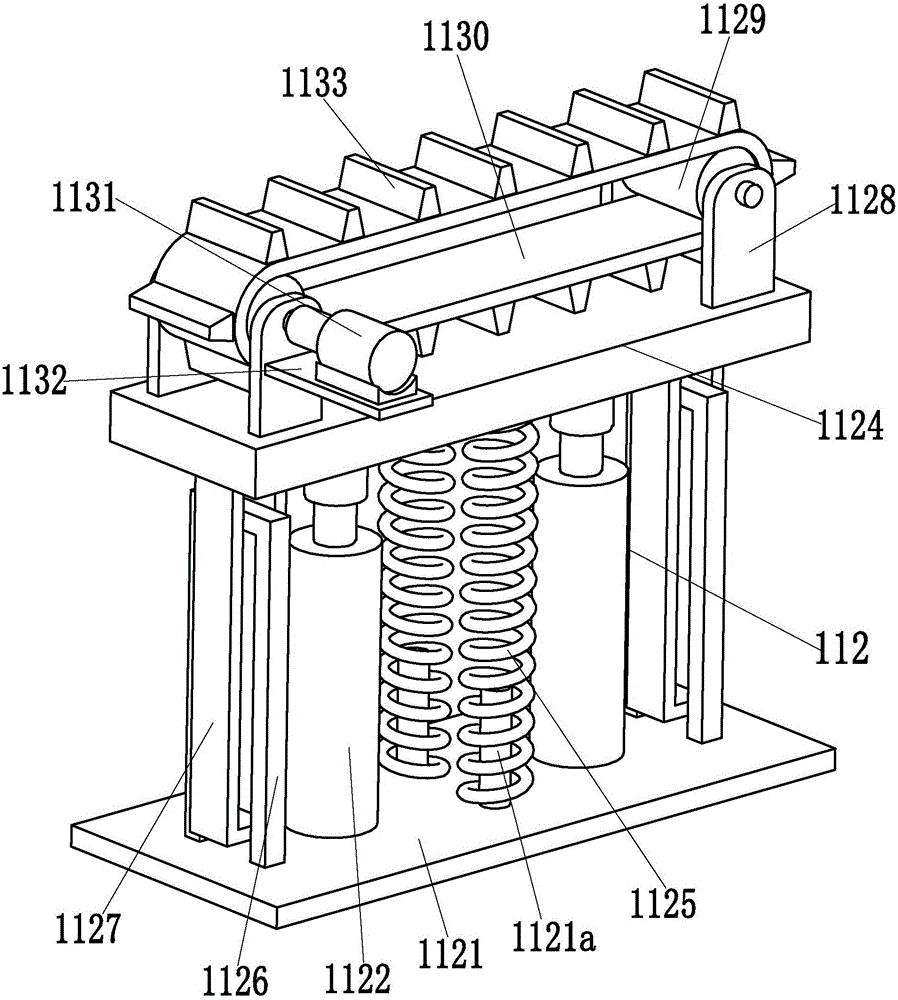

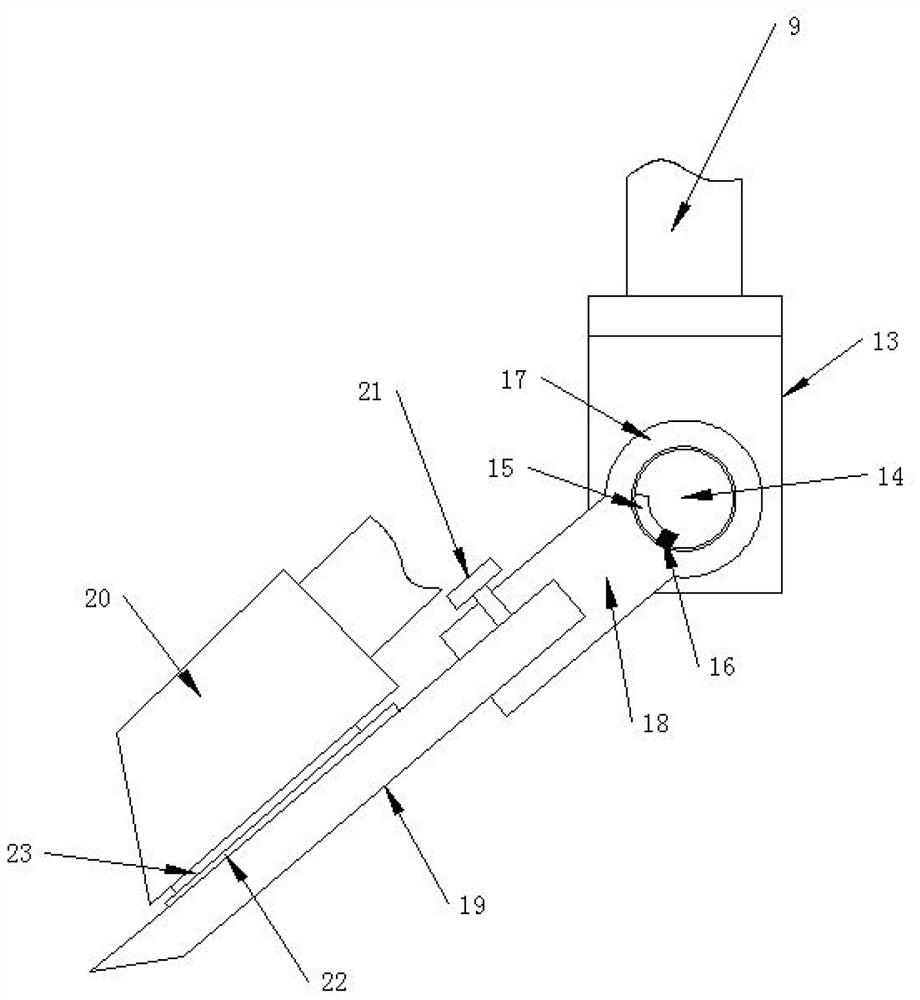

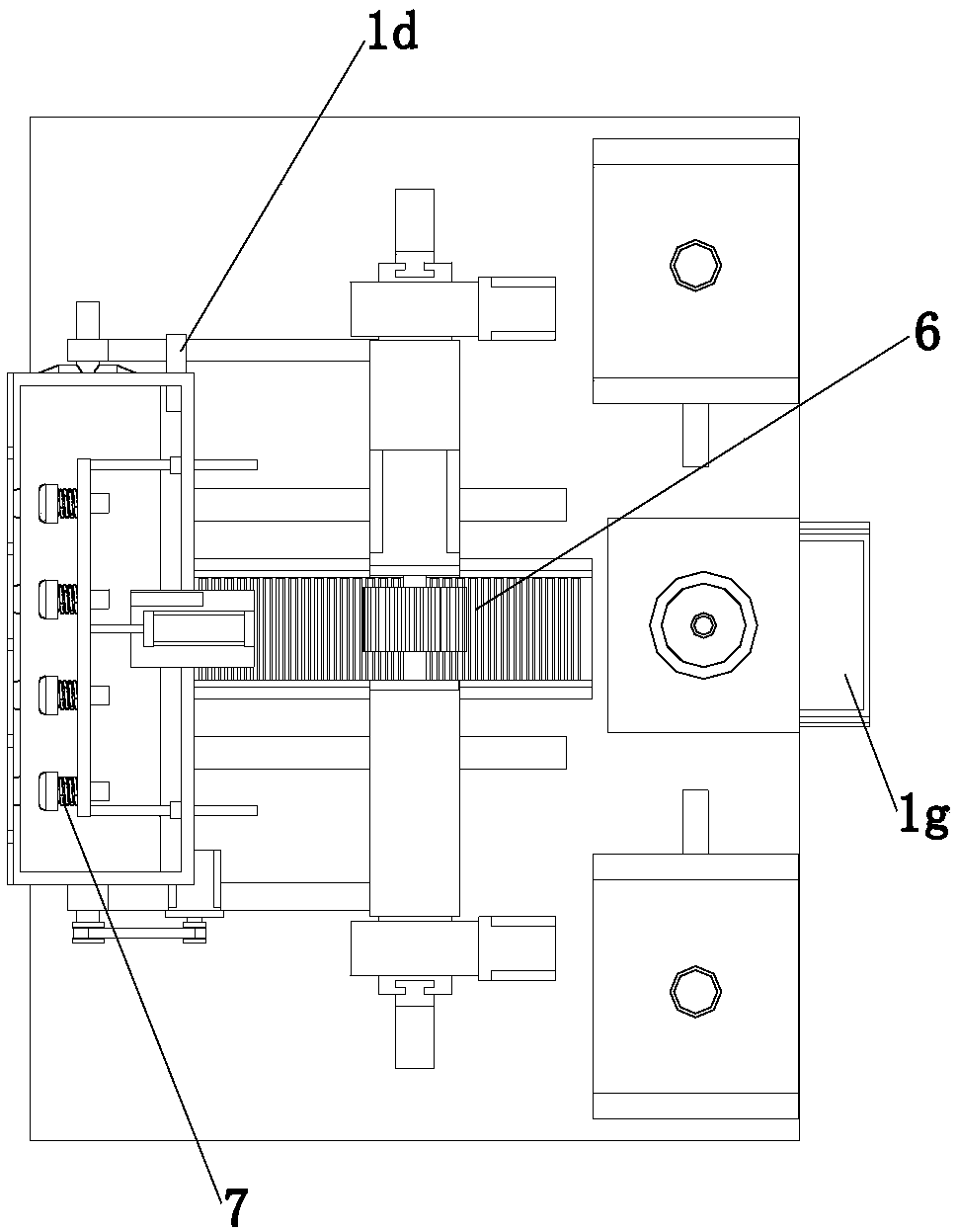

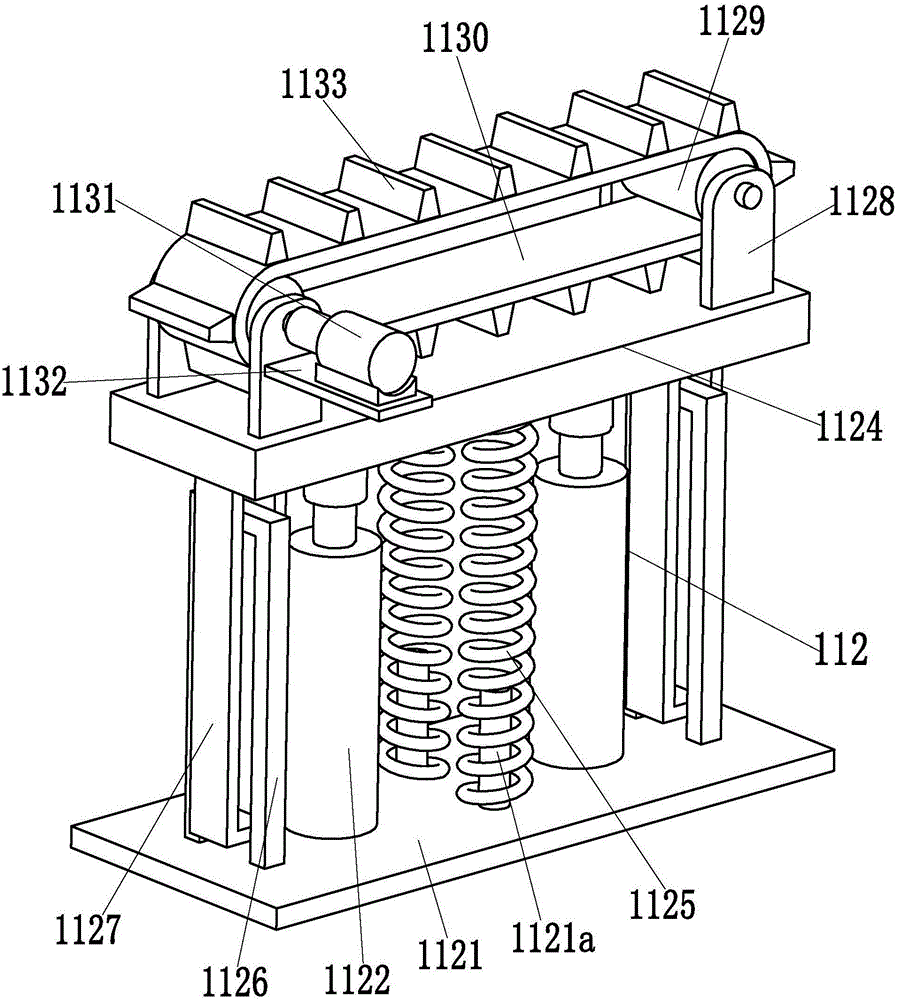

Intelligent cleaning and rust removing equipment for oil transmission pipe inner wall machining

ActiveCN106239332AQuick scrapeQuick functionRevolution surface grinding machinesGrinding drivesHigh pressurePetroleum engineering

The invention relates to intelligent cleaning and rust removing equipment for oil transmission pipe inner wall machining. The equipment comprises an inner wall rotary cleaning device; the inner wall rotary cleaning device can realize high-pressure cleaning function for the inner wall of a pipe, can perform local high-pressure cleaning according to the pipe inner wall demands, is wide in application range, is precise and adjustable in cleaning angle, is fast in cleaning speed, and is high in cleaning efficiency; an inner wall rust removing device is mounted on the right side of the inner wall rotary cleaning device, can realize quick impurity scraping, rust removing and polishing functions of the inner wall for the pipe, and is short in rust removing and polishing time and excellent in rust removing and polishing effect; walk branched chains are respectively welded at the left end of the inner wall rotary cleaning device and the right end of the inner wall rust removing device; and the equipment walks on the inner wall of the pipe through the two walk branched chains. The equipment can realize continuous and stable rust removing and cleaning functions of the inner wall of a petroleum pipe, is fast in treatment speed of the inner wall of the pipe, and is high in treatment efficiency of the inner wall of the pipe.

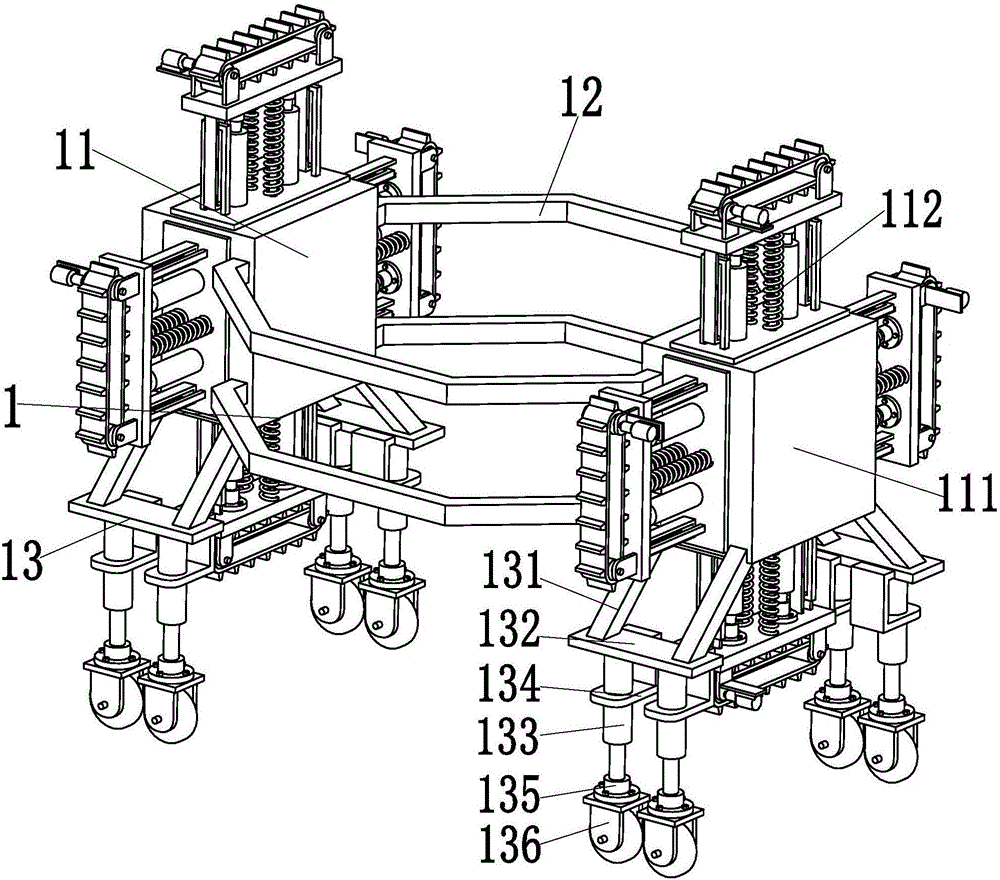

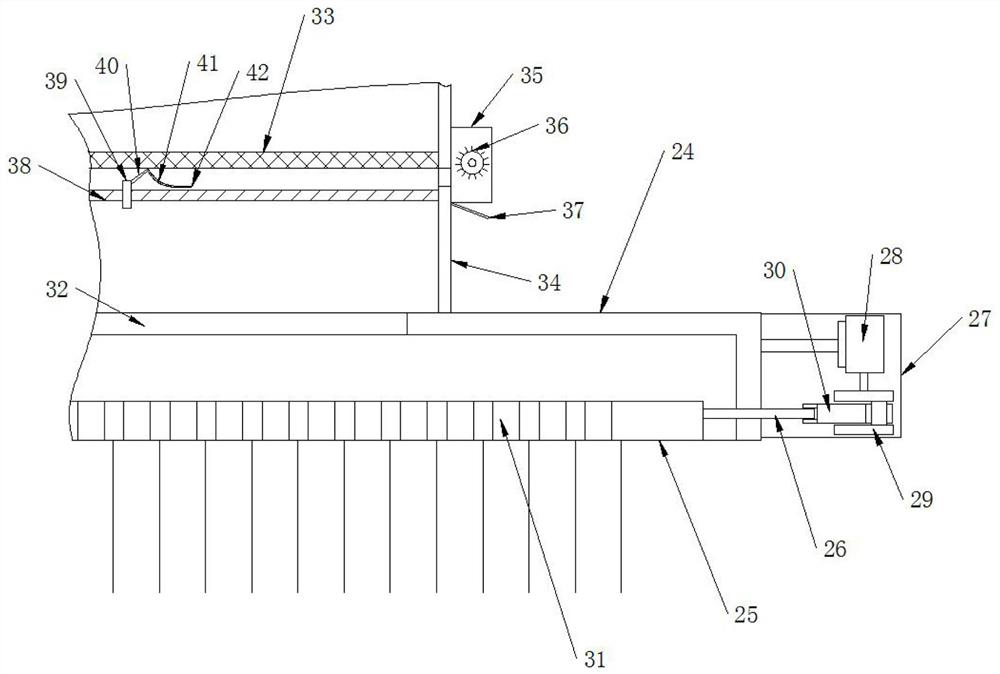

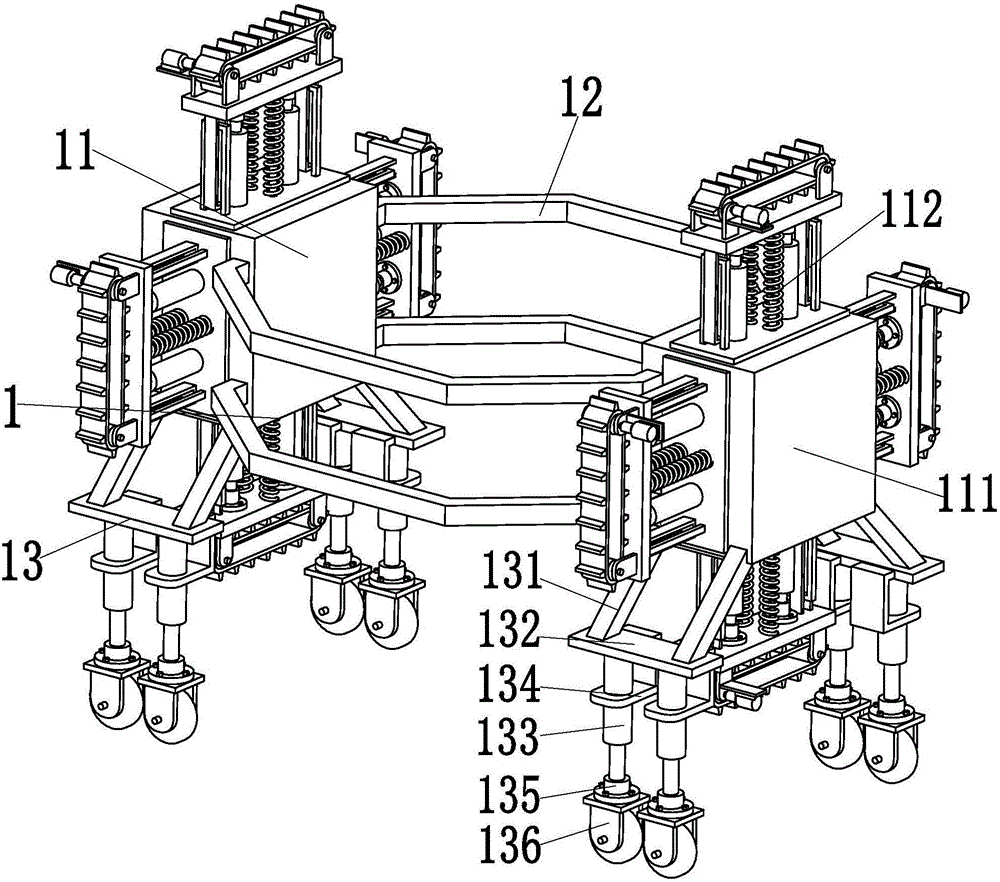

Inner wall fully-automatic treatment robot for gasoline conveying pipeline

ActiveCN106247082AUniform walking supportGood uniform support performanceRevolution surface grinding machinesHollow article cleaningGasolineHigh pressure

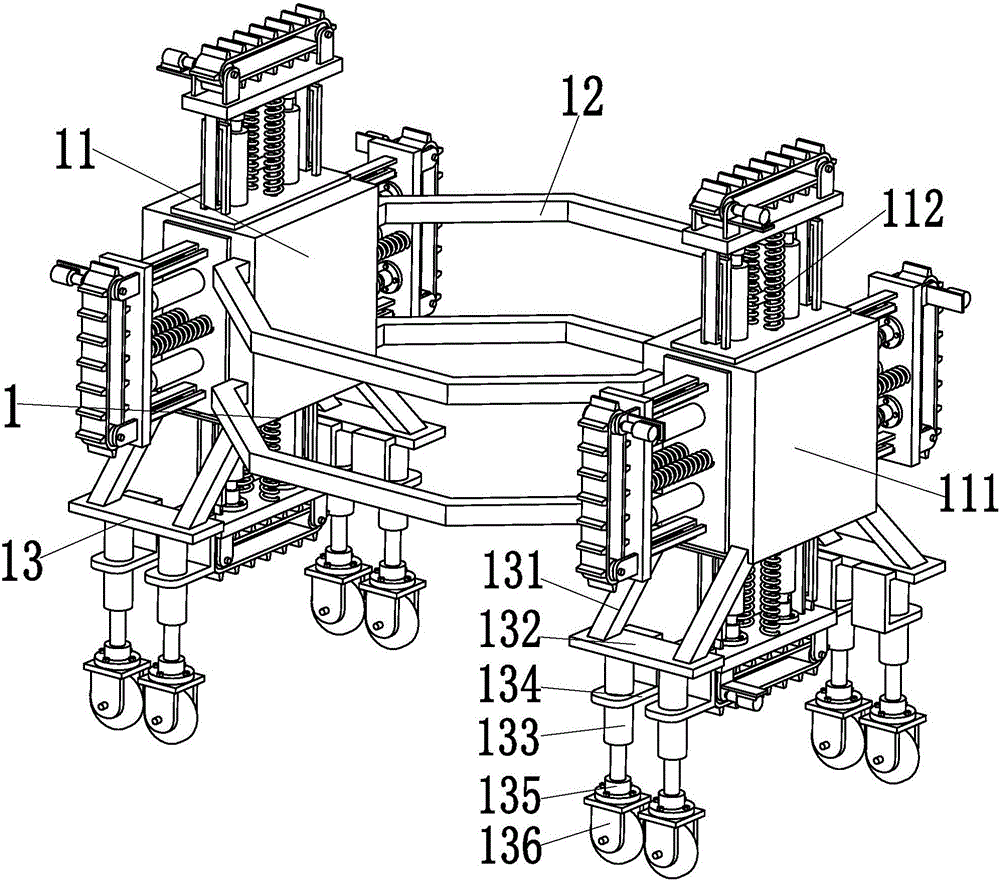

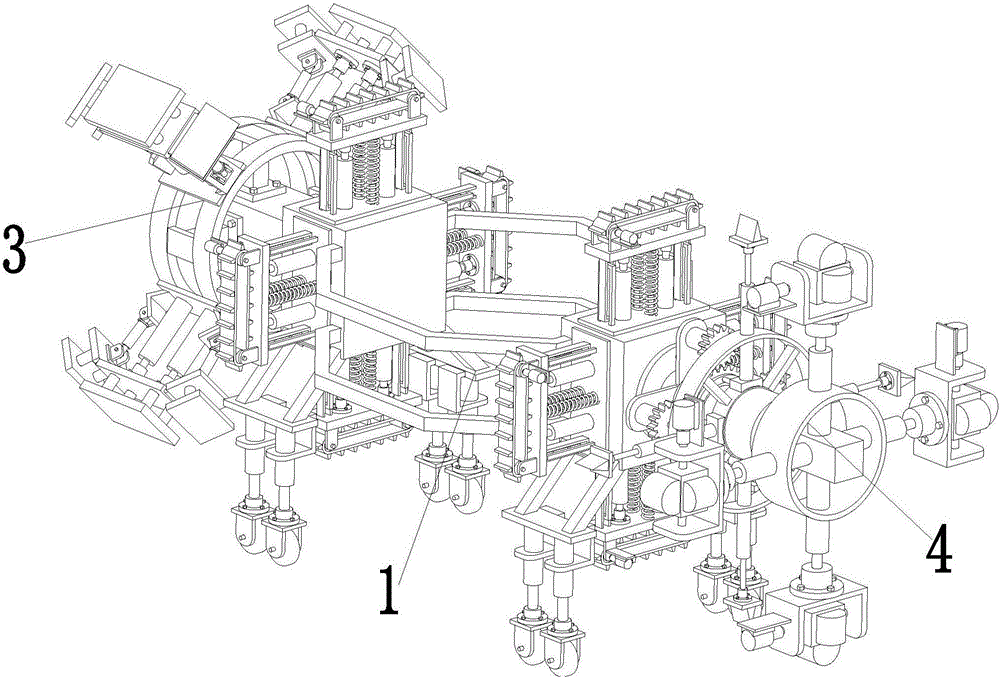

The invention relates to an inner wall fully-automatic treatment robot for a gasoline conveying pipeline. The inner wall fully-automatic treatment robot comprises an inner wall automatic travelling device, wherein the inner wall automatic travelling device travels on the inner wall of the pipeline in a self-stabilizing manner in four directions, has four uniformly-distributed travelling support forces, and has good uniform support performance and self-stabilizing travelling performance; an inner wall rotary cleaning device is installed at the middle part of the inner wall automatic travelling device, is capable of realizing a high-pressure cleaning function for the inner wall of the pipeline and carrying out partial high-pressure cleaning according to the need of the inner wall of the pipeline, and is accurate and adjustable in cleaning angle, fast in cleaning speed and high in cleaning efficiency; and an inner wall rust removal device is installed at the right side of the inner wall automatic travelling device, is capable of realizing rapid impurity scraping and rust removing and grinding functions for the inner wall of the pipeline, and is short in rust removing and grinding time and good in rust removing and grinding effects. The inner wall fully-automatic treatment robot disclosed by the invention is capable of realizing continuous and stable rust removal and cleaning functions for the inner wall of the gasoline pipeline, has no need of equipment replacement operation during the process, and is fast in pipeline inner wall treatment speed and high in pipeline inner wall treatment efficiency.

Owner:上海泰梧科技有限公司

Intelligent device for machining and treating internal walls of petrochemical pipelines

ActiveCN108372453AQuick scrapeQuick functionRevolution surface grinding machinesGrinding drivesPetrochemicalHigh pressure

The invention relates to an intelligent device for machining and treating an internal wall of a petrochemical pipeline, which comprises a internal wall rotary-cleaner, wherein the internal wall rotary-cleaner can carry out a high-pressure cleaning function on the internal wall of the pipeline, partial high-pressure cleaning can be carried out according to the requirement of the internal wall of the pipeline, so the application range is wide; a cleaning angle is accurate and adjustable, the cleaning speed is high, and the cleaning efficiency is high. An internal wall rust remover is mounted atthe right side of the internal wall rotary-cleaner, the internal wall rust remover can carry out a rapid impurity scraping and rust-removing grinding function on the internal wall of the pipeline, therust-removing grinding time is short, and the rust-removing grinding effect is good. Two travelling branches are respectively welded to the left end of the internal wall rotary-cleaner and the rightend of the internal wall rust remover, and the intelligent device can travel on the internal wall of the pipeline by means of the two travelling branches. The intelligent device can continuously and stably carry out rust removal and cleaning functions on the internal wall of a petroleum pipeline, the speed of treating the internal wall of the pipeline is high, and the efficiency of treating the internal wall of the pipeline is high.

Owner:海力德工业(湛江)有限公司

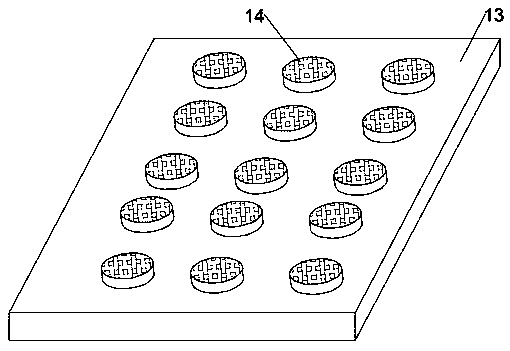

Anode mud cleaning device for electrolytic lead anode plates

ActiveCN102899691AQuick scrapeClean scrape offPhotography auxillary processesElectrolysis componentsElectrolysisElectrical and Electronics engineering

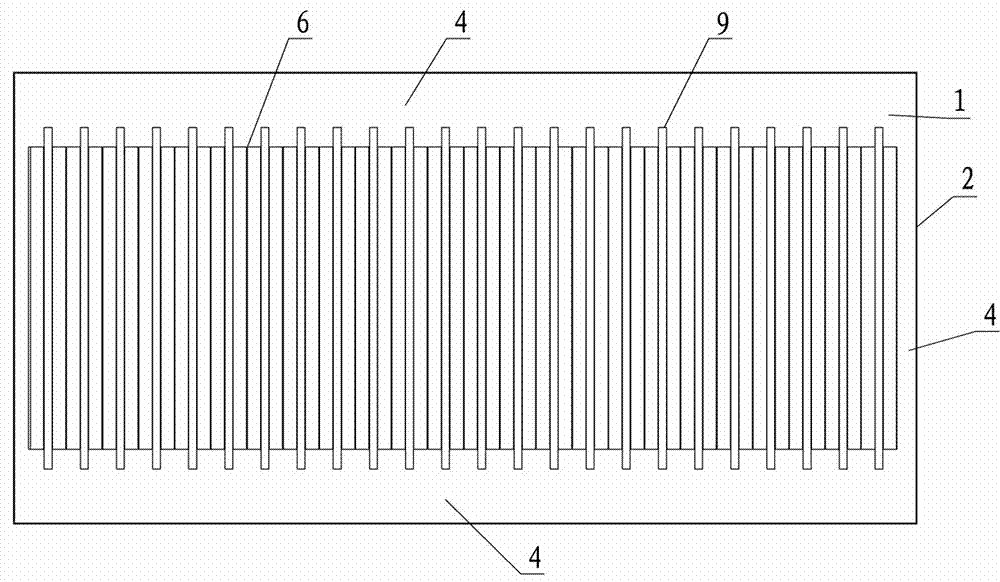

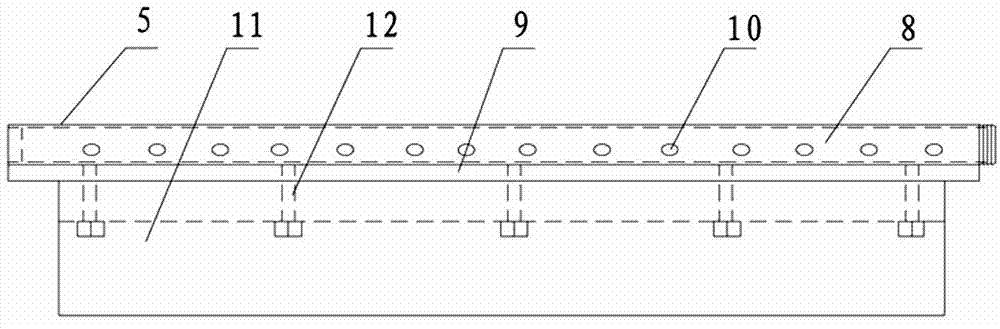

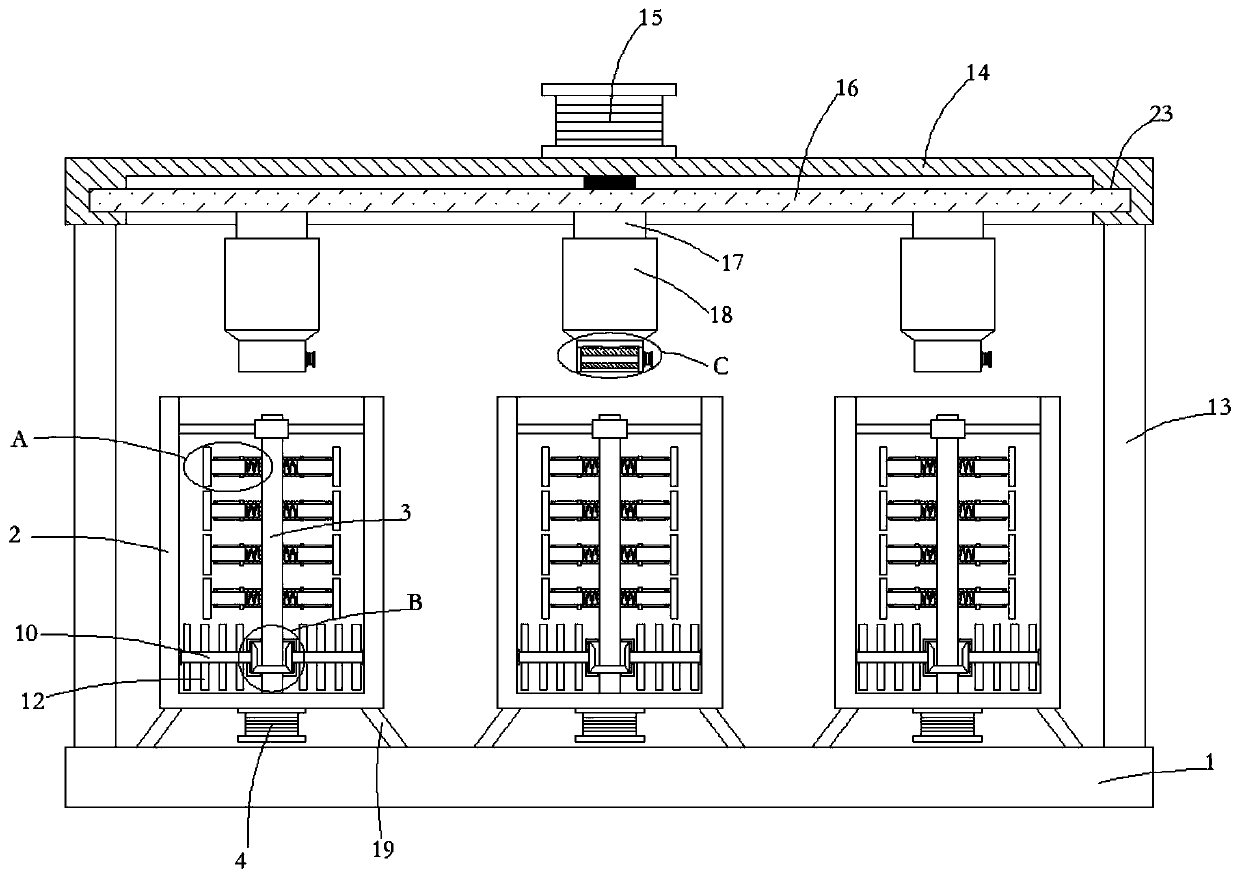

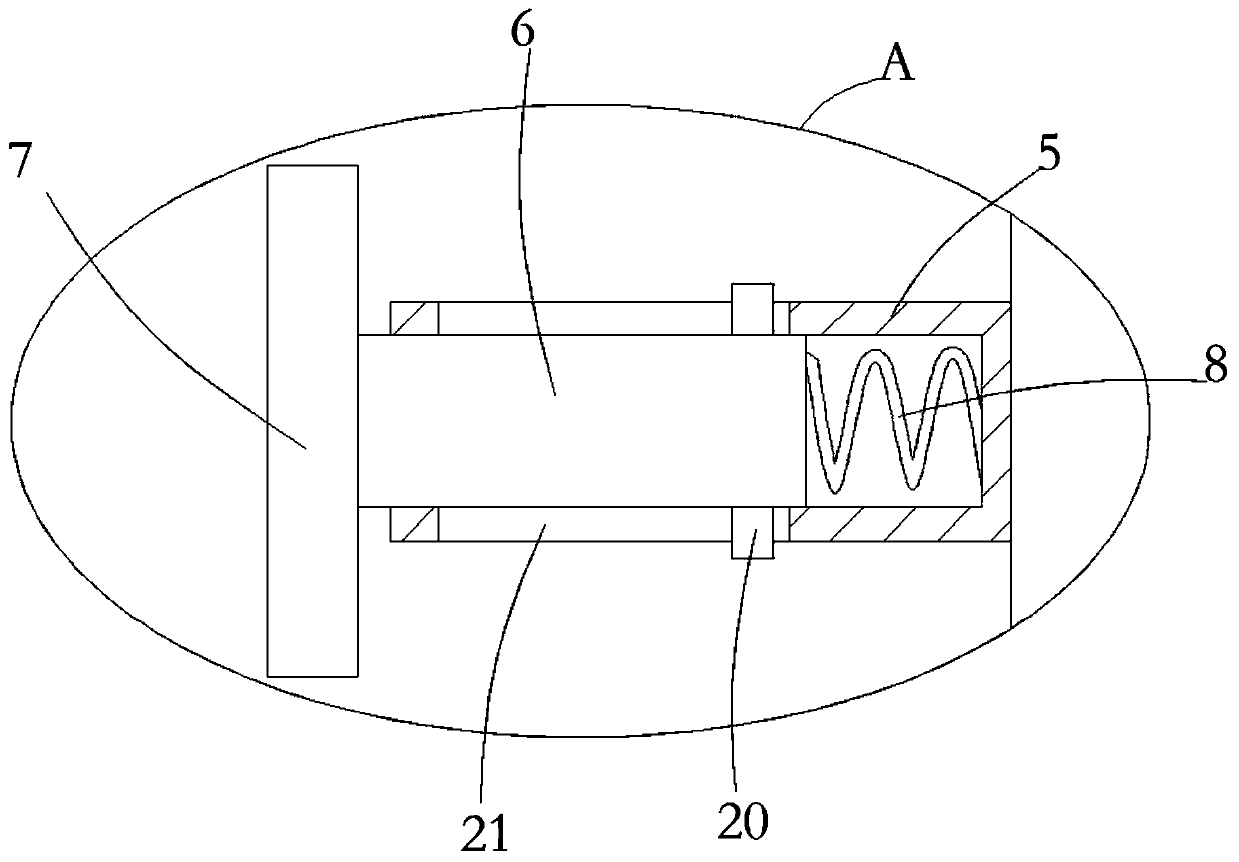

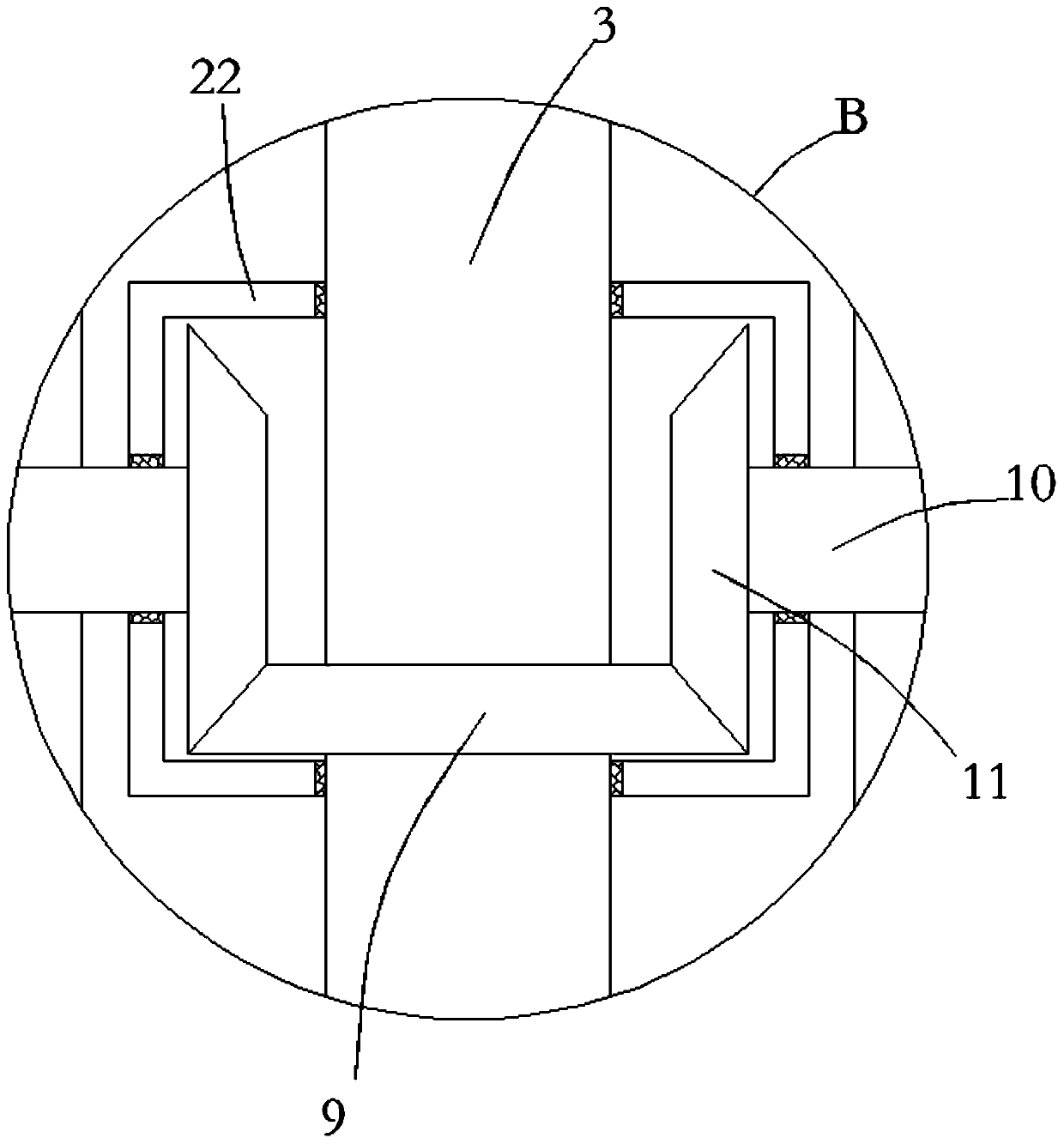

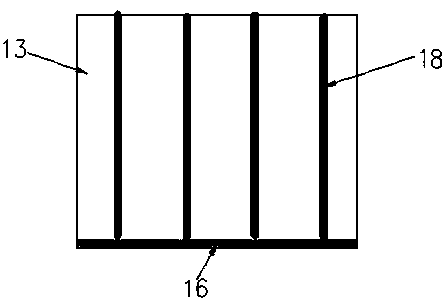

The invention discloses an anode mud cleaning device for electrolytic lead anode plates. The device mainly solves the technical problems of the large device maintenance amount, the low working efficiency, the high cost and the like which are caused by the fact that anode plates can only be cleaned manually or in a semi-mechanized mode in existing electrolytic lead processes. The technical scheme includes that more than two supports (3) in a rectangular frame shape are sleeved inside a box body (1), supports (3) are connected with one another through a crossbeam at the bottom, straight beams on side faces and more than two steel plates to form internal rectangular-frame-shaped cleaning grooves (6), each of scrapers (5) comprises bearing plates (9) and a reversed v-shaped mud scraping body (11), bearing plates (9) are fixedly connected with mud scraping bodies (11), two ends of bearing plates (9) are connected with connecting plates (4), liquid spraying devices are arranged on bearing plates (9), and more than two scrapers (5) are installed on cleaning grooves (6) in a crossing mode. The device can be widely applied to cleaning and collecting processes of anode mud on electrolytic lead anode plates of electrolysis processes.

Owner:湘潭大众整流器制造有限公司

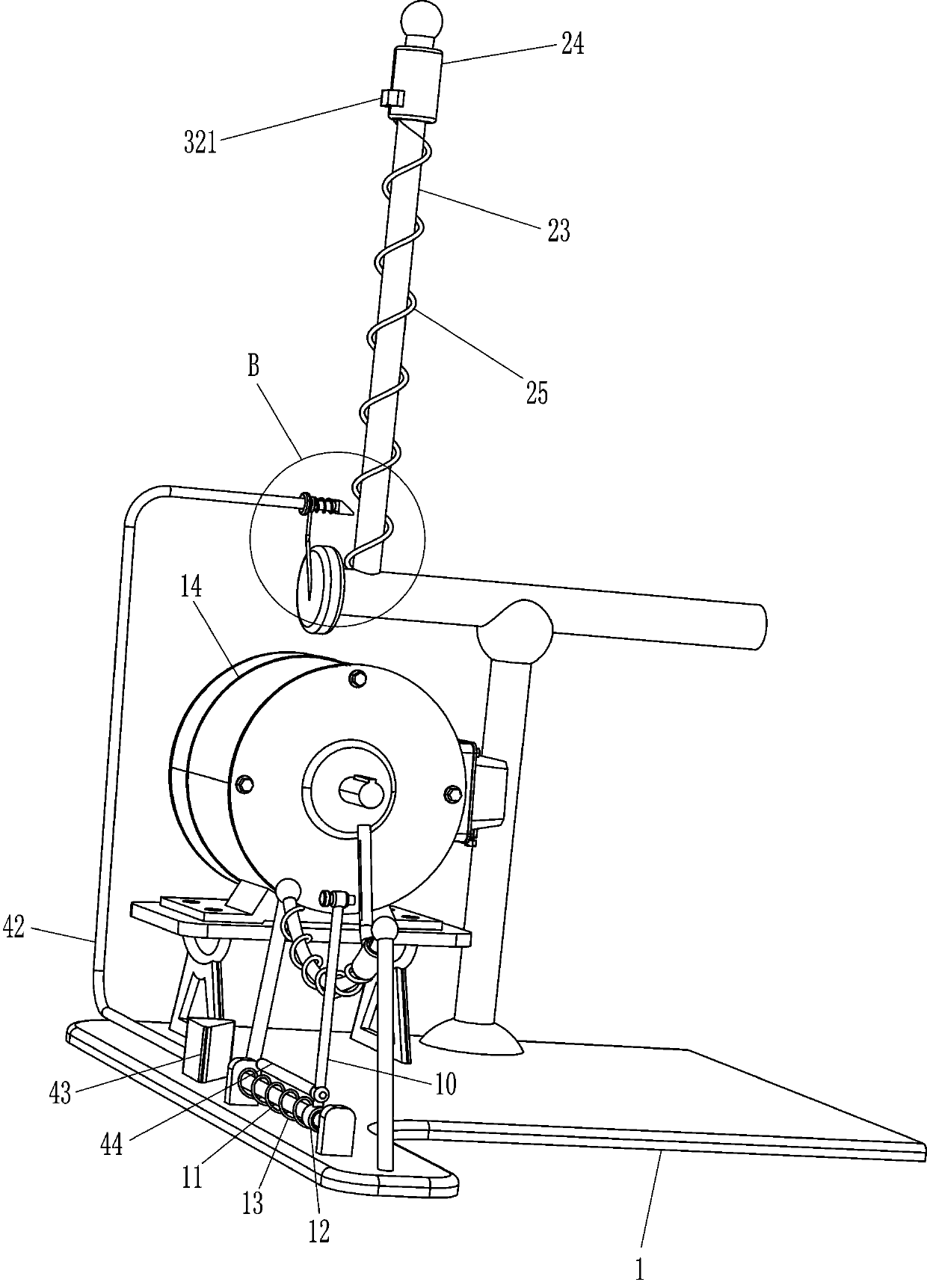

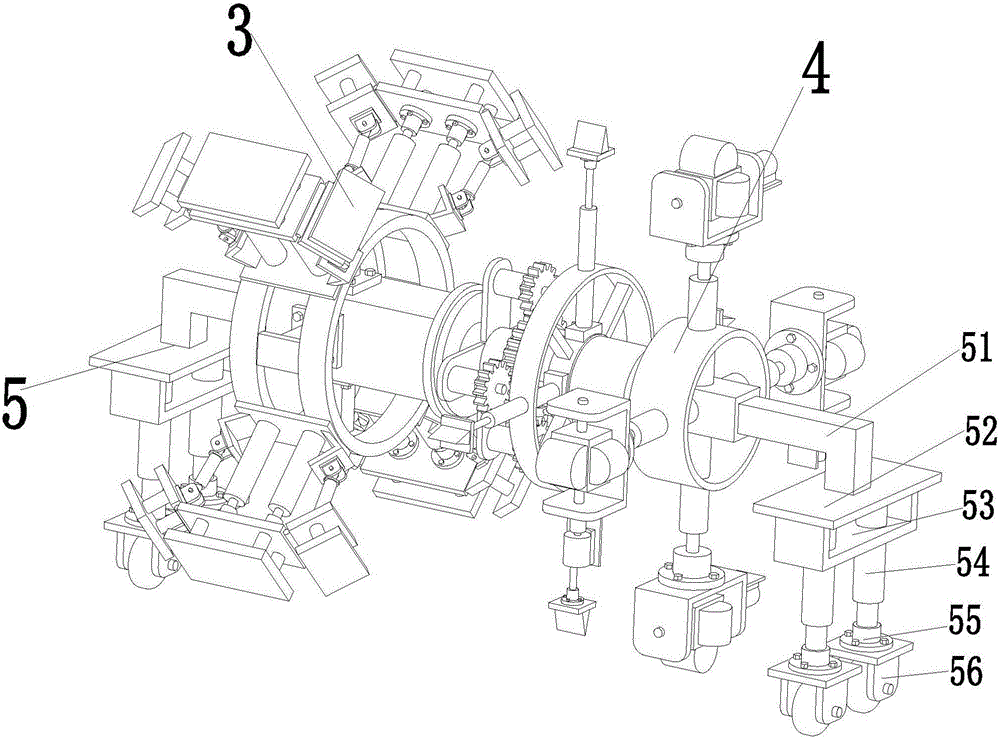

Automatic rust-removing polisher for inner wall of petroleum pipeline

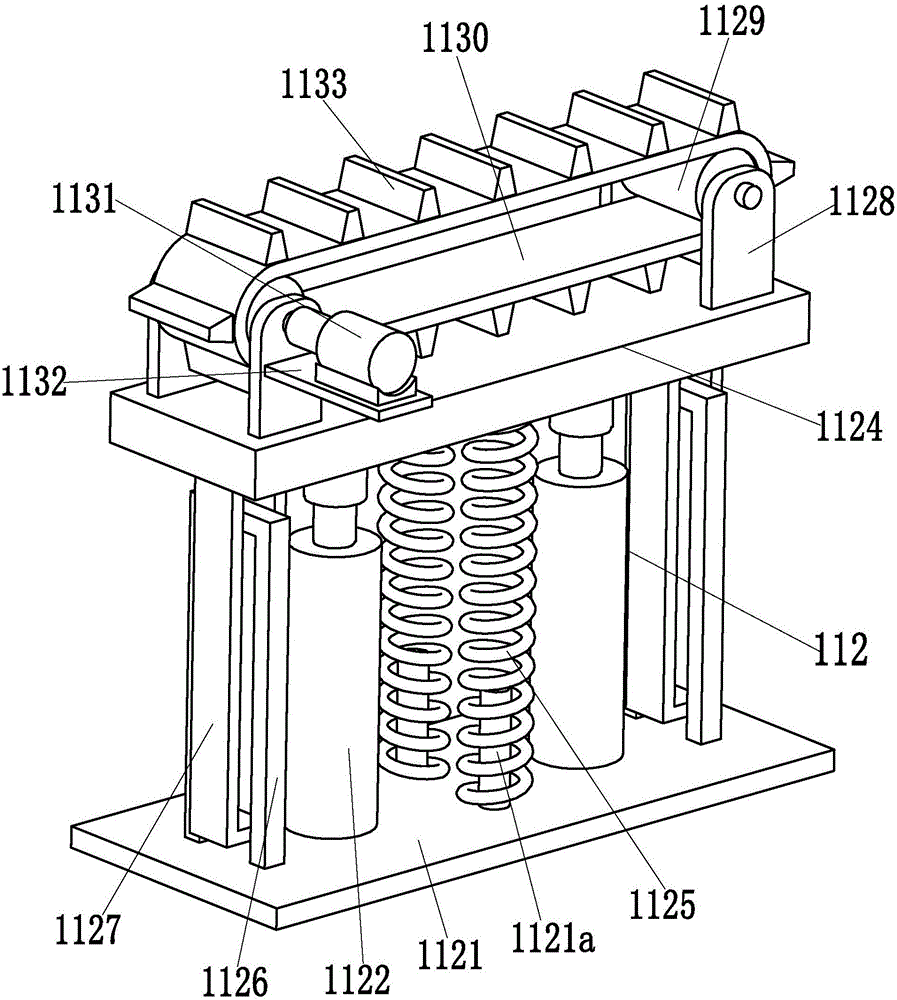

InactiveCN105965364AUniform walking supportGood uniform support performanceGrinding drivesHollow article cleaningRolloverVertical vibration

The invention relates to an automatic rust-removing polisher for the inner wall of a petroleum pipeline. The automatic rust-removing polisher comprises an inner wall automatic walking device which can walk on the inner wall of the pipeline in four directions in a self-stabilization mode, has four kinds of walking support force uniformly distributed and is good in uniform supporting performance and self-stabilization walking performance. Situations including rollover and vertical vibration possibly existing in the walking process are eliminated, an inner wall rust removing device is installed at the right side of the inner wall automatic walking device and can fast scrap impurities on the inner wall of the pipeline, remove rust and polish the inner wall, the rust removing and polishing time is short, and the rust removing and polishing effect is good; the inner wall automatic walking device comprises two inner wall automatic walking branch chains, four connecting rib columns are symmetrically connected between the two inner wall automatic walking branch chains, and two telescopic walking branch chains are symmetrically installed at the lower ends of the two inner wall automatic walking branch chains. The automatic rust-removing polisher can stably scrap the impurities on the inner wall of the pipeline, remove rust and polish the inner wall and is high in working efficiency.

Owner:王雁 +13

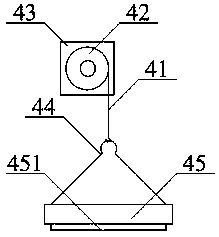

Multi-function mineral resource comprehensive utilization equipment

ActiveCN108554628AHeight adjustableMagnetic selection works smoothlyWithdrawing sample devicesCleaningMineral SourcesEngineering

The invention discloses multi-function mineral resource comprehensive utilization equipment. The multi-function mineral resource comprehensive utilization equipment comprises a first stage bracket, ahorizontal column, a second stage bracket, a strong magnetic separation iron elevator, a sliding tube, an adjusting bolt, a first stage switch, a second stage switch, a third stage switch, an ore-transmitting conveyor, an ore-transmitting hopper, a impunity-removing filter hopper structure, a scraper structure, a sliding block, a sliding groove, a bottom block, a fastening bolt, a ore hauling conveyor and a sampling rod structure. The first stage bracket is longitudinally installed on the lower left portion of the horizontal column in a bolted mode. The second stage bracket is longitudinally installed on the lower right portion of the horizontal column in a bolted mode. The arrangement of a connecting rope with a hook, a winding wheel, a winding motor, a cable and a strong magnetic separation iron plate is conducive to adjusting the height of the strong magnetic separation iron plate according to the magnetic separation demand, so as to facilitate the smooth magnetic separation work; the strong magnetic separation iron plate is made of a round stainless steel plate; and a strong magnetic sheet adopts circular permanent magnet sheet and is conducive to the rapid absorption of iron impurities in the mineral resources, so as to guarantee the purity of the mineral resources.

Owner:滦平县聚源矿业有限责任公司

Photovoltaic panel cleaning tool assembly

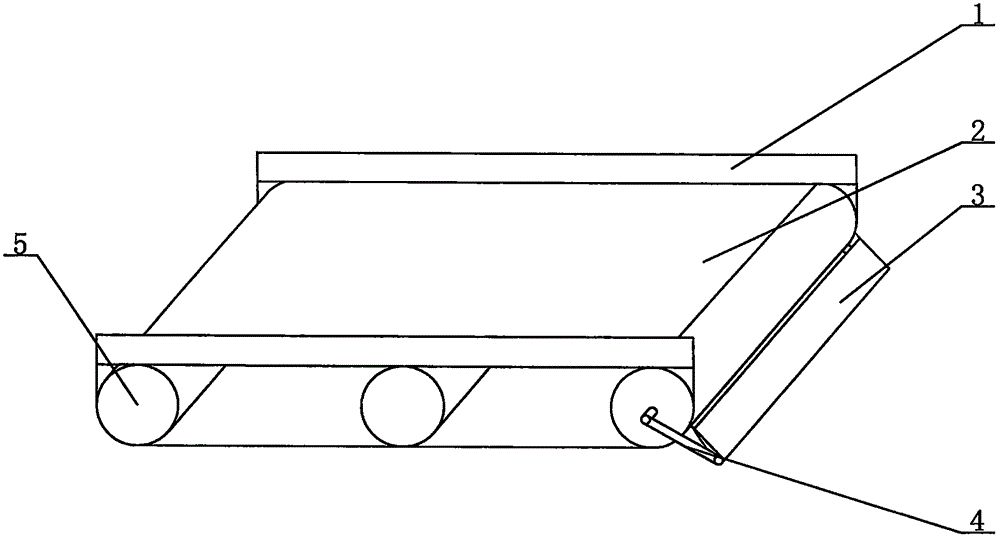

ActiveCN112691959AImprove scraping efficiencyGuaranteed cleanlinessDispersed particle filtrationDrying solid materials without heatPhysicsEngineering

The invention discloses a photovoltaic panel cleaning tool assembly, and relates to the technical field of surface cleaning. The photovoltaic panel cleaning tool assembly comprises a working platform, a conveying belt is rotatably arranged on the working platform, and the working platform is sequentially provided with a glue scraping device, an ash cleaning device, a water spraying device, a water guide device, a drying device and a wiping device in the feeding direction of the conveying belt. The problems that the surface of a photovoltaic panel is prone to cracking due to rigid contact between a glue cleaning part and the surface of the photovoltaic panel in the prior art; a film is adhered to other surfaces of the photovoltaic panel or adhered to the glue cleaning part, so that operators need to clean the film and the glue cleaning part subsequently; the number of times of contact with the surface of the photovoltaic panel is low, so that the wiping effect is common, and a filtering assembly needs to be frequently disassembled and cleaned; cleaning liquid is prone to flowing into all parts of a cleaning tool, and the cleanliness of the working environment is affected; and due to the fact that a drying assembly is low in efficiency, the drying time is prolonged are solved.

Owner:山东瑞智投新能源科技有限公司

Construction site steel pipe surface cleaning equipment

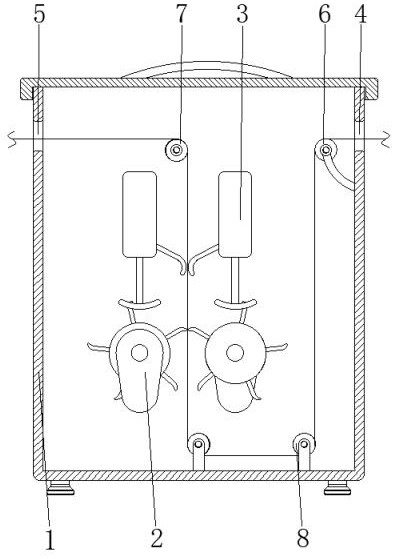

ActiveCN112354979AReduce labor intensityReduce cleanup stepsHollow article cleaningDirt cleaningSurface cleaningPipe

The invention relates to the field of cleaning devices, in particular to construction site steel pipe surface cleaning equipment. The equipment comprises a base and a cleaning box and further comprises a controller, a conveying mechanism, a beating mechanism and a scraping mechanism. The conveying mechanism is arranged at the top of the base to be used for conveying steel pipes and comprises a transmission assembly and two conveying tables. The beating mechanism is arranged at the top of the inner side of the cleaning box and used for beating the steel pipes, the beating mechanism comprises ahammer head and a rotating assembly, the scraping mechanism is arranged at the top of the inner side of the cleaning box and used for scraping impurities such as concrete on the surfaces of the steelpipes, the scraping mechanism comprises a scraping head, a pushing assembly and a limiting assembly, and the transmission assembly is electrically connected with the controller. According to the construction site steel pipe surface cleaning equipment, manpower is automatically replaced, the cleaning efficiency is high, the labor intensity is low, the noise is low, meanwhile, the power consumptionis low, the cleaning cost can be reduced, the cleaned impurities can be effectively collected, and pollution is avoided.

Owner:巢湖市鼎力铁塔有限公司

Cloth cleaning device for textile processing

ActiveCN113584769AAvoid deformationAvoid breakingTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsMechanical engineeringIndustrial engineering

The invention discloses a cloth cleaning device for textile processing. The device comprises a box body, a flexible cleaning device and a water removal device; the flexible cleaning device is arranged in the center of the interior of the box body and close to the bottom; the water removal device is arranged in the box body and located above the flexible cleaning device; a driving roller is rotationally connected between the two corresponding sides of the inner wall of the box body; a cam is arranged at one end of the driving roller; a brush cleaning device is arranged in the driving roller and located at the surface position; and the brush cleaning device is connected with the driving roller in a matched mode. The invention relates to the technical field of textile processing equipment. According to the cloth cleaning device for textile processing, the effects of flexible cleaning and moisture removal are achieved; the cloth can be flexibly cleaned, so that rigid contact is avoided, the cloth is not prone to deformation or damage, and the cleaning efficiency is high; moisture attached to the cloth is removed in time, so that subsequent rapid drying is facilitated; and the safety and reliability are achieved, and the use performance is improved.

Owner:南通刚正纺织品有限公司

Building wall surface waterproof construction device

The invention relates to the field of building equipment, in particular to a building wall surface waterproof construction device. The building wall surface waterproof construction device comprises anold coating scraping mechanism, a painting mechanism, a bearing plate and a lifting mechanism; the bearing plate is of a cuboid structure; the lifting mechanism comprises a lifting block and a lifting assembly; the painting mechanism is arranged on the lower portion of the old coating scraping mechanism; the old coating scraping mechanism comprises a receiving box, a feeding assembly and a knocking assembly; the knocking assembly is arranged on the receiving box; and the painting mechanism comprises two connecting plates which are arranged at the bottom of the lifting block in a spaced mode,a smearing assembly is arranged between the two connecting plates, and four self-locking universal wheels are arranged at the bottom of the bearing plate. The building wall surface waterproof construction device has the beneficial effects that old coating can be quickly removed through the old coating scraping mechanism, extra tools for removing the oil coating does not need to be carried, waterproof paint can be smeared on the wall surface firstly through the painting mechanism, then the coating is smeared, material changing and cleaning are not needed in the process, and thus the workload ofworkers is reduced.

Owner:华安检测集团有限公司

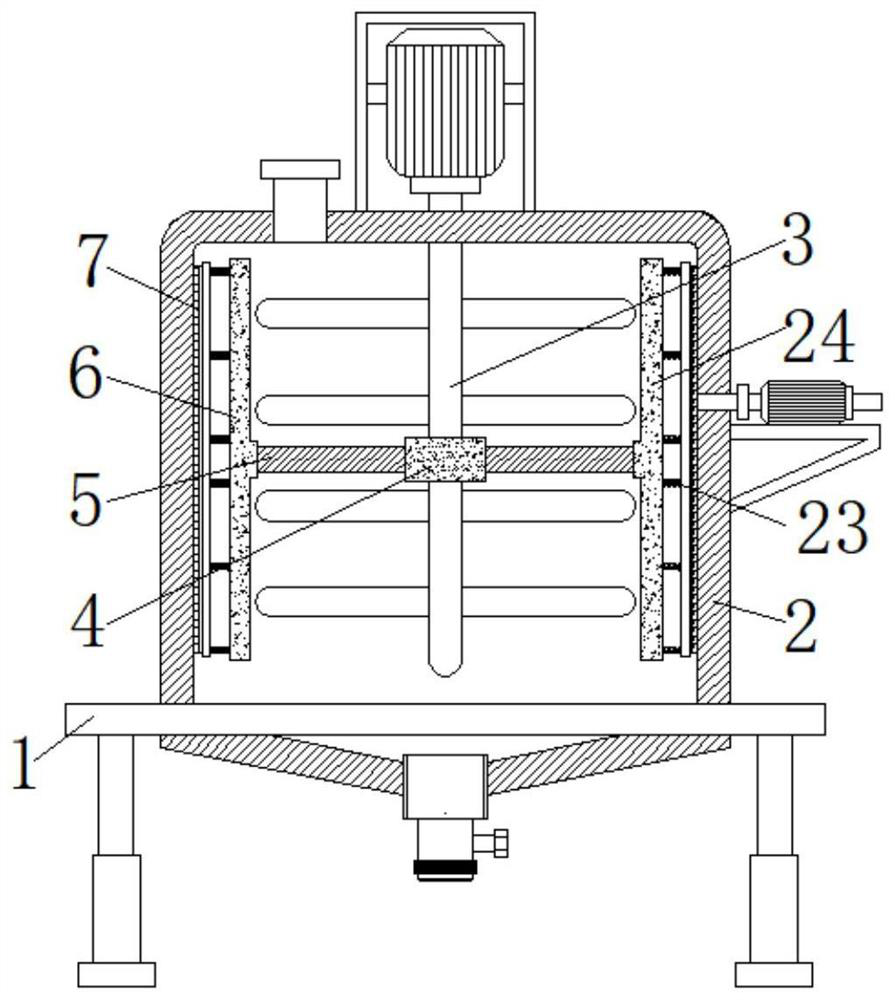

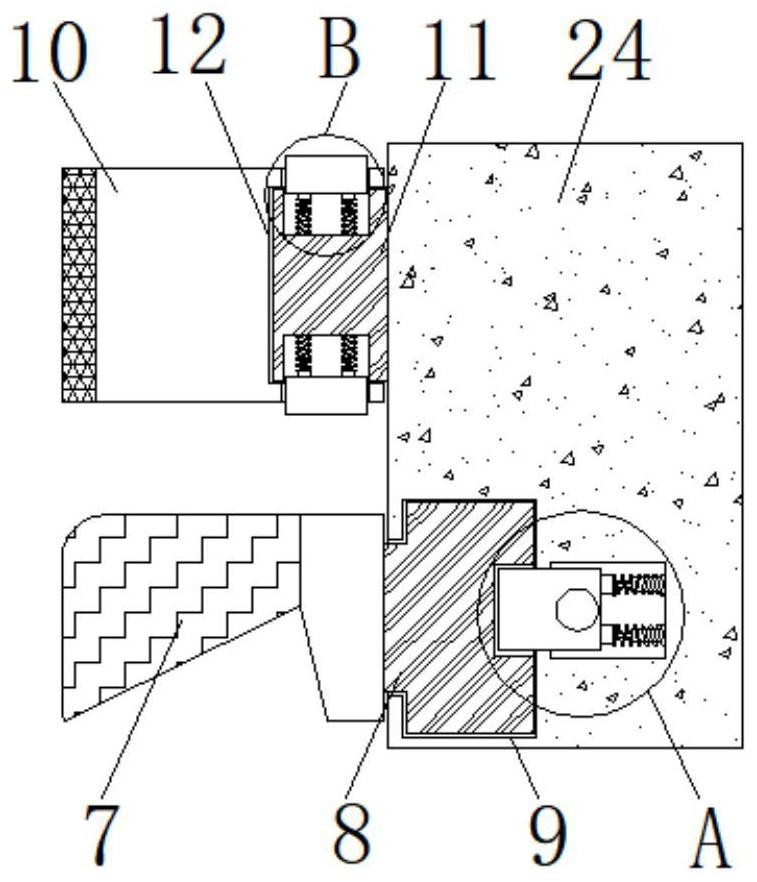

Polycarboxylate water reducing agent production device having reverse mixing and stirring function

InactiveCN110935377AWith reverse mixing functionIncrease production capacityRotary stirring mixersTransportation and packagingBall bearingElectric machine

The invention relates to the technical field of production of a polycarboxylate water reducing agent and discloses a polycarboxylate water reducing agent production device having reverse mixing and stirring function. The device includes a pedestal, wherein a plurality of stirring boxes are uniformly fixed to the upper end of the pedestal and are arranged annularly. The upper end of each stirring box has an opening structure, wherein a first stirring rod is rotatably connected to the center of the bottom inner wall of each stirring box through a ball bearing; a driving motor is connected fixedly to the bottom of each stirring box; the outlet shaft on the upper end of each driving motor penetrates through the bottom of each stirring box and is fixedly connected to the lower end of each firststirring rod; a plurality of fixed barrels are uniformly fixedly connected to the upper rod wall of the first stirring rods; one end, far away from the first stirring rod, of each fixed barrel has anopening structure; an extension rod is movably connected in each fixed barrel in a sleeving manner. The device can form reverse stirring, so that materials are mixed more completely, and production of the polycarboxylate water reducing agent can be accelerated.

Owner:徐州巨龙新材料科技有限公司

Bamboo joint skin scraping device

InactiveCN111283835AQuick placementQuick take outTree debarkingCane mechanical workingElectric machineryEngineering

The invention relates to a skin scraping device, in particular to a bamboo joint skin scraping device. The technical problem to be solved by the invention is to provide the bamboo joint skin scrapingdevice capable of automatically scraping bamboo joints, reducing the safety risk and improving the working efficiency. The bamboo joint skin scraping device comprises a mounting frame, a first arc-shaped clamping plate, a second arc-shaped clamping plate, a discharging and blanking assembly, a pushing assembly, a skin scraping assembly, a sliding assembly, a fixing assembly, a pulling assembly andthe like; and a first arc-shaped clamping plate is arranged at the top of the mounting frame, and a second arc-shaped clamping plate is rotationally arranged on the first arc-shaped clamping plate. According to the bamboo joint skin scraping device, through cooperation of the second arc-shaped clamping plate and a first connecting rod, bamboo joints can be rapidly placed and taken out, manual knee jacking is not needed, through cooperation of a gear motor and a scraper, the bamboo joints can be rapidly scraped, and the working efficiency is improved; and through cooperation of a second sliding rod and a first wedge-shaped block, a fourth sliding sleeve can be rapidly fixed, and preparation before scraping is made.

Owner:重庆市奉节县竹轩农业开发有限公司

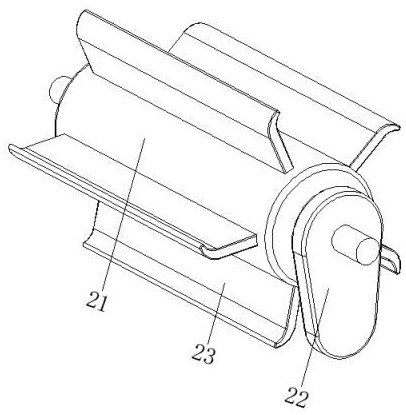

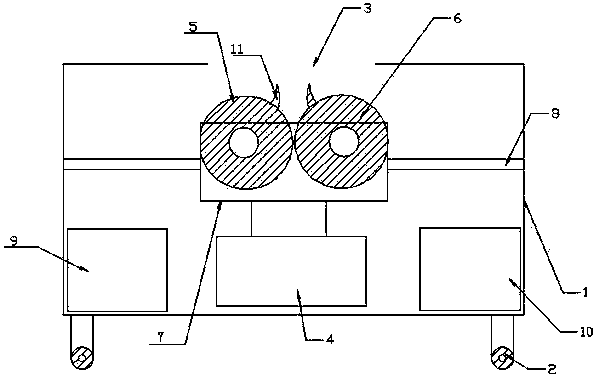

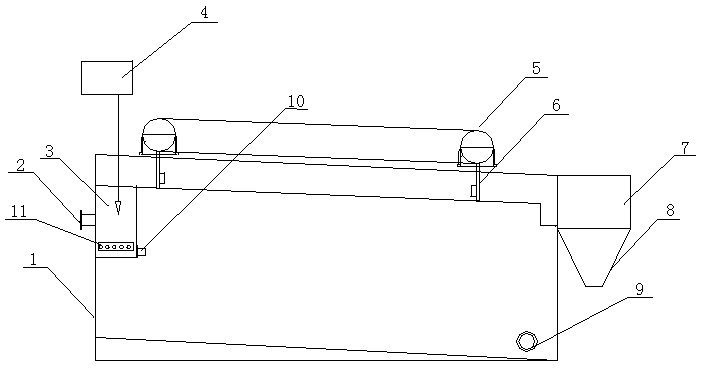

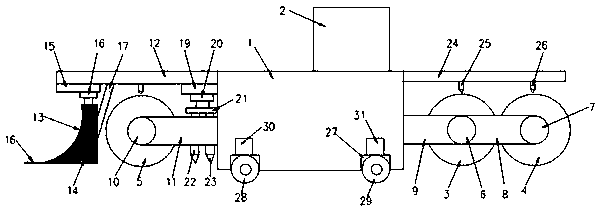

Rapid and effective brushing machine for knitwear

InactiveCN104213390AQuick scrapeFast extract processingMechanical cleaningPressure cleaningBrush toothGear drive

The invention belongs to the technical field of clothes production machinery, and particularly discloses a rapid and effective brushing machine for knitwear. The rapid and effective brushing machine comprises a rectangular frame, universal wheels, a feed inlet, a drive motor, a first rotary brush roll, a second rotary brush roll, a gearbox and brush teeth. The universal wheels and the feed inlet are respectively arranged on the rectangular frame; the drive motor, the first rotary brush roll, the second rotary brush roll and the gearbox are arranged inside the rectangular frame; the drive motor is connected with the first rotary brush roll and the second rotary brush roll through the gearbox; and the brush teeth are respectively arranged on the first rotary brush teeth and the second rotary brush teeth. The drive motor and the gearbox drives the first rotary brush roll and the second rotary brush roll to do different-way engagement motion; the flexible brush teeth scrapes chips rapidly; thus work efficiency is high. A stop plate can effectively prevent the scraped chips from being carried to the outside of the rectangular frame by the first rotary brush roll and the second rotary brush roll, so that the whole process is environmental friendly and free of pollution. Dual centrifugal suction machines remove the chips rapidly to prevent the same flying anywhere, so that normal production efficiency is guaranteed.

Owner:TAICANG SHUNFENG SPORTS

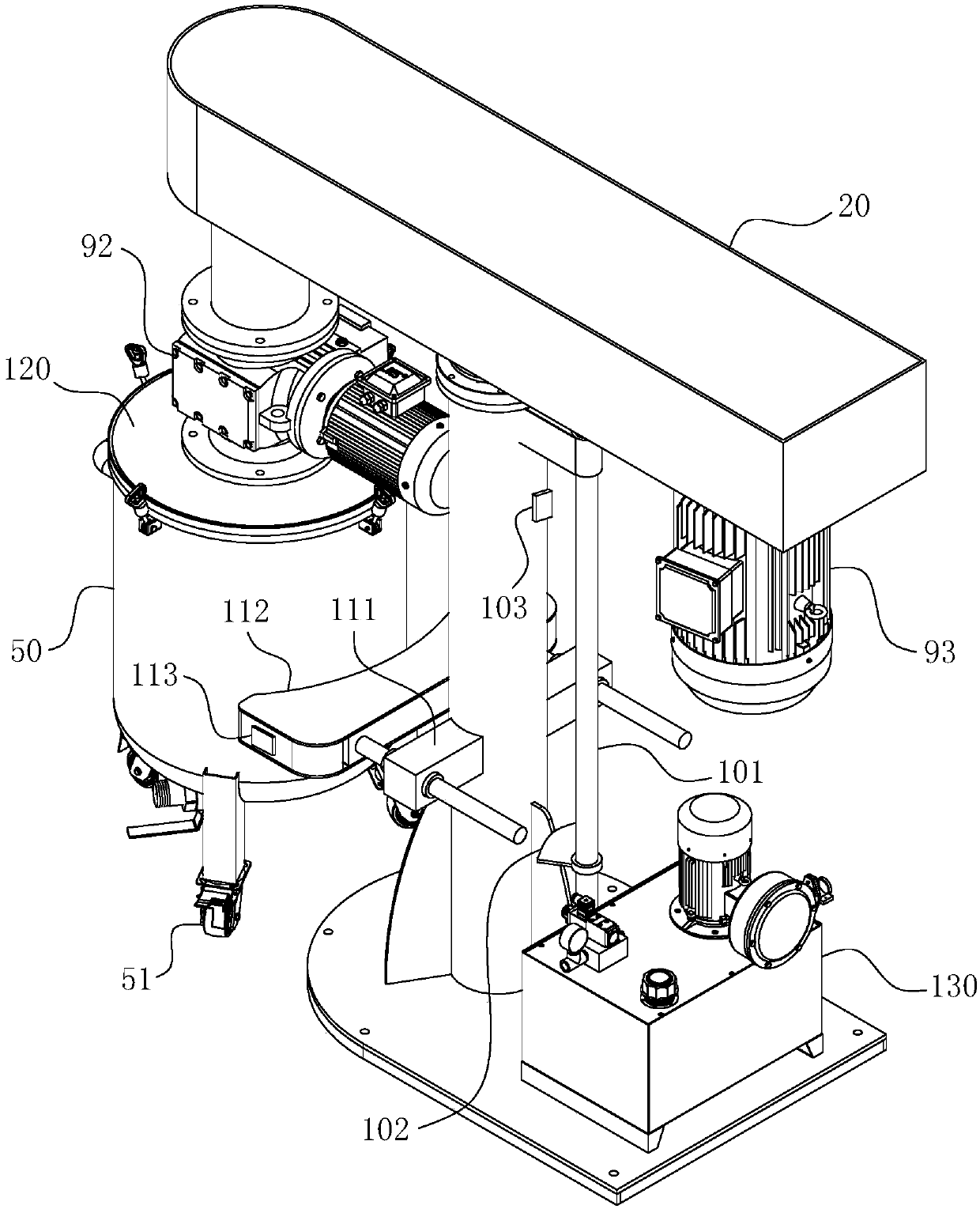

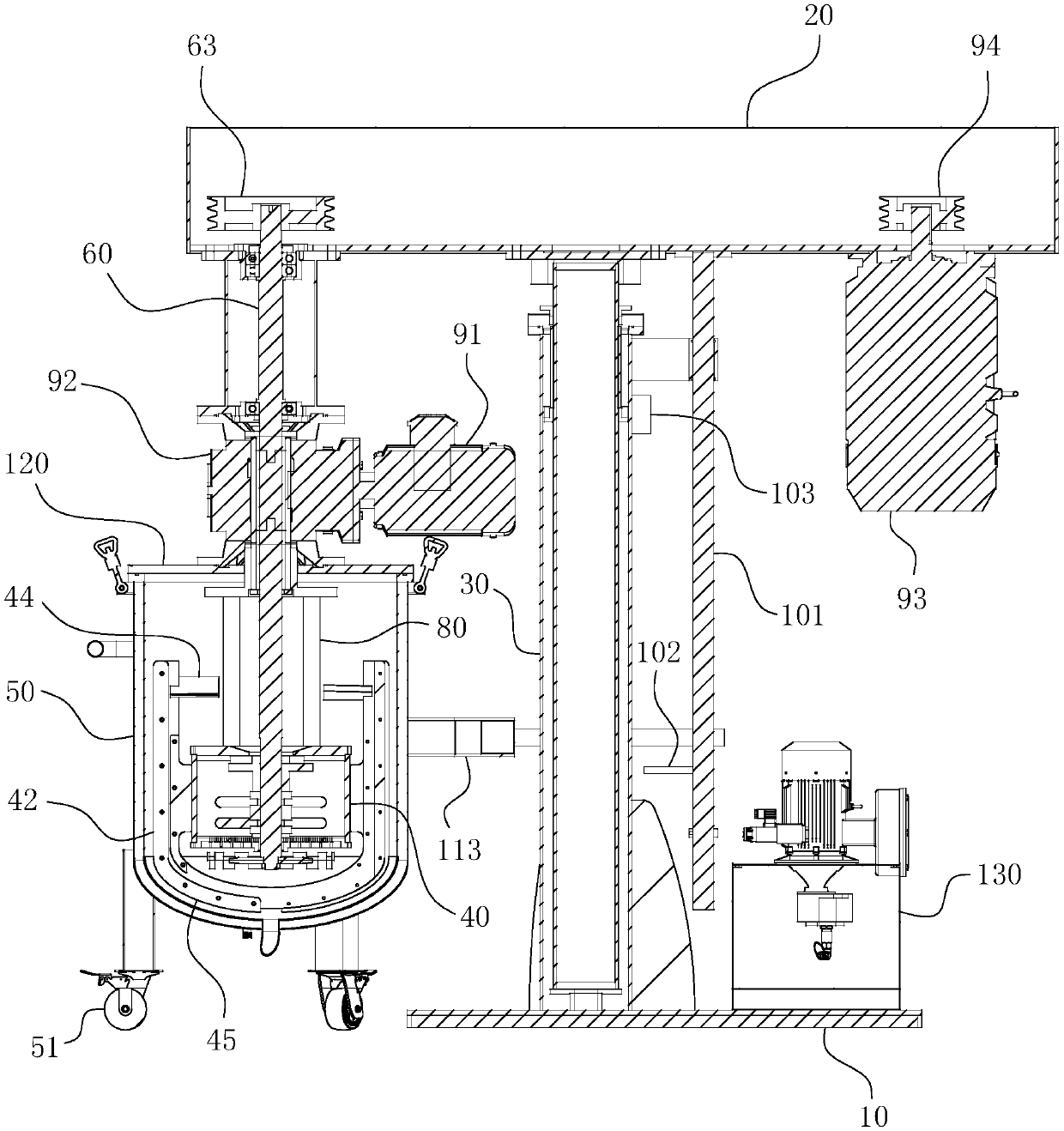

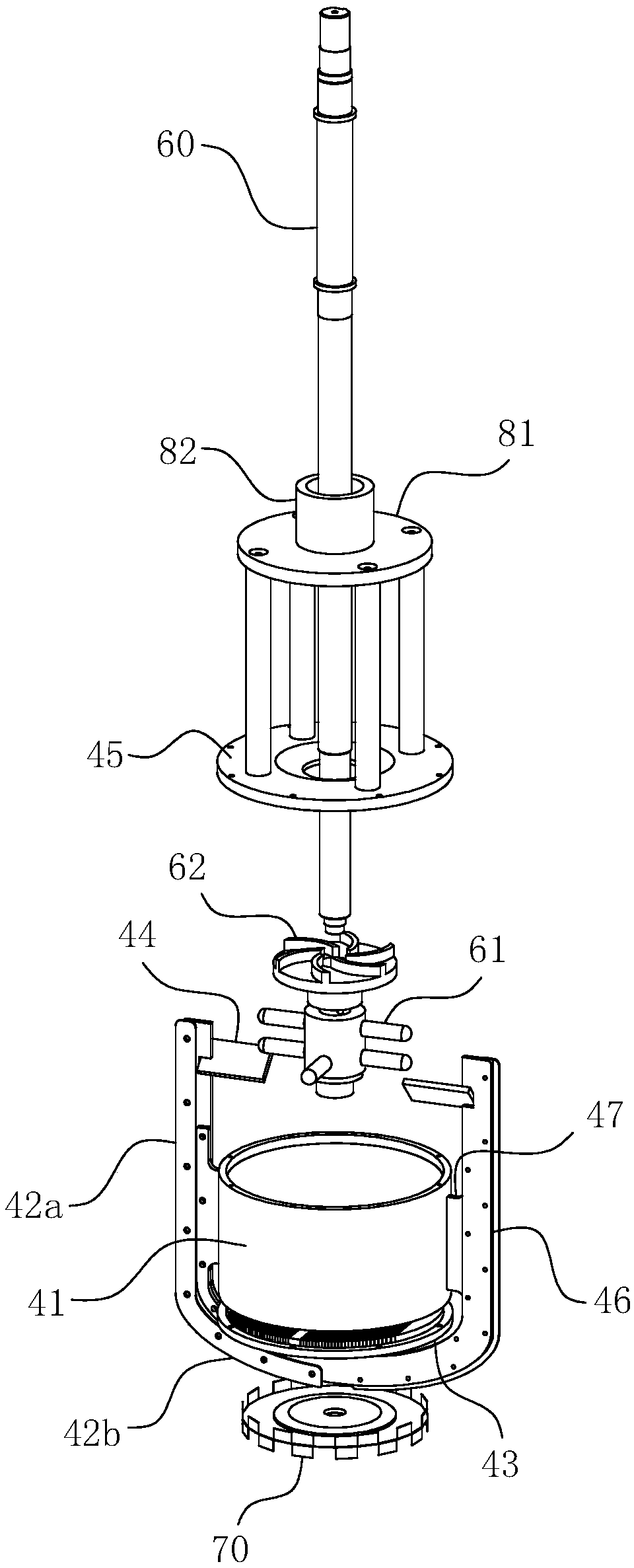

Concentric double-axis vacuum hydraulic basket grinding machine

ActiveCN109590078AEfficient mixingEfficient grindingGrain treatmentsCantileverMechanical engineering

The invention belongs to the field of grinding equipment, in particular to a concentric double-axis vacuum hydraulic basket grinding machine. The grinding machine comprises a base, a frame, a liftingassembly, a grinding basket and a cylinder. The grinding basket comprises a cylinder body, an end cap and a filter plate. The end cap and the filter plate are vertically coaxially penetrated by a stirring shaft and the stirring shaft is respectively rotatably matched with the end cap and the filter plate. A basket support is coaxially arranged with the stirring shaft but dose not interfere the stirring shaft. The top end of the basket support is matched with the output end of a second power source, and the bottom end of the basket support is coaxially fixed at the end cap for driving the grinding basket to produce a coaxial rotating action opposite to the turning direction of the stirring shaft. A cantilever extends radially outwardly at the outer wall of the grinding basket, and the extending end of the cantilever arm is fixedly connected with a scraper for scraping the attachment at the wall of a cylinder chamber. The invention has the advantages of high grinding efficiency, good stirring effect, good product fineness, convenient and reliable operation.

Owner:费曹民

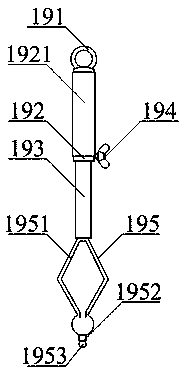

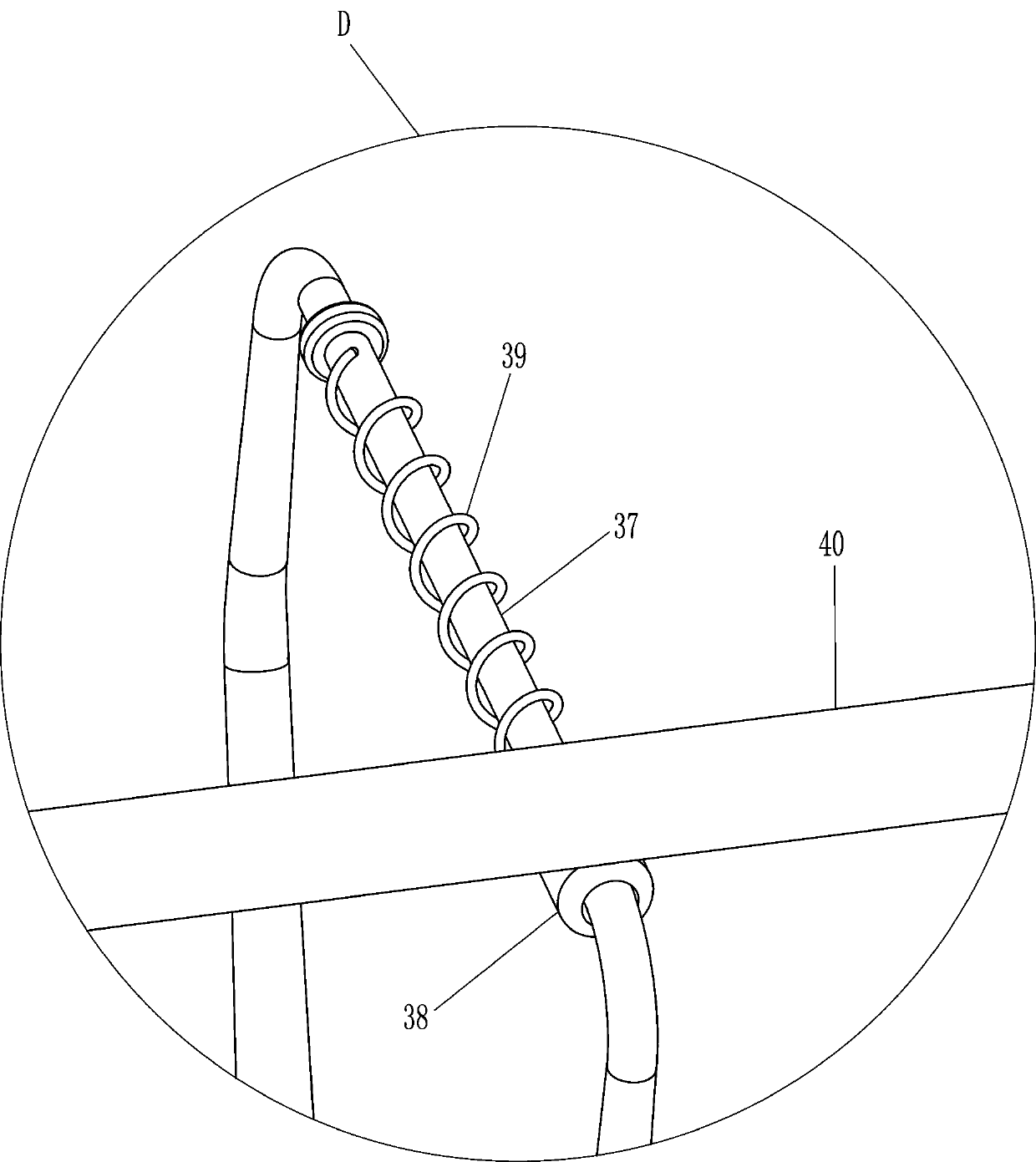

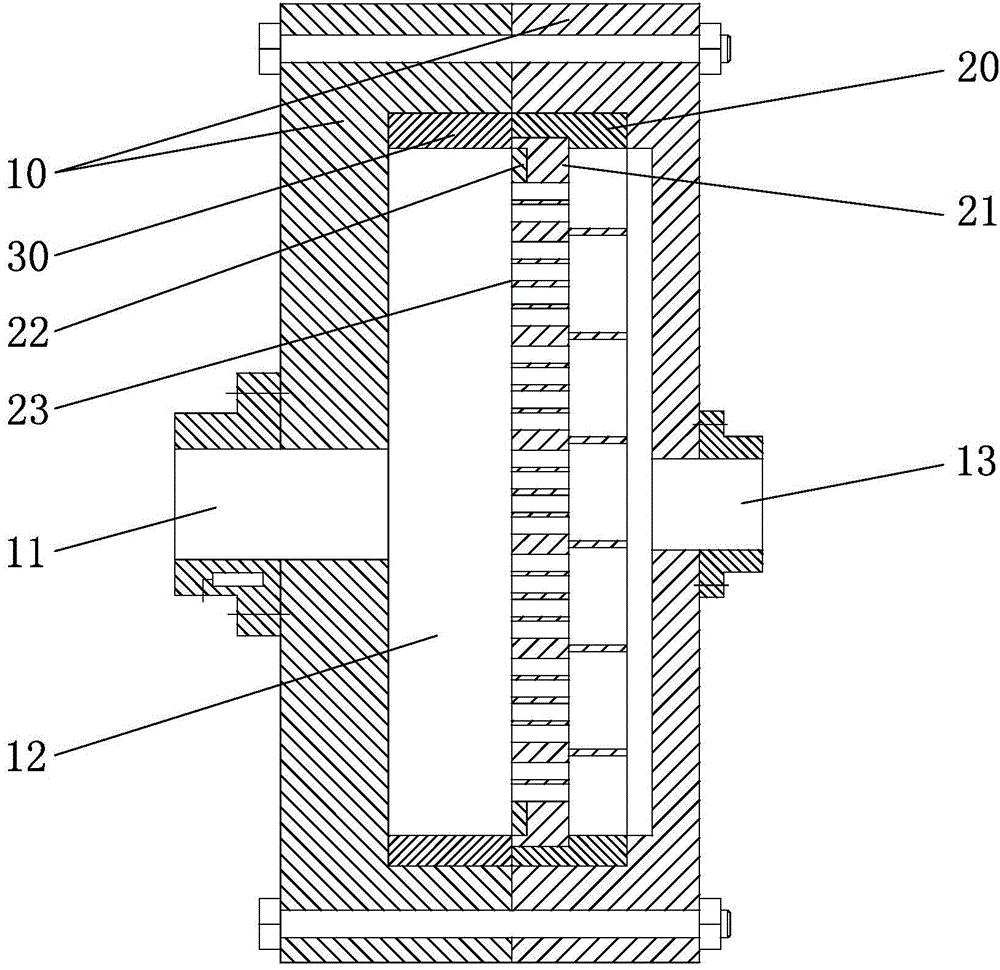

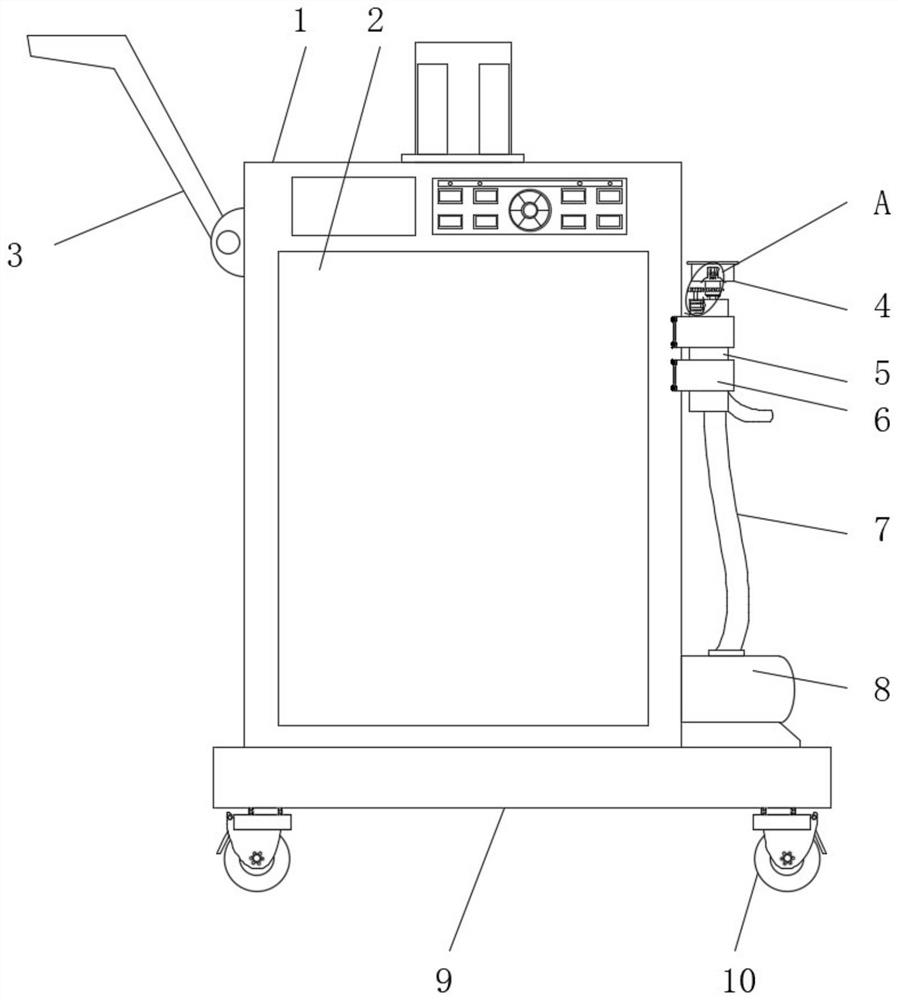

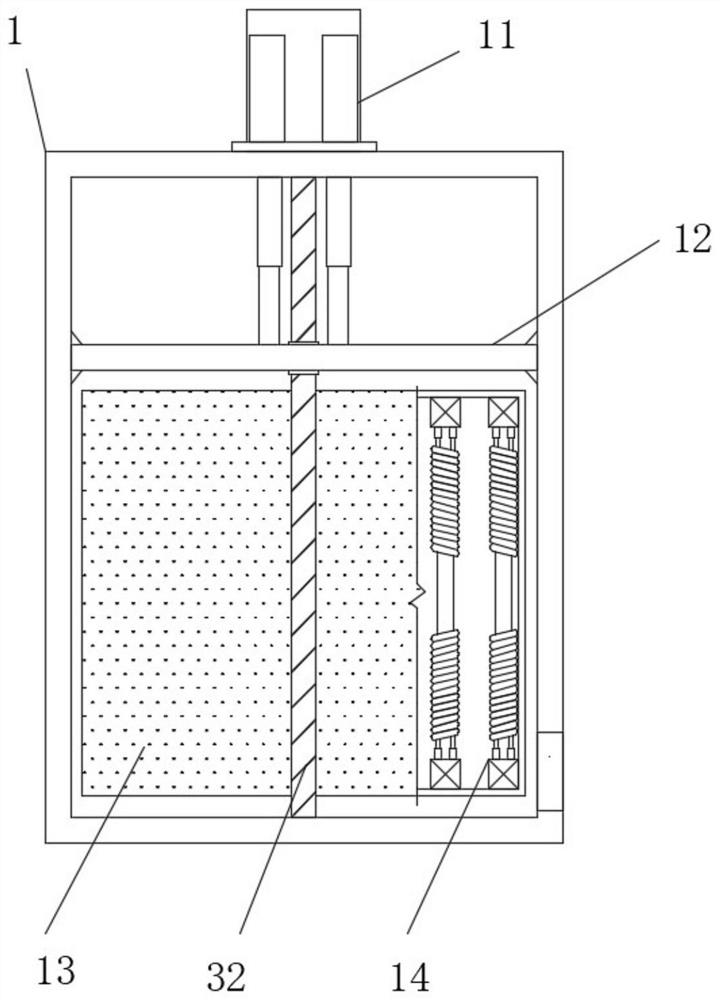

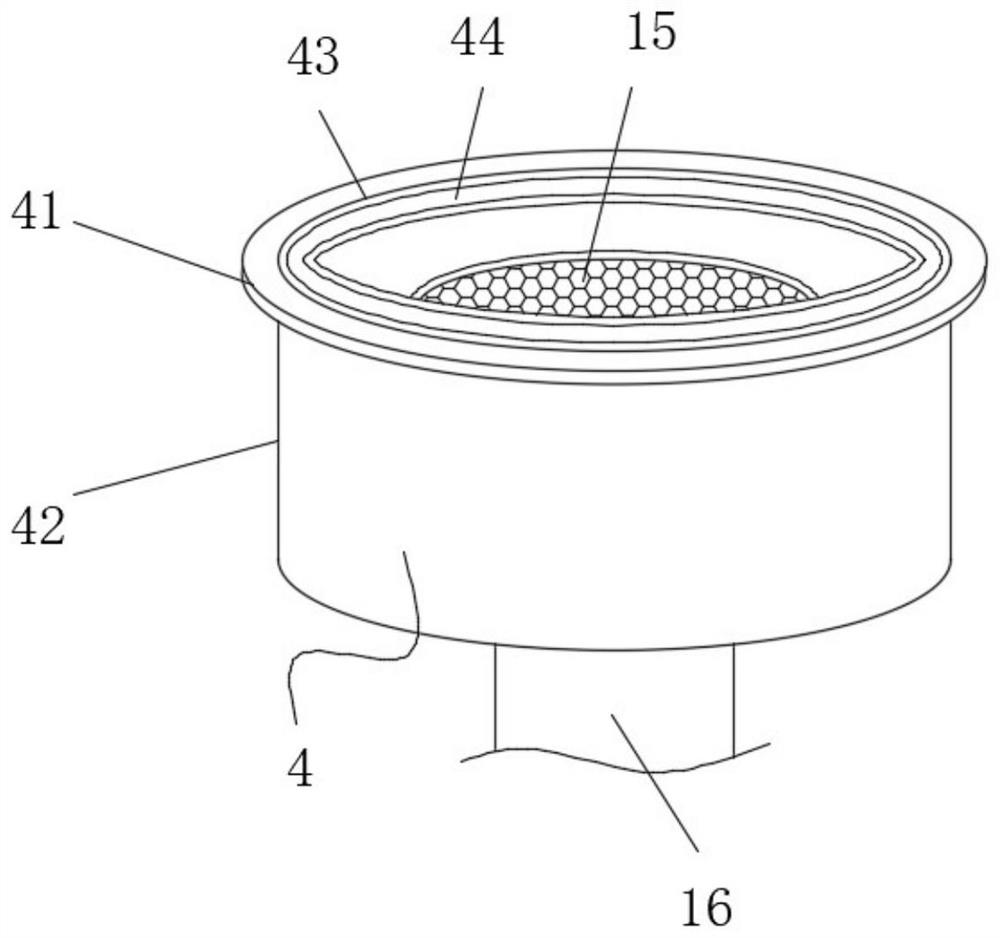

Intelligent drying and rust removing all-in-one machine used for inner wall of oil pipeline

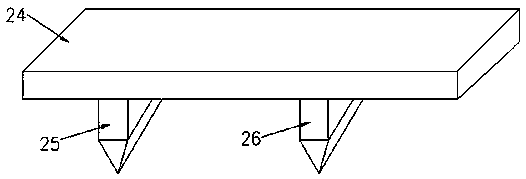

The invention relates to an intelligent drying and rust removing all-in-one machine used for the inner wall of an oil pipeline. The intelligent drying and rust removing all-in-one machine comprises an inner wall drying device. The inner wall drying device can achieve the fast drying function of the pipeline inner wall. Local fast drying can be performed according to the practical situation of the pipeline inner wall, and the applied range is wide. An inner wall rust removing device is installed at the right side of the inner wall drying device. The inner wall rust removing device can achieve the functions of fast impurity scraping and rust removal polishing on the pipeline inner wall. Travelling branched chains are welded to the left end of the inner wall drying device and the right end of the inner wall rust removing device correspondingly. The intelligent drying and rust removing all-in-one machine can walk on the pipeline inner wall through the two travelling branched chains. The two travelling branched chains comprise L-shaped travelling support pillars. The two L-shaped travelling support pillars on the two travelling branched chains are welded to the inner wall drying device and the inner wall rust removing device correspondingly. Travelling base plates are welded to the tail ends of the L-shaped travelling support pillars. According to the intelligent drying and rust removing all-in-one machine, the continuous and stable rust removing and drying functions of the oil pipeline inner wall can be achieved, the treatment speed of the pipeline inner wall is high, and treatment efficiency of the pipeline inner wall is also high.

Owner:DAQING CITY HUAYU PETROLEUM MASCH MFG CO LTD

Lithium-ion battery slurrying and mixing plate

InactiveCN109078541AAchieving mixing and stirringWell mixedTransportation and packagingRotary stirring mixersSlurryEngineering

The invention discloses a lithium-ion battery slurrying and mixing plate, and belongs to the technical field of battery production equipment. The problems that slurry is quite high in viscosity, and is easily attached to side walls, so that a mixing plate is difficult to clean are solved. The lithium-ion battery slurrying and mixing plate is technically characterized by comprising a battery slurrystirring structure, and further comprises a shell, a stirring cavity and scraping assemblies, wherein a stirring cavity is formed in the shell; a flow guiding plate is obliquely arranged on the bottom of the stirring cavity, a discharging opening is formed in the position, which is in contact with the right side wall of the shell, of the right end of the flow guiding plate, a supporting cross plate is vertically arranged on the top of the stirring cavity, a feeding opening is formed in the position, which is in contact with the side wall of the shell, of the left end of the supporting cross plate, the feeding opening communicates with the stirring cavity, and the scraping assemblies are symmetrically arranged on the two sides of the stirring cavity. Residual slurry of the inner wall of the shell can be scraped off, meanwhile, it can be ensured that the slurry is mixed uniformly and fully, the work load of people is greatly relieved, and the quality of produced lithium batteries is also ensured.

Owner:山东天瀚新能源科技有限公司

Quick foreign matter remover

ActiveCN104526908AOutstanding and Beneficial Technical EffectsIncrease productivityCleaning using toolsForeign matterFilter effect

The invention belongs to the technical field of a filtering device and relates to a quick foreign matter remover. The quick foreign matter remover is characterized in that a horizontal material collecting cavity is arranged in the middle of a shell; the front side and the rear side of the middle of the shell are respectively provided with a feeding opening and a discharging opening; the material collecting cavity is internally provided with a power device for driving a frame horizontally sliding; filtering nets are arranged in two small frames which are horizontally arranged in the frame in parallel; when the small frames are arranged at the central position of the material collecting cavity, the periphery of the small frame in the middle is connected with the shell in a sealing manner; the front side and the rear side of the filtering net on each small frame are respectively communicated with the feeding opening and the discharging opening; the upper end of each small frame is provided with a foreign matter scraper which is driven to slide up and down and scrape foreign matters by the power device; or groove holes formed in the two sides of the shell and the upper part of the material collecting cavity are internally provided with foreign matter scrapers which are driven to slide up and down by the power device. The quick foreign matter remover has the advantages that the filtering effect is good, and the foreign matter removal without stoppage can be realized, so that the quick foreign matter remover is applicable to various specifications and types of reclaimed plastic granulators.

Owner:陈艳

Oily waste water treatment system

InactiveCN107285429AIncomplete cleaningEasy to handleFatty/oily/floating substances removal devicesTreatment involving filtrationFailure rateWater treatment system

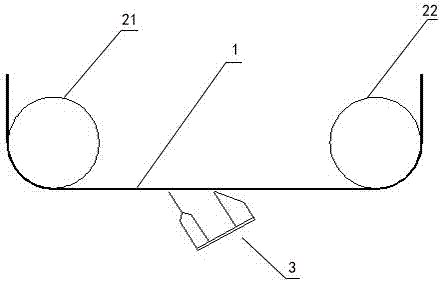

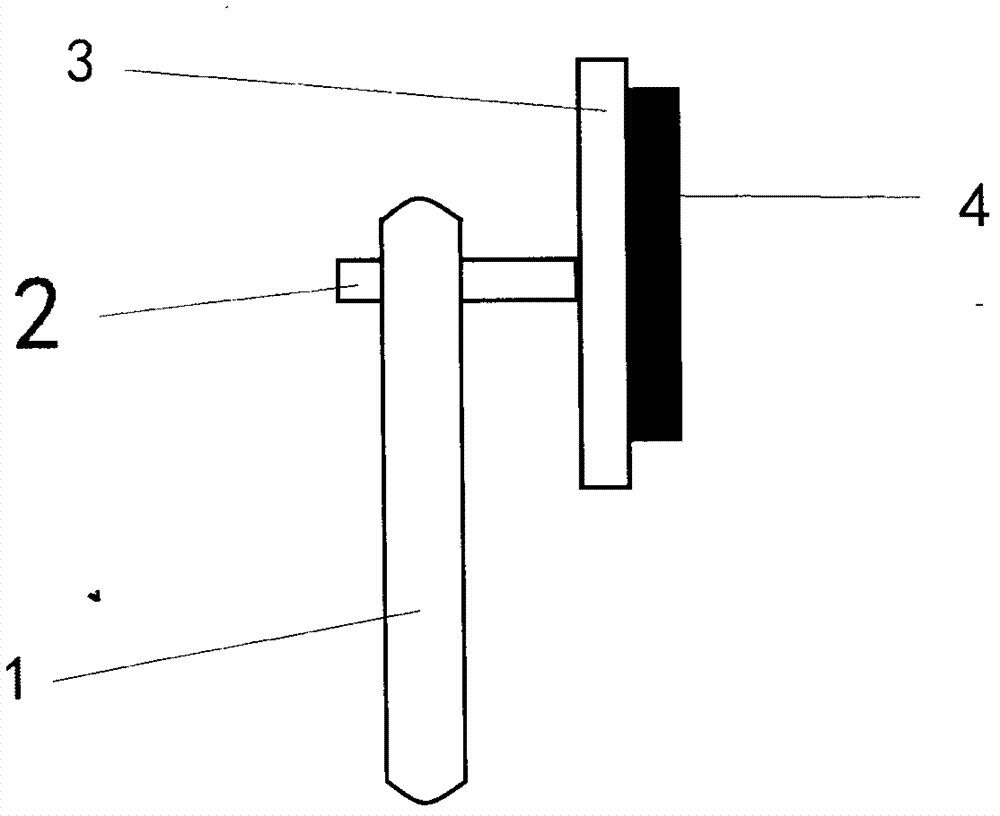

The present invention provides an oily wastewater treatment system, which comprises a round roller 1, a motor, a round roller 2, a transmission belt, a fixed plate 1, an oil scraper, a fixed plate 2 and a collection box. The rear end of the round roller 1 is assembled on the The upper position of the front end surface of the vertical plate, the motor is installed at the upper position of the front end surface of the second vertical plate, and the first round roller is connected with the second round roller through a transmission belt. This design realizes the purpose of automatically adjusting the tension of the conveyor belt in the present invention. The collection box is arranged on the lower side of the oil scraper, the first fixed plate is installed on the right end surface of the vertical plate one, the second fixed plate is installed on the right end surface of the vertical plate two, the rear side of the lower end surface of the oil scraper is connected with the fixed plate The upper surface of the first end fits together, and the front side of the lower end of the oil scraper is attached to the upper end face of the second fixed plate. This design increases the sterilization function of the present invention. The present invention has high working efficiency, small footprint, low failure rate, and high stability. Well, high reliability.

Owner:惠天昱

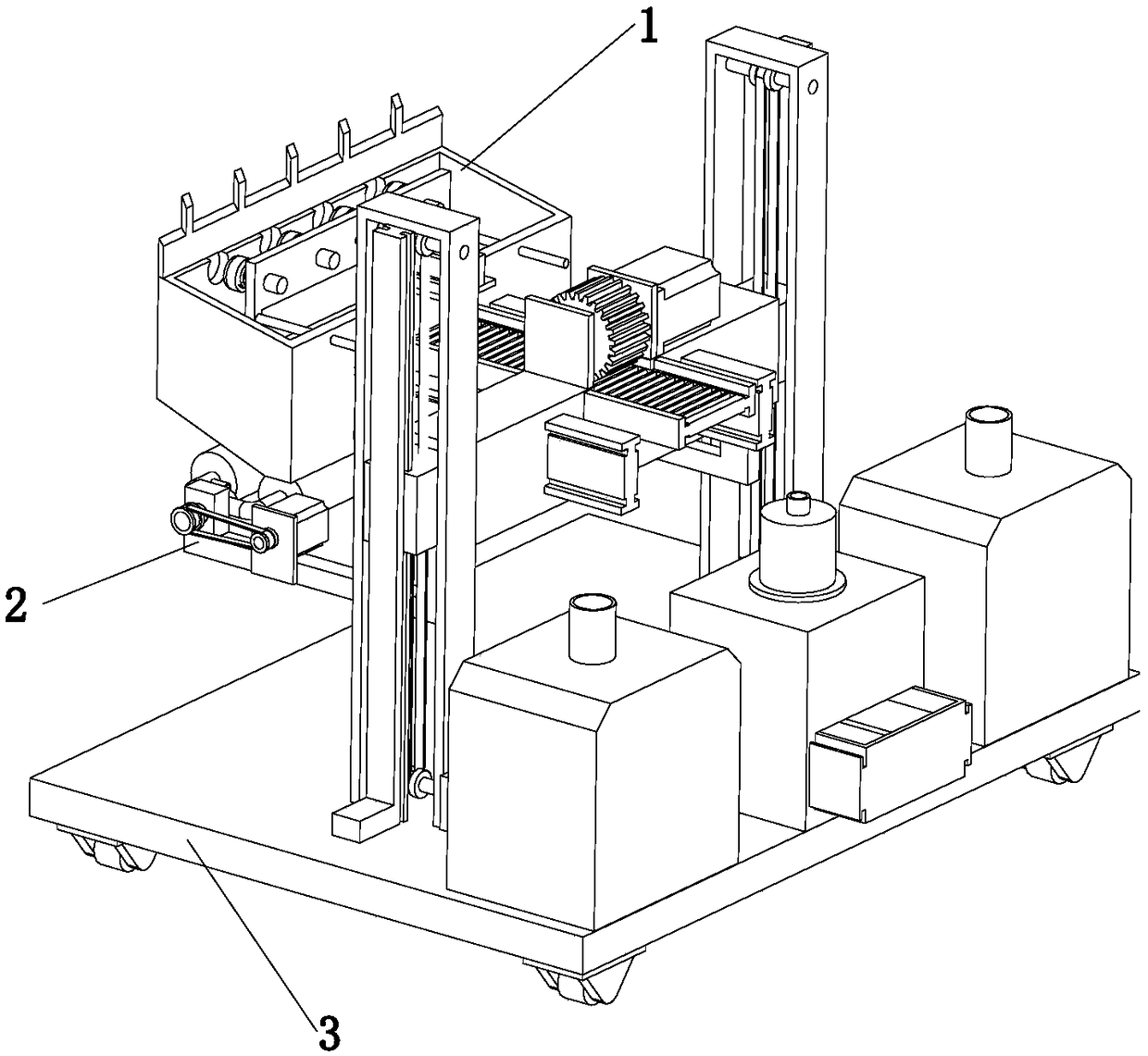

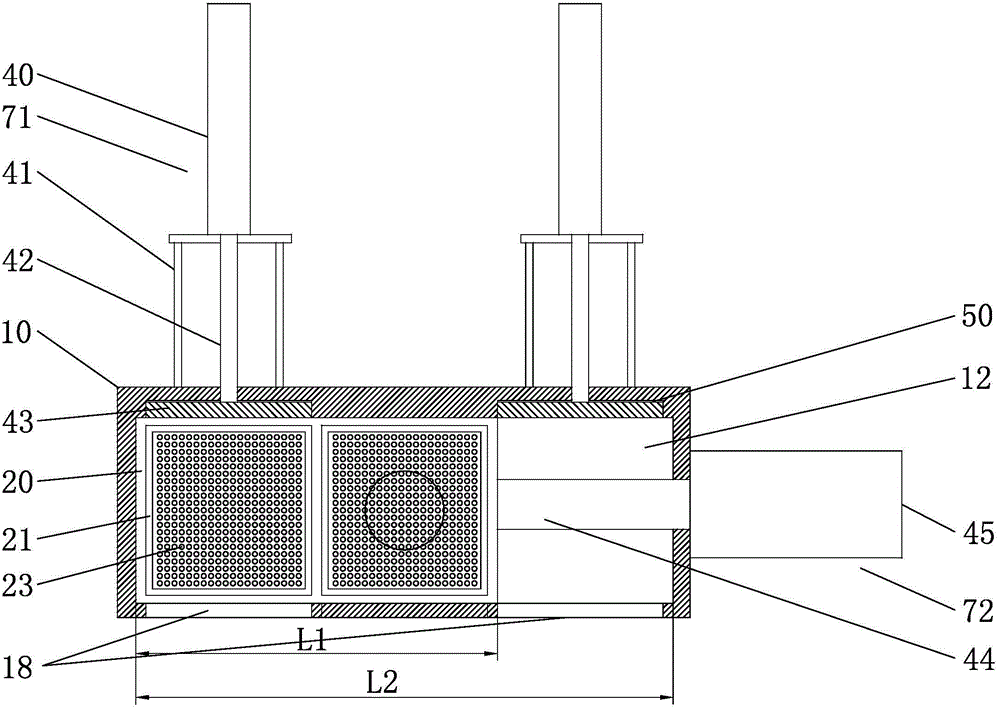

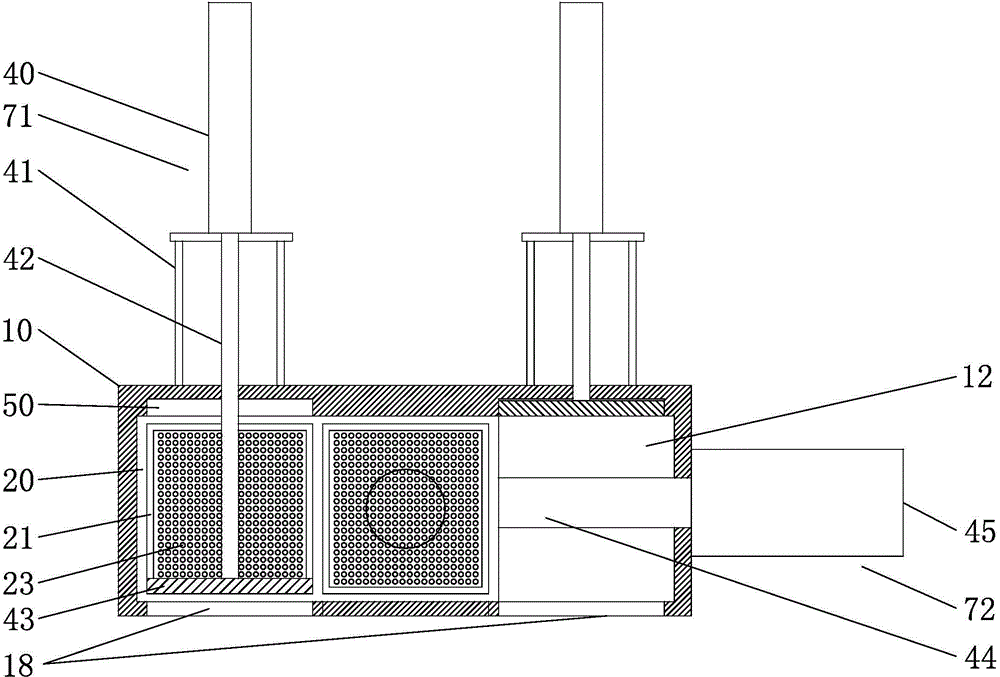

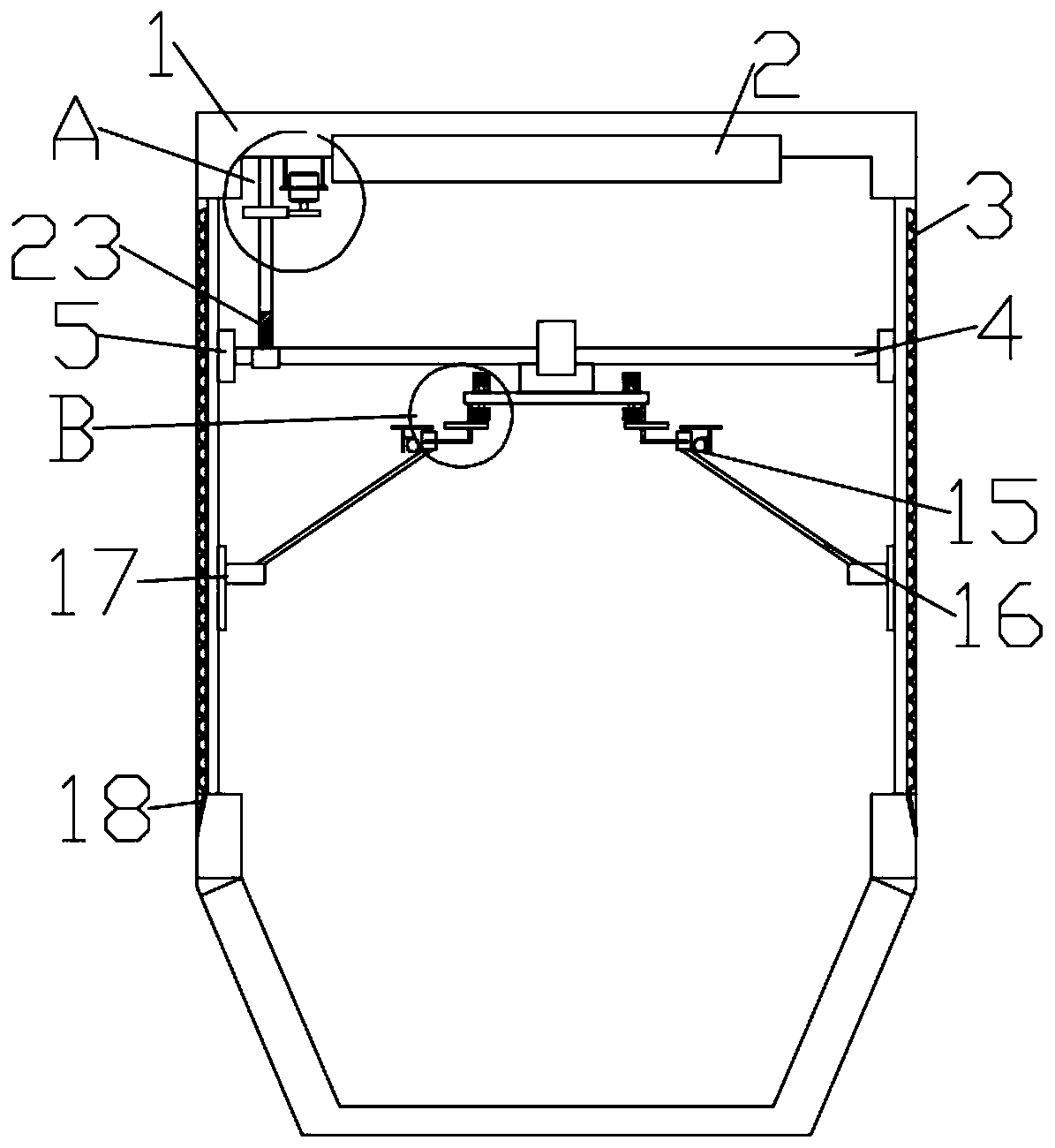

Integrated intelligent treatment equipment for inner wall of diesel pipeline

ActiveCN106239167AUniform walking supportGood uniform support performanceRevolution surface grinding machinesGrinding drivesChanging equipmentImpurity

The invention relates to integrated intelligent treatment equipment for the inner wall of a diesel pipeline. The integrated intelligent treatment equipment comprises an inner wall automatic walking device, wherein the inner wall automatic walking device walks on the inner wall of the pipeline in four directions in a self-stabilizing manner, has four walking support forces which are uniformly distributed, is great in uniform support performance, and is great in self-stabilizing walking performance; an inner wall drying device is mounted at the left end of the inner wall automatic walking device, and the inner wall drying device can realize a rapid drying function on the inner wall of the pipeline, can carry out partial rapid drying according to actual conditions of the inner wall of the pipeline, is great in power saving performance and is great in drying effect; and an inner wall rust removing device is mounted at the right side of the inner wall automatic walking device, and the inner wall rust removing device can realize rapid impurity scraping, rust removing and grinding functions on the inner wall of the pipeline, spends short time in rust removing and grinding, and is great in rust removing and grinding effects. The integrated intelligent treatment equipment can realize continuous and stable rust removing and drying functions on the inner wall of the diesel pipeline, does not require equipment replacement operation during the process, is high in pipeline inner wall treatment speed and is high in pipeline inner wall treatment efficiency.

Owner:FOSHAN CITY SHUNDE DISTRICT SHUNHENGXIN DIESEL GENERATOR

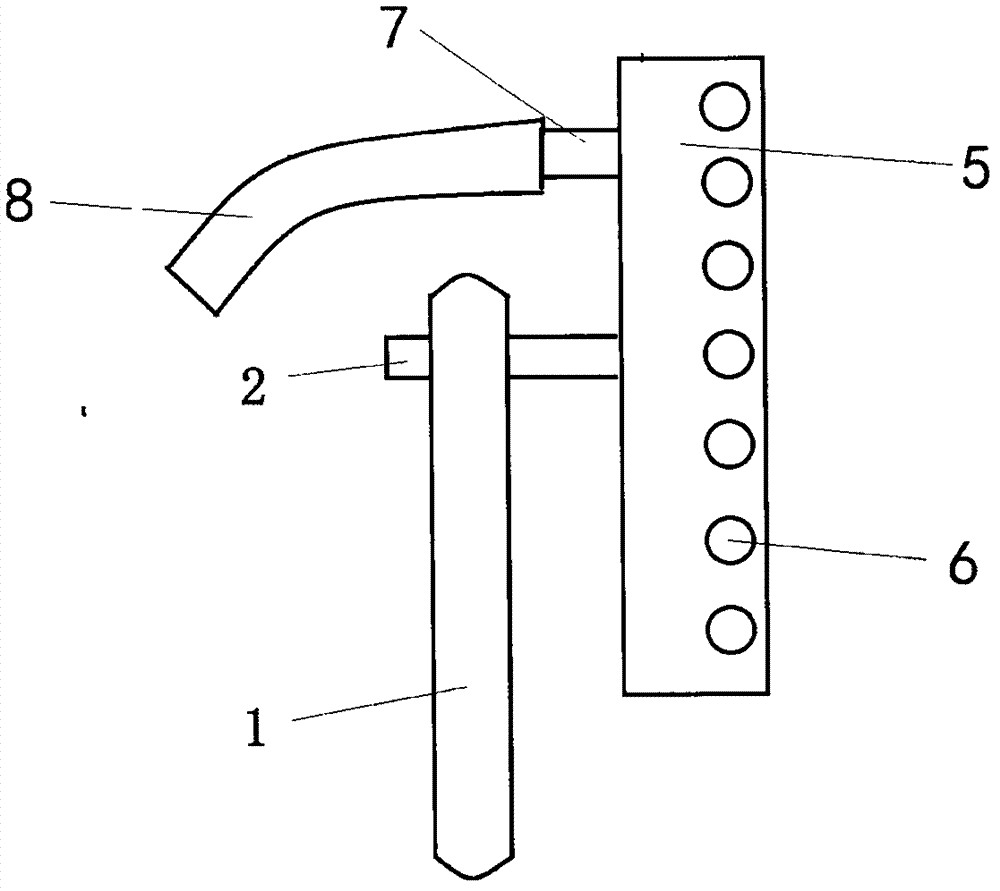

Separation device for removing sludge in oily wastewater

InactiveCN103508525AAchieve primary separationEfficient separationWater/sewage treatment by flocculation/precipitationWater/sewage treatment by flotationSludgeBiochemical engineering

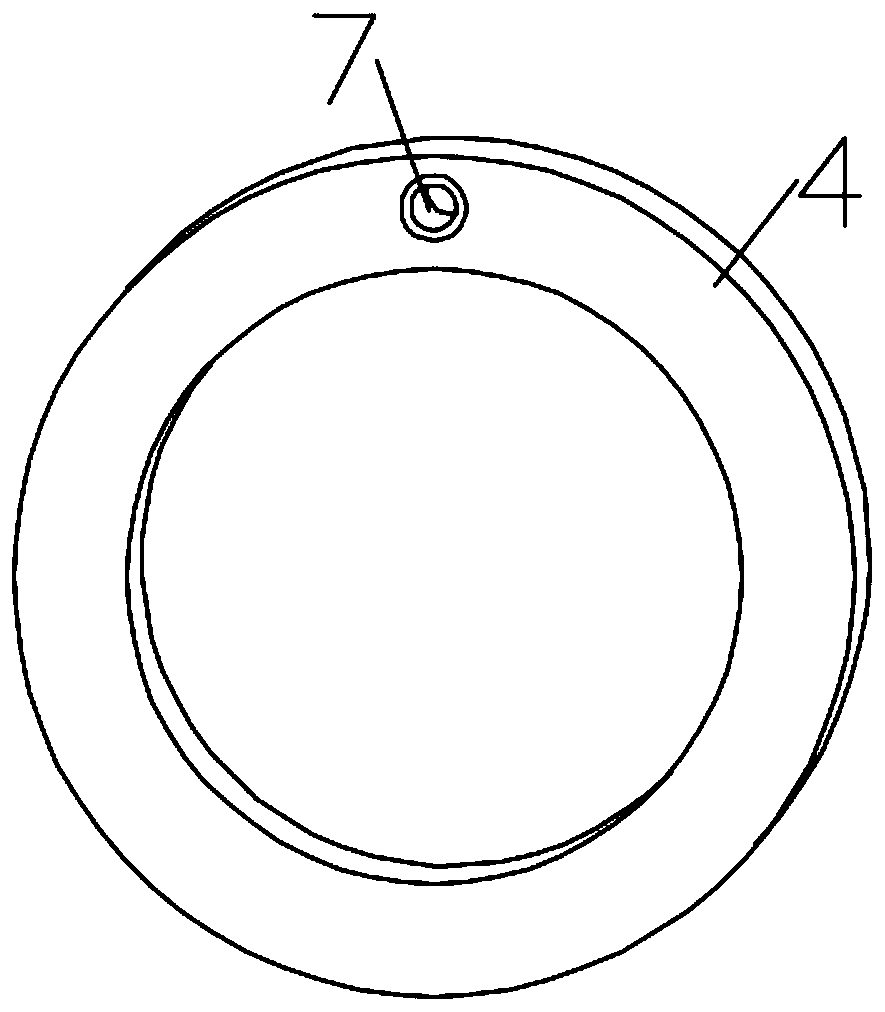

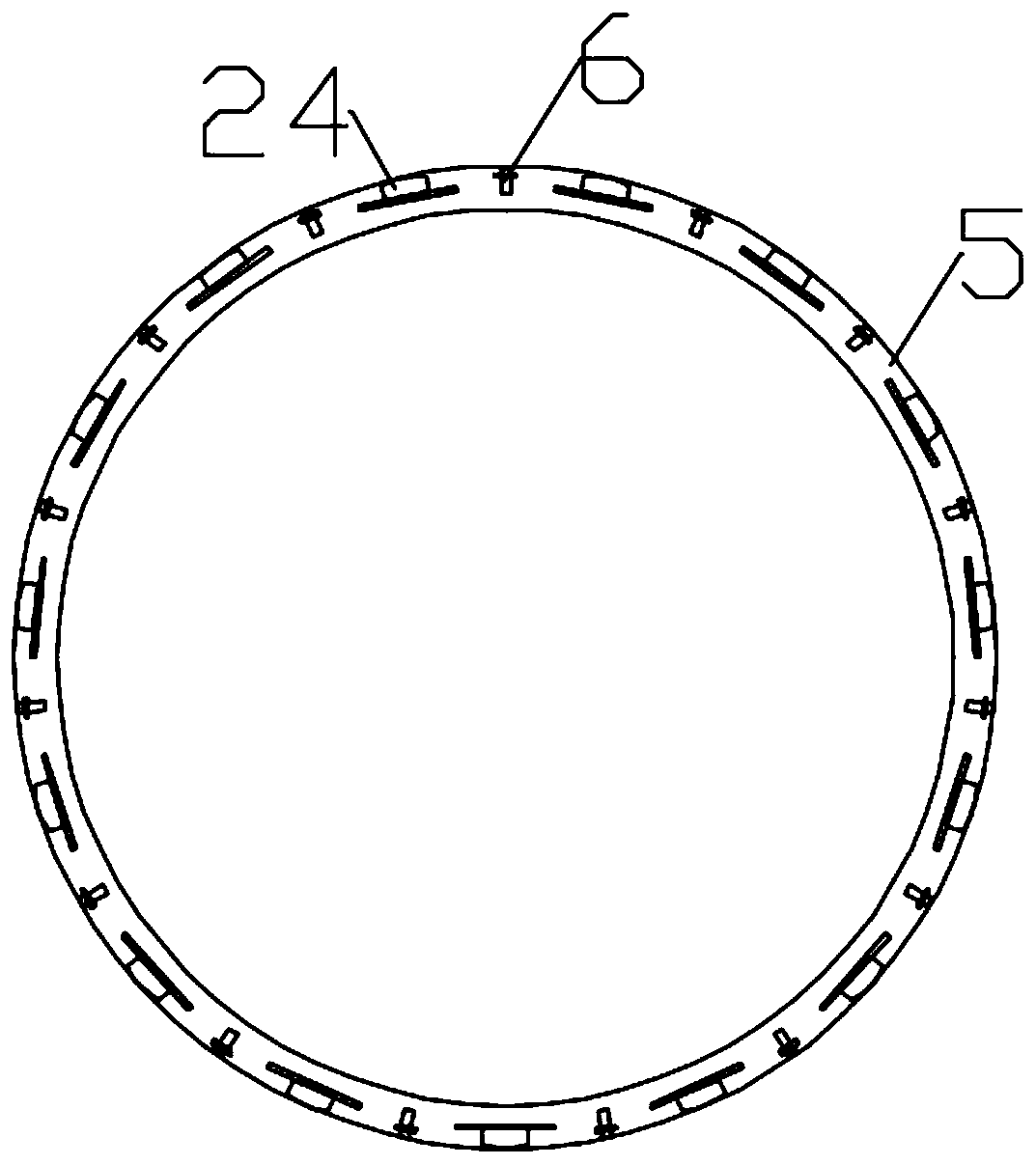

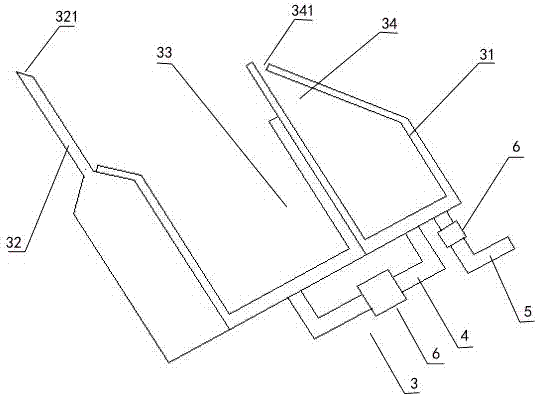

The invention discloses an impurity removal device for removing suspended substances in oily sewage, which comprises an impurity removal groove (1) and an impurity removal structure, wherein the impurity removal groove (1) is provided with a water inlet pipe (8) and a water outlet (11); the impurity removal structure comprises a disk (2) and a motor (3); the disk (2) is linked with the motor (3); the disk (2) is fixed to the side wall of the impurity removal groove (1) through a rotating shaft; the motor (3) is fixed to a support table (4) on the lateral side of the impurity removal groove (1); the side wall on which the disk (2) is positioned is provided with an open hole (6); the open hole (6) is provided with an oblique scraper (7) and a guide groove (9); a collecting groove (10) is arranged right below the tail end of the guide groove (9); and a propeller (5) is also arranged in the impurity removal groove (1). By adopting the structure, the impurity removal device is simpler in structure and convenient for operation, and the suspended substances can be thoroughly removed more easily, thereby further enhancing the impurity removal quality.

Owner:SICHUAN WEST POLY XIN CHEM PACKING

Street lamp with self-cleaning function

InactiveCN111486376AAvoid breedingAvoid corrosionMechanical apparatusLighting elementsMaterials scienceLight fixture

The invention discloses a street lamp with a self-cleaning function, belonging to the technical field of street lamps. The invention aims to solve the problems that since an existing device cannot clean the interior of a protective cover, dust is accumulated and the light-emitting efficiency of the device is affected. The device is technically characterized in that the device comprises a shell anda lamp mounting base, wherein the lamp mounting base is fixedly mounted at the top of the shell, an LED street lamp is fixedly mounted on the lamp mounting base, a lifting ring is fixedly mounted inthe shell, the lifting ring is sleeved with a cleaning assembly used for cleaning the inner wall of the shell, and the upper portion of the lifting ring is connected with a driving mechanism used fordriving the cleaning assembly. According to an embodiment of the invention, the cleaning assembly and an ultraviolet sterilization lamp are arranged, so disinfection effect is achieved, breeding of bacteria in the device is avoided, and internal elements are prevented from being corroded; cleaning efficiency is improved due to the arrangement of a vibration motor, dirt is rapidly scraped due to the arrangement of a scraping assembly; and the light emitting efficiency of the lamp is improved.

Owner:QINGDAO LANHISUN NEW ENERGY TECH

Coating device for permeable base materials

PendingCN106944315AAvoid the appearance of flowers, lines and other phenomenaQuick scrapeLiquid surface applicatorsCoatingsEngineeringFeed tank

The invention discloses a coating device for permeable base materials. The coating device comprises coating base materials, back rolls and a feeding and scraping mechanism, wherein the coating base materials are transmitted by the back rolls; the feeding and scraping mechanism is mounted under the coating base materials, and comprises a feeding tank and a scraping knife; a feeding opening is formed in the upper end of the feeding tank; and the scraping knife is mounted on one side of the feeding tank. The coating device disclosed by the invention is resistant to permeation and uniform in coating, and the phenomena of blurring, grains and the like on the surface due to uneven tension of coating or rotation problem of a guide roller are avoided.

Owner:LINGSHENGCHENG TECH JIANGSU CO LTD

Automobile air-knife window wiper

InactiveCN103241216AIncrease the speed of the side-to-side swingWon't wear outVehicle cleaningEngineeringHigh pressure

An automobile air-knife window wiper comprises a wiper and a swing arm, and is characterized in that the wiper is composed of an air knife which is a tube with a row of gas outlets. Dust and rain on a windshield can be blown away by high-pressure gas blown out from the gas outlets.

Owner:黄建军

Special excreta disposal device for rabbit keeping

Owner:XINAN ERLONG PLANTING FARMERS SPECIALIZED COOP

Road roller for constructional engineering

InactiveCN110820485ARealize soil looseningImprove compactionMechanical machines/dredgersRoads maintainenceStructural engineeringRoad surface

The invention discloses a road roller for constructional engineering. The road roller comprises a machine body, a driving cabin, a first pressing wheel, a second pressing wheel and a third pressing wheel, wherein the driving cabin is fixedly arranged above the machine body; a first bearing and a second bearing are respectively mounted on two sides of the first pressing wheel and the second pressing wheel; the first bearing and the second bearing are connected through a first connecting column; the first bearing is connected with one side of the machine body through a second connecting column;third bearings are mounted on two sides of the third pressing wheel; the third bearings are connected with the other side of the machine body through a third connecting column; a mounting bracket is arranged above the third pressing wheel; one side of the mounting bracket is fixedly connected with the side wall of the machine body; a bulldozing assembly is mounted on one side of the mounting bracket; a soil loosening assembly is mounted on the other side of the mounting bracket; and the bulldozing assembly and the soil loosening assembly are arranged on two sides of the third pressing wheel. The road roller disclosed by the invention is novel in structural design, can perform road rolling operation on a road surface, can perform bulldozing operation on a mound, and facilitates road rolling; and in addition, the soil loosening operation on the road surface can also be realized, and the compaction performance of the road surface is improved.

Owner:徐晓楠

Stirring device for preparing acid-resistant coating

InactiveCN111804228AEasy to depositPromote rapid accumulationRotary stirring mixersTransportation and packagingEngineeringScrew thread

The invention discloses a stirring device for preparing an acid-resistant coating. The device comprises a supporting table, and a stirring tank body is arranged on the supporting table; an inner cavity of the stirring tank body is rotationally connected with a stirring shaft; the outer wall of the stirring shaft is fixedly sleeved with a fixed sleeve seat; threaded grooves are formed in the surfaces of the two sides of the fixed sleeve seat; the inner sides of the threaded grooves are in threaded connection with fixing screws; fixing plates are fixed to the surfaces of one sides of the fixingscrews; and a plurality of sets of fixing springs distributed at equal intervals are fixed to the surfaces of one sides of the fixing plates. Through the arrangement of a scraping plate, the coating accumulated on the inner wall of the stirring tank body can be conveniently and rapidly scraped, and the utilization rate of the coating is guaranteed; by arranging a cleaning brush head, the inner wall of the stirring tank body can be conveniently and rapidly cleaned, and the working efficiency of the device is improved; and through the arrangement of plug pins and buckles, the scraping effect ofthe scraping plate on the coating is guaranteed, and the cleaning effect of the cleaning brush head on the inner wall of the stirring tank body is also guaranteed.

Owner:青岛格林沃德新材料科技有限公司

Filter with automatic cleaning function for coating production

PendingCN114797210AWon't clogImprove filtering effectStationary filtering element filtersElectric machineryEngineering

The invention discloses a filter with an automatic cleaning function for coating production, and relates to the technical field of coating production. Comprising a filter body, an access door is arranged in the middle of the filter body, a feeding pipe is connected to the upper portion of the filter body, a discharging pipe is connected to the lower portion of the filter body, and the filter further comprises a motor, a rotating pipe, an inverted-cone-shaped filter screen and a vibration assembly. When the conical filter screen vibrates, impurities attached to the conical filter screen can be vibrated, filter holes in the conical filter screen cannot be blocked, the automatic cleaning effect is achieved, the situation that the filtering effect is reduced due to the fact that the filter holes are blocked is avoided, when the conical filter screen moves upwards, the upper surface of the conical filter screen can be attached to the lower surface of a first scraper blade, coagulated blocks in coating can be extruded, and the coating quality is improved. And crushing the mixture into a small-volume coating.

Owner:JIANGSU KANGAITE ENVIRONMENTAL ENG GRP CO LTD

Quick paint spraying device with anti-splashing mechanism for fabricated building

InactiveCN112756157ARealize all-round mixing treatmentGuaranteed liquidityMovable spraying apparatusConstruction engineeringStructural engineering

The invention discloses a quick paint spraying device with an anti-splashing mechanism for a fabricated building, and belongs to the technical field of fabricated buildings. The quick paint spraying device comprises a paint bucket, the anti-splashing mechanism, a paint pump, a lifting frame, a stirring assembly, a positioning assembly and a driving motor; A middle screw rod is installed inside, an electric push rod is started, the electric push rod can push the lifting frame downwards, paint is pressed into the paint pump, and when the lifting frame descends, a mounting threaded sleeve of the stirring assembly in the lifting frame can drive stirring blades to rotate; and the paint in the paint bucket can be effectively stirred in all directions while paint pressing and spraying are carried out, the overall flowability and the using effect of the paint are guaranteed, meanwhile, outer scraping plates with second outer jacking springs are installed at the top and the bottom of the lifting frame, when the lifting frame moves up and down, paint or particles attached to the paint inner wall of the paint bucket can be rapidly scraped off, accumulation of the particles is avoided, and it is guaranteed that solid particles in the paint can be effectively stirred and dissolved.

Owner:温州艾米华农业科技有限公司

Integrated radio frequency communication passive device

ActiveCN107403980AImprove insulation efficiencyReduce the degree of impactWaveguide type devicesEngineeringSpherical form

The invention provides an integrated radio frequency communication passive device. The integrated radio frequency communication passive device comprises a cylinder, a spherical groove, a sphere, a ventilation hole, a scrapping plate, an elongate box, a pull rod, a through hole and a plug cover, wherein the cylinder is arranged on an upper end surface of the elongate box, the sphere is arranged in the cylinder, the spherical groove is formed in an upper surface of the cylinder, and the ventilation hole is formed in a lower end surface of the cylinder. By the design, drying agent particles are prevented from being leaked; the through hole is formed in a right end surface of a sealing plate, the plug cover is arranged at a right side of the through hole, the elongate box is arranged on an upper end surface of a passive device body, the scrapping plate is arranged in the elongate box, a left end of the pull rod is arranged at a middle position of a right end surface of the scrapping plate, and a right end of the pull rod is arranged at a middle position of a left end surface of the plug cover; by the design, the purpose of rapidly scrapping the drying agent particles is achieved; and the integrated radio frequency communication passive device has the advantages of long service lifetime, high anti-interference capability, good stability and high reliability.

Owner:ANHUI LUXUN ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com