Patents

Literature

38results about How to "Large atomization area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

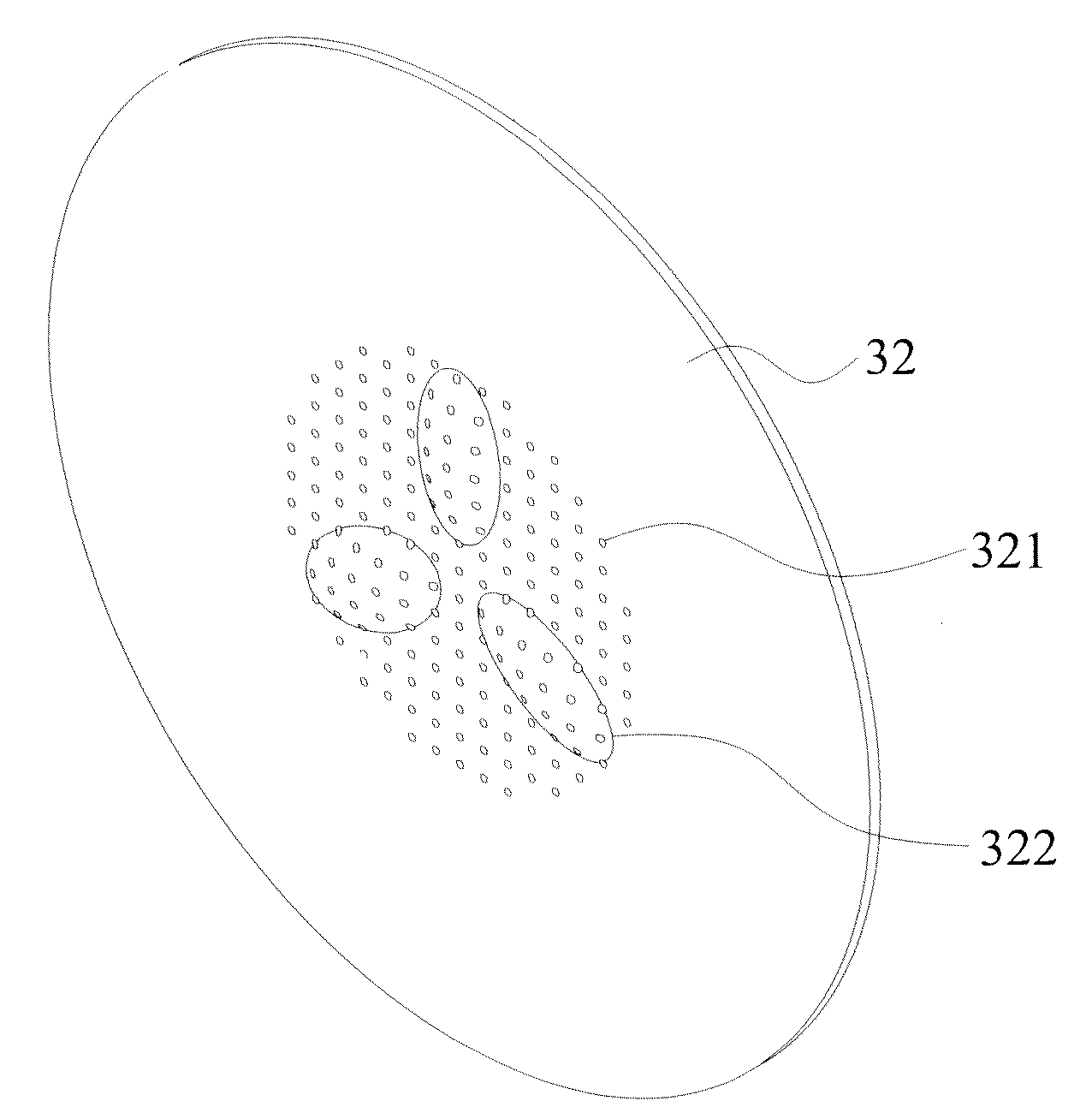

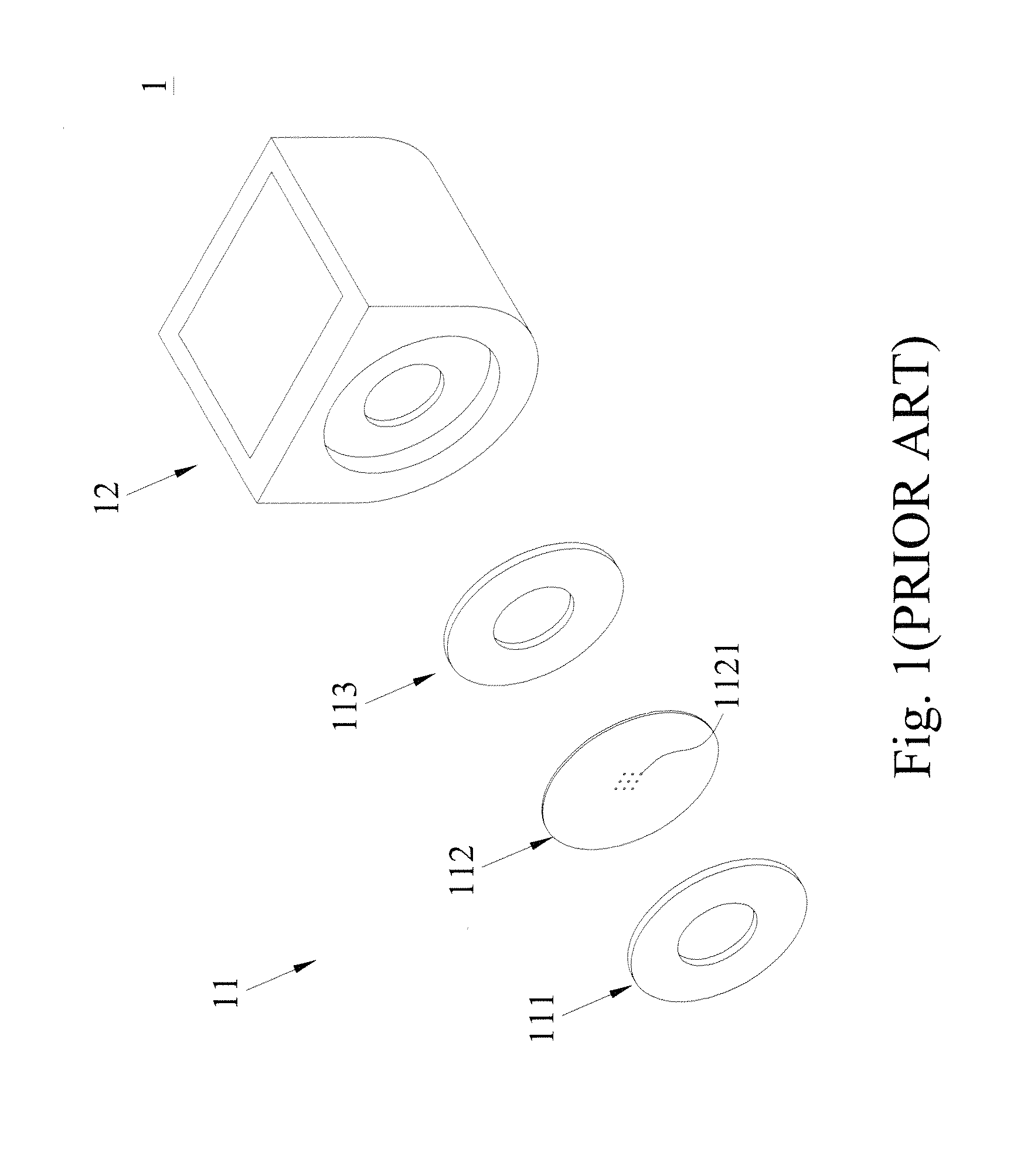

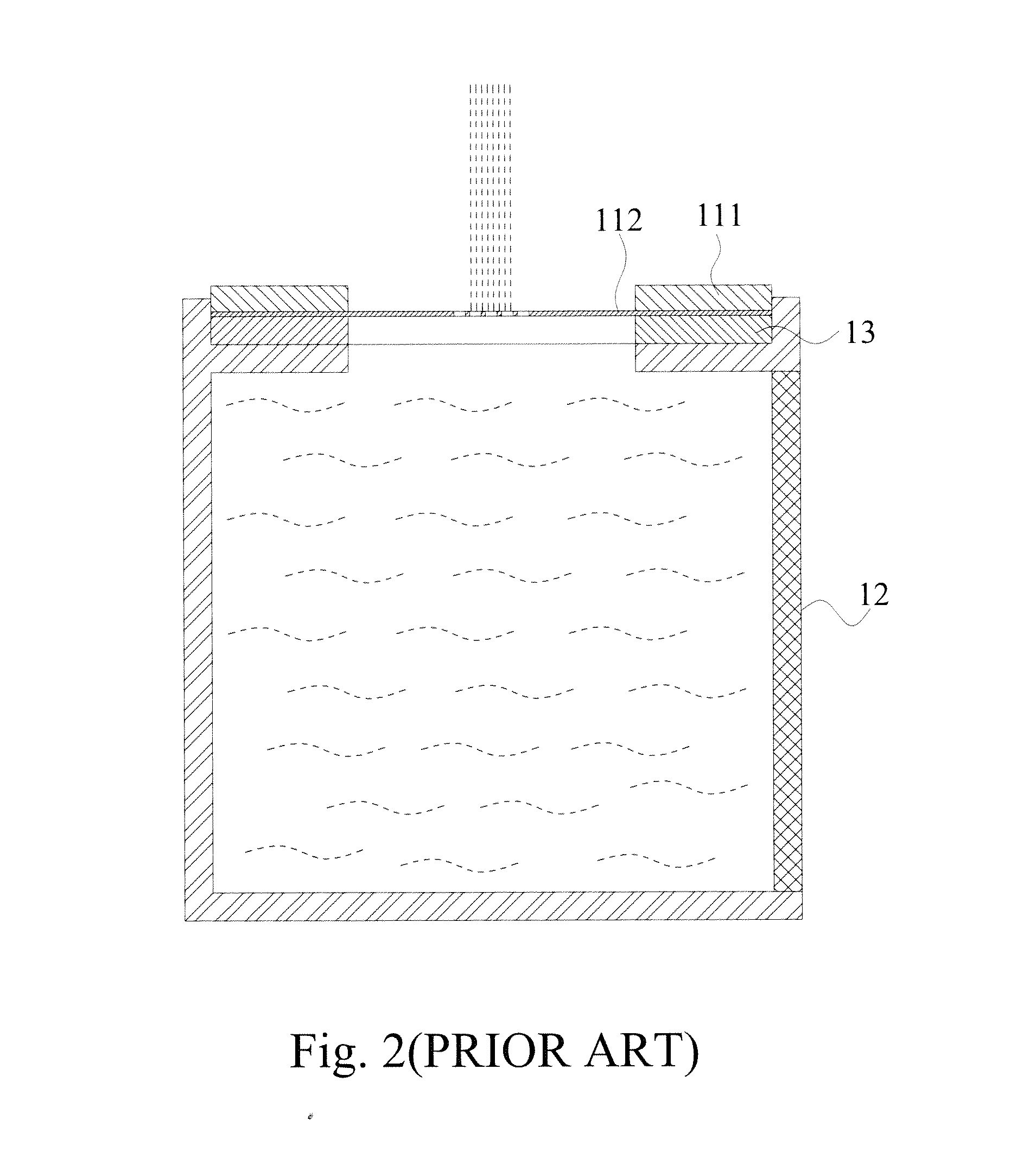

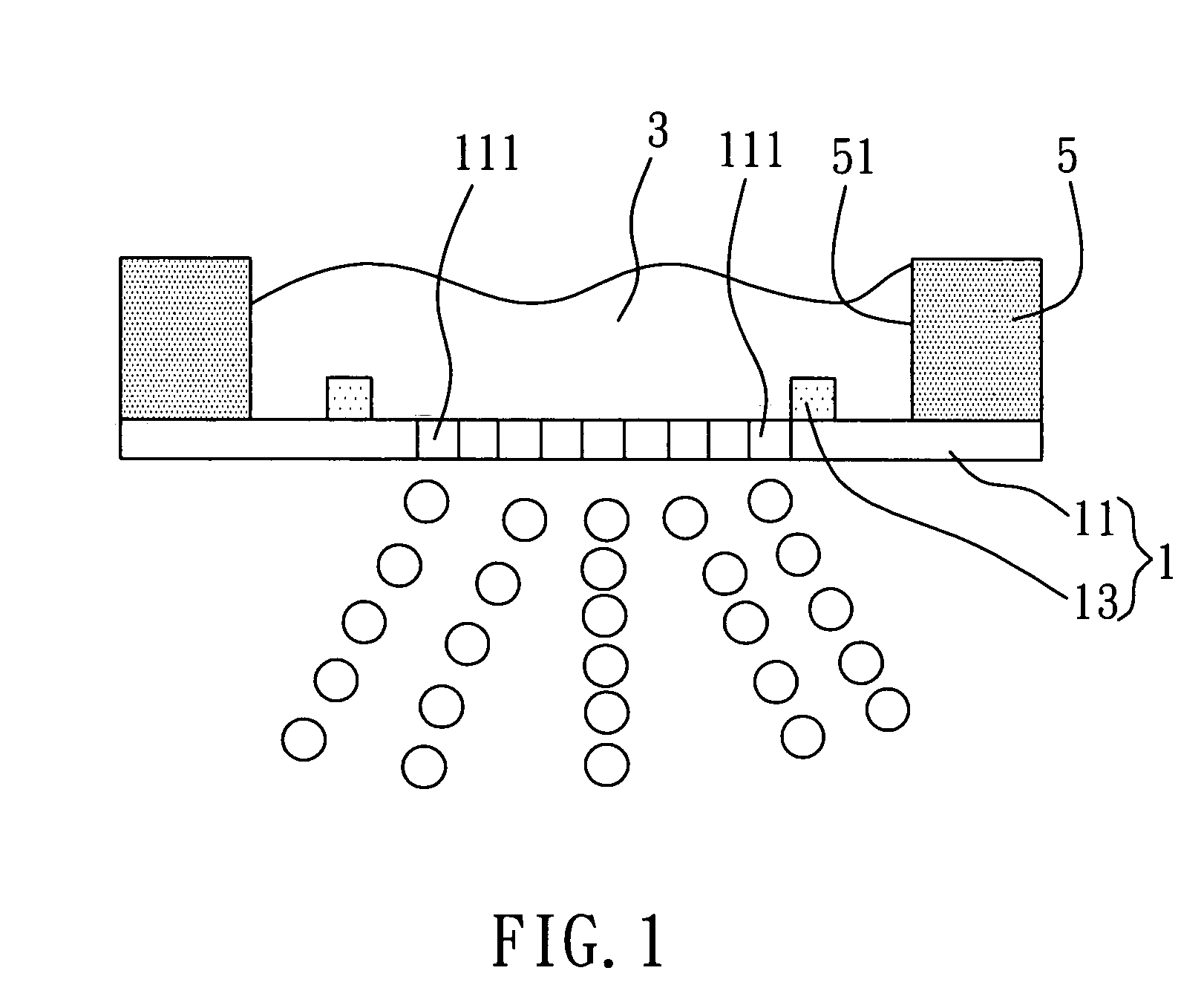

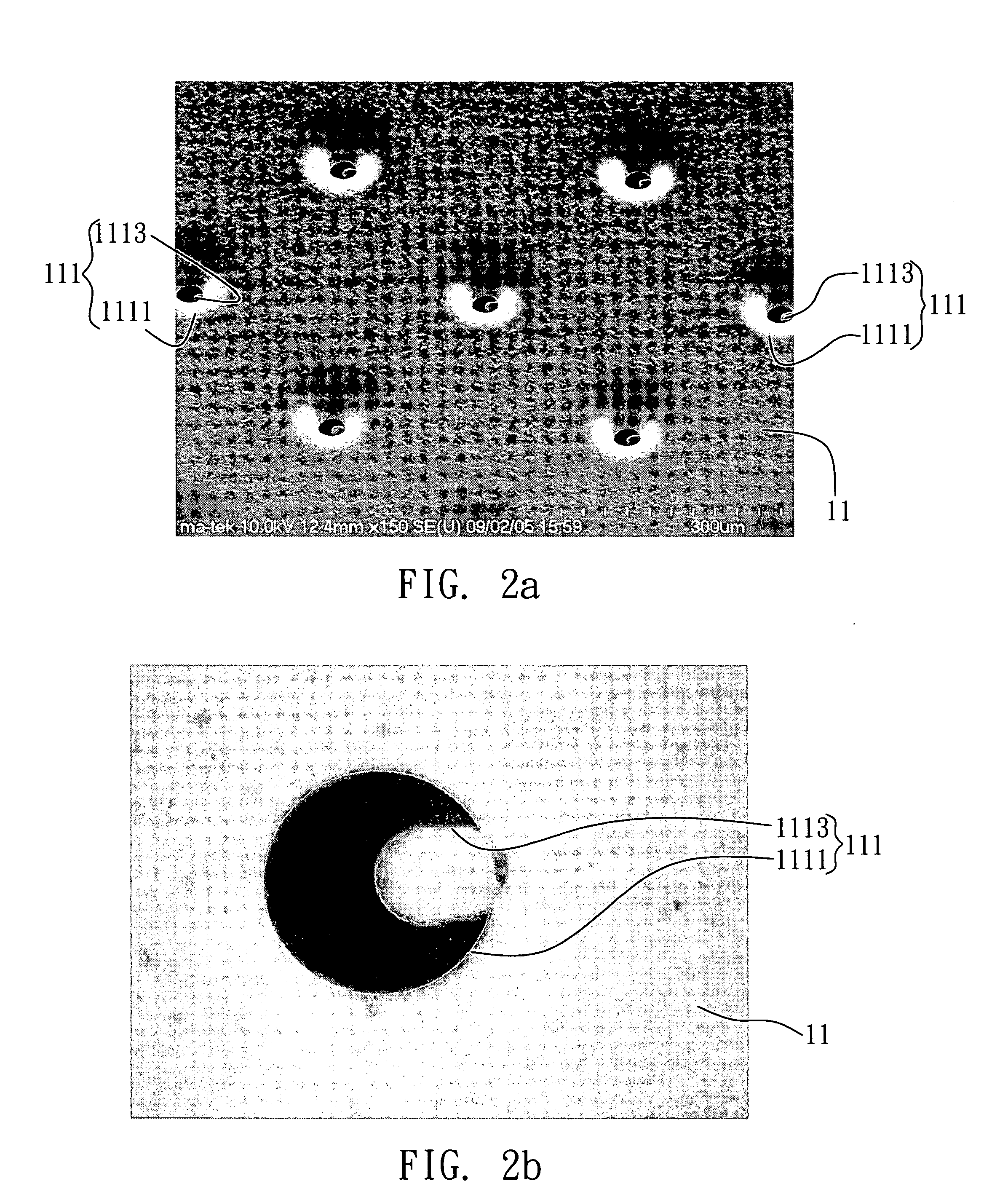

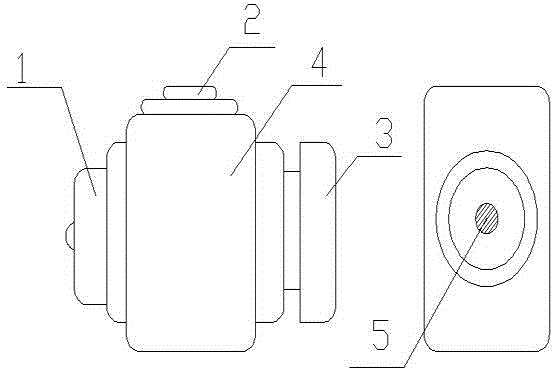

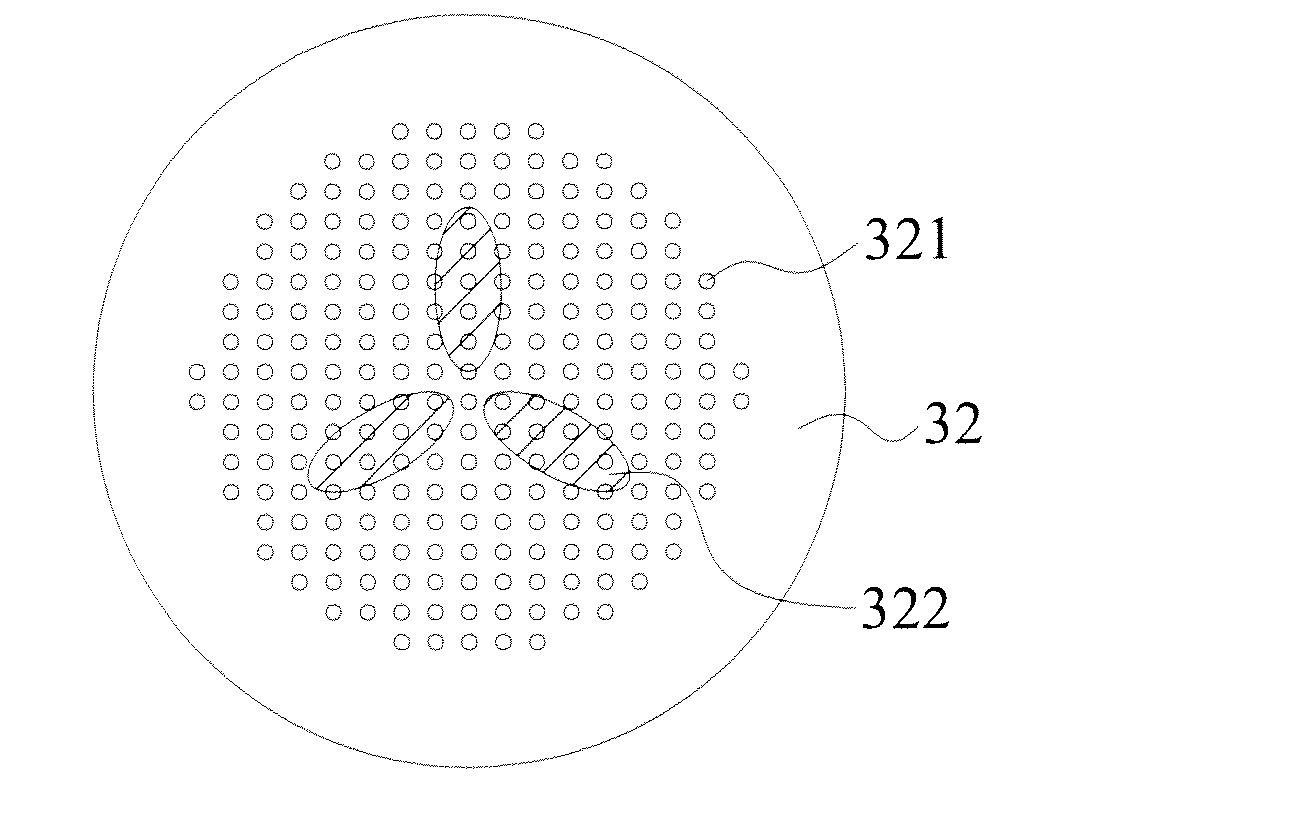

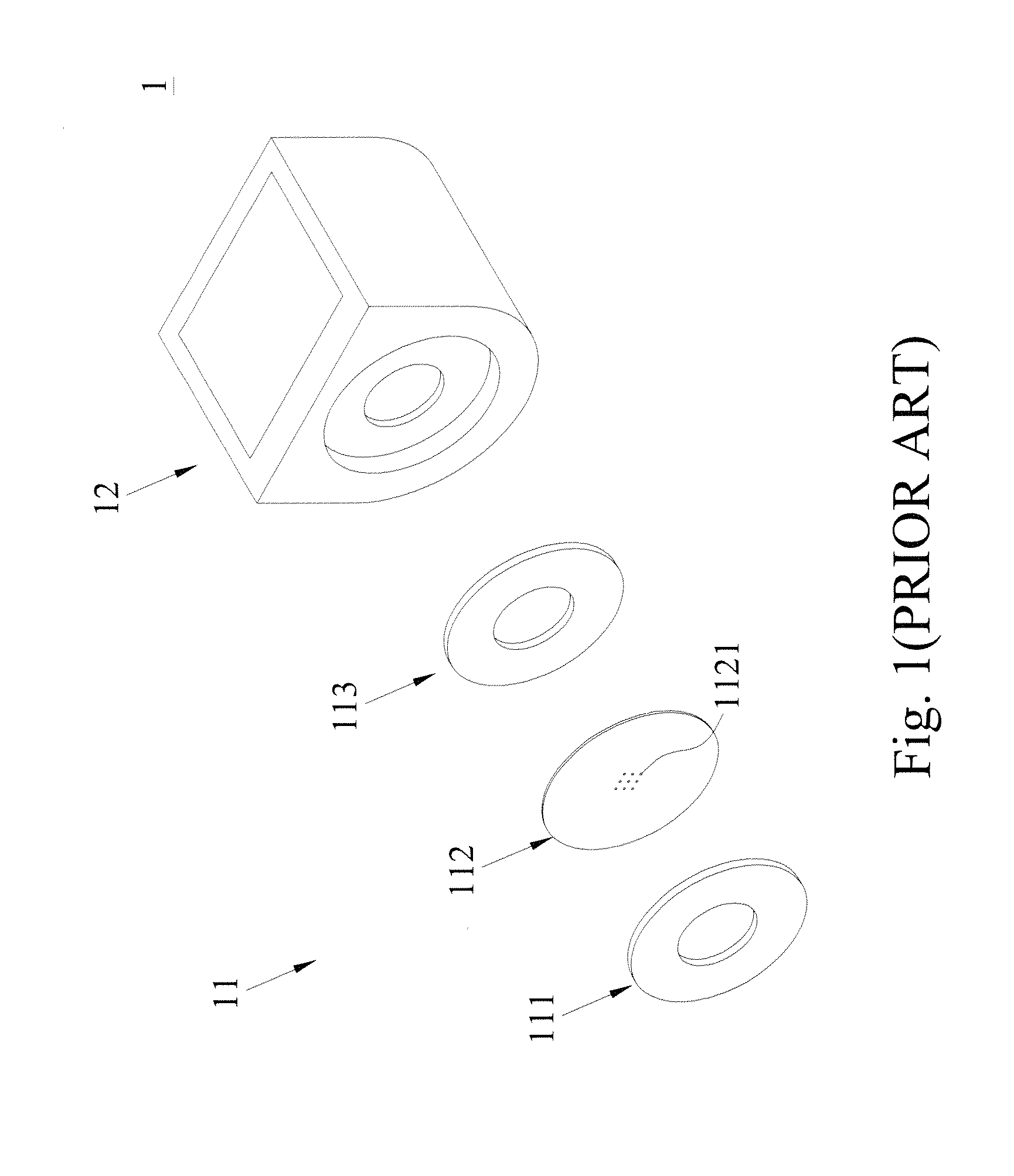

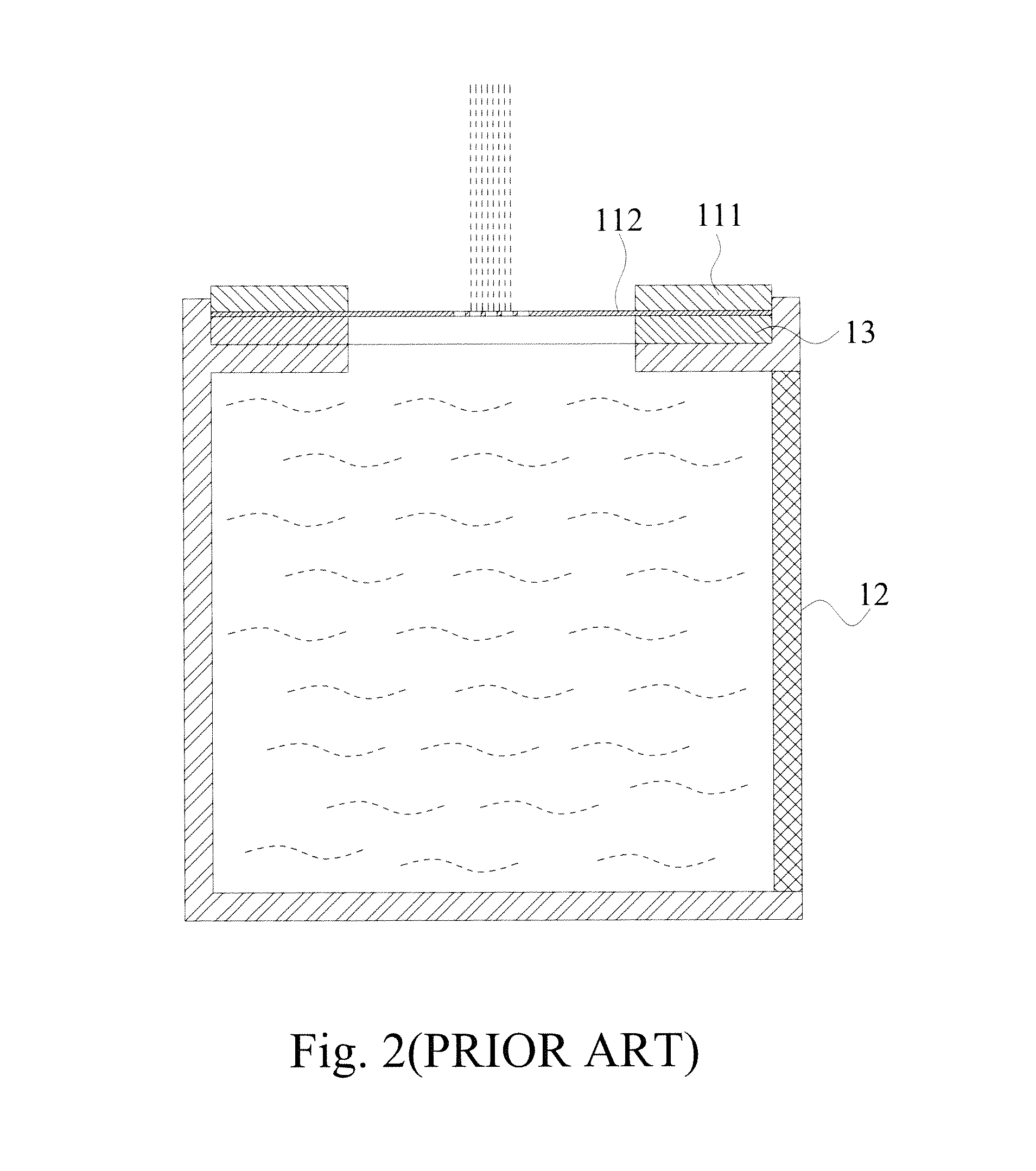

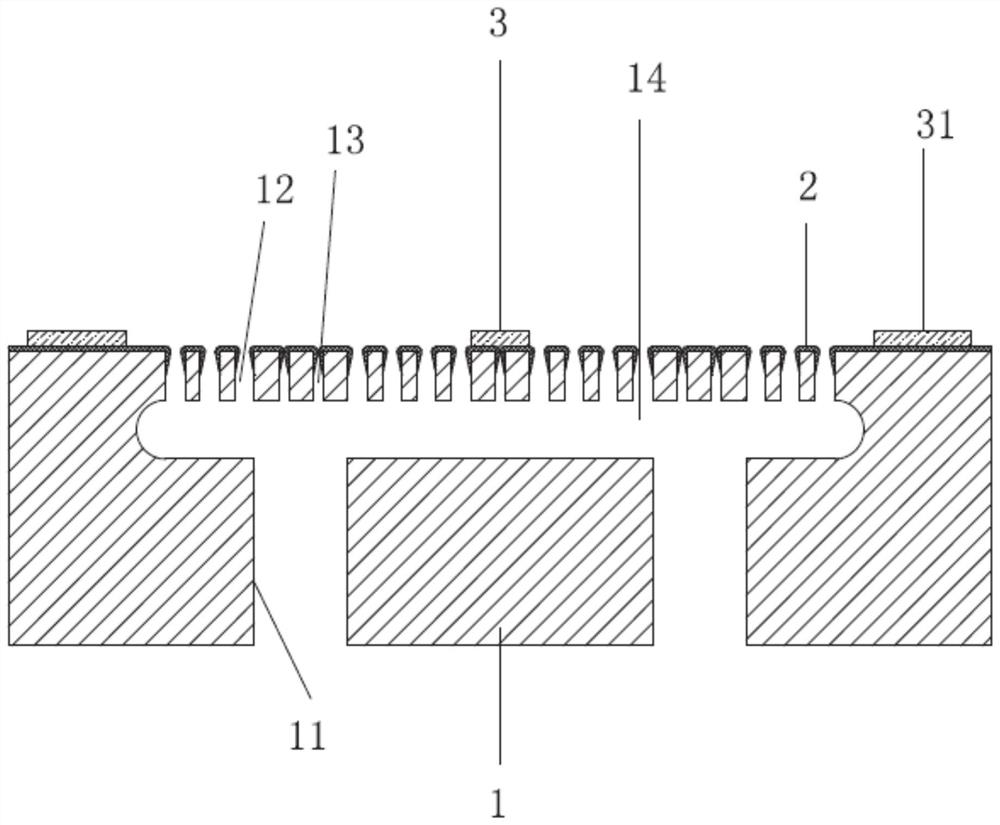

Nozzle plate and atomizing module using the same

ActiveUS20120205468A1Large atomization areaImprove stabilityDust removalFire preventionCircular discStress concentration

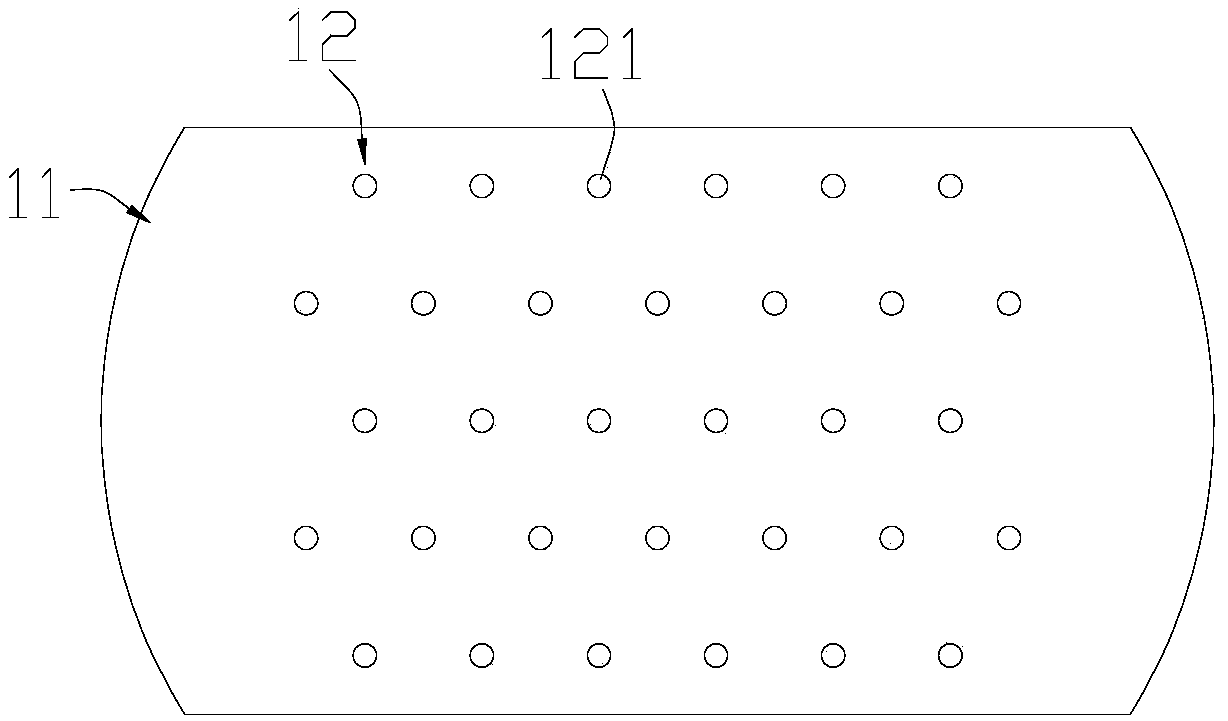

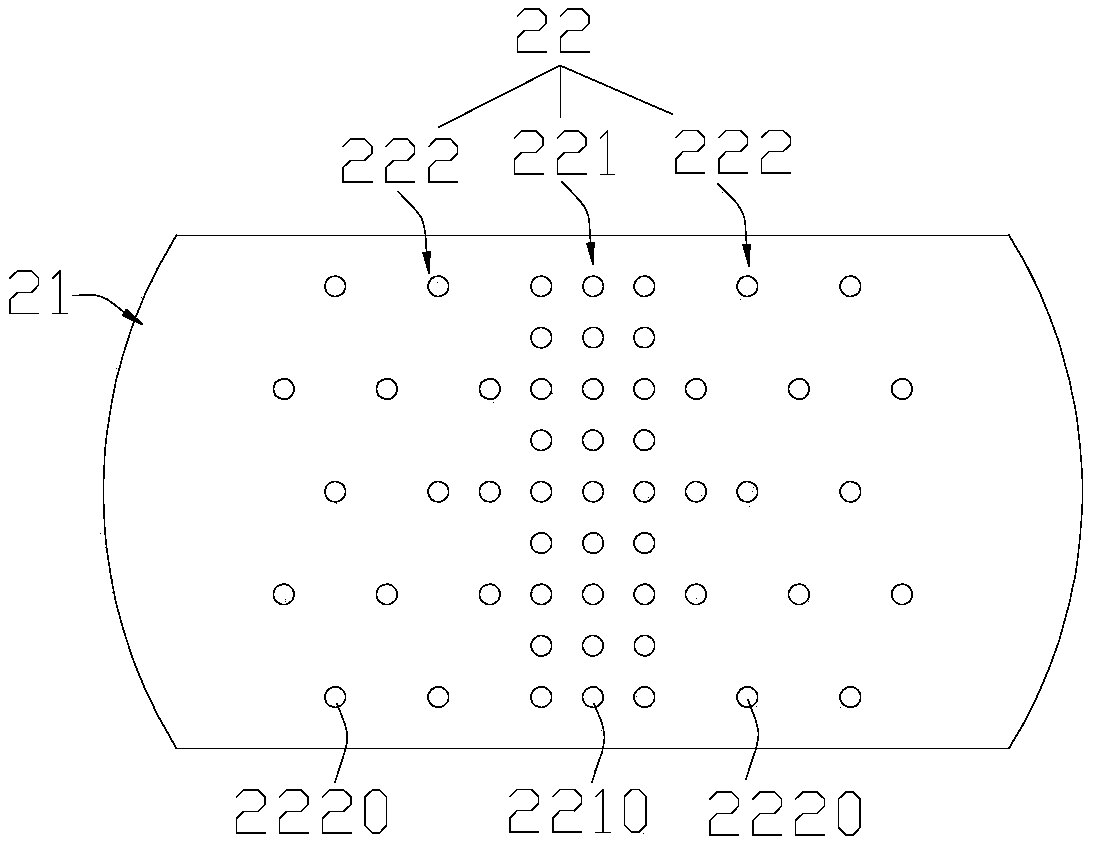

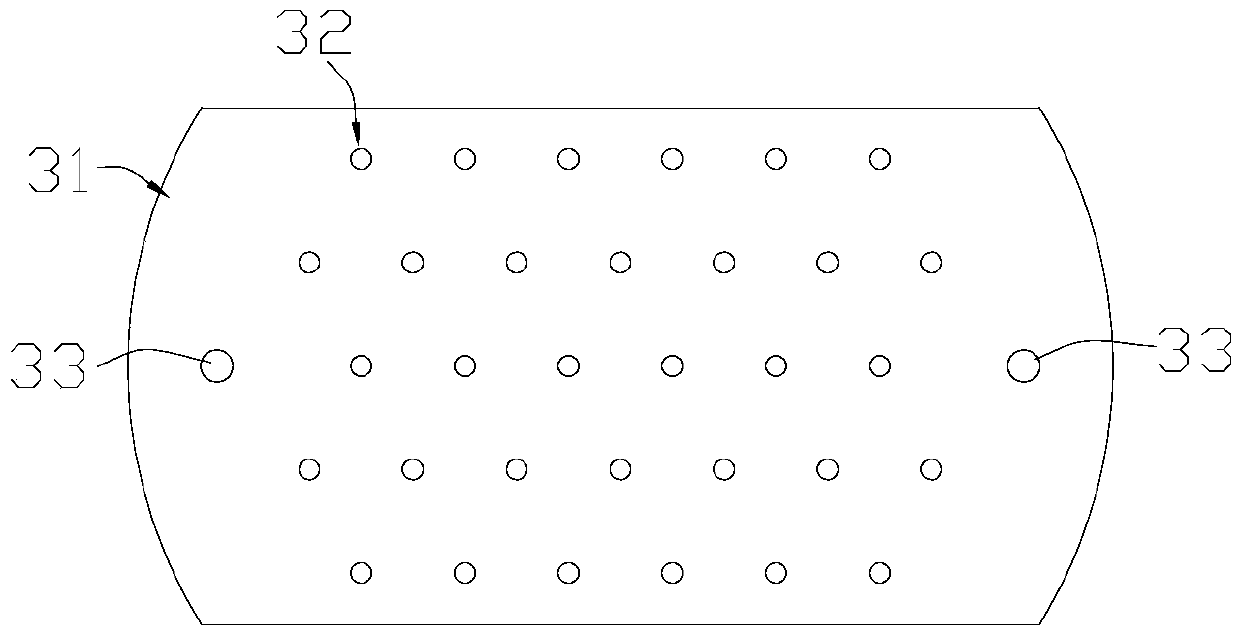

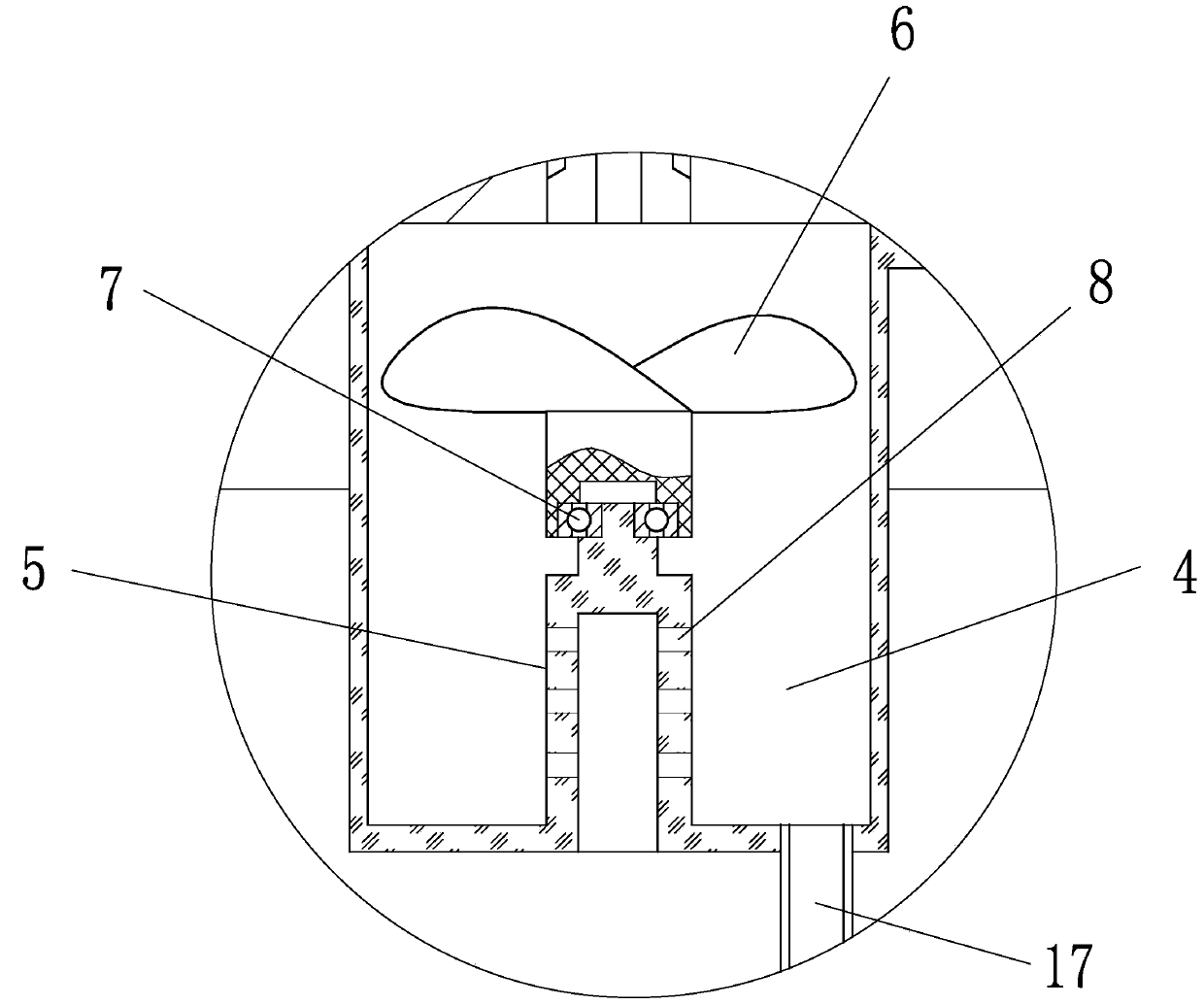

A nozzle plate and an atomizing module using the nozzle plate are disclosed. The atomizing module is installed at a cavity and includes a piezoelectric circular plate, a braking circular plate and a nozzle plate. The braking circular plate is installed on a side of the piezoelectric circular plate. The nozzle plate is a circular disc clamped between the piezoelectric circular plate and the braking circular plate, and the nozzle plate includes firing holes and first protrusions. Each first protrusion is non-circular and protruded in a direction towards the piezoelectric circular plate or the braking circular plate to form a multi-curved surface structure radially or circularly arranged into a specific geometric pattern. The nozzle plate can increase the atomizing area, atomizing quantity and liquid-gas exchange rate to prevent excessive stresses from concentrating at the center of the nozzle plate or vibrations from cracking or breaking the nozzle plate.

Owner:MICRO BASE TECH CORP

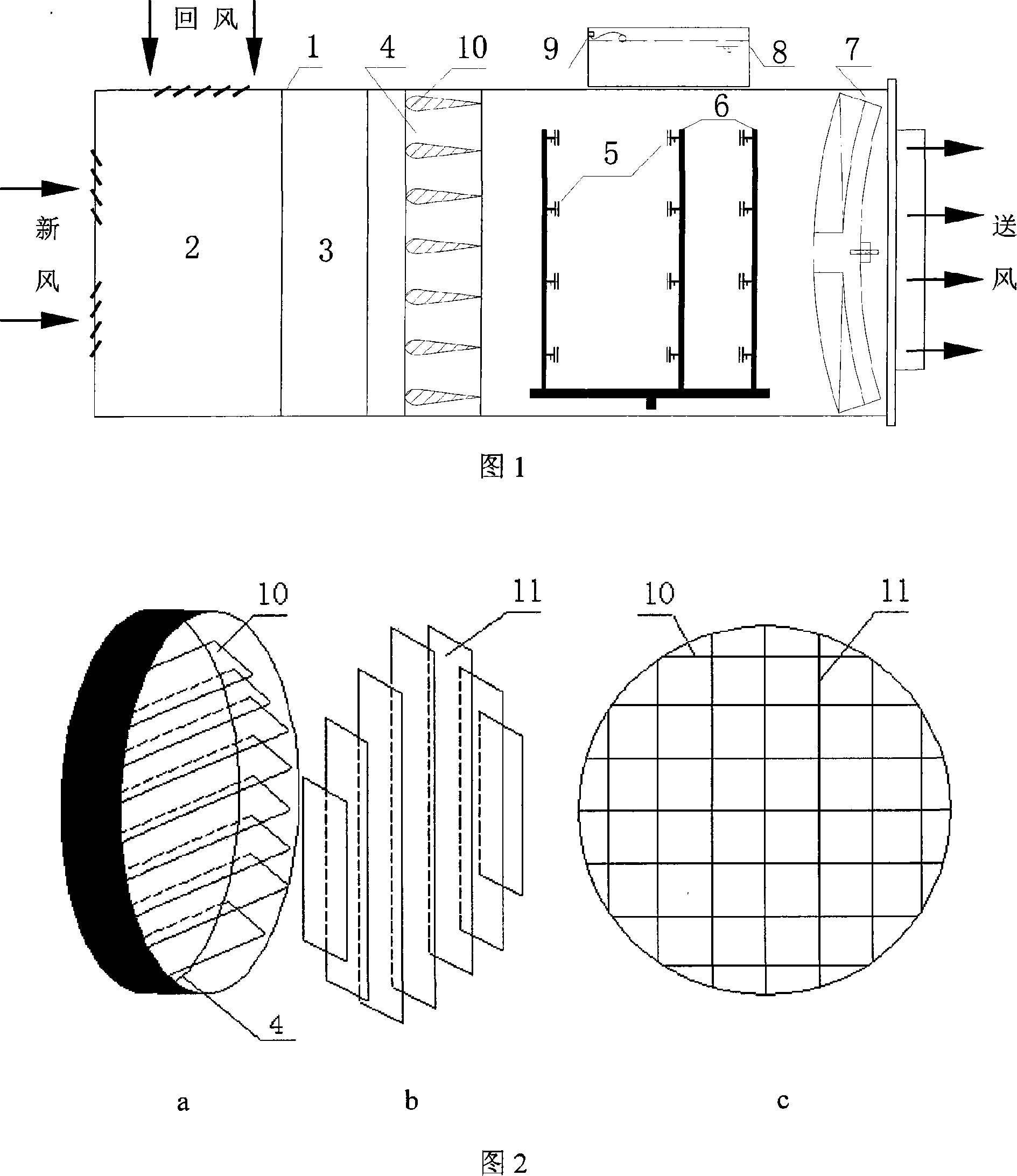

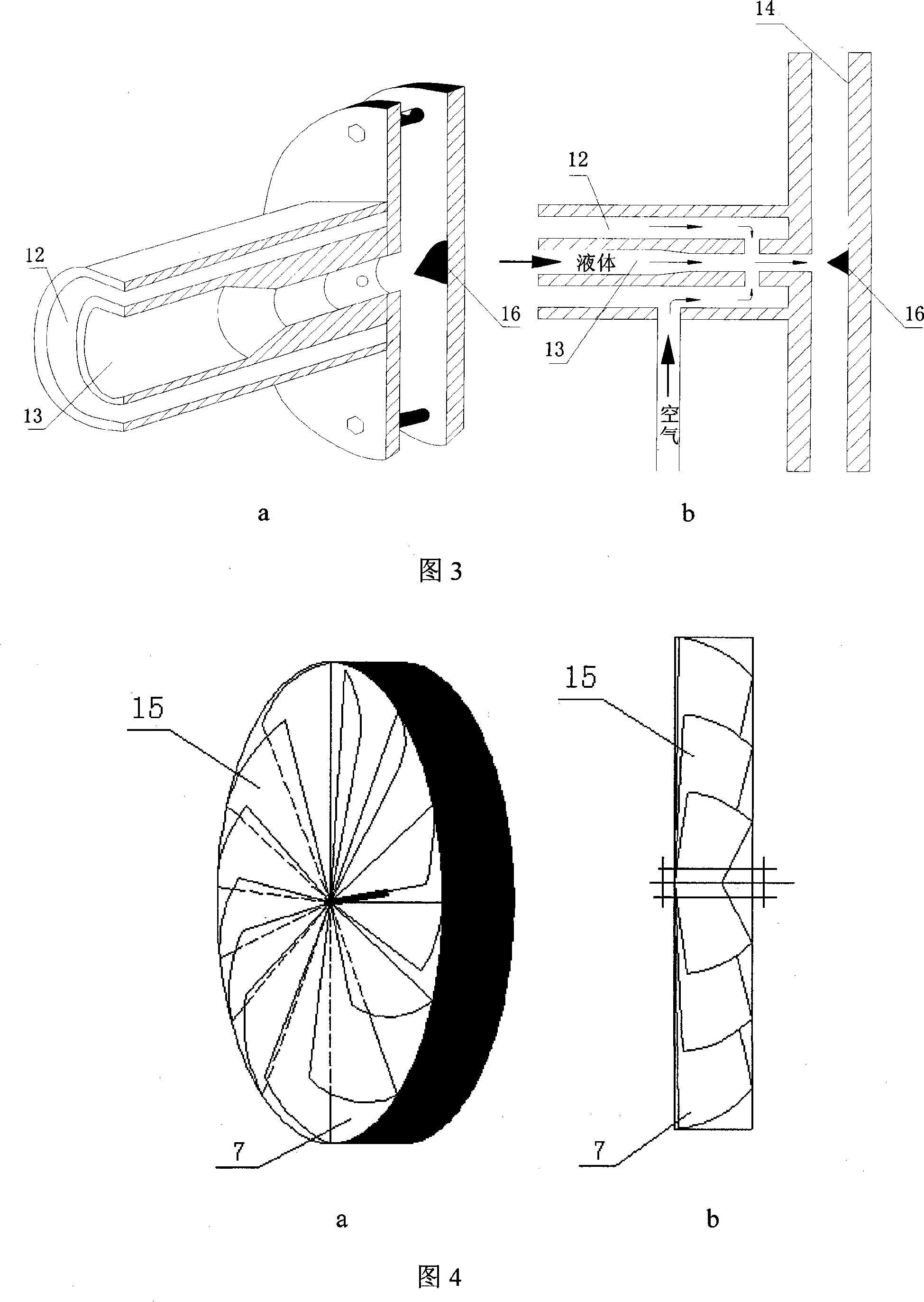

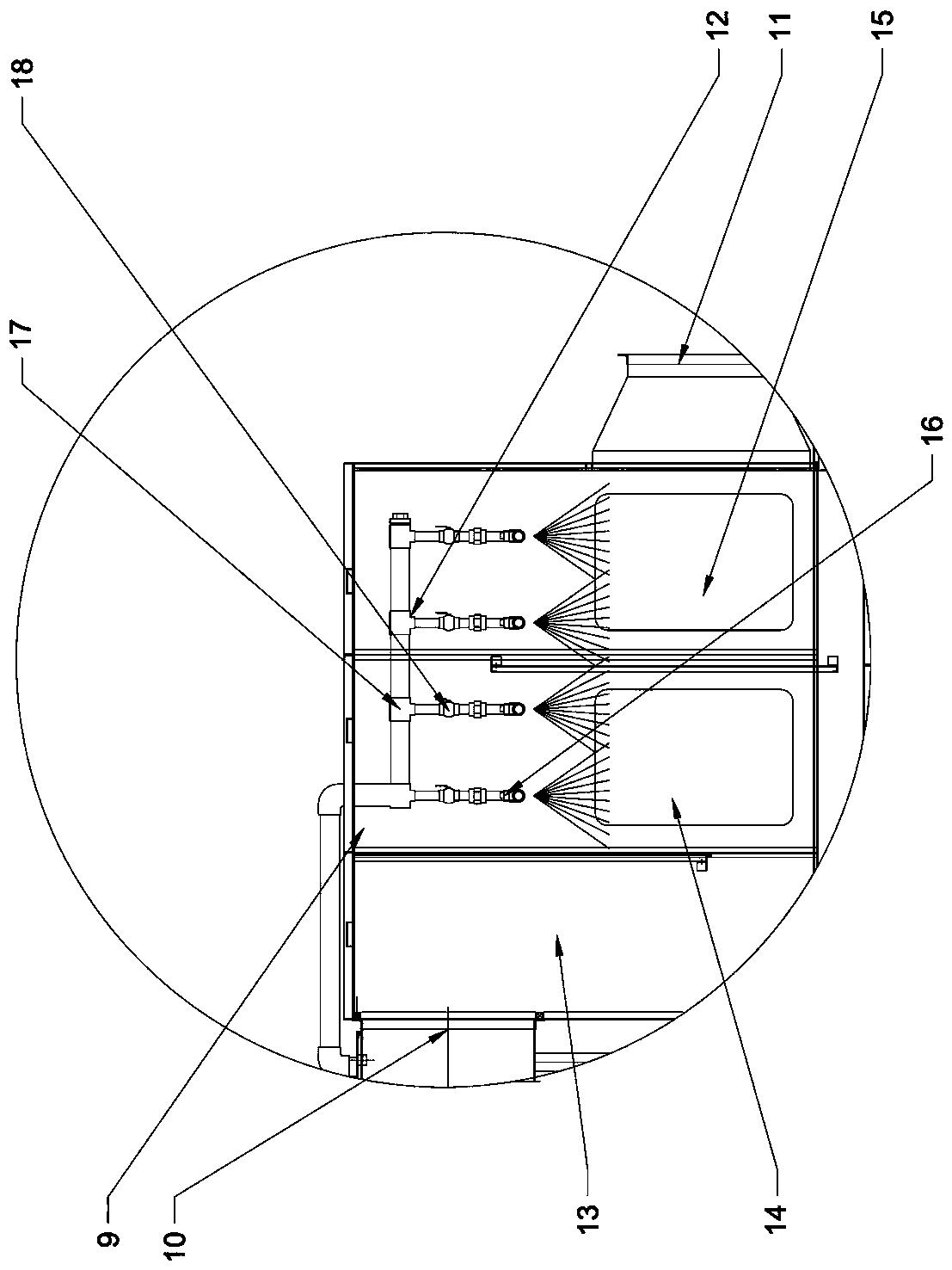

Hydrokinetic type supersonic wave air-conditioning spray chamber

InactiveCN101105318ALarge atomization areaUniform atomization effectLighting and heating apparatusAir humidification systemsAir compressionSupersonic waves

The invention discloses a hydrodynamic ultrasonic water spraying chamber for air conditioner, which comprises a housing, wherein an axial flow fan, a diversion grid, a spraying plate are sequentially equipped inside the housing according to the direction of inlet air, and a plurality of spraying nozzles and mangers are equipped on the spraying plate. The chamber also comprises a water supply system, and an air compression system. The spraying nozzle comprises two assembled cylinder walls forming an internal passage and an external passage, the walls of the internal passage and external passage are communicated at certain site, a target plate is equipped at the air outlet end of the two cylinder walls and perpendicular with the walls, the target plate is spaced with the port of the wall, and a triangle pyramid is equipped on the site of the target plate corresponding to the air outlet port of the wall. The invention integrally utilizes ultrasonic agglomeration, coagulation and collision detention three action principles to improve the structure, so as to remarkably improve the purification efficiency and heat transfer and mass transfer efficiency of sub-micron level dust in the air.

Owner:SHAANXI JINYI VENTILATION TECH

Spraying device

InactiveUS20070158477A1Increase spray areaImprove homogeneitySpray nozzlesFire rescueEngineeringNozzle

A spraying device for atomizing a liquid is proposed. The spraying device includes a nozzle plate and an actuator. The nozzle plate is provided with a plurality of nozzle apertures. Each of the nozzle apertures includes an entry end for the liquid to enter and an exit end for the liquid to exit. The entry end and the exit end of at least one of the nozzle apertures are asymmetrical structures. The actuator is integrated with the nozzle plate to actuate atomization of the liquid. The spraying direction of a liquid droplet after the liquid is atomized can be controlled by modifying the shape of the exit end of the nozzle aperture.

Owner:IND TECH RES INST

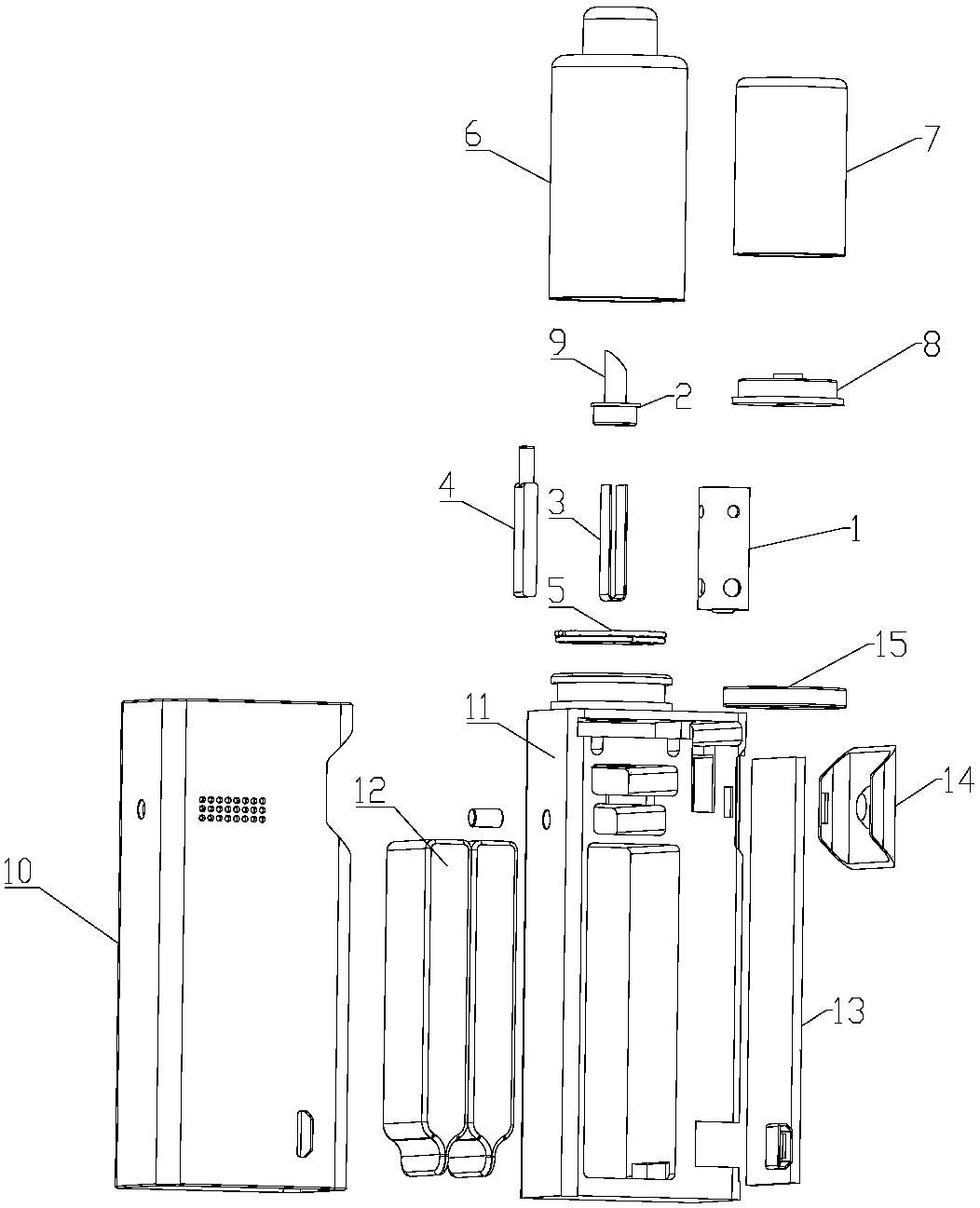

Atomization sheet for electronic cigarette and atomizer

PendingCN109619687AIncrease contact areaLarge atomization areaTobacco devicesEngineeringElectronic cigarette

The invention discloses an atomization sheet for an electronic cigarette and an atomizer. The atomization sheet comprises a sheet-shaped atomization sheet body with the surfaces in contact with a liquid drainage piece and a hole part formed in the atomization sheet body; the hole part runs through the two opposite surfaces of the atomization sheet body. According to the atomization sheet for the electronic cigarette, the sheet shape is arranged, the sheet-shaped atomization sheet body and the liquid drainage piece are in contact with drainage liquid for atomization, the contact area between the atomization sheet body and the liquid drainage piece is large, and the atomization area is large accordingly; the hole part in the atomization sheet is arranged to adjust the resistance value of theatomization sheet, it is achieved that heat of the atomization sheet is evenly distributed, atomization is even, and the experience feeling of the electronic cigarette is improved; the structure is simple, automatic production is convenient, and the production cost is reduced.

Owner:O NET AUTOMATION TECH SHENZHEN

Cold mist system

InactiveCN105157146AAtomization temperature synchronizationAvoid drippingMechanical apparatusFluid circulation arrangementGreenhouseSpray nozzle

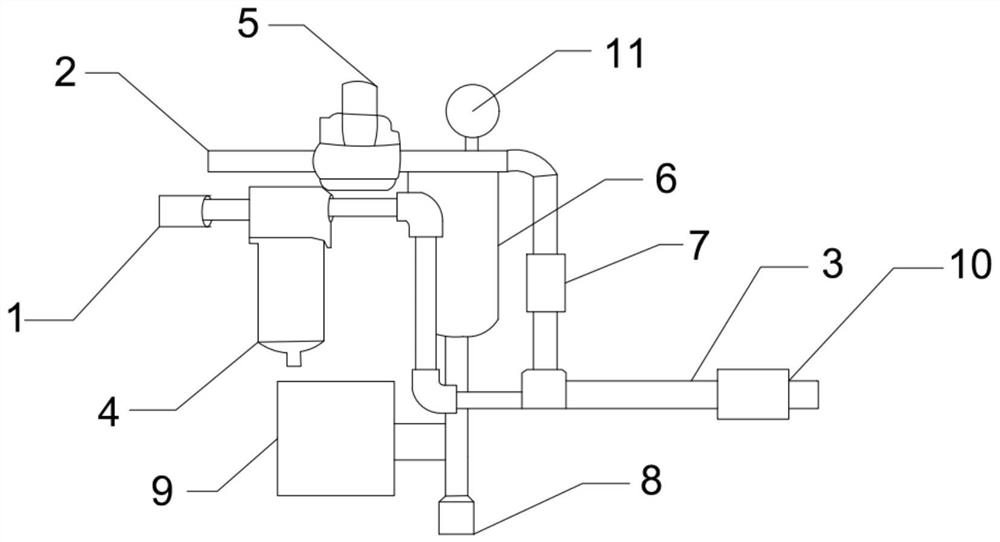

The invention discloses a cold mist system. The cold mist system comprises a water tank, a refrigeration unit and a high-pressure spraying machine, wherein the refrigeration unit and the high-pressure spraying machine are connected with the water tank through a pipeline. The cold mist system is characterized in that a circulation pump is connected between the water tank and the refrigeration unit and enables water inside the water tank to constantly refrigerate among the circulation pump, the water tank and the refrigeration unit in a circulation mode; the high-pressure spraying machine comprises a high-pressure pump and atomizing spraying nozzles connected with the high-pressure pump through a high-pressure conveying pipeline, and an adjusting valve is arranged between the high-pressure pump and the atomizing spraying nozzles and connected with the water tank through a pipeline. The adjusting valve can adjust the flow of cooling water output by the high-pressure pump and can make the cooling water rapidly pass through the high-pressure pump and enter the atomizing spraying nozzles to be sprayed out, the flow of cold mist sprayed by the atomizing spraying nozzles is uniform with the flow of the cooling water output by the high-pressure pump after adjustment is performed by the adjusting valve, and therefore atomizing temperature and the temperature of the cooling water before the cooling water enters the high-pressure pump are roughly uniform. The sprayed cold mist can be used for human body skin experience, greenhouse planting cooling, farm cooling and others.

Owner:HUNAN HUAQIANG CULTURE TECH CO LTD

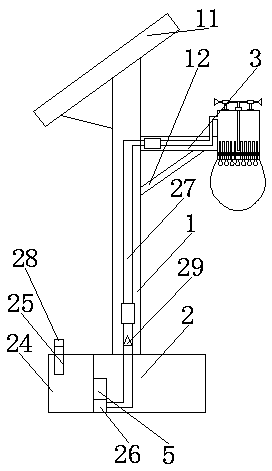

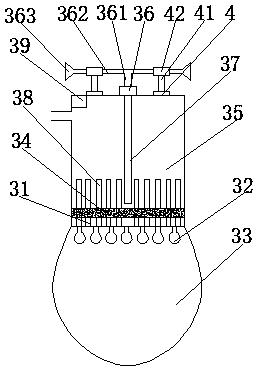

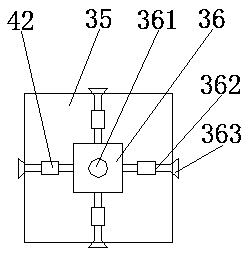

Solar street lamp with deinsectization function

InactiveCN109506190AIncrease the atomization areaImprove insecticidal effectLighting support devicesLighting elementsEngineeringSolar street light

The invention discloses a solar street lamp with a deinsectization function and relates to the technical field of solar street lamps. The street lamp comprises a lamp post, wherein a pedestal is installed at the bottom of the lamp post, a solar panel is installed at the top of the lamp post, and a fixing rod is horizontally arranged above the lamp post; an illumination light is installed at the end, away from the lamp post, of the fixing rod and comprises a horizontally arranged connection block; a bulb is arranged below the connection block, and a lampshade is arranged outside the bulb; a reaction tank is arranged above the connection block; an atomization device is arranged above the reaction tank; and a water absorption piece is arranged below the atomization device, the upper end of the atomization device is connected with one end of a mist guide tube, and the other end of the mist guide tube is connected with one end of a mist exhaust tube, and the other end of the mist exhaust tube is connected with a fog outlet cap. The solar street lamp can effectively kill mosquitoes which are gathered beside the street lamp in summer.

Owner:合肥天沃能源科技有限公司

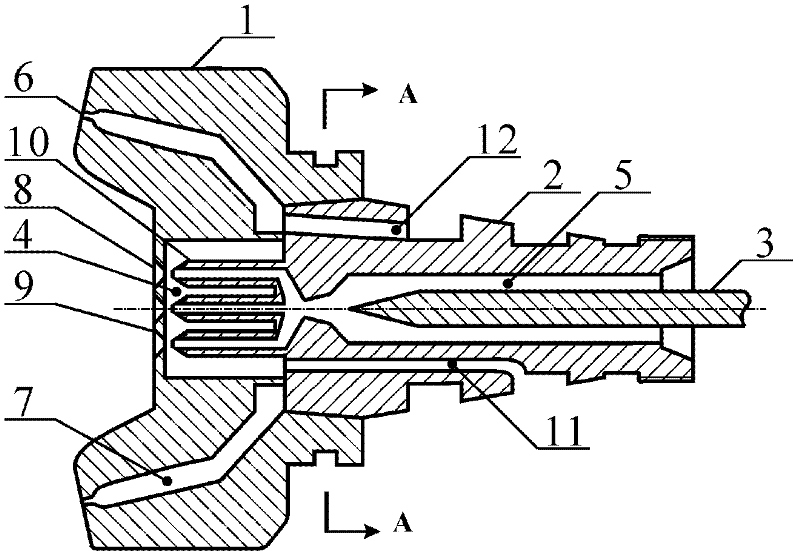

Spray gun spray nozzle capable of realizing minuteness atomization

InactiveCN102500489AEasy to operateHighlight substantive featuresLiquid spraying apparatusWater basedSpray coating

The invention provides a spray gun spray nozzle capable of realizing minuteness atomization. The spray gun spray nozzle adopts an airflow focusing operation mode and is formed by combining an air cap, a material conveyor and a valve needle, wherein a high pressure air chamber is formed between the air cap and the material conveyor, the valve needle extends into the inner wall of the material conveyor, a thin plate of the air cap is provided with material outlet holes, and the outer edge of the air cap is provided with a circle of air curtain spray openings; the rail end of a coating channel of the material conveyor is connected with a material outlet channel, and the material conveyor comprises a group of capillary tube channels; and the number of the capillary tube channels are the same as that of the material outlet holes, the capillary tube channels and the material outlet holes are in one-to-one correspondence and maintain the same central axle. According to the invention, the minuteness atomization can be realized, the spray coating quality can be improved, and the using rate of coating can be increased. The spray gun spray nozzle provided by the invention can replace the existing spray gun spray nozzle to be directly used, is simple and convenient, can be widely applied for spray coating operations in various occasions, and is particularly suitable to be used for the coating of environmental-friendly water-based paint.

Owner:UNIV OF SCI & TECH OF CHINA

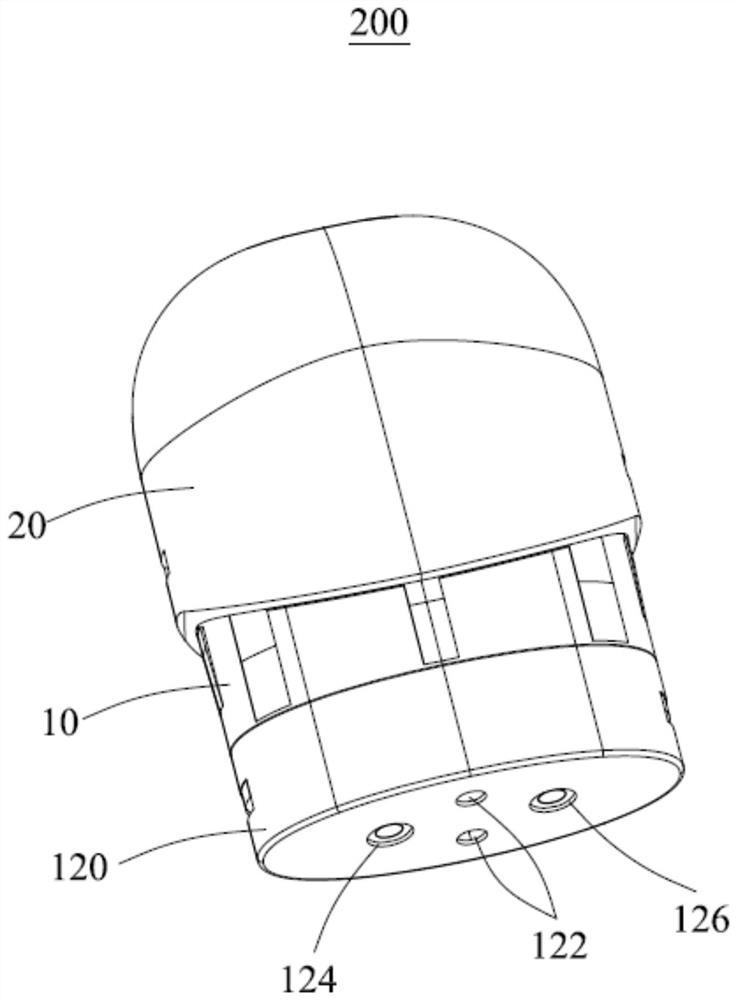

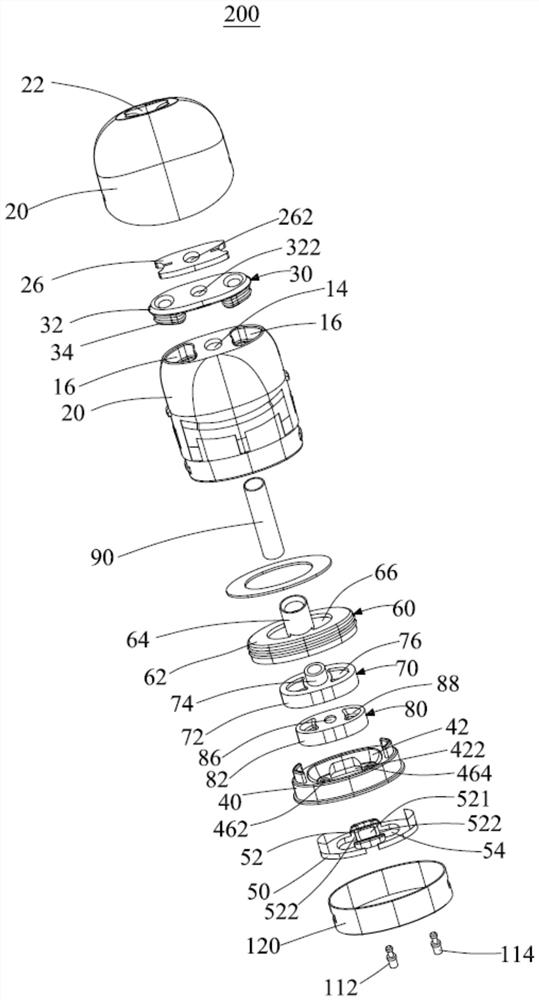

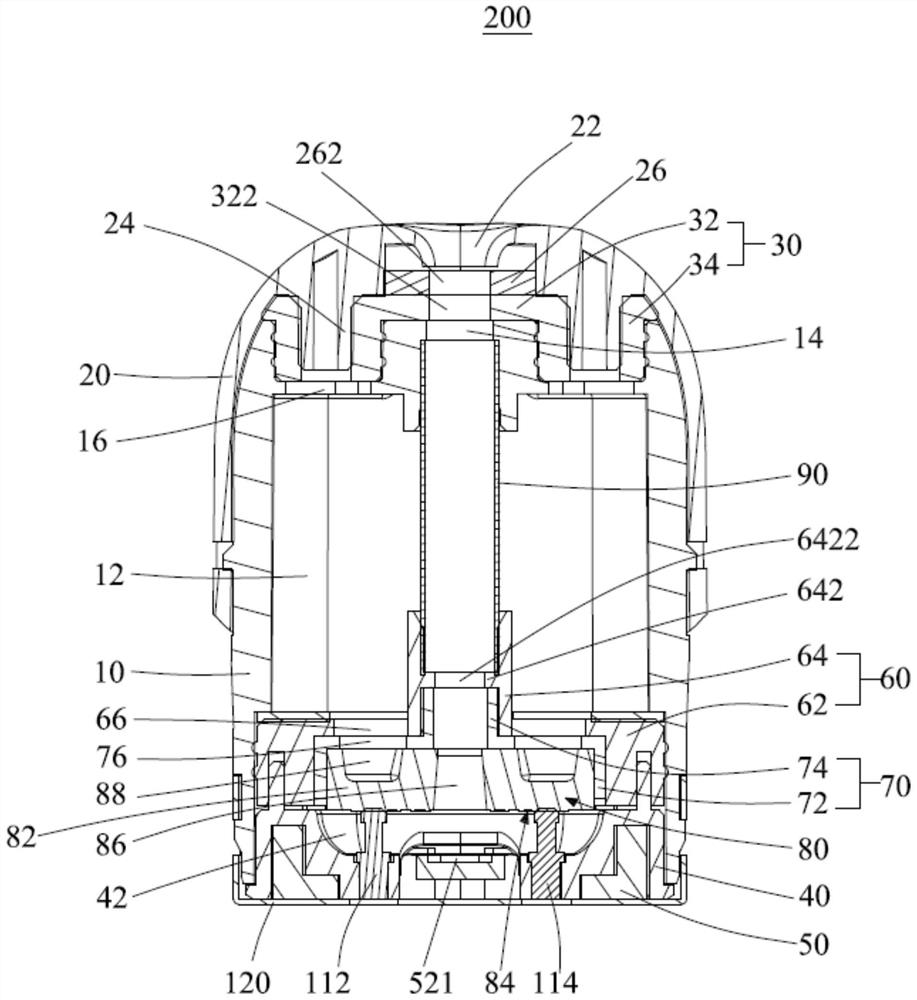

Atomization assembly of electronic cigarette and electronic cigarette adopting atomization assembly

PendingCN110037346AImprove conversion efficiencyImprove efficiency and effectivenessTobacco devicesEngineeringThermal energy

The invention discloses an atomization assembly of an electronic cigarette and the electronic cigarette adopting the atomization assembly. The atomization assembly comprises an atomization core sleeve, an oil guiding cover, a U-shaped induction metal piece, oil guiding cotton and an induction coil, wherein the oil guiding cover is detachably arranged at the end of the atomization core sleeve, theoil guiding cover is provided with a guiding sleeve, the inner portion of the guiding sleeve is communicated, the guiding sleeve extends in the direction away from the atomization core sleeve, the induction metal piece is arranged in the atomization core sleeve, one end of the oil guiding cotton is located in the induction metal piece, the other end of the oil guiding cotton is located in the guiding sleeve, and the induction coil sleeves the atomization core sleeve. The atomization assembly adopting the structure has the advantages that the thermal energy conversion efficiency is high, the atomization effect of smoke oil can be improved, and the installation space is saved. The electronic cigarette adopting the atomization assembly not only has the advantages of the atomization assembly,but also has the advantages that the structure is simple, the cost is low, the assembly and disassembly are convenient, environmental friendliness is achieved, and the requirement of a large amount ofsmoke can be met.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Gas atomization spraying nozzle

The invention discloses a gas atomization spraying nozzle. The gas atomization spraying nozzle comprises a nozzle, an air joint, a liquid joint and a mixing cavity, wherein the mixing cavity is connected to the head surfaced of the nozzle; the air joint is arranged at the upper part of the mixing cavity; the liquid joint is positioned on the back surface of the mixing cavity; the external of the liquid joint is coated with a connecting nut; a thread joint is arranged on the air joint; the nozzle is a circular nozzle; the circular nozzle is provided with a filter screen in a spout; and the filter screen is a stainless steel dense screen. As the nozzle is the circular nozzle, the atomization speed of the nozzle can be largely accelerated, the atomization area can be increased, the water resource needed by the atomization is reduced, the water current overflow caused by overhigh water pressure is prevented, and the workshop ground dryness is kept; and the filter screen is arranged in the spout, so that impurities in running water can be filtered away to prevent the nozzle from being blocked to delay the workshop atomization operation, and the service life of the nozzle is prolonged.

Owner:陈国珍

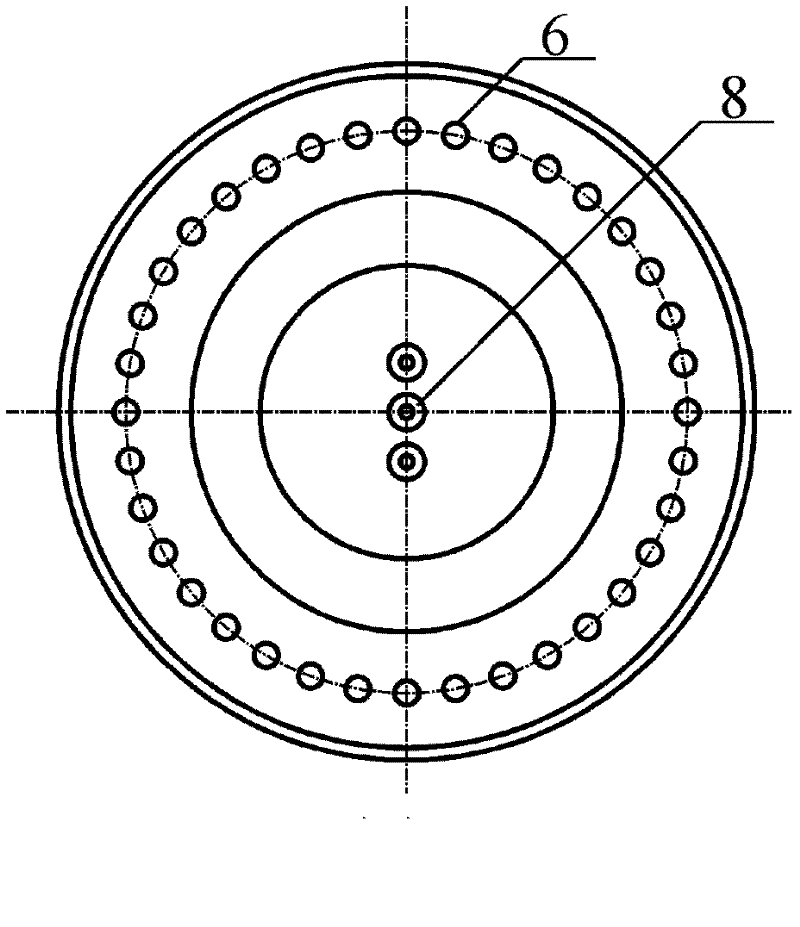

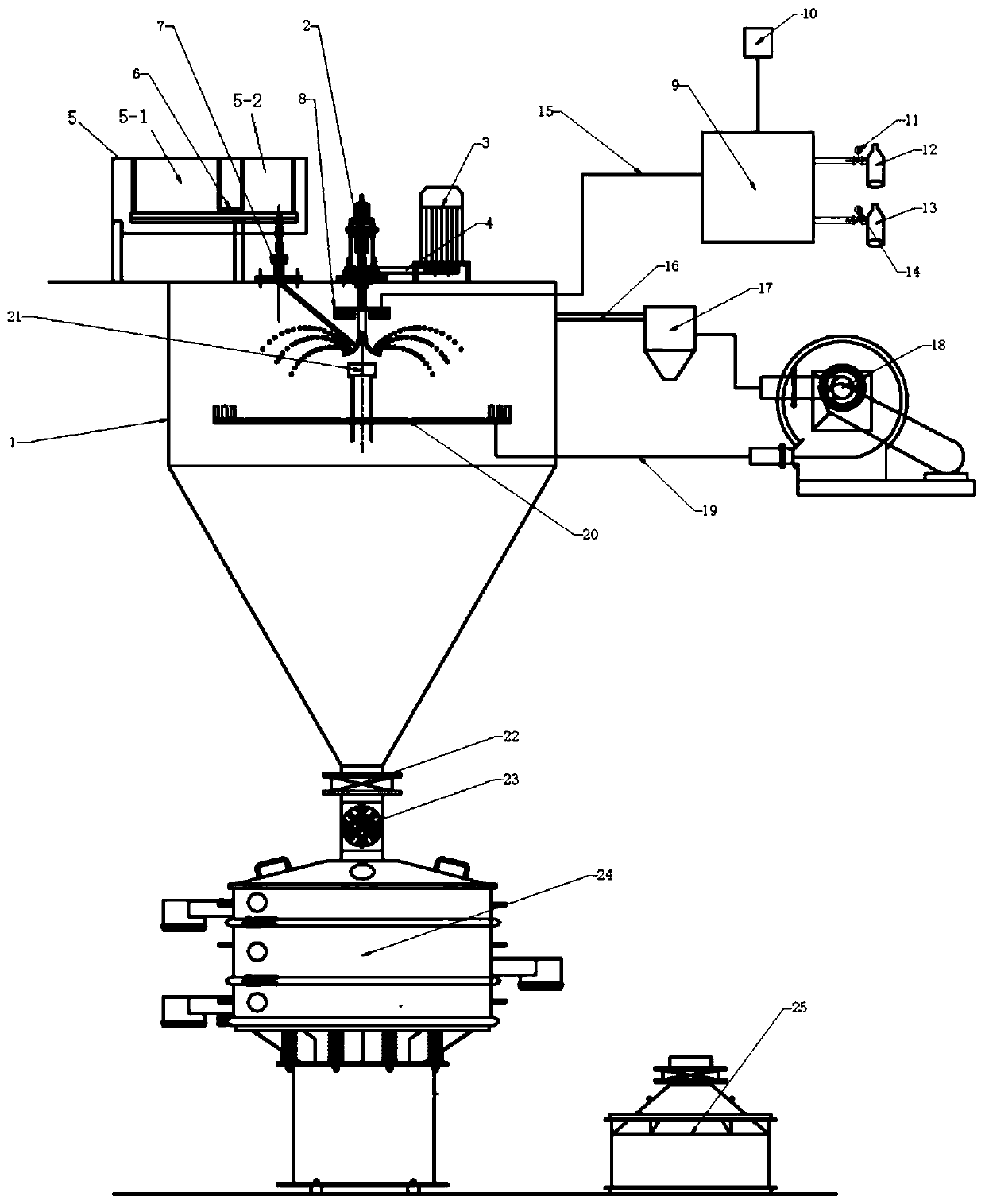

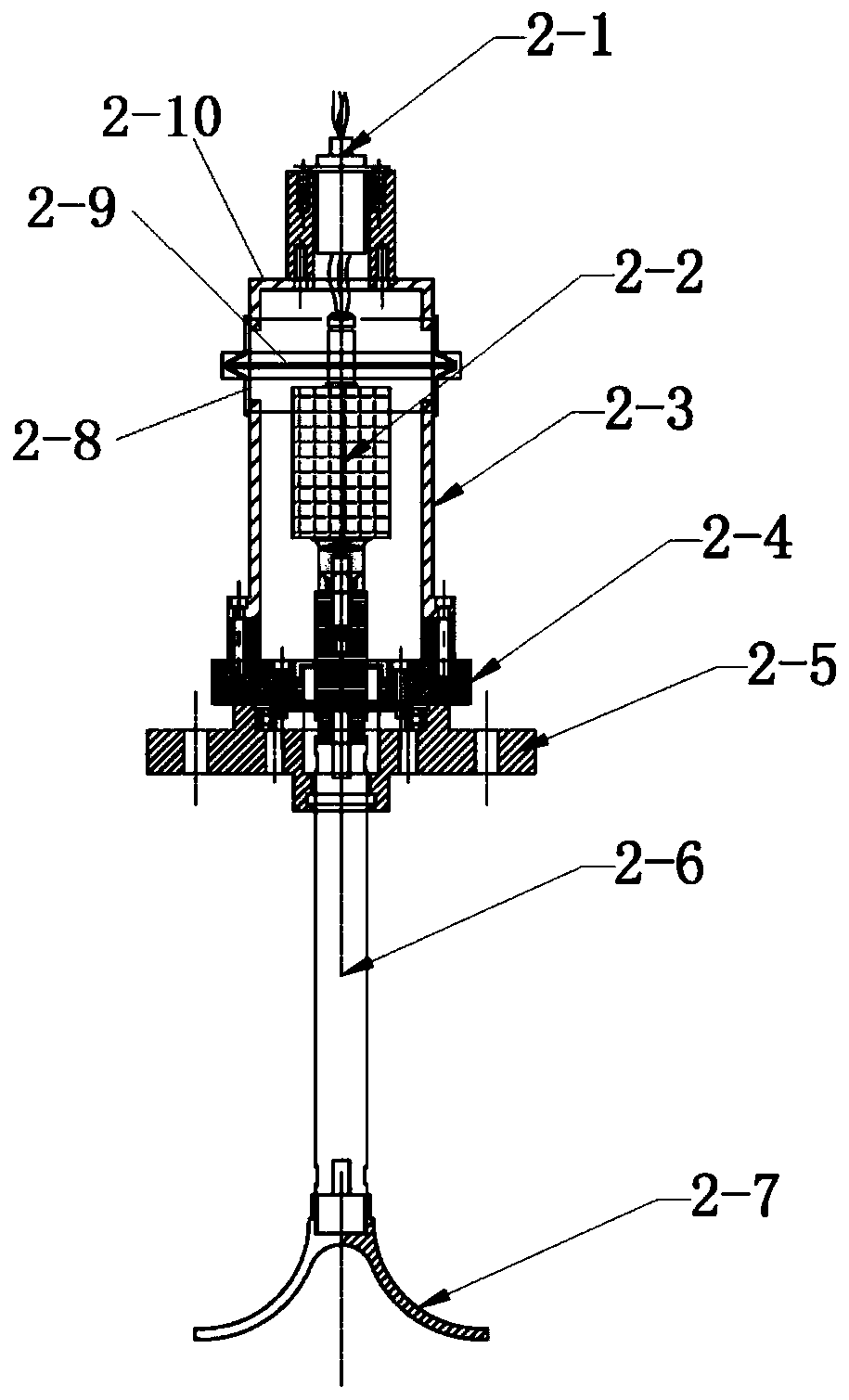

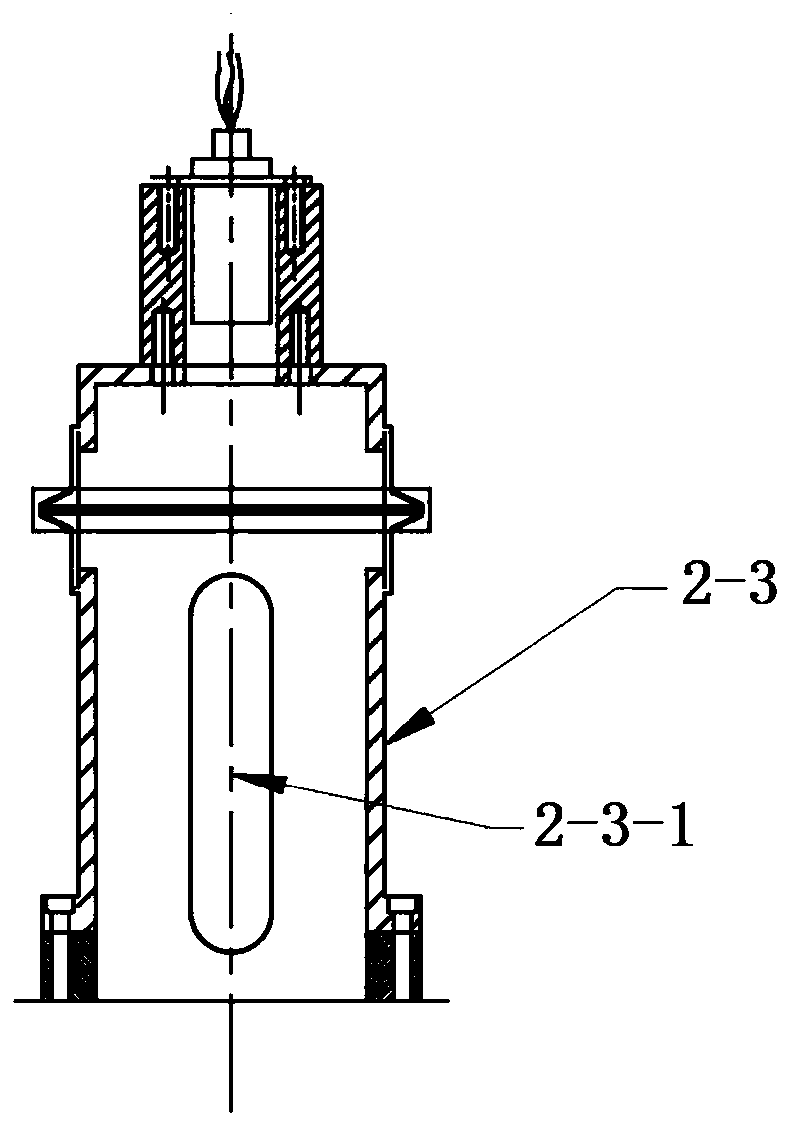

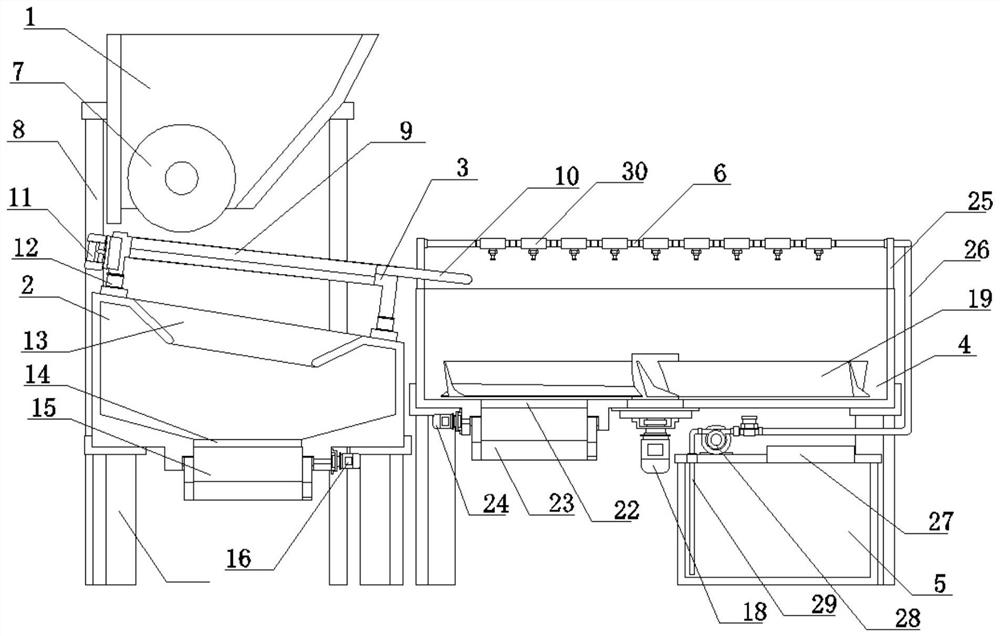

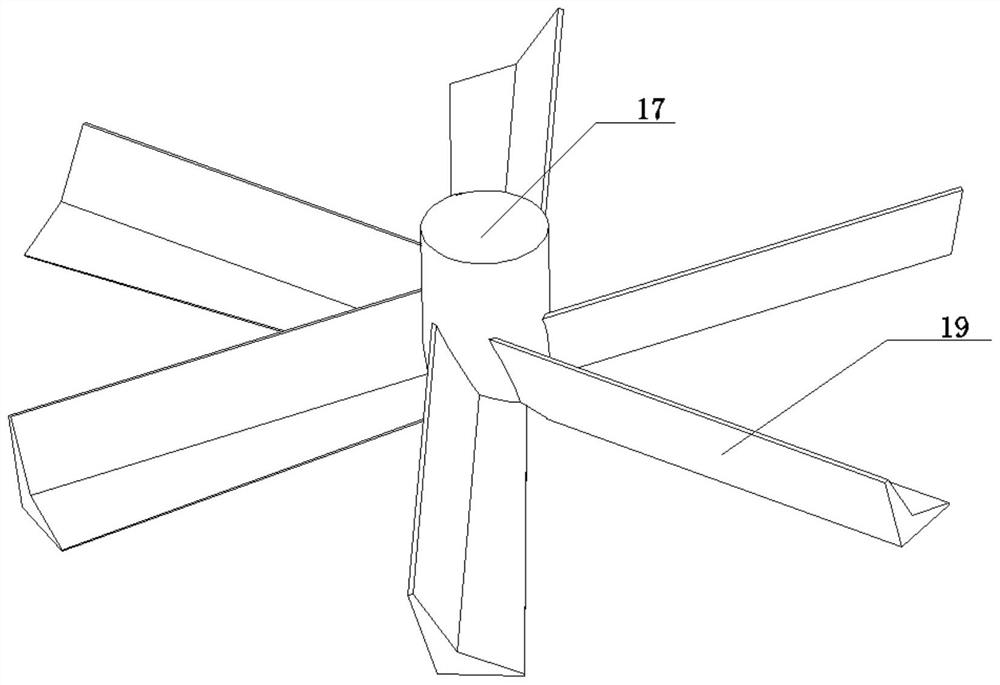

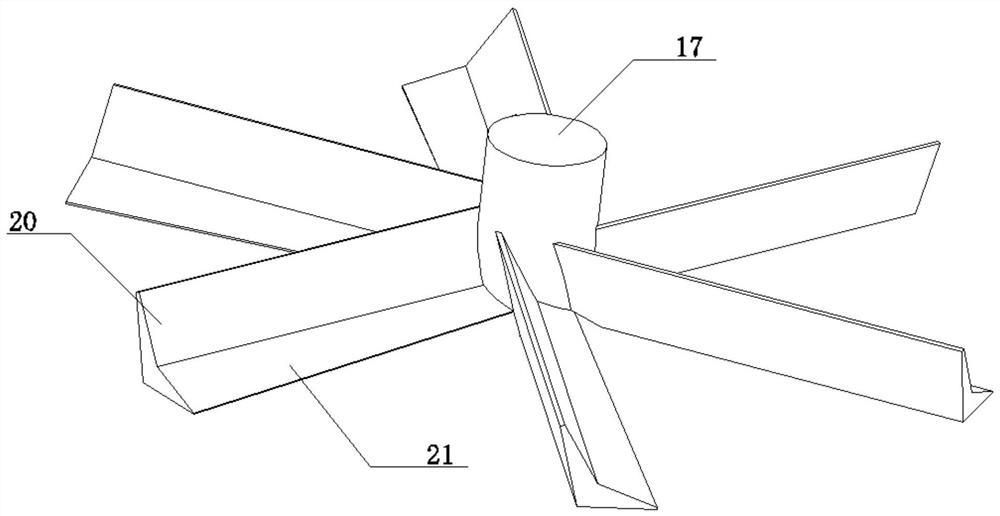

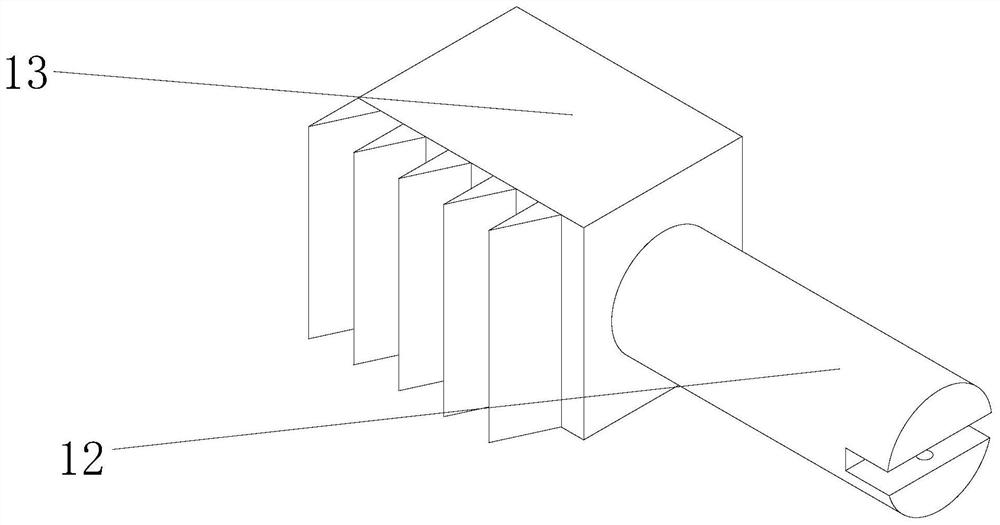

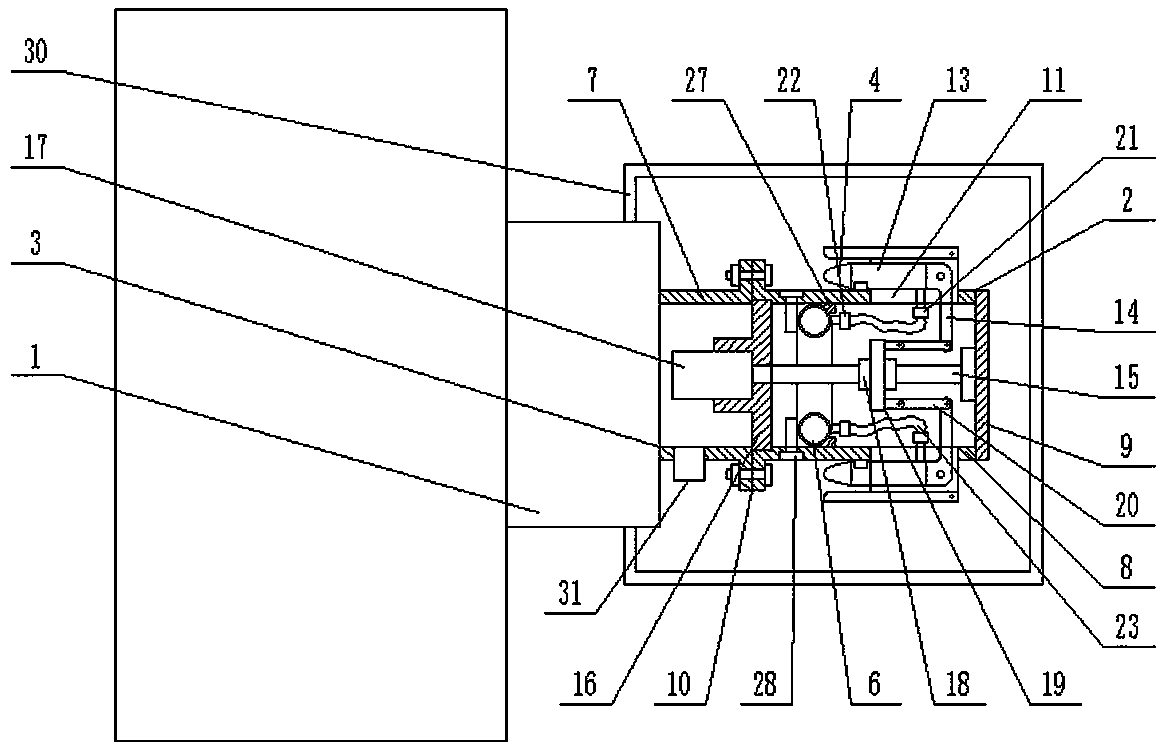

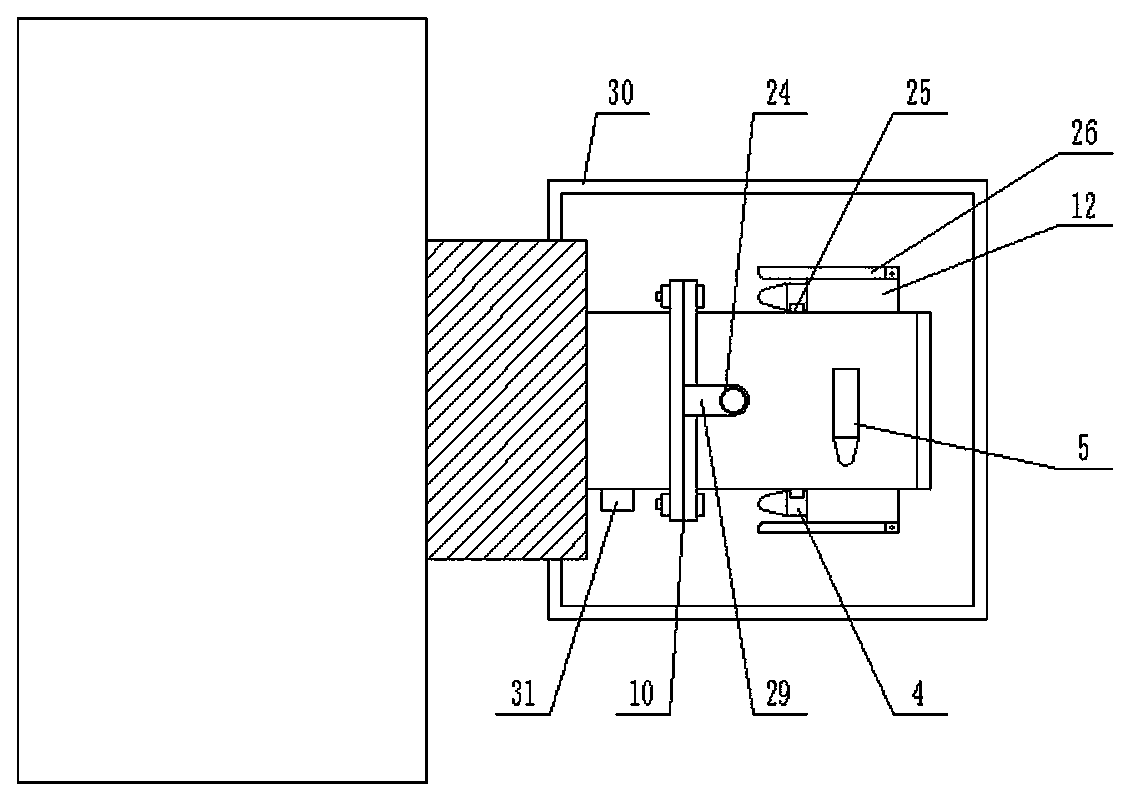

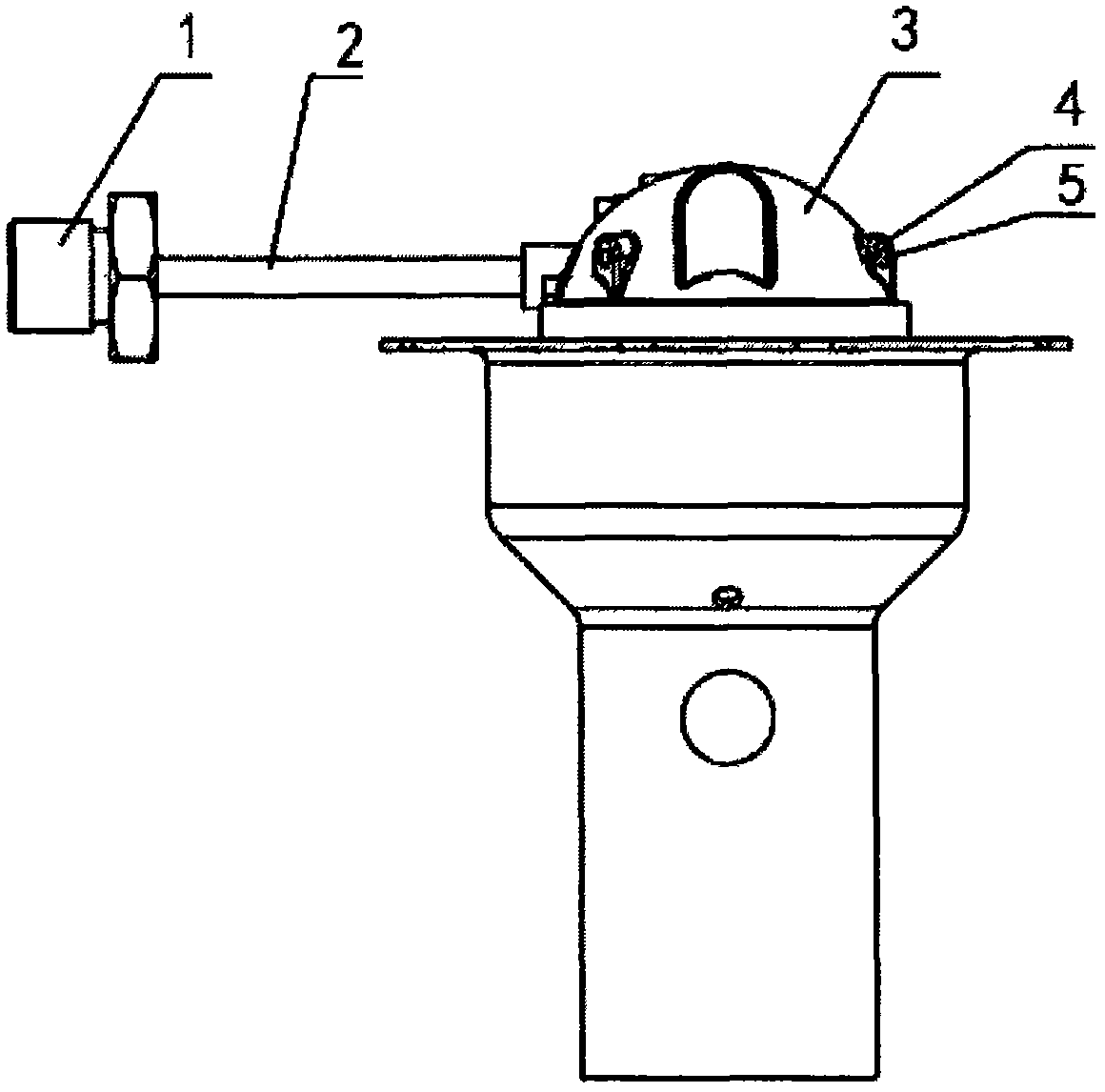

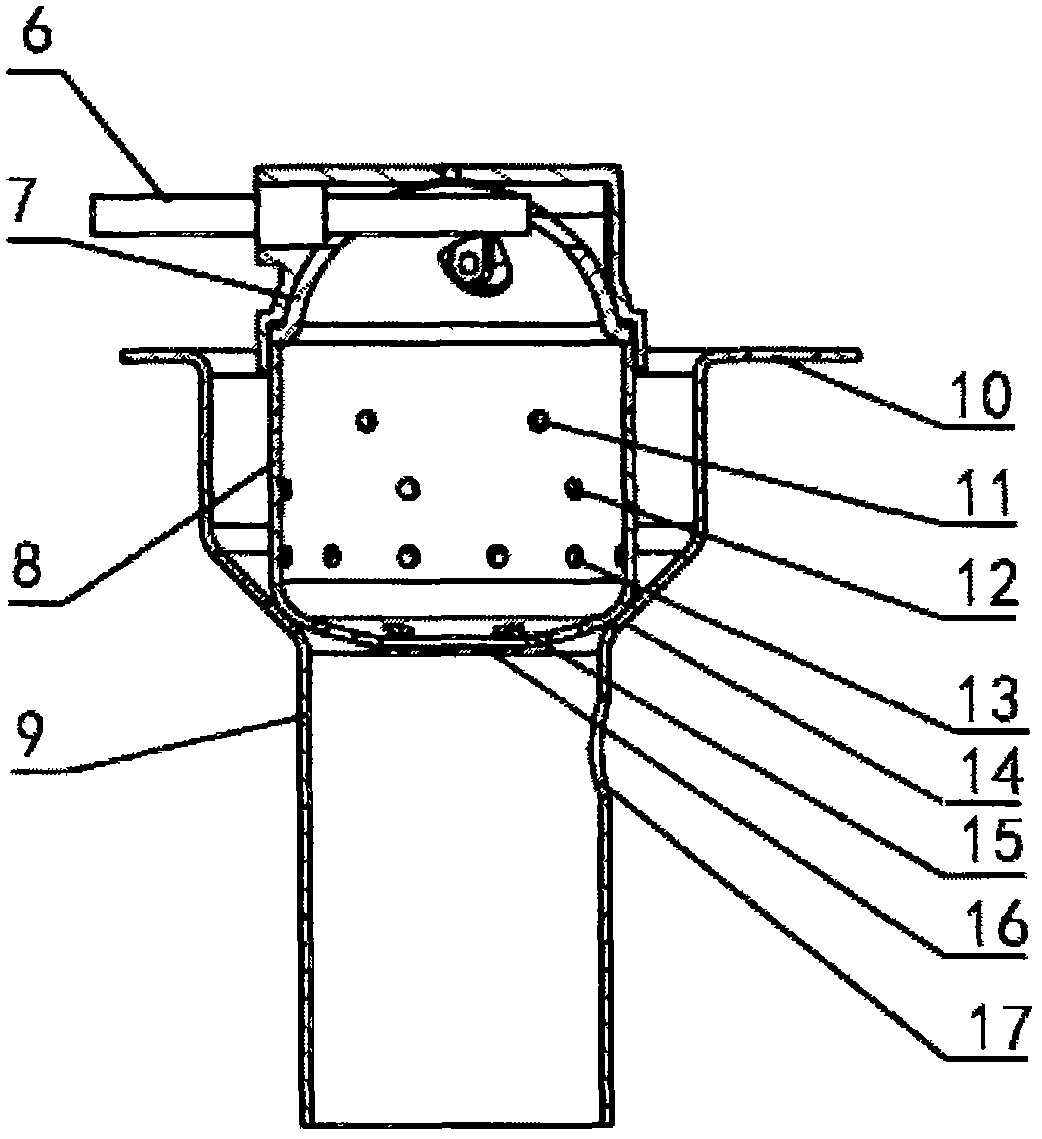

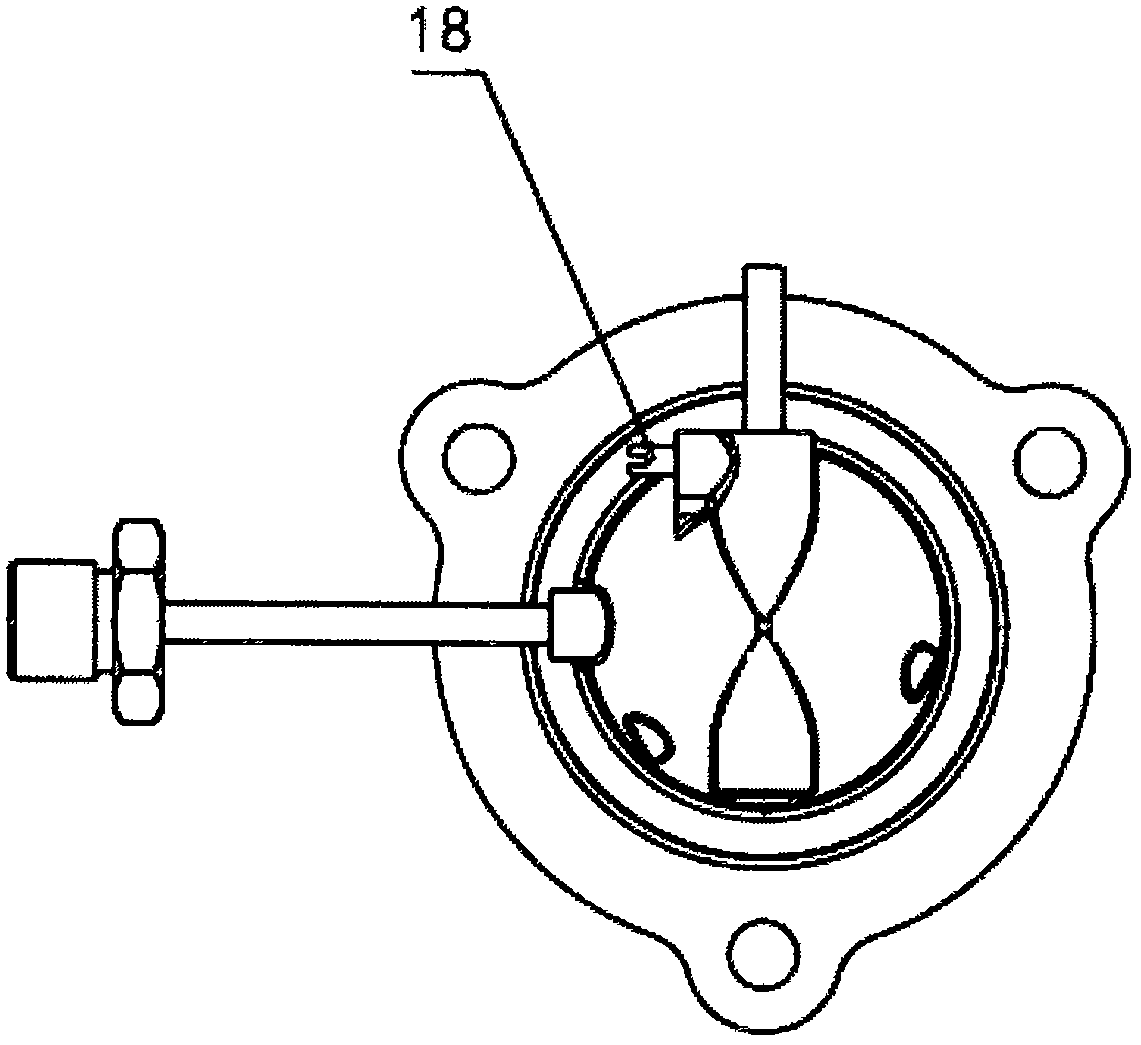

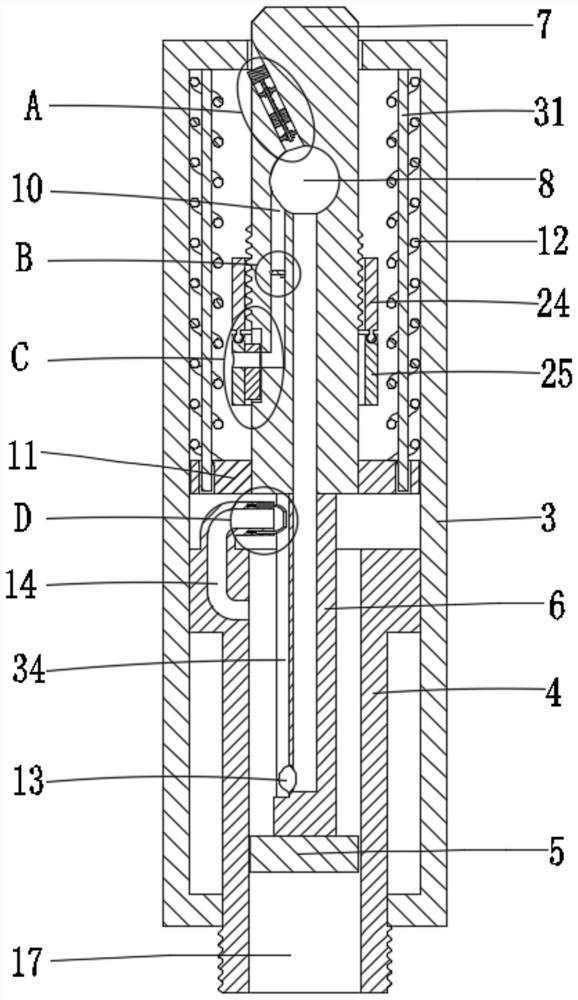

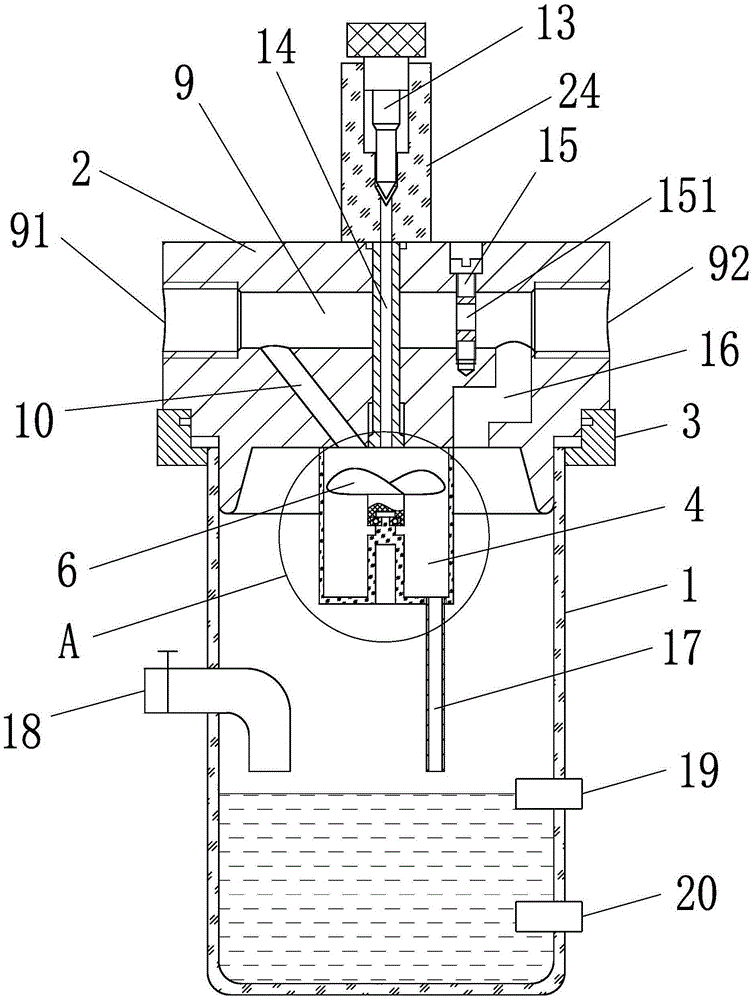

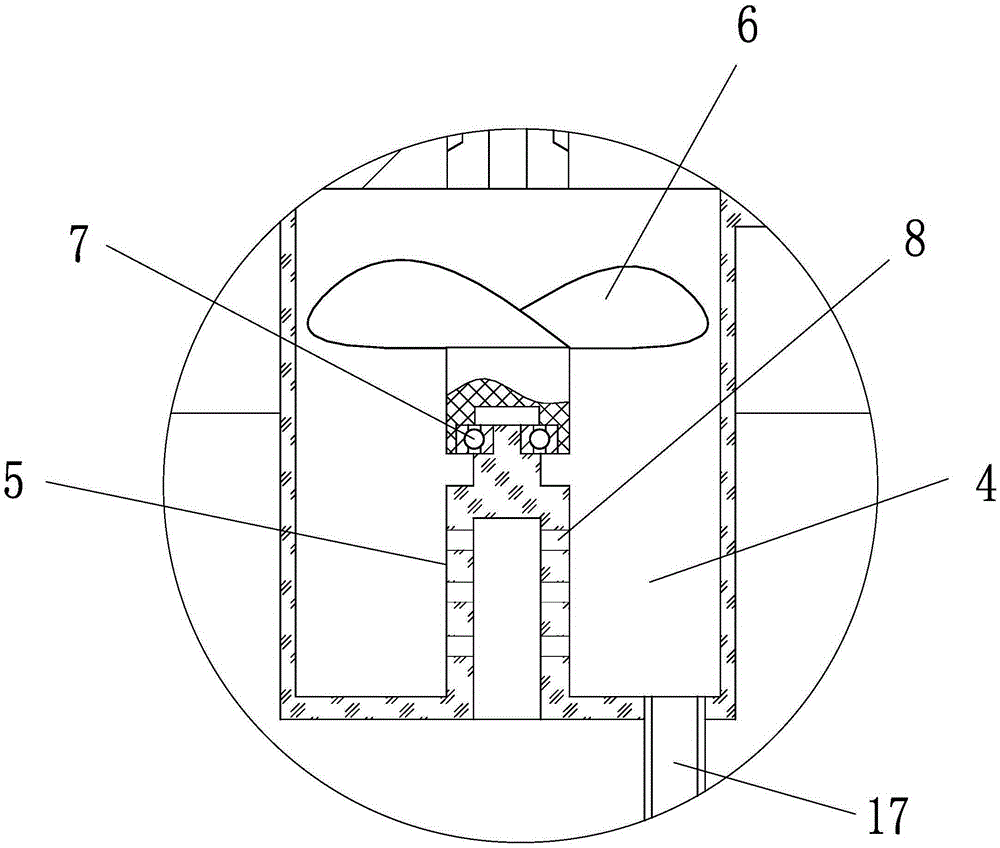

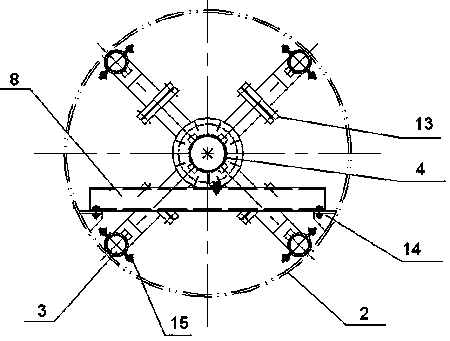

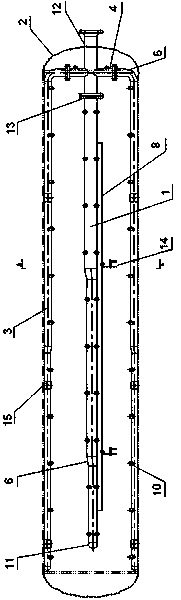

Equipment and method for preparing high-quality spherical welding powder

Provided are equipment and method for preparing high-quality spherical welding powder. The equipment comprises a hopper-shaped atomizing tank (1), a supply device arranged on one side of the top of the atomizing tank, a rotary ultrasonic atomizing device (2) arranged in the center of the top of the atomizing tank, a cooling airflow disc (8) arranged in the atomizing tank and located on the lower portion of the ultrasonic atomizing device, an infrared radiation heater (21), a fluidifying sorting airflow disc (2), an atomizing area cooling device, a fluidifying sorting device, an ultrasonic screening machine (24) or a circulation tank (25). The infrared radiation heater (21) and the fluidifying sorting airflow disc (2) are located below the cooling airflow disc, the atomizing area cooling device and the fluidifying sorting device are arranged outside the atomizing tank, and the ultrasonic screening machine (24) or the circulation tank (25) are arranged at the bottom of the atomizing tank. The equipment is high in atomization efficiency and control precision and easy to operate, the prepared spherical welding powder is good in sphericity degree, the surface of the powder is smooth andfree of defects, and the crystal structure meets the high-quality requirement of tin cream.

Owner:云南锡业锡材有限公司

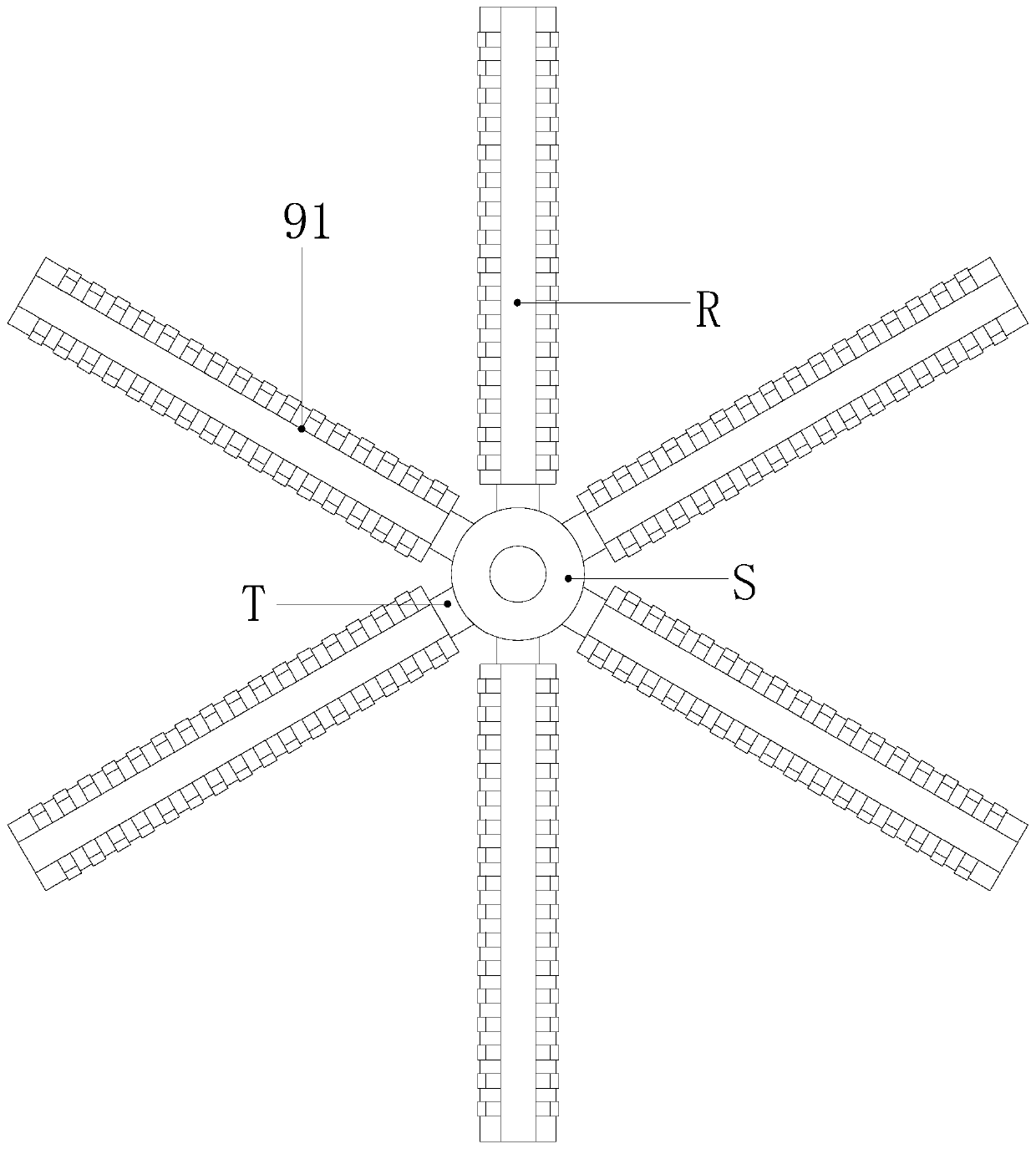

Large-area sterilization and purification system for hospital environment

InactiveCN113375262AIncrease the disinfection areaEasy to useMechanical apparatusLighting and heating apparatusEnvironmental engineeringMechanical engineering

The invention relates to the field of medical disinfection, in particular to a large-area sterilization and purification system for a hospital environment. The large-area sterilization and purification system comprises a rotary disinfection adding pipe, spray branch pipes, a disinfection atomizing nozzle, a driving fluted disc and a rotary driver, wherein the upper end of the rotary disinfection adding pipe is uniformly fixed and communicates with a plurality of spray branch pipes; the outer ends of the spray branch pipes are connected with the disinfection atomizing nozzle through sealing threads in a matched manner; the driving fluted disc is fixedly connected to the rotary disinfection adding pipe; and the driving fluted disc drives the rotary driver through gear engagement. The large-area sterilization and purification system has the beneficial effects that the large-area sterilization and purification system can be applied to disinfection of large-area spaces with large public spaces such as hospitals; large-area disinfection and sterilization are realized through the disinfection effect of rotary spray; air on the ground is disinfected and then blown upwards, so that the atomizing area is enlarged; the disinfection effect is improved; and the displacement is automatically controlled, so that the movable disinfection area is enlarged, and disinfection of the large space is realized.

Owner:李风椿

Dampening equipment capable of uniformly atomizing and spraying and used for flour processing

The invention relates to the technical field of flour processing, in particular to dampening equipment capable of uniformly atomizing and spraying and used for flour processing. The dampening equipment comprises an unloading assembly, a screening assembly, a dampening assembly and a stirring assembly, wherein the unloading assembly is positioned above the screening assembly; the screening assemblycomprises an impurity box and a screen rack; the screen rack is positioned below an unloading hole of an unloading hopper; the screen rack is arranged at the upper end of the impurity box; the stirring assembly comprises a stirring tank which is positioned below one side of the screen rack; a stirrer is arranged inside the stirring tank; the dampening assembly comprises a water tank and a spray tube; and the spray tube is positioned above the stirring tank. The stirring assembly can be arranged for turning and stacking wheat grains, a stirring motor drives stirring blades to rotate in the stirring tank through a rotary shaft, the stirring blades shovel in the wheat grains on the bottom through a lower wing plate, and an upper wing plate guides the wheat grains to the upper layer of a wheat stack; and the wheat grains are continuously turned over and stacked, so that uniform dampening of the wheat grains is guaranteed, and flour yield of wheat is higher.

Owner:梧州青弧农业有限公司

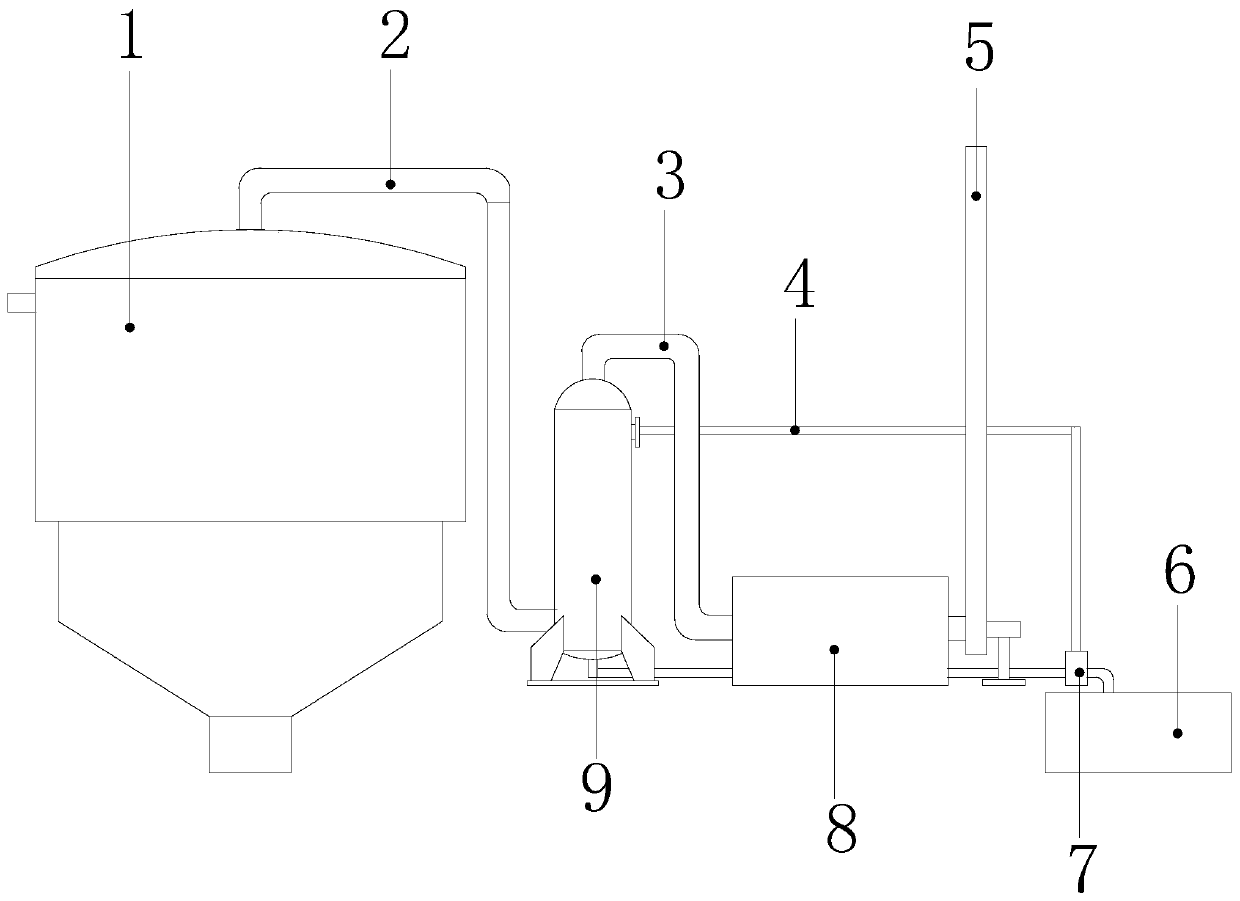

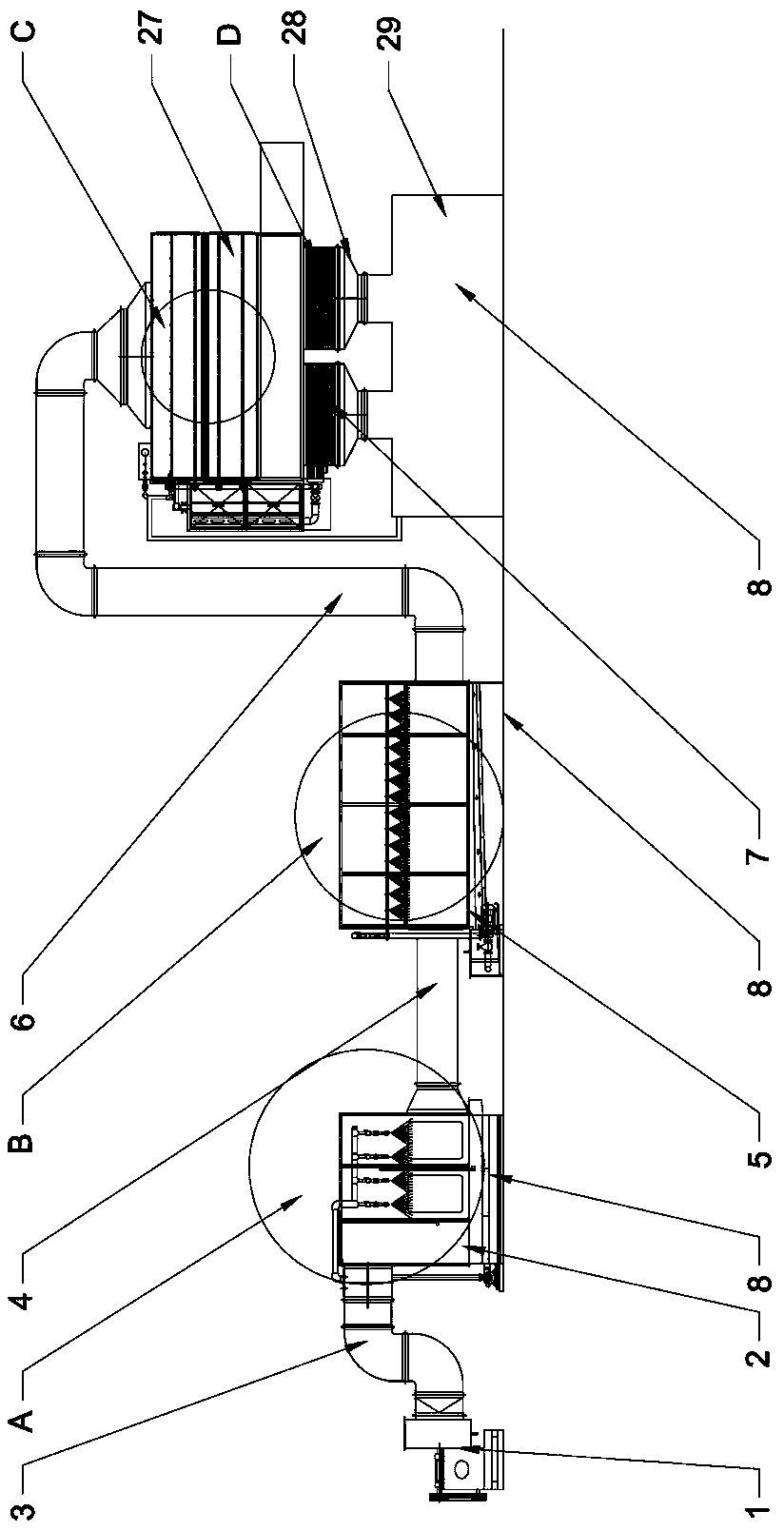

Waste incineration exhaust gas deacidification treatment system

InactiveCN111442285ALarge atomization areaComprehensive deacidification treatmentUsing liquid separation agentIncinerator apparatusParticulatesExhaust fumes

The invention discloses a waste incineration exhaust gas deacidification treatment system. The waste incineration exhaust gas deacidification treatment system structurally comprises waste incinerationequipment, an incineration exhaust gas pipeline, a smoke pipeline, a water supply pipe, a smoke discharge pipe, a circulating water tank, a high-pressure water pump, a smoke purifier and a deacidification water mist spraying tower, and the waste incineration equipment is connected with the deacidification water mist spraying tower through the incineration exhaust gas pipeline. Compared with the prior art, the waste incineration exhaust gas deacidification treatment system has the beneficial effects that through combination arrangement of parts such as a tilting nozzle, a top arc plate, an exterior plate, an inner supporting plate, a bottom arc plate and a separation arc plate, a novel spraying pipe is constituted, a function of preventing blocking of particulate matter is achieved, the particulate matter can be effectively prevented from making contact with a spray head, the spray area can further be enlarged, thus all exhaust gas can be subjected to spraying deacidification, and thusspraying deacidification is more comprehensive, higher in efficiency and better in effect; and meanwhile, the spray head can be prevented from being blocked by the particulate matter, thus the deacidified gas can be normal discharged, and the efficiency of waste incineration treatment is advantageously improved.

Owner:汪志辉

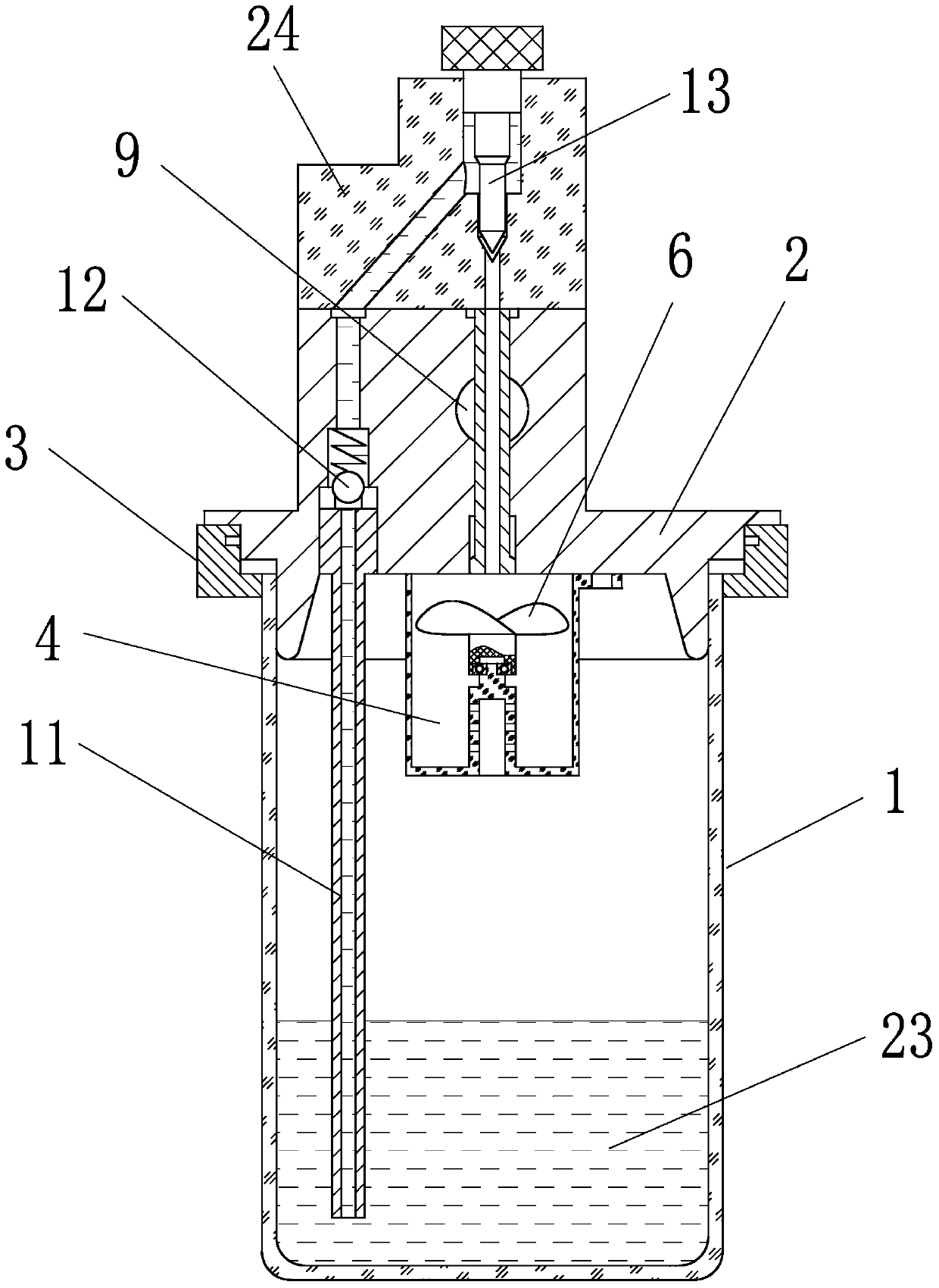

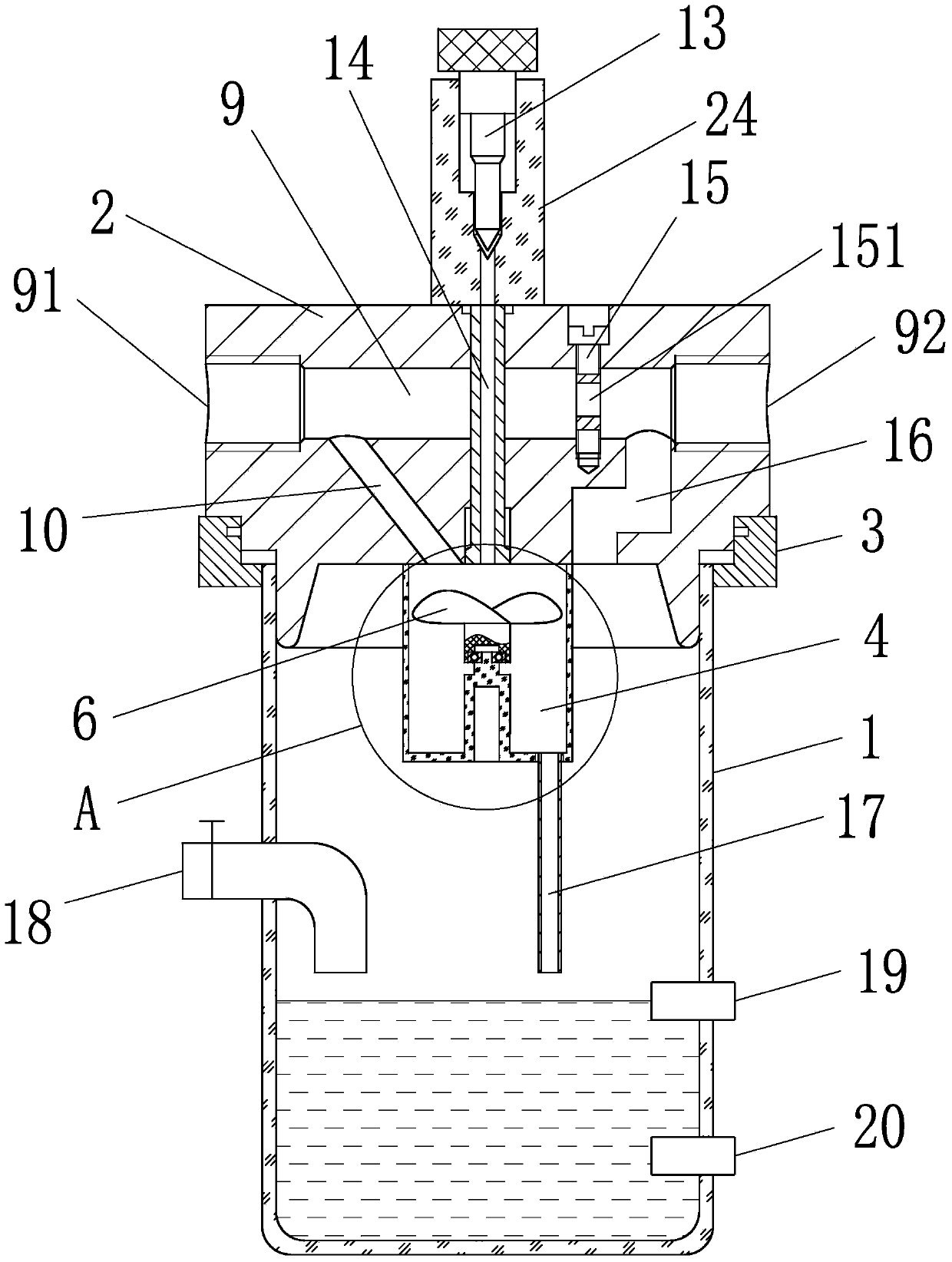

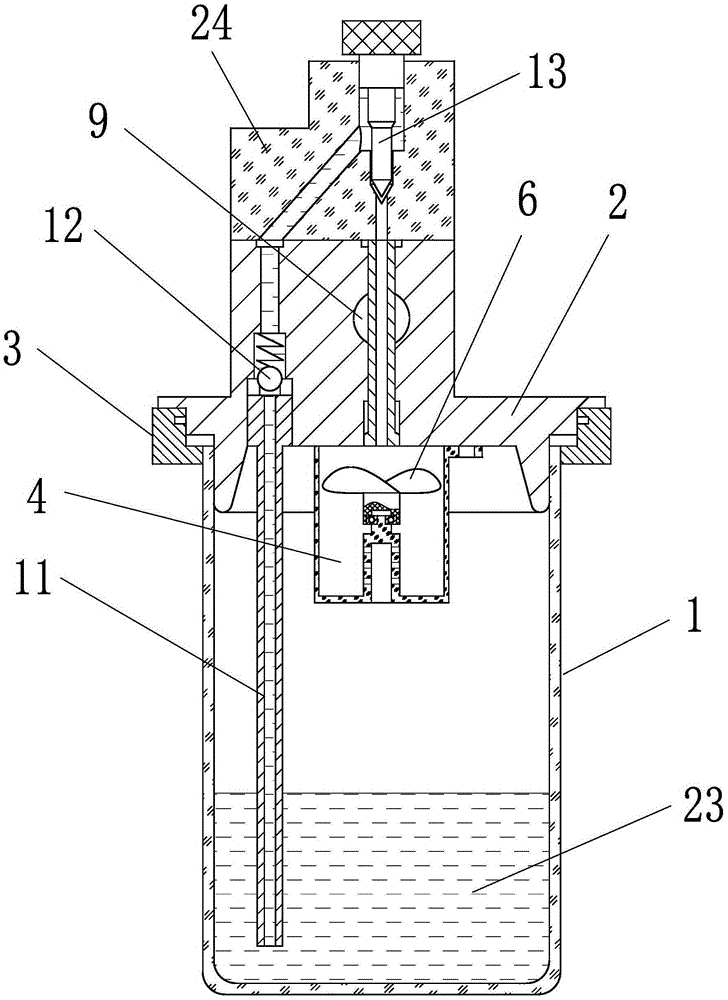

Gas-liquid two-phase mist generator and generation method thereof

The invention relates to a humidifier, and in particular to a gas-liquid two-phase mist generator and a generation method thereof. The gas-liquid mist generator comprises a liquid storage tank; the upper end of the liquid storage tank is sealed with a valve cover, and a gas guiding channel horizontally penetrates through the valve cover; the lower end surface of the valve cover is provided with a first atomizing chamber and an oil suction pipe inserted into the liquid storage tank; an input end of the gas guiding channel is communicated with the first atomizing chamber through an inclined hole; the chamber of the liquid storage tank is communicated with an output end of the gas guiding channel; scattering wheels are horizontally arranged in the first atomizing chamber; the top of the valve cover is provided with a regulating needle valve; the oil suction pipe is communicated with an inlet of the regulating needle valve; an outlet of the regulating needle valve vertically corresponds to the first atomizing chamber; and the first atomizing chamber through an outlet of the first atomizing chamber is communicated with the liquid storage tank. The invention can effectively mix gas and liquid and realize two times of mixing, and has the beneficial effects of good atomizing distribution uniformity, simple structure and no blocking.

Owner:HUZHOU TEACHERS COLLEGE

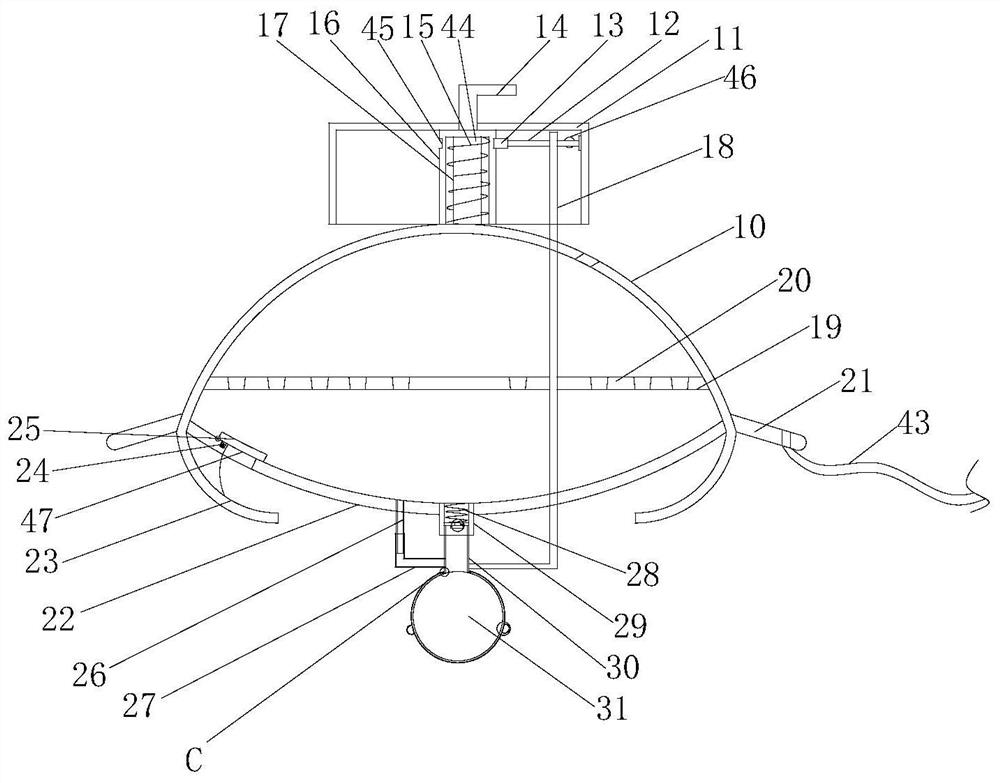

Silver carp and bighead carp trapping device for reservoir farmhouses

PendingCN112219800AAccurate fishingSolve the problem of heavy workload of repeated net castingFishing netsTrappingEngineering

The invention relates to the technical field of animal husbandry fishing equipment, and discloses a silver carp and bighead carp trapping device for reservoir farmhouses. The device comprises a firstshell, a floating block is fixedly connected to the side wall of the first shell, the cross section of the first shell is hemispherical, and a fishing device is arranged on the top face of the first shell and comprises a second shell, a rotating handle, a first spring, a round rod and a first vertical rod. When silver carp and bighead carp suck food, a second pull rod is driven to move downwards,the second pull rod is separated from a first pull rod, the round rod enables a fishing net wound on the side wall of the round rod to be thrown out in the mode, the fishing net slides into water fromthe side wall of the first shell, the silver carp and bighead carp below the first shell are netted in the fishing net, and the silver carp and bighead carp can be fished conveniently; and the rotating handle is rotated on the shore to enable the first spring to store power, only when the silver carp and bighead carp suck the food, the second pull rod is pulled to be opened to replace blind throwing of the fishing net by people ashore, no silver carp or bighead carp shoal exists below the place where the fishing net is not completely opened and thrown, the net vacancy rate is reduced, and thecatching efficiency and catching accuracy are improved.

Owner:修殿斌

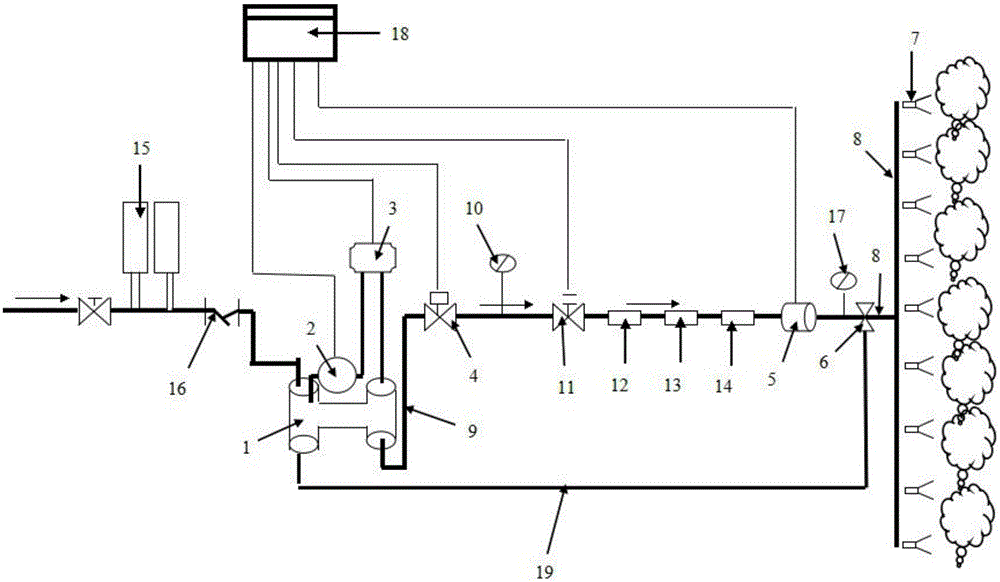

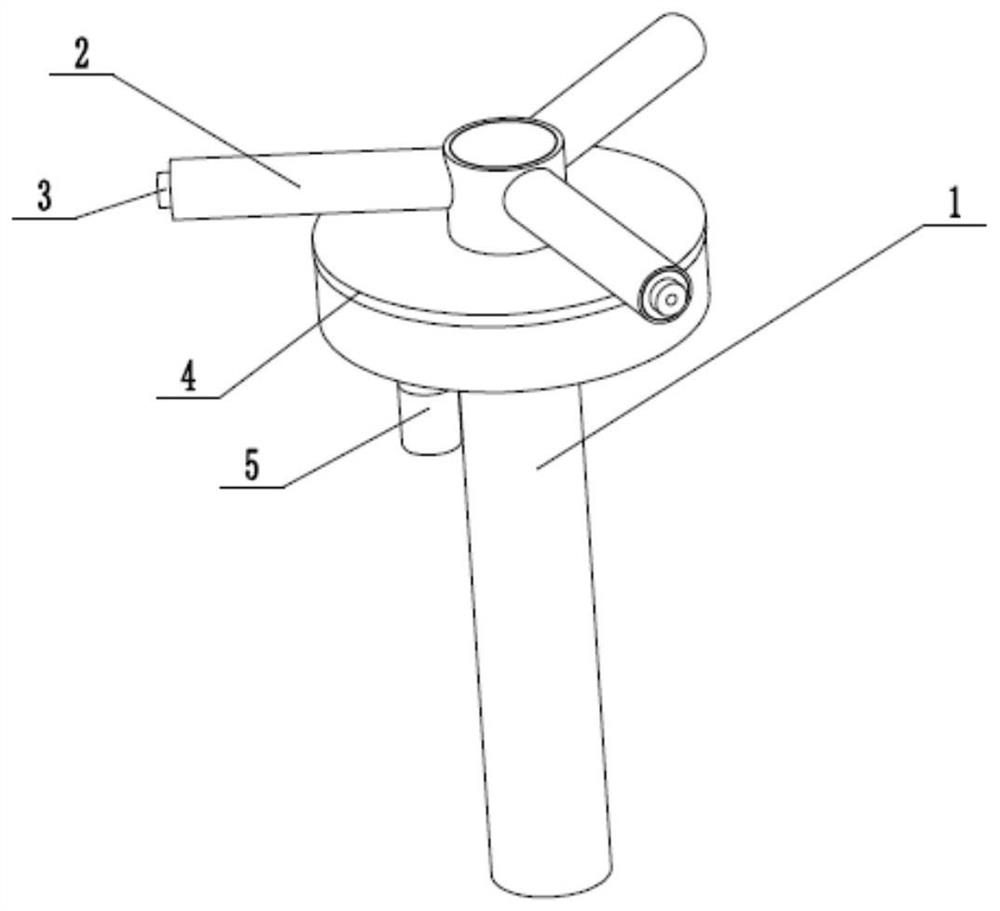

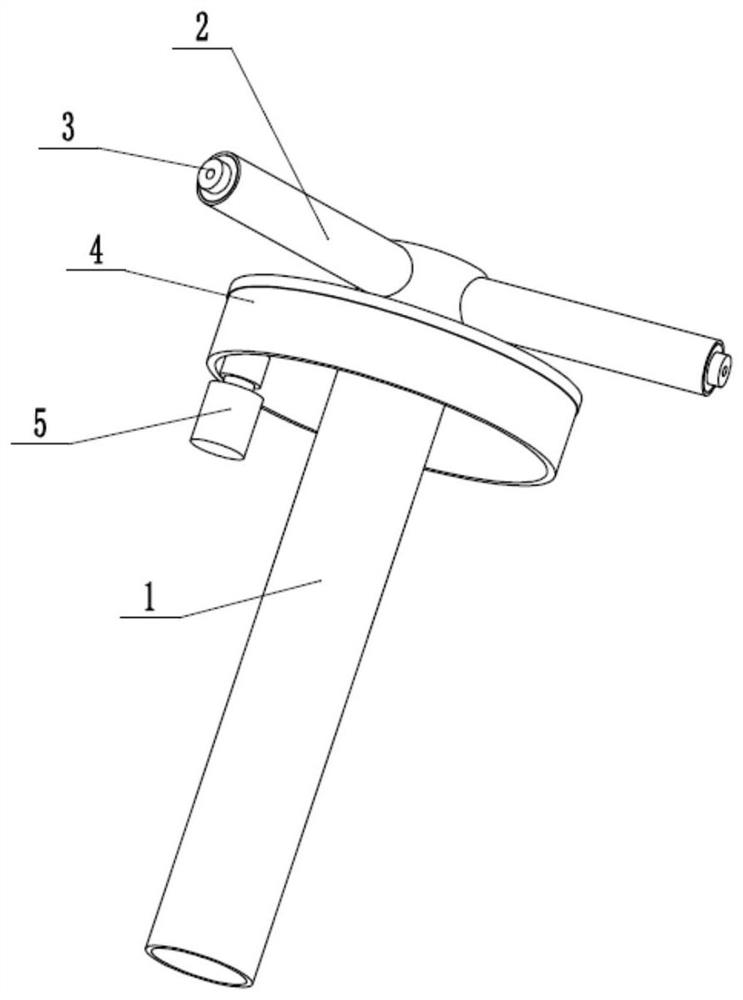

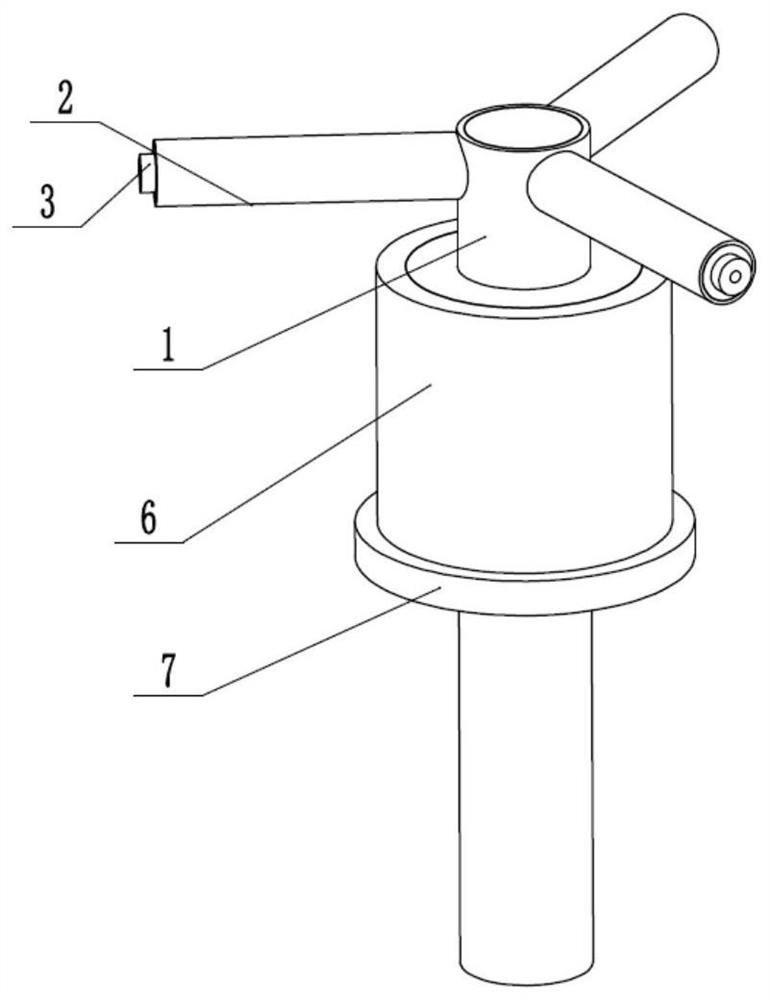

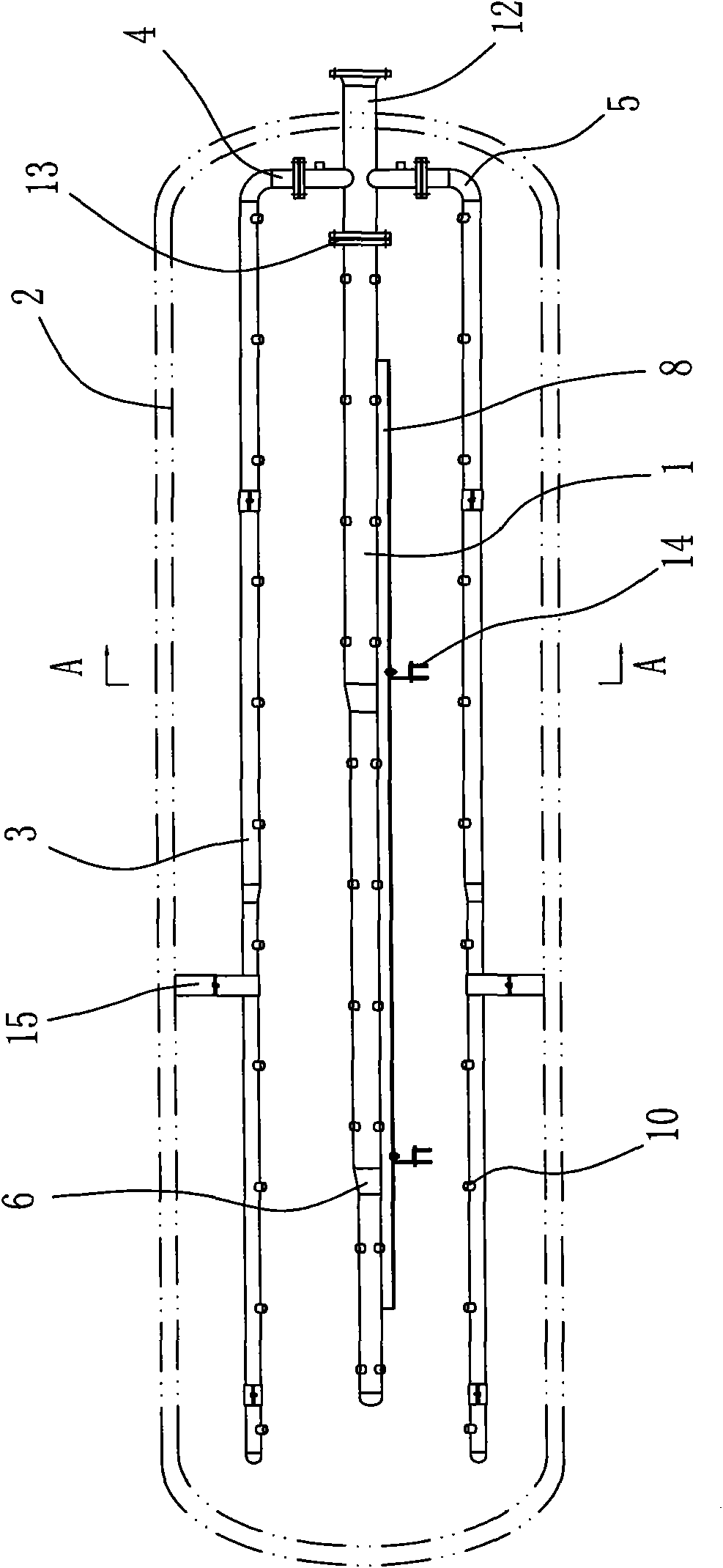

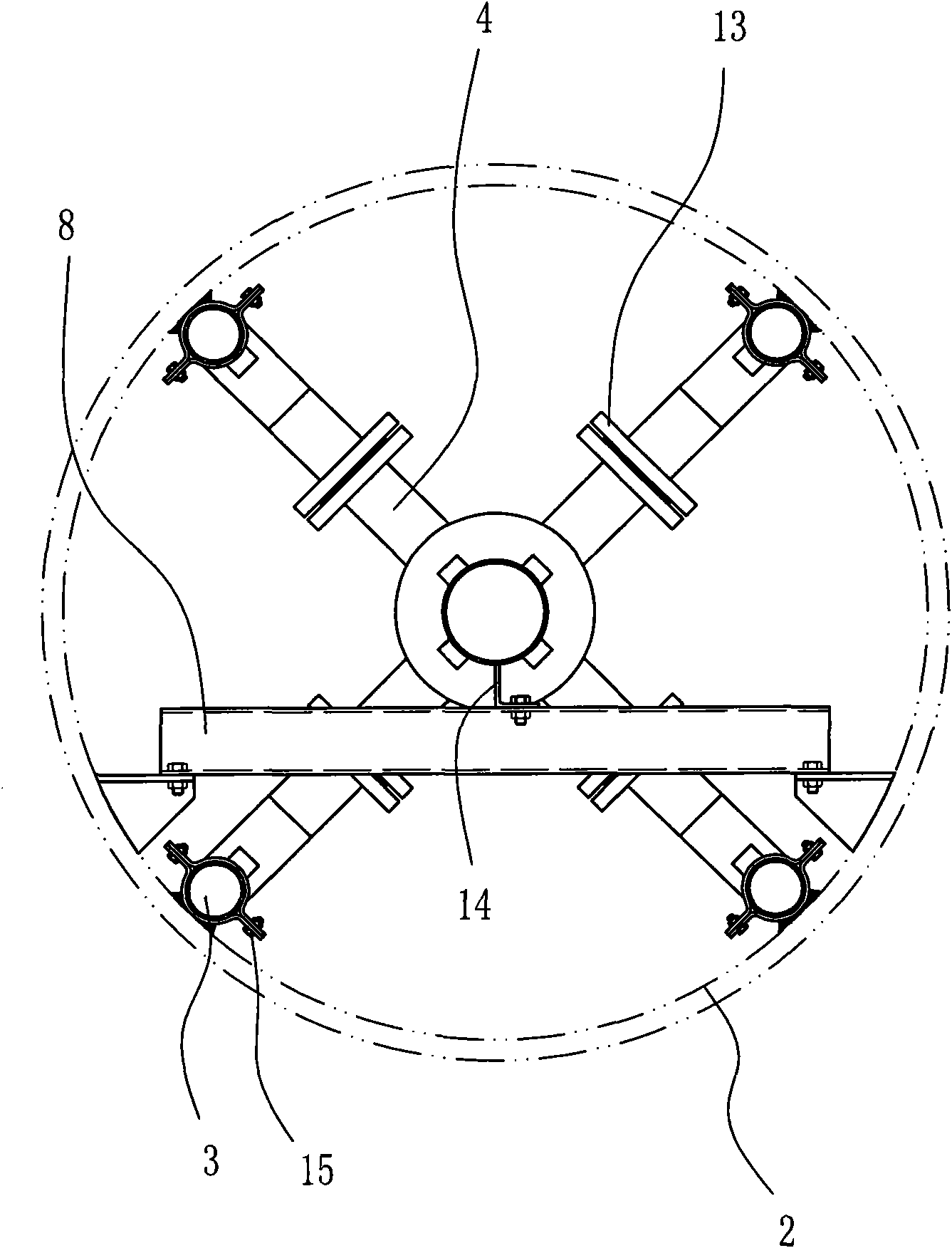

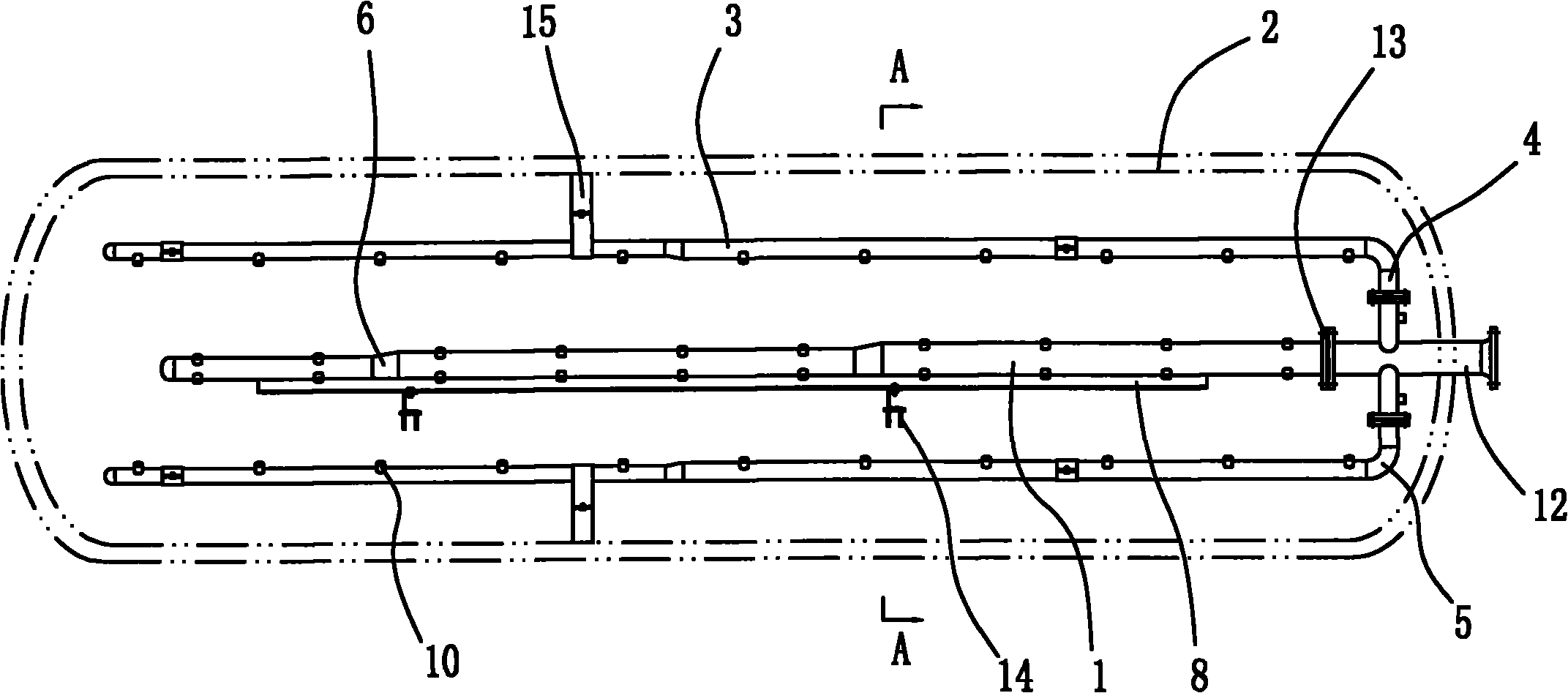

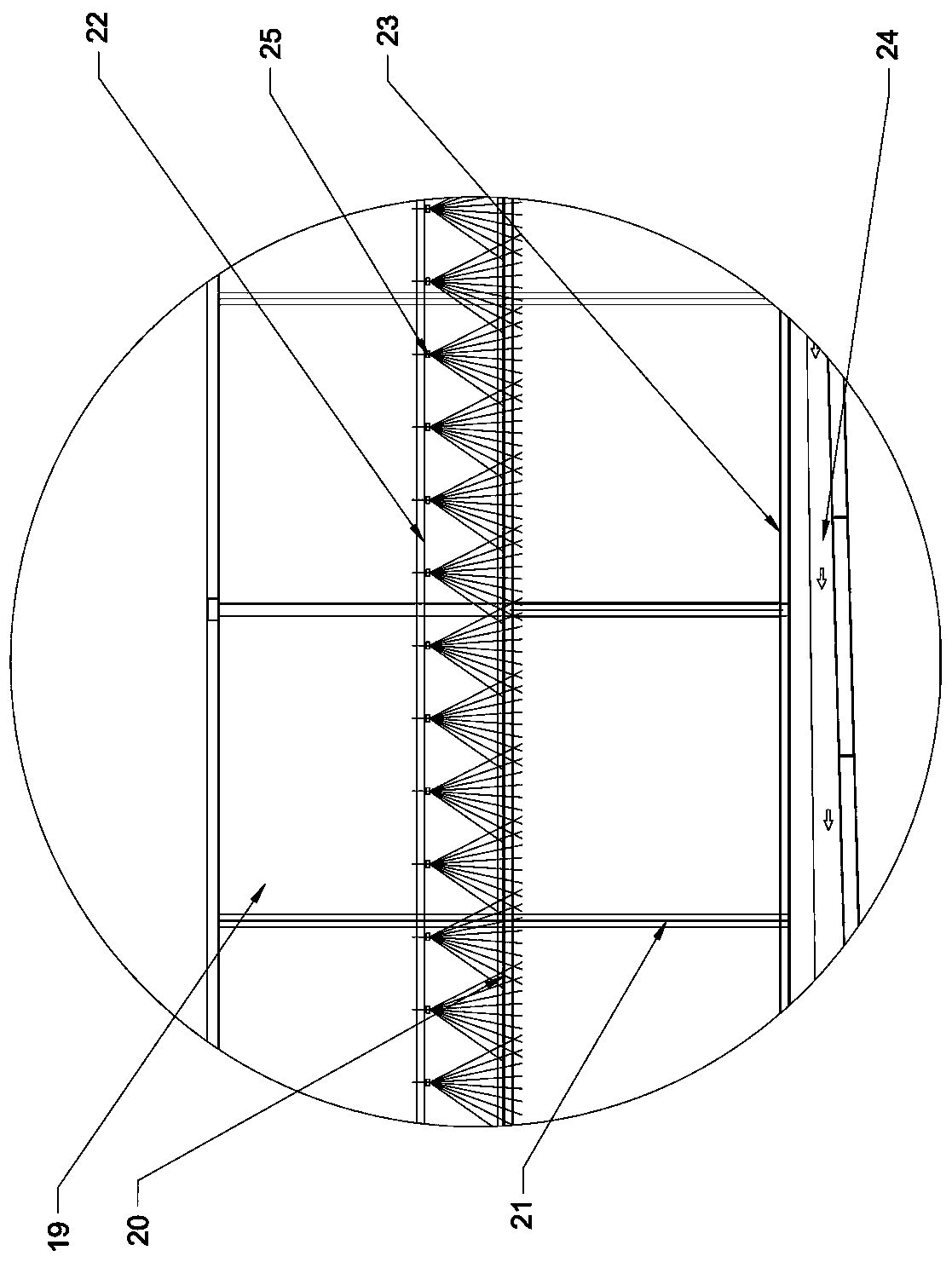

Preparation method of distributor of reaction tank nozzle

InactiveCN101890327AReasonable distributionIncrease the atomization areaChemical/physical/physico-chemical nozzle-type rreactorsEngineeringNozzle

The invention provides a preparation method of a distributor of reaction tank nozzles The distributor contains the following parts: a charge hole, an adapter, an elbow and a plurality of liquid pipelines, wherein one liquid pipeline is a middle pipeline, the middle pipeline and the charge hole are arranged on the same straight line; the other liquid pipelines are peripheral pipelines; and the liquid pipelines are communicated with the charge hole through the adapter. The preparation method comprises the following steps: connecting 5-13 liquid pipelines with the charge hole; installing a plurality of sockets facing to different direction on each liquid pipeline, arranging the sockets in a staggered manner; and installing the nozzles on the sockets. Experiment and use result show that the distributor of reaction tank nozzles prepared by the method of the invention has large atomizing area and atomizing volume, and can better increase and improve the transparency, color and luster of the product and the reaction conversion rate.

Owner:朱荣

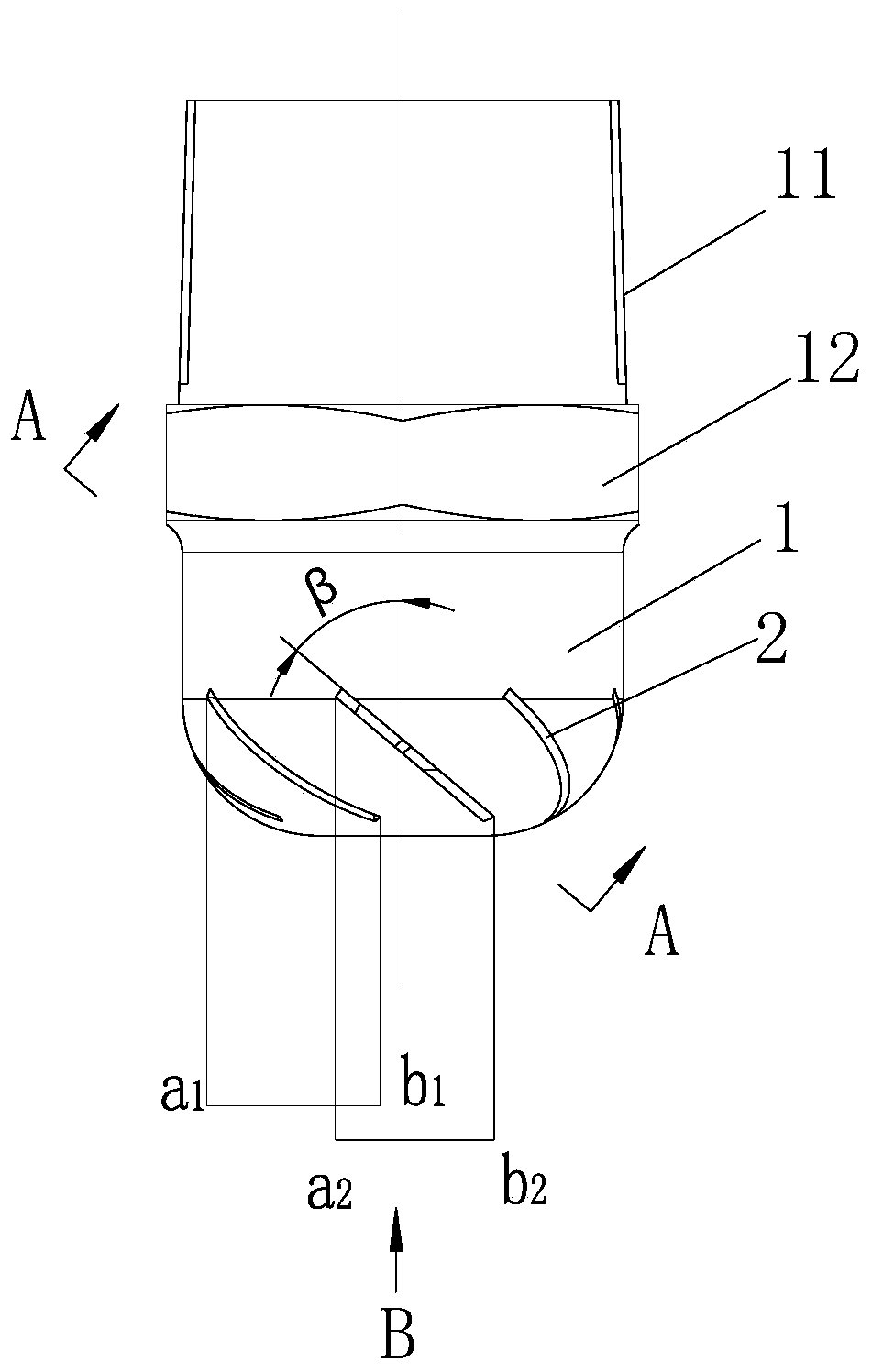

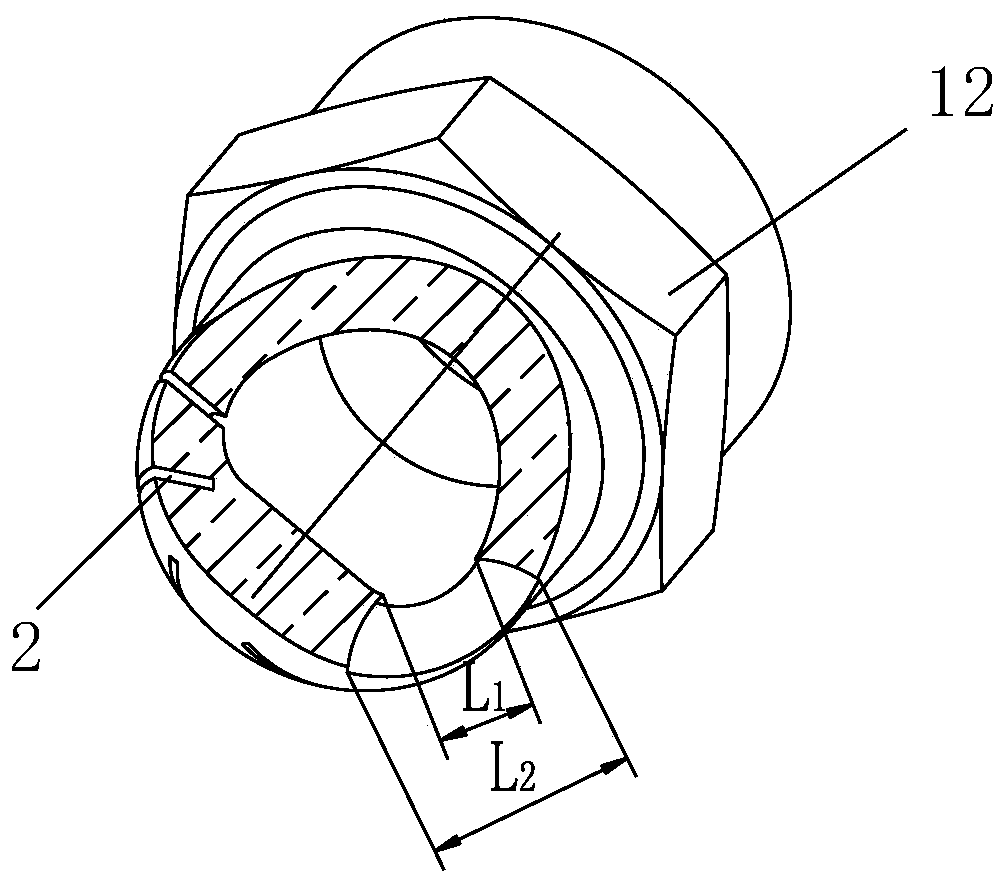

Nozzle plate and atomizing module using the same

ActiveUS8870100B2Improve stabilityLarge atomization areaDust removalMovable spraying apparatusCircular discStress concentration

A nozzle plate and an atomizing module using the nozzle plate are disclosed. The atomizing module is installed at a cavity and includes a piezoelectric circular plate, a braking circular plate and a nozzle plate. The braking circular plate is installed on a side of the piezoelectric circular plate. The nozzle plate is a circular disc clamped between the piezoelectric circular plate and the braking circular plate, and the nozzle plate includes firing holes and first protrusions. Each first protrusion is non-circular and protruded in a direction towards the piezoelectric circular plate or the braking circular plate to form a multi-curved surface structure radially or circularly arranged into a specific geometric pattern. The nozzle plate can increase the atomizing area, atomizing quantity and liquid-gas exchange rate to prevent excessive stresses from concentrating at the center of the nozzle plate or vibrations from cracking or breaking the nozzle plate.

Owner:MICRO BASE TECH CORP

Self-dedusting intelligent coal mining machine

ActiveCN109184687AImprove dust removal effectAvoid smashingSlitting machinesAutomatic controlSynchronous control

The invention relates to a self-dedusting intelligent coal mining machine, and belongs to the technical field of coal mining machines. The self-dedusting intelligent coal mining machine specifically comprises a rocker arm of the coal mining machine and a spraying device which is fixed on the rocker arm. The spraying device comprises a mounting tube, movable atomizing nozzles which are mounted around the mounting tube and can freely adjust the angle, and a fixed atomizing nozzle which is fixed on the mounting tube. The movable atomizing nozzles and the fixed atomizing nozzle are connected to awater distribution pipe, which is connected to a water supply pipe of the coal mining machine. The movable atomizing nozzles are used for synchronous control with the coal mining machine; the movableatomizing nozzles are used for spraying in the direction of a coal cutting roller; and the fixed atomizing nozzle is used for spraying on a scraper conveyer. The self-dedusting intelligent coal miningmachine of the invention is simple to operation and convenient to control. By the automatic control, the dedusting effect is better.

Owner:田波

Slag exhaust gas circulating filtration device

The invention relates to a slag exhaust gas circulating filtration device in the field of environmental protection. The slag exhaust gas circulating filtration device comprises an auxiliary gas inletsystem, the tail end of the auxiliary gas inlet system is fittingly provided with a primary spraying device, and the auxiliary gas inlet system is connected with the same through a first pipeline. A secondary spraying device is fittingly arranged beside the primary spraying device, the primary spraying device and the second spraying device are connected through a second pipeline, a third sprayingdevice is fittingly arranged beside the second spraying device, and the secondary spraying device and the third spraying device are connected through a third pipeline. The primary spraying device, thesecond spraying device and the third spraying device are fittingly provided with sewage collection and treatment systems respectively. By filtration through the multiple spraying devices, multistageharmless treatment of blast-furnace slag exhaust gas is realized, generated wastewater is repeatedly filtered through the sewage collection systems, and cost reduction is realized.

Owner:JIANGDU SHUNDA MACHINERY

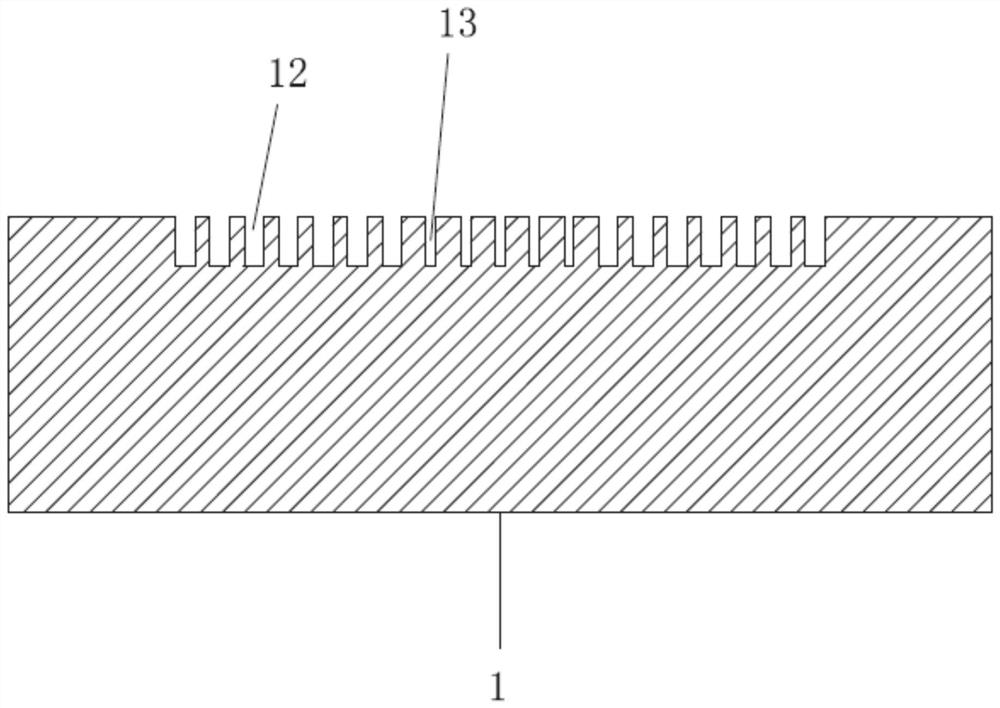

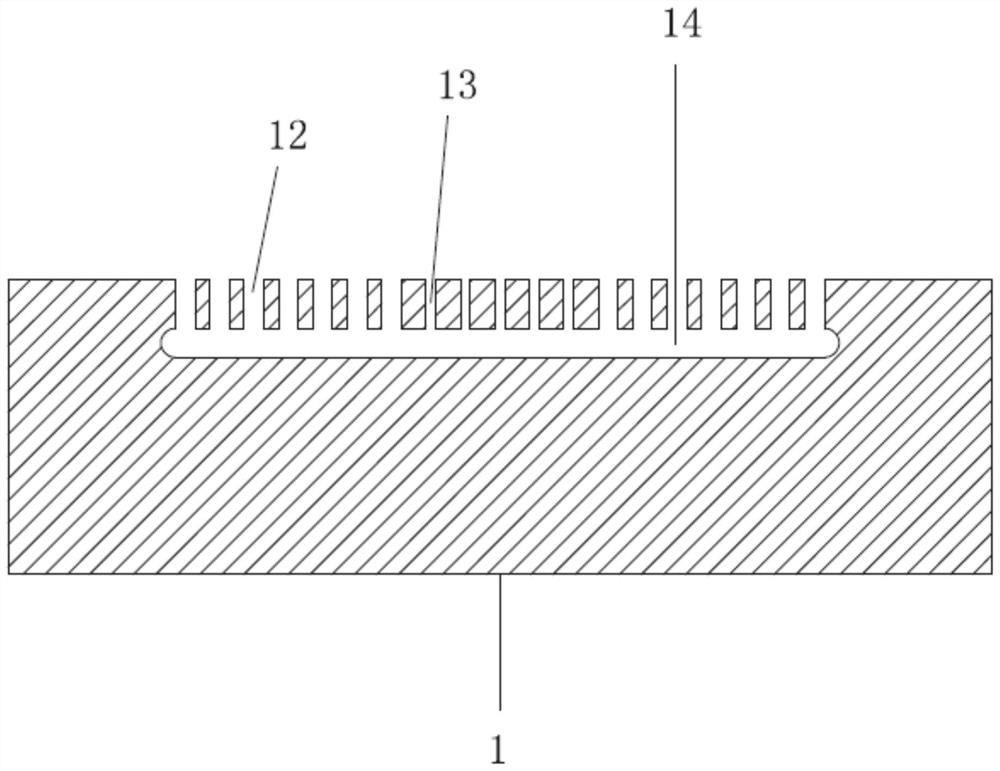

MEMS silicon-based pore cavity atomizing core and manufacturing method thereof

PendingCN114158783AEffective lockingGood oil locking performanceTobaccoContact electrodeSilicon based

The invention discloses an MEMS silicon-based pore cavity atomization core which comprises a silicon substrate, a filling layer and a heating wire, a plurality of micropores are formed in the surface of one side of the silicon substrate, at least one liquid inlet hole is formed in the surface of the opposite side of the silicon substrate, the micropores comprise atomization holes and release holes, a liquid storage cavity is formed in the silicon substrate, the release holes are communicated with the liquid storage cavity, and the liquid storage cavity is communicated with the filling layer. The atomization hole is communicated to the liquid storage cavity, the liquid inlet hole is communicated to the liquid storage cavity, the filling layer is manufactured on the surface of one side of the micropore in the silicon substrate and seals the top of the release hole, the heating wire is manufactured on the surface of the filling layer, and a contact electrode is arranged at the end of the heating wire. The invention further discloses a manufacturing method of the MEMS silicon-based hole cavity atomizing core. Compared with the prior art, the atomization core is good in oil locking performance, high in machining yield, large in atomization heating area and high in temperature uniformity during heating, and materials are harmless to human bodies.

Owner:美满芯盛(杭州)微电子有限公司

Spray head suitable for perfluorohexanone

PendingCN110478835ALarge atomization areaNo dead corner coverageFire rescueEngineeringMechanical engineering

Owner:HUNAN PANLONG SAFETY SYST

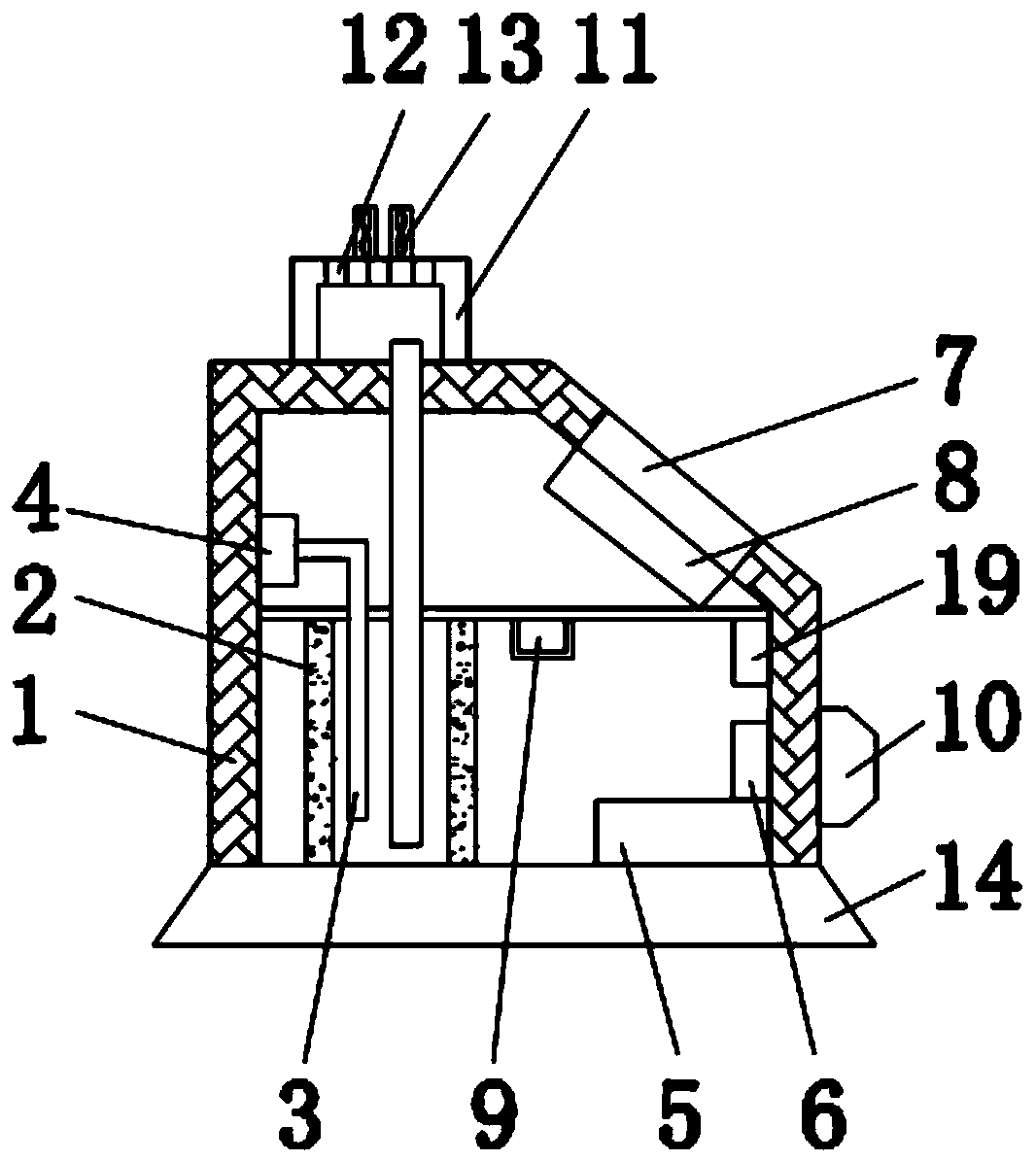

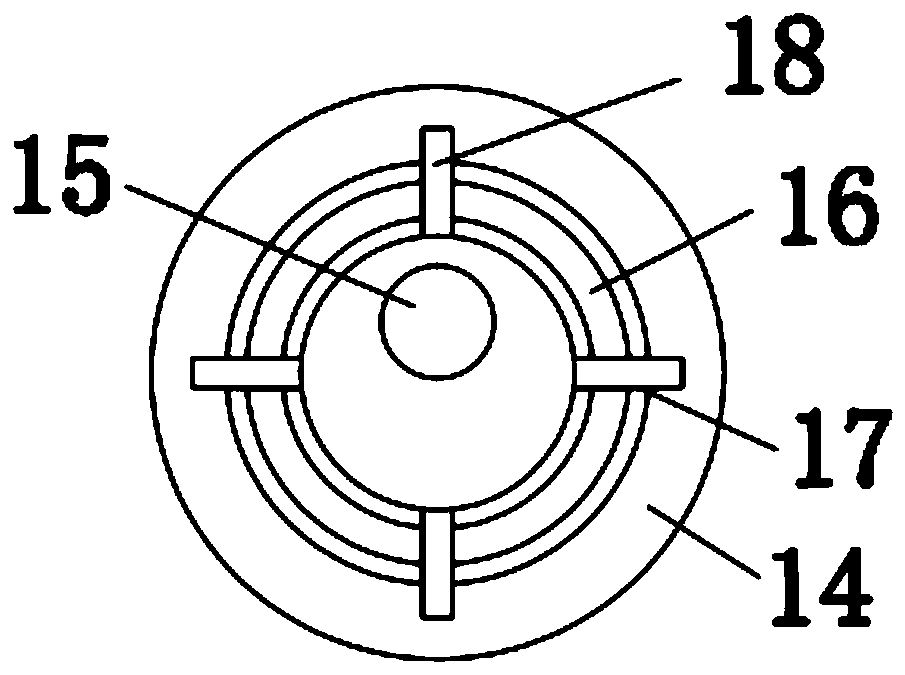

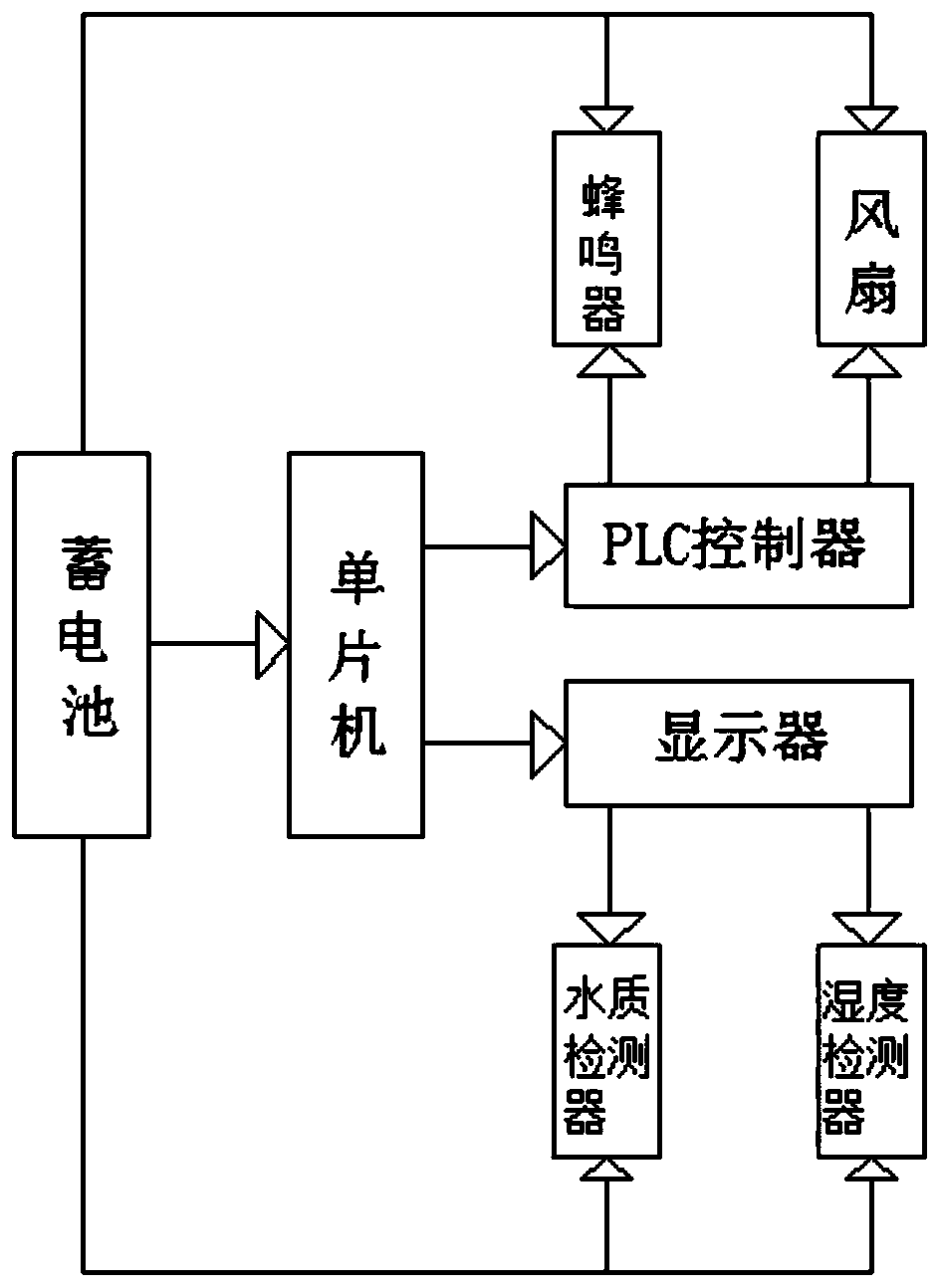

Intelligent humidifier and control system thereof

InactiveCN110822607AReduce usageEasy to limitMechanical apparatusSpace heating and ventilation safety systemsWater storageWater storage tank

The invention discloses an intelligent humidifier and a control system thereof. The intelligent humidifier and the control system comprise a humidifier body, wherein a water storage tank is arranged inside the humidifier body; a water quality detection probe is arranged inside the water storage tank and is electrically connected with a water quality detector; the water quality detector is fixedlyconnected with the inner wall of the humidifier body through a bolt; the interior of the humidifier body is fixedly connected with a storage battery through a bolt; the storage battery is electricallyconnected with a PLC; the outer surface of the humidifier body is embedded with a display; the display is electrically connected with a single chip microcomputer; the single chip microcomputer is electrically connected with a water level detection module; the water level detection module is electrically connected with the PLC; and the upper surface of the humidifier body is fixedly connected witha rectangular bin through a bolt. According to the intelligent humidifier and the control system, the water quality can be conveniently detected, the use of the water with bacteria is avoided, the power-off protection of the humidifier can be conveniently realized, the service life is prolonged, the atomization area can be increased, the purchase quantity of the humidifiers is reduced, and the cost is reduced.

Owner:ANHUI TAIDE ELECTRONICS TECH

Efficient dry fog dust suppression device

PendingCN114733290AEasy to adjustLarge atomization areaUsing liquid separation agentSustainable biological treatmentAir filtrationAir filter

The invention discloses an efficient dry fog dust suppression device which comprises an air pipe and a water pipe which are connected in parallel, and the outlet ends of the air pipe and the water pipe are connected with a mixing pipe; the air pipe is connected with an air filtering piece in series, and the water pipe is connected with a pressure reducing piece, a water quality filtering piece and a flow adjusting piece in series. The water quality filtering piece is connected with a sewage draining exit, and the sewage draining exit is connected with a sewage draining ball valve in series. The dust suppression device is high in practicability and functionality and can be widely applied to the technical field of dust suppression devices.

Owner:山东兴中电器有限公司

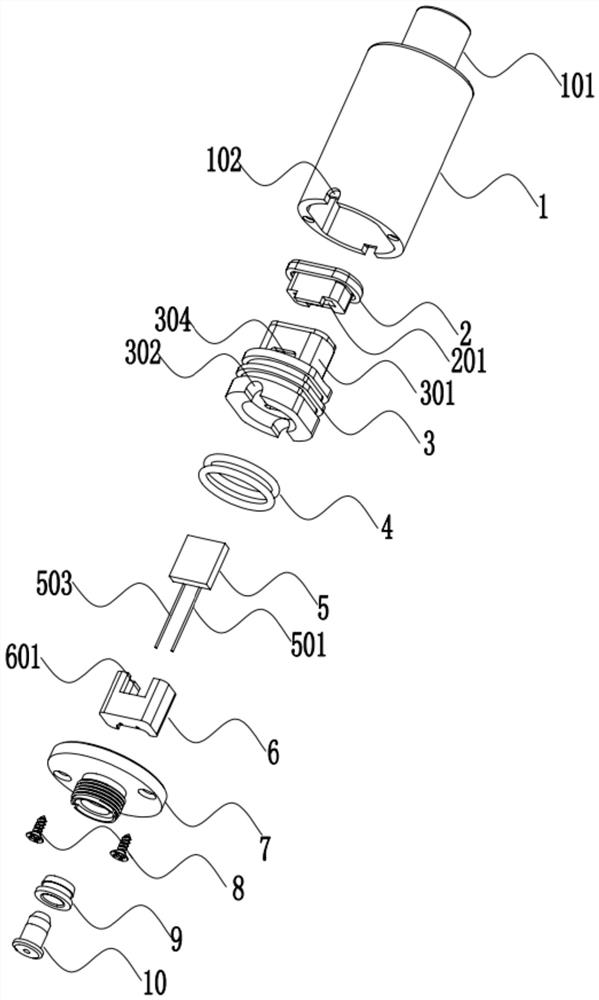

Atomizing core and atomizer applying same

Owner:ALD GRP

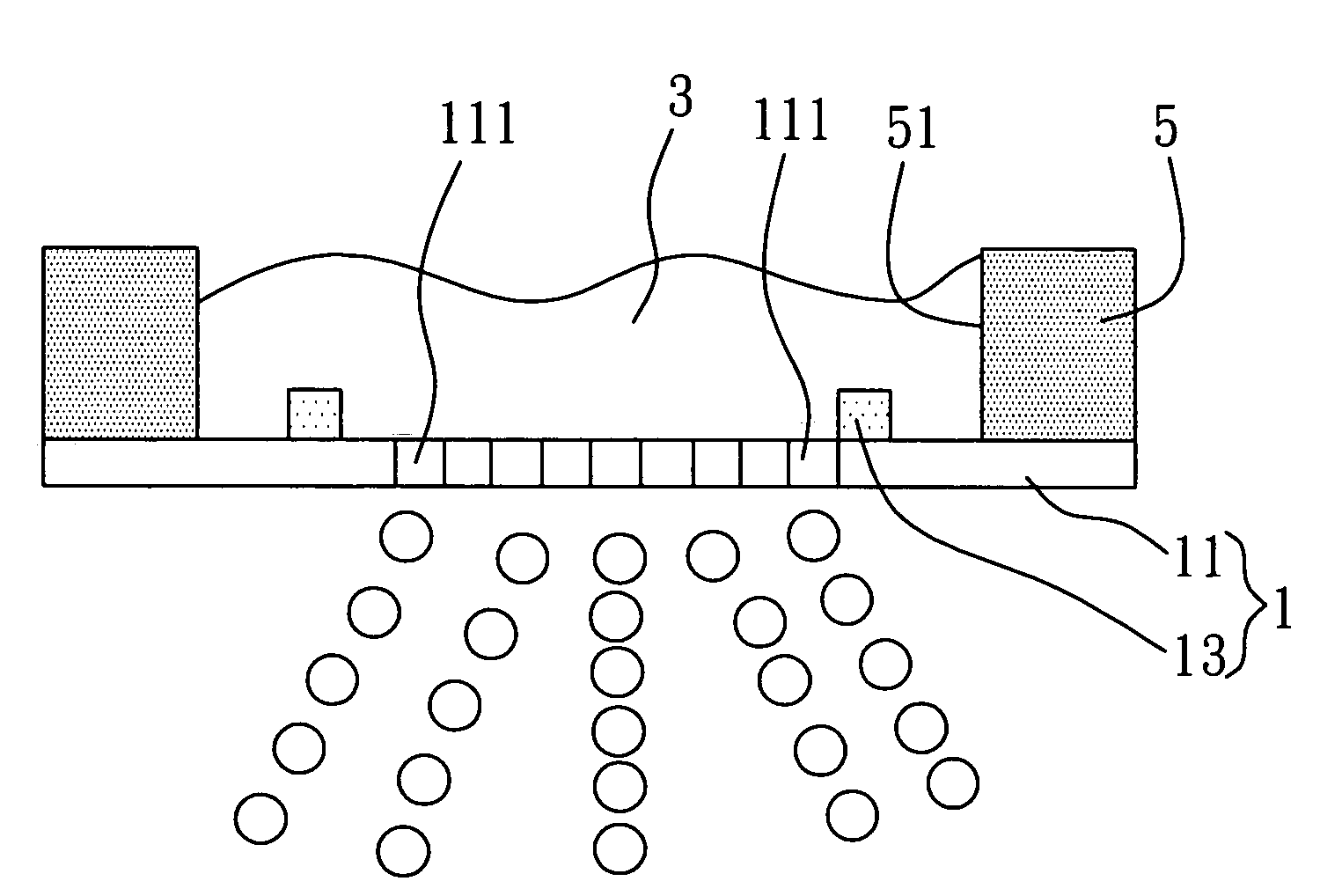

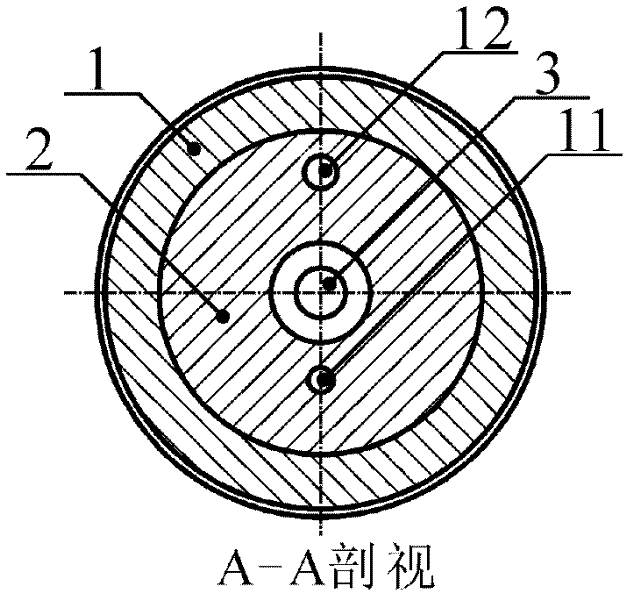

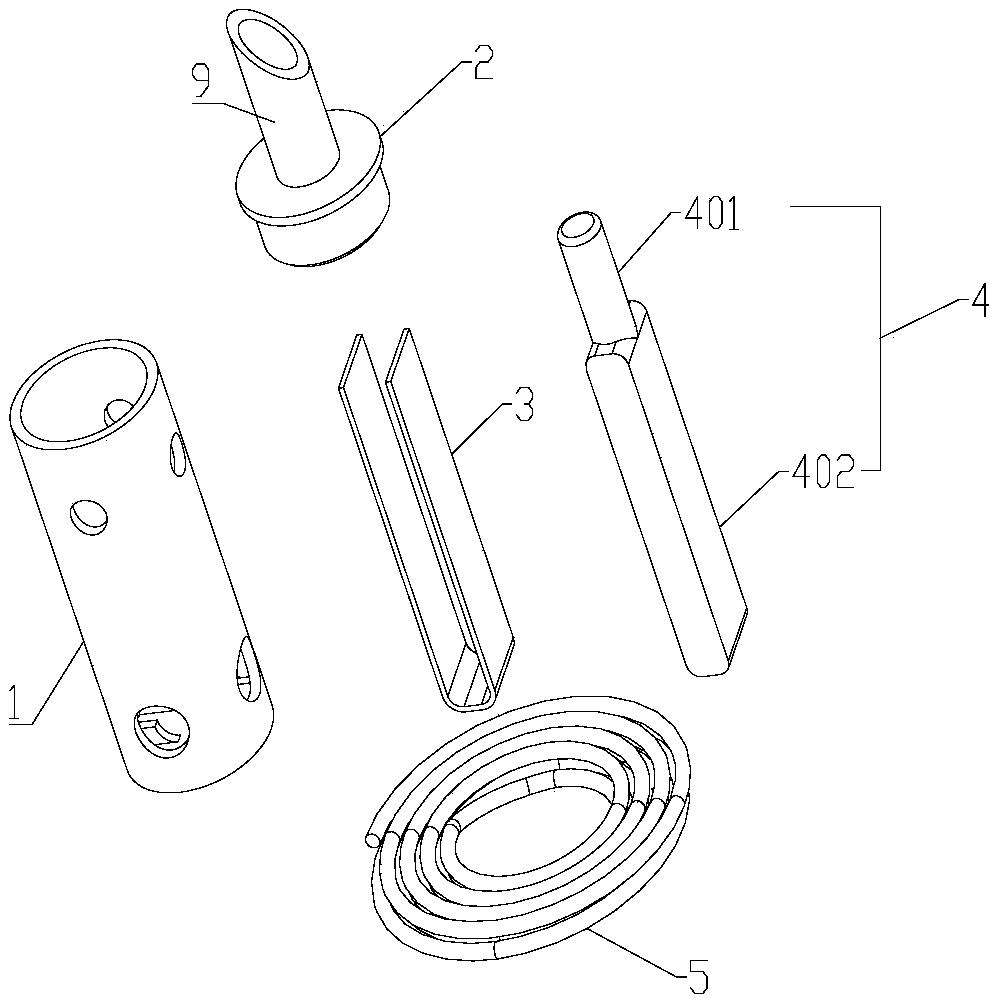

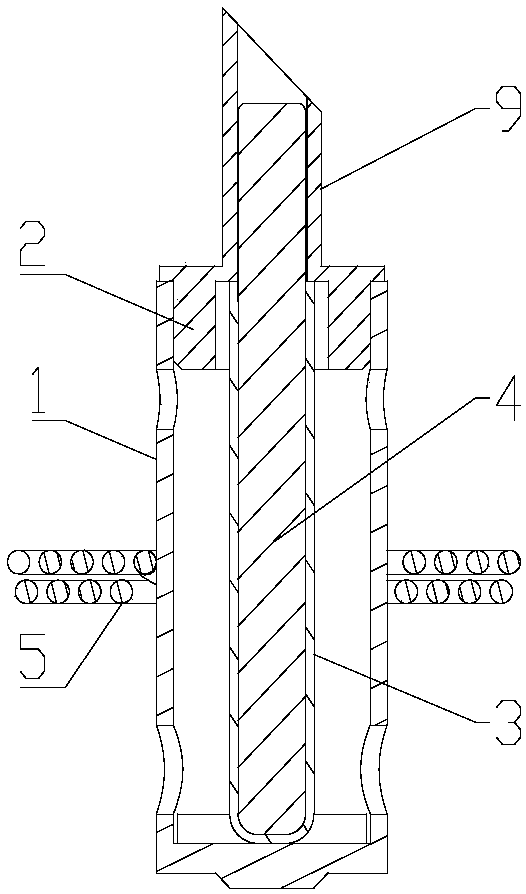

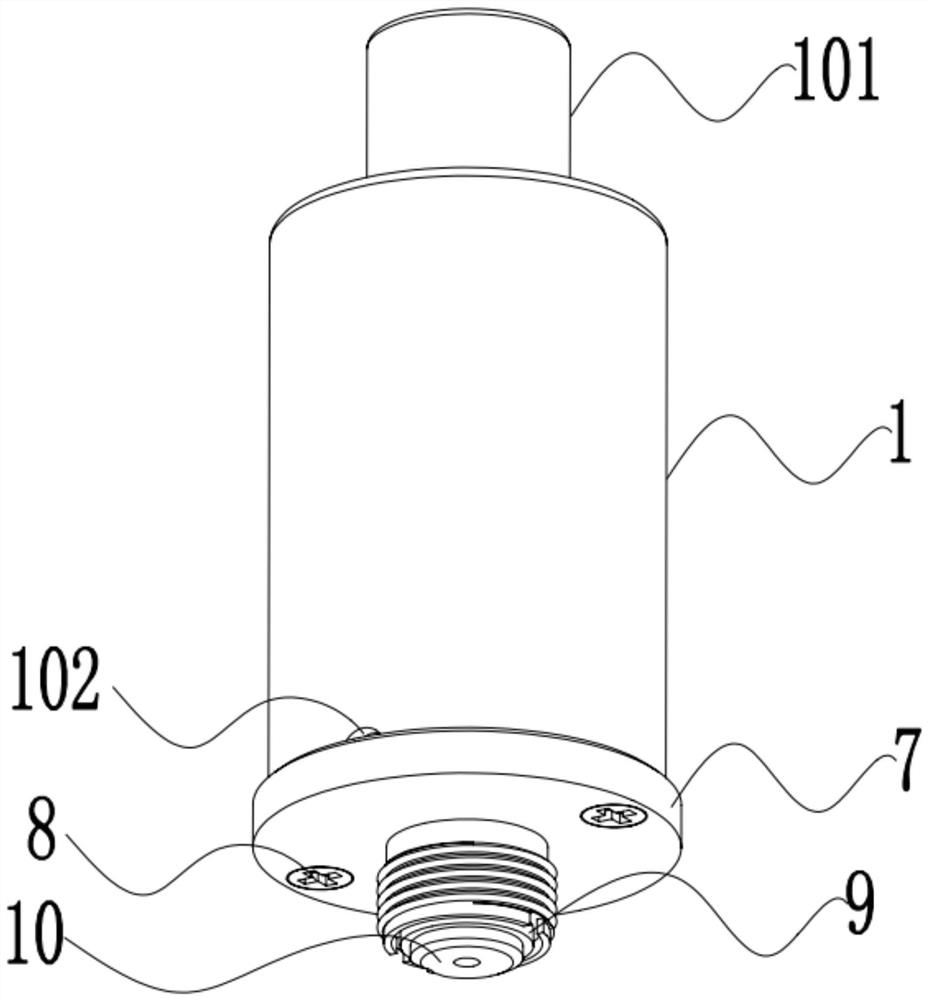

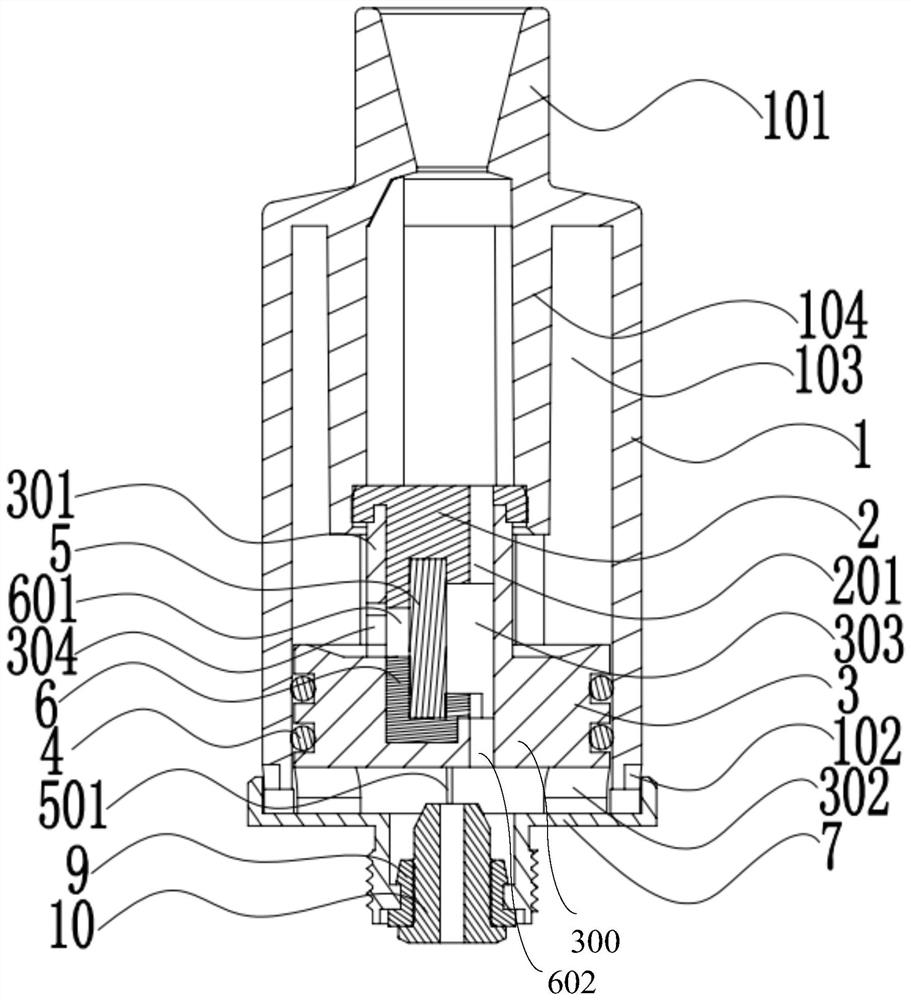

Mini combustor

The invention relates to a mini combustor. The mini combustor is characterized by comprising an atomizing cover (3), an atomizing net (7), an air cover (8) and a flame jetting pipe (9), wherein the atomizing net (7) is mounted in the atomizing cover (3); an opening in the lower part of the atomizing cover (3) is connected to an opening in the upper part of the air cover (8) to form a mini combustion chamber body; an outlet in the lower part of the air cover (8) is connected to the flame jetting pipe (9); fuel oil enters the combustion chamber body from the atomizing cover (3) through an oil inlet pipe (2); and a plurality of duct holes (5) are designed in the atomizing cover (3). The mini combustor has the advantages of being small in size, light in weight, low in energy consumption, fastto ignite, high in combustion stability, low in igniting environment temperature and the like; and the mini combustor is applicable to an outdoor furnace, a cooling liquid heating device, a low-temperature starting device of a diesel engine, etc.

Owner:北京美寒机械设备有限公司

Atomizing core, atomizer and electronic cigarette

The invention discloses an atomizing core, an atomizer and an electronic cigarette, the atomizing core comprises an atomizing main body made of a porous material, one side of the atomizing main body is provided with an oil absorbing side for absorbing oil, the other side of the atomizing main body is provided with a smoke outlet side for discharging smoke, and the side wall of the smoke outlet side is provided with an electric heating element. According to the atomization core, the porous material is used for absorbing oil, meanwhile, the fixed electric heating element is used for heating, heating is uniform and stable, the atomization area is large, cigarette blockage is avoided, and the taste is good.

Owner:SHENZHEN EIGATE TECH CO LTD

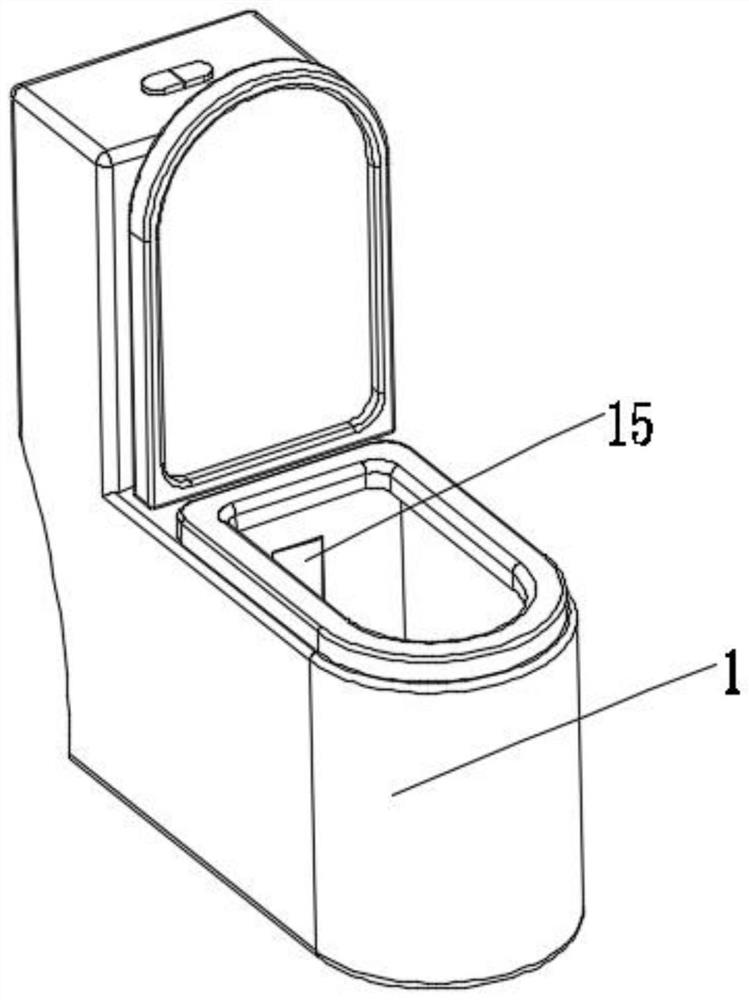

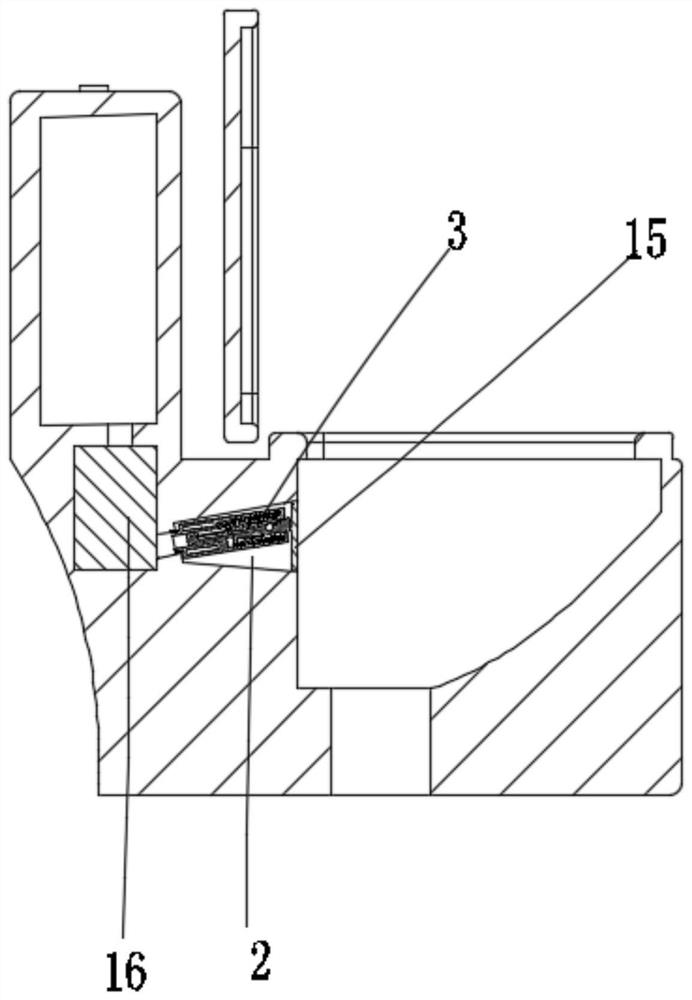

Intelligent closestool cleaning nozzle

InactiveCN112227483ASimple structureImprove comfortLavatory sanitoryHigh pressure waterElectronic component

The invention relates to the technical field of nozzles, in particular to an intelligent closestool cleaning nozzle which comprises a closestool, a hidden cavity formed in the rear portion of the closestool and a pipe body arranged in the hidden cavity, a piston pipe is fixedly connected into the lower portion of the pipe body, a piston matched with the piston pipe is arranged in the piston pipe,and a top pipe coaxial with the piston is arranged at the top of the piston. An atomization spray washing pipe communicated with the top pipe is arranged at the top end of the top pipe, an atomizationmixing cavity is formed in the top of the atomization spray washing pipe, a spraying channel is obliquely formed in the top of the atomization spray washing pipe, and a spraying mechanism is arrangedin the spraying channel; the pipe body is simple in structure, no electronic element is used, the cost is reduced, the service life of the device is effectively prolonged, high-pressure water drivesthe atomization spray washing pipe to extend out of the hidden cavity, water is made to be diffused and sprayed outwards in a vortex and mist state, the atomization area is increased, the hip cleaningcomfort is improved, and meanwhile, the gas-liquid ratio of the atomized liquid can be adjusted through the adjusting mechanism according to the actual use condition.

Owner:廖虹

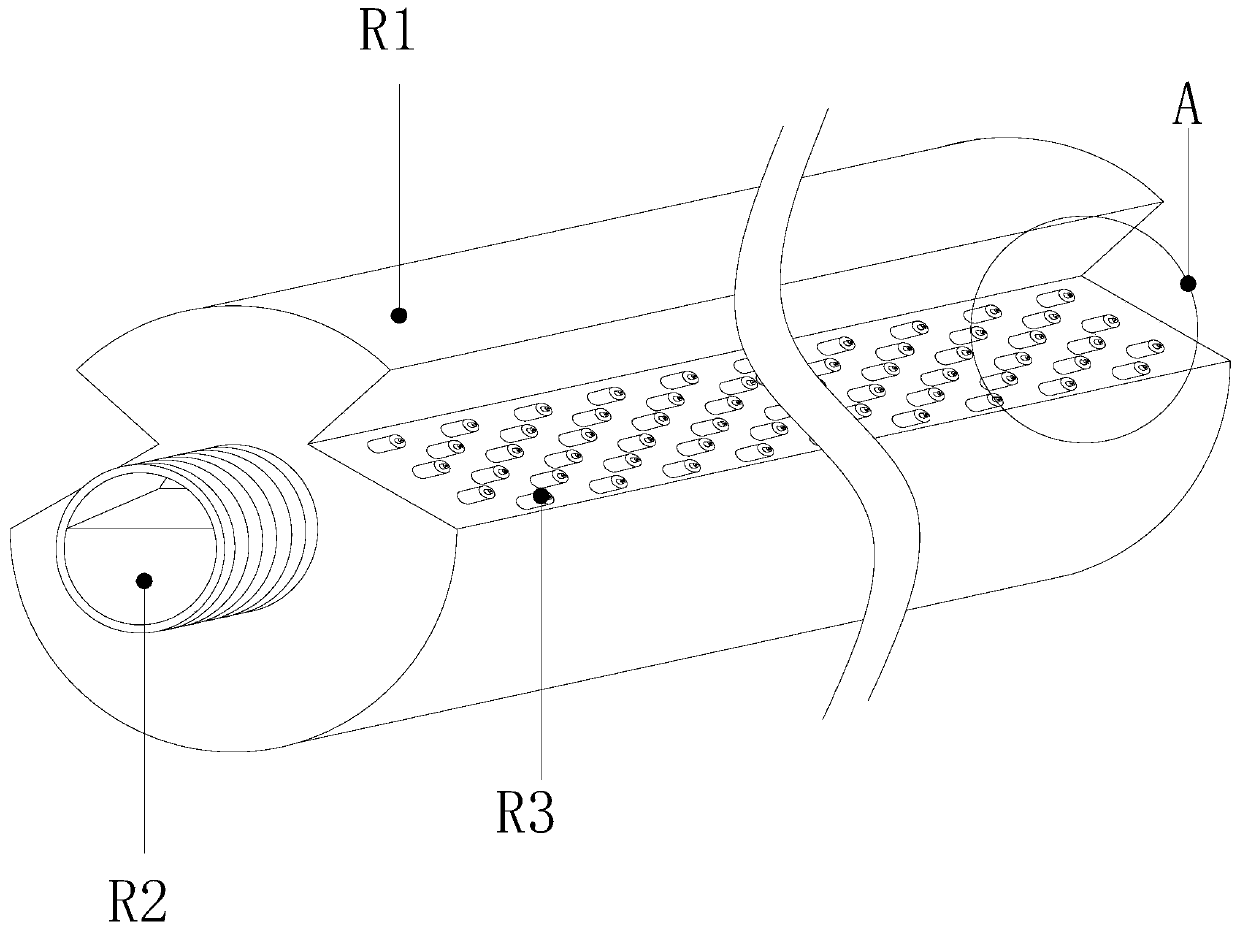

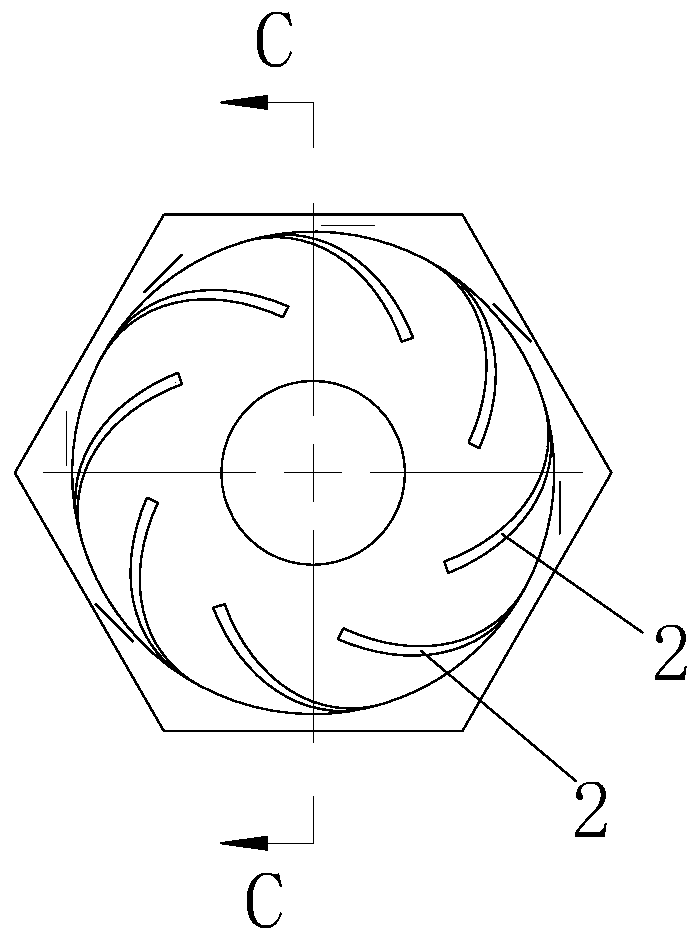

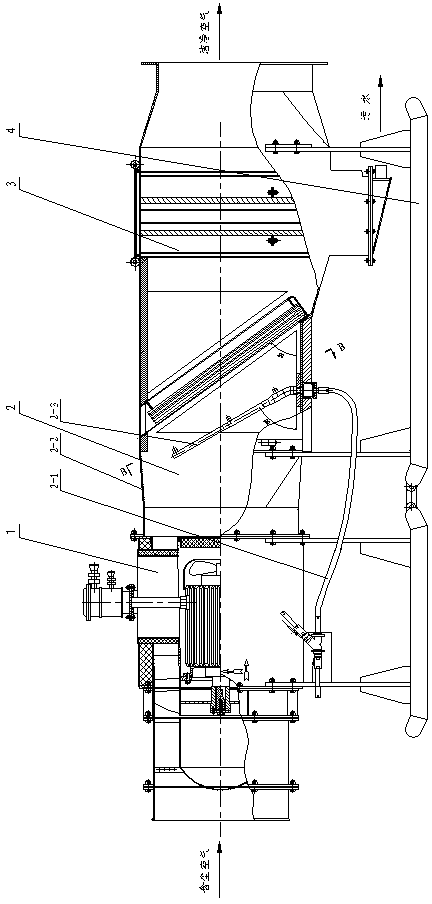

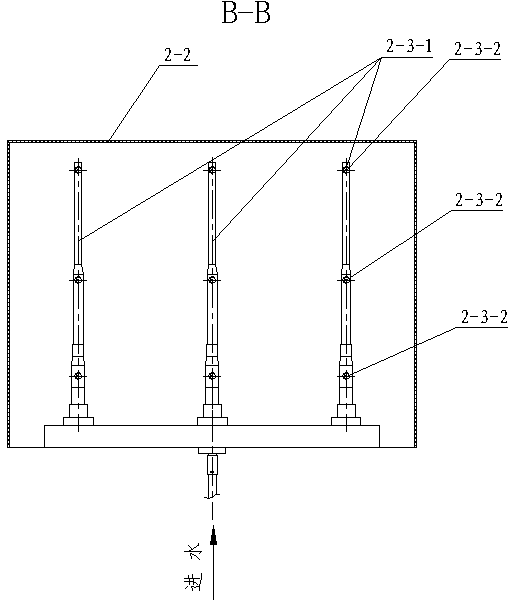

Baffle wet dust removal fan with water flow atomizing systems

InactiveCN105507936ALarge atomization areaExtend the atomization timeDust removalFire preventionSpray nozzleFilter system

The invention discloses a baffle wet dust removal fan with water flow atomizing systems, relates to underground equipment for coal mines, and particularly relates to the technical field of dust removers. The baffle wet dust removal fan comprises a skid shoe base. A fan power section, a dust removal purification section and a liquid and gas separation and dehydration section are sequentially connected onto the skid shoe base from front to back; the dust removal purification section comprises a water supply and filter system and a gas flow diffusion wind tunnel; the dust removal purification section further comprises the water flow atomizing systems, the water flow atomizing systems comprise three atomizing pipes, the three atomizing pipes are connected into the gas flow diffusion wind tunnel, water inlet ends of the three atomizing pipes are connected with the water supply and filter system, the diameters of the three atomizing pipes are gradually reduced from the water inlet ends to water outlet ends, and spray nozzles are connected onto the three atomizing pipes. The three water flow atomizing systems comprise reducer water supply pipelines and the spray nozzles and are equidistantly and parallelly distributed. According to the reducer water supply pipeline design scheme, the baffle wet dust removal fan has the advantages that the purpose of guaranteeing identical water pressures at the various spray nozzles of the water supply pipelines can be achieved, and accordingly atomizing effects can be guaranteed.

Owner:JIANGSU JIHAO ENVIRONMENTAL PROTECTION EQUIP

Gas-liquid two-phase fine mist generator and generating method thereof

The invention relates to a humidifier, and in particular to a gas-liquid two-phase mist generator and a generation method thereof. The gas-liquid mist generator comprises a liquid storage tank; the upper end of the liquid storage tank is sealed with a valve cover, and a gas guiding channel horizontally penetrates through the valve cover; the lower end surface of the valve cover is provided with a first atomizing chamber and an oil suction pipe inserted into the liquid storage tank; an input end of the gas guiding channel is communicated with the first atomizing chamber through an inclined hole; the chamber of the liquid storage tank is communicated with an output end of the gas guiding channel; scattering wheels are horizontally arranged in the first atomizing chamber; the top of the valve cover is provided with a regulating needle valve; the oil suction pipe is communicated with an inlet of the regulating needle valve; an outlet of the regulating needle valve vertically corresponds to the first atomizing chamber; and the first atomizing chamber through an outlet of the first atomizing chamber is communicated with the liquid storage tank. The invention can effectively mix gas and liquid and realize two times of mixing, and has the beneficial effects of good atomizing distribution uniformity, simple structure and no blocking.

Owner:HUZHOU TEACHERS COLLEGE

Method for manufacturing nozzle distributor of reaction vessel

ActiveCN102343248BJet effect is similarEven spraying effectChemical/physical/physico-chemical nozzle-type rreactorsEngineeringDistributor

The invention provides a method for manufacturing a nozzle distributor of a reaction vessel. The method comprises the following steps: 1, connecting five to thirteen liquid pipelines to a feed inlet; 2, arranging a plurality of sockets with openings with different orientations on each liquid pipeline in a malposed manner; and 3, arranging a nozzle on each socket. Experiments and uses prove that the nozzle distributor of the reaction vessel manufactured with the method of the invention has the advantages of high atomization area and large atomization volume, and can satisfactorily increase and improve the transparency and the color of products, and the reaction conversion rate.

Owner:SHANGHAI TAIJIE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com