Dampening equipment capable of uniformly atomizing and spraying and used for flour processing

A technology of uniform atomization and watering, applied in the field of flour processing, can solve the problems of poor turning effect, low work efficiency, high labor intensity of operators, etc., to expand the atomization area, reduce labor intensity and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

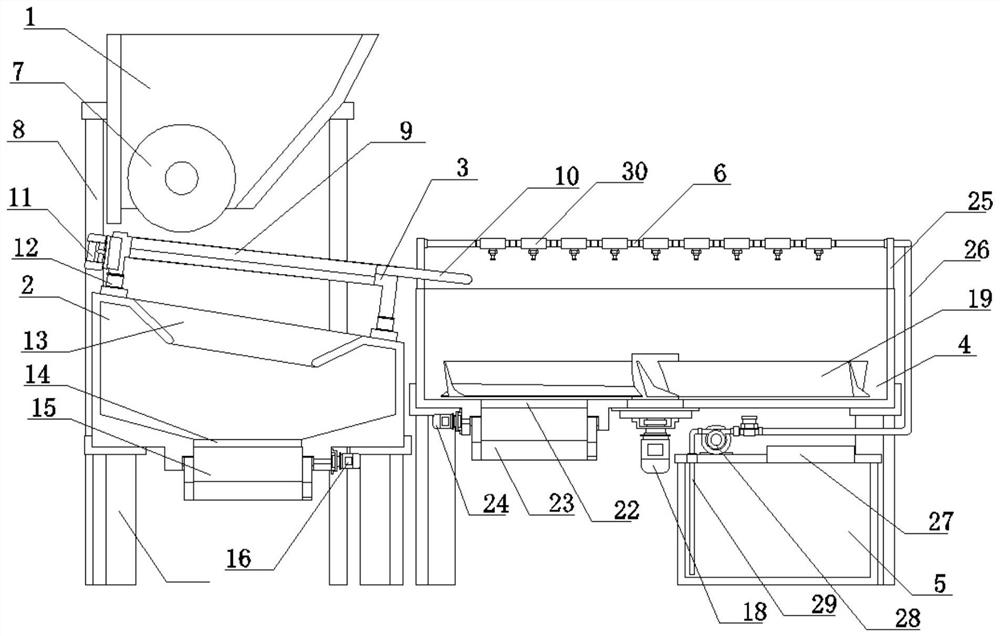

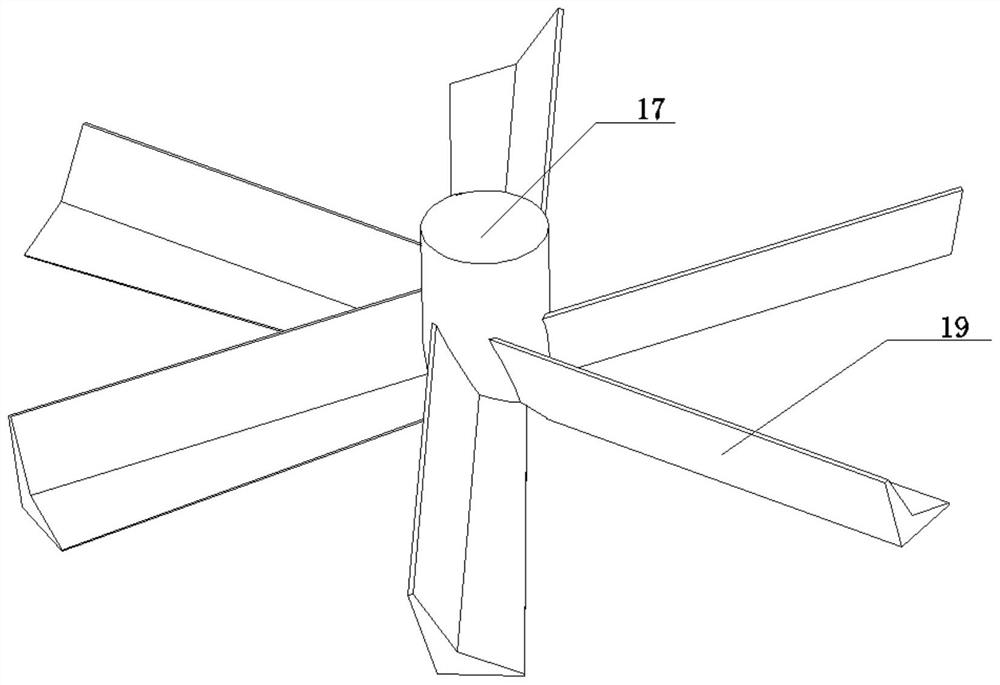

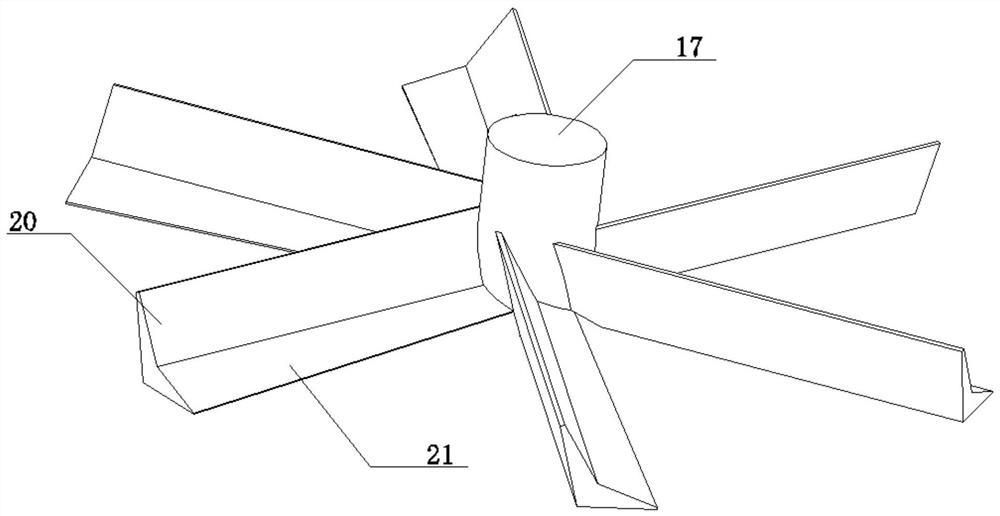

[0044] A water-using equipment for flour processing capable of uniform atomization and spraying, comprising a feeding assembly, a sieving assembly, a watering assembly and a stirring assembly, the feeding assembly includes a lowering hopper 1, the lowering hopper 1 is located above the sieving assembly, and the sieving assembly The material assembly includes a trash box 2 and a screen frame 3, the screen frame 3 is located below the discharge port of the lower hopper 1, the screen frame 3 is arranged on the upper end of the trash box 2, and the stirring assembly includes a stirring pool 4, and the stirring pool 4 is located on the screen Below one side of the network frame 3 , an agitator is arranged inside the stirring tank 4 , and the water landing assembly includes a water tank 5 and a spray pipe 6 , and the spray pipe 6 is located above the stirring tank 4 .

[0045] Wherein, the bottom end of the lower hopper 1 is connected to the connecting shaft of the feeding roller 7 i...

Embodiment 2

[0052] A water-using equipment for flour processing capable of uniform atomization and spraying, comprising a feeding assembly, a sieving assembly, a watering assembly and a stirring assembly, the feeding assembly includes a lowering hopper 1, the lowering hopper 1 is located above the sieving assembly, and the sieving assembly The material assembly includes a trash box 2 and a screen frame 3, the screen frame 3 is located below the discharge port of the lower hopper 1, the screen frame 3 is arranged on the upper end of the trash box 2, and the stirring assembly includes a stirring pool 4, and the stirring pool 4 is located on the screen Below one side of the network frame 3 , an agitator is arranged inside the stirring tank 4 , and the water landing assembly includes a water tank 5 and a spray pipe 6 , and the spray pipe 6 is located above the stirring tank 4 .

[0053] Wherein, the bottom end of the lower hopper 1 is connected to the connecting shaft of the feeding roller 7 i...

Embodiment 3

[0061] A water-based equipment for flour processing capable of uniform atomization and spraying, including the following specific operation methods:

[0062] 1. Pour the wheat grains into the feeding hopper 1, and drive the feeding roller 7 to rotate through the feeding motor, and the wheat grains in the feeding hopper 1 fall into the upper end of the screen 9 at a constant speed with the rotation of the feeding roller 7;

[0063] Two, the vibrating motor 11 drives the screen frame 3 to vibrate, and the wheat grain moves to the mixing tank 4 while vibrating on the screen 9, and impurities such as sand and stone doped in the wheat grain enter the impurity box 2 through the screen 9, and the wheat grain Enter the stirring tank 4 through the blanking plate 10;

[0064] 3. The water pump 28 draws out the water in the water tank 5 through the suction pipe 29, and introduces the water into the spray pipe 6 through the water guide pipe 26, and then atomizes the water through the atom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com