Patents

Literature

142results about How to "Normal discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

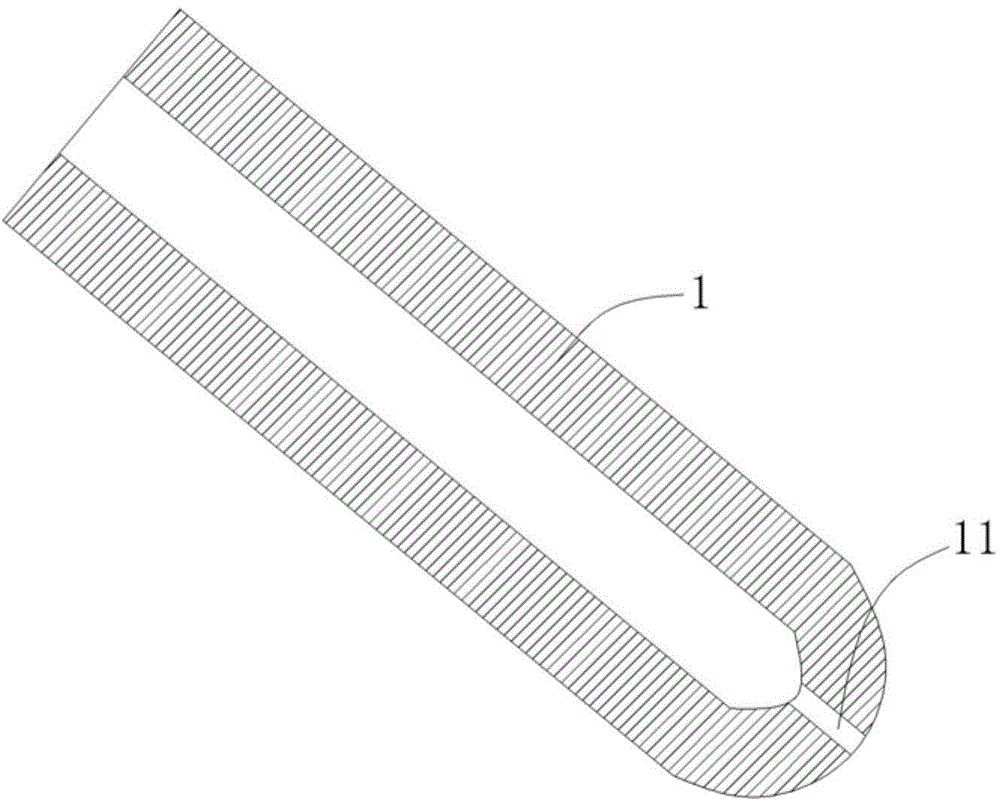

Cross-shaped double-jacketed drainage tube

The invention discloses a cross-shaped double-jacketed drainage tube, which comprises an inner drainage tube, a connection piece, an outer catheter, an inner catheter, supporting frames, a catheter head and a pressure sensor, wherein the left end of the inner drainage tube is opened and the right end is closed; the wall of the right end of the inner drainage tube is provided with inner drainage holes; the connection piece is used for mounting the inner drainage tube in the pipeline of the inner catheter; the left end and the right end of the outer catheter are opened respectively; the wall of the right end of the outer catheter is provided with a plurality of drainage slots; the inner catheter is arranged in the pipeline of the outer catheter via the supporting frames; the left end and the right end of the inner catheter are opened, and the left end is connected with the outer catheter wall; the inner catheter wall is provided with a pressure monitoring channel, a transfusion channel and outer drainage holes; the catheter head comprises a clamping head clamped in and blocking the left-end opening of the inner catheter and a blocking body correspondingly blocking the right end part of the outer catheter; a gap is formed between the left end surface of the blocking body and the right end surface of the outer catheter; and the pressure sensor is communicated with the pressure monitoring channel.

Owner:GUANGZHOU SUN SHING BIOTECH CO LTD

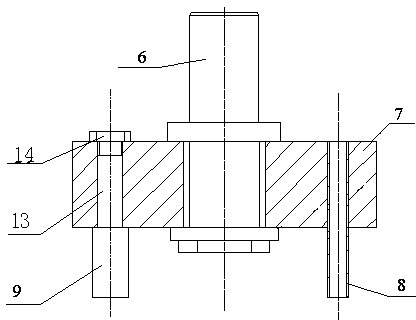

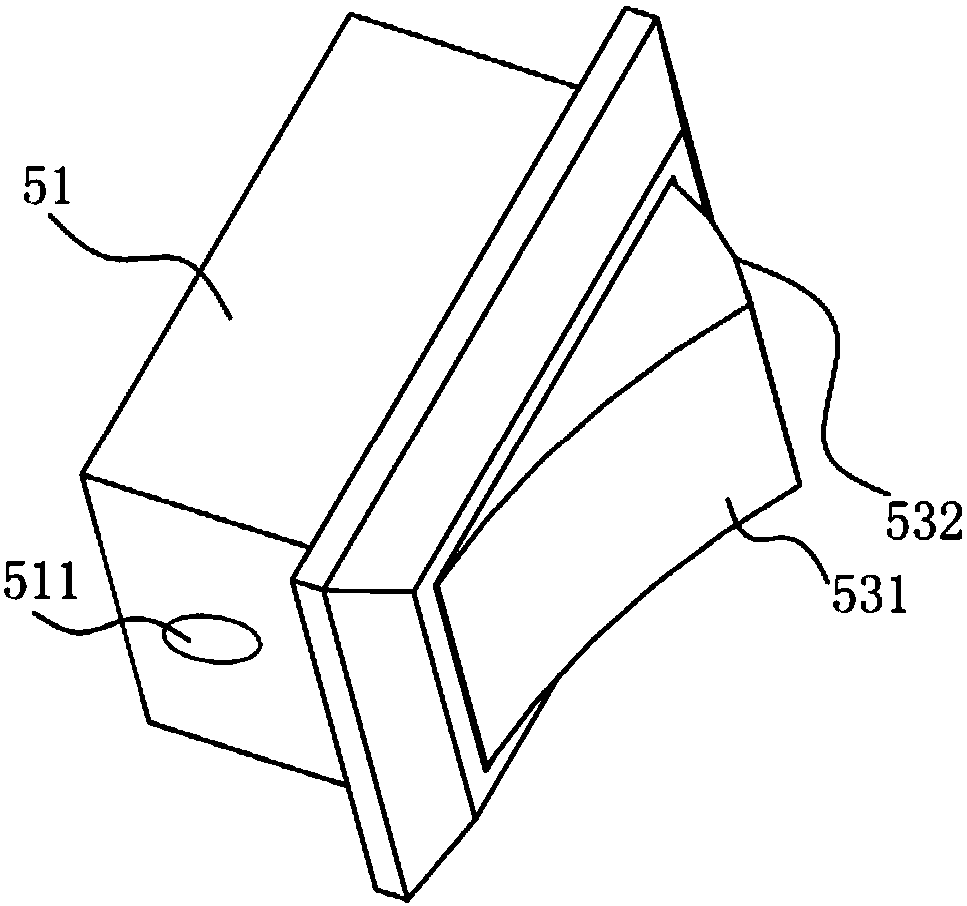

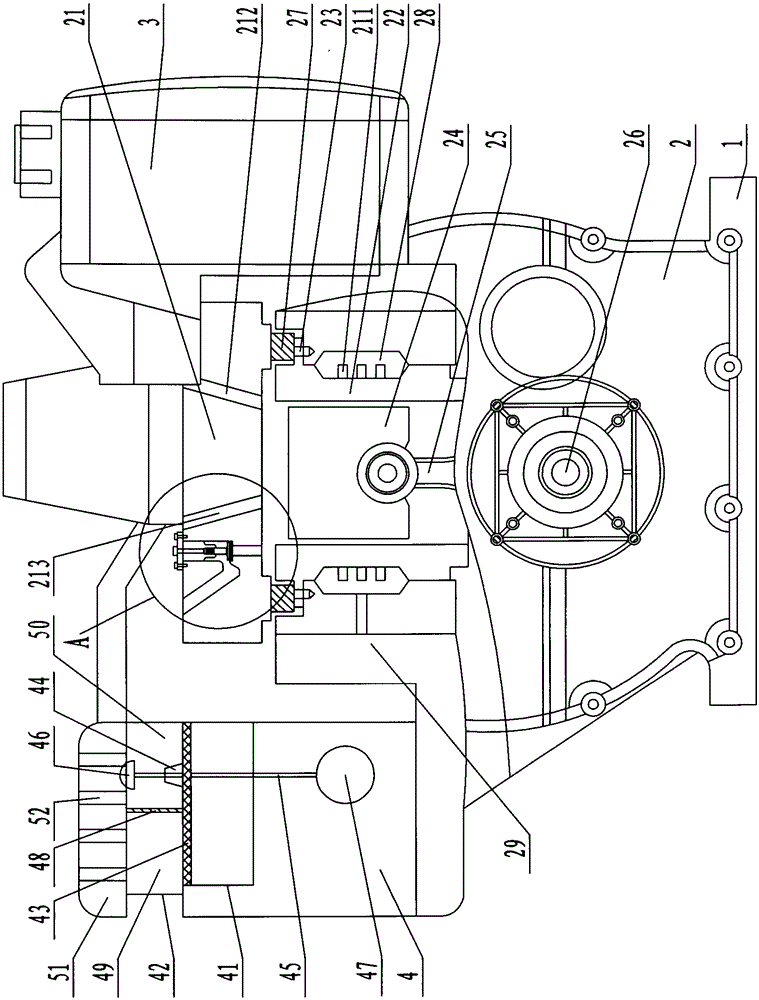

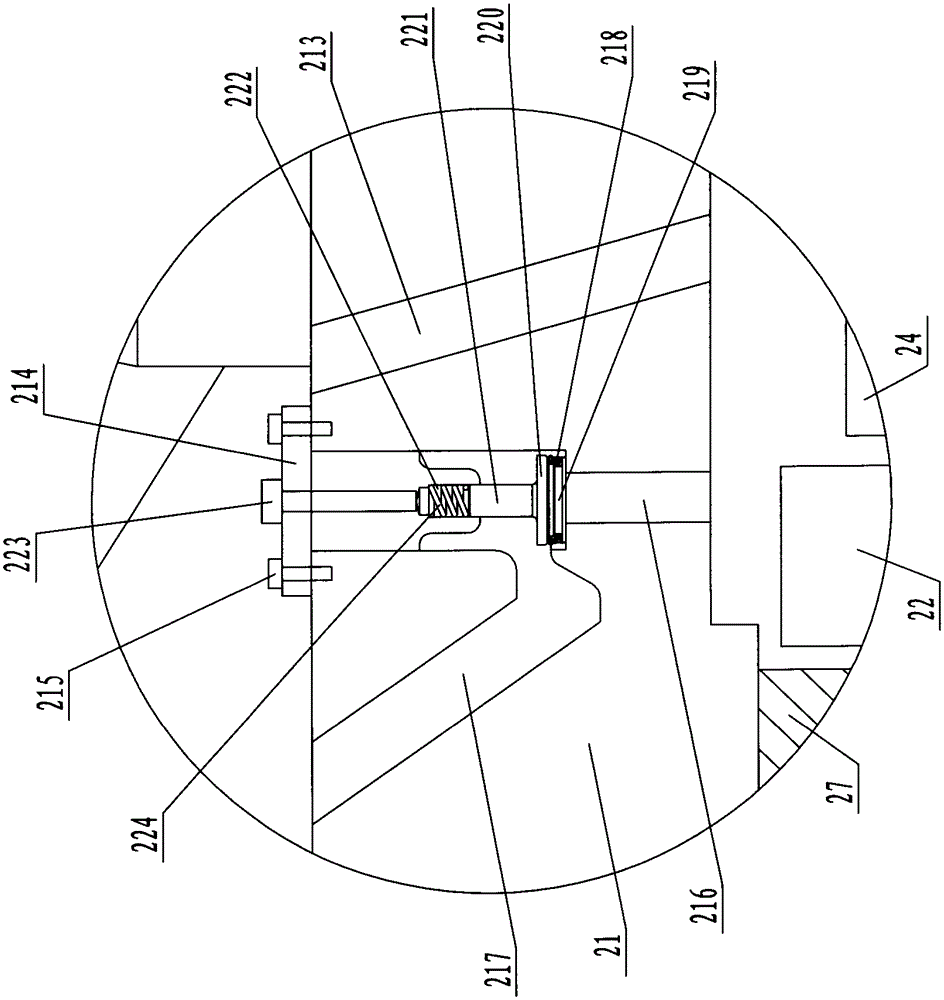

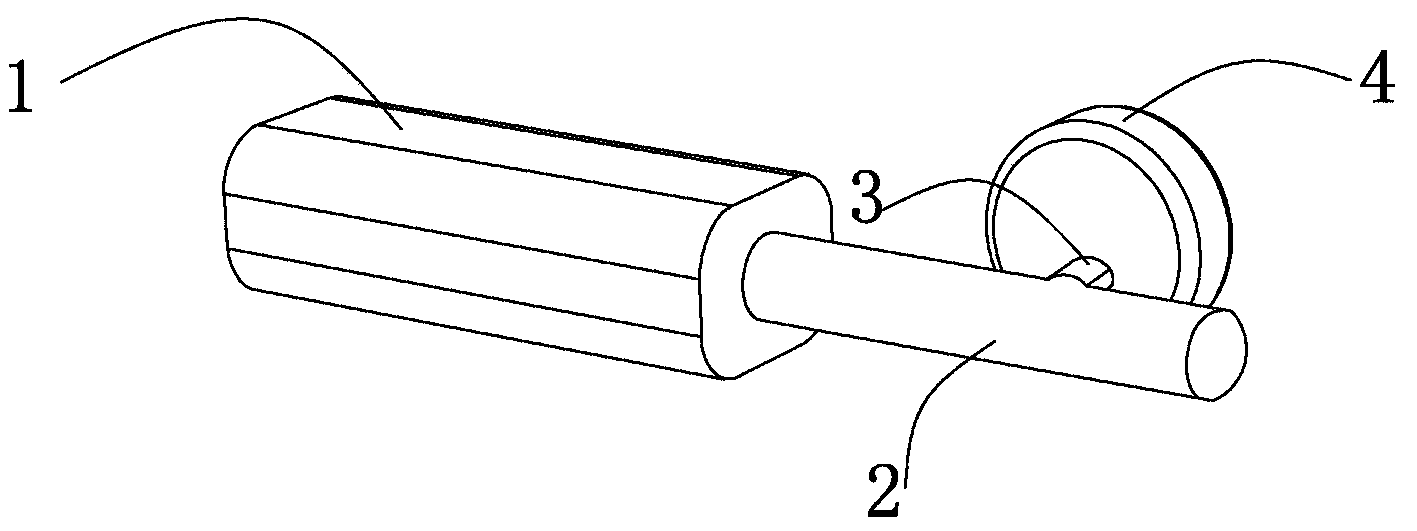

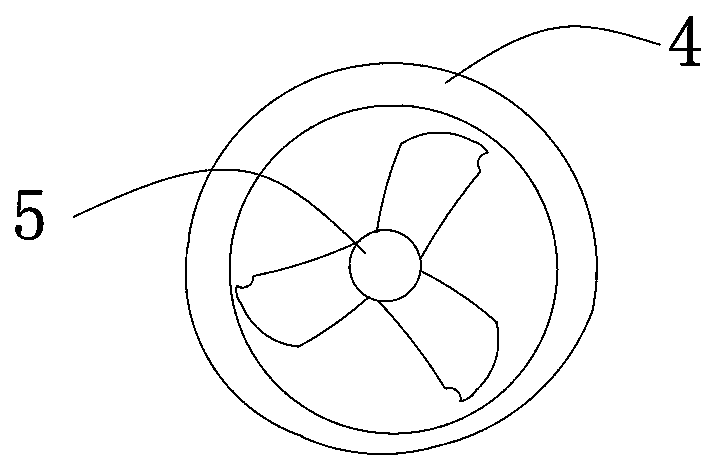

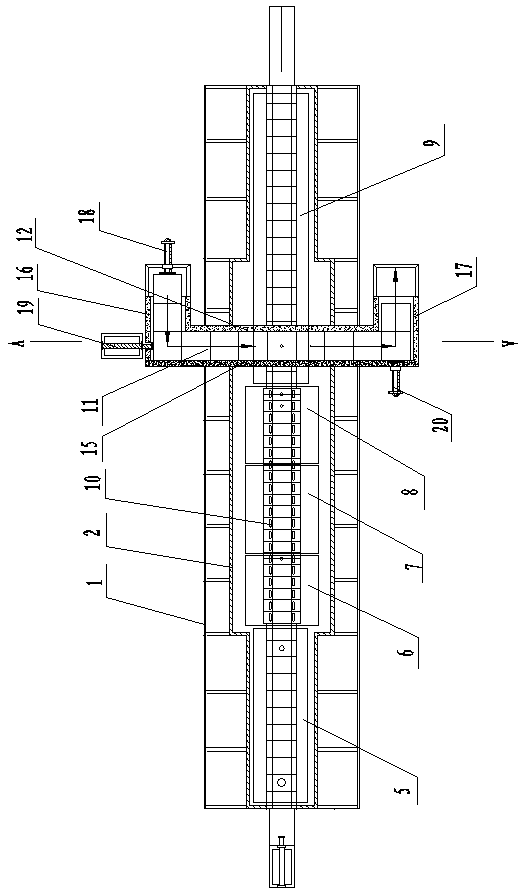

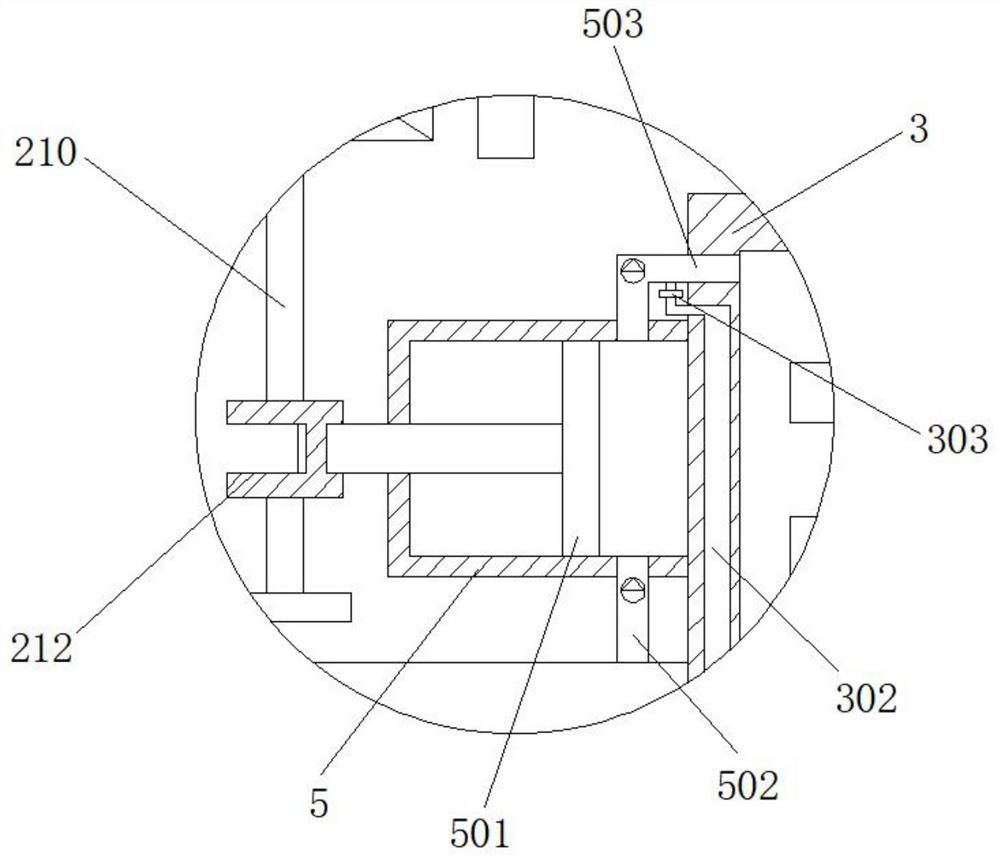

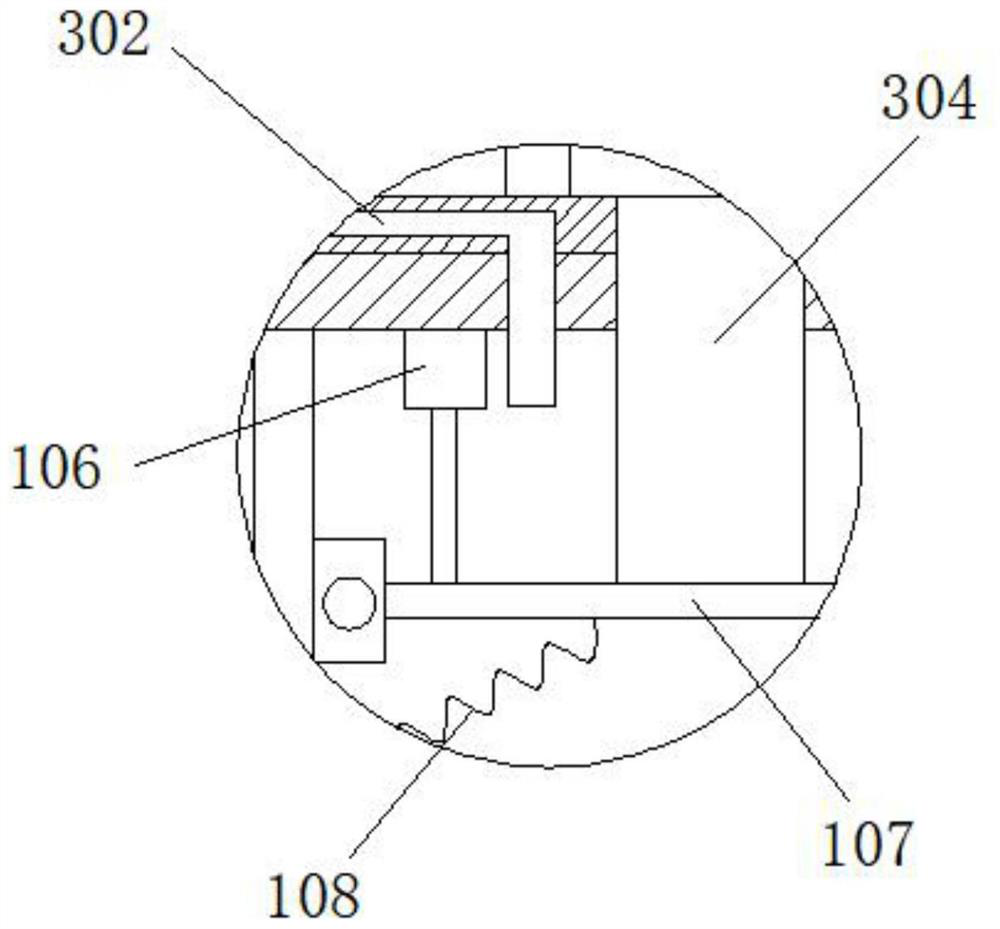

Electric spark milling and mechanical grinding combined machining device

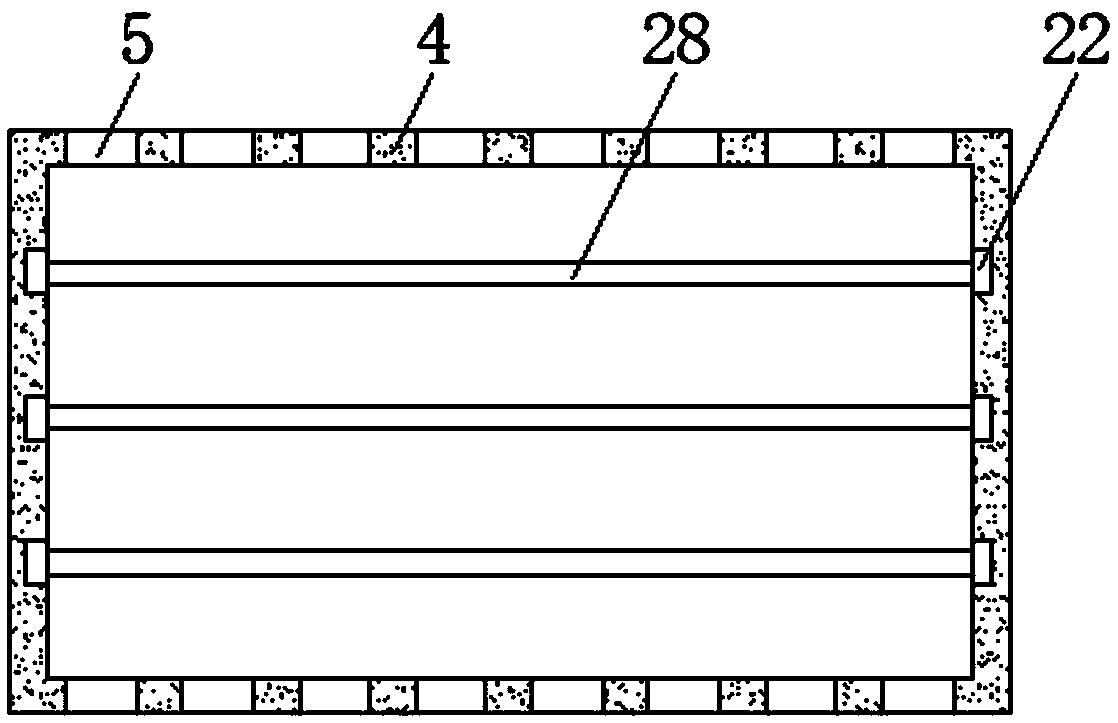

The invention discloses an electric spark milling and mechanical grinding combined machining device. The combined machining device comprises a servo system (1), a milling machine chuck (2) connected with the servo system (1), a combined machining cutter (3) connected with the milling machine chuck (2), a rotary table (4) installed under the combined machining cutter (3) and a pulsed power supply (5) connected with the combined machining cutter (3). According to the combined machining device, discharge electrodes and material grinding rods are mounted on an electrode plate, mechanical grinding is carried out while electric discharge machining is conducted, no short out phenomena or arc discharge phenomena exist, electrode losses are even, quality of machining surfaces is good, compensation is easily achieved, machining efficiency is quite high, precision is high, the mirror surface effect can be achieved through machining, swarf removal is facilitated, and the combined machining device can be widely applied to machining insulators, semiconductors and other workpieces.

Owner:YANCHENG INST OF TECH

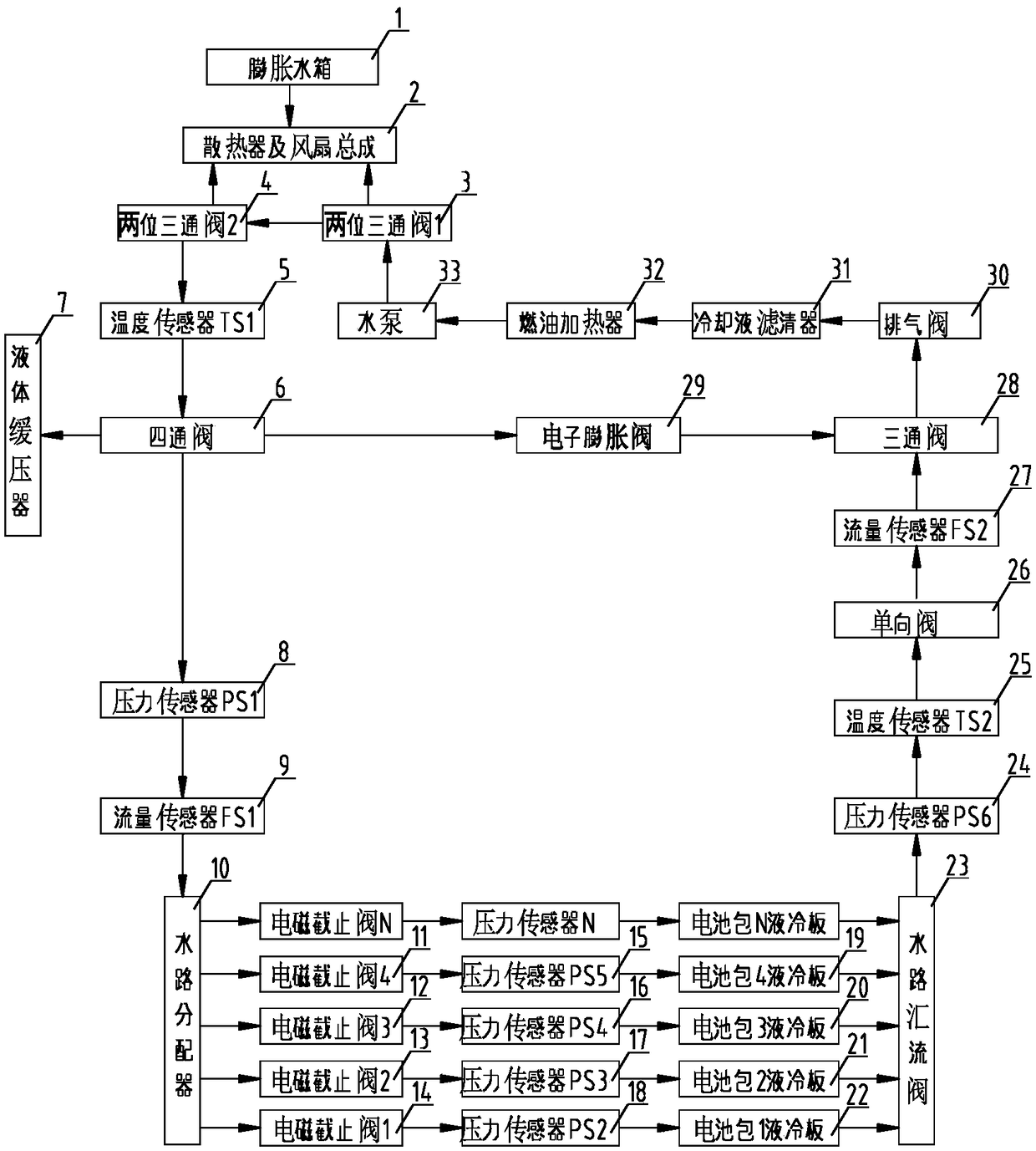

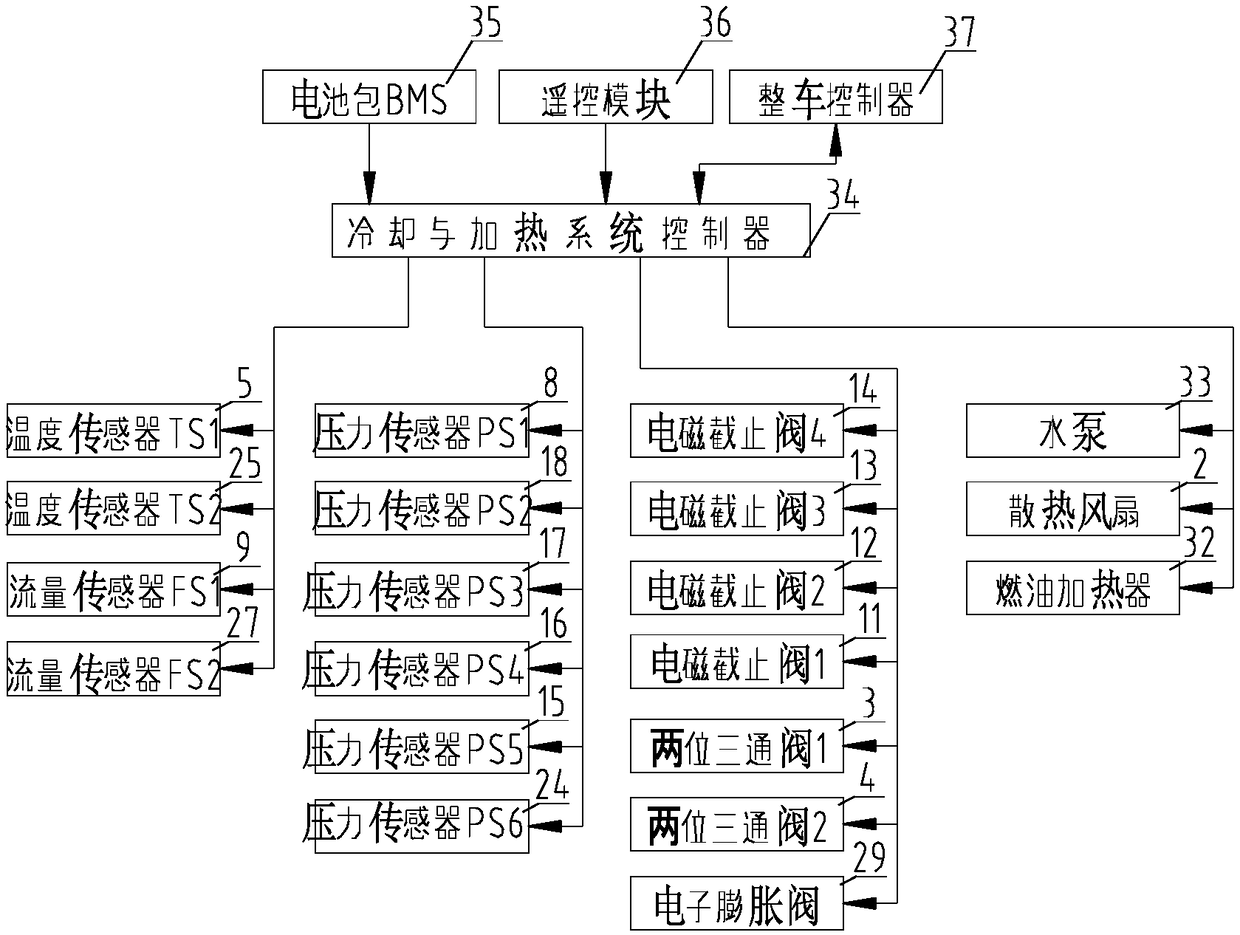

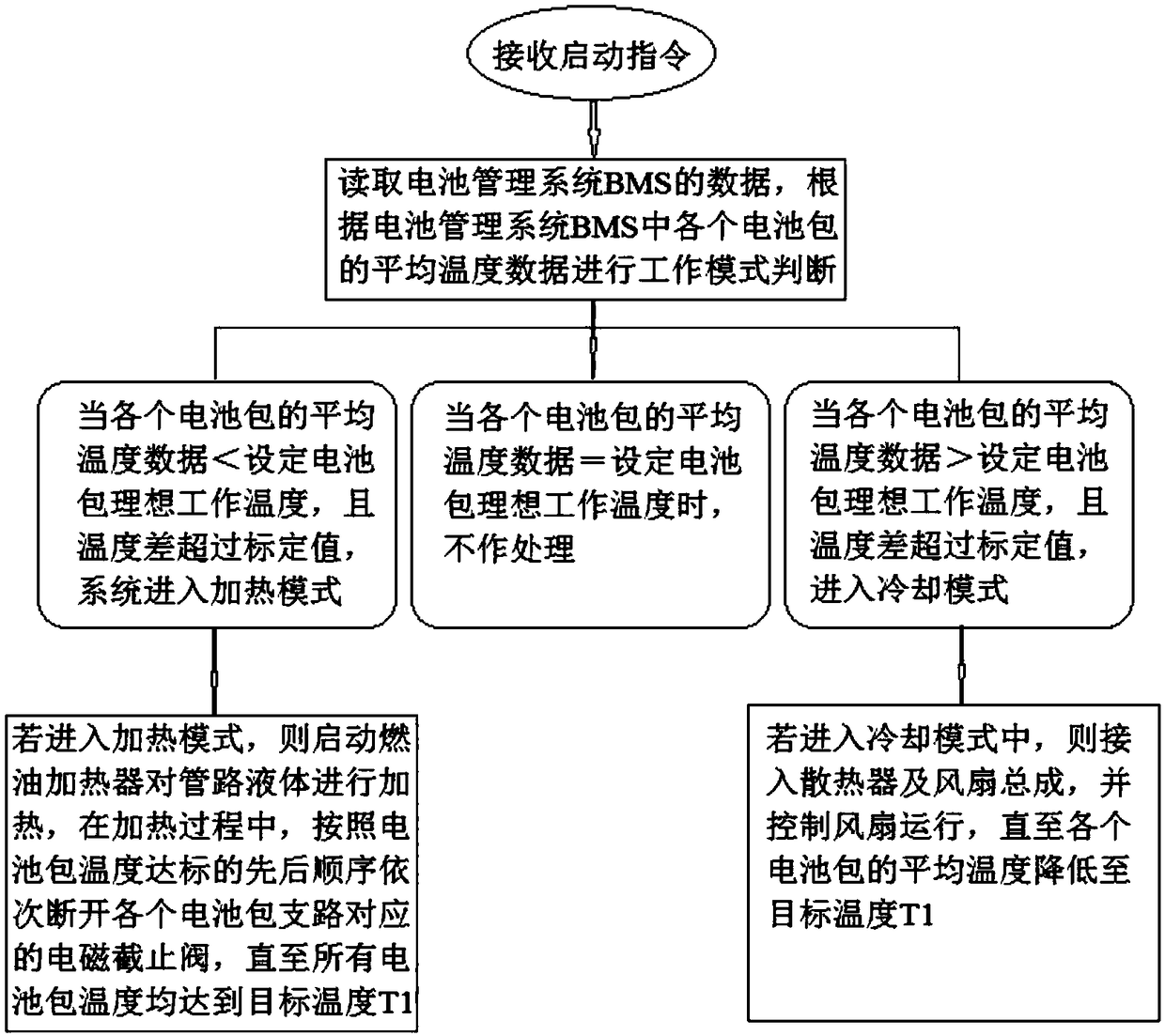

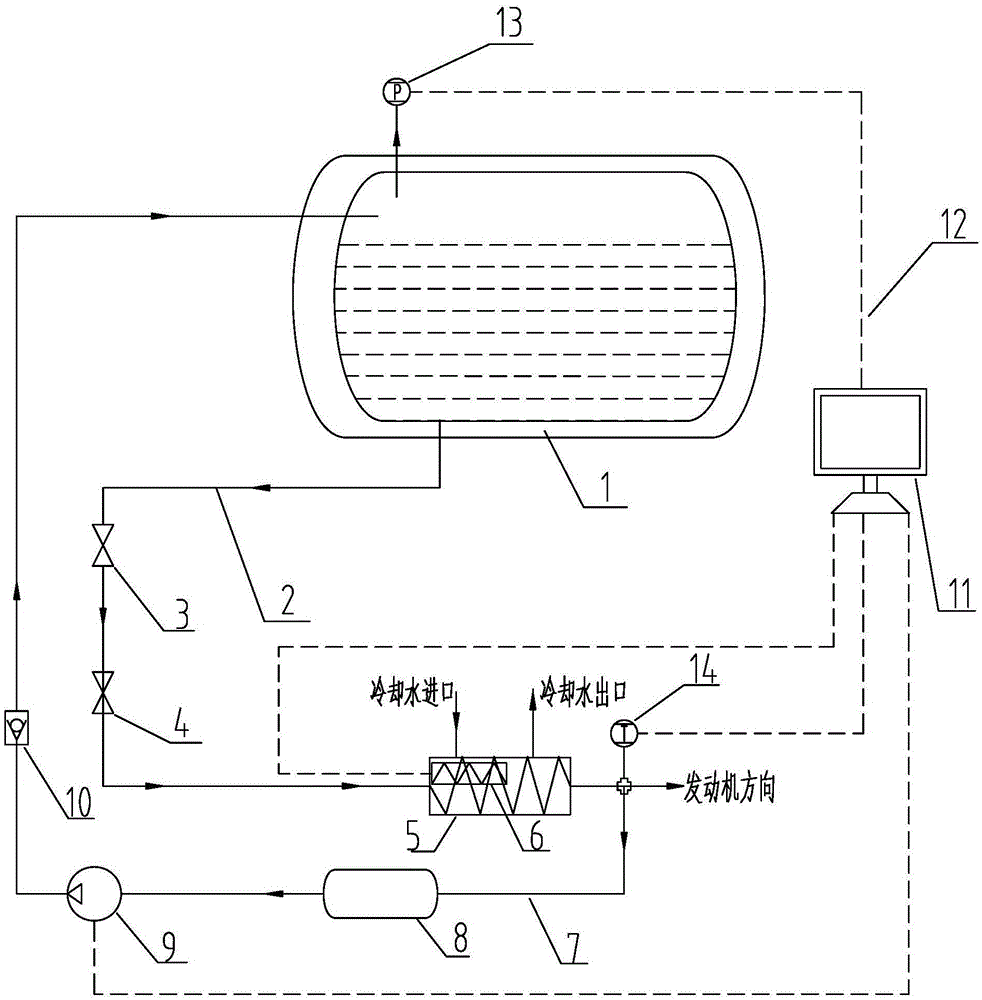

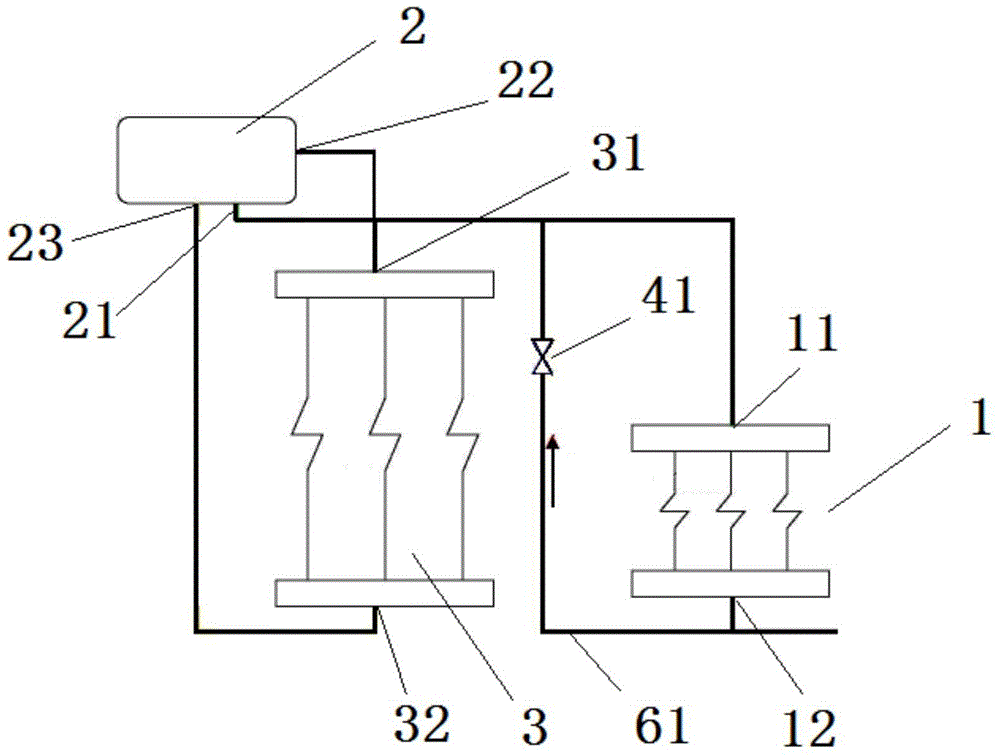

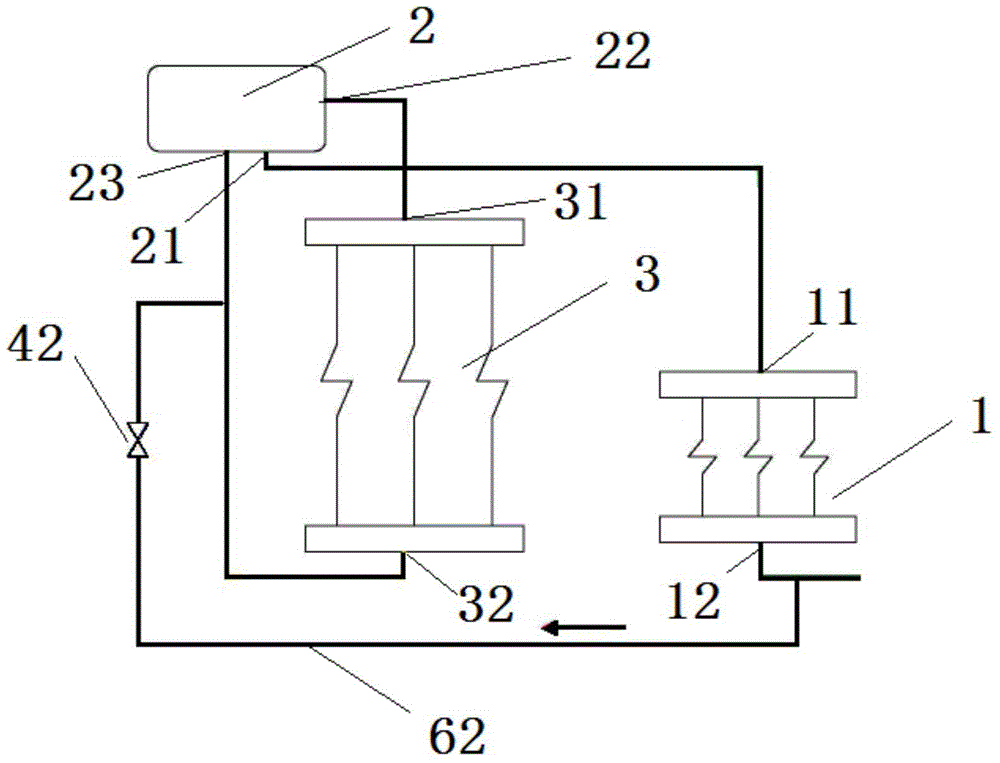

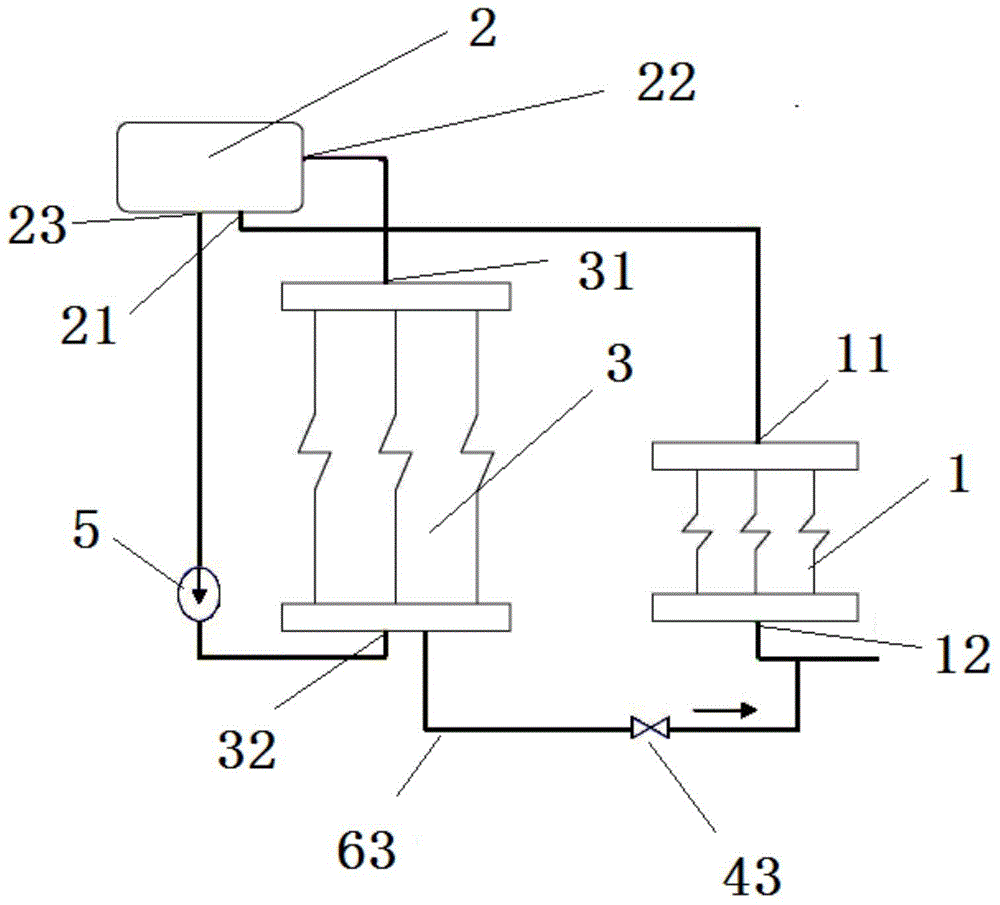

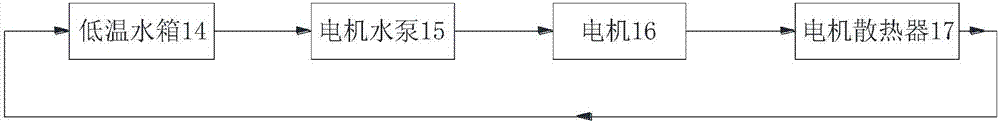

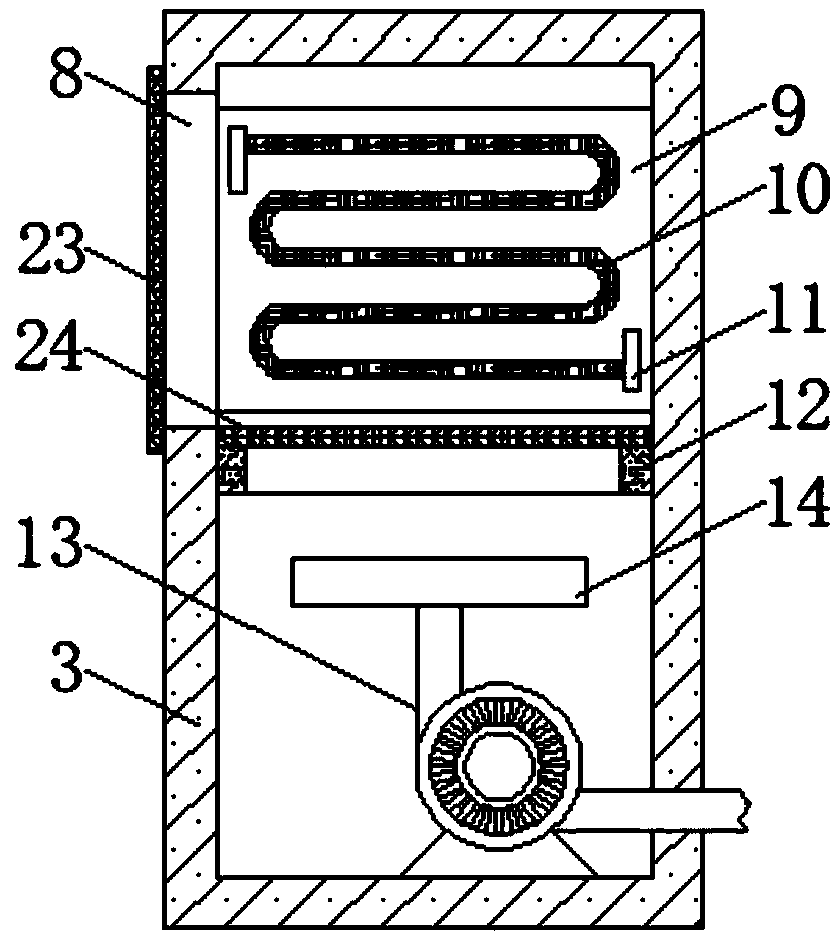

Battery pack temperature control system and method

PendingCN109411850AEffective coolingNormal dischargeCells structural combinationVehicular energy storageExpansion tankTemperature control

The invention relates to the technical field of electric vehicles, in particular to a battery pack temperature control system and method. The battery pack temperature control system comprises an expansion water tank, a radiator and a fan assembly, as well as a main pipe for connecting a water pump, a fuel heater, temperature sensors and a plurality of battery pack liquid-cooling plates; the expansion water tank is communicated with the radiator and a fan assembly water inlet. The battery pack temperature control system also comprises a water path distributor and a water path collector valve; the main pipe is divided into a plurality of branch pipes through the water path distributor; the branch pipes are gathered to the main pipe through the water path collector valve; the battery pack liquid-cooling plates are arranged on the branch pipes in parallel; the temperature sensors include temperature sensor TS1 arranged between the downstream of the water pump and the upstream of the waterpath distributor and temperature sensor TS2 arranged between the upstream of the water pump and the downstream of the water path collector valve. Temperature differences of the battery packs are decreased, measuring precision is improved, the battery pack target temperature is more accurate to calculate, and overall life of each battery is extended.

Owner:DONGFENG ELECTRIC VEHICLE

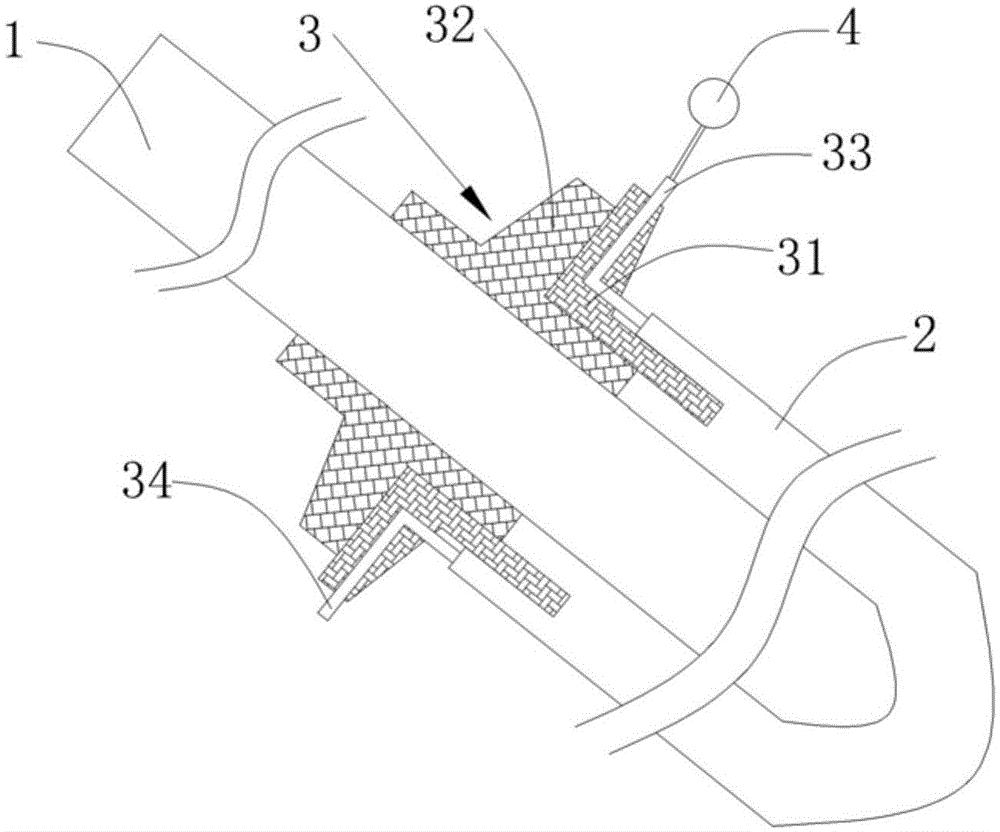

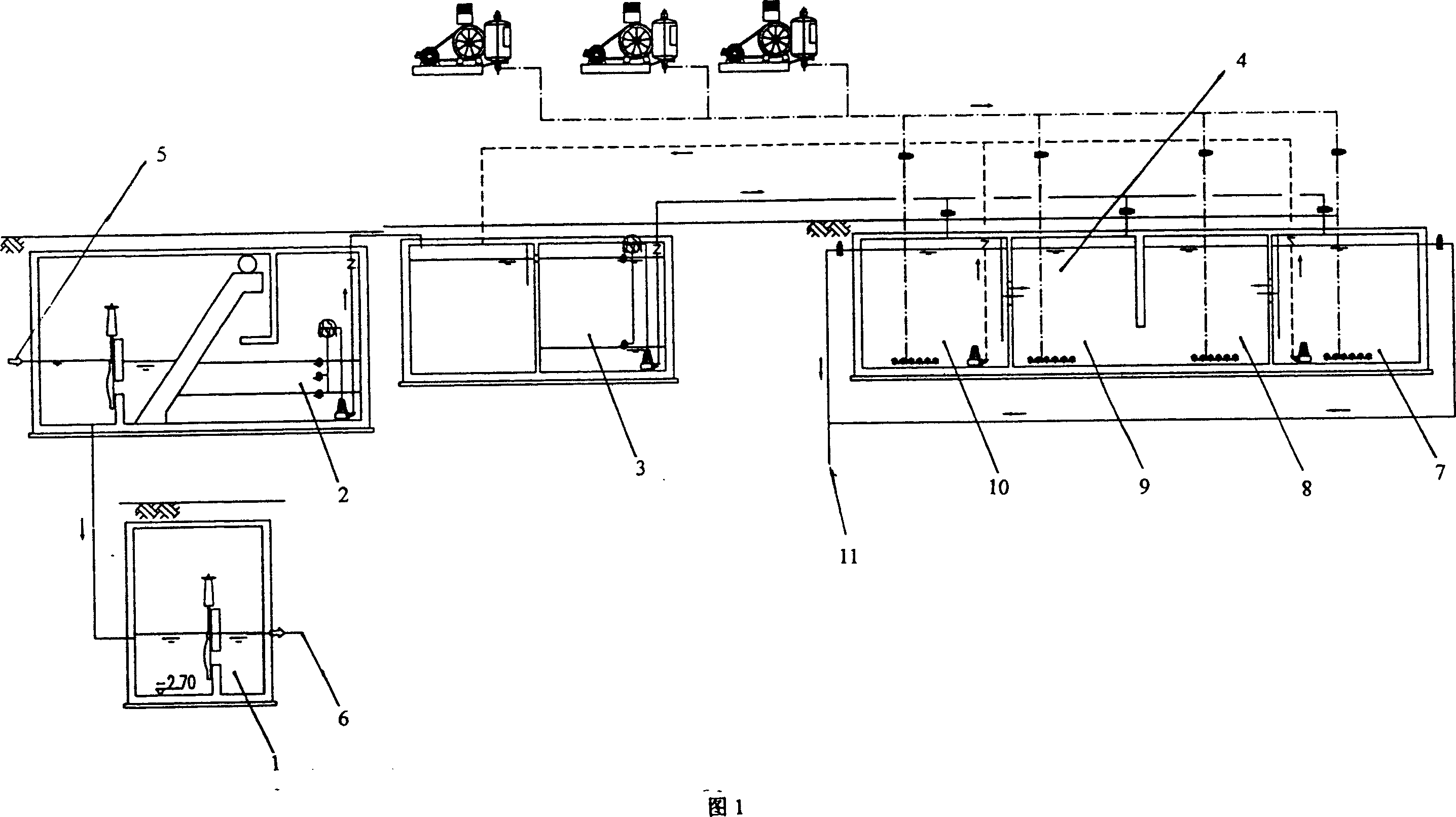

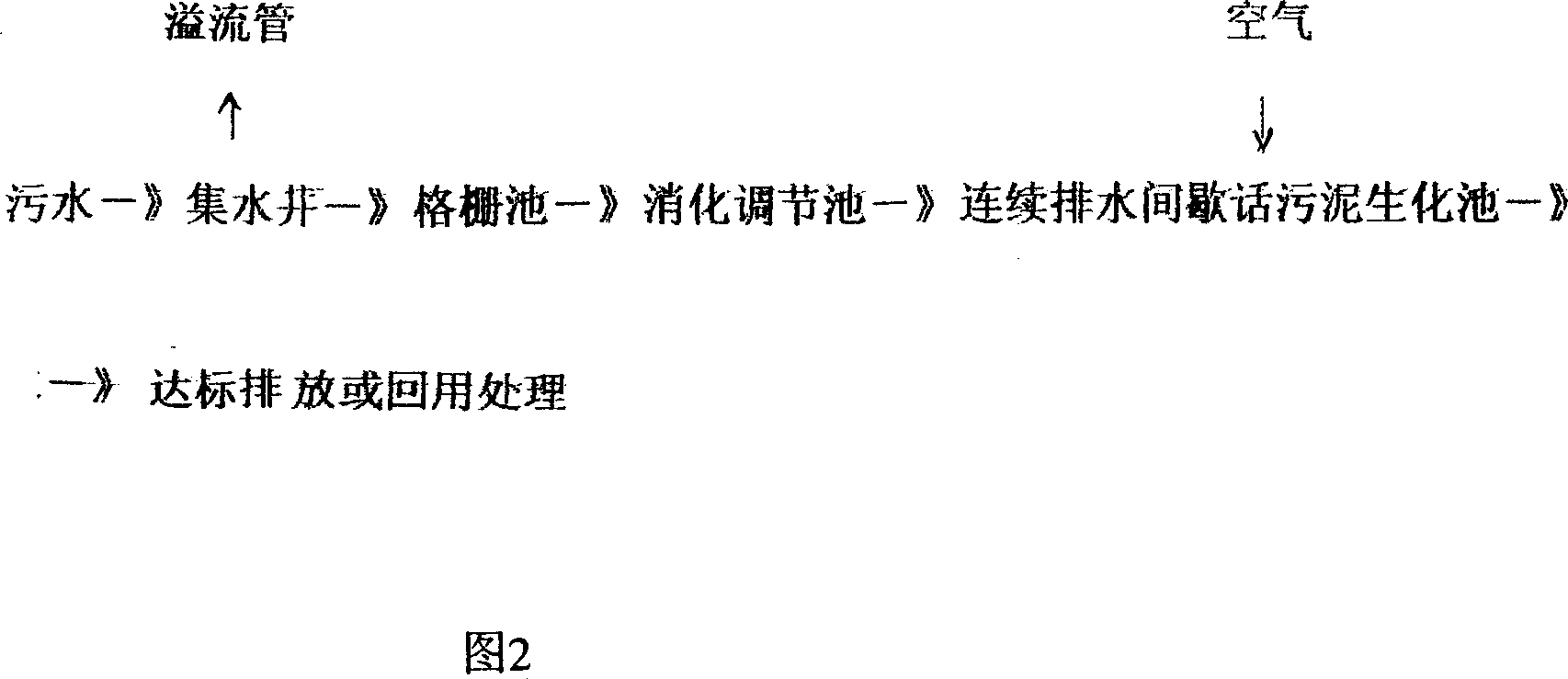

Activated sludge method processing technique at sewage continuous drainage interval

InactiveCN101108757ANormal dischargeEnsure complete removalSustainable biological treatmentBiological water/sewage treatmentNitrogen removalActivated sludge

The invention discloses a sewage continuous drainage interval activated sludge process disposal technology. The sewage enters a catch pit and a grille pool from the pipe network collection and stay. An overflow pipe is near the catch pit. The garbage is intercepted by a buried grille pool and conducts sand setting and reducing processing via a digestive and adjustive pool functioning as adjusting the water volume, acidification and hydrolysis, and finally enters the sewage continuous drainage interval activated sludge process (XUCE) biochemical pool. The buried grille pool has four lattices and works alternatively to reach the aim of phosphorus and nitrogen removal, and removes various contaminations to make the sewage drained reaching the standard or reuse after through the disposal technology. The XUCE disposal technology is advanced, free from noise and smell, convenient in management, low in operation cost and easy in maintenance.

Owner:厦门中联环环保工程有限公司

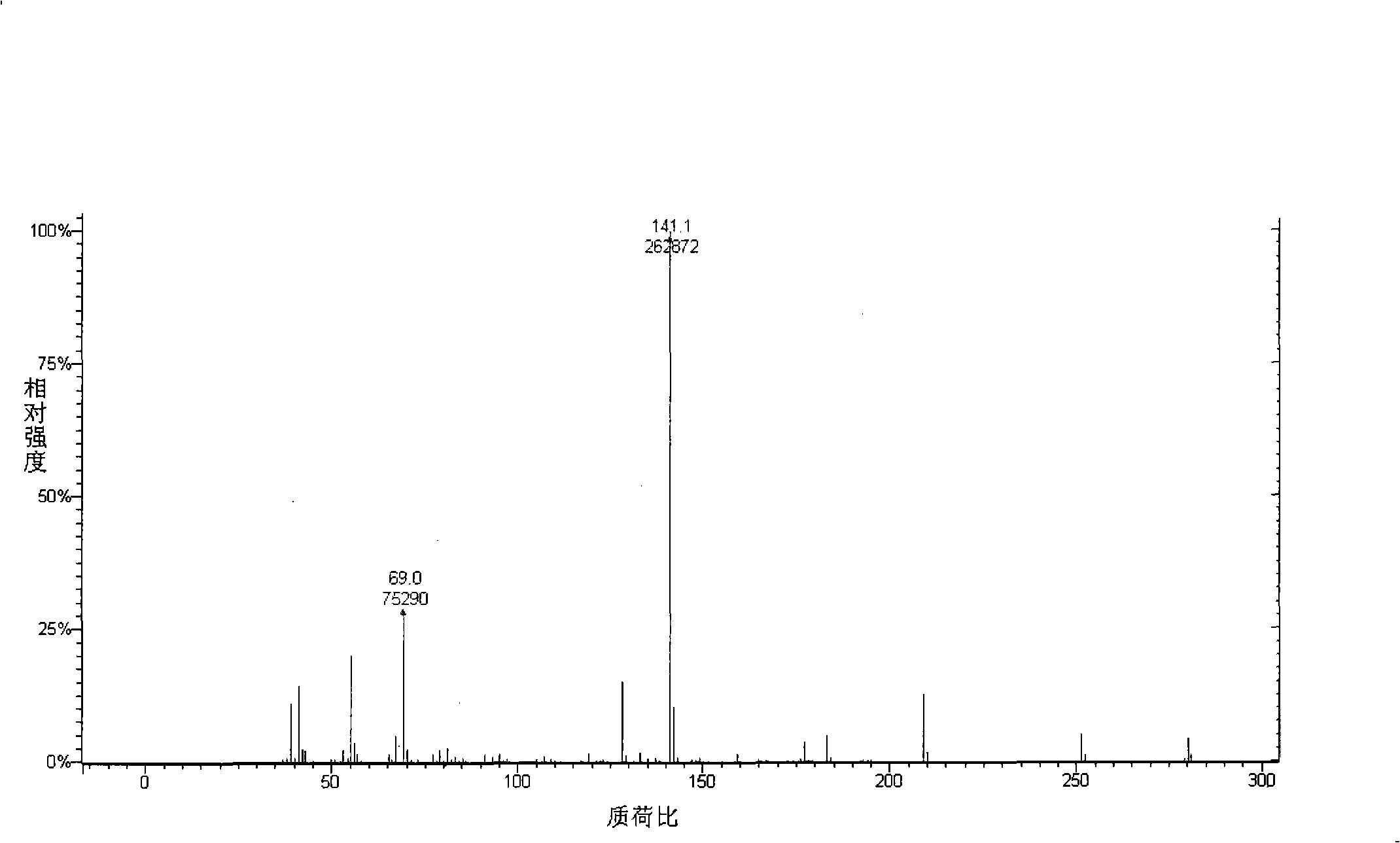

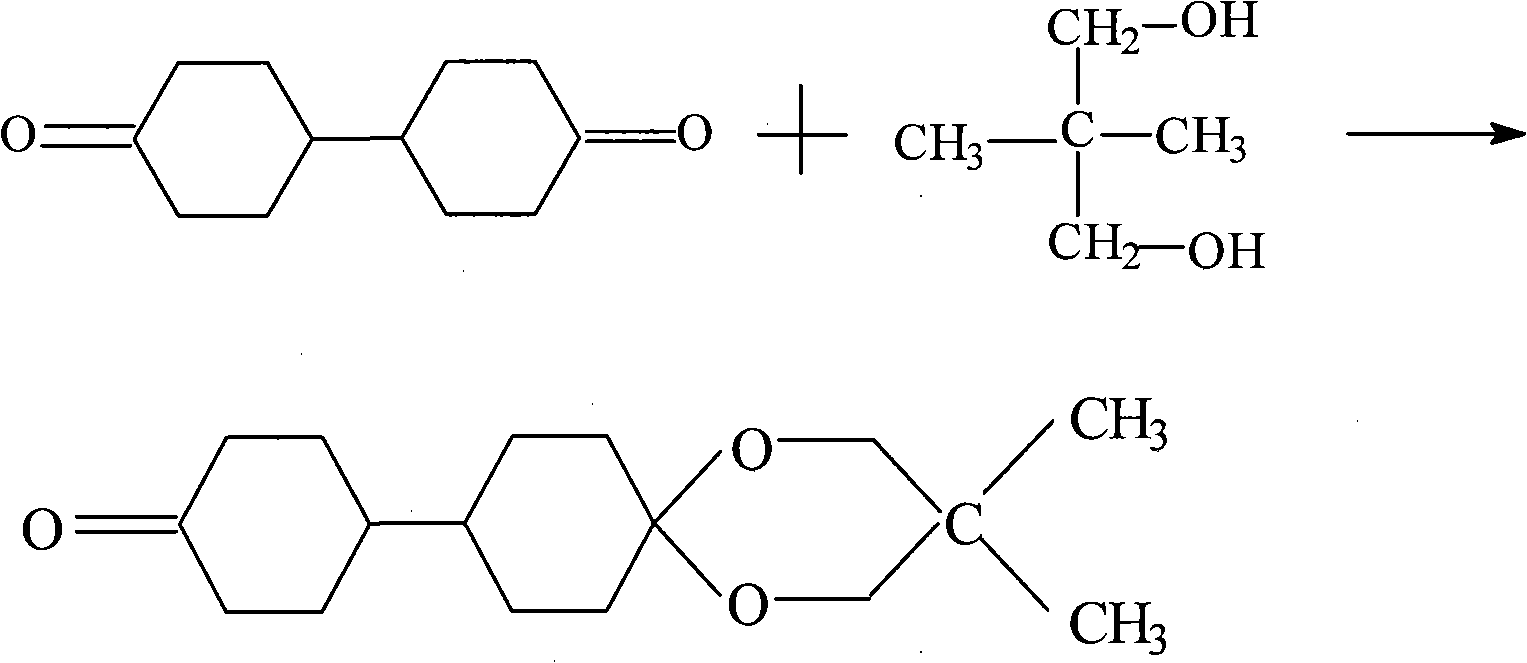

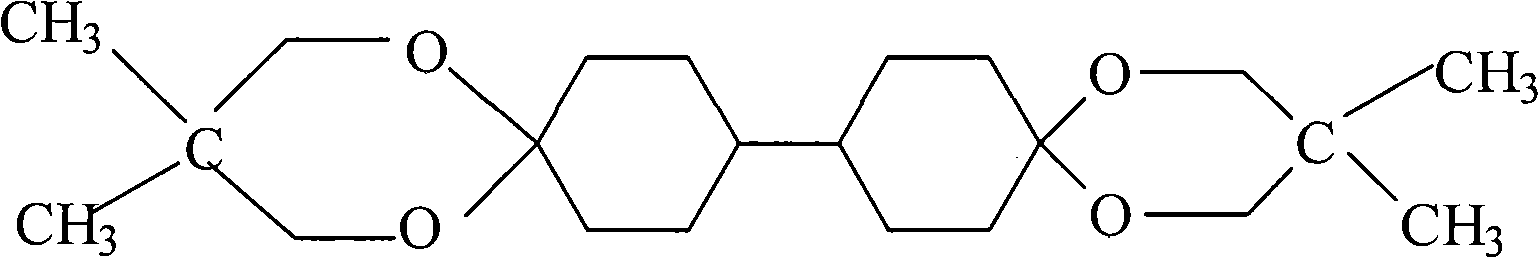

Preparation of bicyclohexyl neopentyl glycol single ketal

ActiveCN101407512AHigh yieldHigh purityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsReaction temperatureStrong acids

The invention relates to preparation of an organic compound, in particular to a method for preparing dicyclohexyl pentanediol mono-ketal and belongs to the technical field of organic compound preparation. The method takes dicyclohexyl diketone and neopentyl glycol as the raw materials to carry out the catalytic reaction under the catalyst of inert solvent cyclohexane and strong acid cation exchange resin, the reaction temperature is 0 to 110 DEG C, the dicyclo mono-ketal is prepared, and the conversion rate can reach 80 to 95 percent; simultaneously, dicyclohexyl pentanediol mono-ketal with high yield and high purity is obtained by acetone-water system, and the method is beneficial to later preparation of mono-crystalline, alkene and the like.

Owner:HEBEI MAIERSTON ELECTRONICS MATERIAL

Intelligent supercharging device and method for low-temperature thermal insulation container

ActiveCN105156881AGuaranteed uptimeEasy to useContainer filling methodsPressure vesselsControl systemThermal insulation

The invention discloses an intelligent supercharging device and method for a low-temperature thermal insulation container. The device comprises the low-temperature thermal insulation container and an electrical control system. A liquid outlet of the low-temperature thermal insulation container is connected with a stop valve through a liquid outlet pipeline. The stop valve is connected with an overflow valve through a liquid outlet pipeline. The overflow valve is connected with a vaporizer through a liquid outlet pipeline. The vaporizer is further internally provided with a heater. The outlet end of the vaporizer is connected with an engine, and the other end of the vaporizer is connected with a buffering tank through a supercharging pipeline. The buffering tank is connected with an air pump through a supercharging pipeline. The air pump is connected with a one-way valve through a supercharging pipeline. The one-way valve is connected with an air inlet in the upper portion of the low-temperature thermal insulation container through a supercharging pipeline. The electrical control system is connected with the heater, the air pump, a pressure sensor installed on the low-temperature thermal insulation container, and a temperature sensor installed at the outlet end of the atomizer through a control circuit. By means of the intelligent supercharging device and method for the low-temperature thermal insulation container, rapid and safe supercharging can be achieved for the low-temperature thermal insulation container within short time.

Owner:湖北三江航天江北机械工程有限公司

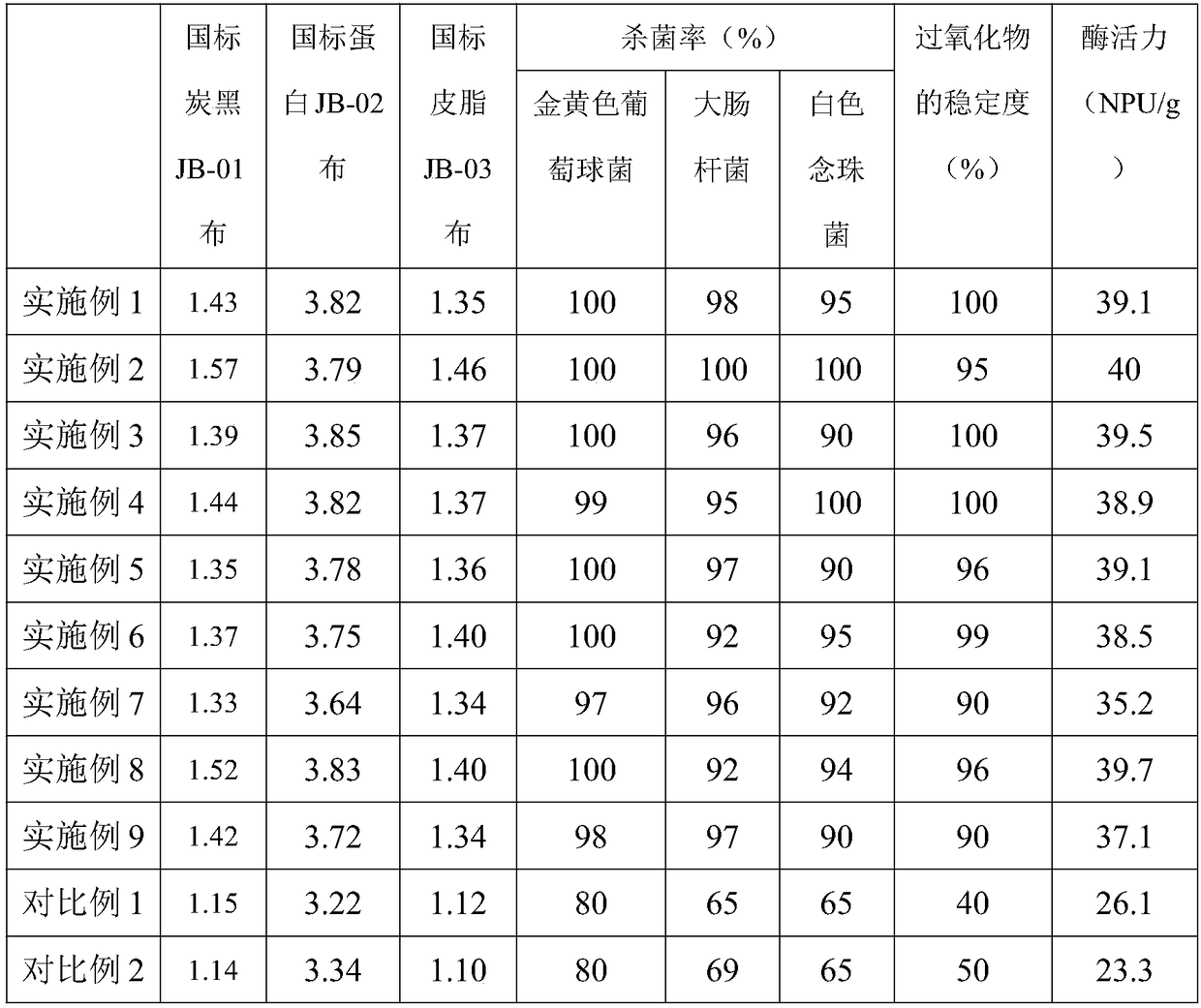

Safe, skin-friendly, specialized sterilizing, environment-friendly efficient decontaminating aerobic soaking powder composition

InactiveCN108359543ALess irritatingEasily biodegradableInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsIrritationFatty acid methyl ester

The invention discloses a safe, skin-friendly, specialized sterilizing, environment-friendly efficient decontaminating aerobic soaking powder composition. The composition is prepared from the following raw materials by mass percent: 20-40% of activity enhancer, 20-50% of plant surfactant, 5-20% of external stabilizer, and 10-25% of other additives, wherein the activity enhancer is prepared from bio-enzyme preparation, whitener and activator, and the plant surfactant is selected from any one or more of fatty acid methyl ester sulfonate, alkyl glycoside, sapindoside, tea saponin and gleditsioside. In the washing powder composition, plant surfactant replaces chemical surfactants in traditional washing powder, further the plant surfactant is made of natural plants and does no causes pollutionin processing, so that the final product has no toxicity to human body, has small irritation and is easy to biodegrade.

Owner:北京狮尚科技有限公司

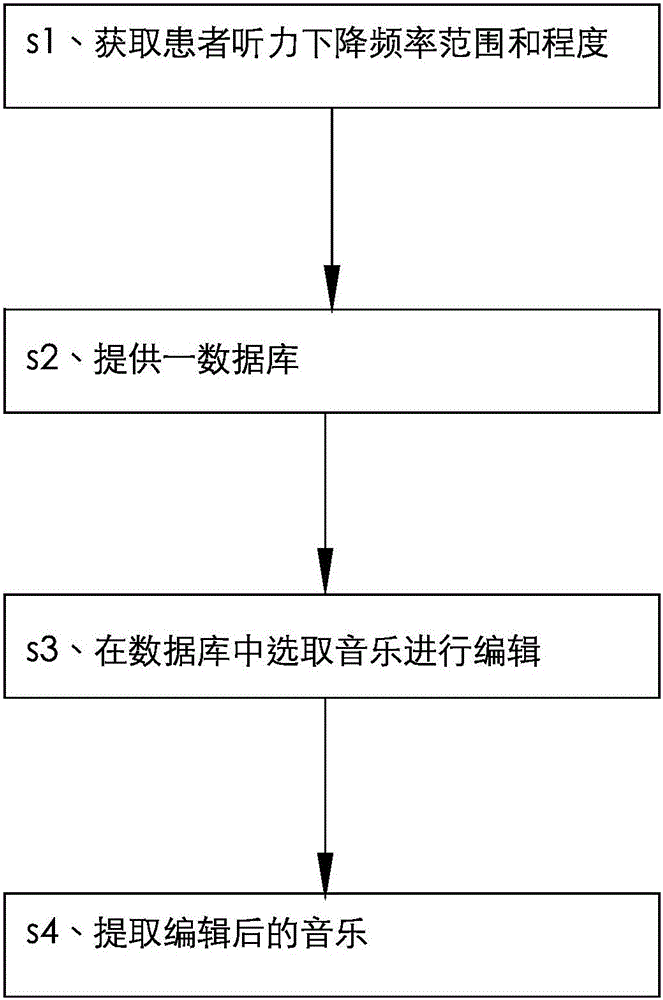

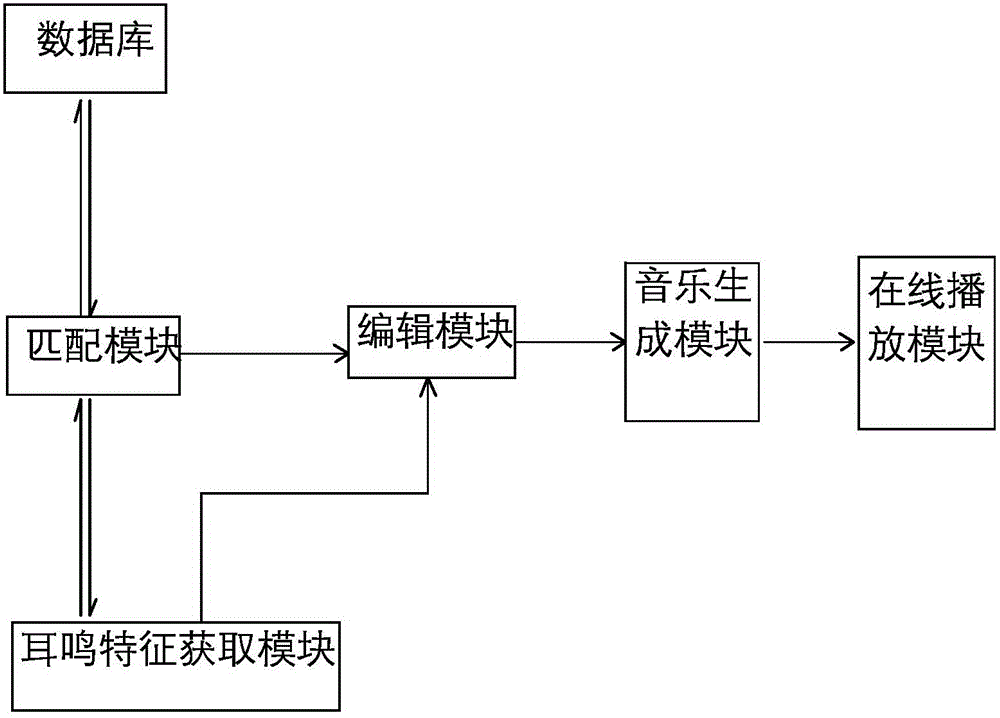

A tinnitus treating music generating method and a tinnitus treating system

InactiveCN105999509AReduce the impactDecreased tinnitus response intensitySleep inducing/ending devicesElectrophonic hearingHearing perception

The invention relates to a tinnitus treating music generating method and a tinnitus treating system. The method comprises the steps of S1, acquiring the hearing loss frequency range and degree (decibels) of a patient; S2, establishing a database storing a plurality of pieces of audio information which are divided into a plurality of categories according to the frequency; S3, selecting a category that can cover the hearing loss frequency range of the patient from the database, selecting a piece of audio information from the category for editing, and increasing the decibels of the music piece with the frequency range the same as the hearing loss frequency range of the patient in the audio information to a normal sense range; S4, extracting the edited music as tinnitus treating music. The method designs music pieces with the same frequency intervals according to the hearing loss frequency and range of a patient, compensates for the hearing lost in a sound-rich environment from two aspects of frequency and intensity, eliminates excessive discharge corresponding to a cerebral neuron hearing loss area, reduces the influence of provocative factors and thus eliminates tinnitus reaction.

Owner:苏州桑德欧声听觉技术有限公司

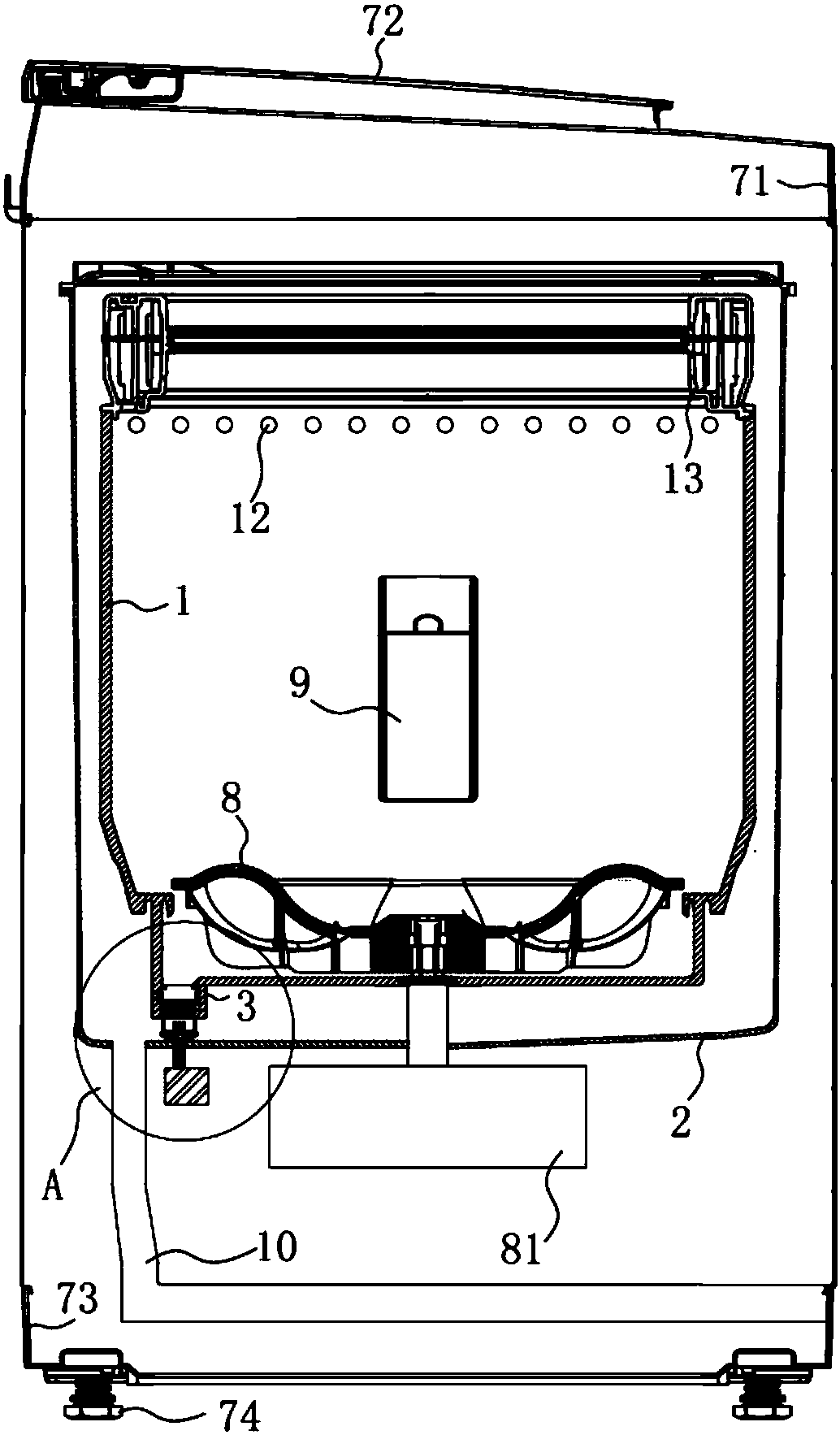

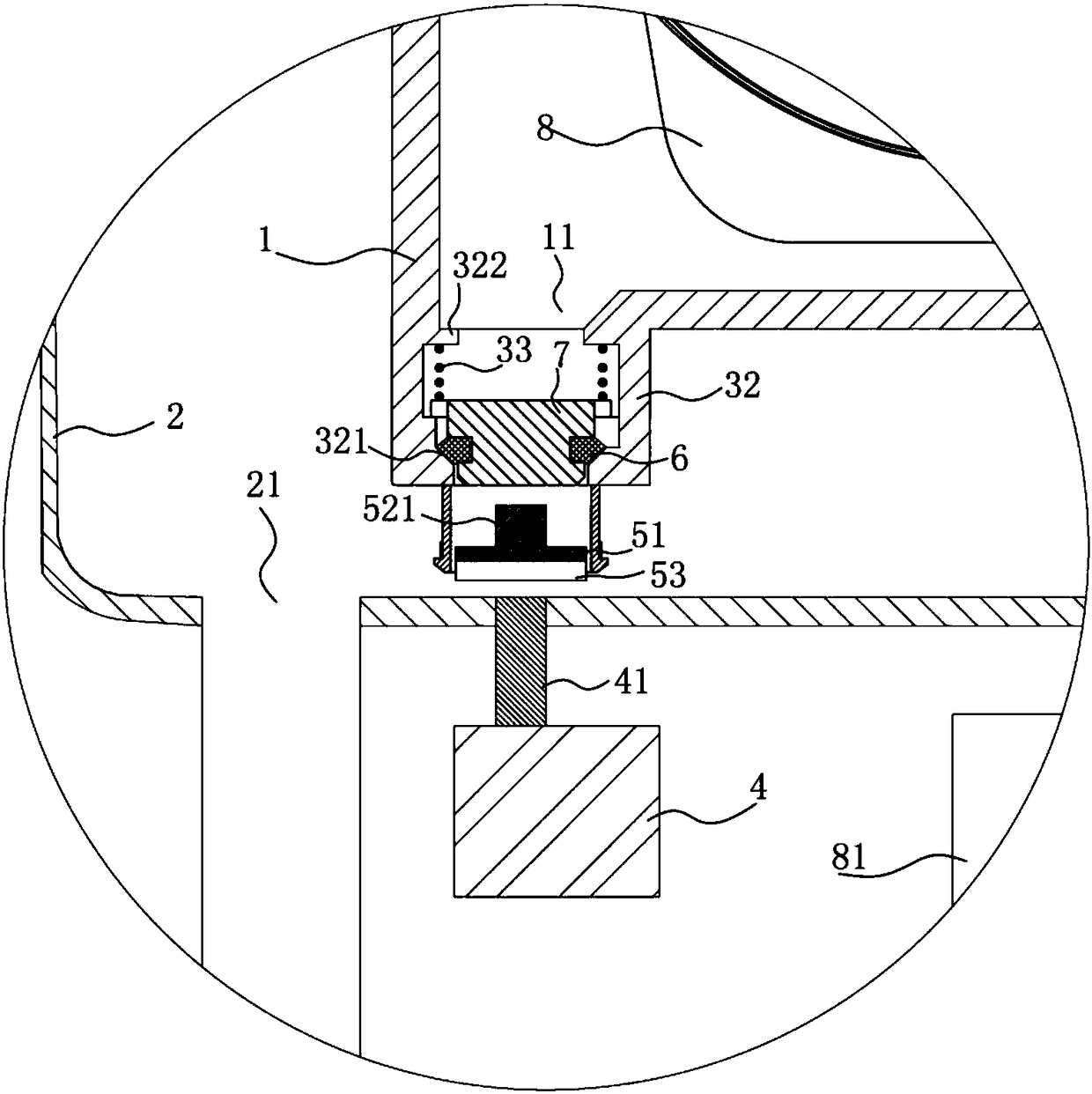

Washing machine

ActiveCN108396518AAvoid breedingReduce Laundry Water ConsumptionOther washing machinesTextiles and paperWater useWater resources

The invention relates to a washing machine. The washing machine comprises an inner barrel and an outer barrel and is characterized in that the bottom or the lateral wall of the inner barrel is provided with an inner barrel draining hole, the inner barrel draining hole is provided with a draining valve, the outer barrel is provided with a power device for pushing the valve element of the draining valve and an outer barrel draining hole, one end, close to the outer barrel, of the draining valve is provided with a draining switch, and the extending shaft of the power device extends and touches the draining switch to open or close the draining valve. The washing machine has the advantages that when the draining valve is closed, water in the inner barrel cannot flow into the outer barrel, dirt,detergent and the like can be prevented from remaining on the barrel wall, and accordingly bacterium breeding is prevented; meanwhile, water in the inner barrel cannot flow into the outer barrel, clothes washing water use amount can be reduced effectively, and water resources can be saved; the draining valve can be opened or closed without draining valve positioning. Due to the fact that the outer barrel draining hole is arranged in the bottom of the inner barrel and the bottom of the outer barrel, water passing the draining valve accumulates at the bottom of the outer barrel and cannot filla space formed by the inner barrel and the outer barrel, and the problem of dirt accumulation can be avoided.

Owner:QINGDAO JIAONAN HAIER WASHING MACHINE +1

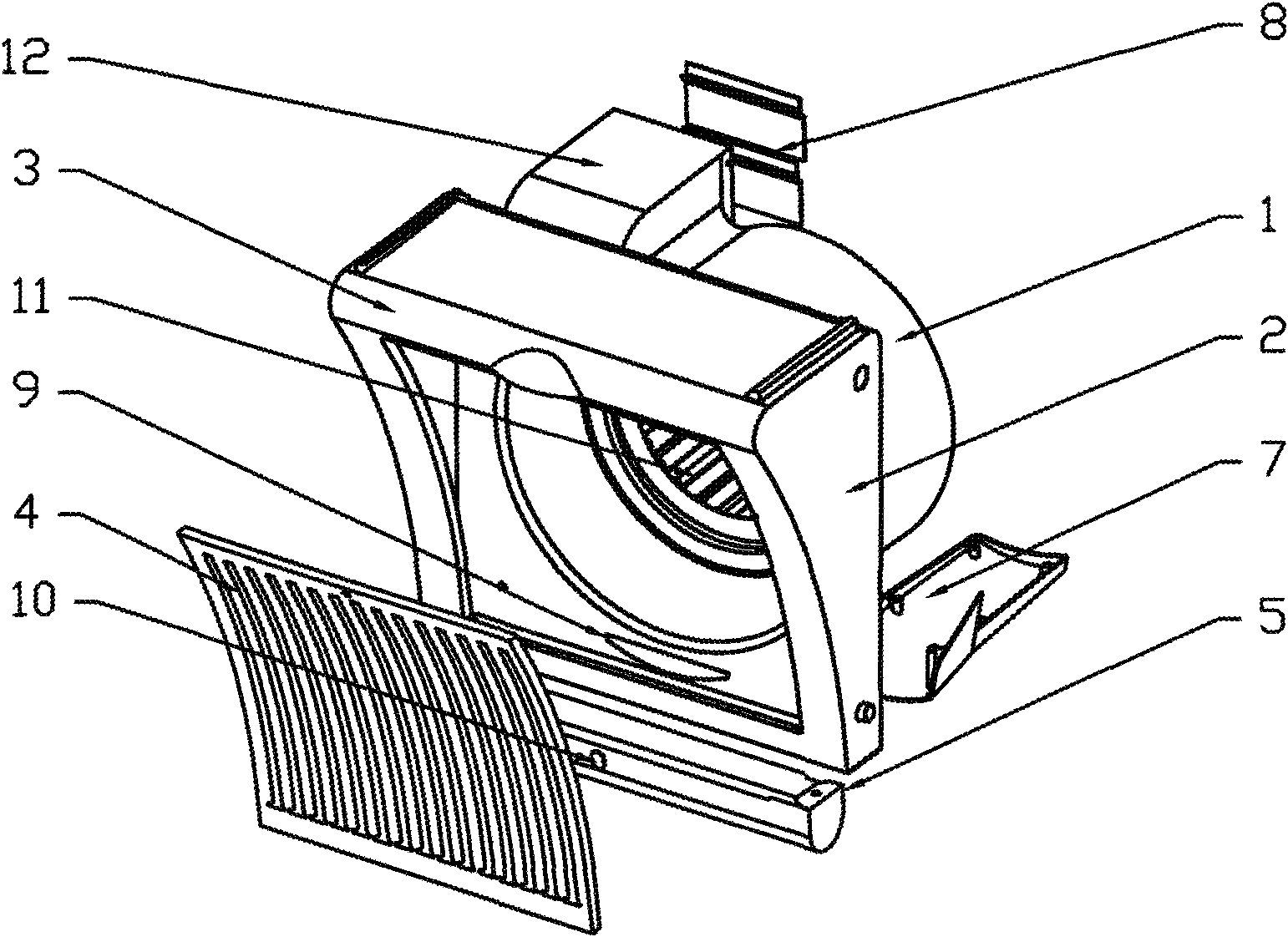

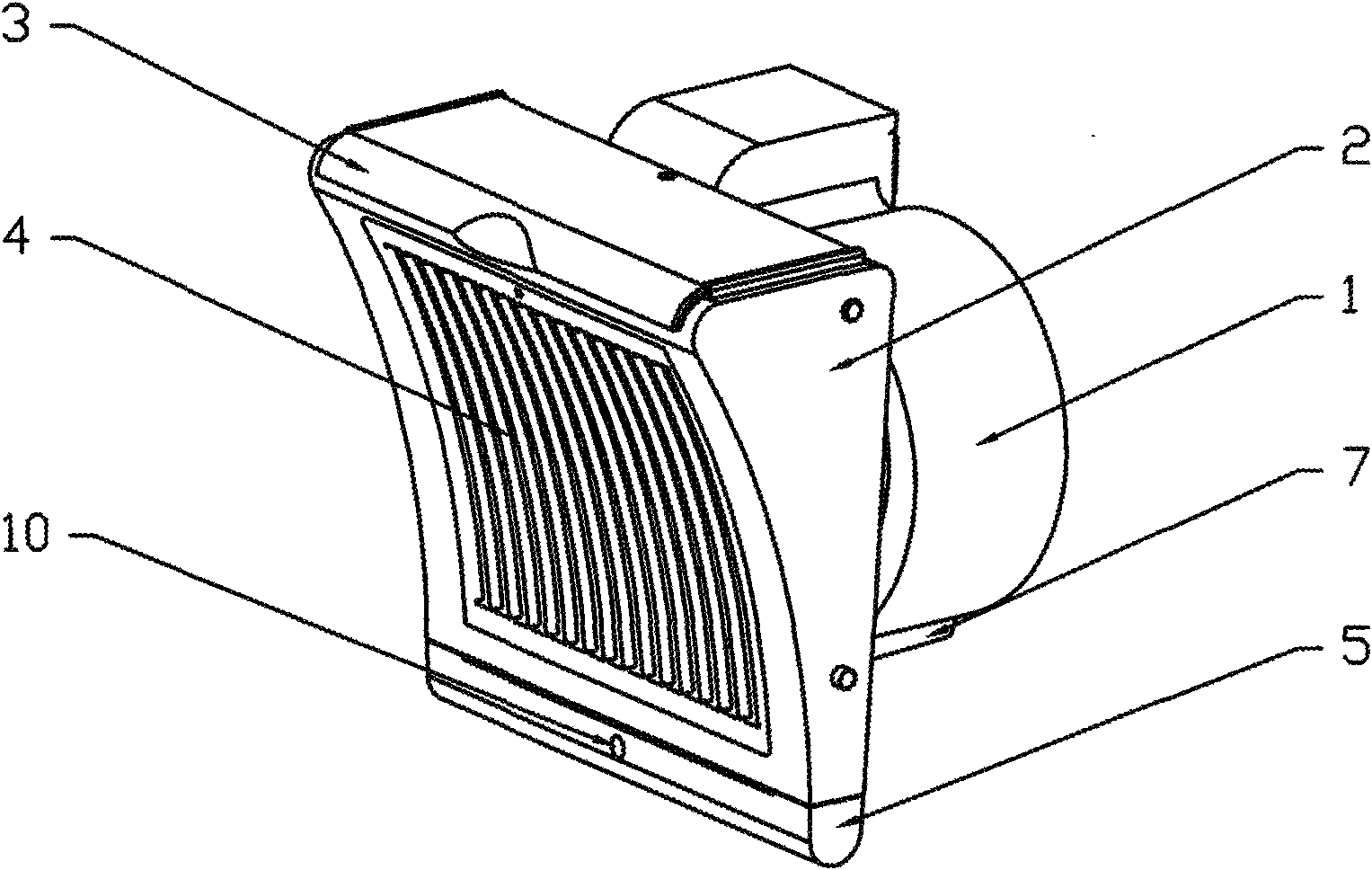

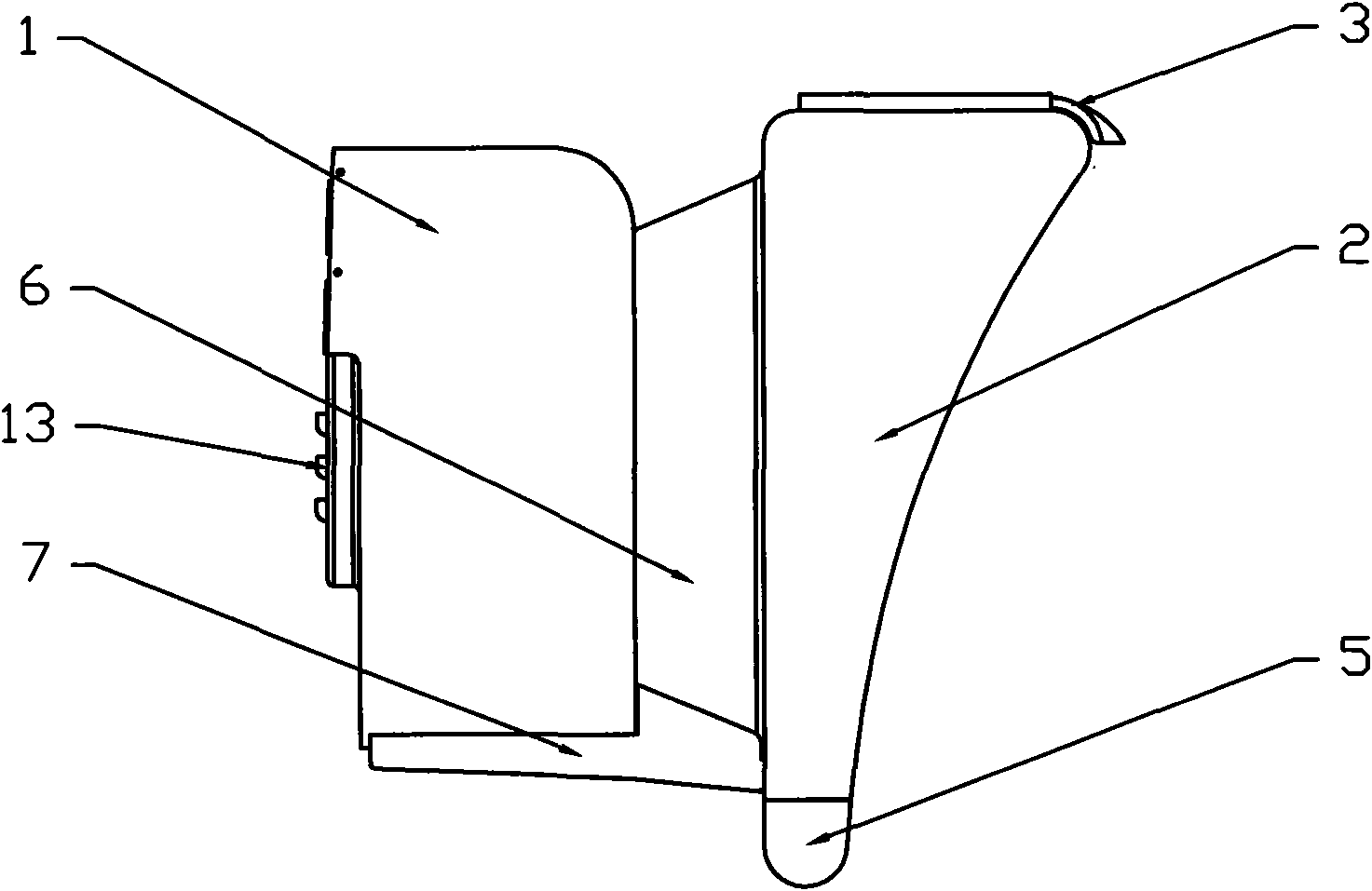

Turbine oil smoke absorbing fan

The invention discloses a turbine oil smoke absorbing fan composed of a main shell with an oil smoke absorbing air inlet, a power air drafting device connected with the main shell, and an air outlet. The power air drafting device is a turbine fan blade driven by a motor, a turbine shell connected with a main shell framework is arranged outside the turbine fan blade, and the turbine shell is a cylindrical structure. The air outlet is arranged at the side of the turbine shell and communicated with the inner cavity of the turbine shell integrally. The main shell is composed of a ventilating duct connected with the turbine shell, and an oil smoke absorbing cavity connected with the ventilating duct and extended forwards. A grid-type net is arranged at the air inlet at the front end of the oil smoke absorbing cavity. The invention adopts a technique that combines the turbine structure of a range hood with a main structure of an exhaust fan, not only has the advantage that the range hood highly effectively separates the oil smoke, but also inherits the advantages that the exhaust fan has a simple structure and small volume. The turbine oil smoke absorbing fan can not only separate the oil smoke for two times and greatly decrease the pollution levels of fan and air, but also greatly decrease cost.

Owner:GUANGDONG MACRO GAS APPLIANCE

Boiler thermodynamic system and boiler

InactiveCN104879743AGuaranteed uptimeMeet the requirements of emission standardsWater feed controlEmission standardEngineering

The invention relates to a boiler thermodynamic system and a boiler. The boiler thermodynamic system comprises an economizer (1). The boiler thermodynamic system further comprises a temperature adjusting device used for adjusting the temperature of smoke at the outlet of the economizer. By means of the technical scheme, the temperature adjusting device of the boiler thermodynamic system can adjust the water temperature or flow in the economizer (1), and therefore the temperature of the smoke at the outlet of the economizer is adjusted. Due to the fact that the outlet of the economizer is communicated with an SCR denitration system, the smoke enters the SCR denitration system through the inlet of the SCR denitration system from the outlet of the economizer, the temperature of the smoke at the outlet of the economizer is adjusted through the temperature adjusting device, then the temperature of the smoke at the inlet of the SCR denitration system is adjusted, and even when the boiler runs in the low-load state, the temperature of the smoke cannot be greatly reduced, in other words, the SCR denitration system can normally run, and the emission of the nitrogen oxide can meet the requirement of the Thermal Power Plant Atmospheric Pollutant Emission Standard.

Owner:CHINA SHENHUA ENERGY CO LTD +2

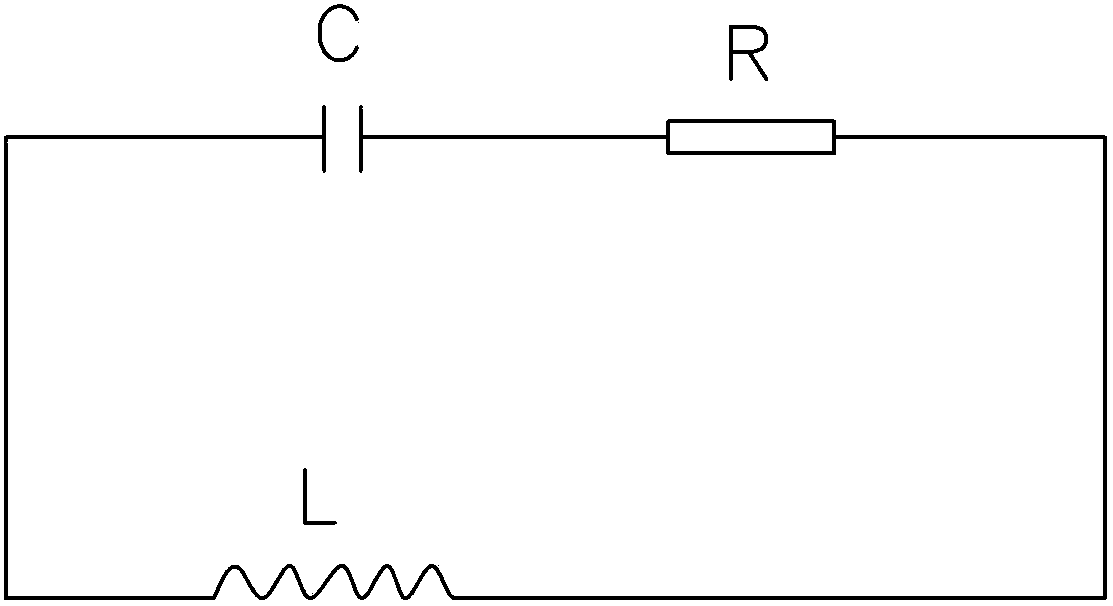

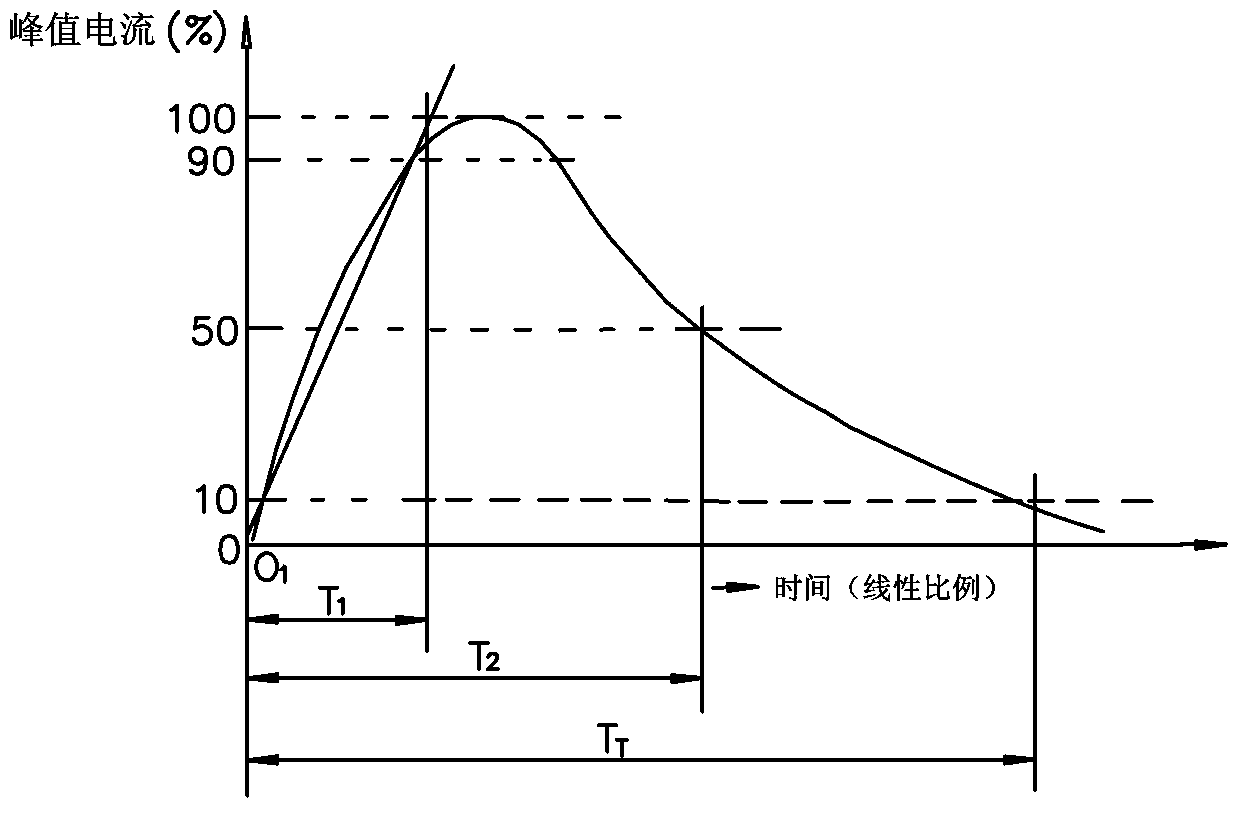

Lightning current surge testing stand

This invention discloses a lightning current surge testing stand, comprising a cabinet, a through-flow fixture, an oscilloscope and an LER discharging circuit. A main power switch is positioned on the cabinet panel, a single-push button, a constant-impacting button, a time relay, a counting relay, an output terminal, through-flow sampling port, a voltage-limitation sampling port, a digital voltmeter, a manual operation potentiometer knob, a booster knob and a protection switch for a voltage-sensitive through-flow fixture. The LCT discharging circuit electrically connected to electrical members on the cabinet panel is positioned within the cabinet; a piezoresistor to be detected is positioned within the through-flow fixture; the oscilloscope is connected to the through-flow sampling port; the single-push button is pushed and the wave shape is observed; the voltage setting value is adjusted until the 8 / 20 Mu wave shape of the specific peak value is shown on the circuit; the voltage setting value is fixed; the next batch of the piezoresistors are enclosed and the change of the voltage of the piezoresistor after the through-flow test is compared. In this invention the charging and discharging of the capacitor are controlled by the electric circuit, which simplifies the operation, and pushing the button for one time remotely can finish 1-99 times of surge test.

Owner:KUSN WANFENG ELECTRONICS

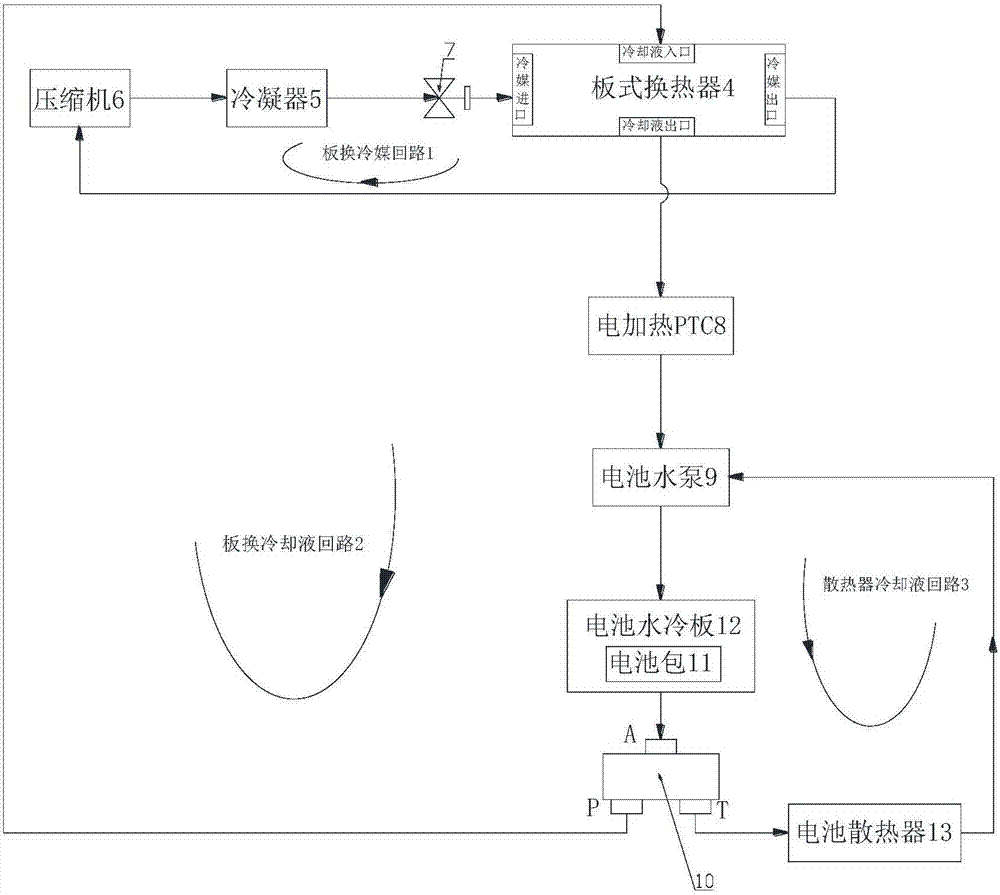

Intelligent new energy vehicle whole vehicle heat management system

ActiveCN107054061AMeet cooling needsRealize energy savingVehicular energy storageElectric/fluid circuitSocial benefitsSystems design

The invention discloses an intelligent new energy vehicle whole vehicle heat management system and belongs to the technical field of new energy electric vehicles. The problems that a traditional electric vehicle heat management system is unreasonable in design, limited in function, poor in cooling effect, large in occupied space and large in energy dissipation are solved. The intelligent new energy vehicle whole vehicle heat management system mainly comprises a battery heat management subsystem, a motor heat management subsystem and an ECU controller. The energy utilization rate is very high, the energy saving effect is very obvious, the system design concept is ingenious, the structure design is simple and feasible, realization is easy, purchasing cost of main engine plants is effectively reduced, the economic and social benefits are greatly increased, high practicability is achieved, and important significance is achieved for development of new energy electric vehicles in our country.

Owner:扬州嘉和新能源科技有限公司

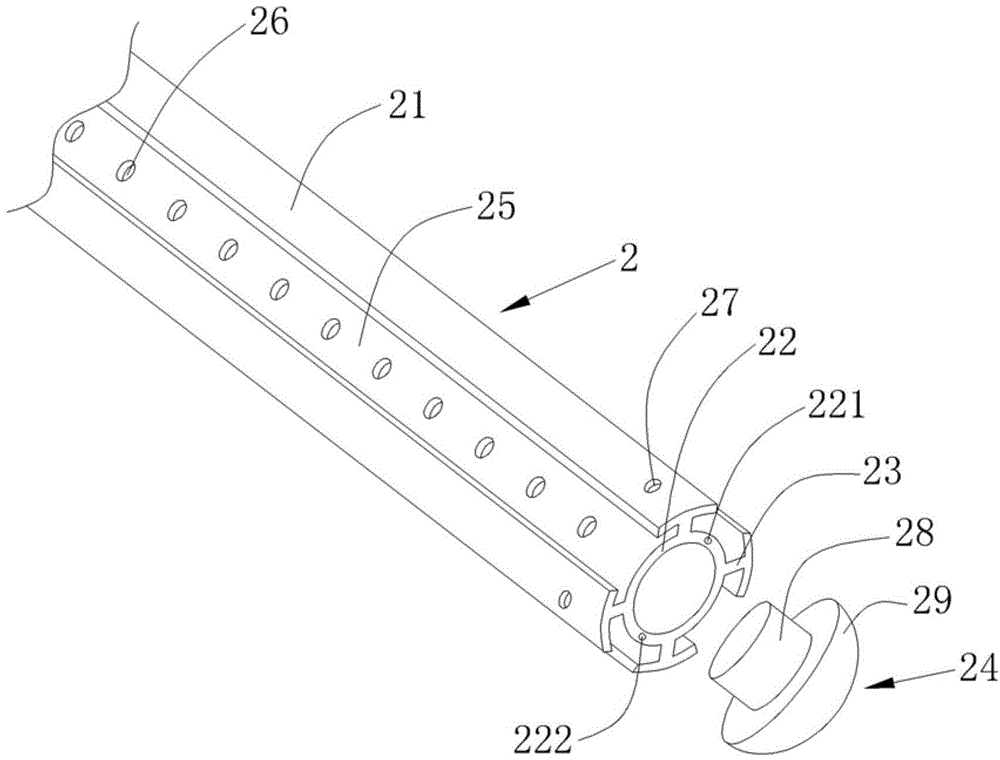

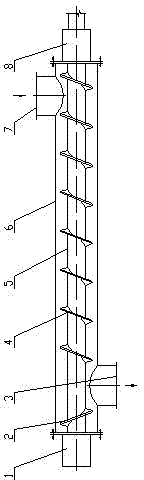

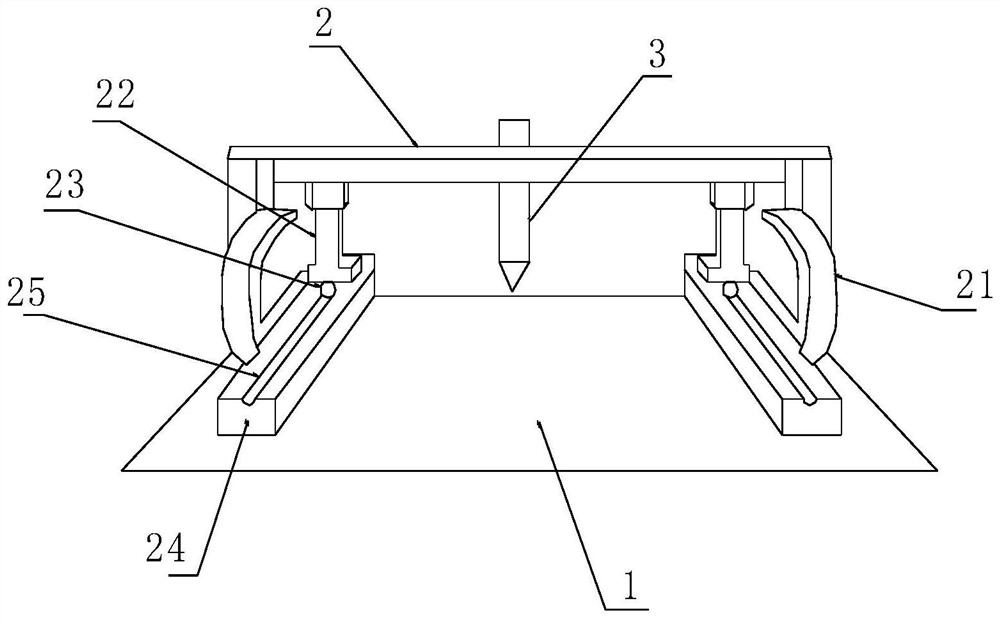

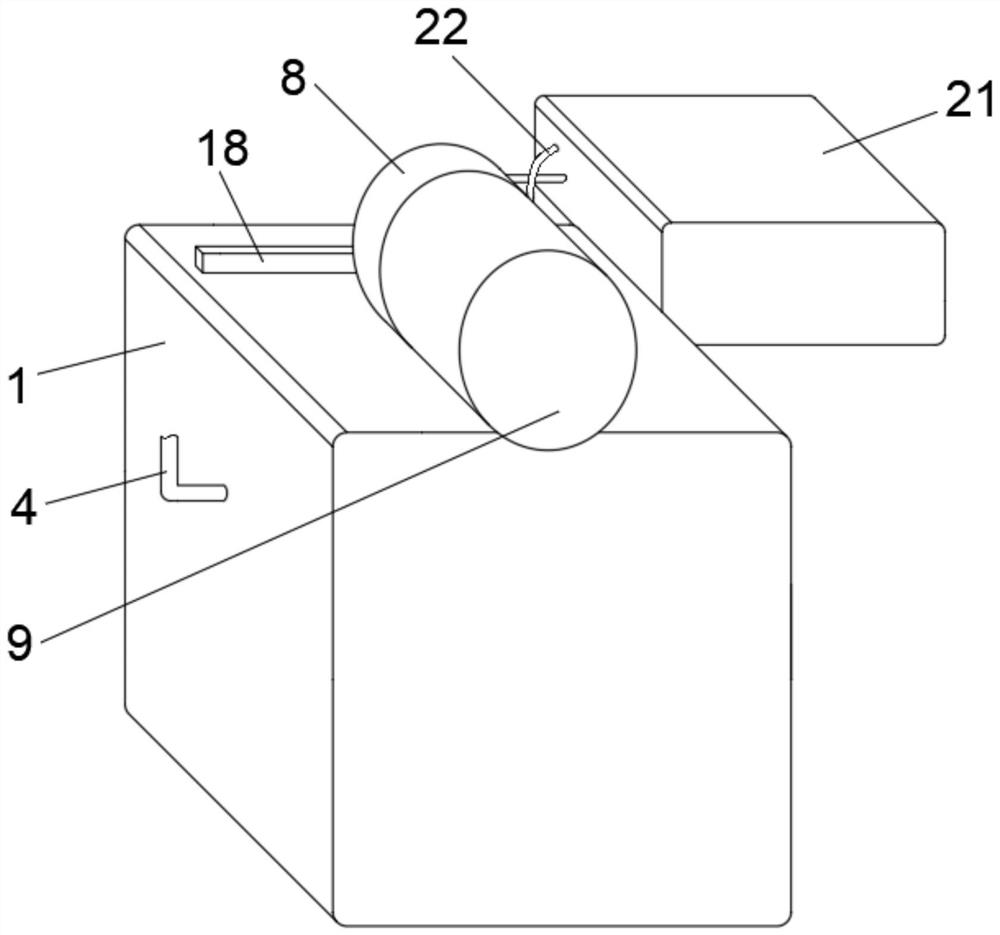

Novel anti-blocking reverse feeding device

InactiveCN104709677ANormal dischargeAvoid cloggingConveyorsPackagingEngineeringMechanical engineering

The invention discloses a novel anti-blocking reverse feeding device for feeding smashed straws in the fuel production by straws. The novel anti-blocking reverse feeding device is a horizontal long cylinder, and comprises a back shaft head, a reverse shaft page, forward shaft pages, a spiral shaft and a front shaft head, wherein a discharge port is formed in the left lower end of the cylinder; an opening is formed in the right upper end of the cylinder; the two ends of the cylinder are respectively connected with the front shaft head and the back shaft head; the reverse shaft page is mounted at the left end of the spiral shaft; and the forward shaft pages are mounted at the right end of the spiral shaft to the right end of the discharge port. The reverse shaft page is mounted at the left end of the discharge port, and is opposite to the rotating angles of the forward shaft pages; and the angle difference is 180 degrees. The novel anti-blocking reverse feeding device has the following beneficial effects: because of the effect of the reverse shaft page, materials are locally alternated and circulated to be normally discharged, so that the powder conveying blockage phenomenon is prevented, and the production is normally performed.

Owner:天津市福达生物科技有限公司

Single-cylinder diesel engine

The invention discloses a single-cylinder diesel engine which is novel in structure. The single-cylinder diesel engine comprises a base, a cylinder body arranged on the base, an oil tank and a water tank. A cylinder cover matched with the cylinder body is arranged on the cylinder body. A cylinder sleeve is fixedly arranged in the cylinder body through screws. A piston is arranged in the cylinder sleeve in a sliding mode. The lower end of the piston is connected with a crank mechanism through a connecting rod, wherein the crank mechanism is arranged inside the lower end of the cylinder body. A cylinder gasket is arranged between the cylinder sleeve and the cylinder cover. A cooling water cavity is formed between the middle of the cylinder sleeve and the cylinder body and communicated with the water tank through a connecting pipe. A plurality of annular reinforcing ribs are arranged on the cylinder sleeve in the cooling water cavity. A guiding base, a sliding rod, a buoy and a floater are all arranged in a buoy cavity. A cover is arranged at a water adding opening. A plurality of ventilation holes are evenly formed in the cover.

Owner:JIANGYU JIANGSU POWER MACHINERY LIMITED

Waterproof exhaust pipe

InactiveCN104033227ASolve the problem of flameoutExtended service lifeExhaust apparatusSilencing apparatusCentrifugal forceExhaust pipe

The invention discloses a waterproof exhaust pipe and relates to the field of vehicle fittings. The waterproof exhaust pipe comprises a muffler, a tail pipe, a branch pipe and a blower housing, wherein the tail pipe is connected with the muffler, the branch pipe is arranged on the tail pipe, the blower drum is connected with the tail pipe through the branch pipe, a blower is mounted in the blower housing, an air outlet of the blower is arranged in the branch pipe, and the branch pipe and the outlet direction of the tail pipe form an included angle ranging from 135 degrees to 150 degrees. The blower is mounted on the tail pipe, and rotates to generate centrifugal force when an outlet of the exhaust pipe is immersed by water, so that water is displaced so as not to enter the tail pipe and tail gas generated by an automobile can normally exhaust, the problem of engine flameout caused by water inflow of the exhaust pipe is effectively solved, service life of an engine is prolonged, convenience is provided for users and investment is saved.

Owner:廖大涌

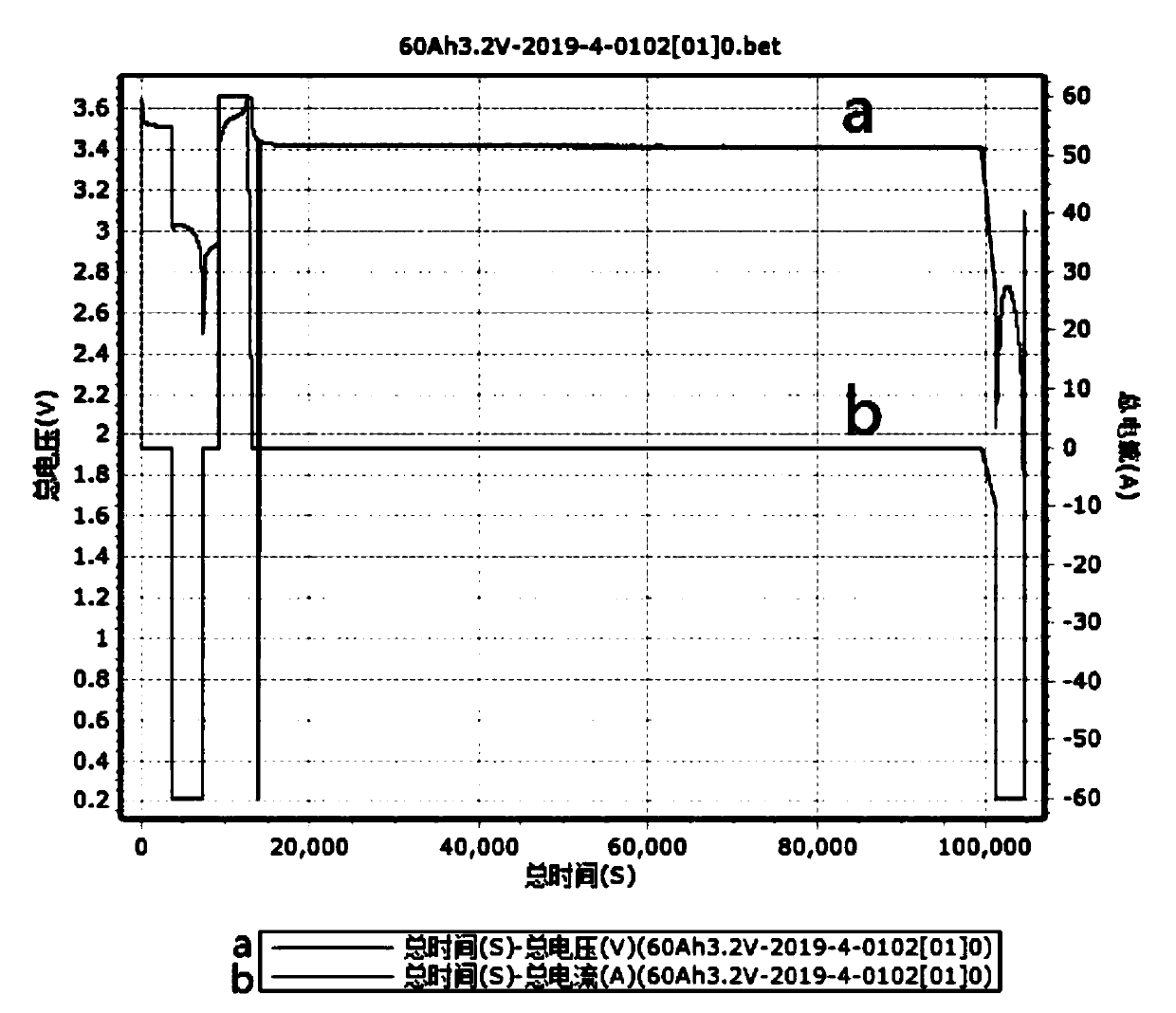

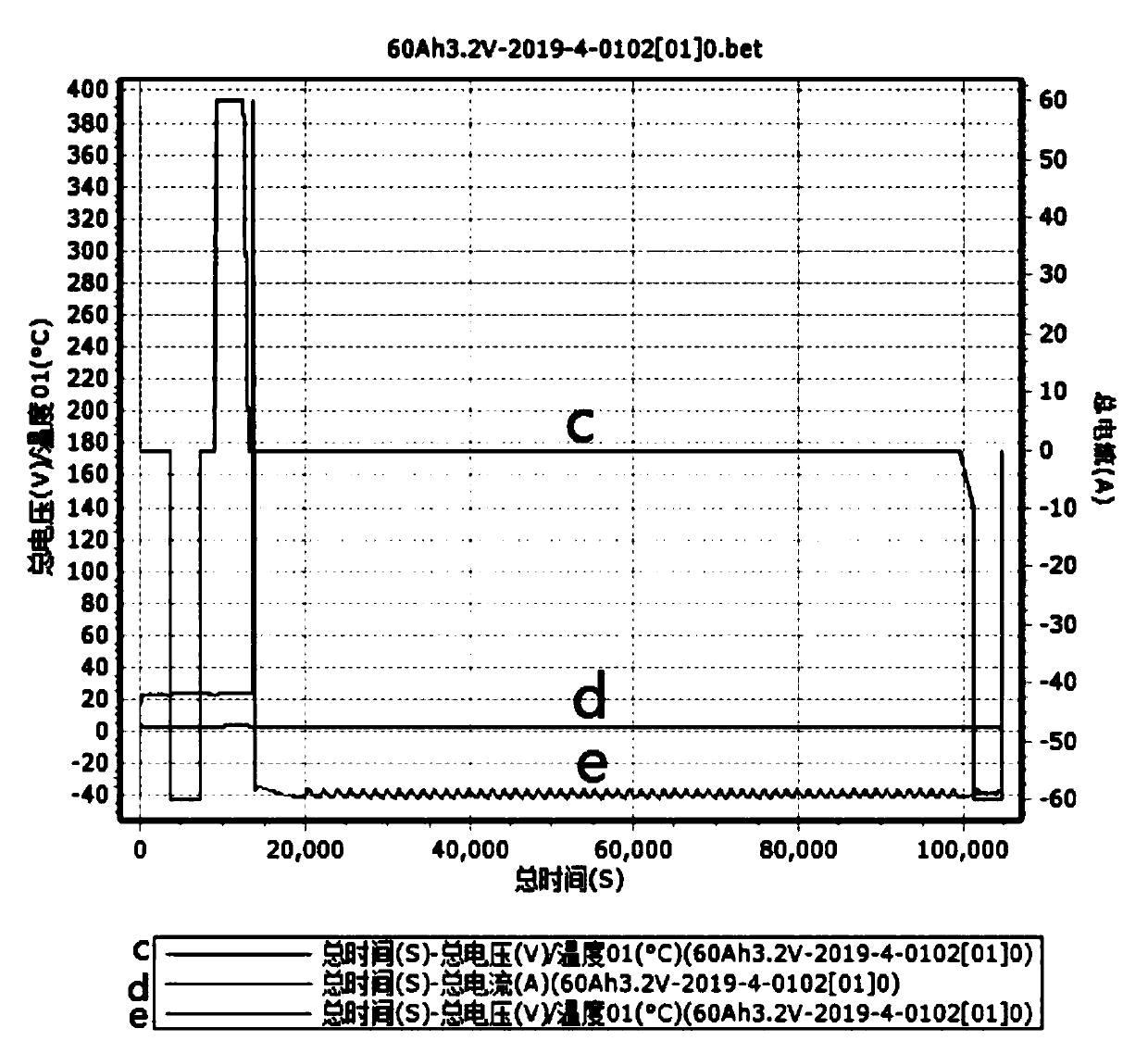

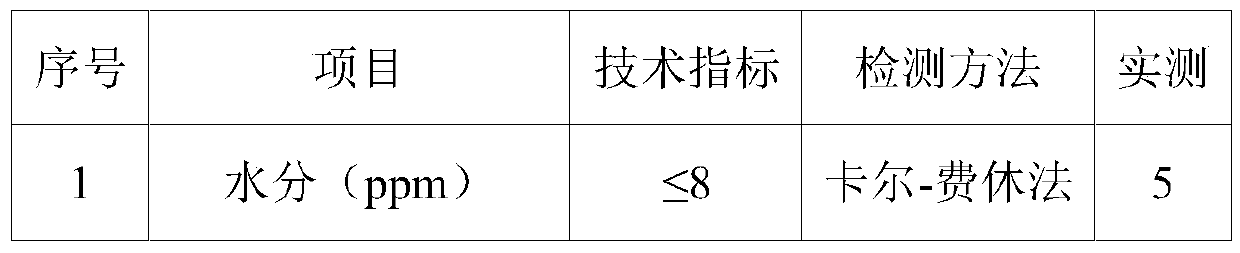

Lithium iron phosphate battery, electrolyte and manufacturing method of lithium iron phosphate battery

InactiveCN110556582ALower internal impedanceNormal dischargeSecondary cells servicing/maintenanceOrganic electrolytesDischarge efficiencyLithium vanadium phosphate battery

The invention discloses a lithium iron phosphate battery, an electrolyte and a manufacturing method of the lithium iron phosphate battery and belongs to the lithium battery technology field. In the invention, a low-temperature electrolyte containing ethyene catrbonate, ethyl methyl carbonate, dimethyl carbonate, propylene carbonate, lithium hexafluorophosphate, propane sultone, vinylene carbonateand lithium difluoroborate is used as the electrolyte of the lithium iron phosphate battery. An anode plate and a cathode plate of the lithium iron phosphate battery are improved so that an internal impedance of the lithium iron phosphate battery is reduced. The lithium iron phosphate battery can normally discharge in an environment of minus 40 + / -3 DEG C, and discharge efficiency in a low-temperature environment is relatively high so that a service life of the lithium iron phosphate battery can be prolonged, and an energy-saving effect can be achieved.

Owner:营口路航新能源科技有限公司

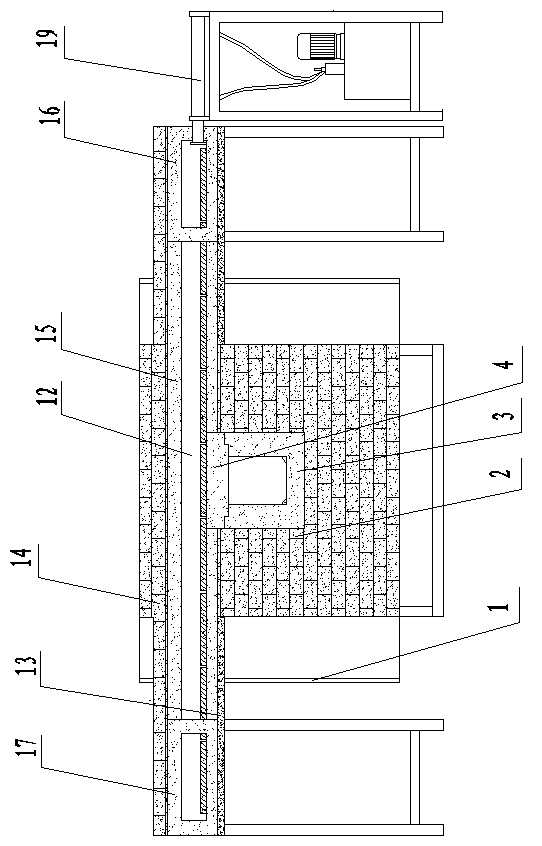

Single-hole single-pushing glost firing kiln utilizing residual heat of cooling area of high-temperature electrical kiln

The invention discloses a single-hole single-pushing glost firing kiln utilizing residual heat of a cooling area of a high-temperature electrical kiln, and relates to a kiln. The single-hole single-pushing glost firing kiln comprises a shell body of a high-temperature push plate electrical kiln with 1700 DEG C and a kiln body of the high-temperature push plate electrical kiln with 1700 DEG C, an inner container and a crown brick are arranged in the kiln body of the high-temperature push plate electrical kiln with 1700 DEG C, the crown brick is matched at the upper top end of the inner container, a pre-heating area, a low temperature area, a high temperature area, a constant temperature area and the cooling area are respectively arranged inside the kiln body of the high-temperature push plate electrical kiln with 1700 DEG C from front to back in sequence, a plurality of silicon molybdenum rods are arranged in the low temperature area, the high temperature area and the constant temperature area, and a single-hole single-pushing glost firing kiln body is arranged above the cooling area of the kiln body of the high-temperature push plate electrical kiln with 1700 DEG C and is communicated with the cooling area of the kiln body of the high-temperature push plate electrical kiln with 1700 DEG C. The kiln can utilize waste heat to carrying out firing, reduces energy consumption, and meanwhile reduces energy waste, a kiln body does not need to be additionally built for the glost firing kiln, and equipment funds are reduced.

Owner:陈秋生

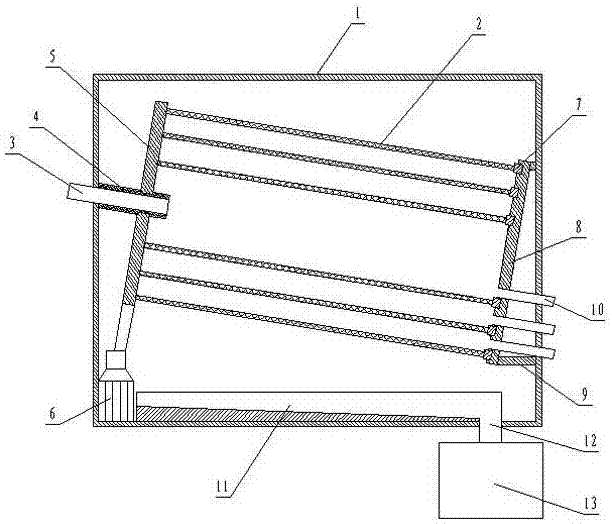

Tea leaf sorting device

InactiveCN107497661AAvoid dustImprove screening effectSievingPre-extraction tea treatmentEngineeringTea leaf

The invention discloses a tea sorting device, which comprises a casing, in which a plurality of mutually nested sorting net cylinders are arranged, a feeding channel is arranged on one side of the casing, and a fixed sleeve is arranged outside the feeding channel , one end of the fixed sleeve is fixedly connected with the inner wall of the housing, the fixed sleeve is covered with a turntable, the turntable and the fixed sleeve are rotatably connected, the side wall of the housing is provided with a drive device, and the drive device is connected to the turntable by transmission. The left side of each sorting net tube is fixedly connected with the turntable, and the right side of each sorting net tube is provided with a connecting ring, and the housing is also equipped with a fixed plate, which is fixedly connected with the inner wall of the housing through a bracket, and the connecting ring It is rotatably connected with the fixed plate, and each sorting net cylinder is provided with a corresponding discharge channel, and the discharge channels are all set on the fixed plate. The invention has simple structure, reasonable design, good sorting effect and improved production efficiency.

Owner:镇江市丹徒区西林茶叶专业合作社

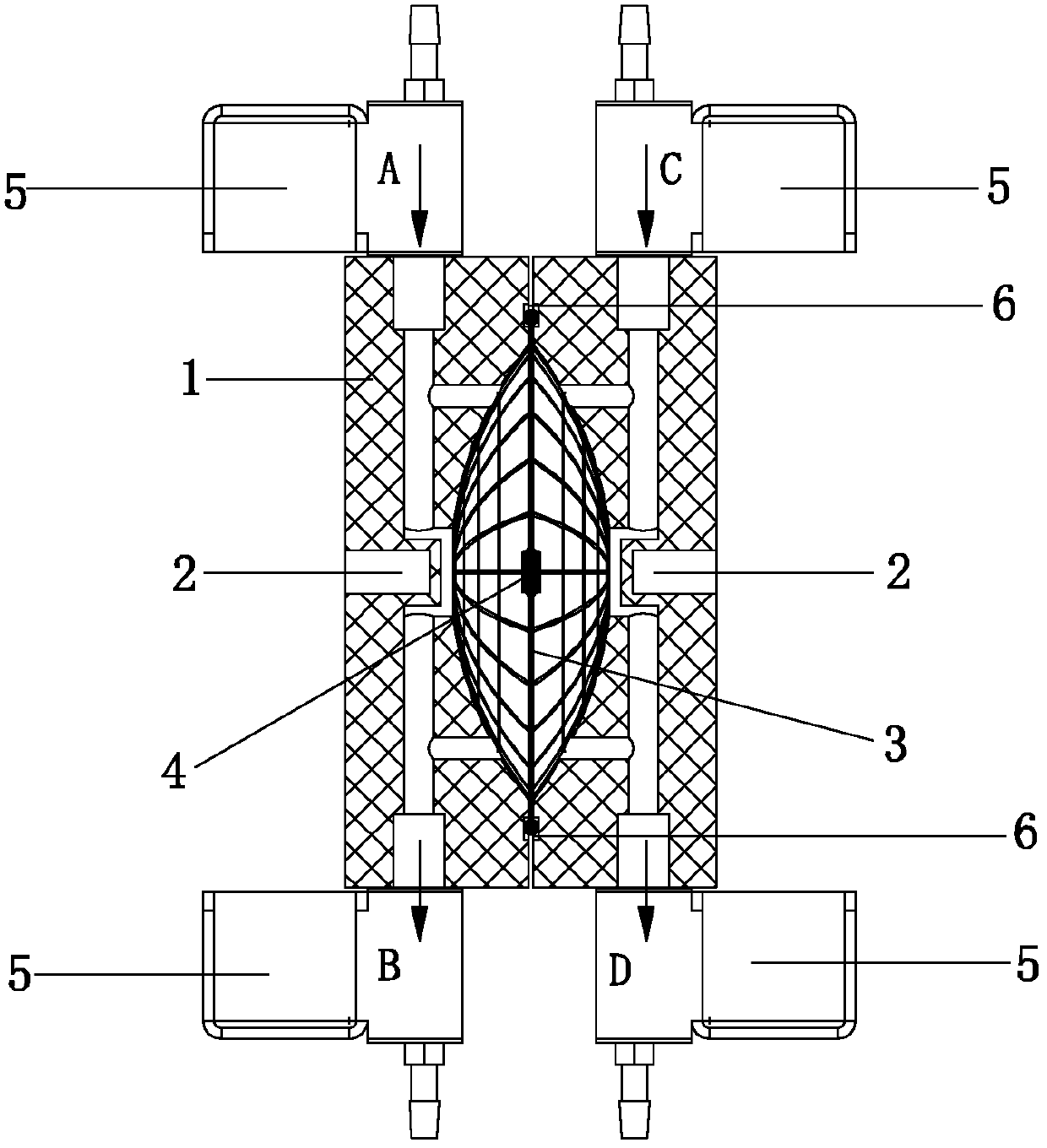

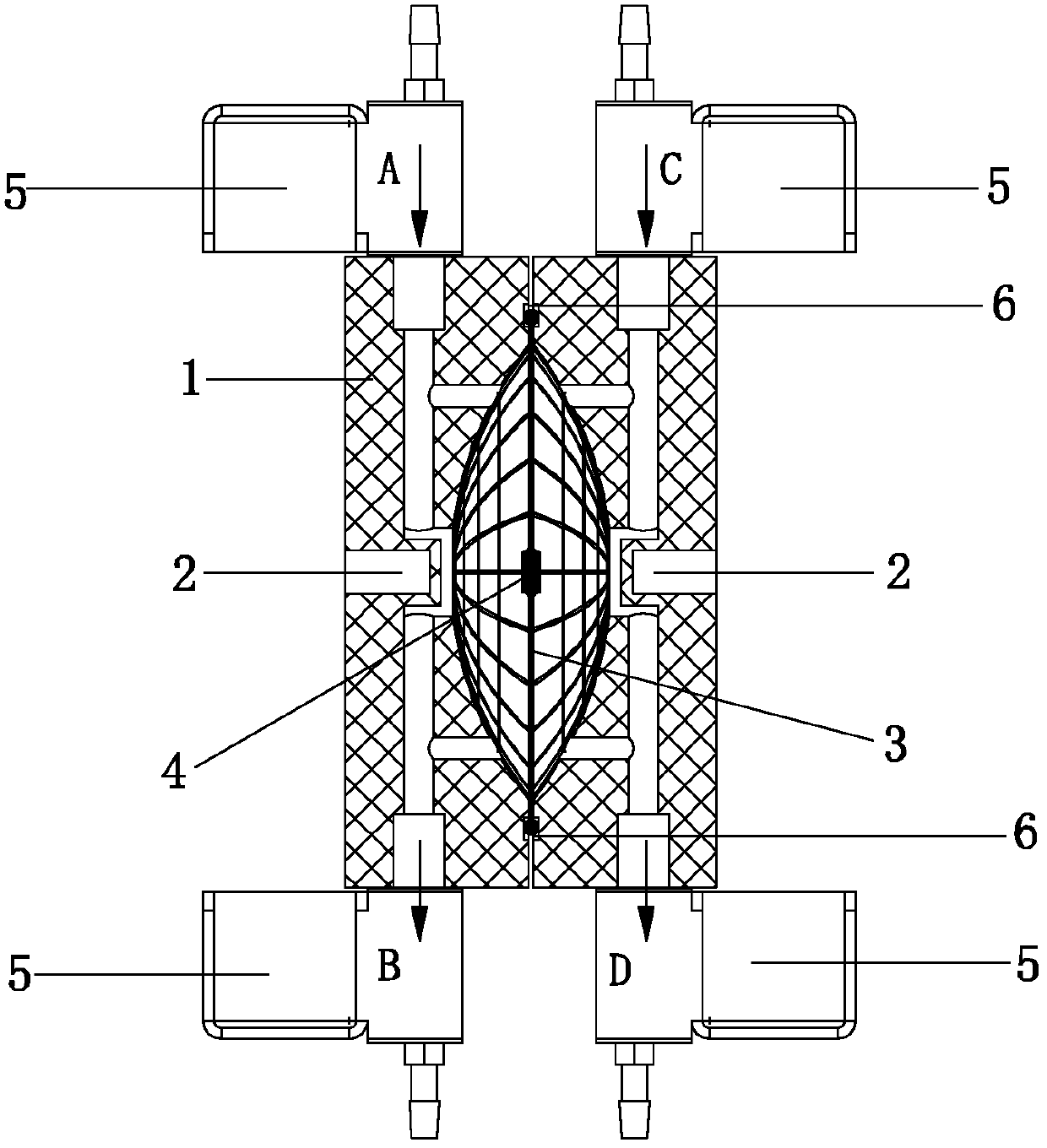

Balancing chamber with function of detection

InactiveCN102631720AEnsure safetyBalanced dischargeDialysis systemsMagnetic tension forceDialysate flow

The invention discloses a balancing chamber with the function of detection, comprising a balancing chamber body, wherein the balancing chamber body is internally divided by an elastic membrane into two chambers, each chamber is provided with a water inlet and a water outlet, a magnetic sheet is embedded in the elastic membrane, magnetic force induction mechanisms are arranged at the both sides of the balancing chamber body respectively, and an induction relationship can be formed between the magnetic sheet and the magnetic force induction mechanisms when the elastic membrane is adhered to the wall of the chambers. Compared with the prior art, the balancing chamber with the function of detection disclosed by the invention can detect whether the capacity of every chamber in the balancing chamber reaches the standard, so as to keep the amount of dialysate and waste dialysate flowing into and out of a dialyzer in balance and guarantee the safety of patient in the process of dialysis treatment.

Owner:GUANGDONG BIOLIGHT MEDITECH CO LTD

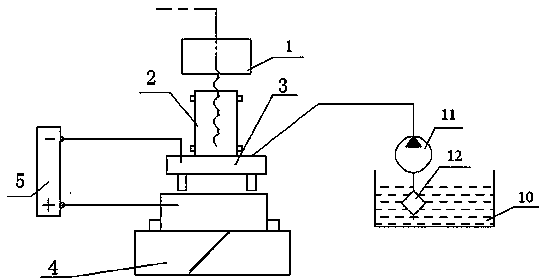

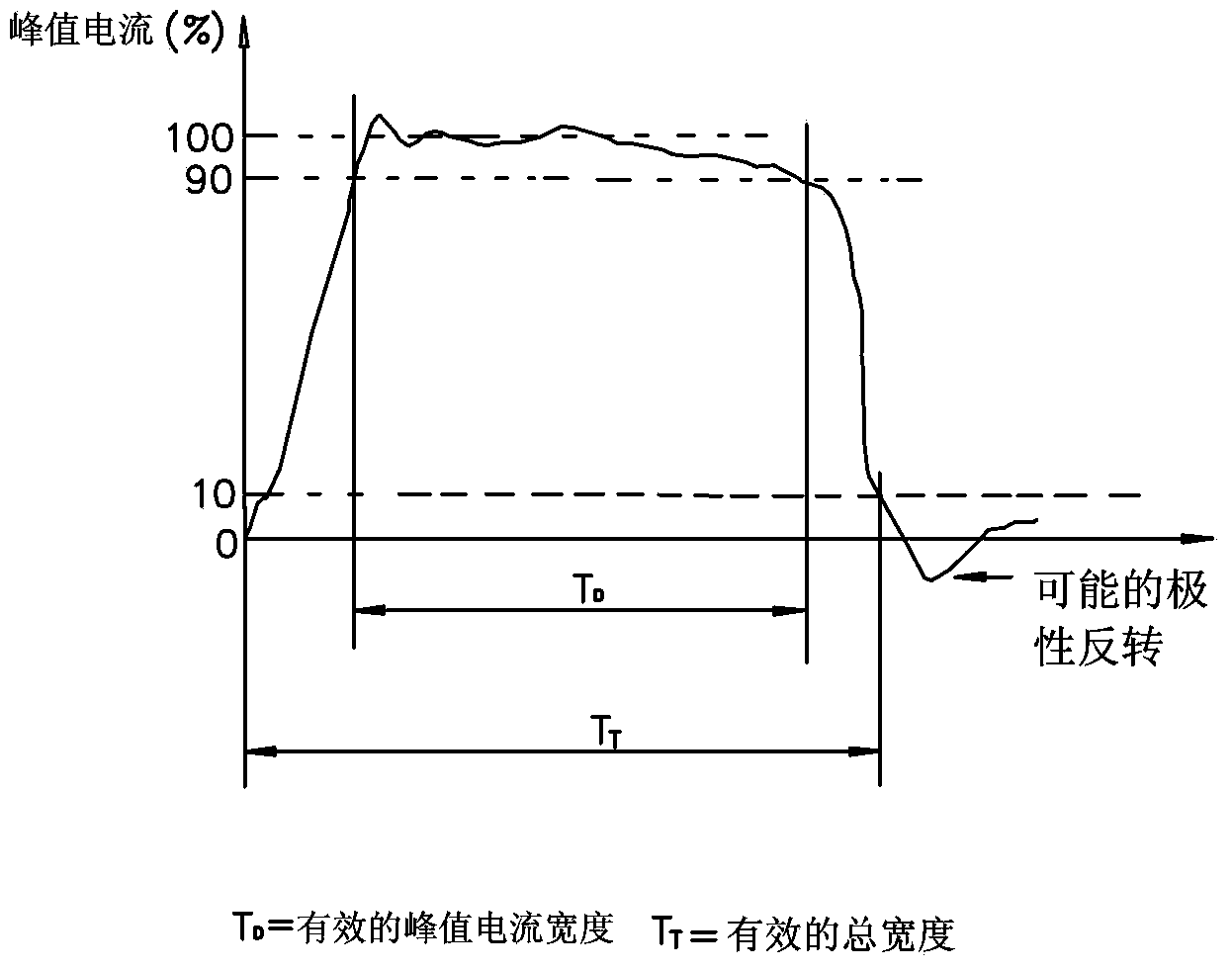

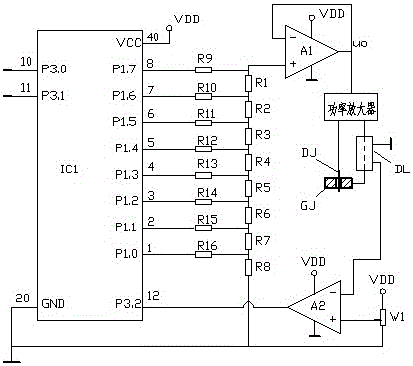

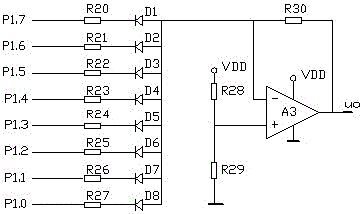

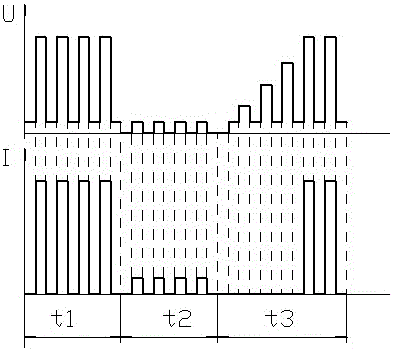

Pulsed power supply for electric spark machine tool

The invention relates to a pulsed power supply for an electric spark machine tool. The pulsed power supply for the electric spark machine tool comprises a pulse signal forming circuit, a power amplifier for carrying out power amplification on a pulse signal, and a current detecting circuit for detecting output current of the power amplifier. The pulse signal forming circuit comprises a single-chip microcomputer IC1 and a D / A (Digital-to-Analog) converter. The single-chip microcomputer is connected with an input port of the D / A converter; the output end of the D / A converter is connected with the input end of the power amplifier; an electrode DJ as a load and a workpiece GJ are connected into an output circuit of the power amplifier; a voltage value of a discharge pulse is automatically controlled through the single-chip microcomputer, so that the voltage of the discharge pulse outputted by a pulsed power supply is matched with the cutting speed, the normal spark discharge is maintained, the machining efficiency and the machining quality are improved, and meanwhile, the inconvenience caused by adjusting the cutting speed through manual work is avoided; and the current detecting circuit detects short-circuit current when a low-voltage detecting pulse occurs, so that a wire electrode can be prevented from being damaged, the occurrence of arc discharge can be prevented when the workpiece is deviated from an electrode, and the reduction of the finish degree of the workpiece is avoided.

Owner:保时杰数控机床江苏有限公司

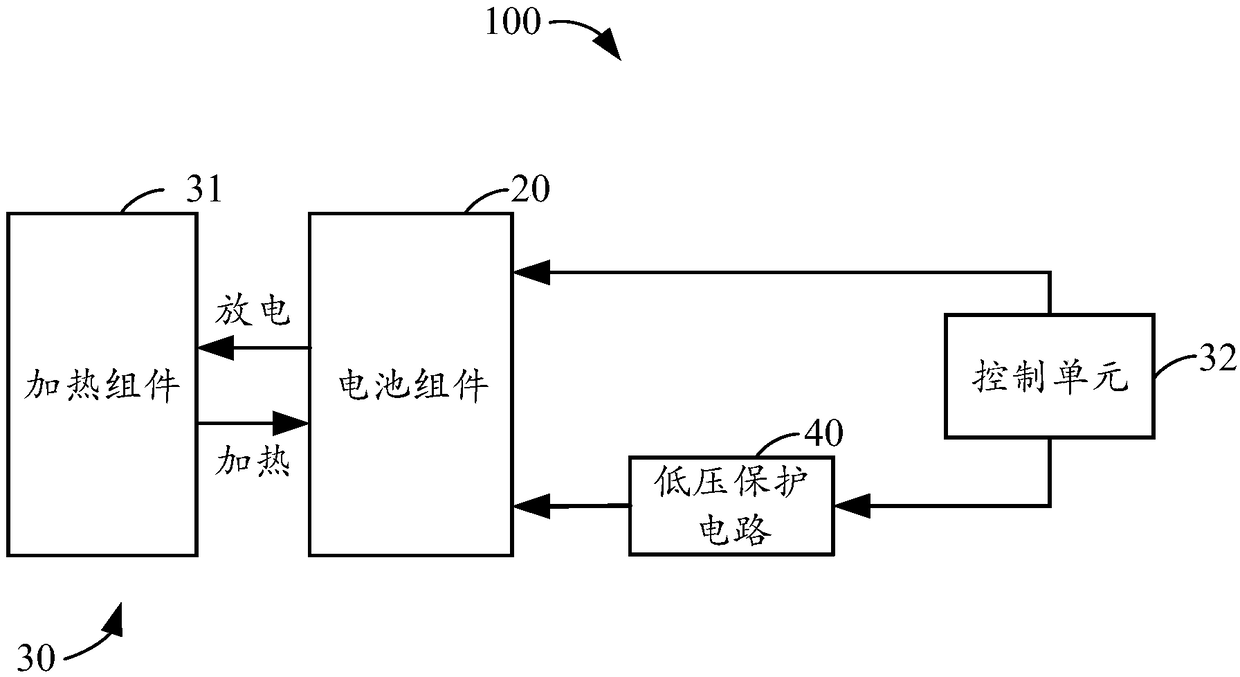

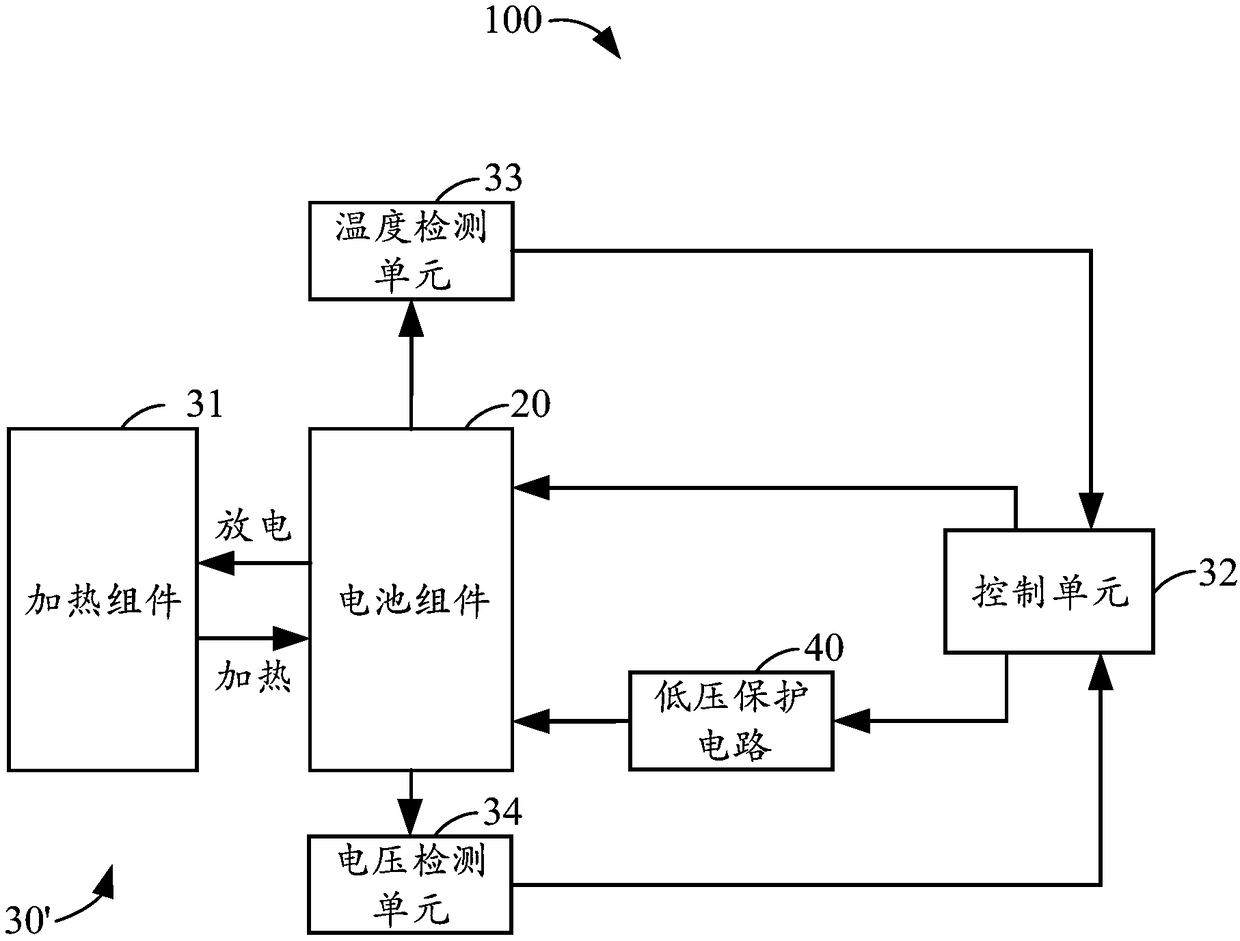

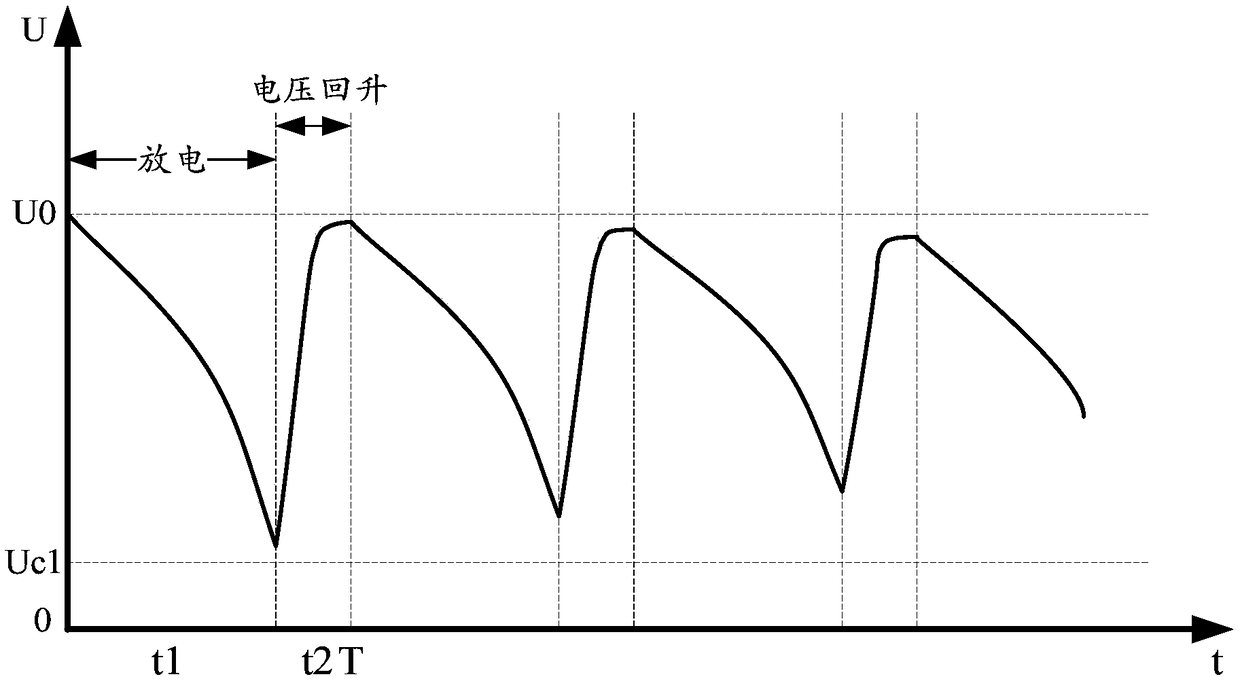

Start the heating device of the power supply and its battery pack

ActiveCN109066016AImprove heating efficiencyReturn to normal external dischargeCells structural combinationVehicular energy storageElectrical batteryHeating efficiency

The present application provides a heating device for starting a power supply and a battery pack thereof. The heating device comprises a heating assembly and a control unit. The heating assembly is arranged on the battery module and receives the discharge of the battery module to heat the battery module. When the temperature of the battery pack is lower than a preset temperature threshold, the control unit controls the battery pack to periodically discharge the heating assembly to avoid triggering low voltage protection of the battery pack during discharge of the battery pack to the heating assembly. The control unit controls the battery pack to periodically discharge the heating assembly to avoid triggering low voltage protection of the battery pack during discharge of the battery pack tothe heating assembly. The heating apparatus provided by the present application controls the battery pack to periodically discharge the heating assembly and the battery pack to periodically dischargethe heating assembly, The battery module can effectively prevent the discharge of the battery module to the heating assembly from triggering the low-voltage protection of the battery module, therebyensuring that the battery module can normally discharge the heating assembly in a low-temperature environment, and can improve the heating efficiency of the battery module, so that the battery modulecan quickly recover the function of normal external discharge.

Owner:SHENZHEN CARKU TECH

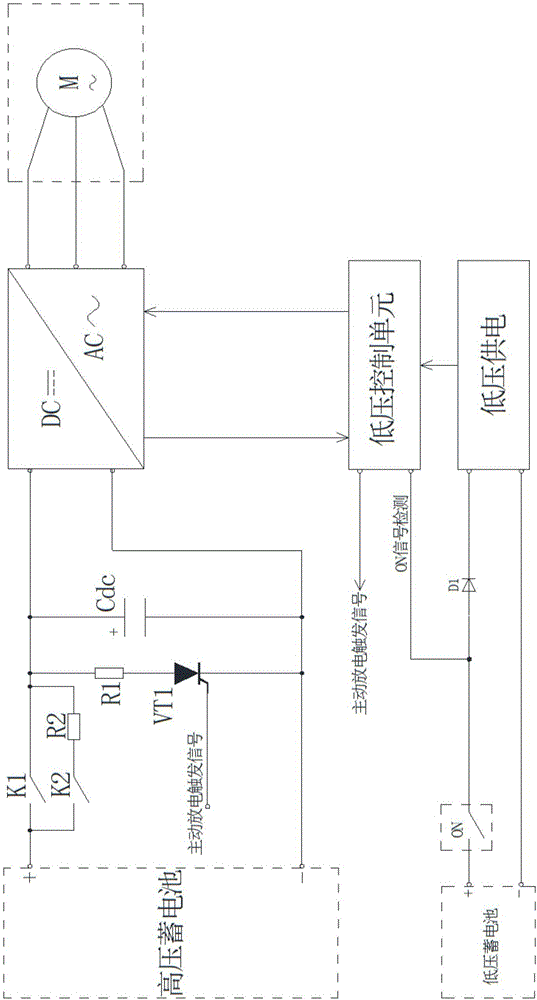

Active discharge control circuit of motor controller of electric vehicle and controller

PendingCN106655372ALow costReduce the burden onBatteries circuit arrangementsAC motor controlThyristorIgnition switch

The invention provides an active discharge control circuit of a motor controller of an electric vehicle and the controller, and aims to solves the conditions that burden of the controller is increased and torque abnormity, rotary speed abnormity, discharge failure and other abnormity conditions are easily caused in a discharging mode by adopting an inversion unit in the prior art. The active discharge control circuit of the motor controller of the electric vehicle comprises a discharge main circuit and a discharge control circuit; the discharge main circuit comprises a discharge resistor R1 and a thyristor VT1 which are connected in series; and the motor controller of the electric vehicle comprises a high-voltage storage battery, an inversion circuit, a low-voltage power supply circuit, a low-voltage storage battery, a direct current capacitor Cdc, an ignition switch ON, a discharge main circuit and a low-voltage control unit. By adoption of the mode that the discharge resistor and the thyristor are connected in series, the burden of the inversion unit and the control program are relieved compared with the mode of discharging by adopting the inversion unit; and active discharge still can be ensured in failure of the inversion unit, so that reliability is improved.

Owner:CHENGDU RAJA NEW ENERGY AUTOMOTIVE TECH CO LTD

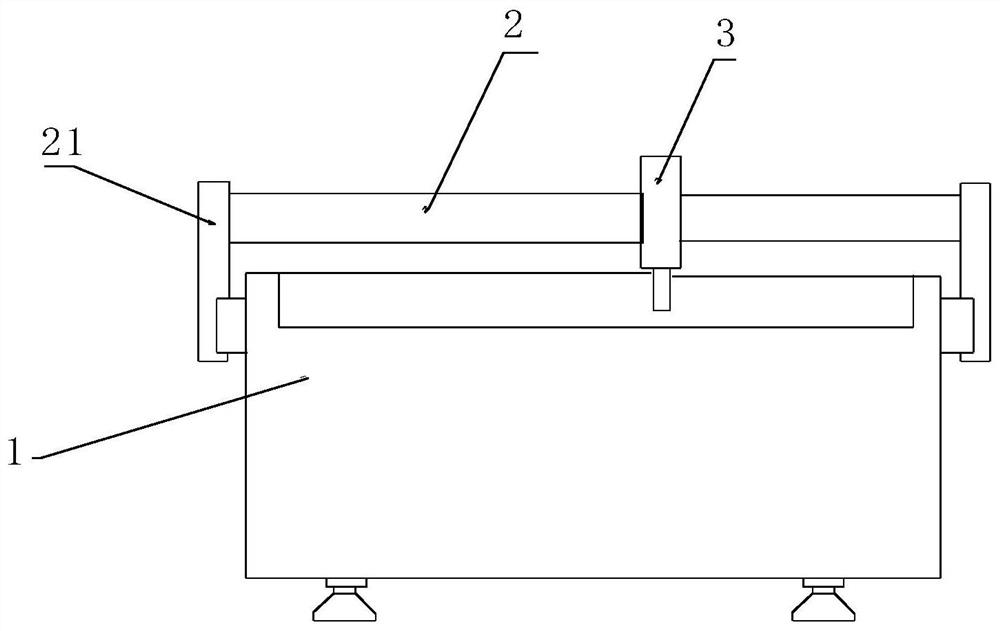

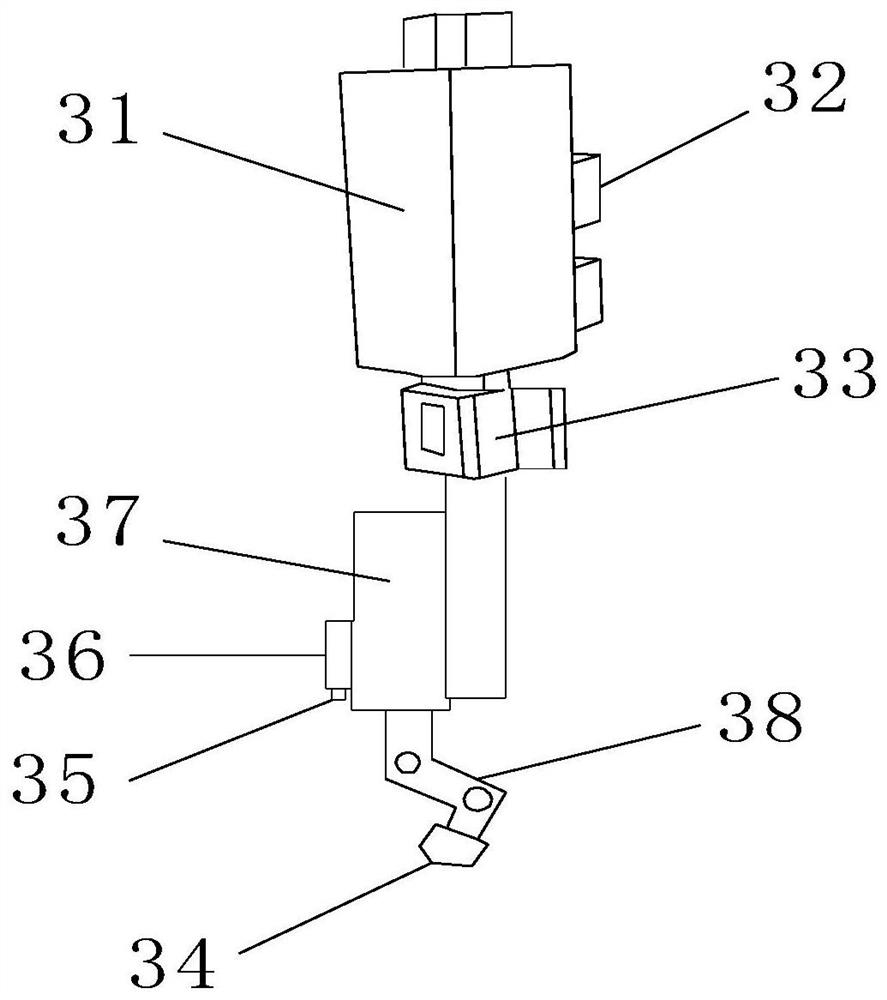

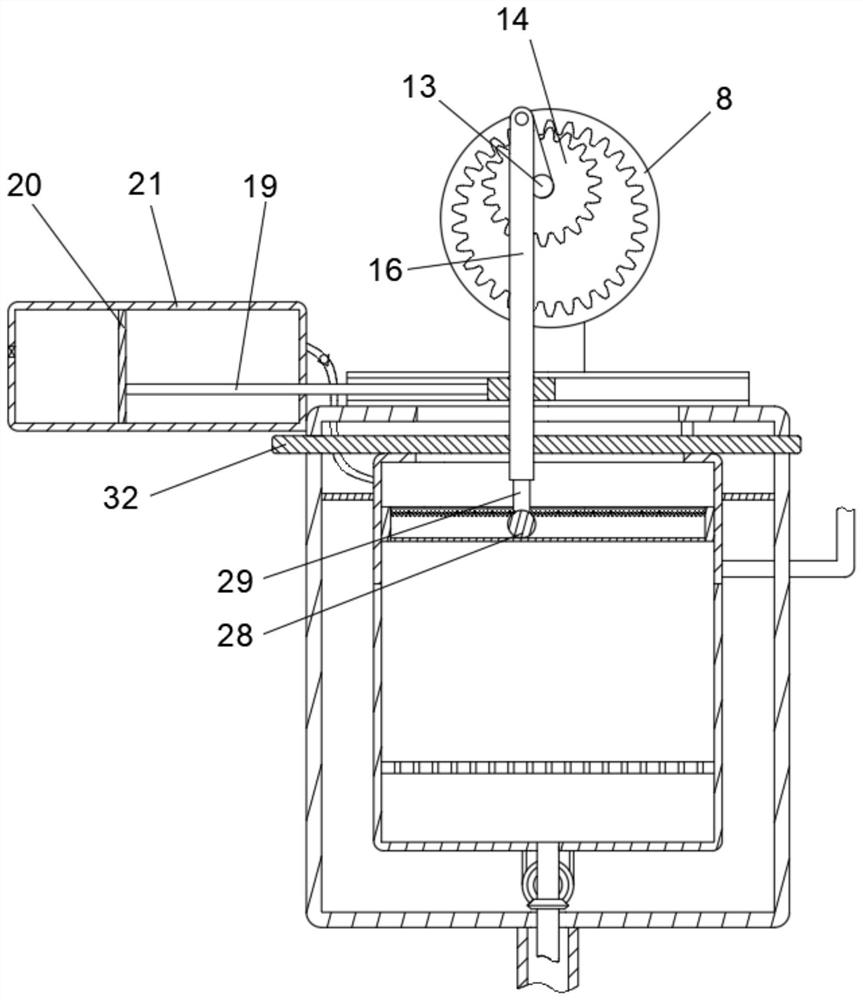

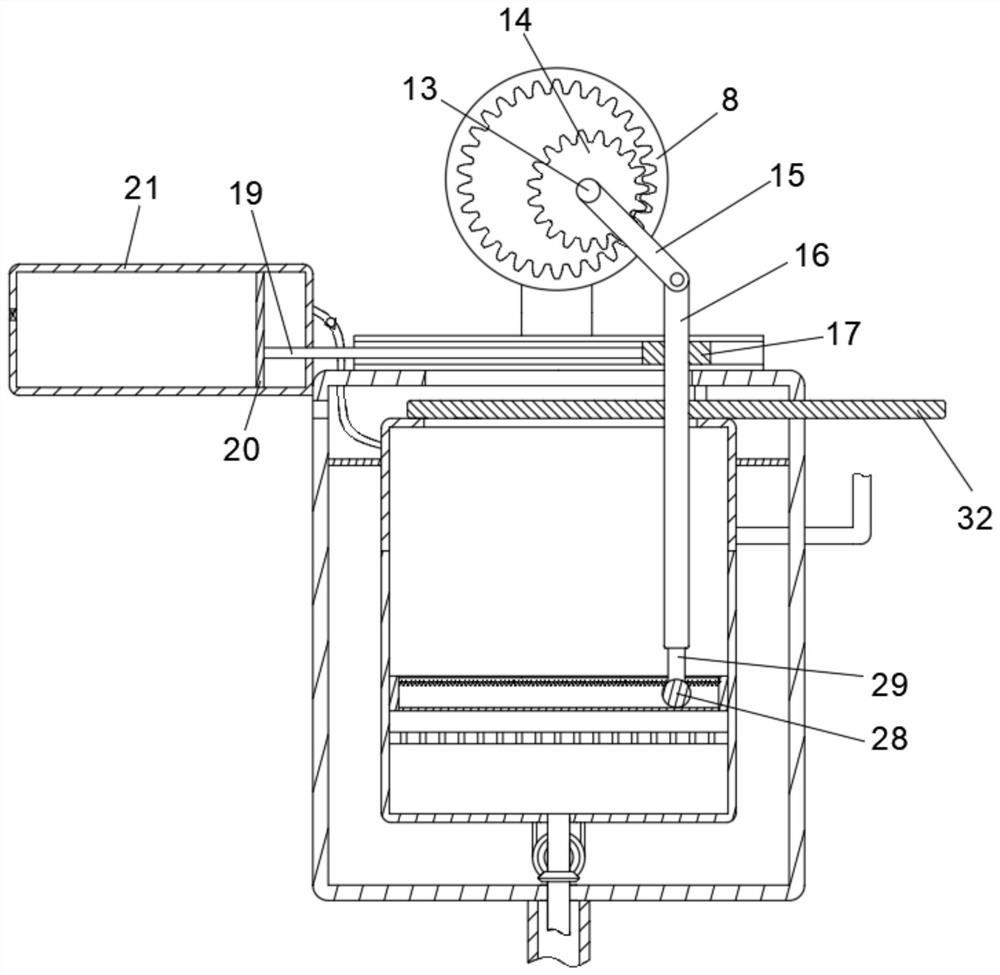

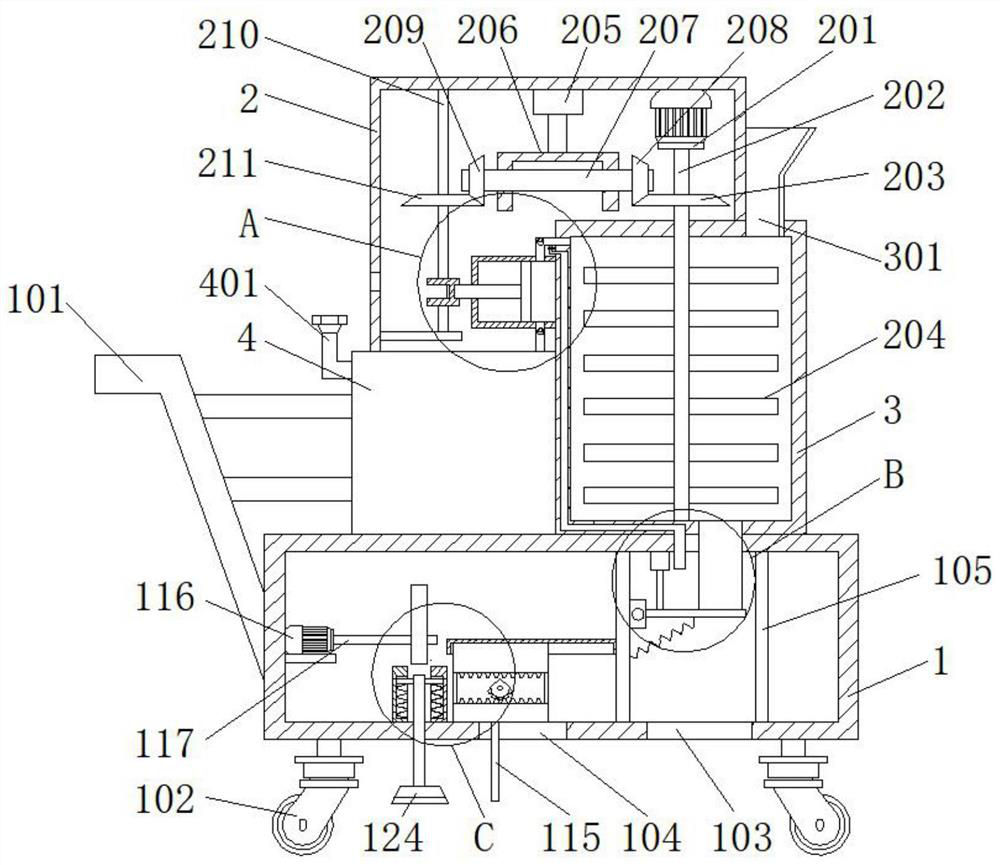

Full-automatic glue sprayer and glue spraying method

InactiveCN111804505ADoes not take up internal spaceNormal dischargeLiquid surface applicatorsCoatingsSprayerEngineering

The invention provides a full-automatic glue sprayer and a glue spraying method. The full-automatic glue sprayer comprises a glue sprayer base, a cross beam, a glue injection barrel, a sliding mechanism, a heating mechanism, a detector and a sliding block controller. The heating mechanism is connected to the outer side face of the glue injection barrel and comprises a liquid inlet pipe, a spiral heating wire, a heat insulation barrel, a sealing plug and a liquid outlet pipe, the bottom of the glue injection barrel is connected with the inner bottom of the heat insulation barrel, the spiral heating wire is arranged in the heat insulation barrel and surrounds the outer surface of the glue injection barrel, the outer side face of the top of the heat insulation barrel communicates with the liquid inlet pipe, and the outer side face of the bottom of the heat insulation barrel communicates with the liquid outlet pipe. An injected sizing material is heated by a water bath method through watersolution heating, so that the heating uniformity is improved. Meanwhile, according to the full-automatic glue sprayer, the glue injection position of a glue spraying head is detected through a detection mechanism, when the glue spraying position is accurate, glue spraying is driven, and when the glue spraying position deviates, the glue spraying position is scanned again through controlling a laser component, and then the glue spraying route of the glue spraying head is rearranged through a main machine, so that the automatic glue spraying process is achieved.

Owner:包头江馨微电机科技有限公司

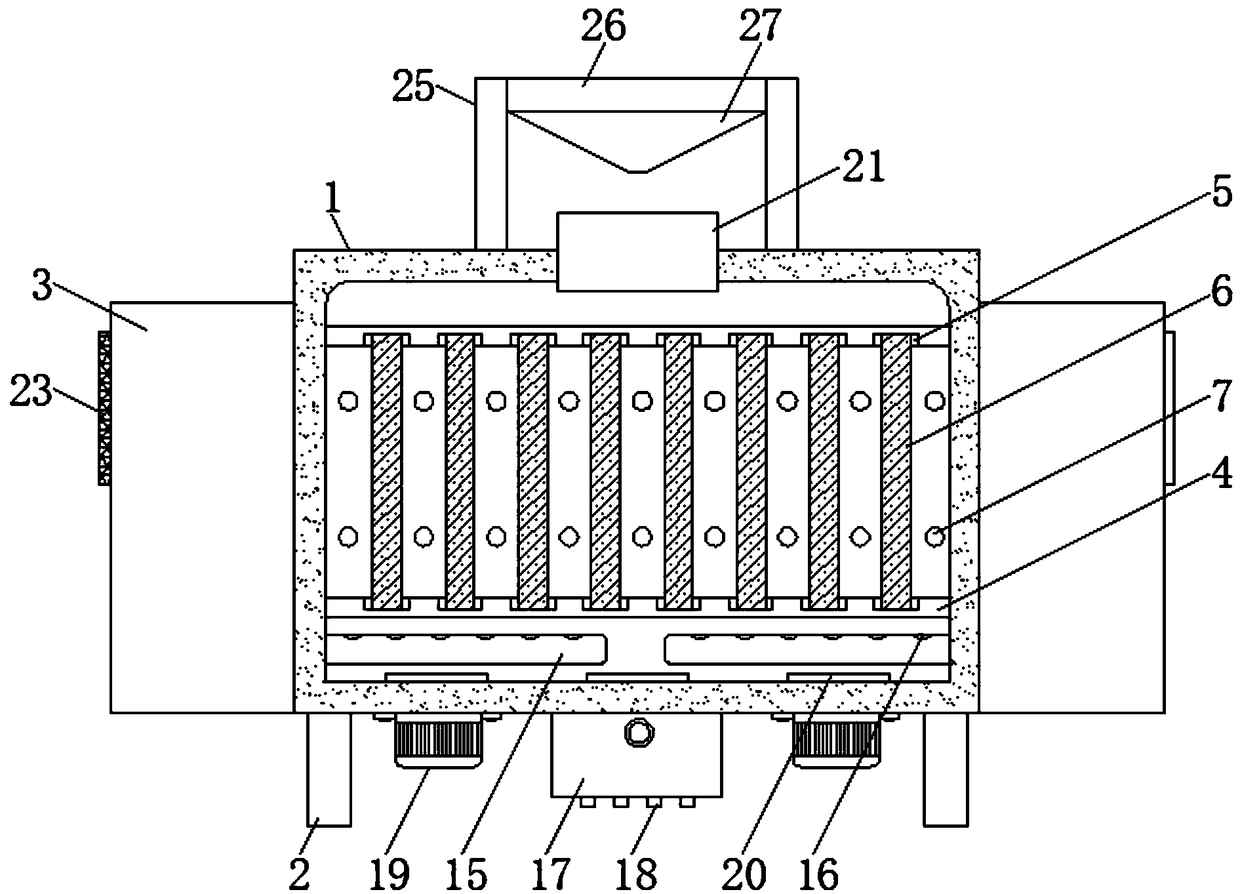

Wood processing dryer with sterilizing function

InactiveCN109084535AEfficient sterilizationEfficient dryingDrying gas arrangementsDrying machines with local agitationUltravioletPulp and paper industry

The invention discloses a wood processing dryer with a sterilizing function. The wood processing dryer with the sterilizing function comprises a first box body. The front surface of the first box bodyis movably provided with a box door. The two sides of the bottom of the first box body are fixedly connected with two supporting legs. According to the wood processing dryer with the sterilizing function, by means of the cooperative using of ultraviolet disinfection lamps, air holes, ceramic installation plates, S-shaped heating wires, metal conducting plates, vent plates, first air blowers, aircollection disks, exhaust guide pipes, vent holes, a steam box, a heating rod, second air blowers, air outlet disks, a third air blower and S-shaped installation grooves, high-temperature gas sterilization, high-temperature steam sterilization and ultraviolet light sterilization can be carried out on wood, under the common cooperation of the three manners, effective drying can be carried out on the wood, effective sterilizing can also be carried out on the wood, following processing of the wood is guaranteed, the quality of the wood is guaranteed, and the safety of the sterilized wood is greatly improved.

Owner:湖州市新庭吉家居科技有限公司

Drainage pump and washing machine with same

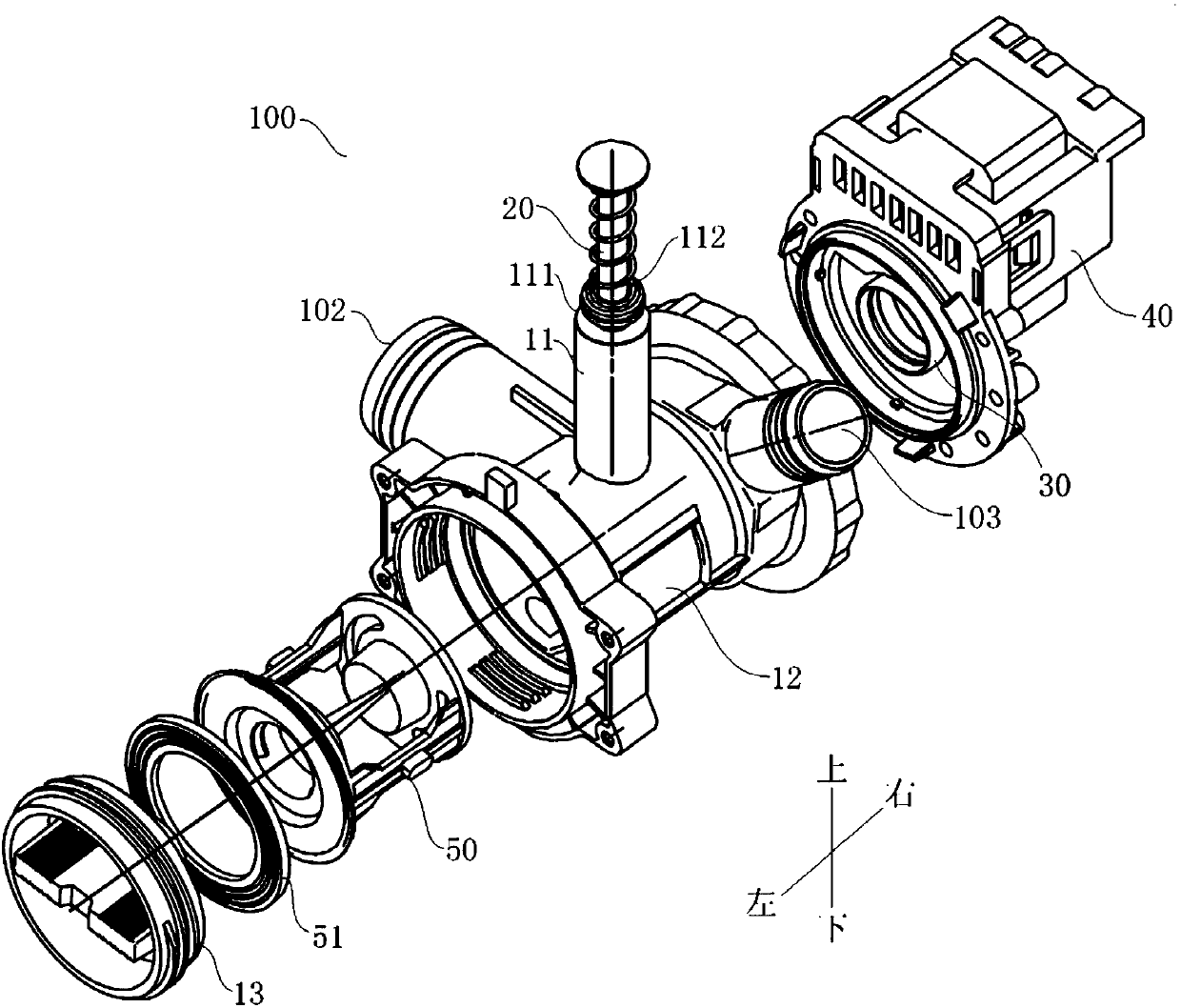

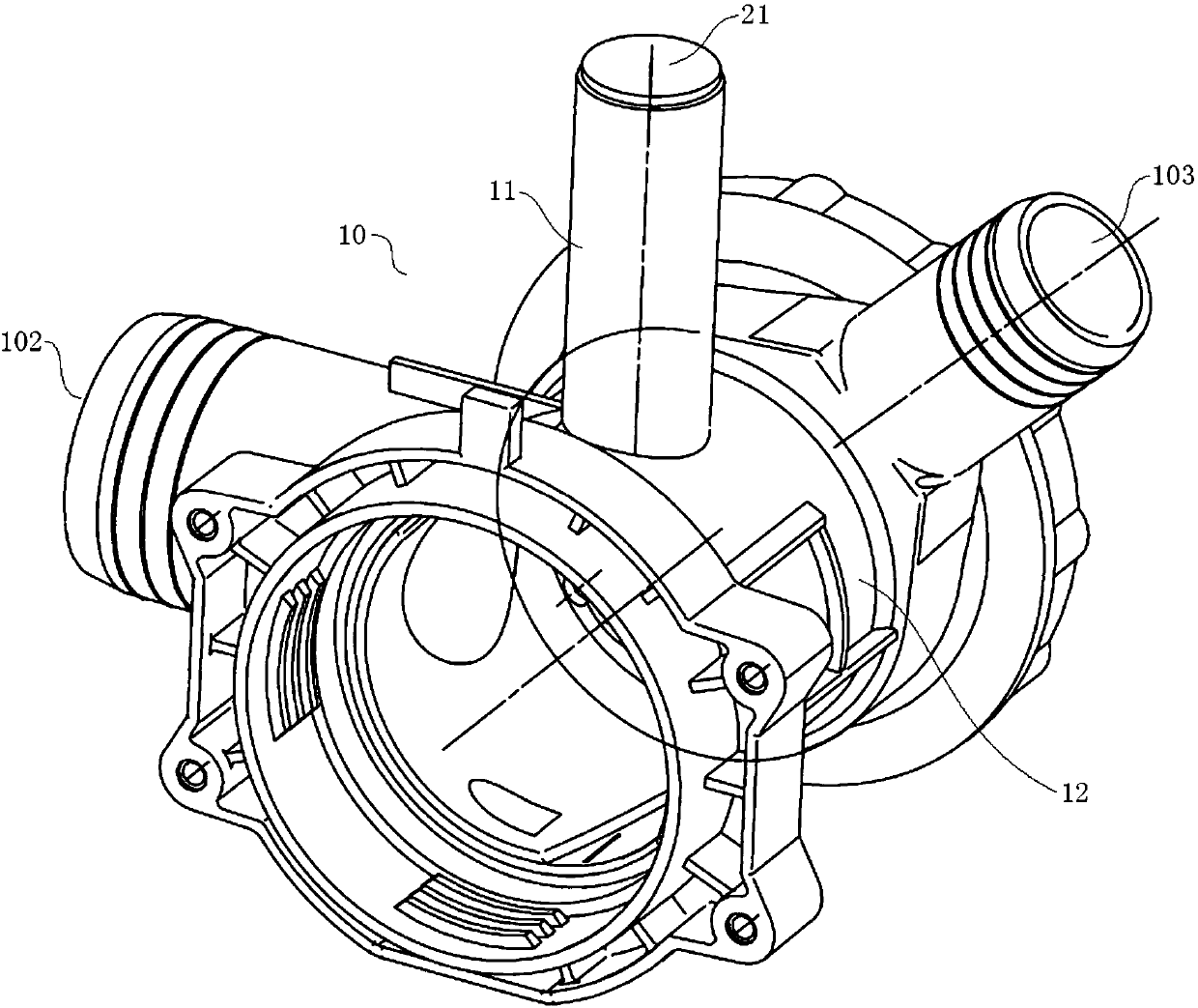

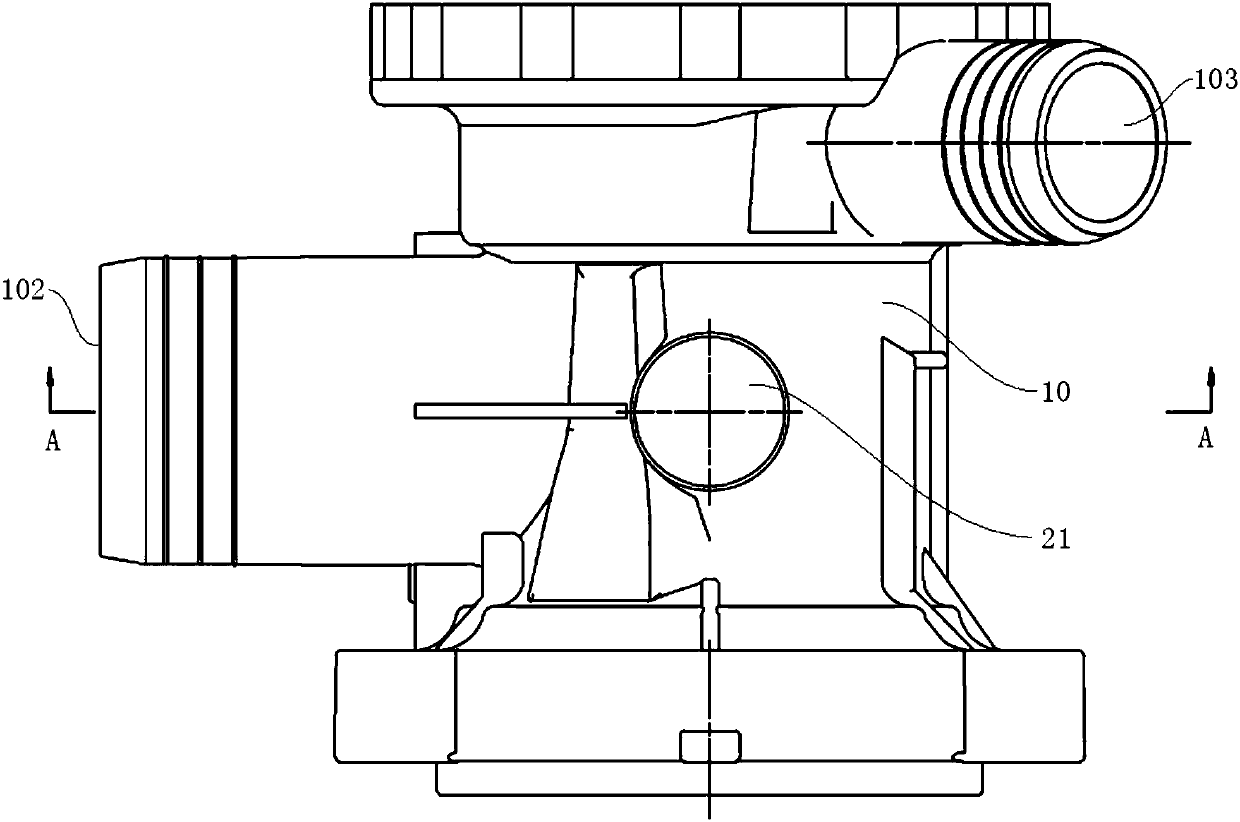

ActiveCN107904870AImprove work efficiencyIncrease or decrease in volumeOther washing machinesTextiles and paperImpellerAir trapping

The invention discloses a drainage pump and a washing machine with the same. The drainage pump includes a pump shell, a piston assembly, an impeller and a driving device, wherein the pump shell is internally provided with a drainage cavity, and a water inlet and a water outlet which are communicated with the drainage cavity are formed in the pump shell; the piston assembly is movably arranged on the pump shell, and an air storage cavity which is communicated with the drainage cavity and has a variable volume is defined on the pump shell by the piston assembly; the impeller is rotatablely arranged in the drainage cavity; the driving device is installed on the pump shell and in transmission connection with the impeller. According to the drainage pump, by arranging the piston assembly, and adopting the piston assembly and the pump shell to define the air storage cavity with the variable volume, the piston assembly can move according to the work conditions of the drainage pump, therefore,the capacity of the air storage cavity can be increased or decreased, it is ensured that water flow can be normally sucked and discharged, the problem of air trapping is effectively solved, and then the work efficiency of the drainage pump is improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Waste incineration exhaust gas deacidification treatment system

InactiveCN111442285ALarge atomization areaComprehensive deacidification treatmentUsing liquid separation agentIncinerator apparatusParticulatesExhaust fumes

The invention discloses a waste incineration exhaust gas deacidification treatment system. The waste incineration exhaust gas deacidification treatment system structurally comprises waste incinerationequipment, an incineration exhaust gas pipeline, a smoke pipeline, a water supply pipe, a smoke discharge pipe, a circulating water tank, a high-pressure water pump, a smoke purifier and a deacidification water mist spraying tower, and the waste incineration equipment is connected with the deacidification water mist spraying tower through the incineration exhaust gas pipeline. Compared with the prior art, the waste incineration exhaust gas deacidification treatment system has the beneficial effects that through combination arrangement of parts such as a tilting nozzle, a top arc plate, an exterior plate, an inner supporting plate, a bottom arc plate and a separation arc plate, a novel spraying pipe is constituted, a function of preventing blocking of particulate matter is achieved, the particulate matter can be effectively prevented from making contact with a spray head, the spray area can further be enlarged, thus all exhaust gas can be subjected to spraying deacidification, and thusspraying deacidification is more comprehensive, higher in efficiency and better in effect; and meanwhile, the spray head can be prevented from being blocked by the particulate matter, thus the deacidified gas can be normal discharged, and the efficiency of waste incineration treatment is advantageously improved.

Owner:汪志辉

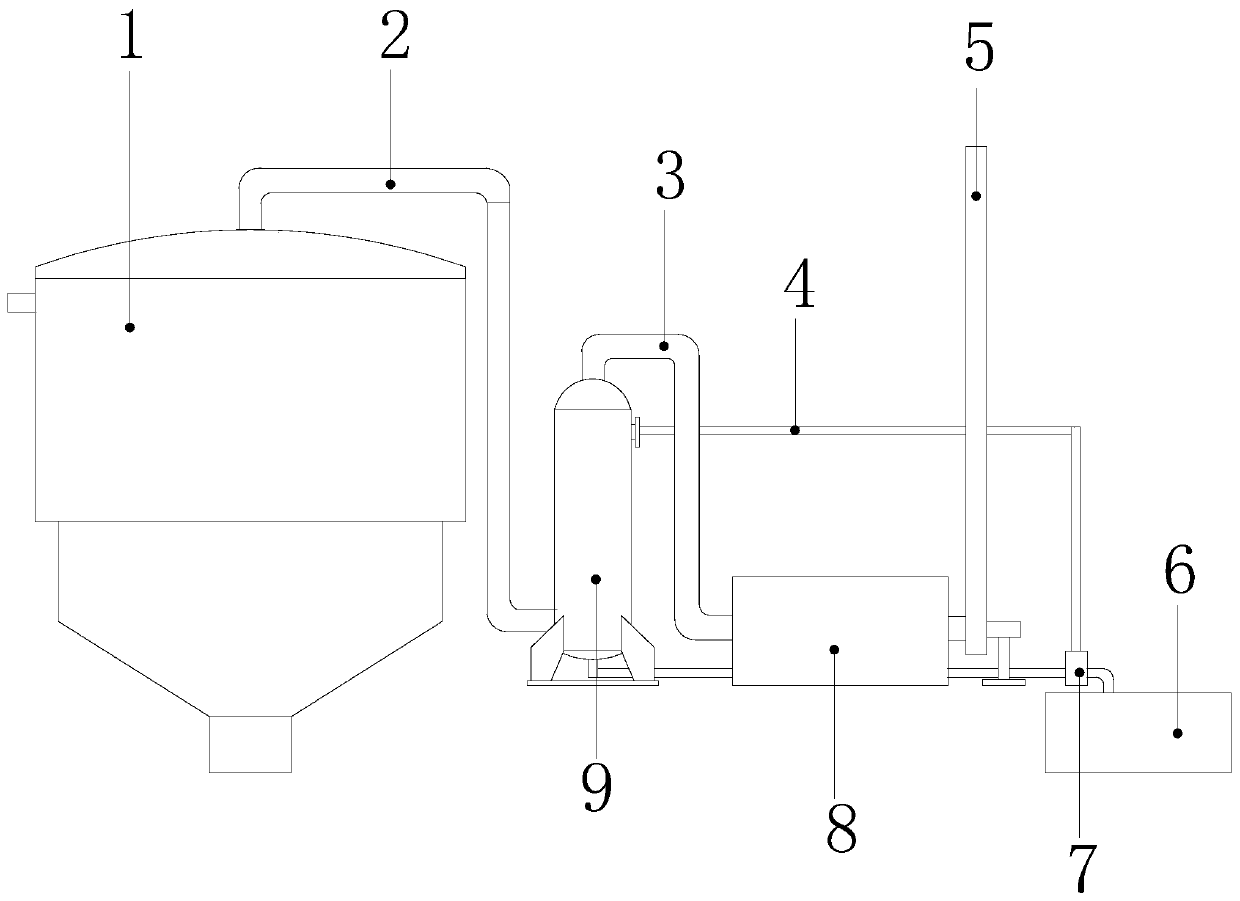

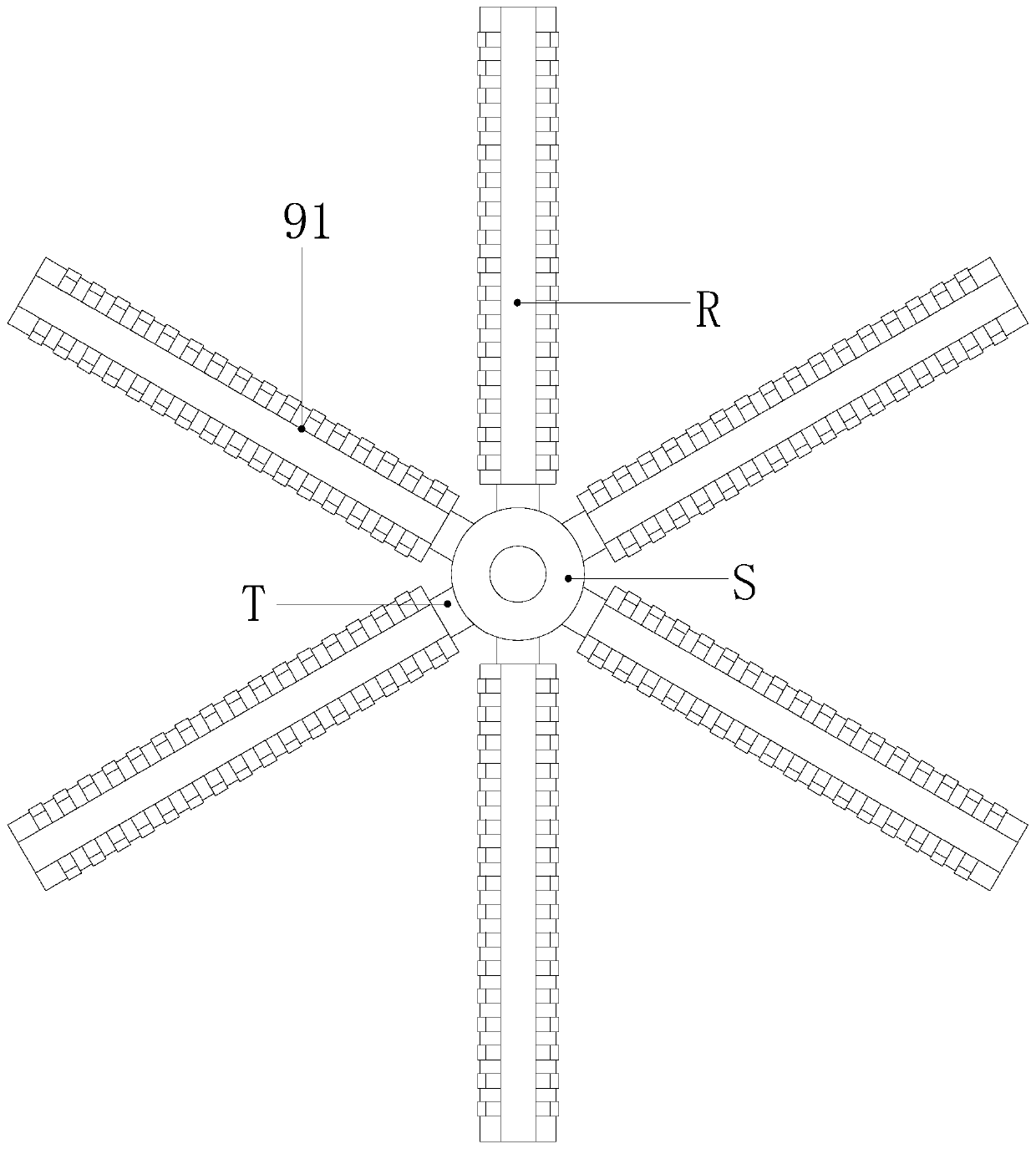

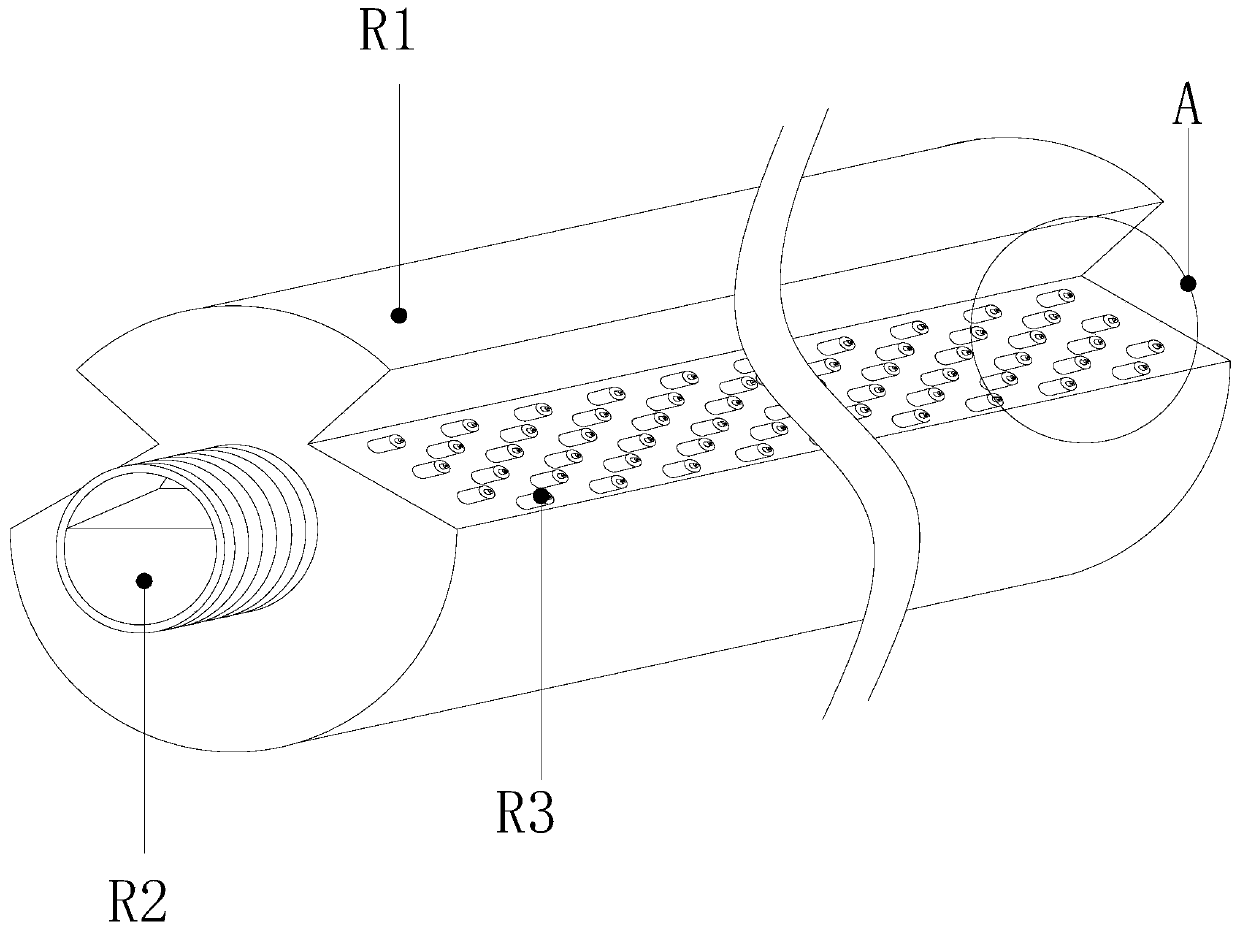

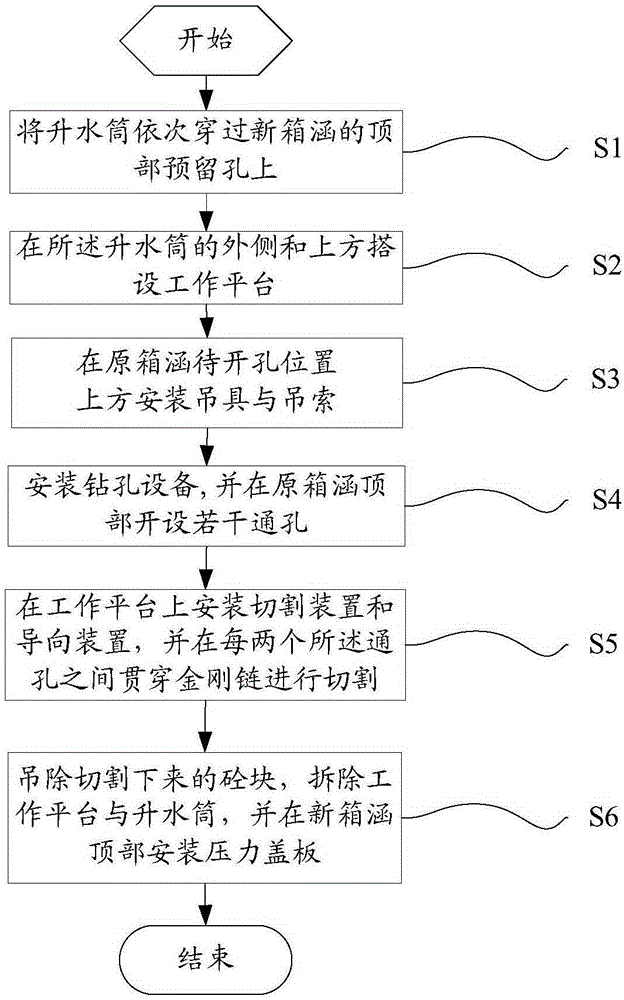

Box culvert underwater access construction method

The invention discloses a box culvert underwater access construction method comprising the following steps: firstly arranging a water lifting barrel on a top preformed hole of a novel box culvert; secondly building a work platform outside and above the water lifting barrel, and mounting a suspender and a suspension cable above an original box culvert to-be holed position; mounting drilling equipment on the work platform and arranging a plurality of through holes on the top of the original box culvert; mounting a cutter and a guide device on the work platform, using a metal chain to penetrate every two through holes, and then the cutter drives the metal chain to be led by the guide device for cutting; finally hanging and removing cut concrete blocks, dismounting the work platform and the water lifting barrel, and mounting a pressure cover plate on the top of the novel box culvert. The box culvert underwater access construction method is low in noises, small in pollution, high in mechanization level, less in operation people, can perform construction of connecting the novel box culvert with the original box culvert with high efficiency while ensuring normal discharge of sewage, thus practically satisfying practical application demands.

Owner:TENGDA CONSTR GROUP CORP

Centrifugal solid-liquid separation equipment for sewage treatment

PendingCN113368558AIncrease air pressureRealize solid-liquid separationSludge treatmentTreatment involving filtrationEngineeringSewage treatment

The invention discloses centrifugal solid-liquid separation equipment for sewage treatment, and relates to the technical field of sewage treatment equipment. The centrifugal solid-liquid separation equipment comprises a shell, an upper cylinder and a lower cylinder are arranged in the shell, the upper cylinder is rotationally connected to the upper surface of the lower cylinder through a fixed shaft, a water inlet pipe is fixedly installed on the surface of the upper cylinder, and the surface of the upper cylinder is fixedly sleeved with a fixing ring; the fixing ring is fixedly installed on the inner wall of the shell. Through mutual cooperation of the structures, water-containing garbage is preliminarily dewatered in a centrifugal rotation and pressurization mode, solid garbage is compressed and dewatered, rolling and puncturing are conducted, the good garbage dewatering effect is guaranteed, the garbage dewatering efficiency is improved, and the problems that a traditional solid-liquid separation device cannot achieve a very high solid-liquid separation effect on solid garbage only through a stirring mode, and a good dehydration rate cannot be guaranteed for some garbage with relatively high water absorption capacity are solved.

Owner:庄昱全

Ground cement laying device and method for construction site

ActiveCN112523041AReduce wasteLow costSolid waste managementRotary stirring mixersArchitectural engineeringElectric machinery

The invention discloses a ground cement laying device and method for a construction site, and belongs to the technical field of constructional engineering. The ground cement laying device for the construction site comprises a box body, the top of the box body is fixedly connected with a material storage box and a water tank, the top of the material storage box and the top of the water tank are fixedly connected with a connecting shell, a third motor is fixedly connected in the connecting shell, and the output end of the third motor is connected with a stirring mechanism; a water supplementingand cleaning mechanism is arranged in the connecting shell, a fourth rotating shaft is arranged in the connecting shell, a second bevel gear and a third bevel gear which are matched with the stirringmechanism and the water supplementing and cleaning mechanism are fixedly connected to the fourth rotating shaft, and a flattening mechanism and a pressing mechanism are arranged in the box body. The ground cement laying device is convenient to use, cement can be supplemented with water and stirred, meanwhile, the discharging plate can be cleaned, cement is prevented from adhering to the discharging plate, normal discharging is guaranteed, and laying efficiency is guaranteed.

Owner:辽宁民盛建安工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com