Gas atomization spraying nozzle

A spray nozzle and gas atomization technology, applied in liquid spray devices, spray devices, etc., can solve the problems of increasing the humidity of the workshop, delaying the workshop atomization, and reducing the service life of the nozzle, so as to expand the atomization area and improve the atomization. Speed, longevity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

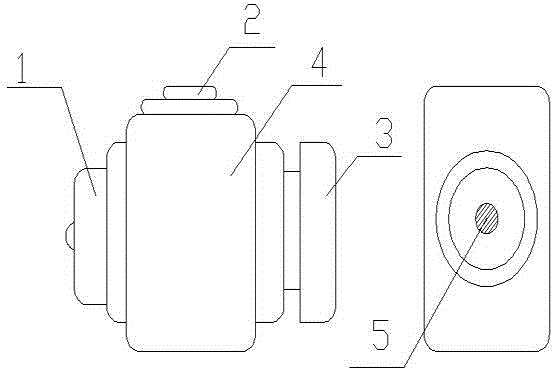

[0009] A gas atomization spray nozzle, comprising a spray head 1, an air joint 2, a liquid joint 3, and a mixing chamber 4, the head surface of the spray head 1 is connected with a mixing chamber 4, the upper part of the mixing chamber 4 is provided with an air joint 2, and the liquid joint 3 is located Behind the mixing chamber 4, the liquid connector 3 is covered with a connecting nut, the air connector 2 is provided with a threaded interface, the nozzle 1 is a circular nozzle, and the circular nozzle is provided with a filter 5 at the nozzle, and the filter 5 is a stainless steel dense mesh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com