Patents

Literature

69results about How to "Improve mud scraping effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

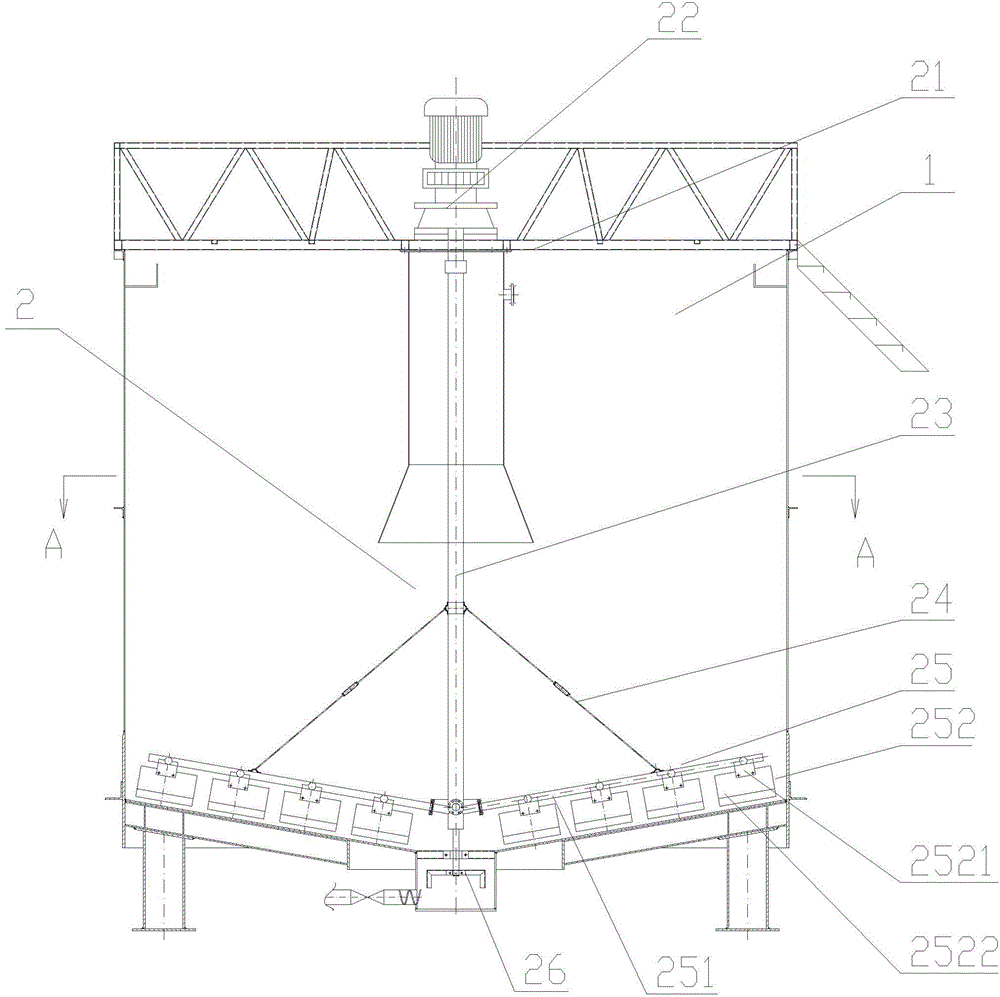

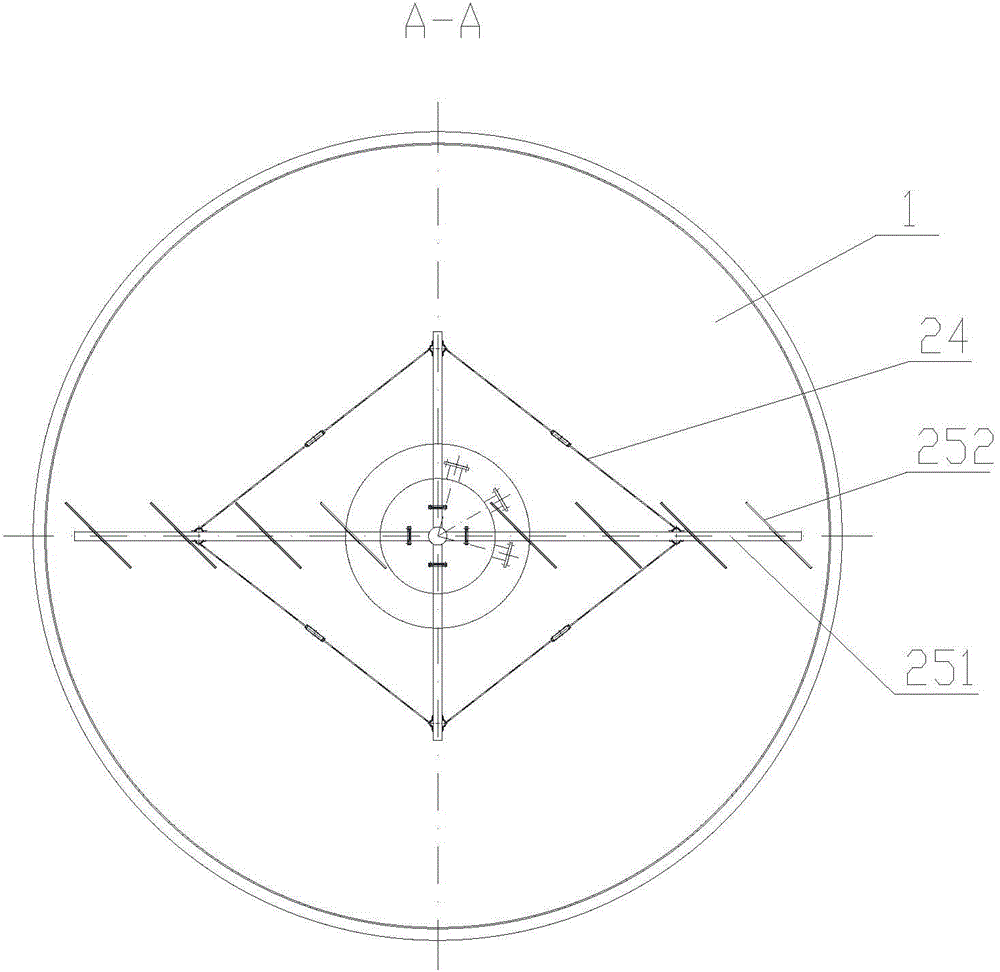

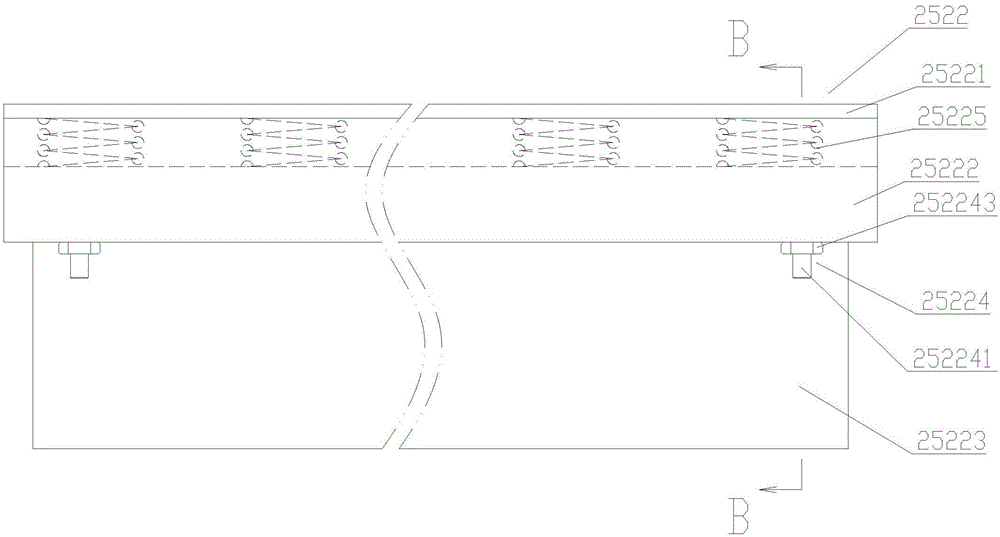

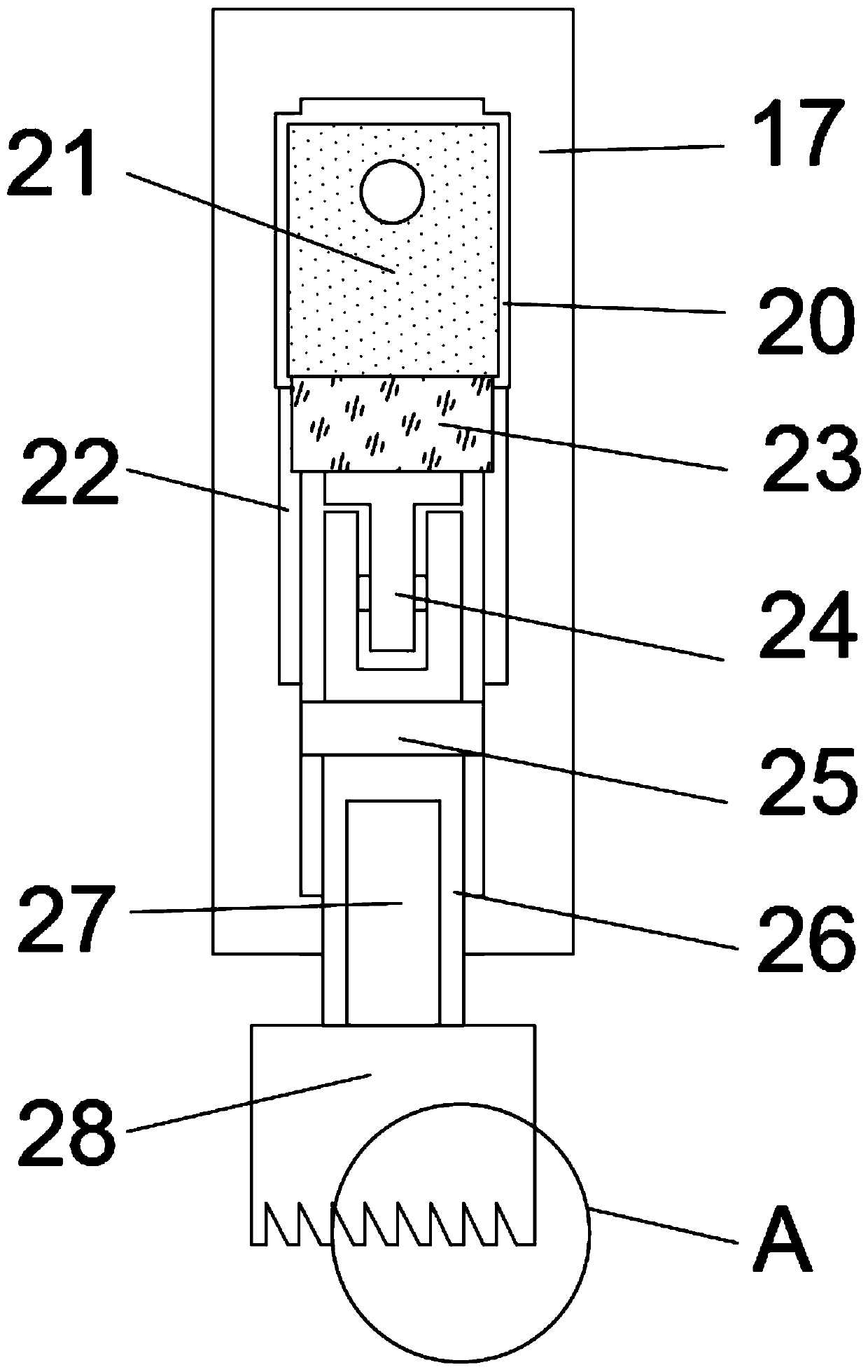

Regulating-type central transmission mud scraper

InactiveCN105617730AAvoid replacementEnsure the design heightSedimentation separationDrive shaftEngineering

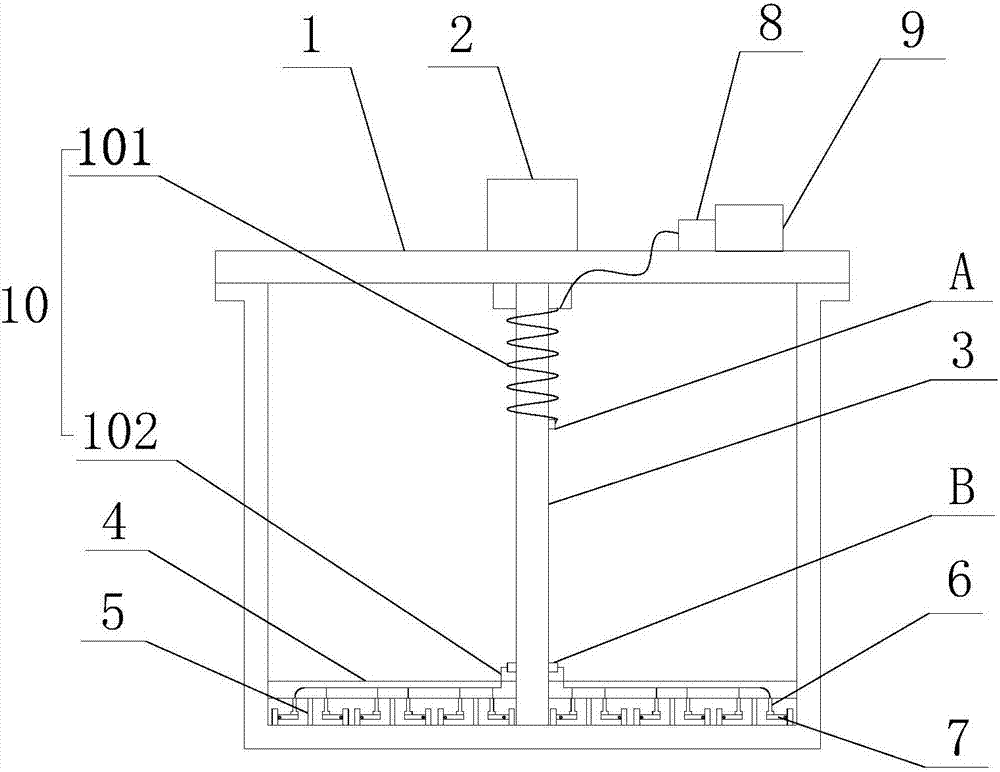

The invention relates to a regulating-type central transmission mud scraper. The regulating-type central transmission mud scraper is characterized in that height of the mud scraper can be regulated according to practical condition, the mud scraping effect is good, efficiency is high, and production cost is reduced. The regulating-type central transmission mud scraper is arranged at center of a sedimentation basin, the mud scraper comprises a support, a motor, a transmission shaft, several pull bars and at least two groups of uniformly distributed mud scraping mechanisms; the mud scraping mechanism comprises a mud scraping arm and several mud scraping board units, the mud scraping board unit comprises a fixing support and an adjustable mud scraping board component, the mud scraping board component comprises a sealing cover, a regulating plate, the mud scraping board, four groups of height regulating mechanisms, and several support springs, the regulating plate is in a recessed shape, the mud scraping board passes through the regulating plate, the sealing cover is arranged at top of the regulating plate, the support spring is arranged between the sealing cover and the mud scraping board, and the mud scraping board comprises a positioning plate and a lower mud scraping board which are combined. The regulating-type central transmission mud scraper is capable of reducing the production cost, and increasing the mud scraping effect and efficiency.

Owner:徐静

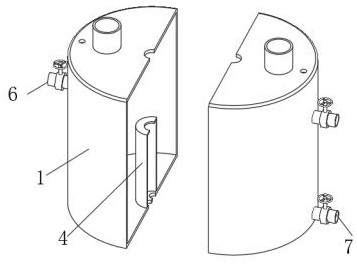

Anode mud cleaning device for electrolytic lead anode plates

ActiveCN102899691AQuick scrapeClean scrape offPhotography auxillary processesElectrolysis componentsElectrolysisElectrical and Electronics engineering

The invention discloses an anode mud cleaning device for electrolytic lead anode plates. The device mainly solves the technical problems of the large device maintenance amount, the low working efficiency, the high cost and the like which are caused by the fact that anode plates can only be cleaned manually or in a semi-mechanized mode in existing electrolytic lead processes. The technical scheme includes that more than two supports (3) in a rectangular frame shape are sleeved inside a box body (1), supports (3) are connected with one another through a crossbeam at the bottom, straight beams on side faces and more than two steel plates to form internal rectangular-frame-shaped cleaning grooves (6), each of scrapers (5) comprises bearing plates (9) and a reversed v-shaped mud scraping body (11), bearing plates (9) are fixedly connected with mud scraping bodies (11), two ends of bearing plates (9) are connected with connecting plates (4), liquid spraying devices are arranged on bearing plates (9), and more than two scrapers (5) are installed on cleaning grooves (6) in a crossing mode. The device can be widely applied to cleaning and collecting processes of anode mud on electrolytic lead anode plates of electrolysis processes.

Owner:湘潭大众整流器制造有限公司

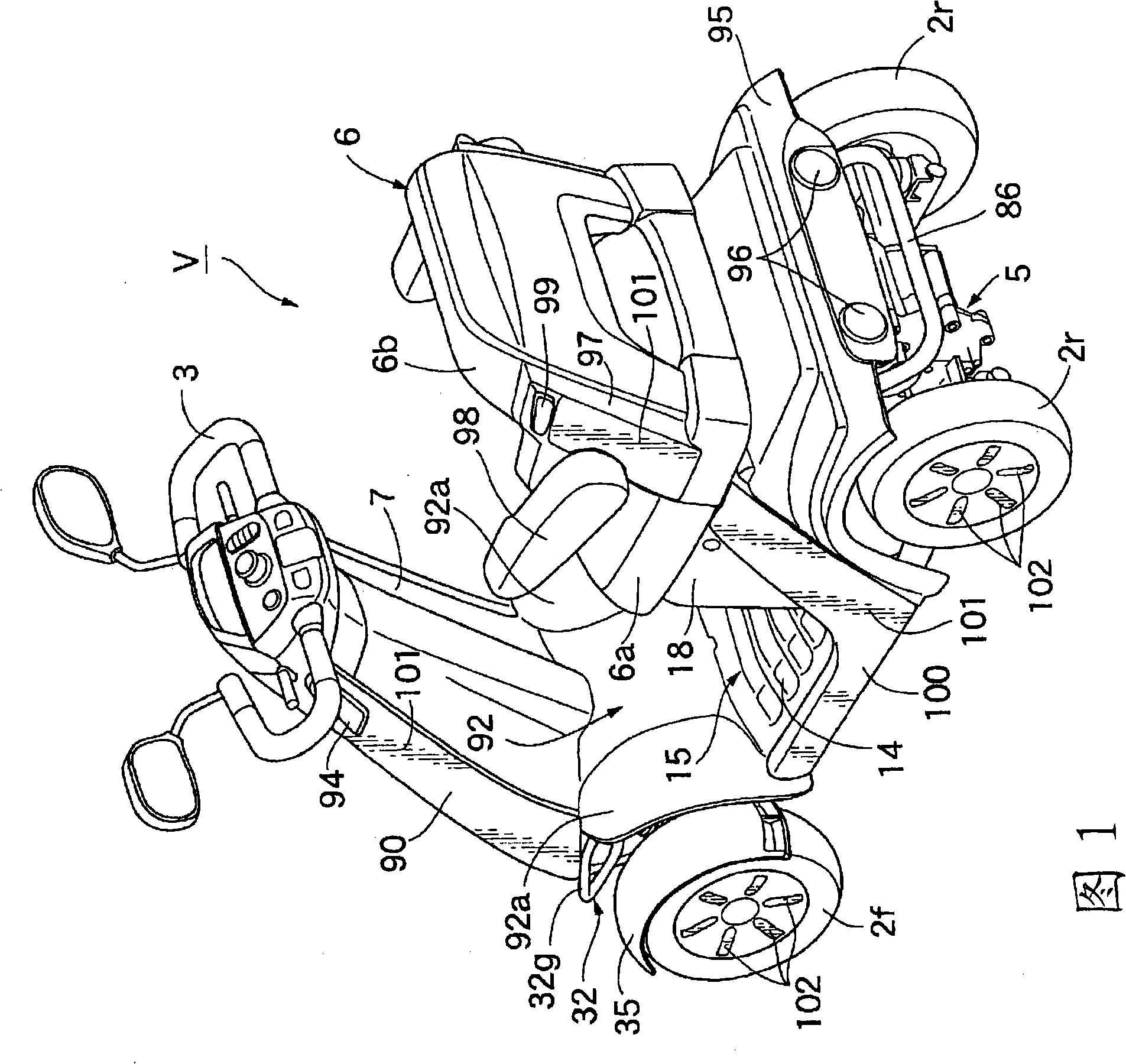

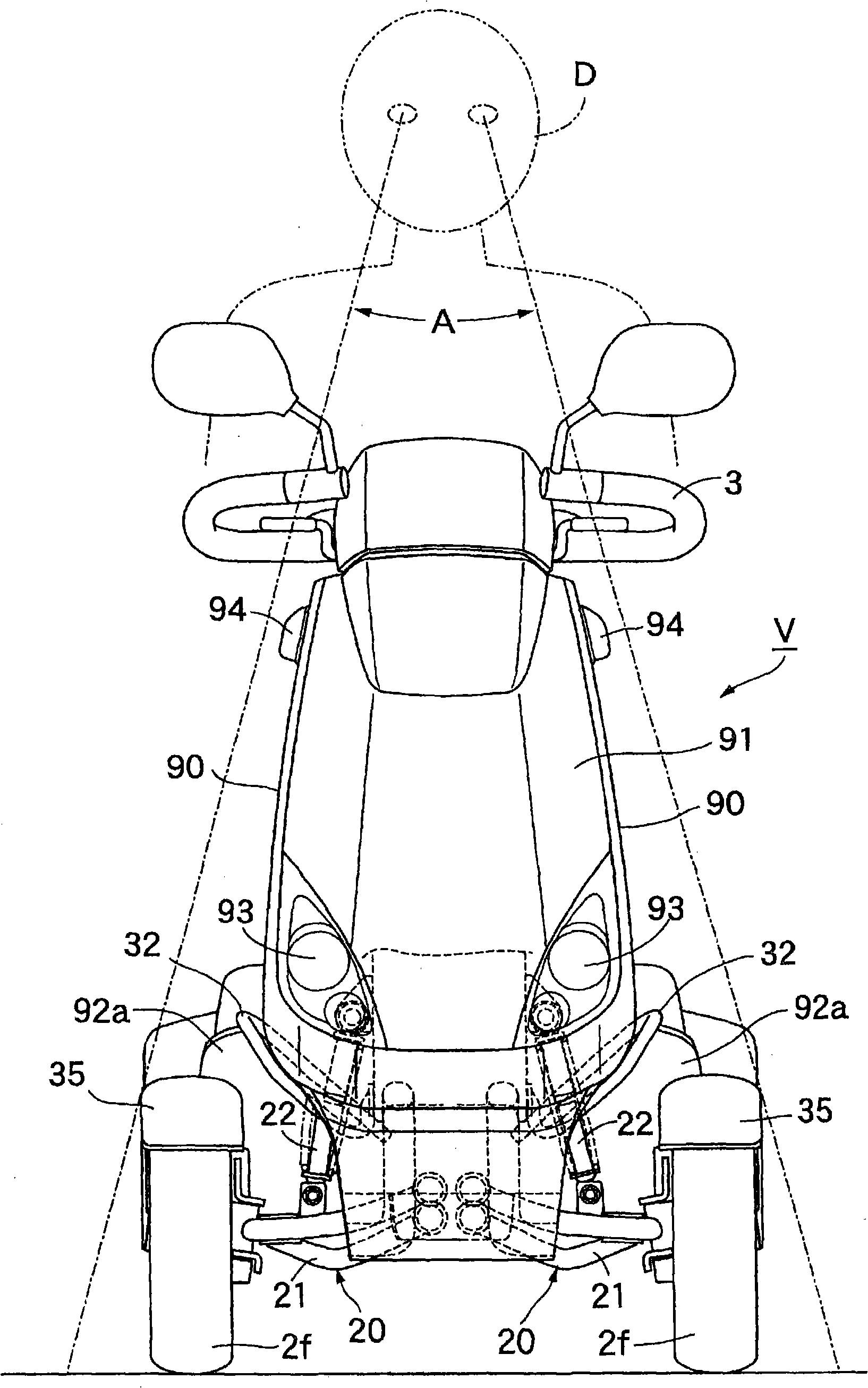

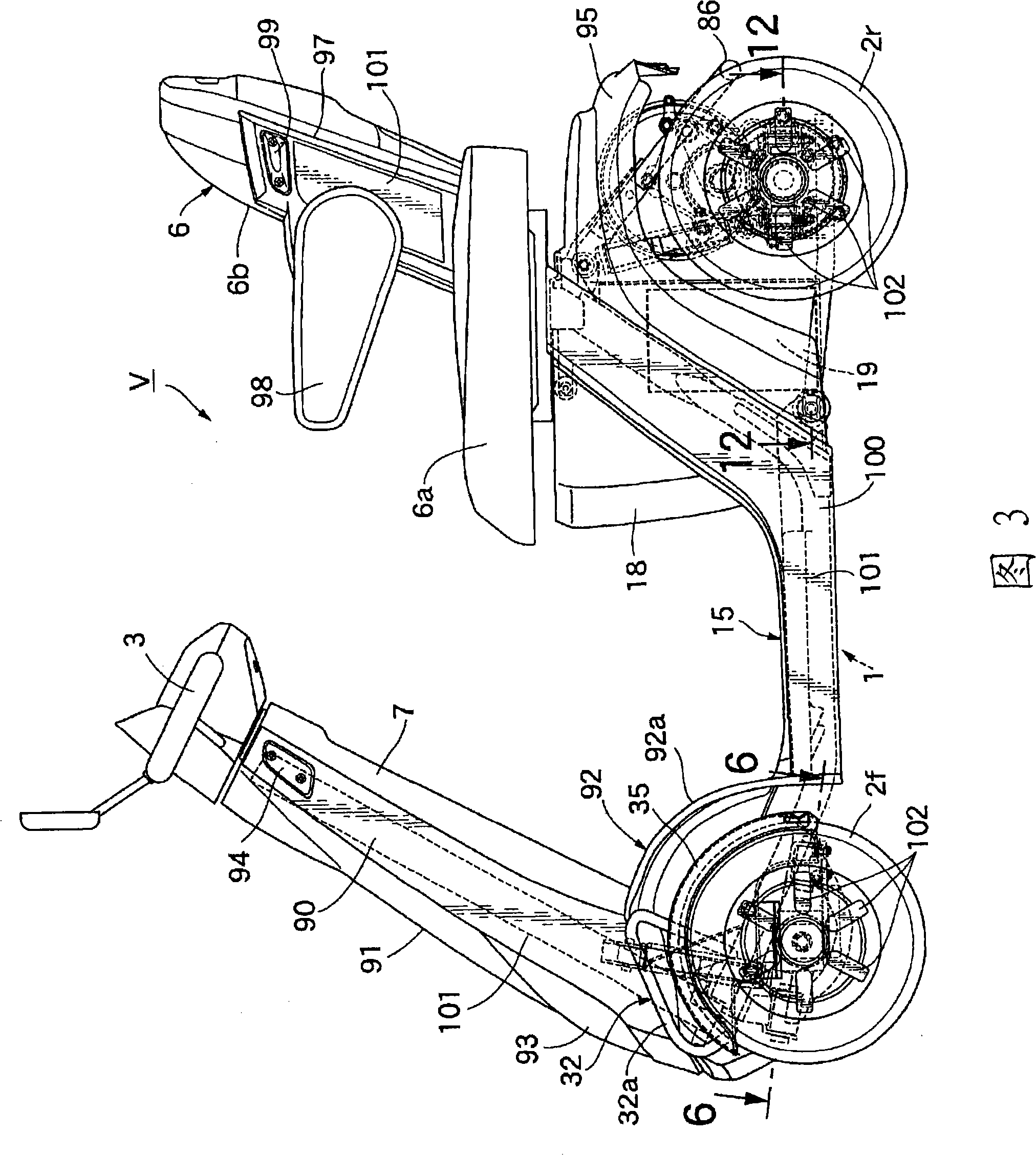

Small-sized vehicle

InactiveCN101291841ASmooth rotationAvoid cloggingCyclesWheelchairs/patient conveyanceEngineeringMechanical engineering

A small-sized vehicle in which a fender (35) is so disposed along the outer peripheral surface of a wheel (2f) as to cover the upper part of the wheel (2f). The fender (35) includes a first soil discharge piece (44) projected from its rear end edge to the outer peripheral surface of the wheel (2f), a slit (46) positioned on the upper side of the first soil discharge piece (44) and extending in the lateral direction of the wheel (2f), and a second soil discharge piece (45) projected from the lower edge of the slit (46) to the outer peripheral surface of the wheel (2f). When the wheel (2f) rotates forward, the first soil discharge piece (44) scrapes down mud on the outer peripheral surface of the wheel (2f), and when it rotates backward, the second soil discharge piece (45) scrapes down the mud on the outer peripheral surface of the wheel (2f) to discharge the mud to the outside through the slit (46). When such a structure that the fender is so disposed along the outer peripheral surface of the wheel as to cover the upper part of the wheel is adopted in the small-sized vehicle, the vehicle can lightly travel even in a muddy place by preventing mud from being caught between the wheel and the fender.

Owner:HONDA MOTOR CO LTD

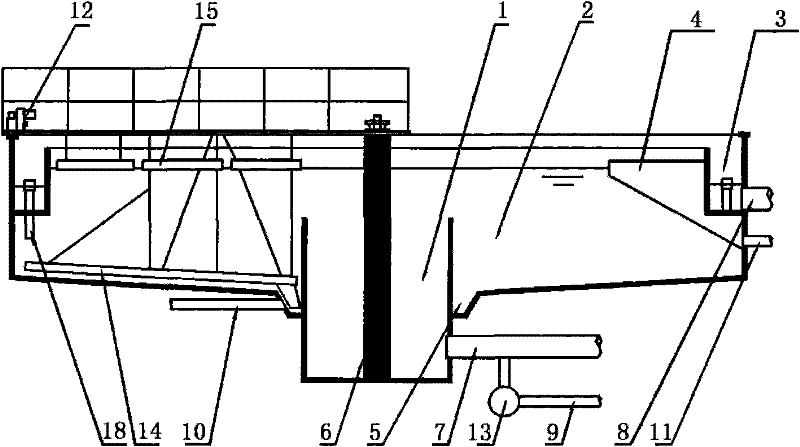

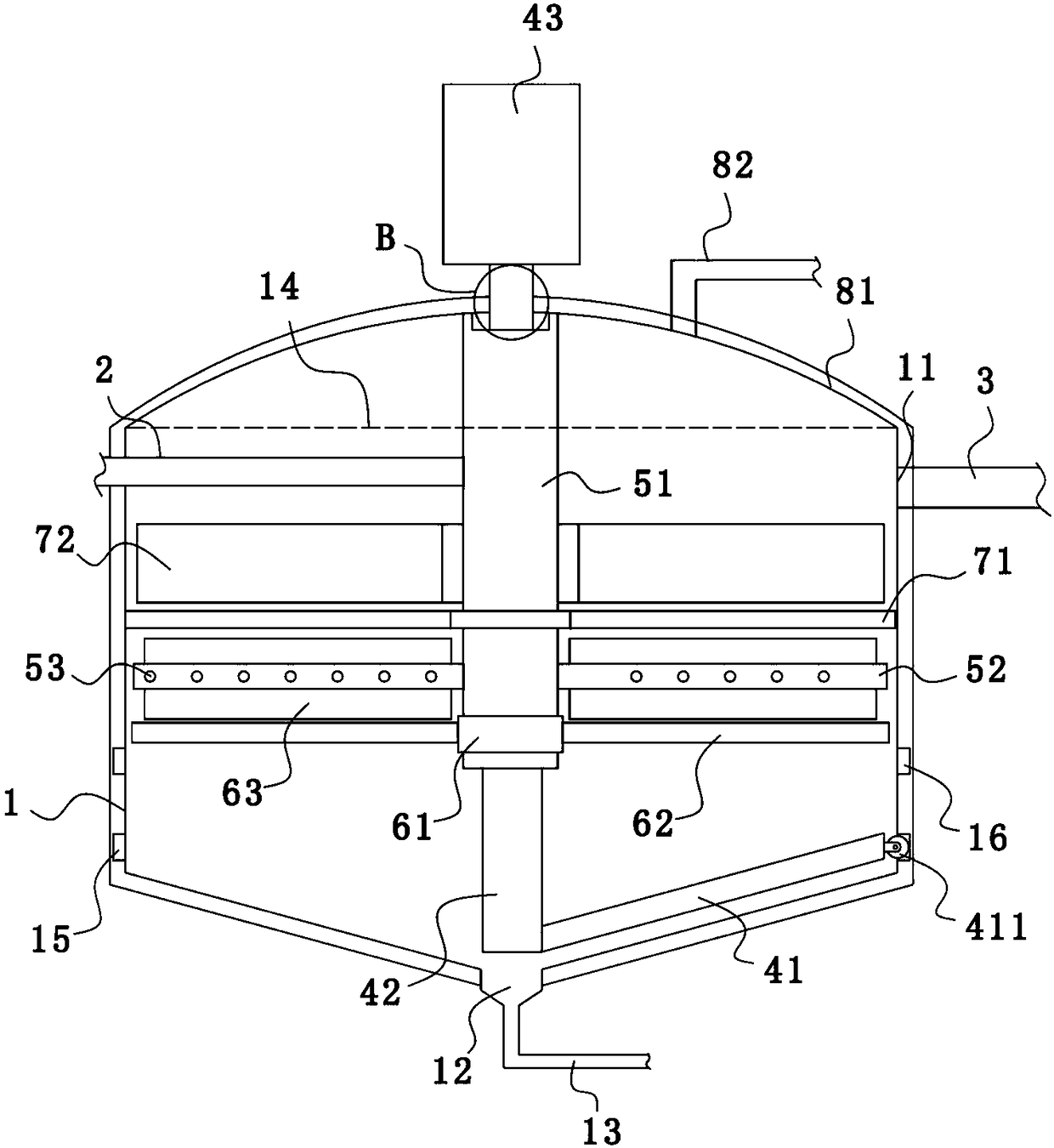

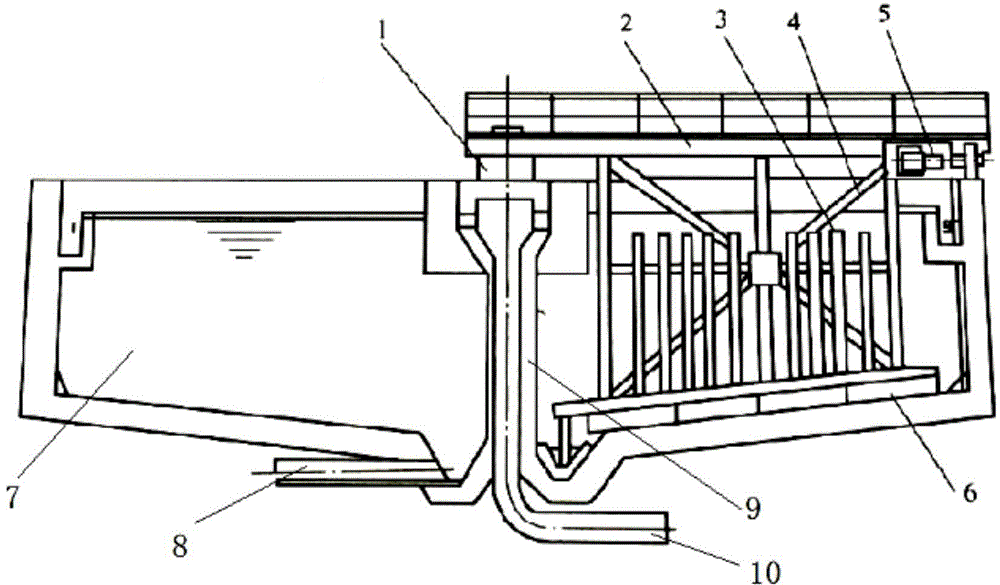

Radial-flow micro-nano air flotation device

InactiveCN102452695AImprove purification effectLow failure rateWater/sewage treatment by flotationMicro nanoSlag

The invention discloses a radial-flow micro-nano air flotation device, which relates to the technical field of water treatment and is used for solving the problems of the need of elevating inflow water for shallow air floatation, complex equipment, high fault rate, unfavorable purifying effect, difficulty in upsizing ordinary dissolved air flotation, difficulty in ensuring the purifying effect, and the like. The radial-flow micro-nano air flotation device provided by the invention comprises a contact area (1), a separation area (2), an outflow channel (3), a slag floating groove (4), a sludge groove (5), a central support post (6), a water inlet pipe (7), a water outlet pipe (8), a dissolved-air water inlet pipe (9), a mud discharge pipe (10), a slag discharge pipe (11), a mud and slag scraping machine (12), a micro-nano bubble generator (13) and the like. The radial-flow micro-nano air flotation device has the outstanding advantages of automatic water inflow, low manufacturing cost, low running cost, good purifying effect, easiness for maintaining, capability of stably running continuously and non-halt overhauling.

Owner:王树岩

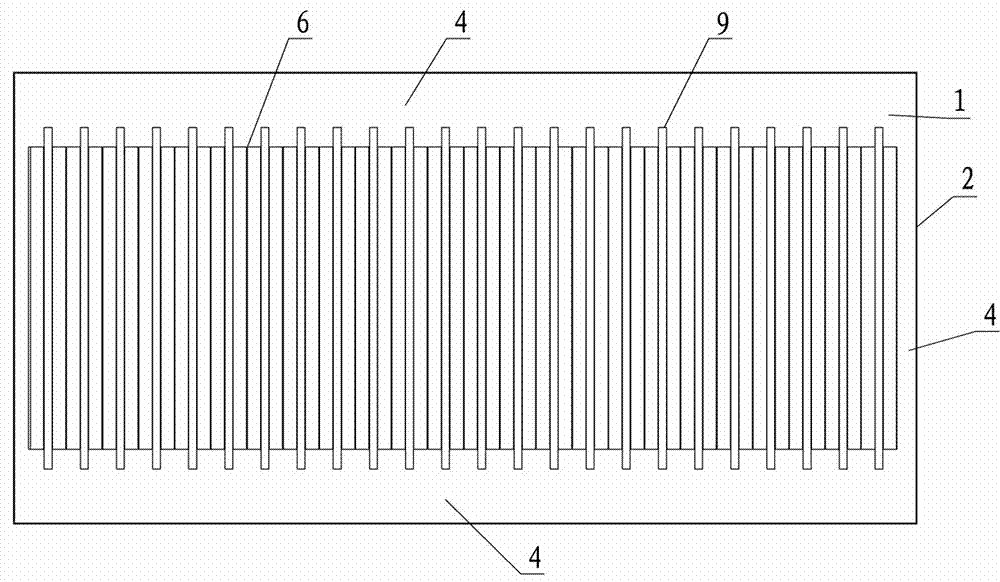

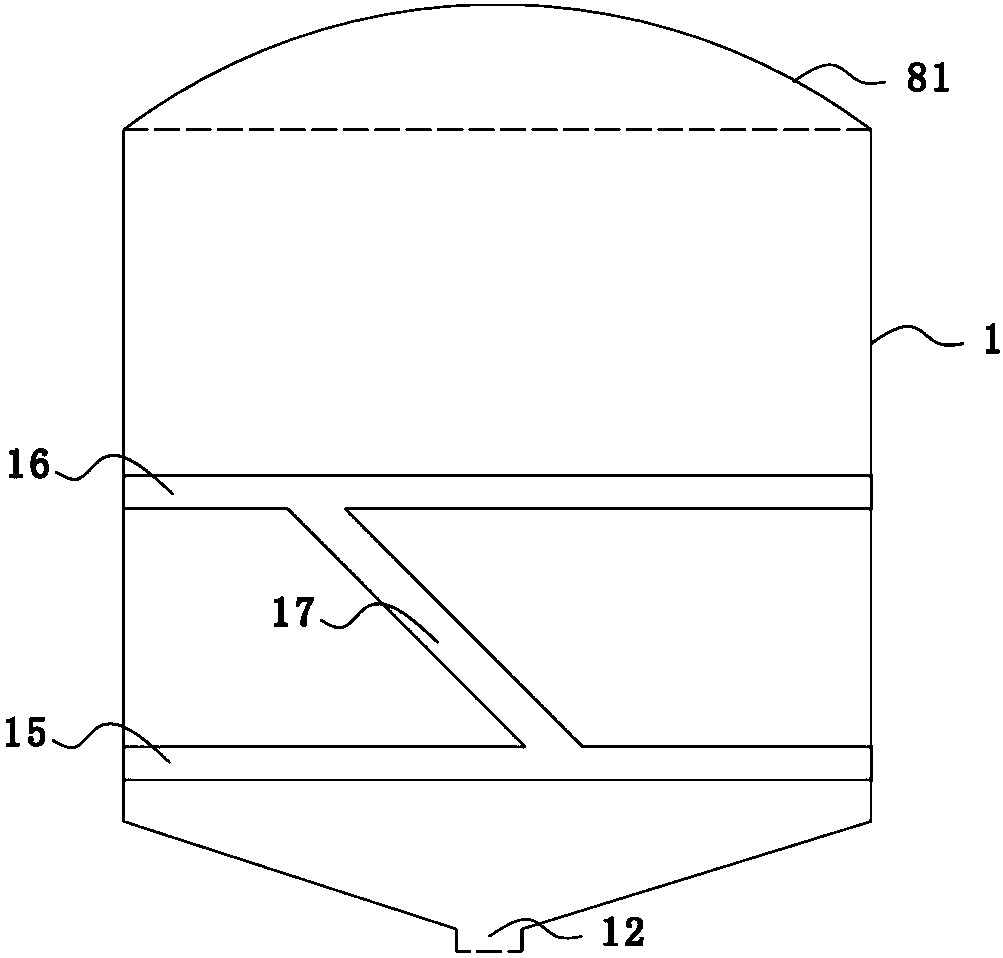

Novel sedimentation pool for sewage plant

ActiveCN108503135AAnaerobic digestion works wellFully contactedWater contaminantsTreatment with anaerobic digestion processesFirst FillFilling materials

The invention discloses a novel sedimentation pool for a sewage plant. The novel sedimentation pool comprises a pool body, a water inlet pipe, a water distribution unit, a biological filling materialunit, a mud scraping device, a gas recovery device and a water outlet pipe, wherein the water distribution unit, the biological filling material unit, the mud scraping device, the gas recovery deviceand the water outlet pipe are arranged in the pool body; the mud scraping device comprises a mud scraping rod arranged at the bottom surface of the pool body, a driving rod fixedly connected with themud scraping rod, a rotating driving element used for driving the driving rod to rotate and a second driving element used for driving the driving rod to vertically act; the water distribution unit comprises a center pipe, a plurality of water distribution pipes and spray heads arranged on the water distribution pipe; the biological filling material unit comprises a first filling material assembly;the first filling material assembly comprises a fixing sleeve, a plurality of filling material frames and a biological filling material; the filling material frames are distributed at intervals in the peripheral direction of the fixing sleeve; the biological filling material is arranged on the filling material frame. The sewage is in sufficient contact with the biological filling; the biologicalfilling has a good anaerobic digestion treatment effect on the sewage; the sewage deposition quantity is reduced; the frequent mud scraping operation is not needed; the energy is saved; the environment is protected; the abrasion of the mud scraping component is small; the service life is long.

Owner:SHAOXING HEQIAO JIANGBIN WATER TREATMENT

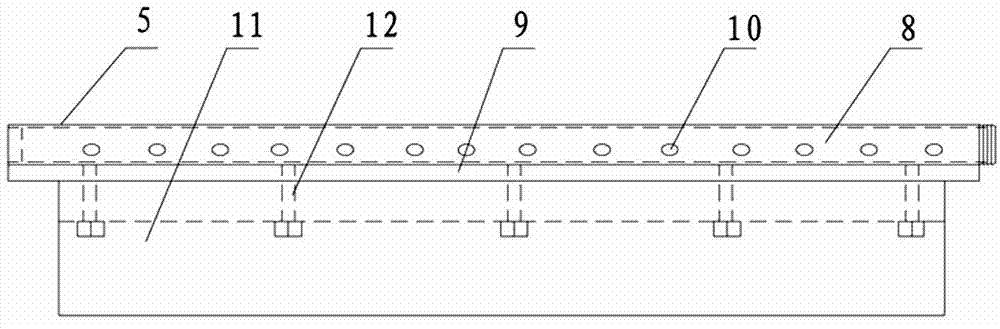

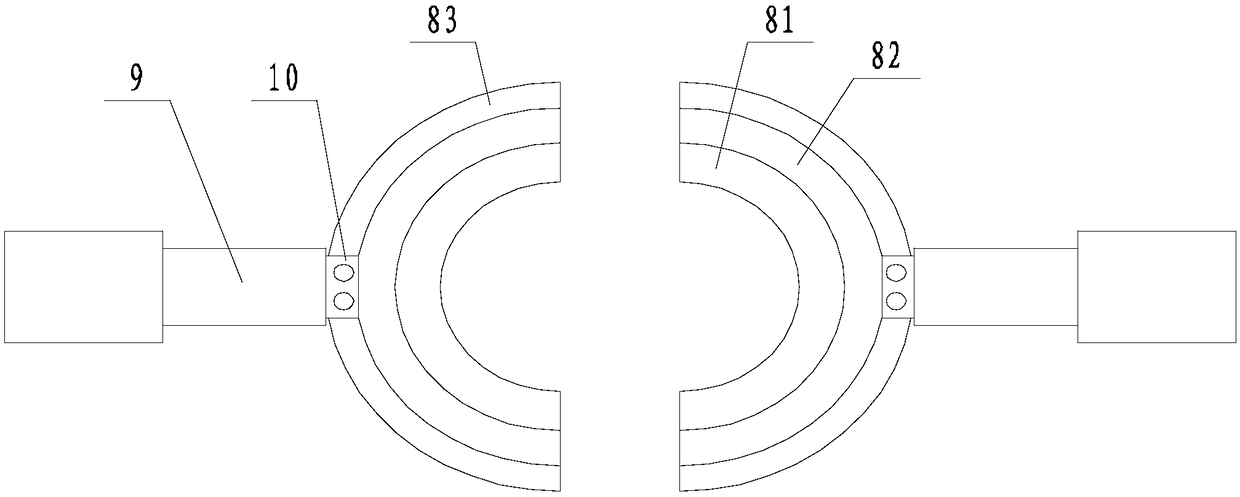

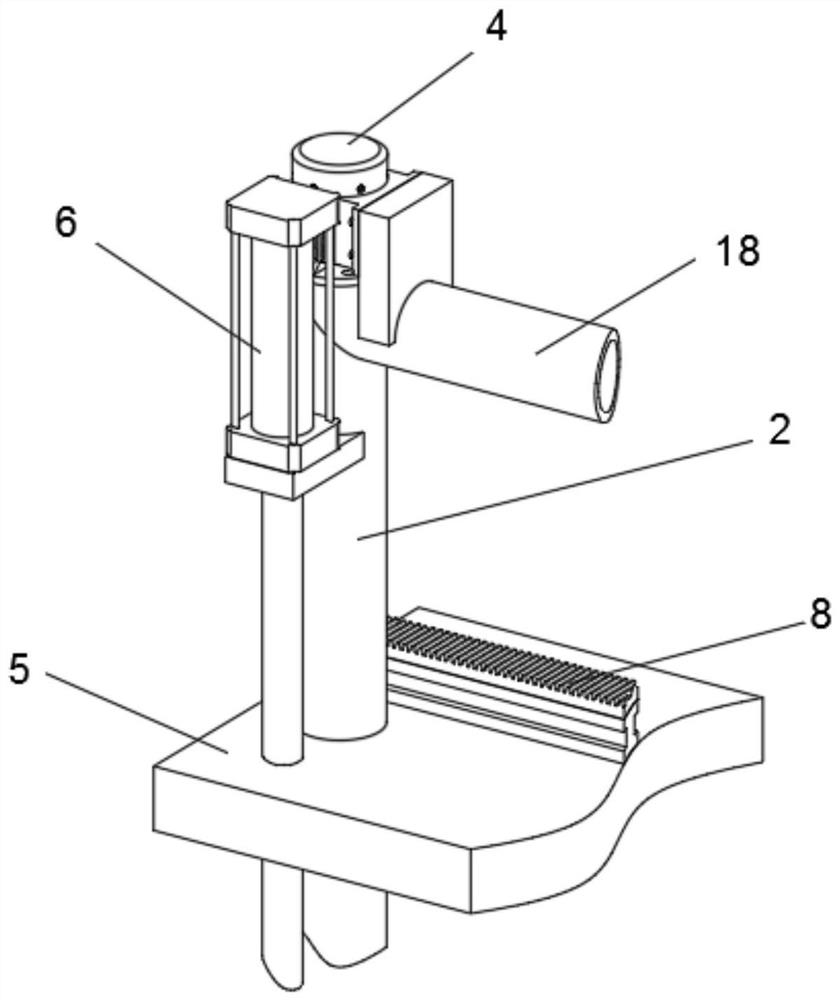

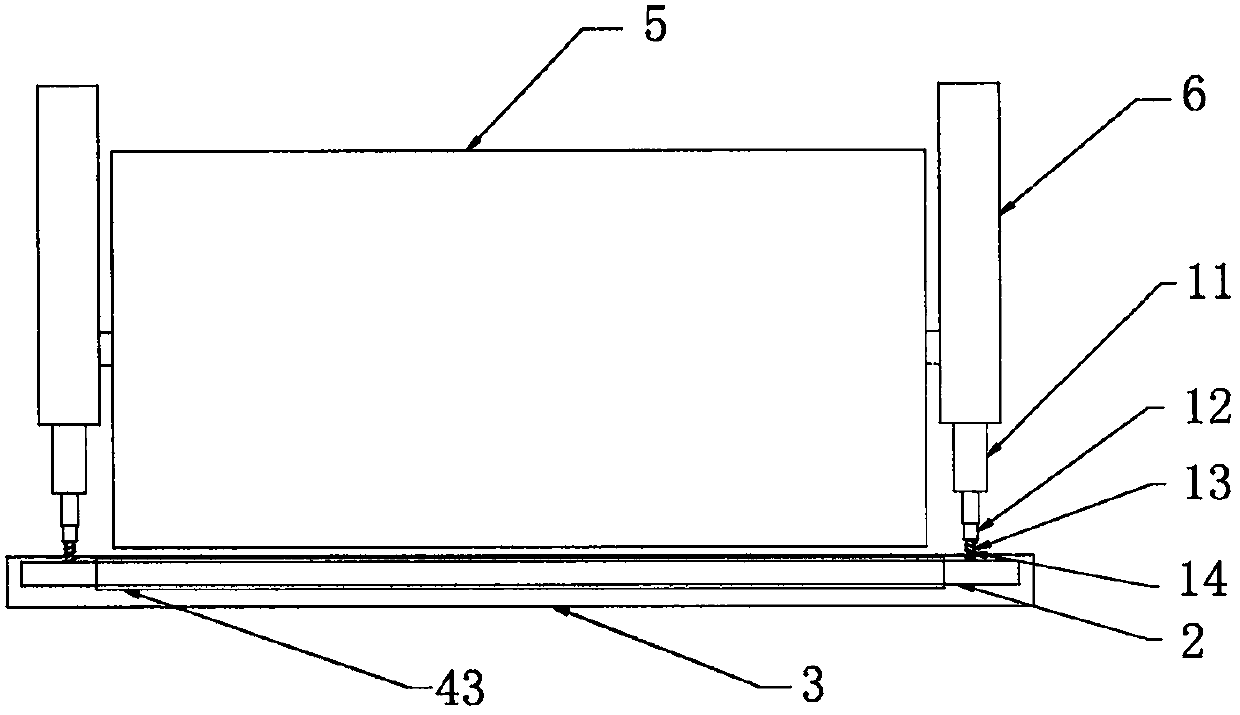

Mud scraping and cleaning device for well logging cable

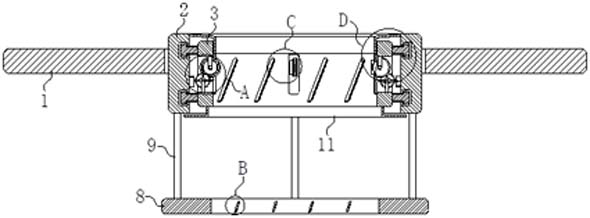

ActiveCN110420902AGuaranteed fitClean up in timeDrying gas arrangementsCleaning using toolsWell loggingEngineering

The invention discloses a mud scraping and cleaning device for a well logging cable. The device comprises a worktable, supporting legs are fixed at the four corners of the lower end surface of the worktable through screws, universal wheels are arranged at the lower ends of the supporting legs, a cleaning box body is fixed on one side of the upper end of the worktable through a screw, mud scrapingdevices are arranged on the side wall of the end, away from the worktable, of the cleaning box body, two mud scraping devices are provided, the middle part of the inner wall of the cleaning box body is fixedly provided with a sealing plate through glue, mounting plates are fixedly connected to the two sides of the inner bottom surface of the cleaning box body through screws, mounting grooves are formed in the upper ends of the mounting plates, the upper end of the sealing plate and the upper ends of the two side walls of the cleaning box body, mounting shafts are rotationally connected betweenthe front and rear end side walls of the mounting grooves through rolling bearings, guide wheels are fixedly connected to the outer walls of rod bodies of the mounting shafts through screws, fixing blocks are fixedly connected to the side walls of the front end of the cleaning box body through screws; and mounting blocks I are arranged on the upper end surfaces of the fixing blocks.

Owner:ANHUI TIANMING CABLE

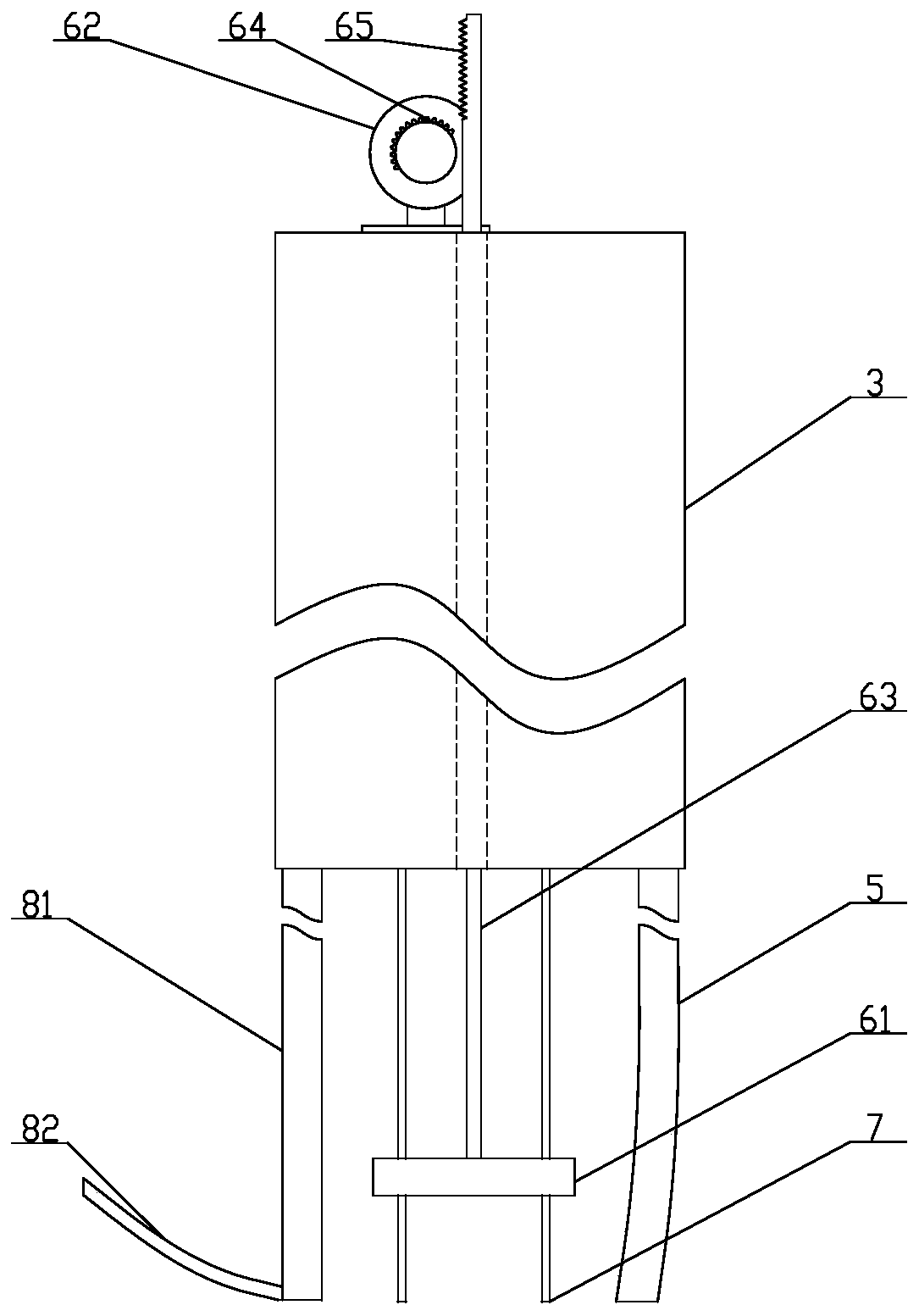

Clarification tank stirring and mud-scraping machine

InactiveCN106823496ACompact structureImprove reliabilitySedimentation settling tanksSocial benefitsDrive shaft

The invention provides a stirring mud scraper for a clarification tank, which includes a steady flow cylinder, a reducer, a sleeve coupling, a working bridge, a lubricating water pipe, a rake frame, a transmission shaft, a mud scraper, a mud discharge pipe and a connecting flange , one end of the reducer is arranged inside the steady flow cylinder and the bottom end of the reducer is connected with a transmission shaft, the steady flow cylinder is arranged inside the working bridge, the surface of one end of the transmission shaft is fixed with a sleeve coupling and The transmission shaft runs through the bottom end of the steady flow cylinder, and the other end of the transmission shaft is provided with a connecting flange, and the connecting flange is connected with a plurality of steel wire ropes. The present invention has compact structure, high reliability, good stability, and no shaking , stable transmission, low power consumption, good mud scraping effect, small footprint, low cost of use, box-shaped structure, greatly lighter than traditional mechanisms, low operating costs, good economic and social benefits, suitable for popularization and use .

Owner:CHONGQING FENGGUI MATERIALS RECOVERY CO LTD

Peripheral transmission concentration mud scraper

The invention discloses a peripheral transmission concentration mud scraper which comprises a pond body, a center rotating support, a main beam, a transmission device and a scraper plate, wherein the pond body is of a half-straddle type structure, a center upright and a water inlet pipe are arranged in the middle of the pond body, the water inlet pipe and the center upright are arranged in parallel, the center rotating support is arranged at the upper end of the center upright, one end of the main bam is connected with the center rotating support, the transmission device is arranged at the other end of the main beam, the transmission device is connected with a hinged scraping arm, the bottom of the hinged scraping arm is connected with the scraping plate, and vertical gird bars are arranged on the scraping plate. The peripheral transmission concentration mud scraper is simple in structure; water enters from the center and is discharged from the periphery, and mud is discharged from the bottom of the center, the vertical grids mainly play roles in slow carding and coagulating, so that the sludge compactness is improved. By adopting the hinged scraping arm, the effect of overload protection is played, the operation cost is effectively lowered; a truss girder is light in mass and good in rigidity; the scraper plate is arranged spirally, so that the mud scraping effect is relatively good.

Owner:CHANGZHOU LIWEI KNIFE

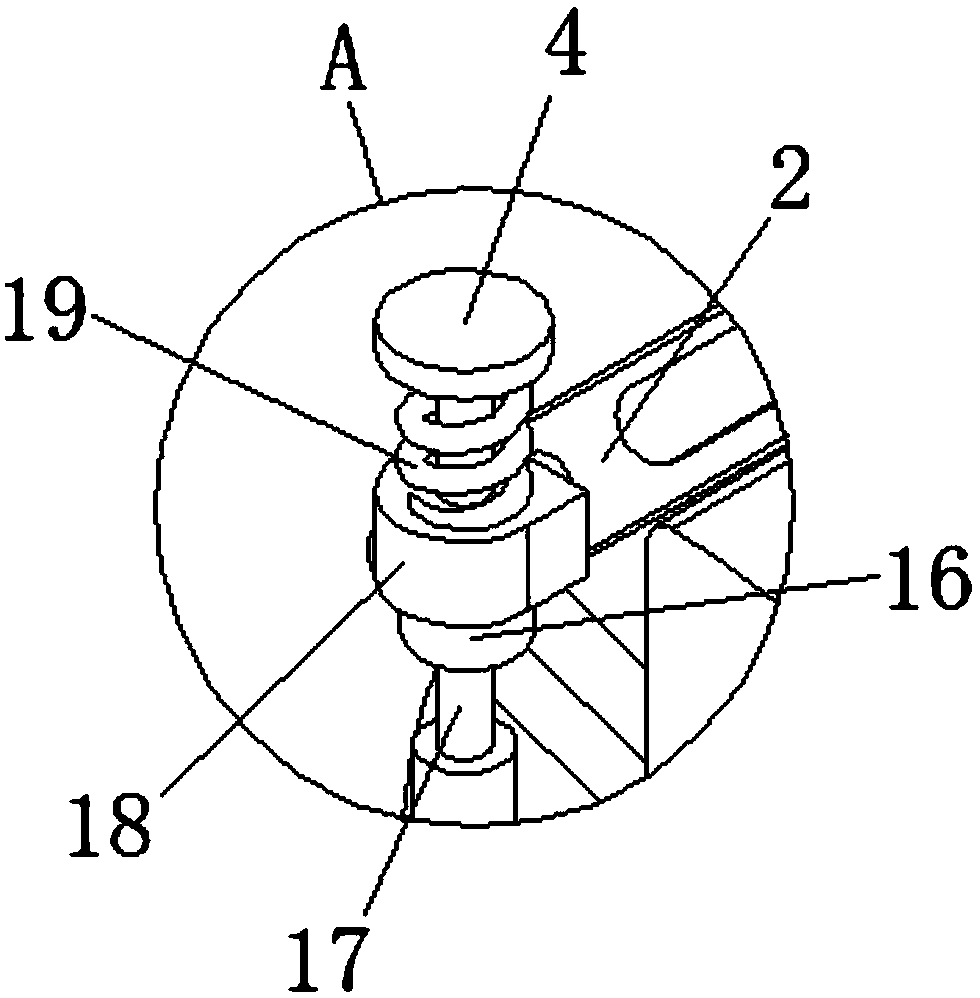

Peripheral transmission aspiration sludge scraper for sewage treatment

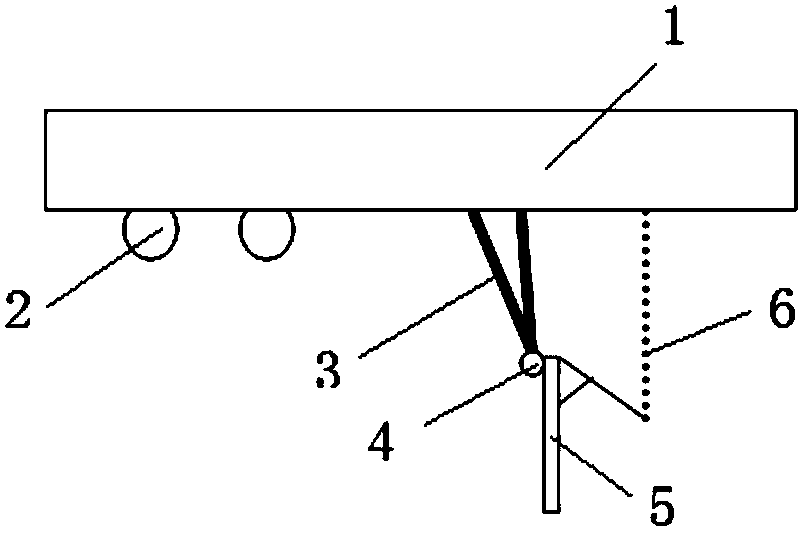

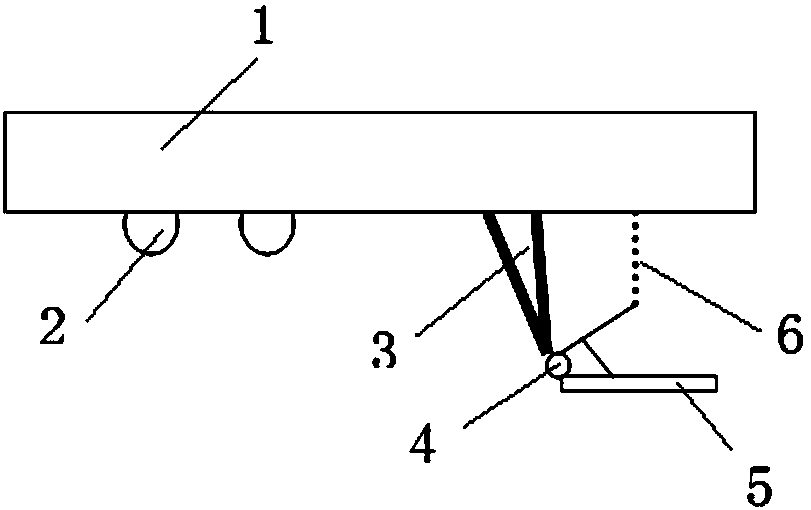

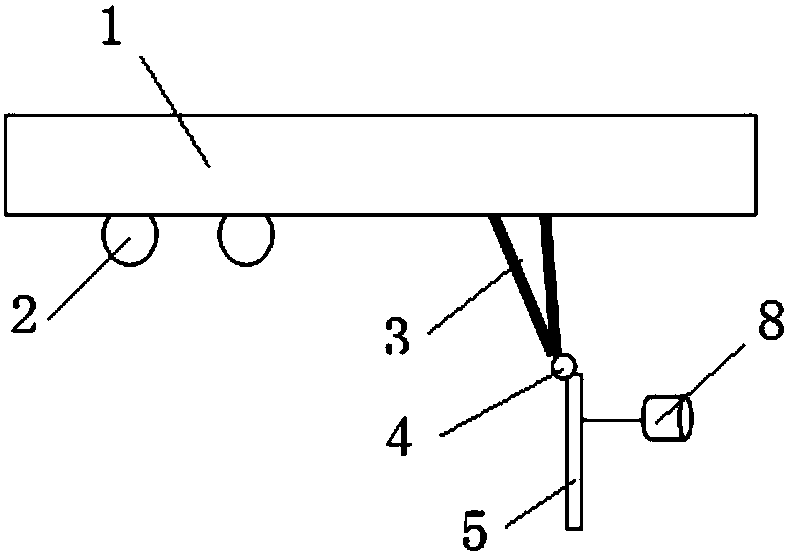

ActiveCN111589192AGood mud scraping effectSolve the problem of poor flatness and low slope surface that is difficult to cleanSettling tanks feed/dischargeSedimentation settling tanksSludgeSewage

The invention discloses a peripheral transmission aspiration sludge scraper for sewage treatment in the technical field of sludge treatment, which comprises a sludge scraping mechanism and an adjusting mechanism, wherein the adjusting mechanism is arranged on the sludge scraping mechanism, and the adjusting mechanism is used for adjusting the sludge scraping form of the sludge scraping mechanism.The sludge scraping mechanism is provided with the adjusting mechanism, so that the sludge scraping mechanism can obtain two different sludge scraping states; the two sludge scraping states adopt bottom sludge scraping and sludge mud scraping of a round sewage pool respectively, the sludge scraping effect is good; a sludge scraping assembly is further arranged on a sludge scraping plate, and the problems that the bottom face and the side face of the round sewage pool are poor in flatness, and the face with the low gradient is difficult to clean are solved.

Owner:江西海瑞天然植物有限公司

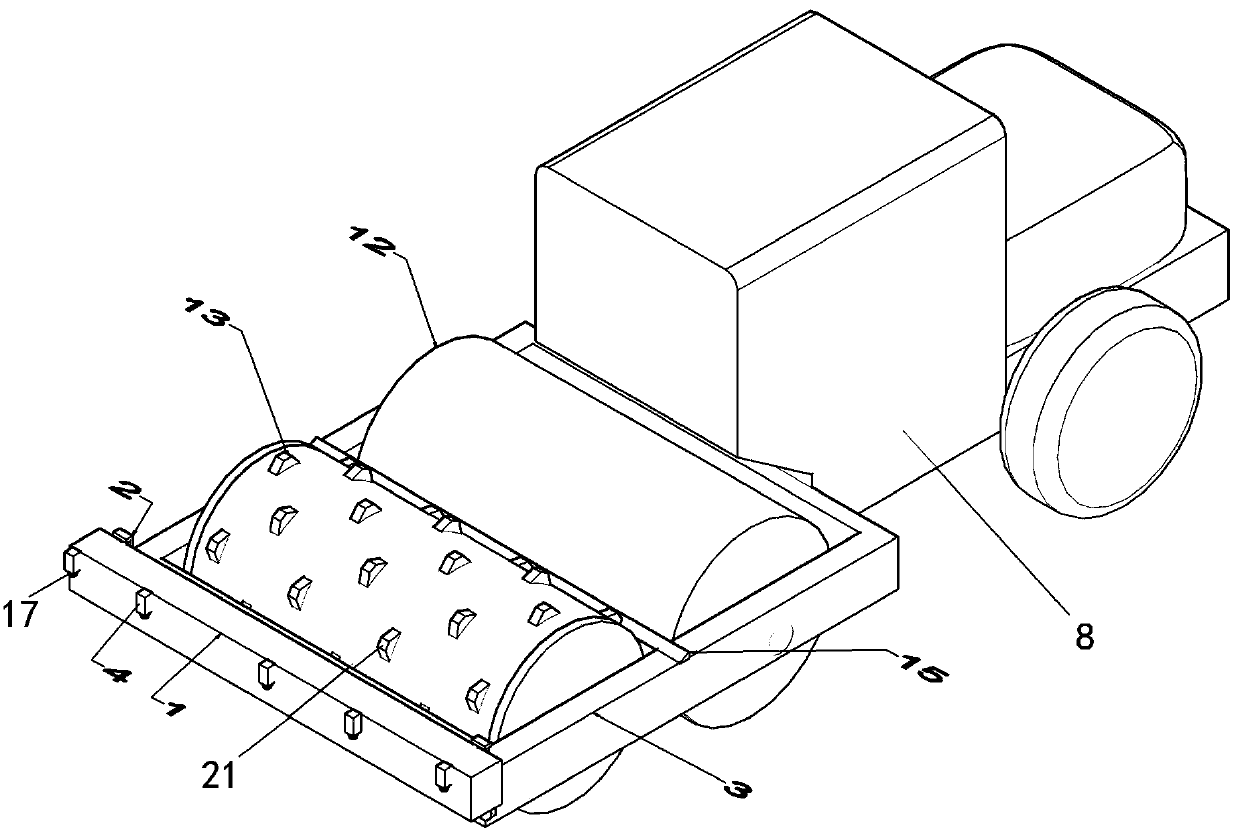

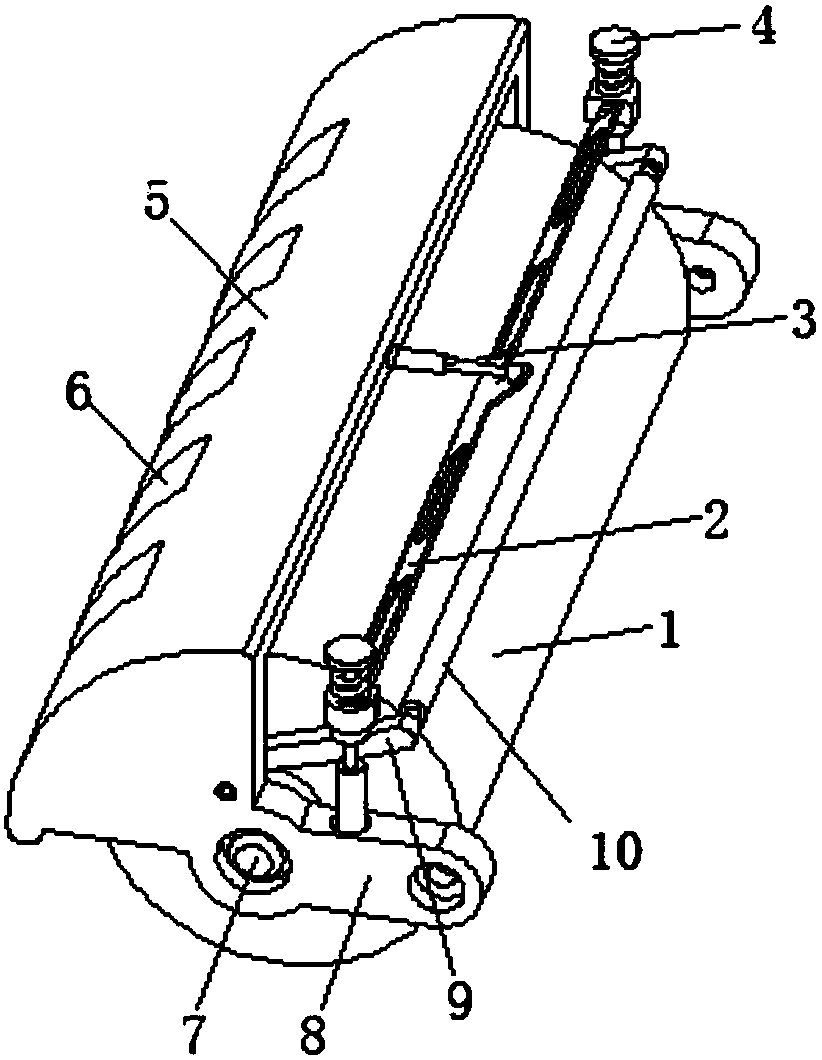

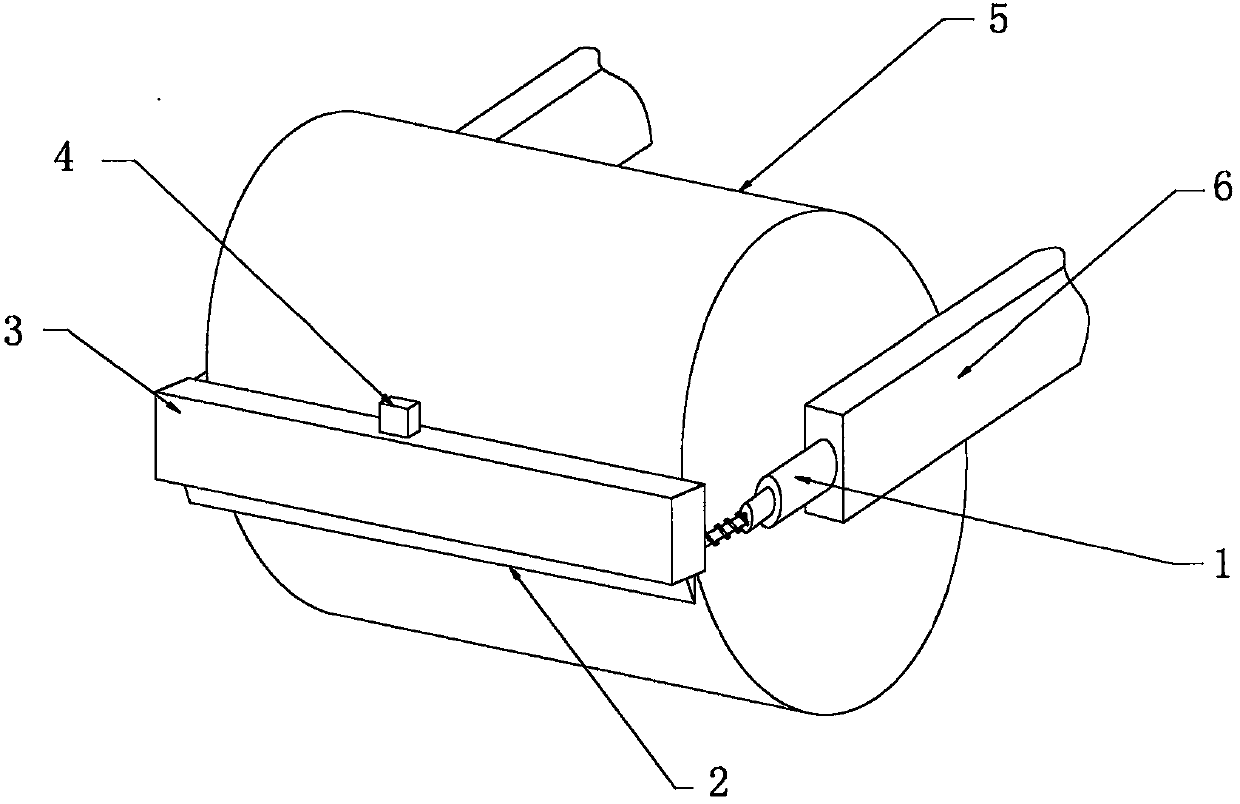

Rolling device and method for realizing rapid water drainage and gas exhaust of rubber soil roadbed

ActiveCN110144794AQuick exclusionImprove rolling efficiencyRoads maintainenceSoil preservationMicrowaveEffective action

A rolling device for realizing rapid water drainage and gas exhaust of a rubber soil roadbed comprises a double-rolling-wheel type road roller vehicle body; a fixing bracket is mounted in front of thedouble-rolling-wheel type road roller vehicle body; a front rolling wheel and a rear rolling wheel are mounted in the fixing bracket; lifting rods with slide blocks are fixed on the two sides of thefront end surface of the fixing bracket; a microwave heating device is mounted on the front end surface of the fixing bracket through a slide block; the front rolling wheel is a tamping roller and comprises an external roller; the external roller is an embedded steel pipe structure which is formed by combining an internal cylinder steel plate and an external cylinder steel plate; a supporting layer is arranged between the internal cylinder steel plate and the external cylinder steel plate; the supporting layer consists of multiple arc plate bodies which are spliced with each other; and mounting grooves with semicircular sections are formed in the two side surfaces of the arc plate bodies. According to the rolling device and method for realizing rapid water drainage and gas exhaust of the rubber soil roadbed, problems that the construction efficiency is low and effective action on rubber soil in the deep layer cannot be generated can be solved, and water and gas in the deep layer of therubber soil roadbed are rapidly and efficiently drained and exhausted.

Owner:CHINA THREE GORGES UNIV

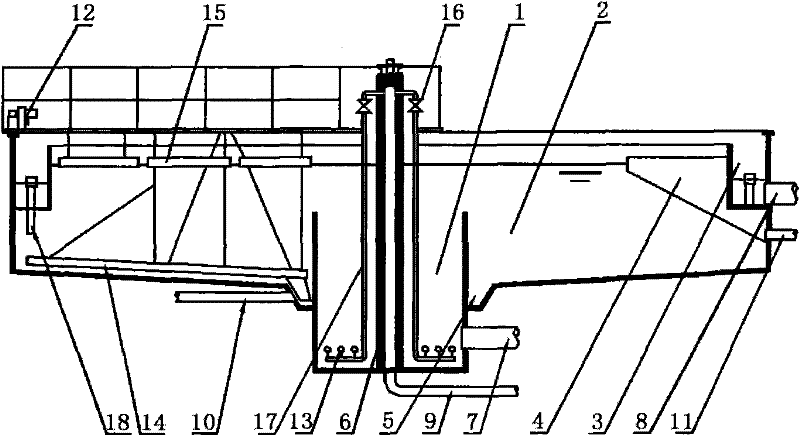

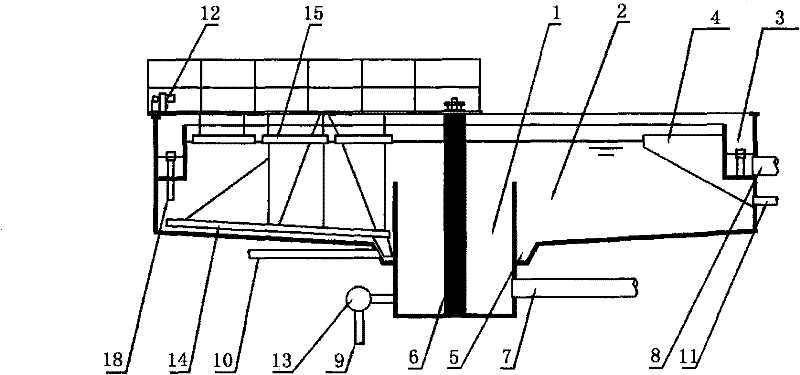

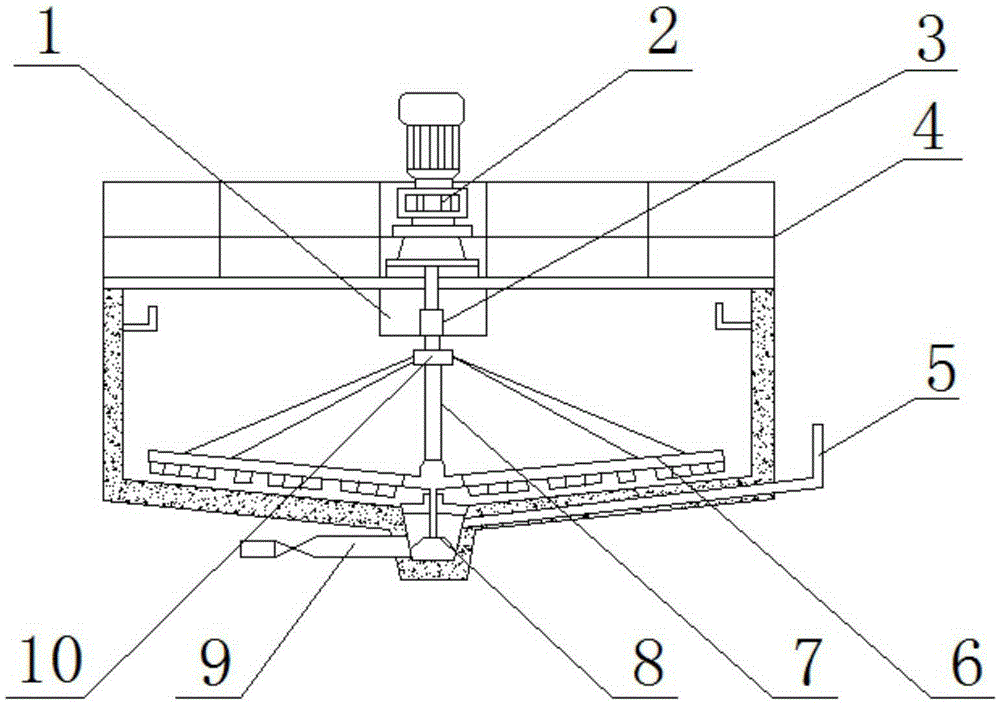

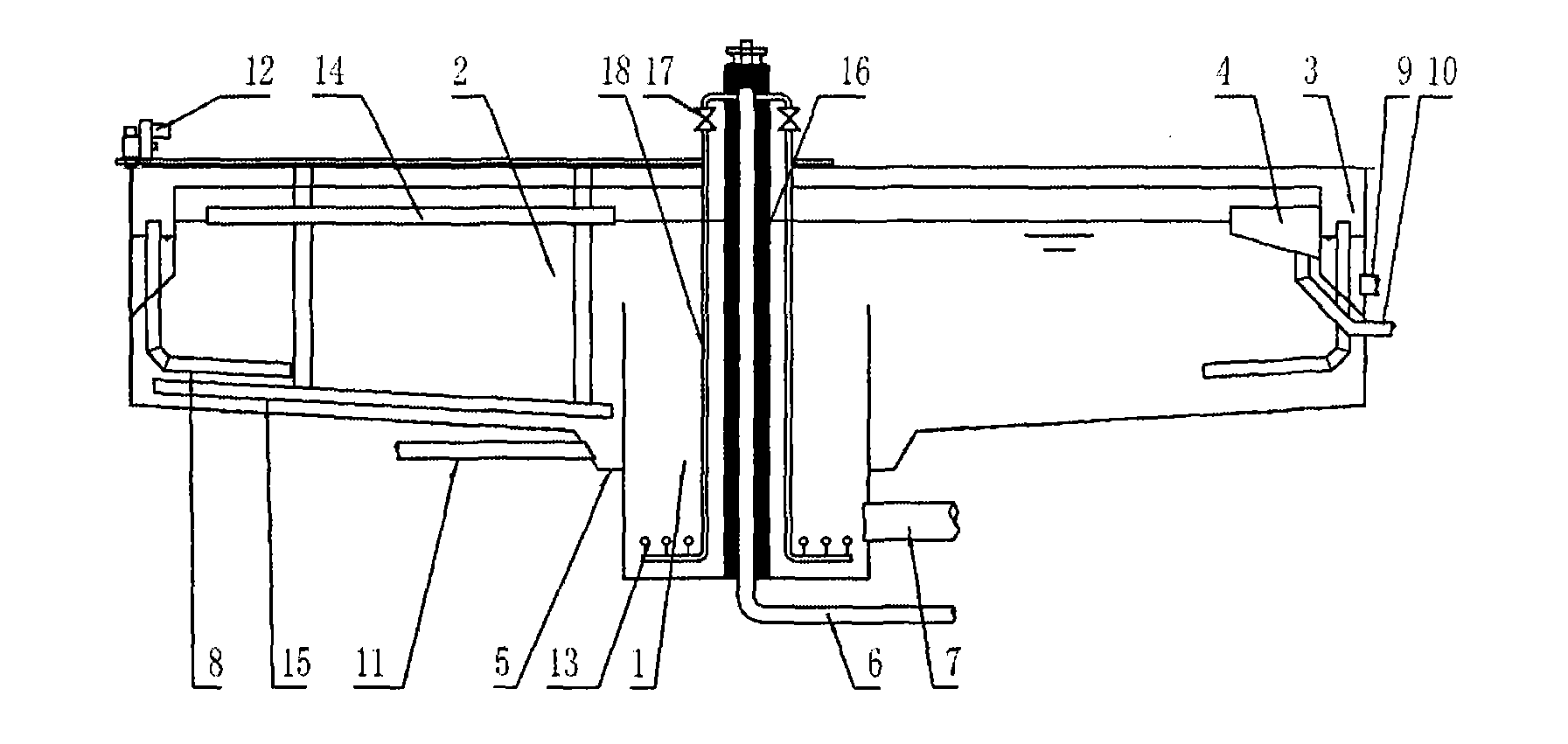

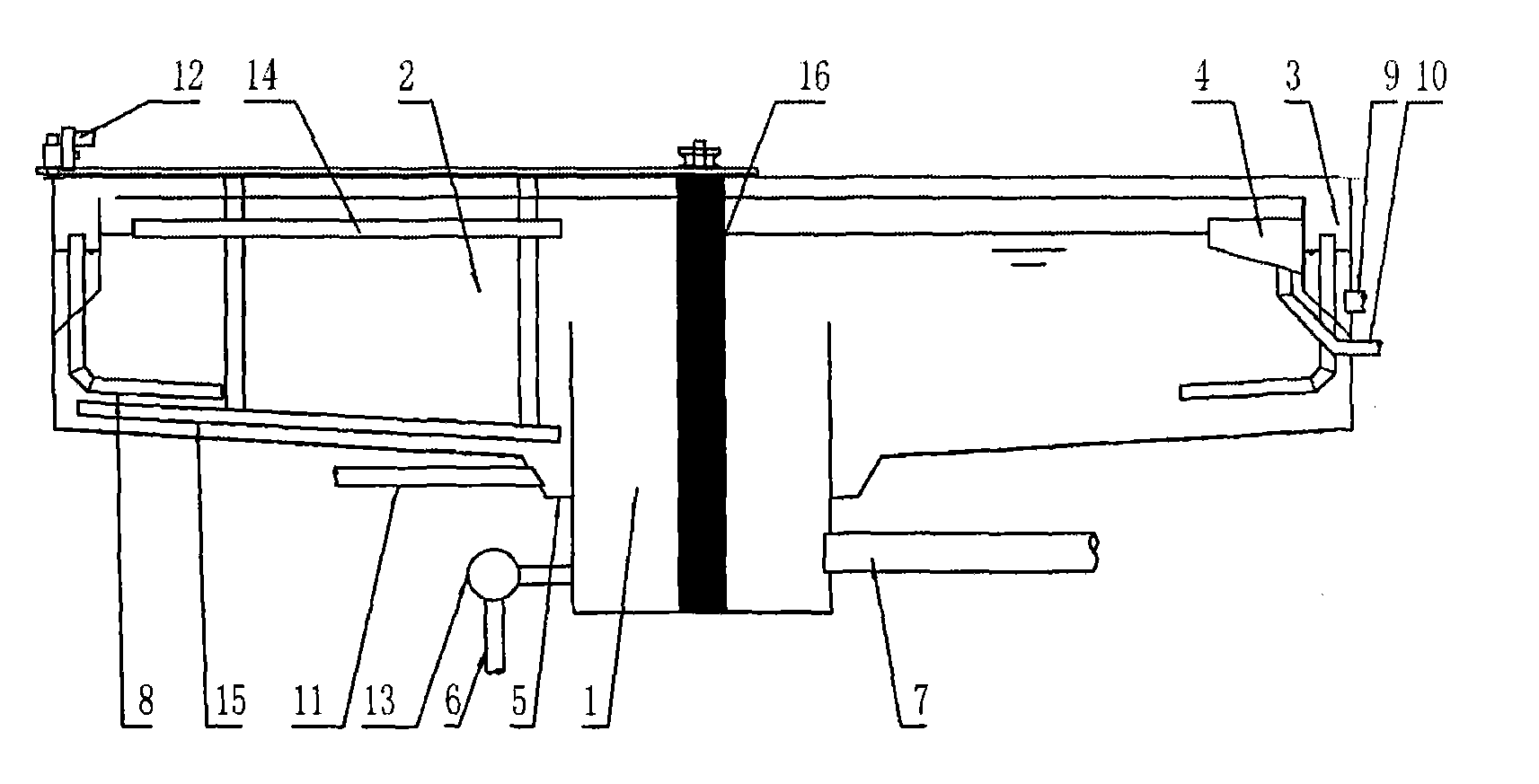

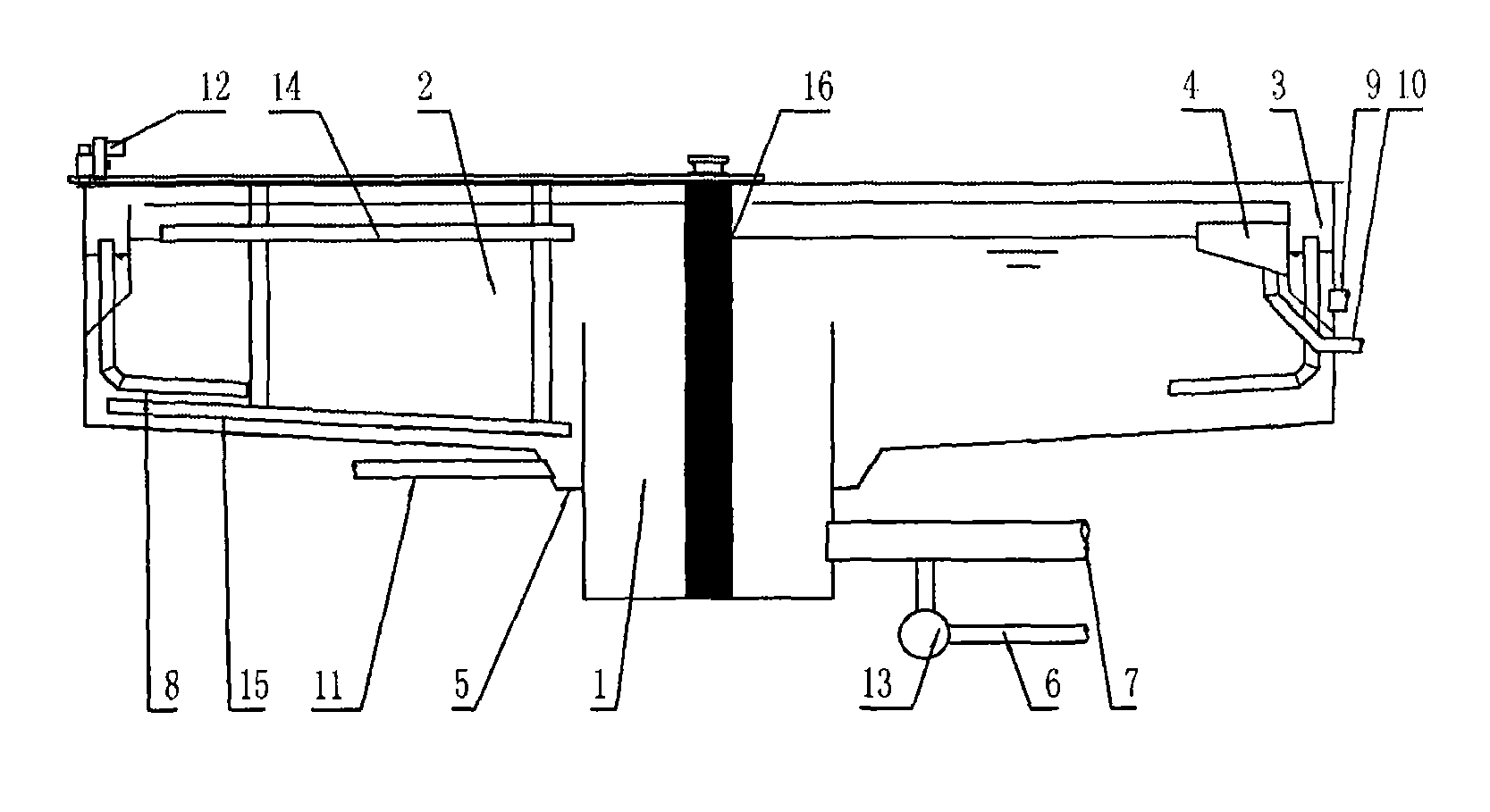

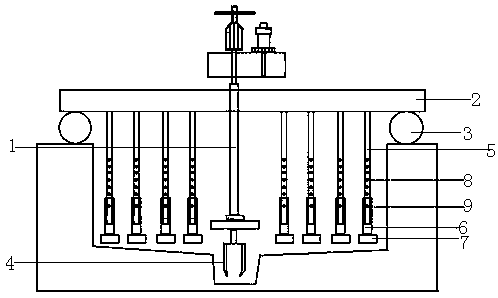

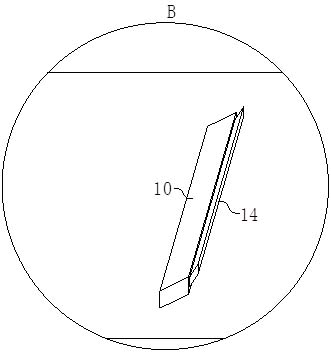

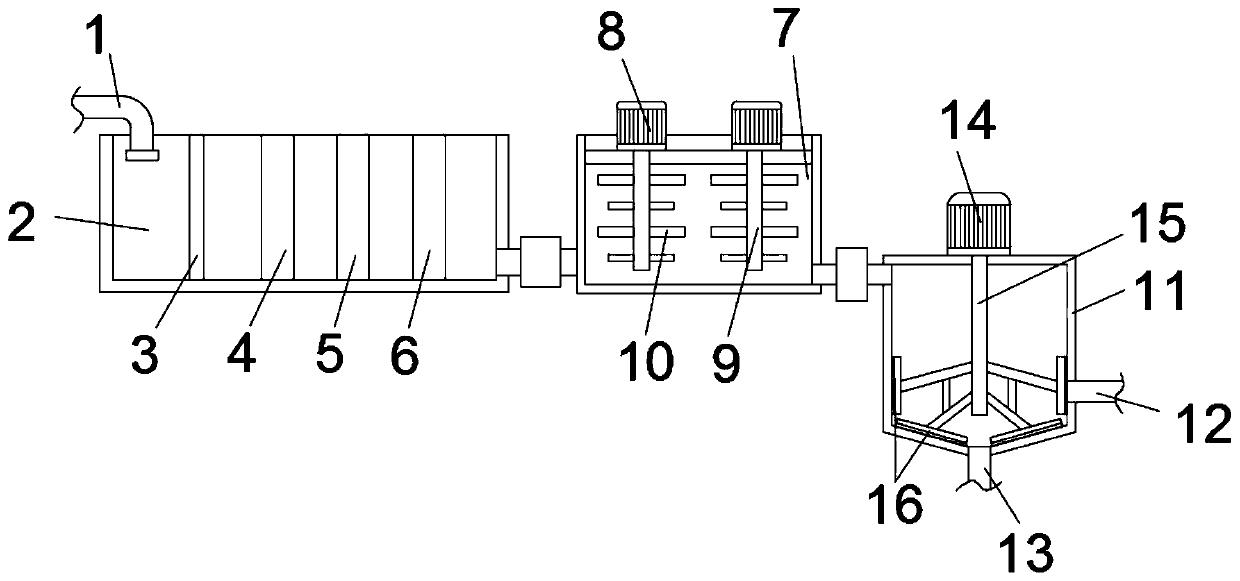

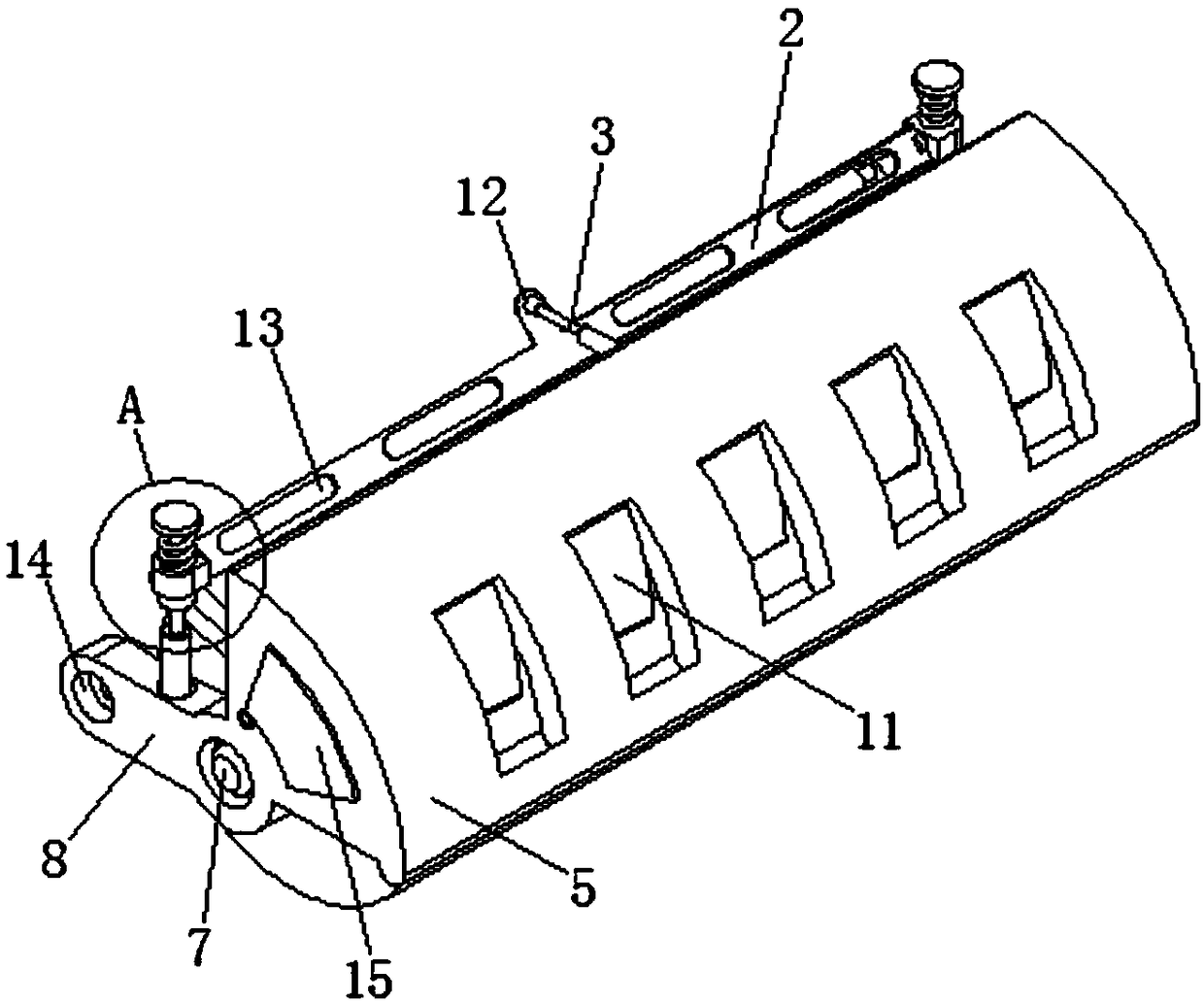

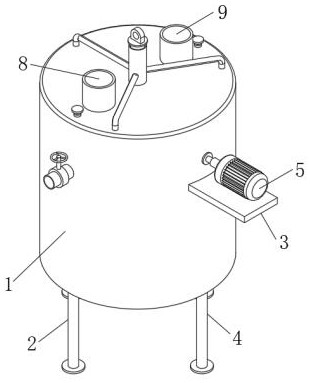

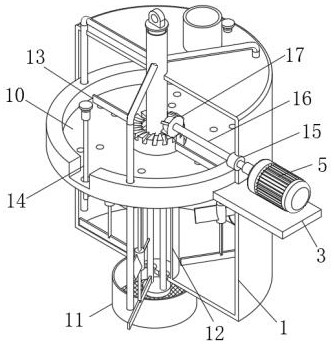

Radial-flow air-flotation thickening apparatus for sludge

InactiveCN104071963AAvoiding pitfalls of drain cleaningImprove mud scraping effectSludge treatment by de-watering/drying/thickeningMicro nanoSludge

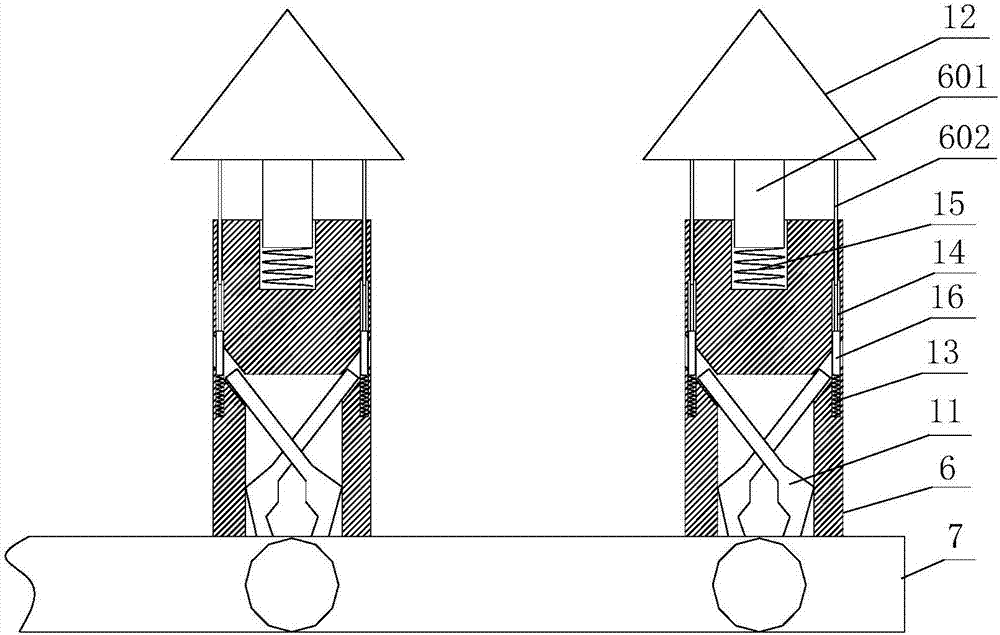

The invention provides a radial-flow air-flotation thickening apparatus for sludge. The apparatus comprises a contact area 1, a separation zone 2, a water outlet channel 3, a scum tank 4, a sludge tank 5, an air-dissolved water inlet pipe 6, a sludge inlet pipe 7, an effluent collecting pipe 8, a water outlet pipe 9, a slag discharge pipe 10, a sludge discharge pipe 11, a sludge and slag scraping machine 12 and a micro-nano bubble releaser 13, wherein the bottom of the sludge and slag scraping machine 12 is equipped with a sludge scraping plate 15 which is used for scraping sludge deposited at the bottom of a pool into the sludge tank 5, a slag scraping plate 14 is installed on a water surface and used for scraping thickened sludge into the scum tank 4, the micro-nano bubble releaser 13 introduces air-dissolved water into the bottom of the contact area 1, the effluent collecting pipe 8 introduces clear water at the bottom of the separation zone into the water outlet channel 3, the contact area 1 is located at the center of the separation zone 2, the water outlet channel 3 is located at the inner side of the separation zone 2, the scum tank 4 is hung on the sidewall of the water outlet channel 3, and the sludge tank 5 is located at the bottom of the separation zone 2. The apparatus has the advantages of a simple structure, easy maintenance, low cost, an ideal sludge thickening effect and applicability to large-scale sewage treatment plants.

Owner:王树岩

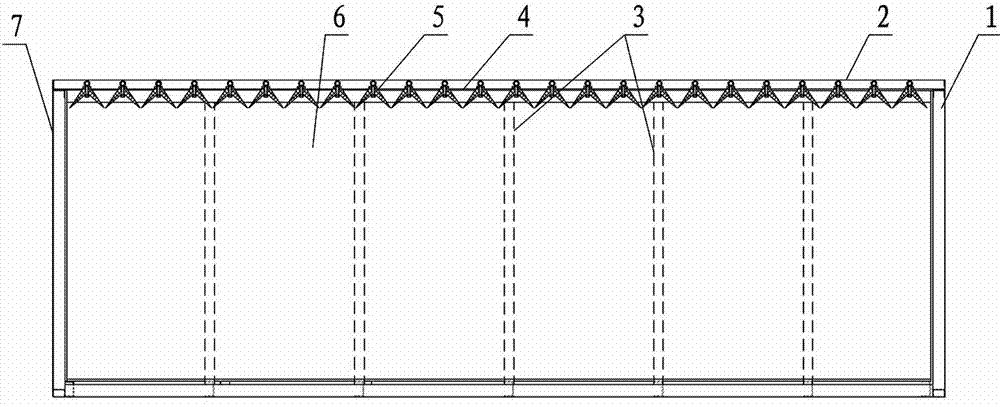

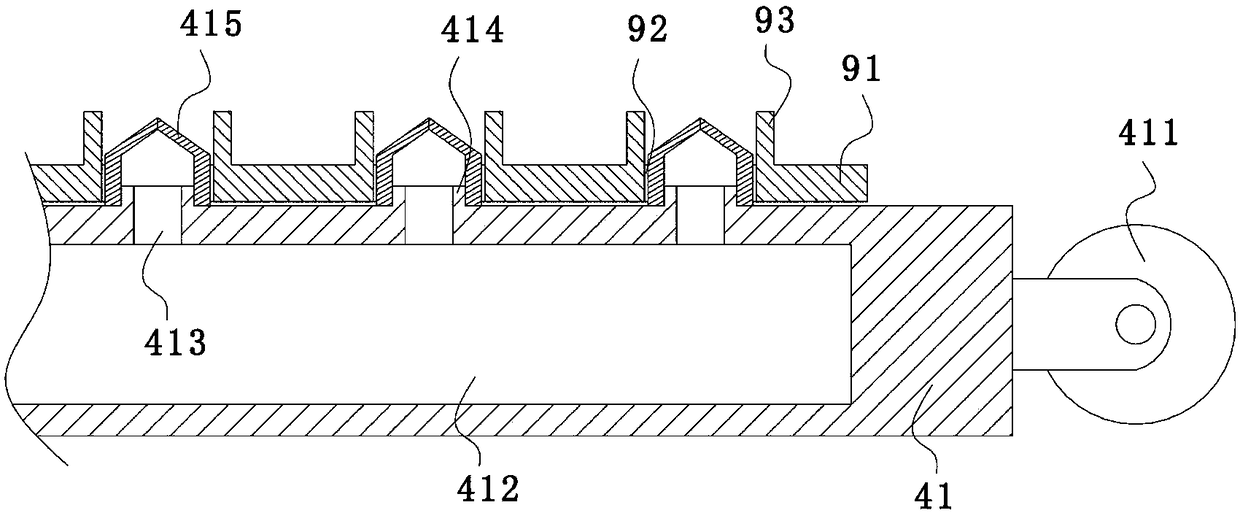

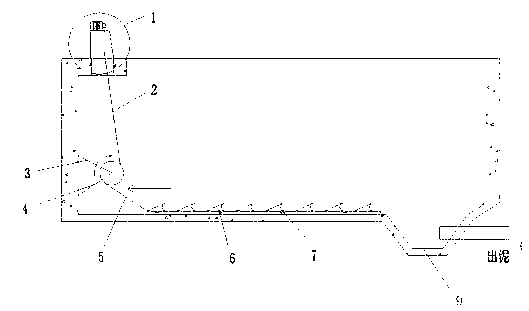

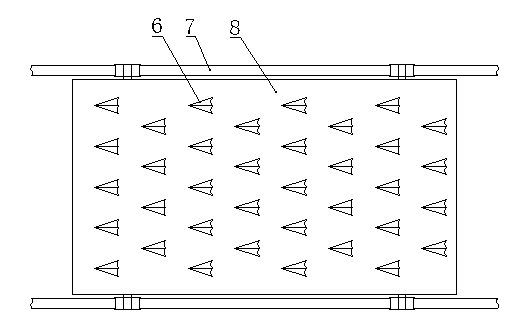

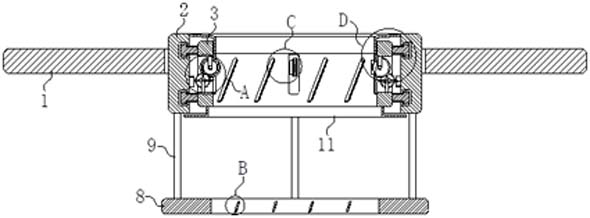

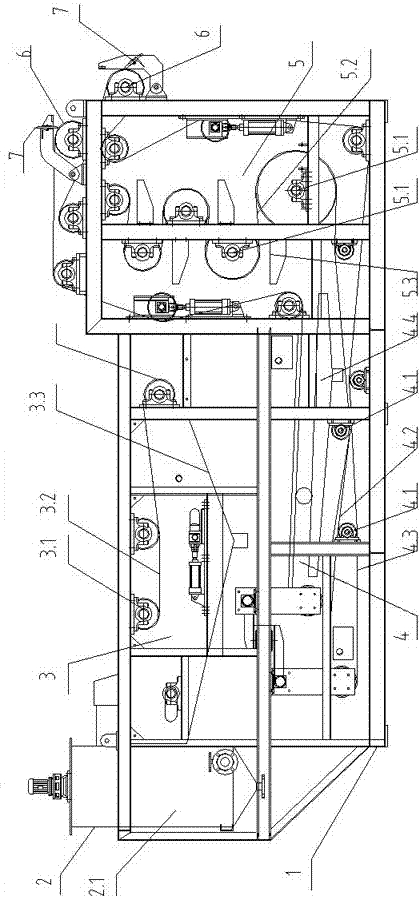

Four-dimensional sewage treatment tank sludge scrapping mechanism

ActiveCN102886160ASimple structureReduce manufacturing costSedimentation separationSludgeSewage treatment

The invention relates to a four-dimensional sewage treatment tank sludge scrapping mechanism which comprises a sewage treatment tank. One end of the sewage treatment tank is provided with a sludge outlet groove. The four-dimensional sewage treatment tank sludge scrapping mechanism has the innovations that the four-dimensional sewage treatment tank sludge scrapping mechanism also comprises an inertia sludge pushing plate, a reciprocating driving mechanism, sludge scrapers and rails; the inertia sludge pushing plate is arranged at the tank bottom of the sewage treatment tank; one end of the inertia sludge pushing plate is connected with the reciprocating driving mechanism; the inertia sludge pushing plate is driven by the reciprocating driving mechanism to reciprocate and move left and right along the tank bottom; the other end of the inertia sludge pushing plate is next to the sludge outlet groove at the tank bottom; both ends of the inertia sludge pushing plate are arranged on the rails at the tank bottom; the inertia sludge pushing plate is subjected to left and right guide limiting by the rails; and a plurality of rows of sludge scrapers are uniformly distributed on the upper surface of the inertia sludge pushing plate. The four-dimensional sewage treatment tank sludge scrapping mechanism has the advantages that the inertia sludge pushing plate and the sludge scrapers on the inertia sludge pushing plate are driven to reciprocate by the reciprocating driving mechanism and sludge is unidirectionally moved by the triangular pyramidal sludge scrapers, so that the sludge scrapping of the sewage treatment tank is implemented; and compared with a conventional traveling scrapping mechanism, the four-dimensional sewage treatment tank sludge scrapping mechanism has simple structure, low manufacturing cost and a good sludge scrapping effect.

Owner:NANTONG BEICHEN MACHINERY EQUIP MFGCO

High-efficiency water-injection mud scraper

InactiveCN107137960AImprove mud scraping effectPlay a cleaning roleSettling tanks feed/dischargeSludgeEngineering

The invention discloses a high-efficiency water-injection mud scraper. The mud scraper comprises a working bridge, a driving mechanism, a rotation shaft, a mud-scraping mechanism and a high-pressure water gun, wherein the mud-scraping mechanism comprises an installation rack and a scraper blade which is fixedly arranged on the installation rack, mud-breaking mechanisms are arranged on the front and reverse sides of the scraper blade, and the mud-breaking mechanisms comprise strip-shaped rods and cross racks which connect the strip-shaped rods and the installation rack; cavities are formed in the strip-shaped rods, and jet orifices are formed in the side walls of the strip-shaped rods; the high-pressure water gun comprises a high-pressure plunger pump, a power device and jet gun heads; the high-pressure plunger pump and the power device are both fixedly arranged on the working bridge, the jet gun heads are fixedly arranged in the cavities, and outlets of the jet gun heads are located in the jet orifices. According to the mud scraper, the jet gun heads are used for spraying high-pressure water to a mud layer, so that sludge which is deposited on the bottom of a pool is diluted, the driving force which is required by the rotation of the rotation shaft is greatly reduced, the energy consumption of the whole machine can be greatly reduced, and the service life of the mud scraper can be greatly prolonged.

Owner:ASIA PACIFIC WATER TREATMENT TIANCHANG

Automobile cushion and manufacturing method thereof

InactiveCN101966830AImprove mud scraping effectImprove aestheticsVehicle arrangementsLayered productsPlastic materialsEngineering

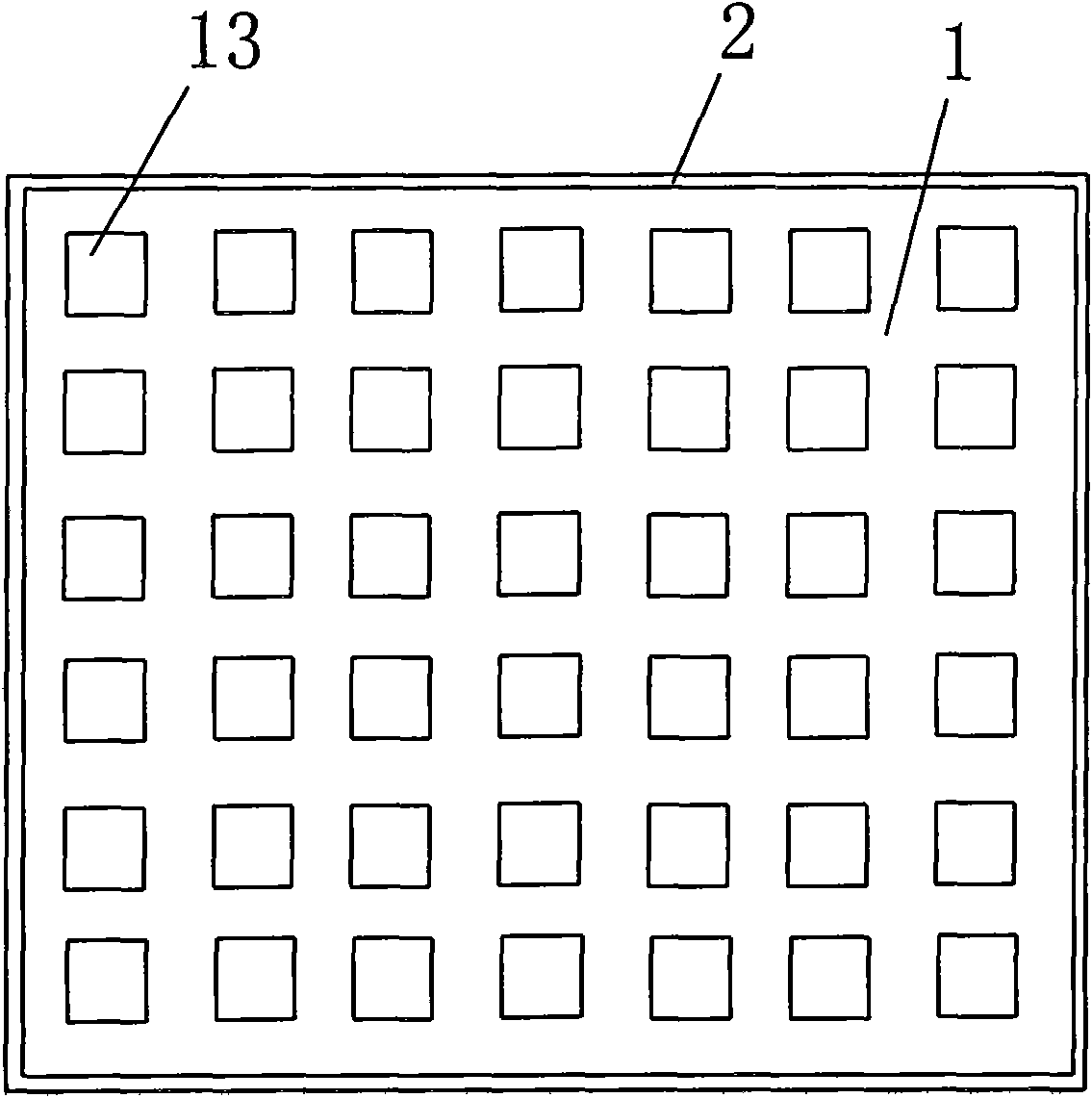

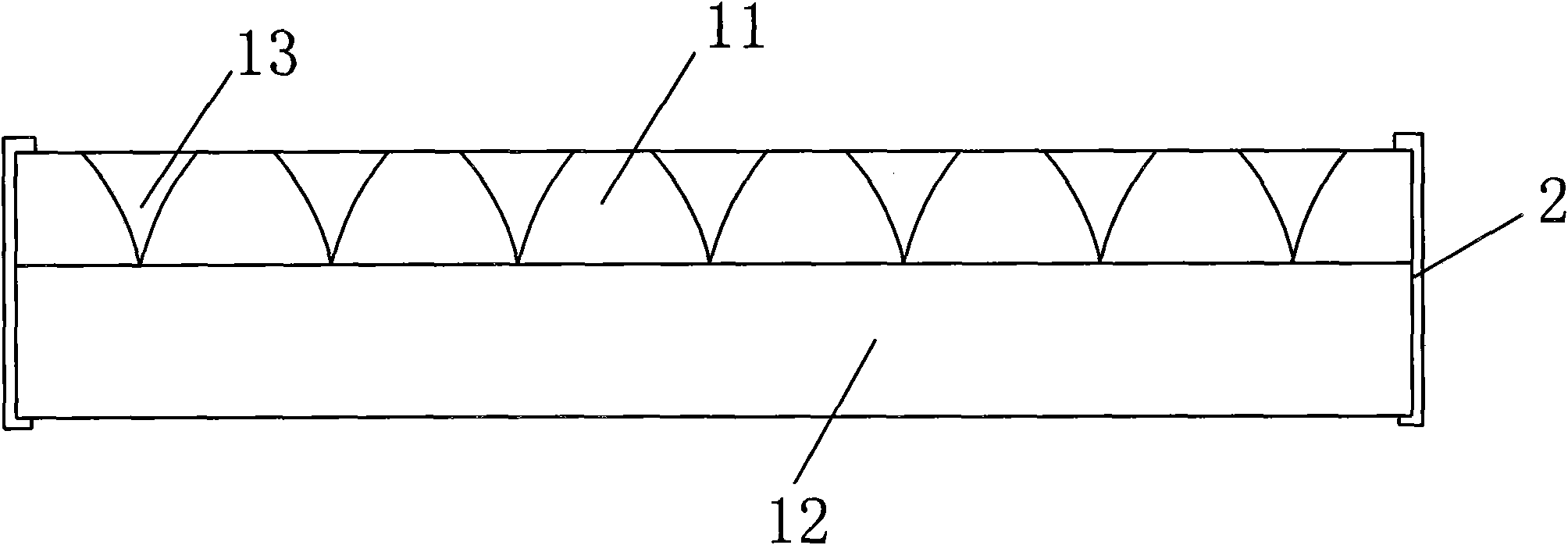

The invention relates to an automobile cushion, which comprises a cushion body and a purfle arranged around the cushion body, wherein the cushion body comprises an upper cushion layer and a bottom layer which are adhered closely; the upper surface of the upper cushion layer is provided with a plurality of concave pattern holes that the section is in a regular shape, the orifice of each concave pattern hole is decrescent from top to bottom, and the concave pattern holes are subject to equidistant spaced arrangement. The automobile cushion has the advantages of wear resistance, dirt resistance, easy cleaning, low cost and easy maintenance. The invention also relates to a method for manufacturing the automobile cushion, which comprises the following steps: (1) preparing a plastic foam material layer and a plastic material layer, wherein the two sides of the plastic foam material layer are provided with the concave pattern holes, and the bottom of the plastic material layer is provided with antiskid grooves or nailing strips; (2) halving the plastic foam material layer into two plastic foam material sheets from the middle of the plastic foam material layer, or removing the middle layer of the plastic foam material layer so as to prepare two same plastic foam material sheets; and (3) taking the plastic material layer as the bottom layer and the plastic foam material sheets as the upper cushion layer obtained in step (1) or (2), adhering the bottom layer and the upper layer so as to obtain the cushion body, and finally, setting the purfle around the cushion body.

Owner:惠州全品科技工业有限公司

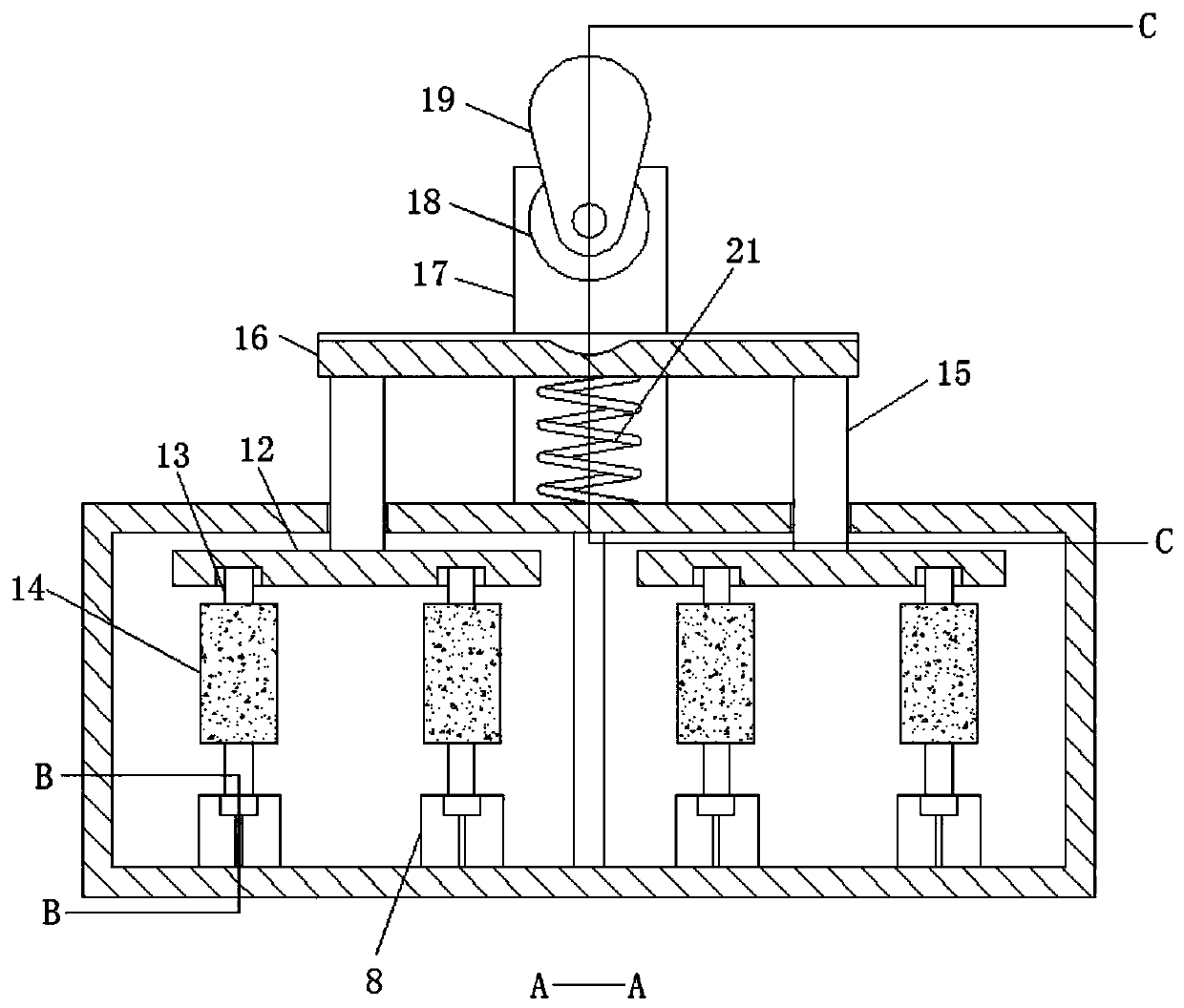

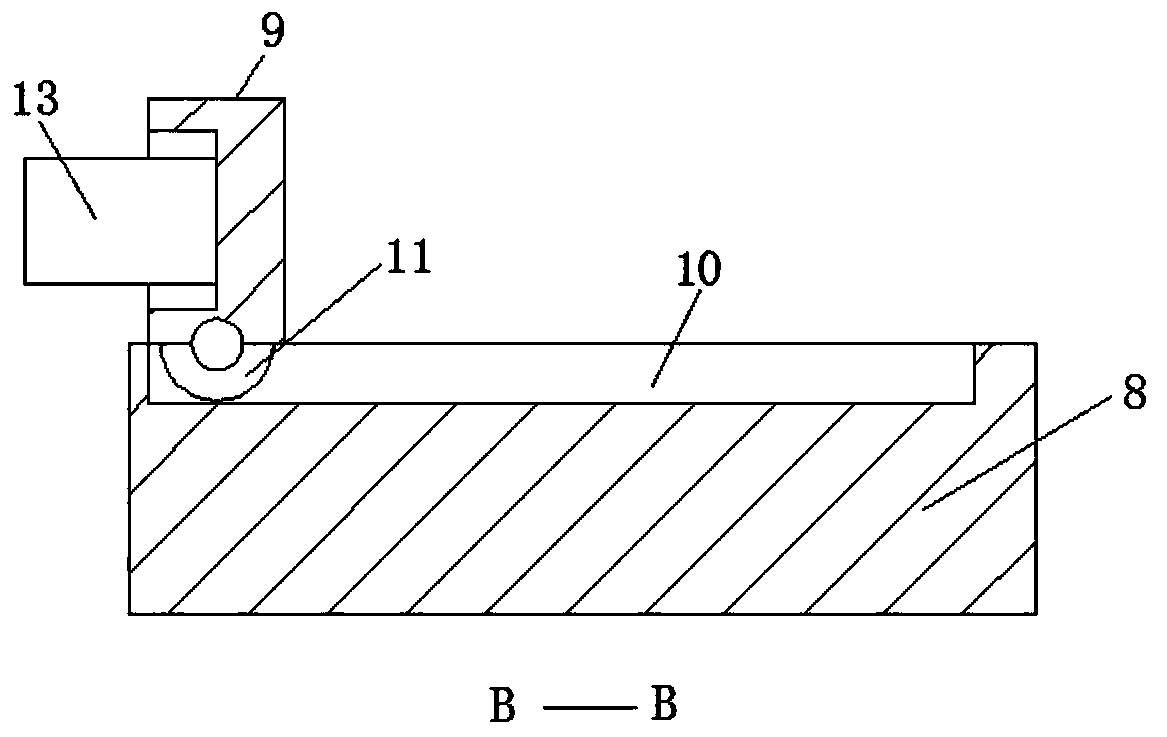

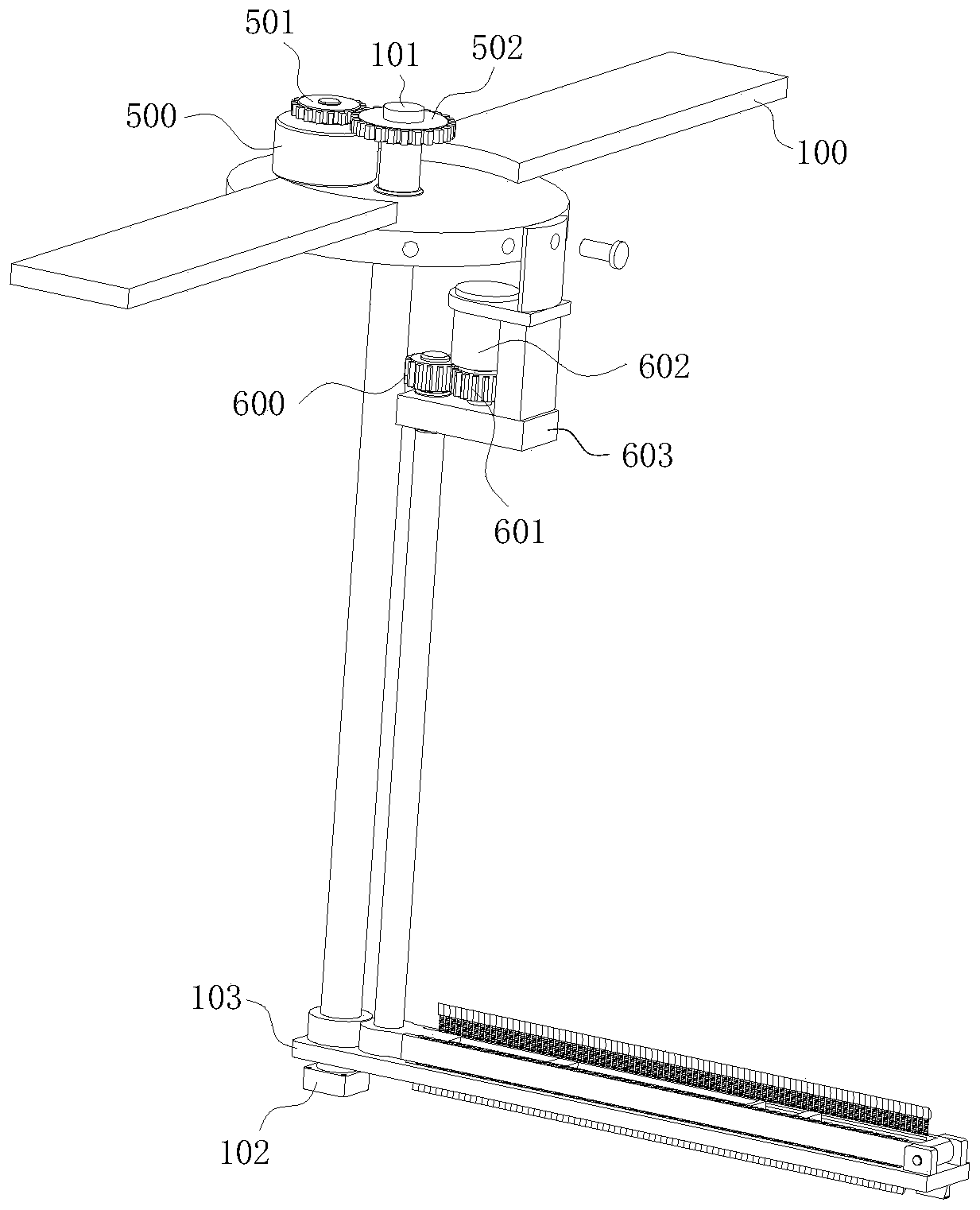

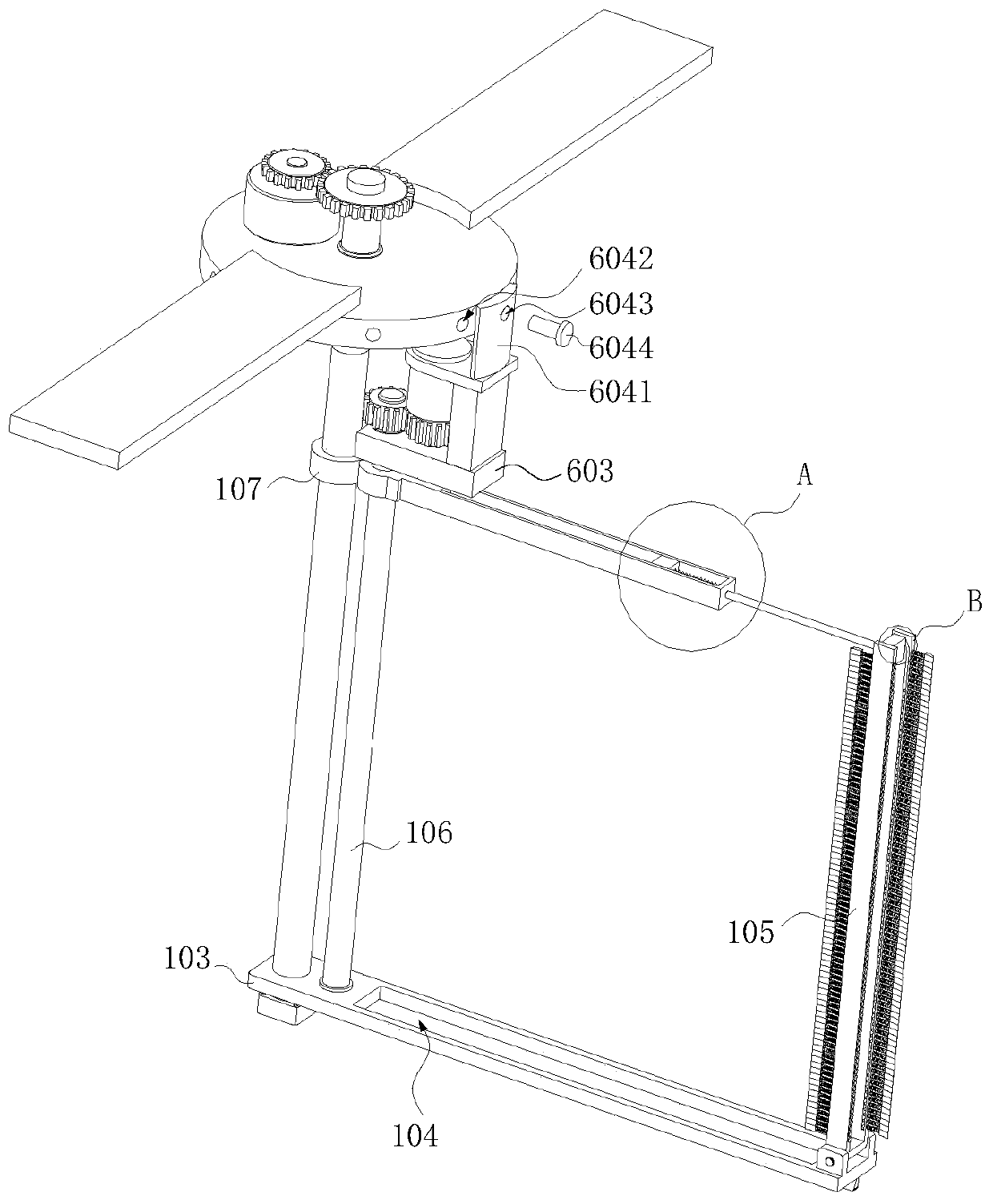

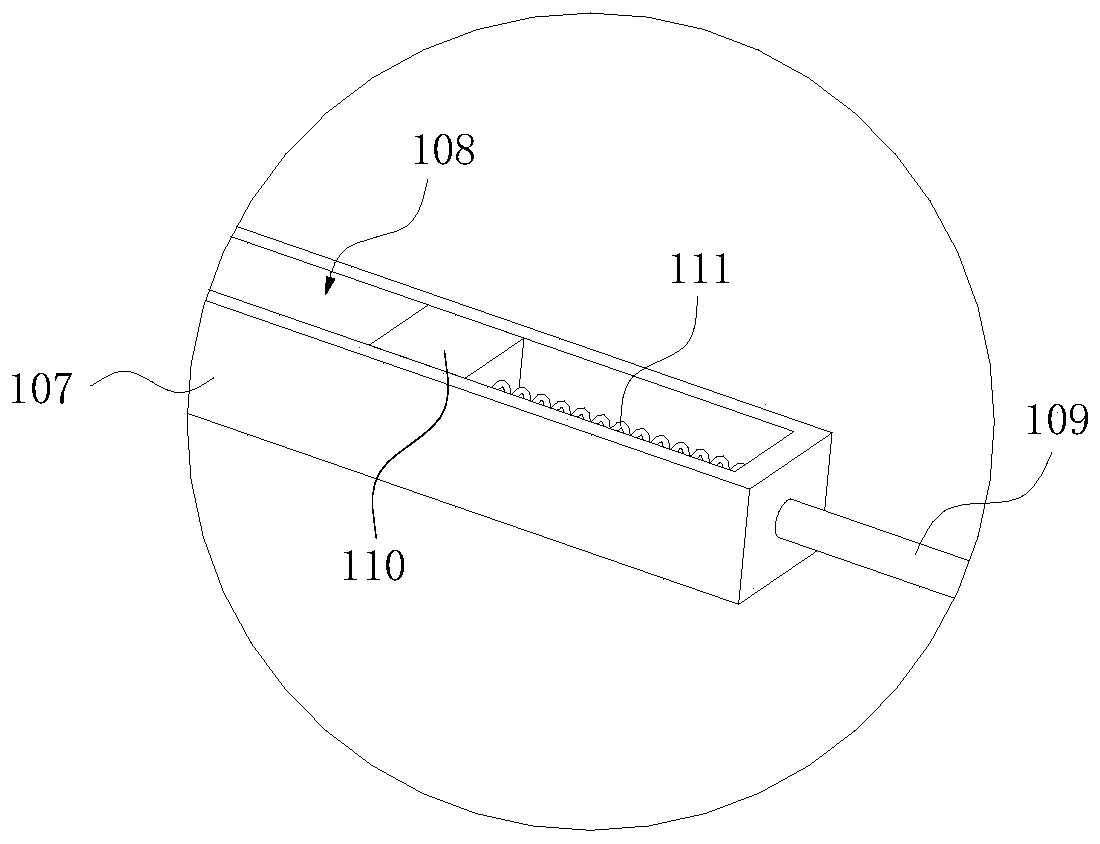

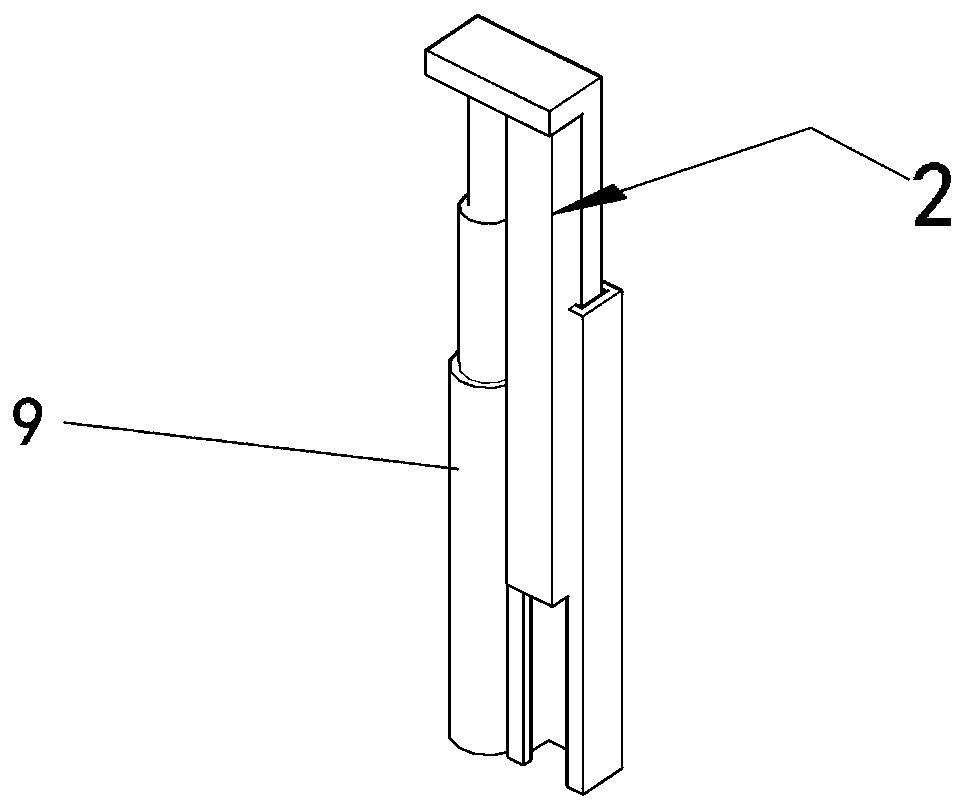

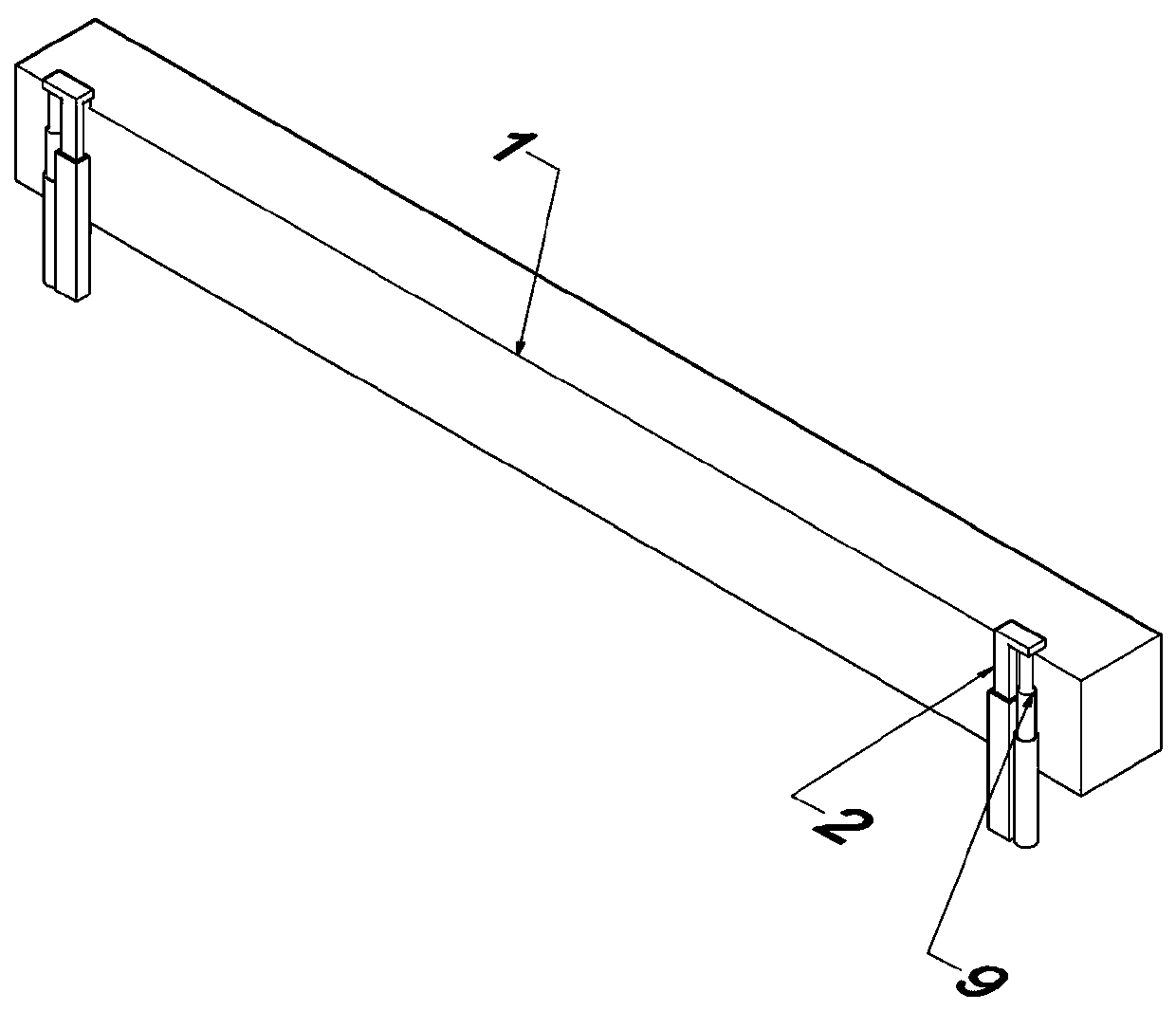

Adjustable mud scraper

InactiveCN110960897AImprove mud scraping effectSimple structureSedimentation settling tanksStructural engineeringMechanical engineering

The invention relates to an adjustable mud scraper. The mud scraper comprises a mud scraper main shaft, a working bridge, a mud scraping mechanism and a transmission device, wherein the top of the mudscraper main shaft is fixedly connected with the transmission device; the mud scraper main shaft penetrates through the middle part of the working bridge; the mud scraper main shaft is fixedly connected with the working bridge; two ends of the working bridge are respectively connected with electric rollers; the bottom of the mud scraper main shaft is fixedly connected with a bottom scraping plate; the mud scraping mechanism is fixedly connected to the bottom of the working bridge; the mud scraping mechanism comprises a fixing rod, a connecting pipe and a mud scraping plate; one end of the fixing rod is fixedly connected to the bottom of the working bridge; a fixing hole is formed in the fixing rod; the connecting pipe is in a hollow pipe shape; a connecting hole matched with the fixing hole is formed in the connecting pipe; and the mud scraping plate is fixedly connected to the bottom end of the connecting pipe. The mud scraper is simple in structure and convenient to operate, the height of the mud scraping shaft can be adjusted up and down according to the depth of the mud scraping pool and other requirements, and the mud scraping effect of the mud scraper is improved.

Owner:扬州市水世界环保设备有限公司

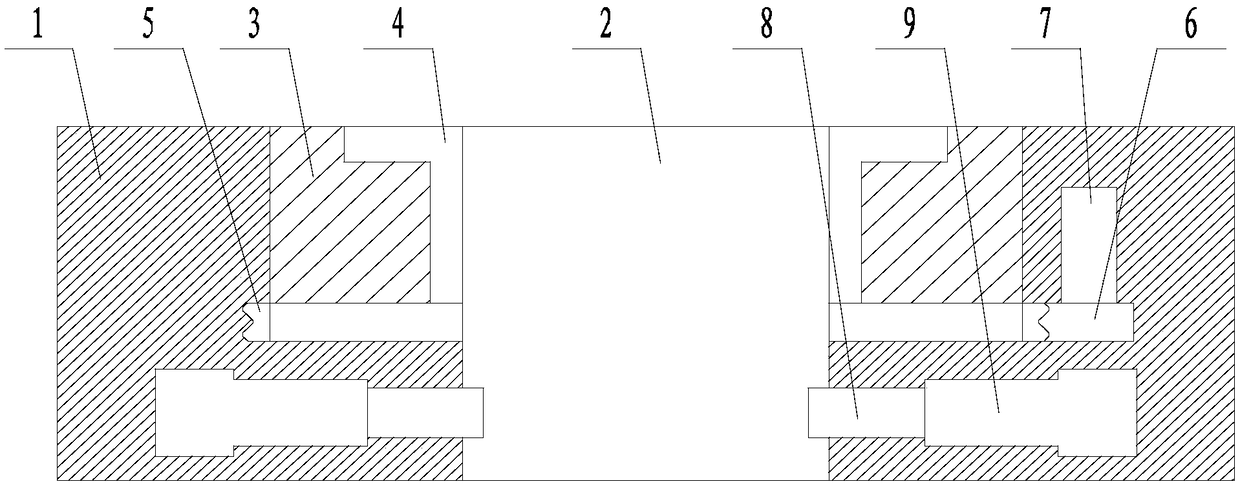

Turntable structure with built-in scraper

InactiveCN109162633AImprove securitySolve the problem of completely scraping mudConstructionsCleaning apparatusEngineeringLinear drive

The invention discloses a turntable structure with a built-in scraper. The turntable structure comprises a base body, a wellhead passage penetrating the base body, an annular rotating member rotatingaround the wellhead passage, and a centering complementing unit matching the annular rotating member. The annular rotating member is connected to an annular turntable; one loop of rack is fixed at theouter edge of the annular turntable in the circumferential direction. A gear and a rotary driving device are arranged in the base body; the gear is meshed with the rack; and the rotary driving devicedrives the gear to rotate. Two scraping pieces distributed symmetrically along the axis of the wellhead passage are arranged below the annular turntable; the scraping pieces are in a semi-annular shape; concave surfaces of the scraping pieces face the axis of the wellhead passage; each scraping piece is driven by one linear driving device to move; and the driving directions of the two linear driving devices are in a collinear state. Therefore, a problem that two drilling workers are need for completing scraping of the circumference of the surface of the drill rod during the drilling startingprocess in the prior art is solved; and thus the manpower consumption is reduced and the automatic scraping is realized.

Owner:四川川油工程技术勘察设计有限公司

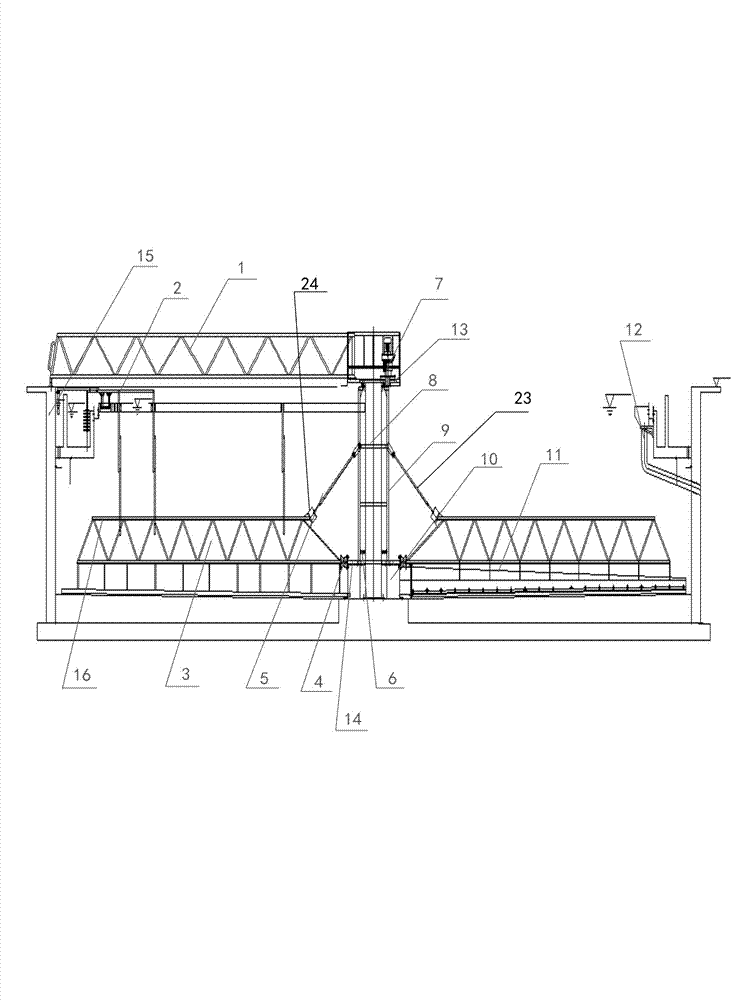

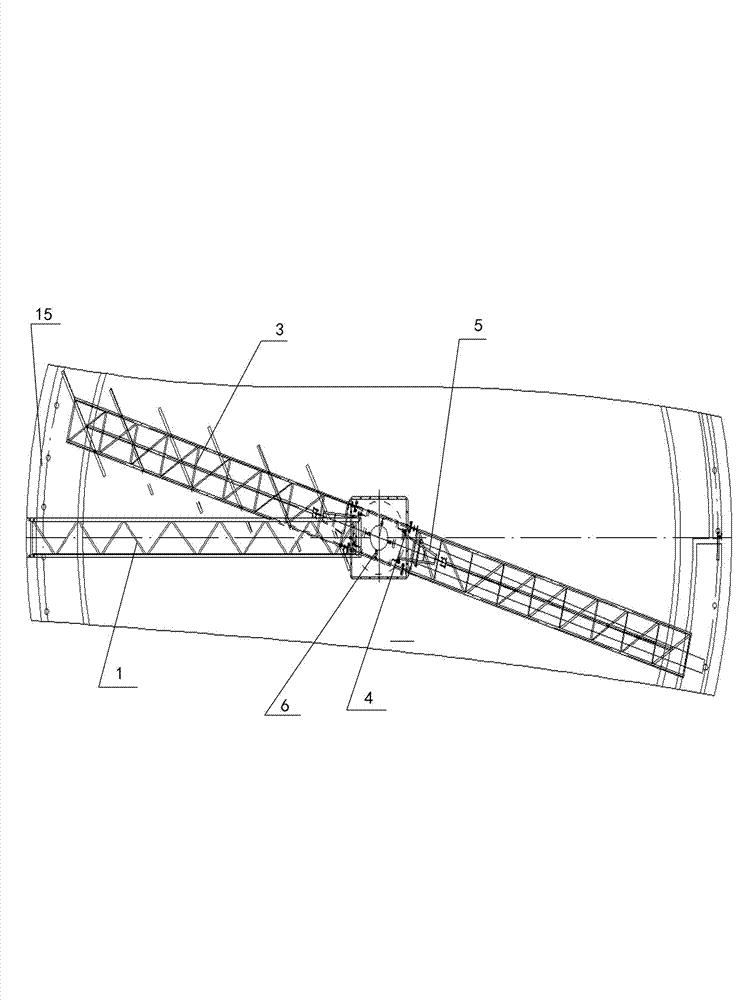

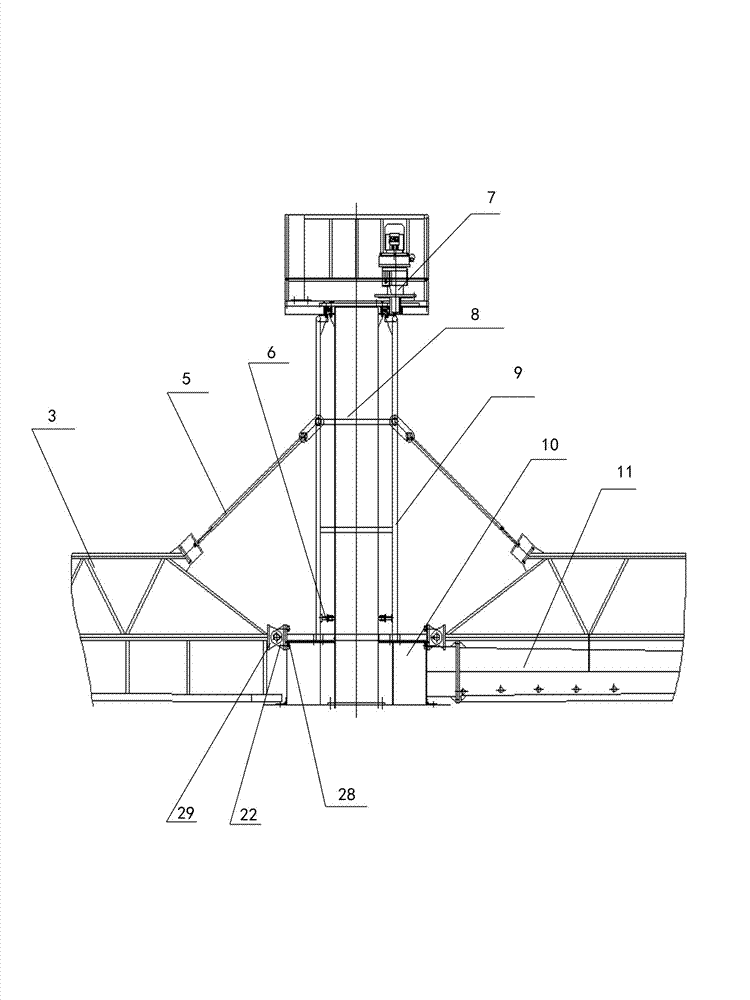

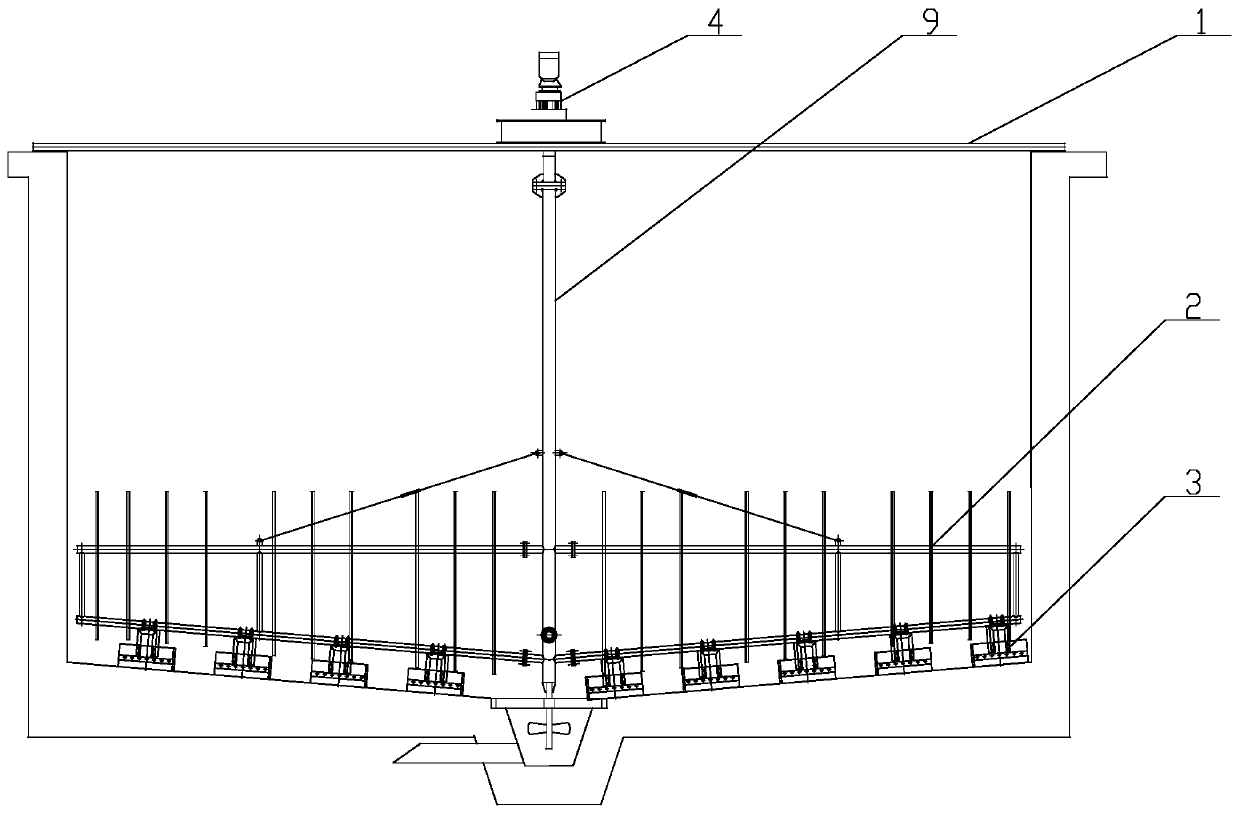

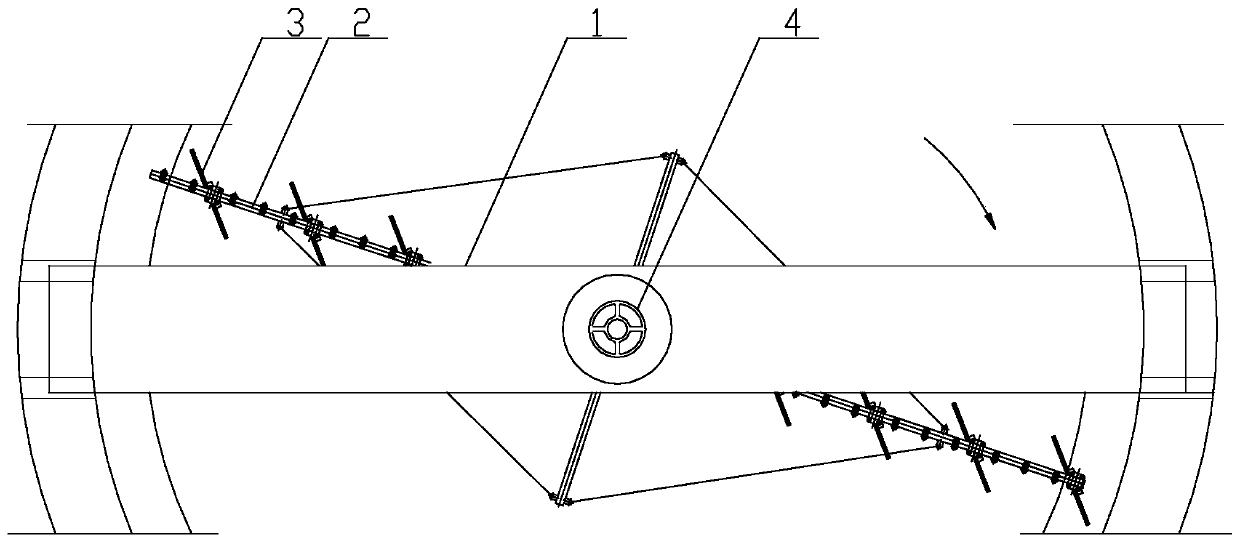

Balanced type single-pipe suction dredge

The invention discloses a balanced type single-pipe suction dredge. The top of a central column (8) is connected with a service bridge (1), a central driving device (7) is arranged at one end of the service bridge (1), which is connected with the central column (8), a central rotating cage (9) which is hung around the central column (8) is connected with a connecting platform (13) on the upper portion of the central column (8), a plurality of balancing devices between the central column (8) and the central rotating cage (9) are evenly distributed around the central column (8), mud-scraping trusses (3) are located on two sides of a fixing base (14) at the bottom of the central rotating cage (9), mud-scraping plates (16) are arranged on upper portions of mud-scraping trusses (3), variable-diameter suction pipes (11) at the bottom of the fixing base (14) are arranged on mud-scraping trusses (3), and a mud-scraping truss adjusting hinging supporting device (4) and a mud-scraping truss adjusting device (5) are respectively connected with one ends of the two mud-scraping trusses (3).

Owner:JIANGSU YATAI WATER TREATMENT ENG

A drill pipe mud scraper

Owner:SHENGLI OILFIELD DONGRUN MACHINERY ENG

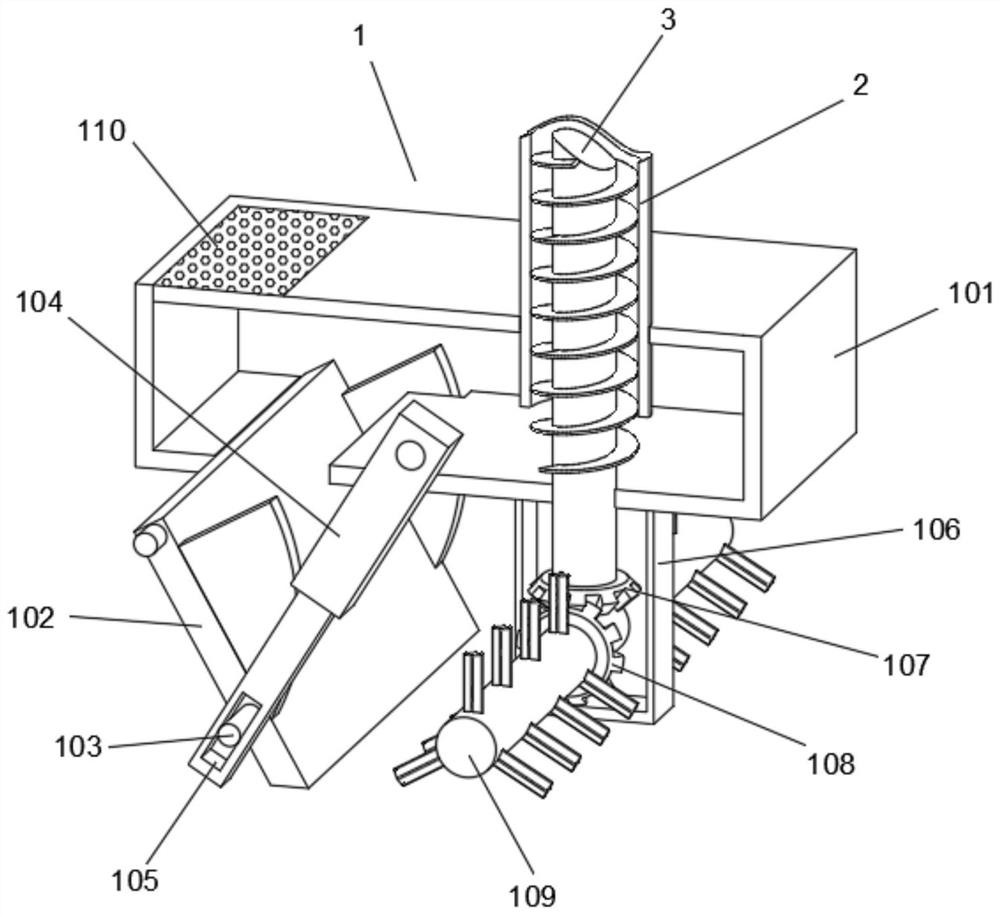

Scraping-amplitude-adjustable sludge cleaning device for water conservancy project and method thereof

PendingCN114232704AEasy to cleanImprove cleaning efficiencySludge treatmentMechanical machines/dredgersSludgeElectric machinery

The invention relates to the technical field of sludge cleaning, in particular to a sludge cleaning device capable of adjusting the scraping amplitude for hydraulic engineering and a method thereof.The sludge cleaning device comprises a scraping assembly, a conveying pipe is fixedly arranged on the top face of the scraping assembly, an auger is arranged in the conveying pipe, a motor A is installed on the top face of the conveying pipe through an installation base, and the conveying pipe is sleeved with a movable block; the upper end of the conveying pipe front wall is provided with a cylinder through a mounting seat. An electric push rod pushes a scraping plate to adjust the scraping amplitude, a crushing roller rotates to crush aquatic plants in sludge, a push block pushes the sludge to slide along a screen, solid impurities in the sludge are conveyed into a collecting tank, a grinding roller extrudes water in the sludge, and the extruded sludge is compacted through a pressing block and a clamping block; different scraping amplitudes for sludge cleaning are adjusted, the sludge cleaning effect and cleaning efficiency are remarkably improved, meanwhile, the scraped sludge is salvaged and treated more conveniently, quickly, flexibly and variably, and the using effect is better.

Owner:陈飞 +4

High-efficiency multistage biological infiltration sewage treatment device and method

InactiveCN111233197AEasy to handleReduce workloadSpecific water treatment objectivesTreatment involving filtrationFlocculationElectric machinery

The invention discloses a high-efficiency multistage biological infiltration sewage treatment device and method. The device comprises a water inlet pipe, a filter tank, a flocculation tank and a sedimentation tank, the filter tank, the flocculation tank and the sedimentation tank are connected by pipes, a water outlet end of the water inlet pipe is positioned on one side close to the top of the filter tank, a grid, a first filter layer, a second filter layer and a third filter layer are sequentially arranged on the inner wall of the filter tank, the top of the flocculation tank is fixedly connected with a plurality of first motors through brackets, shaft extension ends of the first motors are fixedly connected with stirring shafts, a drainage pipe is arranged on the outer wall, close to the bottom, of the sedimentation tank in a penetrating manner, and the bottom of the sedimentation tank is conical. By arranging the filter layer, the first filter layer, the second filter layer and thelike, impurities in sewage can be effectively filtered by utilizing multi-stage biological infiltration, so that the working load of a subsequent treatment device is greatly reduced, the sewage treatment effect is good, the treatment cost of water per unit volume is greatly reduced, and the practicability is high.

Owner:江西挺进环保科技股份有限公司

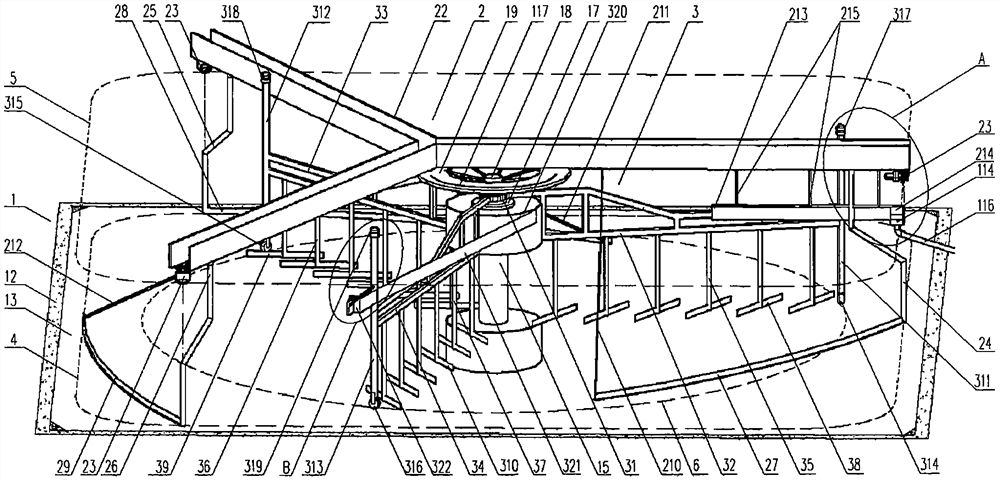

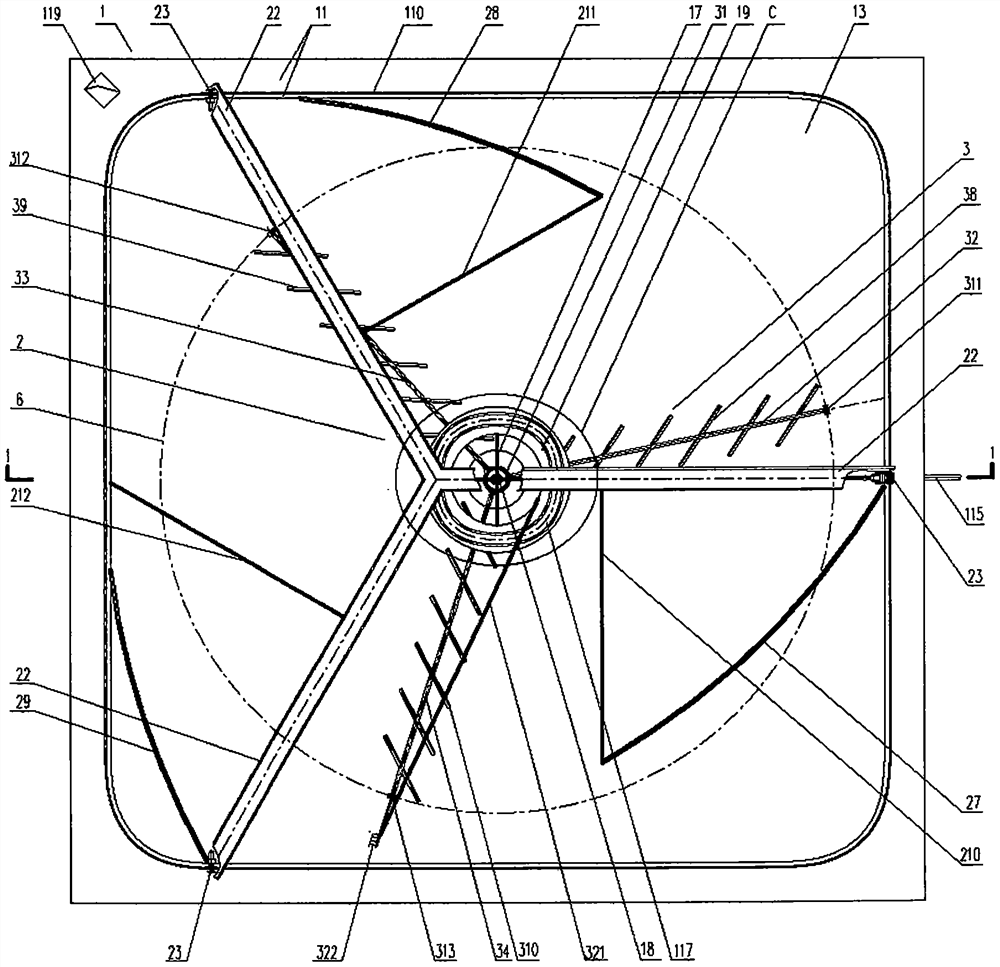

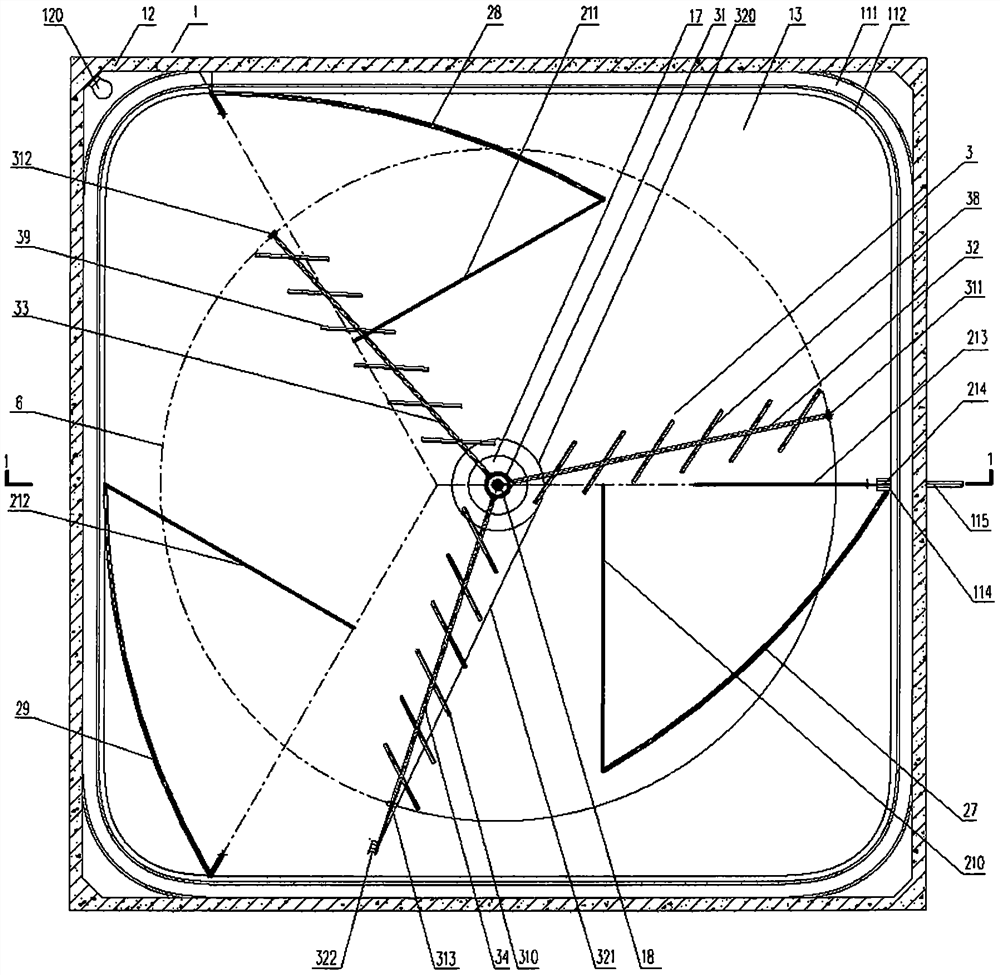

Square sedimentation tank and mud scraper

PendingCN111773776ASmall footprintStrong sludge capacitySettling tanks feed/dischargeSedimentation settling tanksSludgeMechanical engineering

The invention discloses a square sedimentation tank and a mud scraper. The square sedimentation tank and the mud scraper are characterized by consisting of a square tank body, a corner mud scraper anda central mud scraper. The bottom of the square sedimentation tank is square, the center line of the steel rail, the movement track line of the corner mud scraping plate close to the tank wall end and the center line of the horizontal section of the scum baffle coincide in the vertical direction and are quasi-square, and the shape and the size of the corner mud scraping plate are selected from corresponding Lyocell triangles. The corner mud scrapers drive corner mud plates to move along the quasi-square trajectory to scrape the pool bottom sludge near the pool walls and between the included angles of every two adjacent pool walls into the responsible range of the central mud scraper. The central mud scraper is driven by the corner mud scrapers to rotate so as to scrape the sludge in the charge range of the central mud scraper. The square sedimentation tank disclosed by the invention has the advantages of good hydraulic property of the circular sedimentation tank and a high area utilization rate of the rectangular sedimentation tank, and the sludge scraper can simultaneously scrape sludge in the bottom of the square tank and dross on the water surface.

Owner:赵步超

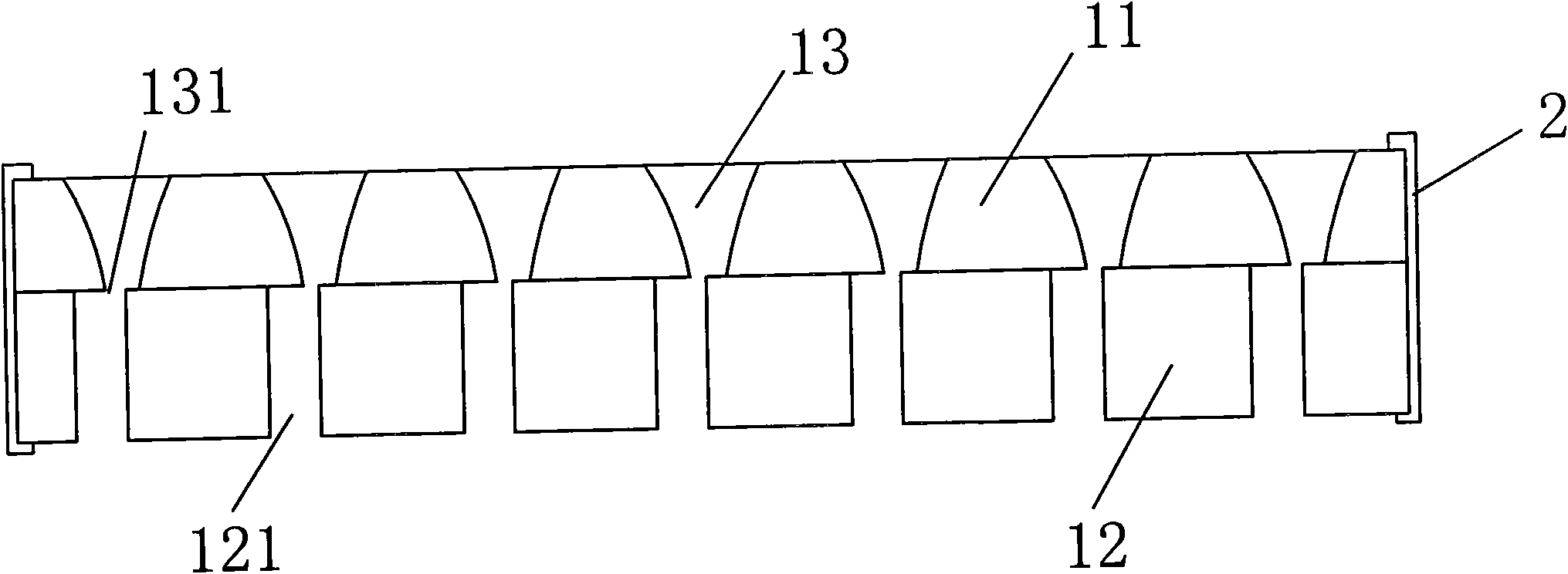

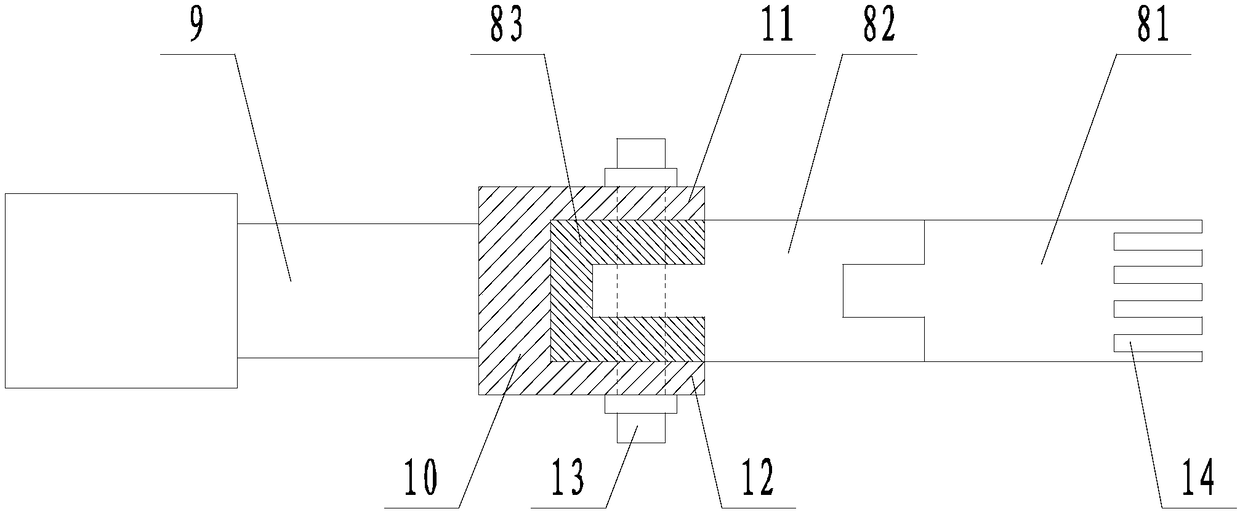

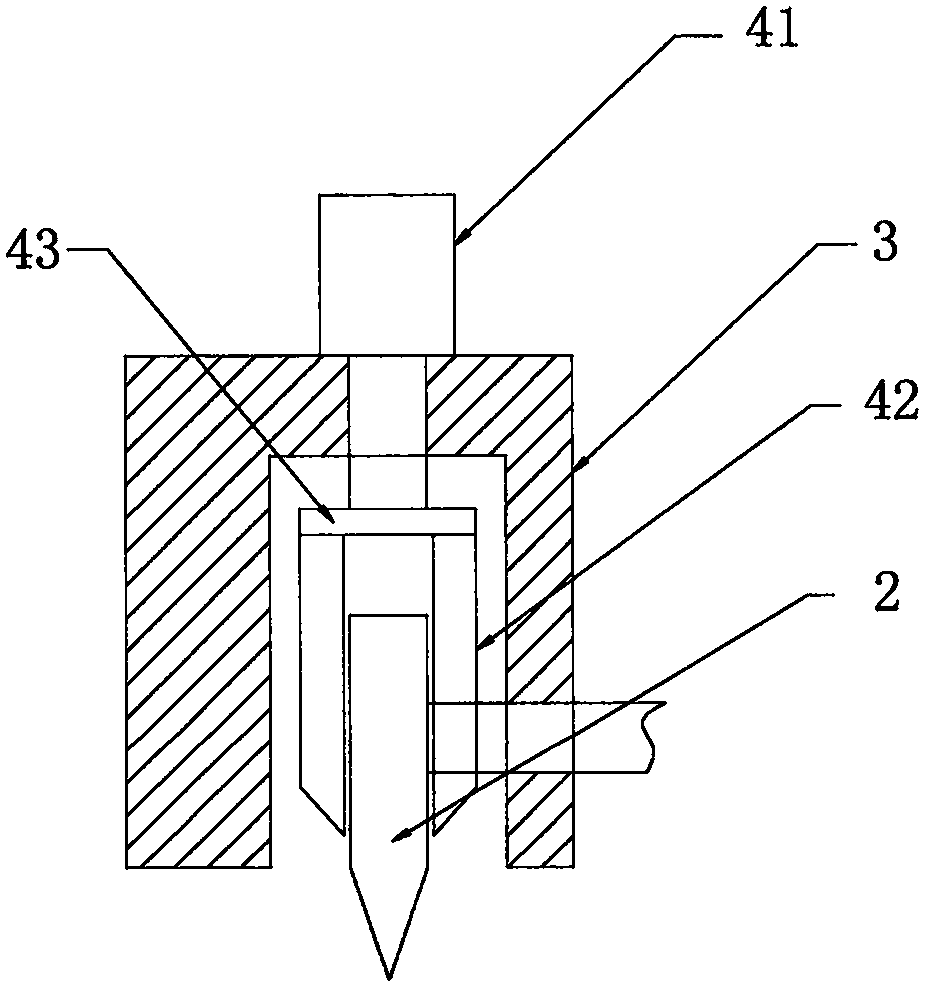

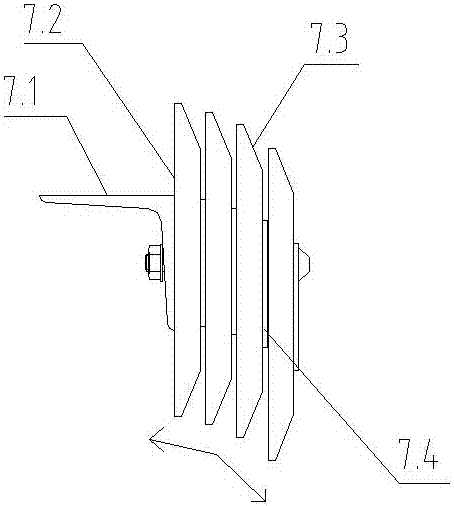

Mud scraping mechanism of drill seeder pressing roller

The invention discloses a mud scraping mechanism of a drill seeder pressing roller. The mud scraping mechanism comprises a pressing roller, wherein a main shaft is arranged in the middle of the pressing roller; an outer protection plate is arranged on the outer side of the pressing roller; the outer protection plate is connected with two ends of the main shaft through bearings; more than four groups of first mud outlet grooves are distributed in equal distances inside the outer protection plate; arc-shaped mud scraping plates are connected with the middle positions inside the first mud outletgrooves through rotating shafts; a mud scraping rod is connected with one end far away from the outer protection plate, of a connecting rod, through a rotating shaft. Due to adoption of three mud scraping mechanisms, namely the mud scraping plate, the mud scraping roller and the arc-shaped mud scraping plate, the mud scraping effect can be greatly improved; due to adoption of the outer protectionplate on the outer side of the pressing roller, mud splashing can be prevented, and in addition, the pressing roller can be protected; due to design of a first mud outlet groove and a second mud outlet groove, soil can be greatly conveniently scrapped off from the pressing roller; the arc-shaped mud scraping plate can be driven by a first electronic telescopic rod in a telescopic manner to rotatearound a sliding plate through the rotating shaft, and the mud scraping angel can be conveniently adjusted.

Owner:吾家农场成都农业有限公司

Drill rod mud scraper

The invention belongs to the technical field of oil drilling, and particularly relates to a drill rod mud scraper. The drill rod mud scraper comprises a pressing plate, a sleeve is inserted into the top of the pressing plate in a penetrating mode, a movable pipe is arranged on the inner side of the sleeve, two limiting rings are fixedly connected to the outer side of the movable pipe, annular limiting grooves are formed in the positions, corresponding to the limiting rings, of the inner side of the sleeve, the limiting rings are located in the limiting grooves, and a plurality of mounting holes are formed in the inner wall of the movable pipe in a penetrating mode. Through the arrangement of the sleeve, in the upward movement process of a drill rod, a roller drives a shifting rod to make contact with a shifting plate under the action of the drill rod through the transmission action of a first gear belt and a second gear, so that the movable pipe drives a first scraper blade on the inner side of the movable pipe to conduct annular mud scraping operation on the surface of the drill rod under the cooperation action of the shifting rod and the shifting plate; and the movable pipe is always in a rotating state, so that the slurry is not easy to attach to the bottom of the movable pipe and the first scraper blade, and the normal work of the first scraper blade is further ensured.

Owner:SHENGLI OILFIELD DONGRUN MACHINERY ENG

Wastewater treatment device for unsaturated polyester resin production and processing

ActiveCN113716639ANo disengagementHeating evenlyNature of treatment waterWater/sewage treatment by heatingProcess engineeringPolyester resin

The invention discloses a wastewater treatment device for unsaturated polyester resin production and processing, and belongs to the field of wastewater treatment. The wastewater treatment device comprises a distillation barrel, a built-in mounting pipe is arranged on the bottom face of the interior of the distillation barrel, a liquid inlet pipe is arranged on the upper face of the distillation barrel, a steam outlet pipe is arranged on the distillation barrel and located on the side face of the liquid inlet pipe, an upper outlet valve is arranged on the upper portion of the side face of the distillation barrel, a lower outlet valve is arranged on the lower portion of the side face of the distillation barrel, and a middle filter plate is arranged in the distillation barrel. According to the wastewater treatment device for unsaturated polyester resin production and processing, through an arranged heat conduction structure, a heating source makes contact with wastewater all the time and is prevented from being separated; through a side face air guide pipe, naturally-rising hot air is guided back to the bottom of the wastewater, and the heating and distillation effect is better; through a mud scraping structure, dirt on the middle filter plate and the bottom surface of the distillation barrel can be scraped; and through a through plug structure, the middle filter plate is avoided from blockage.

Owner:ZHANGJIAGANG JIULI NEW MATERIAL TECH CO LTD

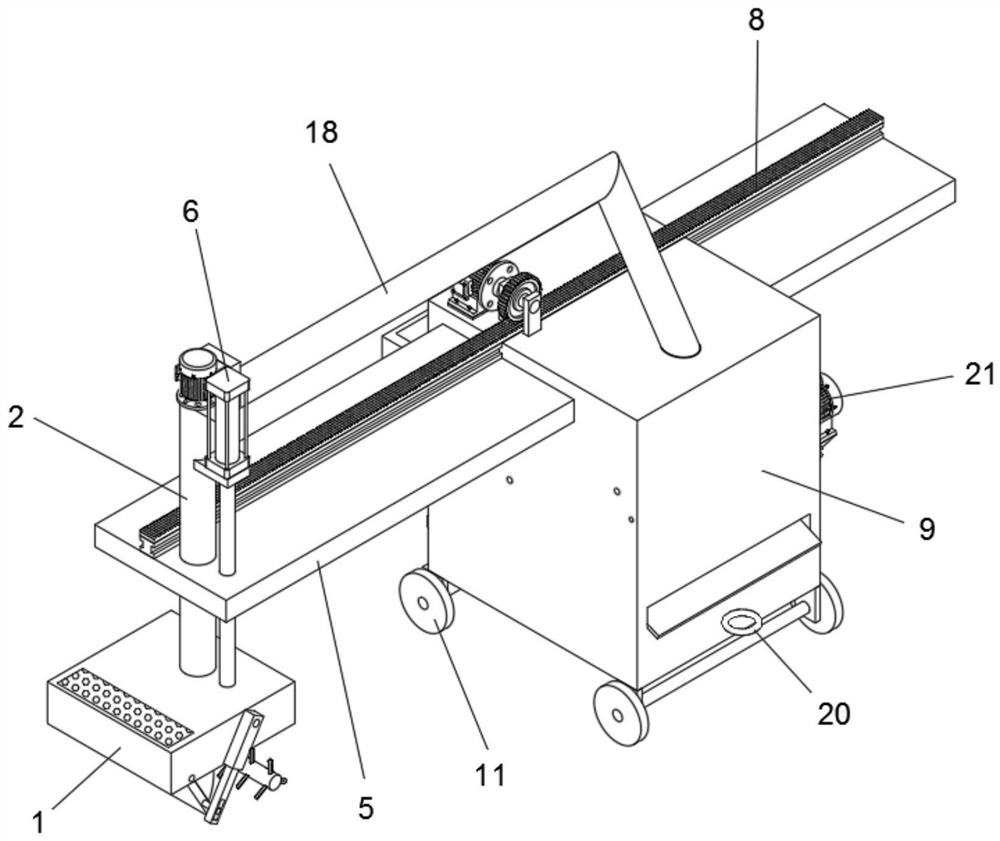

An adjustable road roller mud scraper

InactiveCN106758697BReduce wearReduce labor intensityRoads maintainenceHydraulic cylinderAgricultural engineering

The invention provides an adjustable type road roller mud scraper. The adjustable type road roller mud scraper comprises support transverse beams, a steel wheel, a protective cover, a mud scraper body, hydraulic cylinders, guide sleeves, guide rods, return springs, an electric cylinder, scraping knives and a connecting base, wherein the hydraulic cylinder is arranged in the middle part of front end surface of each support transverse beam; each guide sleeve is assembled at the front end surface of the corresponding hydraulic cylinder; the back end of each guide rod is arranged in the corresponding guide sleeve, and the front end of each guide rod penetrates through the protective cover and is connected with the mud scraper body; each return spring is coated at the outer surface of the corresponding guide rod, the front end of each return spring is connected with the mud scraper body, and the back end of each return spring is connected with the corresponding guide sleeve; the electric cylinder is arranged in the middle part of the upper end surface of the protective cover; the connecting base is arranged in the protective cover; the upper end of the connecting base is connected with the electric cylinder; the upper ends of the two groups of scraping knives are fixedly arranged on the connecting base, and are symmetrically arranged at the front and back sides of the mud scraper body. The adjustable type road roller mud scraper has the advantages that the structure is reasonable, the mud scraping efficiency is improved, the adjusting is convenient, the stability is good, and the reliability is high.

Owner:王江丽

System for discharging sludge at upper layer of floatation tank

InactiveCN107758783AGood mud scraping effectNormal dischargeWater/sewage treatment by flotationSlagSludge

The invention relates to a slag discharge system for the upper layer of an air flotation tank, which includes a slag scraper and a mud layer diversion weir plate, and is characterized in that: one side of the slag scraper is provided with a roller that walks on the guide rail of the pool, and the slag scraper The other side of the car is fixedly connected with a bracket, the top of the bracket is fixedly connected with a rotating shaft, and a slag scraper is slidably connected to the rotating shaft. A steel wire is fixedly connected to the surface of the slag scraper, and the other end of the steel wire is keyed to the output shaft of the motor. Take-up reel connection. Beneficial effects: the mud scraper of the present invention will not bring mud residue back in the return path, and can pass through the diversion weir plate of the mud layer smoothly. The sludge scraper has a good scraping effect, so that the sludge floating in the air flotation tank can be discharged normally, avoiding the problem that the sludge accumulates and thickens, slowly sinks into the pool, and is brought into the outlet system with the water flow, affecting the quality of the outlet water occur.

Owner:天津泰达新水源科技开发有限公司

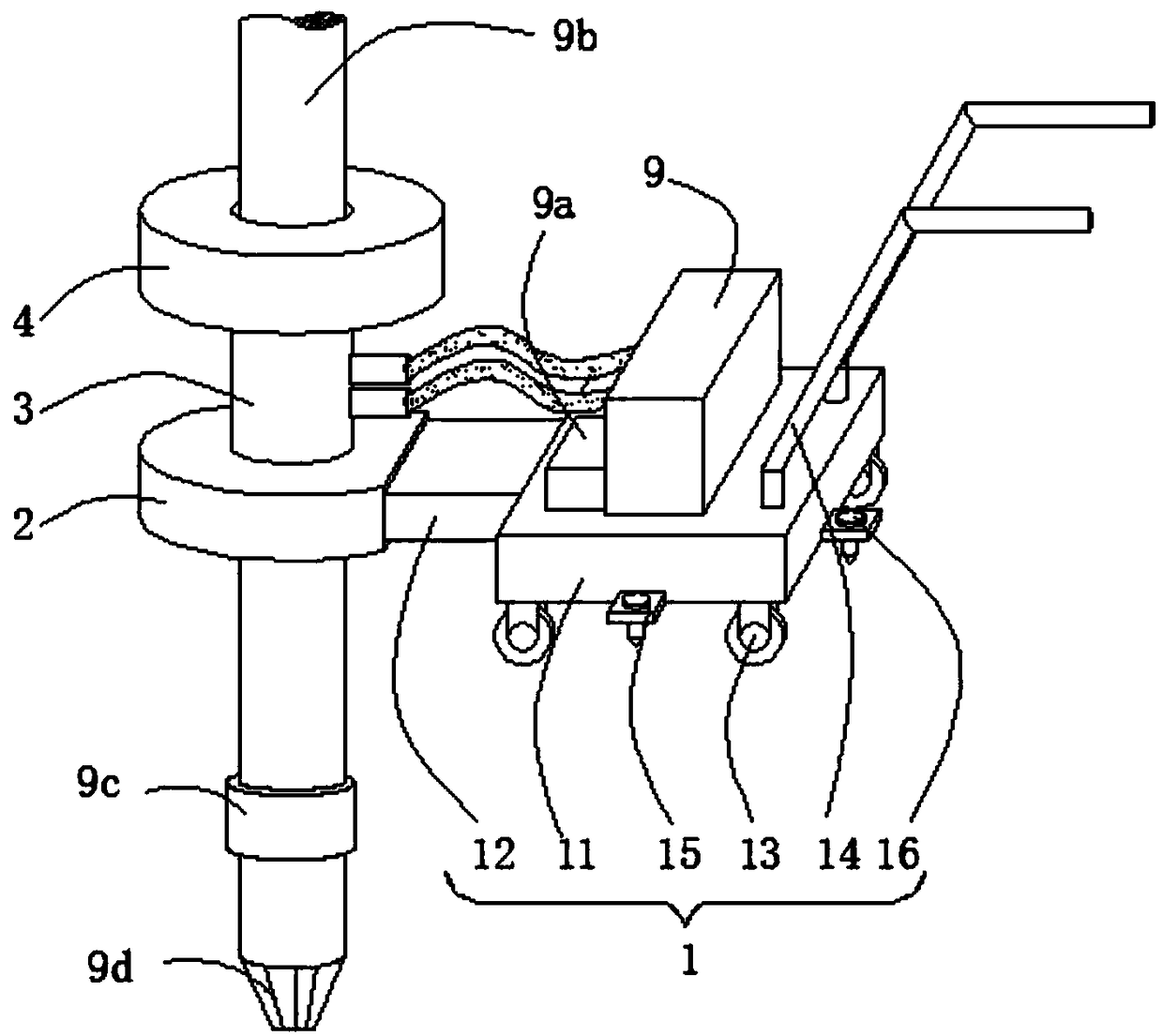

Oil drill pipe cleaning method

The invention relates to the technical field of oil drilling, in particular to an oil drill pipe cleaning method. The method includes steps: S1, connecting the oil drill pipe cleaning device with an oil drill pipe; S2, on the basis of S1, starting the oil drill pipe cleaning device in the S1; S3, cleaning the oil drill pipe by the oil drill pipe cleaning device in the S2; S4, after completion in the S3, separating the oil drill pipe cleaning device from the oil drill pipe. By a mud scraping mechanism, the drill pipe passing through the mud scraping mechanism can be subjected to mud scraping treatment, so that mud on the outer wall of the drill pipe is quickly separated from the drill pipe, subsequent manual clearing is avoided, and the labor amount of workers is effectively decreased.

Owner:英特莱福油气技术河北股份有限公司

an oil drill

InactiveCN108915608BReduce laborCooperate wellEarth drilling toolsDrilling rodsOil canThermodynamics

The invention relates to the technical field of petroleum drilling, in particular to a petroleum drill rod. The petroleum drill rod comprises a transportation mechanism, a first fixed seat, a connecting pipe, a second fixed seat, a cleaning mechanism, a water washing mechanism, a lubricating mechanism, an air drying mechanism, a box body, a power supply box, a drill rod main body, a conversion joint and a drill bit. According to the petroleum drill rod, through a mud scraping mechanism, mud scraping treatment can be carried out on the outer wall of the passing drill rod, so that the mud on theouter wall of the drill rod can be quickly separated from the drill rod without manual cleaning in the later period; through the water washing mechanism and the lubricating mechanism, water and lubricating oil can be arranged to the outside of the drill rod in a spraying mode, so that a lubricating state is always maintained during the machining of the drill rod, and the machining smoothness of the drill rod is improved; the water washing mechanism can spray water to clean the drill rod, and can work together with the mud scraping mechanism, so that the outer wall of the drill rod is cleaner;and the outer wall of the drill rod can be dried by the air drying mechanism, so that the finally recovered drill rod is in a clean and dry state without manual secondary treatment.

Owner:YANCHENG DONGRONG PETROLEUM MACHINERY CO LTD

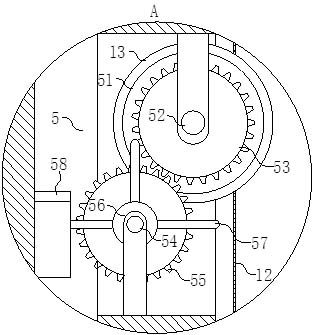

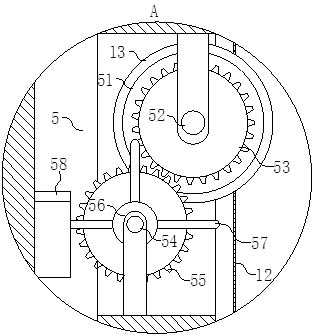

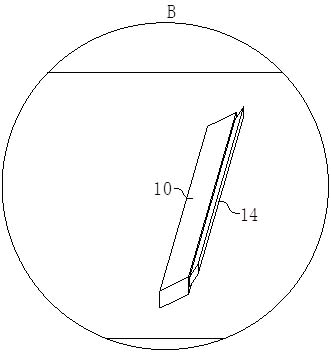

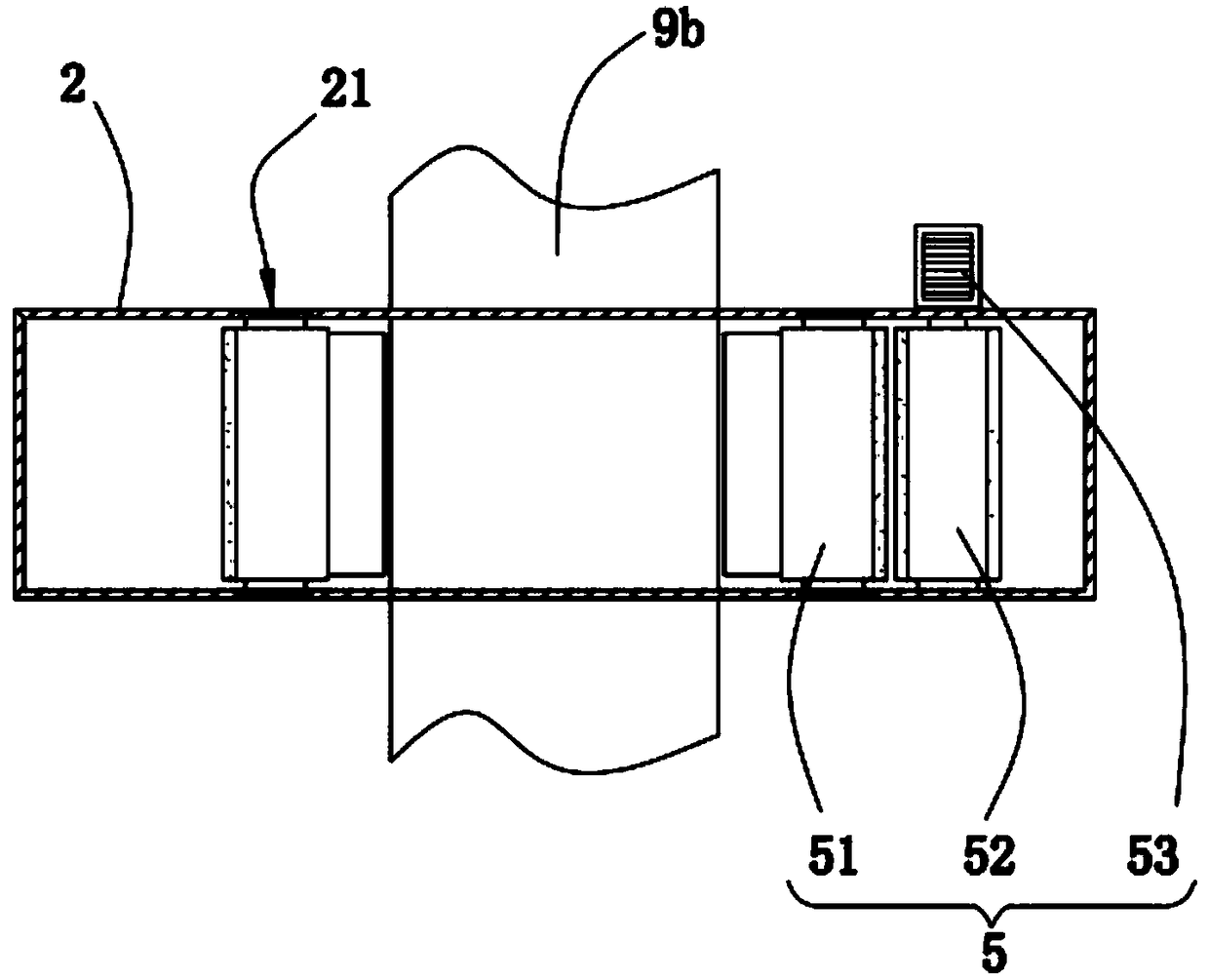

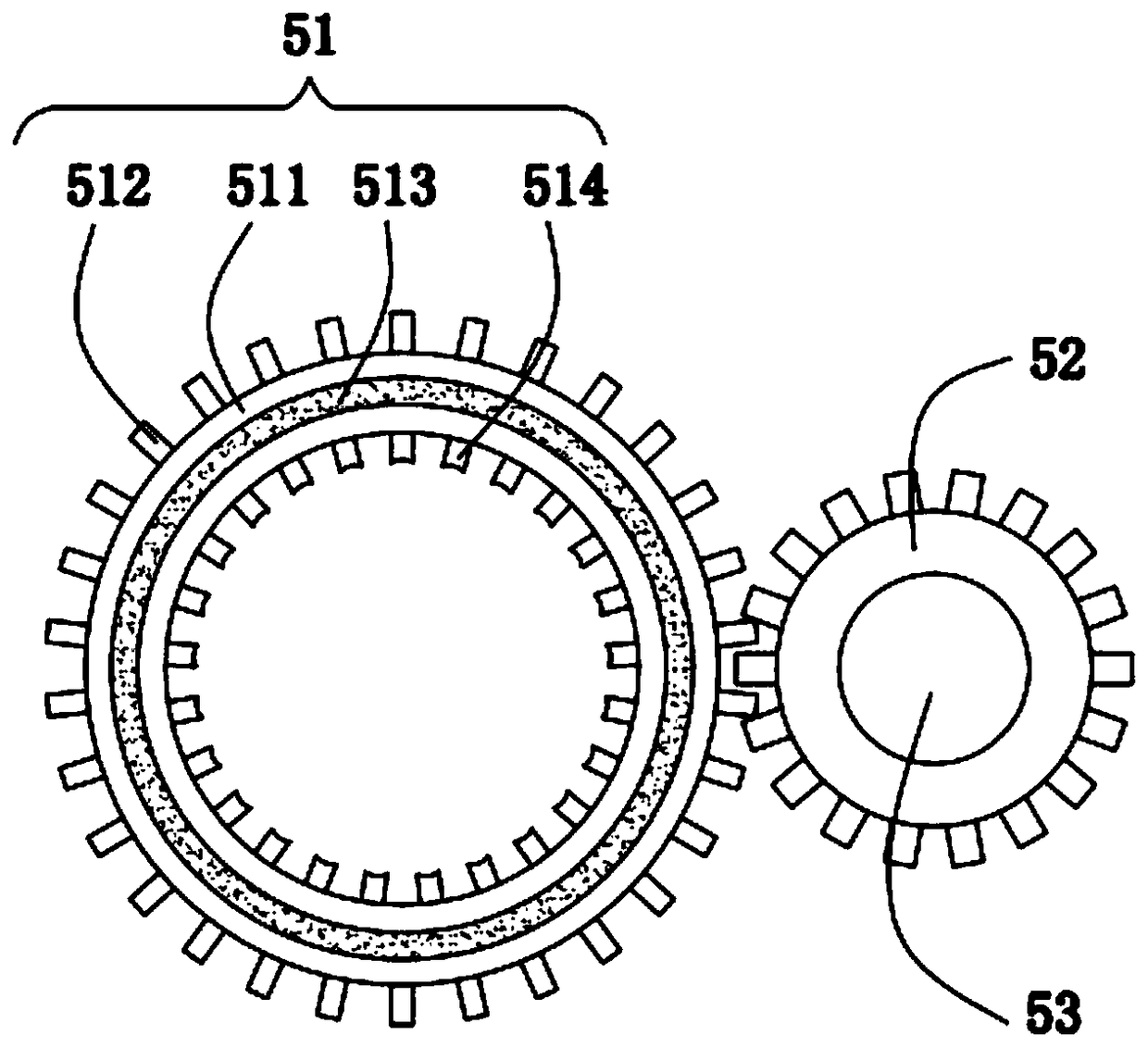

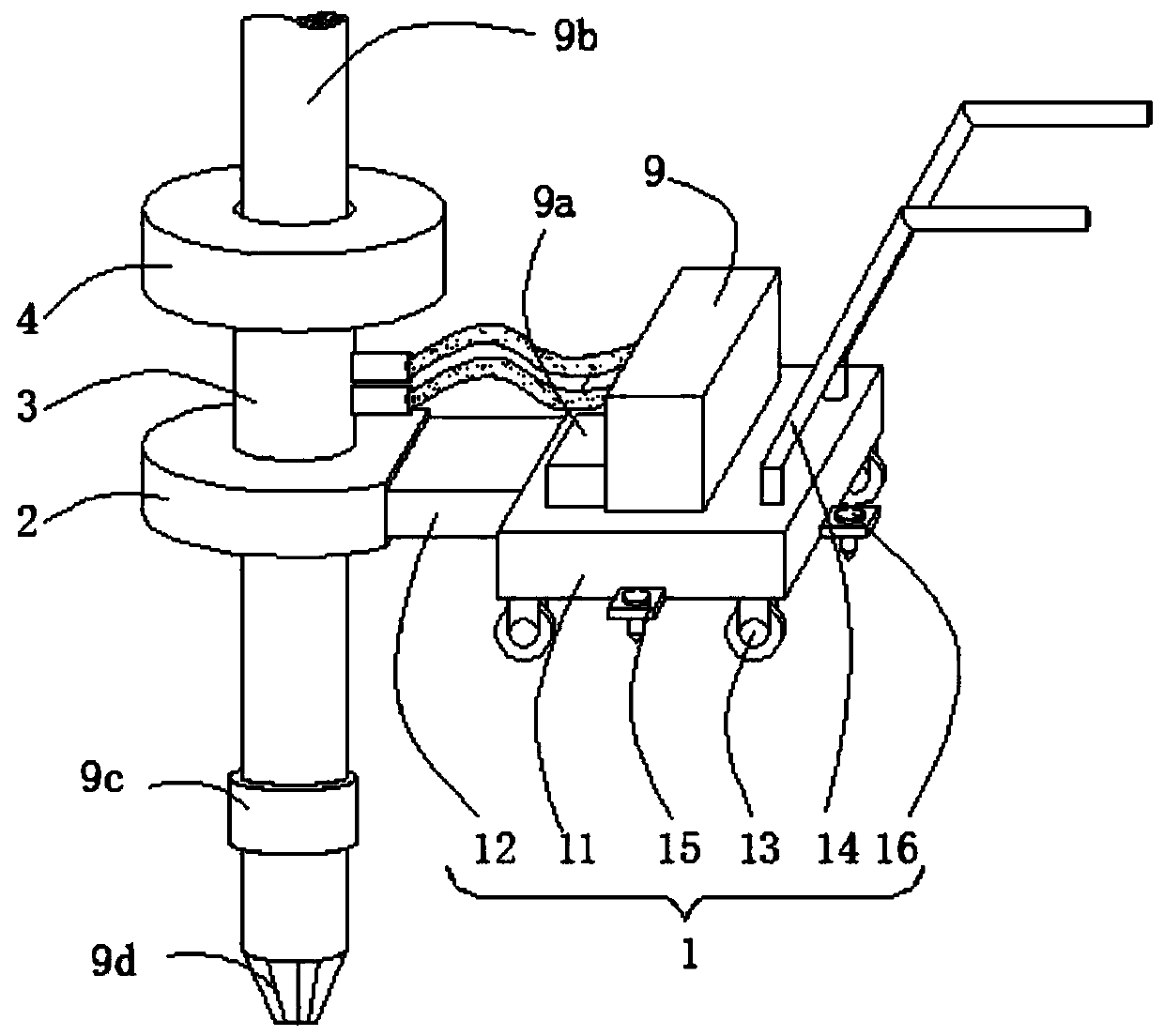

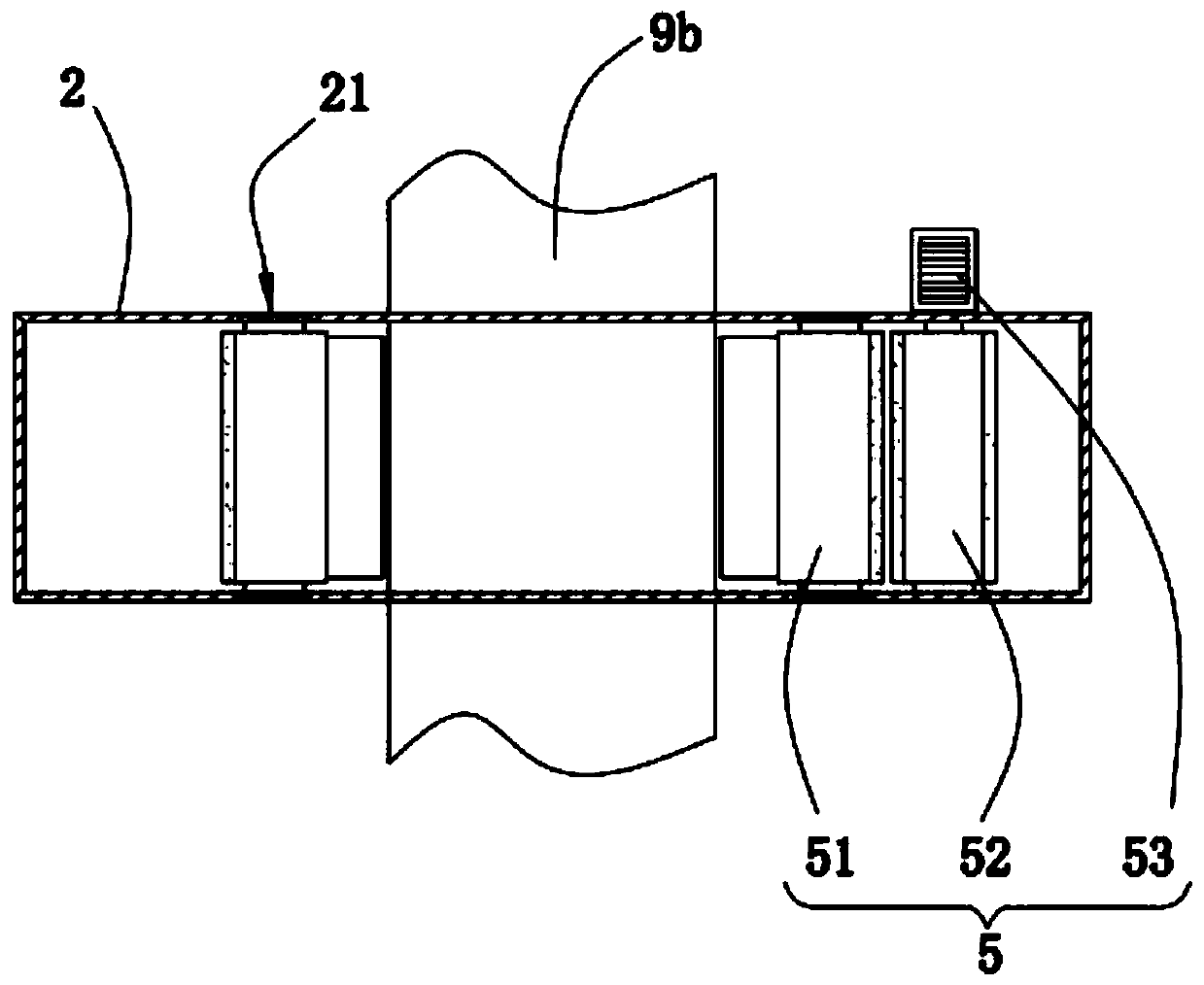

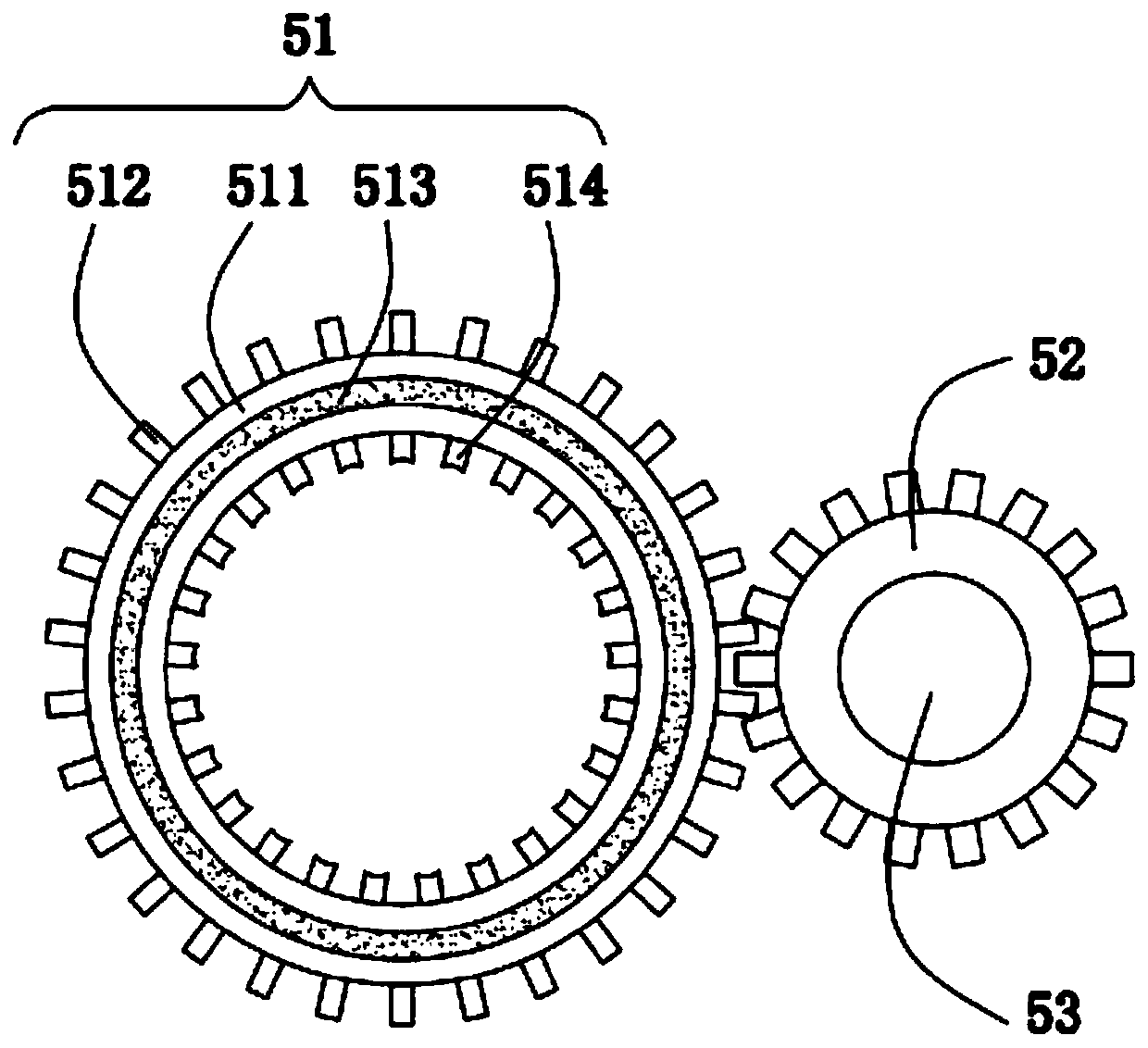

Mud scraper for water treatment

ActiveCN110975352APrevent suspensionImprove mud scraping effectSettling tanks feed/dischargeGear wheelElectric machinery

The invention provides a mud scraper for water treatment, and relates to the technical field of water treatment devices. The mud scraper has a compact structure and a high mud scraping efficiency. Themud scraper comprises a mounting frame, a cross beam, a mud scraping plate and a driving motor, the driving motor is arranged at the top of the mounting frame and drives the cross beam to rotate, themud scraping plate is arranged at the bottom of the cross beam, a scraper and a mud press are arranged at the bottom of the mud scraping plate, the mud press comprises a pressing block and a pressingblock driving mechanism, the pressing block driving mechanism comprises a connecting motor and a connecting rod, the output shaft of the motor is sleeved with a half gear, the bottom of the connecting rod is fixedly connected with the pressing block, and a rack meshed with the half gear is arranged at the top of the connecting rod.

Owner:扬州绿都环境工程设备有限公司

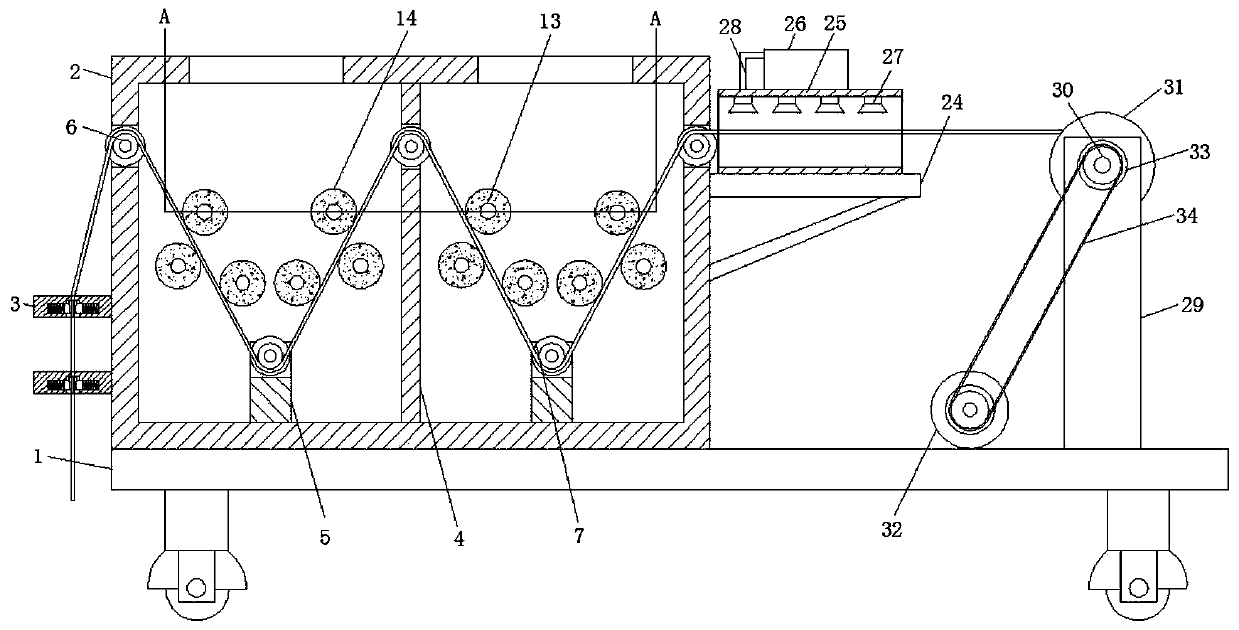

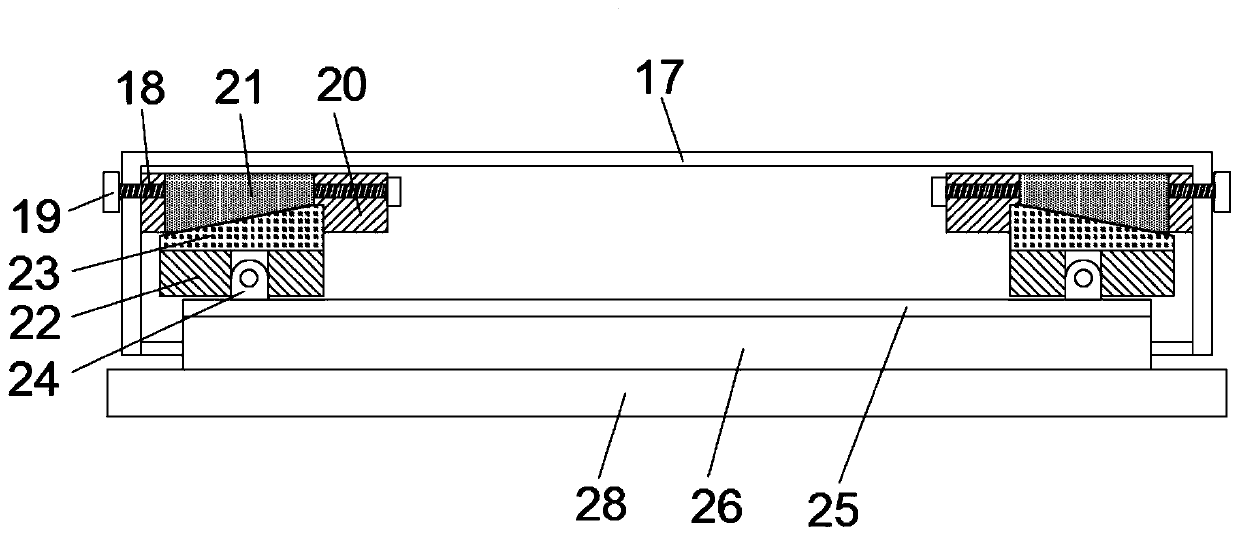

Belt filter press

PendingCN107473563AExtended service lifeReduce water consumption for cleaningSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesFlocculationBelt filter

The invention discloses a belt filter press which mainly comprises a rack, a flocculation zone, a thickening and dewatering zone, a gravity dewatering zone and a squeeze dewatering zone, wherein a flocculation mixer is arranged in the flocculation zone; the thickening and dewatering zone comprises a plurality of horizontally arranged driving rollers and thickening filter belts arranged on the driving rollers; the gravity dewatering zone is positioned below the thickening and dewatering zone and comprises a plurality of arc-shaped cladding rollers, upper filter belts and lower filter belts; the arc-shaped cladding rollers, the upper filter belts and the lower filter belts are fixed on the rack and obliquely arranged; the squeeze dewatering zone comprises a plurality of squeezing rollers which are vertically arranged in a staggered manner as well as squeezing filter belts; mud removing rollers are arranged on the rear parts of the squeezing rollers; and a scraper is connected onto the mud removing rollers. The belt filter press disclosed by the invention is scientific and reasonable in structural design, capable of integrating flocculating, thickening and press filtering, excellent in mud scraping effect, long in service life of the filter belts and few in usage of cleaning water.

Owner:宜兴市建华成套环保有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com