Waste incineration exhaust gas deacidification treatment system

A technology of waste incineration and treatment system, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of clogging of sprinkler heads, affecting the emission of deacidified gas, atmospheric hazards, etc., to achieve stable spraying and improve deacidification treatment. Efficiency, clogging prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

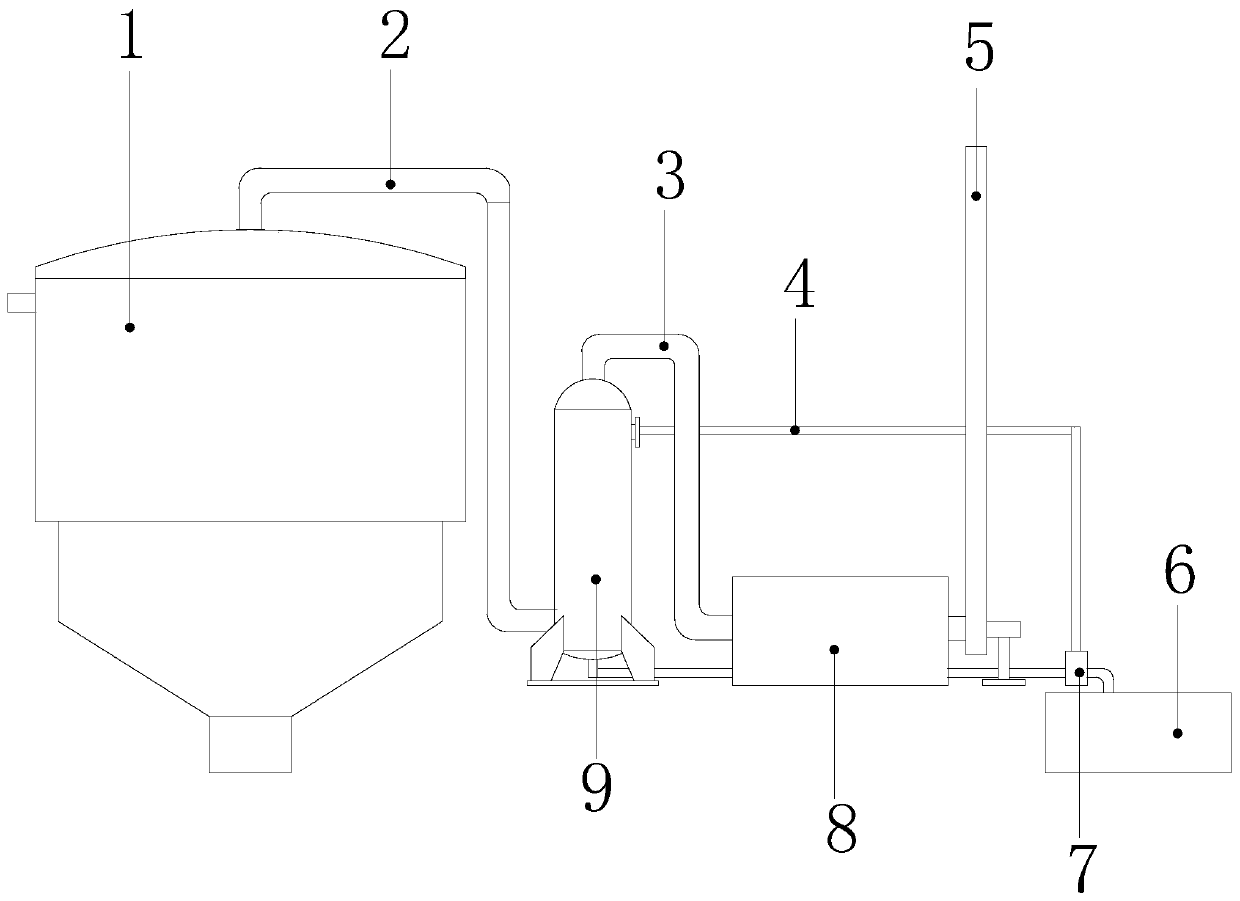

[0034] see figure 1 , the present invention provides a technical solution for waste incineration waste gas deacidification treatment system: its structure includes waste incineration equipment 1, incineration waste gas pipeline 2, flue gas pipeline 3, water supply pipe 4, flue gas discharge pipe 5, circulating water tank 6, High-pressure water pump 7, flue gas purifier 8, deacidification water mist spray tower 9, the waste incineration equipment 1 is connected to the deacidification water mist spray tower 9 through the incineration waste gas pipeline 2, and the deacidification water mist spray tower 9 is connected to the flue gas purifier 8 through the flue gas pipeline 3, the flue gas purifier 8 is connected to the flue gas discharge pipe 5, and the deacidification water mist spray tower 9 is connected to the Circulating water tank 6;

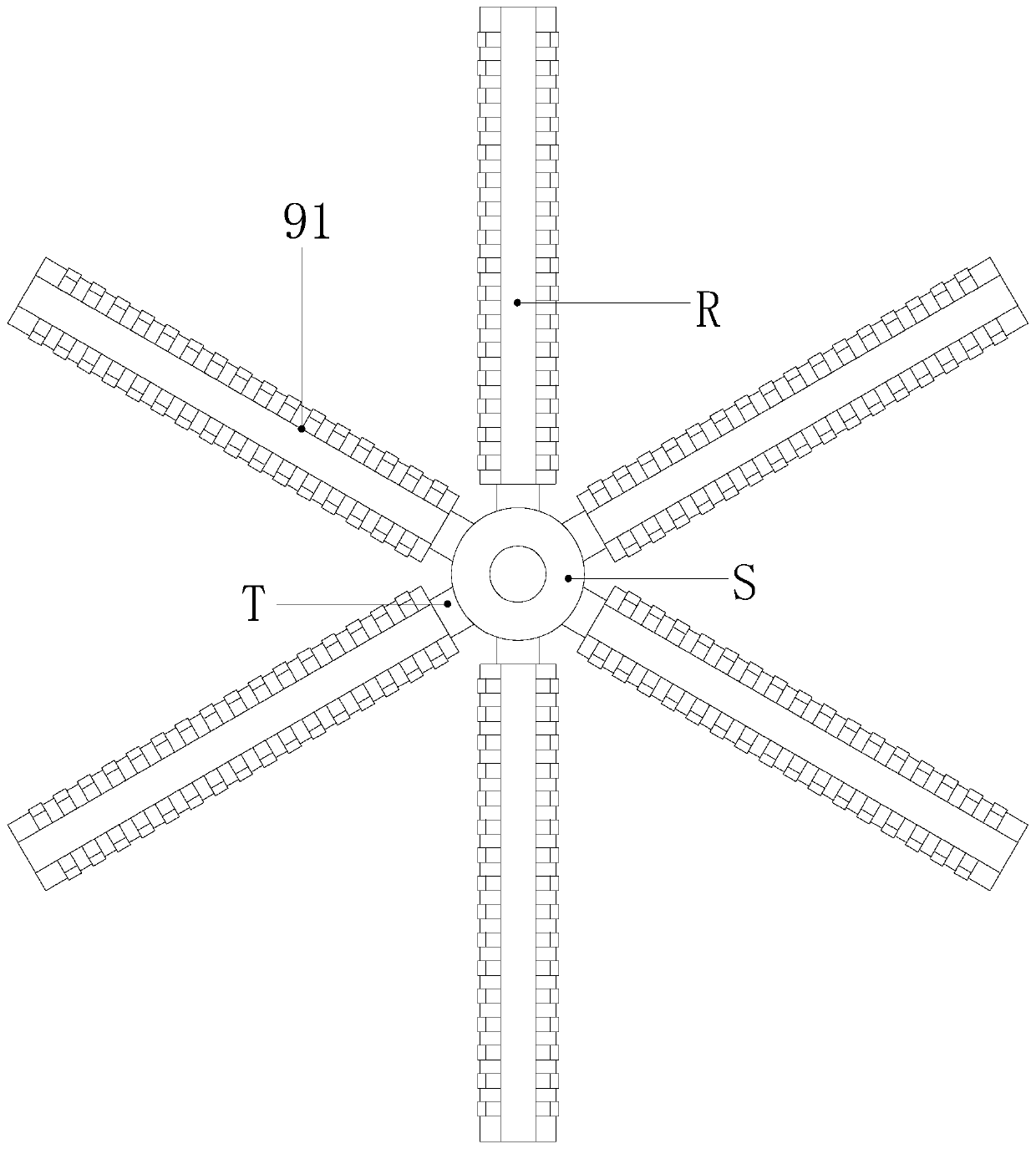

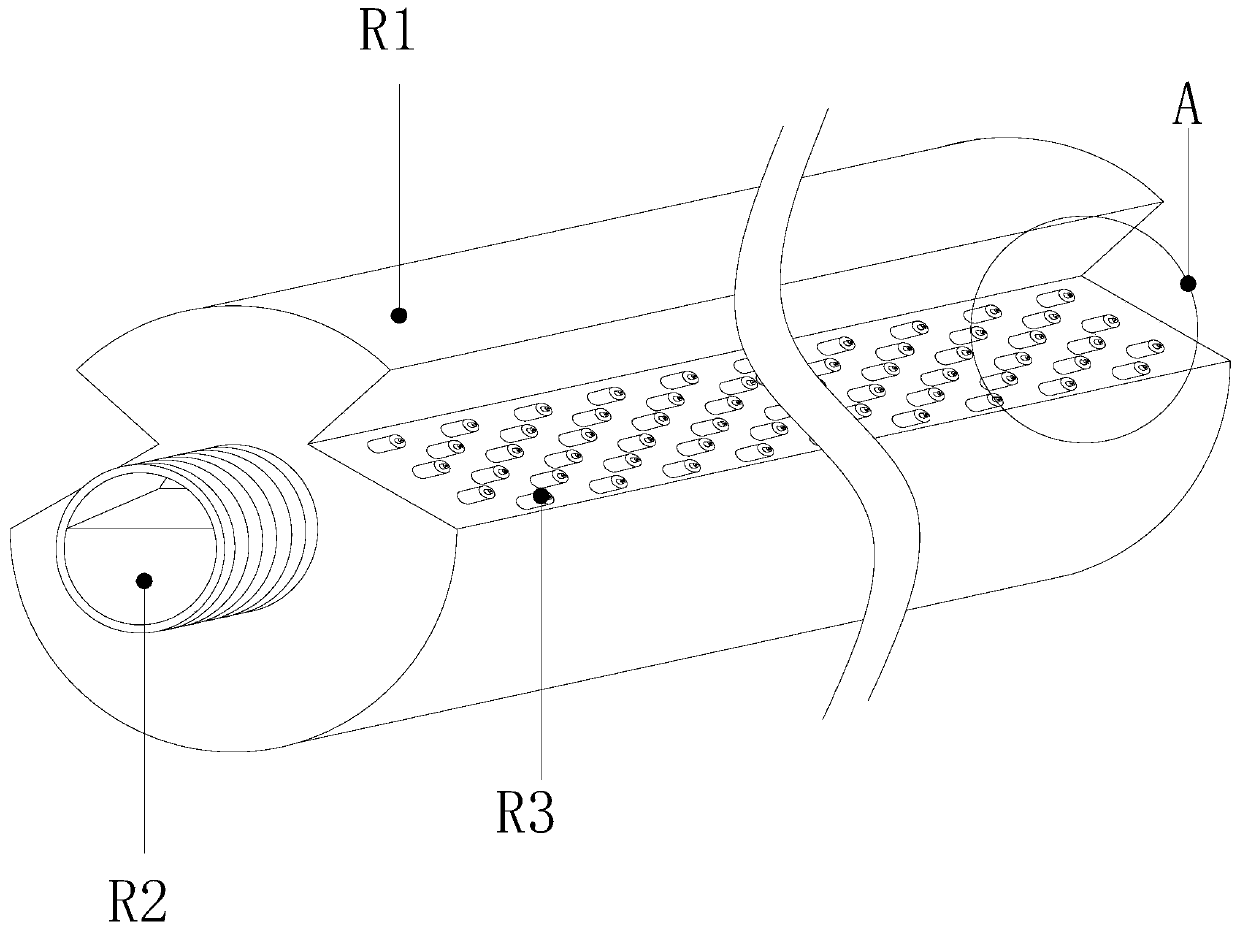

[0035] see figure 2 , the deacidification water mist spray tower 9 is provided with a spray assembly 91, and the spray assembly 91 includ...

Embodiment 2

[0044] see figure 1 , the present invention provides a technical solution for waste incineration waste gas deacidification treatment system: its structure includes waste incineration equipment 1, incineration waste gas pipeline 2, flue gas pipeline 3, water supply pipe 4, flue gas discharge pipe 5, circulating water tank 6, High-pressure water pump 7, flue gas purifier 8, deacidification water mist spray tower 9, the waste incineration equipment 1 is connected to the deacidification water mist spray tower 9 through the incineration waste gas pipeline 2, and the deacidification water mist spray tower 9 is connected to the flue gas purifier 8 through the flue gas pipeline 3, the flue gas purifier 8 is connected to the flue gas discharge pipe 5, and the deacidification water mist spray tower 9 is connected to the Circulating water tank 6;

[0045] see figure 2 , the deacidification water mist spray tower 9 is provided with a spray assembly 91, and the spray assembly 91 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com