A hydrogen-oxygen energy-saving and emission-reducing atomization device

A technology of energy saving and emission reduction and atomization device, which is applied in the direction of spraying device, liquid spraying device, spray booth, etc., and can solve the problems of high energy consumption of atomizer, poor atomization effect, and inability to uniformly atomize hydrogen-oxygen liquid. , to achieve the effect of saving energy and speeding up the atomization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

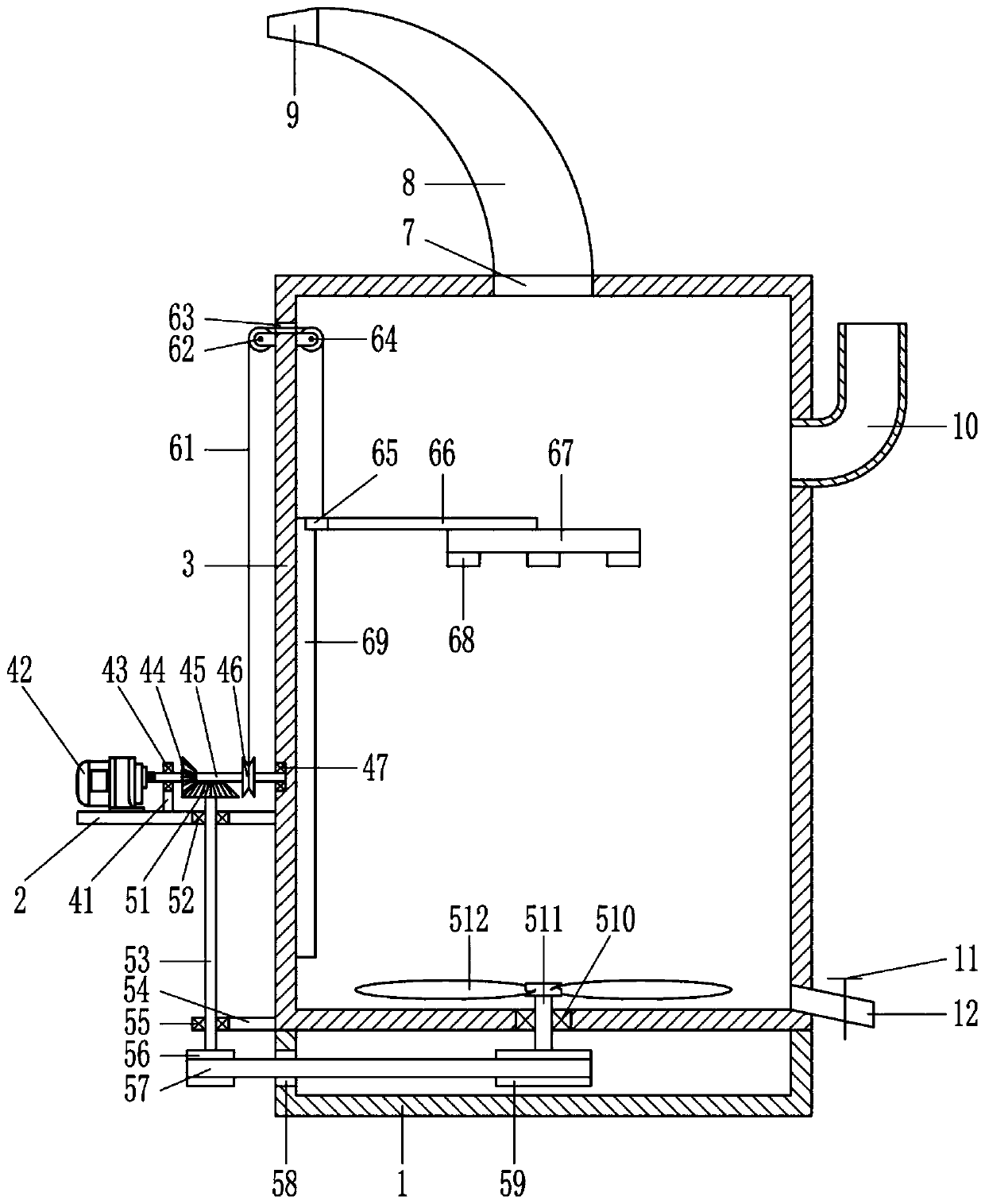

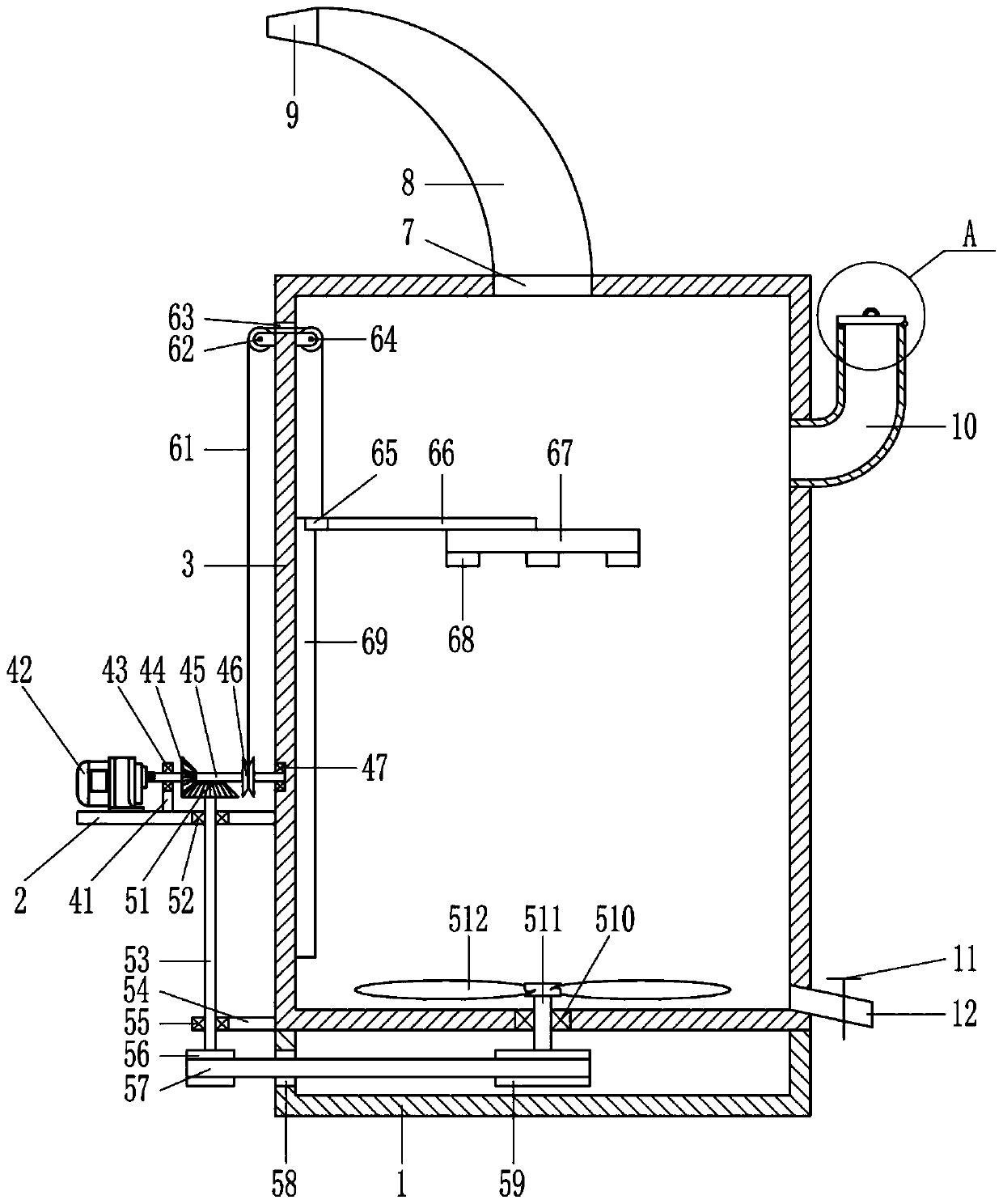

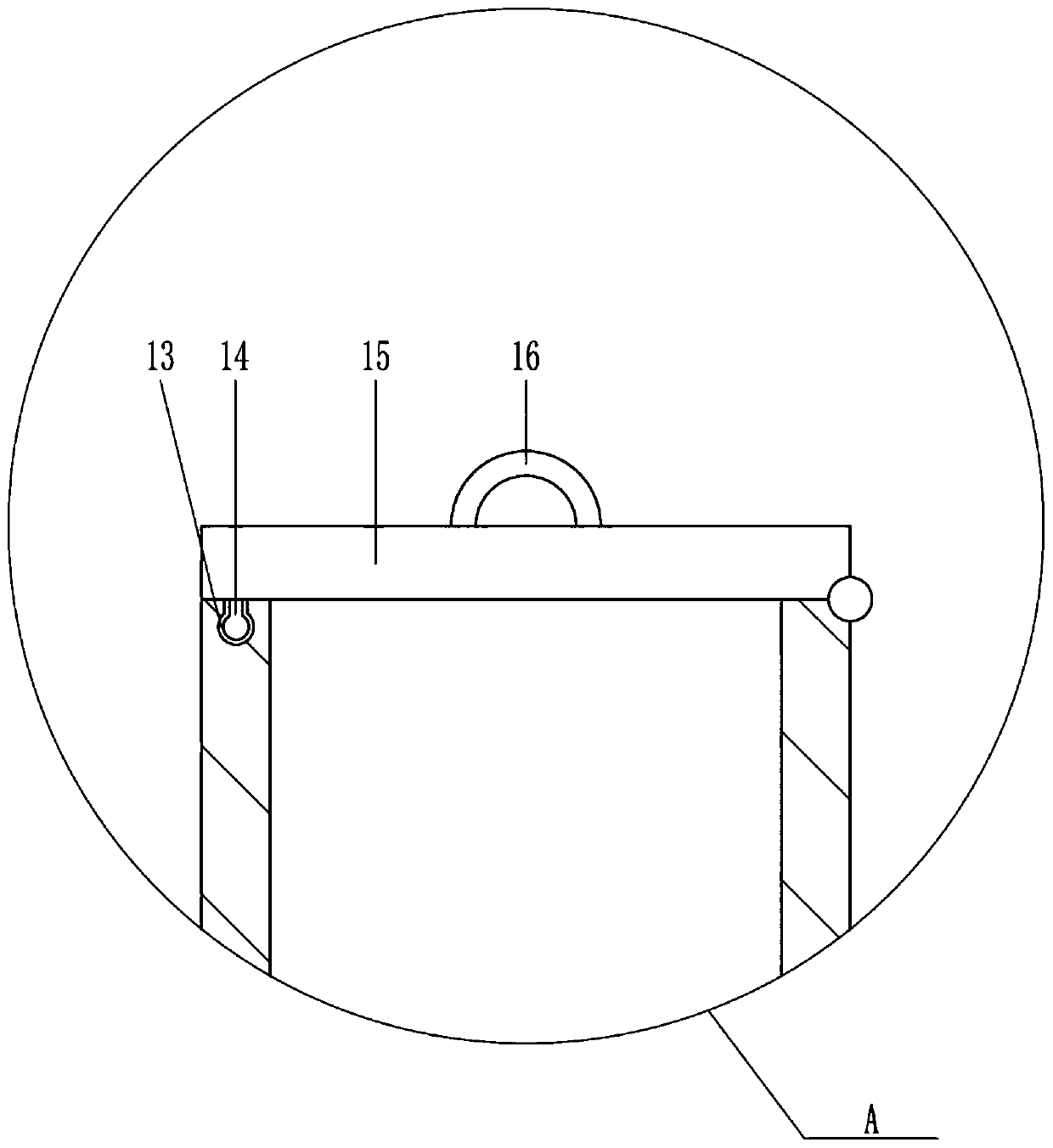

[0026] A hydrogen-oxygen energy-saving emission reduction atomization device, such as Figure 1-7 As shown, it includes a first installation frame 1, a first fixed plate 2, an installation box 3, a driving mechanism 4, an agitating mechanism 5, an atomizing mechanism 6, a hose 8, a joint 9, an inlet hopper 10, a valve 11 and an outlet Water pipe 12; the first installation frame 1 is fixed on the outer bottom of the installation box 3, the first fixing plate 2 is fixed on the side of the installation box 3; the feeding hopper 10 is fixed on the side of the installation box 3 away from the first fixing plate 2 , and communicate with the inside of the installation box 3; the top of the installation box 3 is provided with a third through hole 7; the hose 8 is fixed on the top of the installation box 3, and communicates with the inside of the installation box 3 through the third through hole 7; At the end of the hose 8, the outlet pipe 12 is fixedly connected to the side of the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com