Patents

Literature

61results about How to "Improve deacidification efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing polyol ester lubricating oil by using composite solid acid catalyst

InactiveCN102887825AHigh esterification rateHigh purityOrganic compound preparationCarboxylic acid esters preparationDistillationAcid value

The invention relates to a method for preparing polyol ester lubricating oil by using a composite solid acid catalyst. The method comprises the following steps of: adding a water carrying agent into polyol ester and monobasic fatty acid, performing esterification reaction under the action of the composite solid acid catalyst, and dehydrating and esterfying to obtain raw ester; performing filter pressing on the raw ester to separate the raw ester from the solid acid catalyst, wherein the catalyst can be recycled; and performing reduced pressure distillation on the raw ester to remove the residual fatty acid, and then deacidifying and decolorizing to refine with heating by using a refining adsorption bed layer respectively to obtain low-acid value polyol ester lubricating oil. The method has the advantages that the catalyst can be recycled, the esterification rate is high, an aftertreatment process is simple, and a product is low in acid value, high in purity, environment-friendly and suitable to be produced industrially. The reaction esterification rate can reach over 99 percent, and the acid value of the ester product obtained through refining can be controlled to be less than 0.01mg KOH / g. The product is excellent in visco-temperature performance, high in lubricity and thermal stability, strong in hydrolytic stability, low in volatility and excellent in electrical insulation property.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Multifunctional nano compound treating fluid for protecting paper cultural relics and preparation method thereof

InactiveCN103276627ALittle side effectsImprove efficiencyChemical/biochemical paper treatmentOld paper after-treatmentSolventUltimate tensile strength

The invention discloses multifunctional nano compound treating fluid for protecting paper cultural relics. The multifunctional nano compound treating fluid takes deionized water as a solvent, and comprises nano magnesium hydroxide, nano titanium dioxide and hydroxyethyl cellulose, wherein nano magnesium hydroxide accounts for 0.2-1.0% of the weight of deionized water, nano titanium dioxide accounts for 0.1-0.8% of the weight of deionized water, and hydroxyethyl cellulose accounts for 0.2-0.8% of the weight of deionized water. The invention also discloses a preparation method of the multifunctional nano compound treating fluid. The multifunctional nano compound treating fluid can be used for large-area treatment of the paper cultural relics, and can be used for providing protection for deacidification, solidification, light-resistant degradation and mould proofing of the paper cultural relics during a large-area treatment of the paper cultural relics. The pH value of the paper cultural relics treated by the multifunctional nano compound treating fluid can reach an alkalescence degree, and the paper cultural relics have a certain alkali residue, can resist external acid, can be greatly improved in tensile strength, and have a certain antibacterial property.

Owner:NANJING MUSEUM

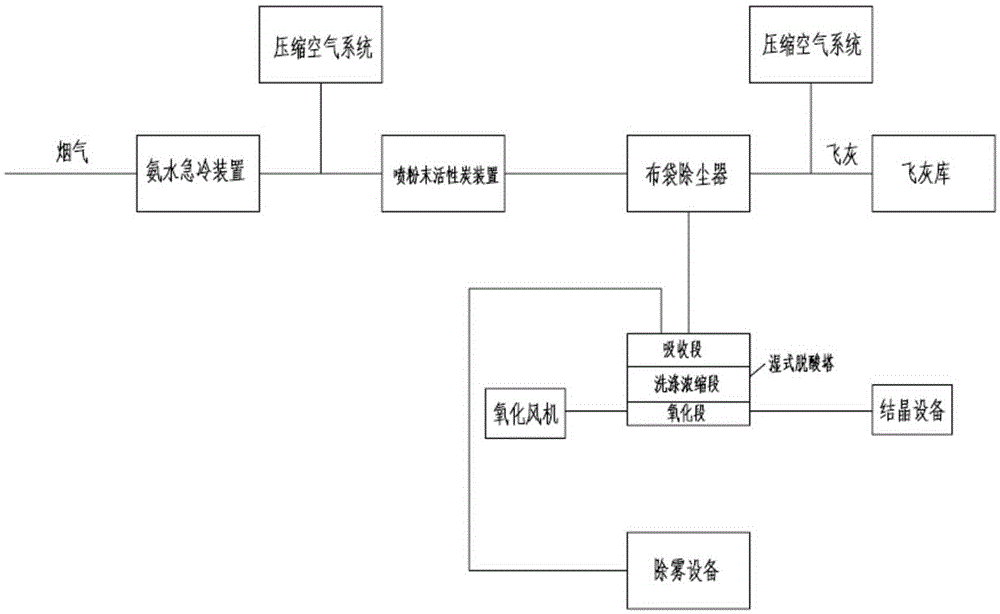

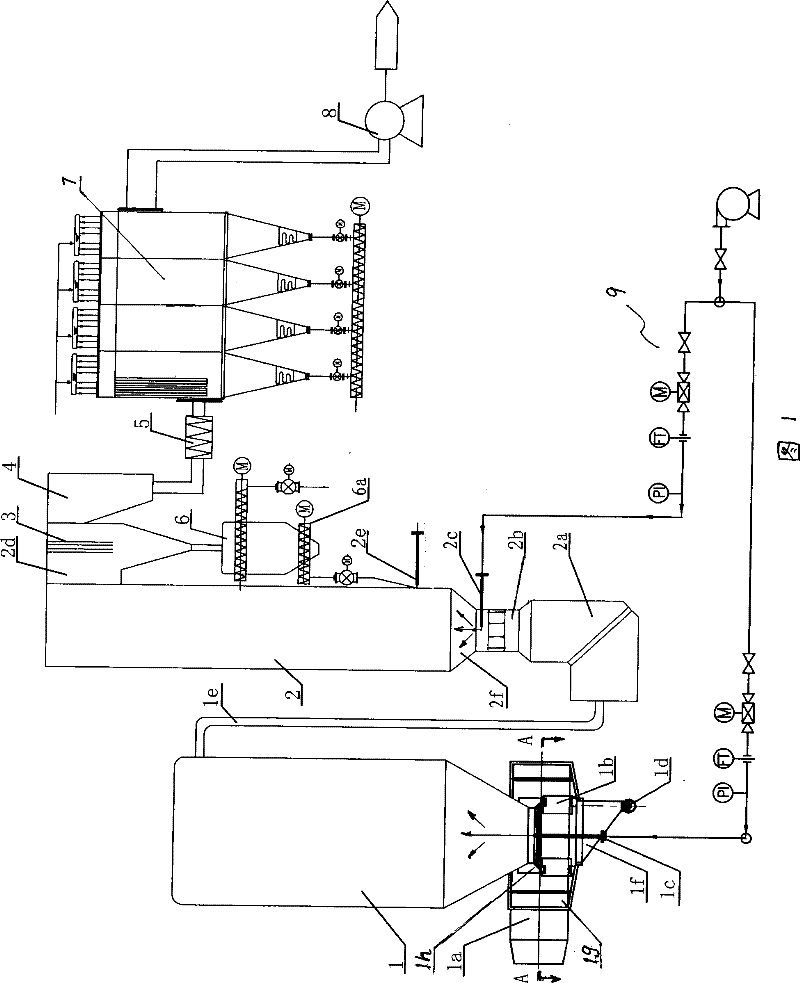

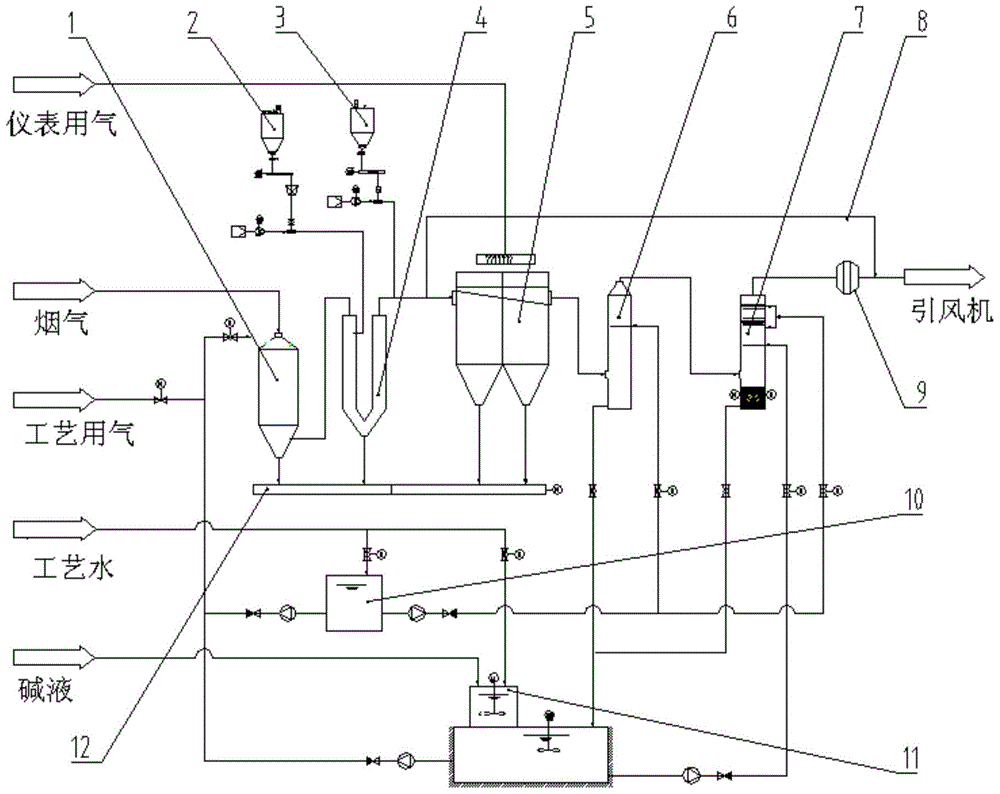

Wet-type purification treatment method and device for flue gas of domestic garbage incineration power plant

ActiveCN105289248ARun smoothlyImprove dust removal efficiencyDispersed particle filtrationBiofuelsActivated carbonDomestic waste

The invention discloses a wet-type purification treatment method and device for flue gas of a domestic garbage incineration power plant. An ammonia water quenching device, a power spray activated carbon device and a bag-type dust collector are sequentially connected through air ducts, the air inlet end of the ammonia water quenching device can be connected with the flue gas outlet end of the domestic garbage incineration power plant, and a compressed air system is further connected to the air duct between the ammonia water quenching device and the power spray activated carbon device; a compressed air system is arranged below a dust hopper of the bag-type dust collector, the dust hopper is connected with a flying dust bin through a pipeline, an outlet flue of the bag-type dust collector is connected with a washing and concentration section of a wet-type deacidifying tower through a pipeline, and the wet-type deacidifying tower comprises an absorption section, the washing and concentration section and an oxidizing section; spray nozzles capable of spraying ammonia water are arranged in the absorption section of the wet-type deacidifying tower, a flue gas exhaust pipeline of the wet-type deacidifying tower is connected with defogging equipment, the oxidizing section of the wet-type deacidifying tower is connected with an oxidation air blower, and an ammonia chloride and ammonia sulfate outlet of the oxidizing section of the wet-type deacidifying tower is connected with crystallizing equipment.

Owner:王全

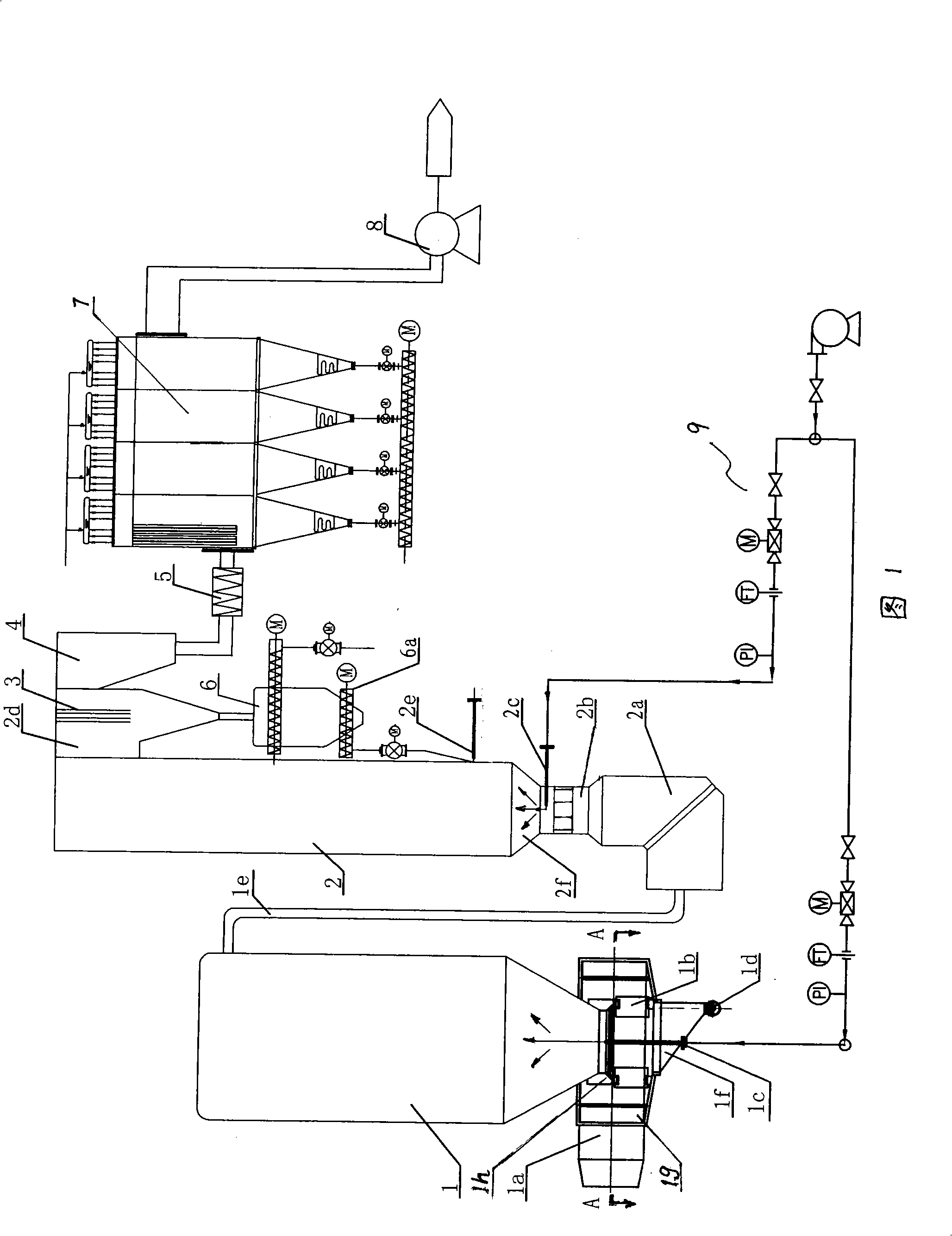

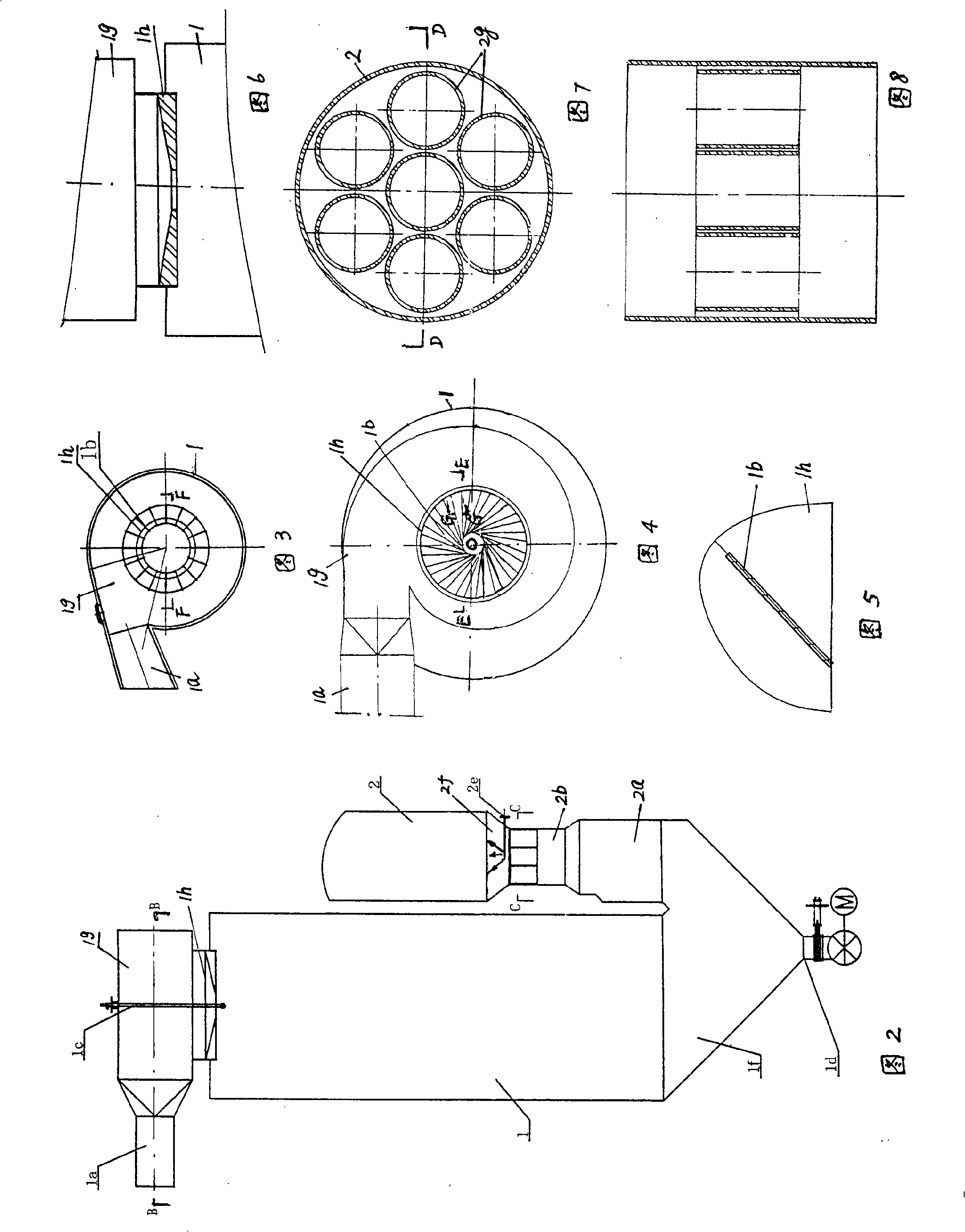

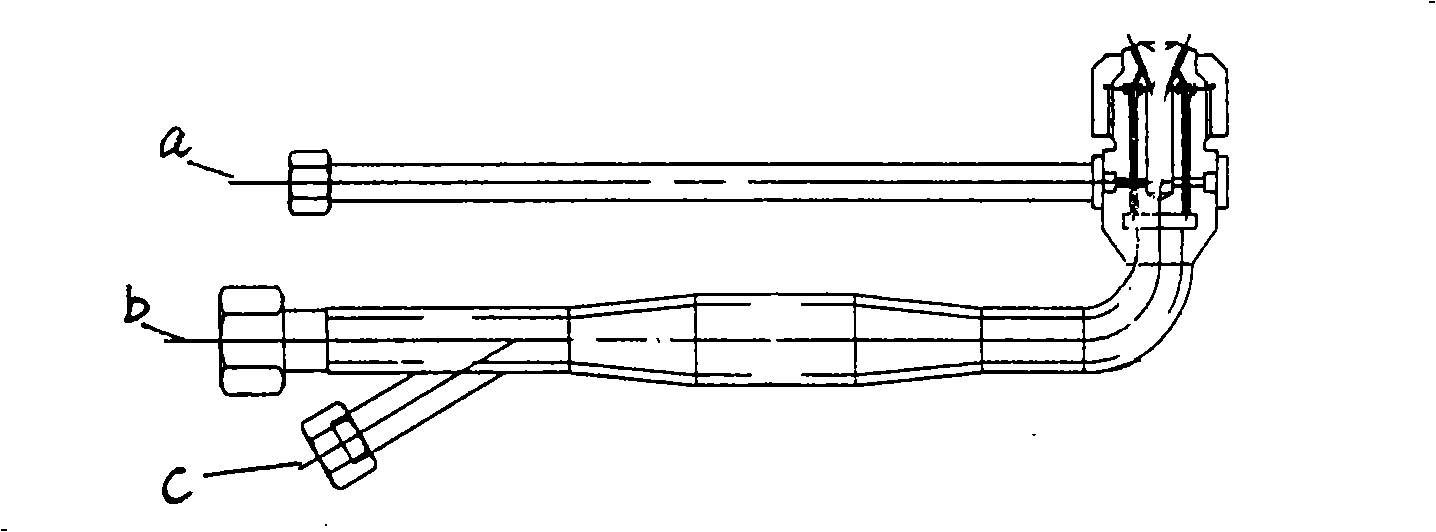

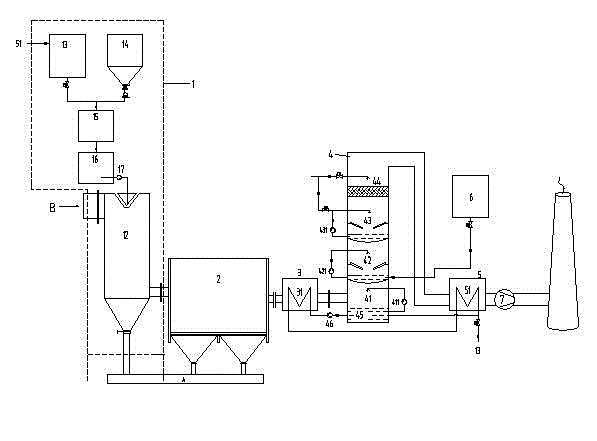

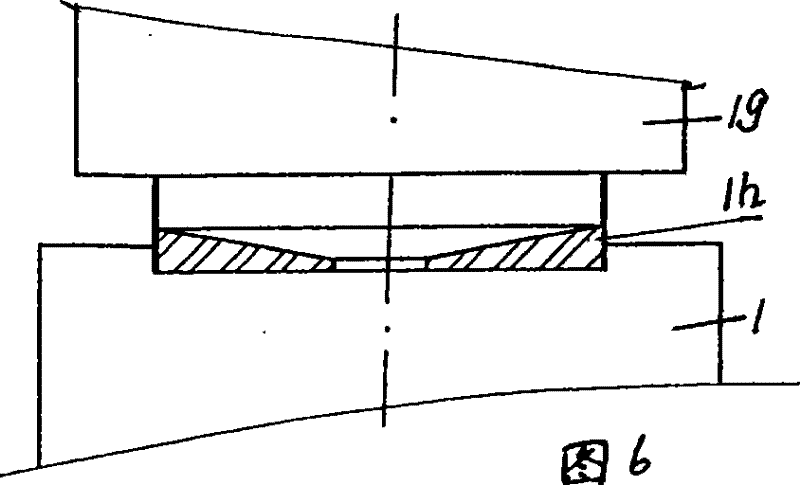

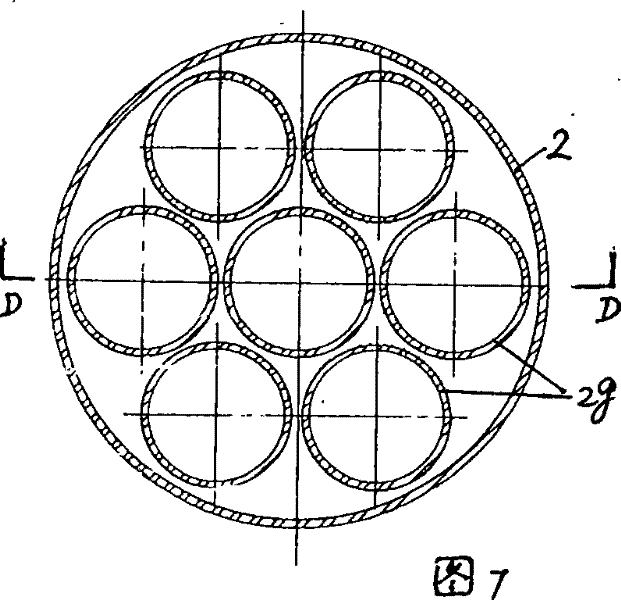

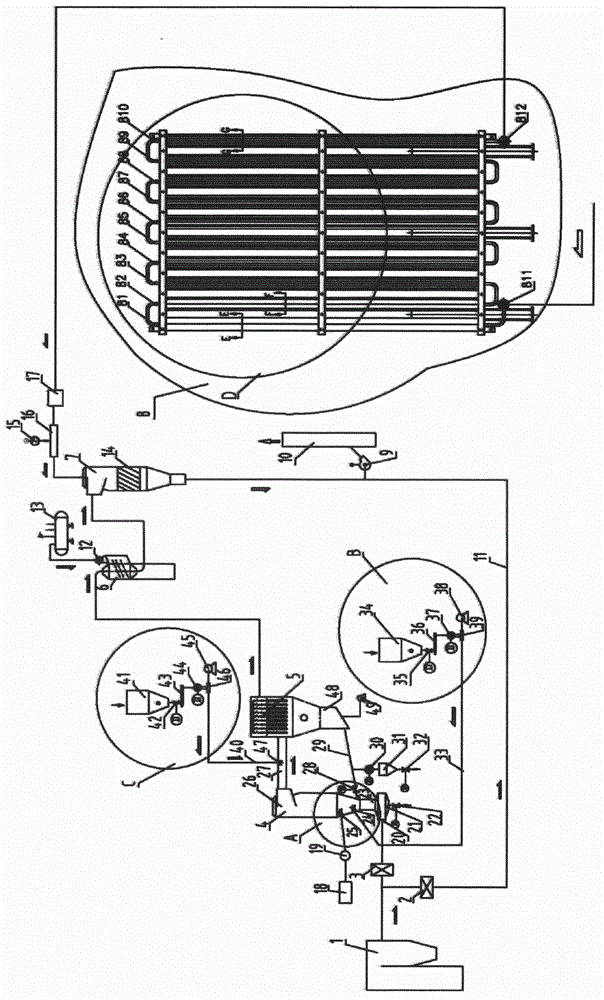

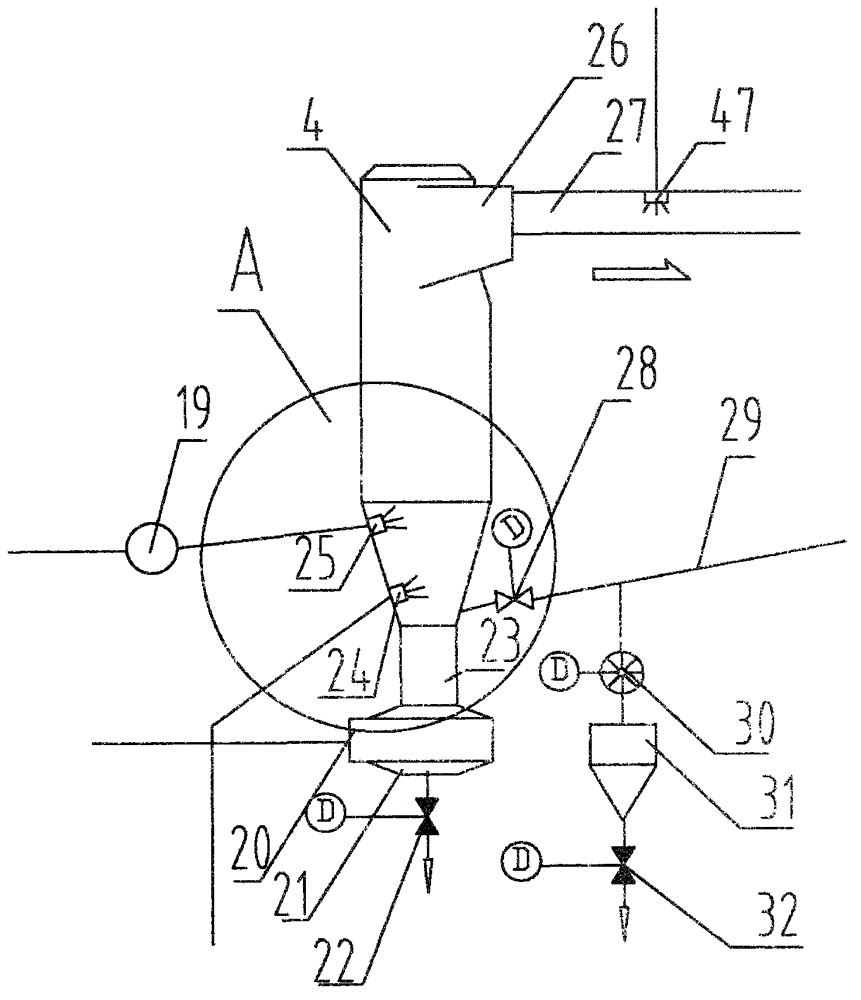

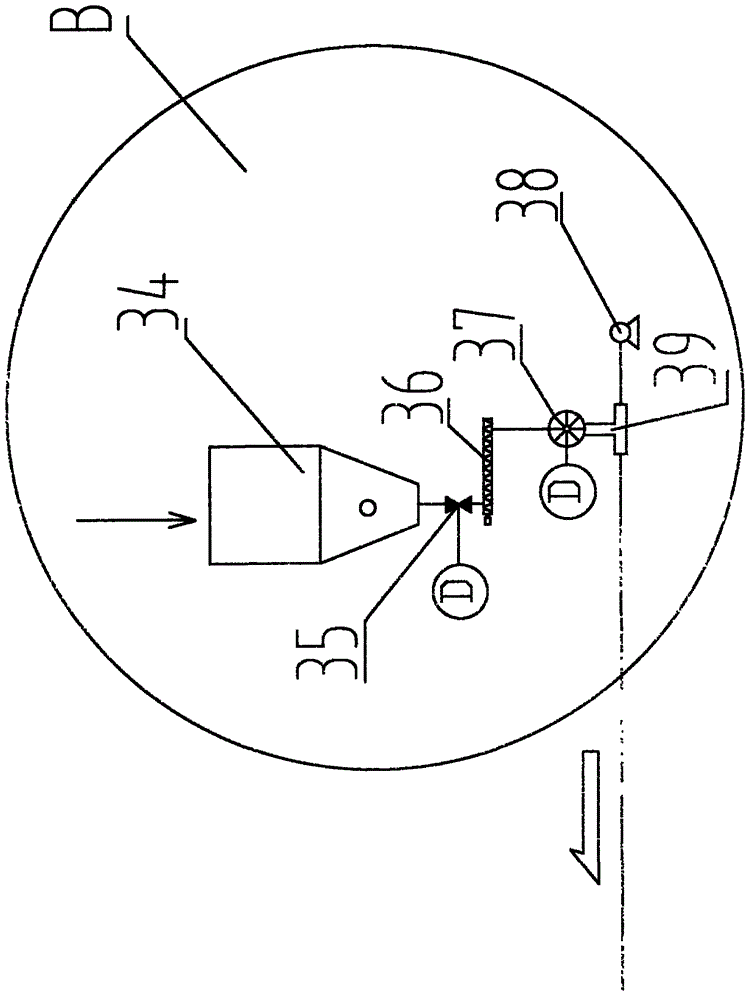

Semi-dry process smoke eliminator with independent temperature-reducing column

ActiveCN101342458AEnhanced rectificationImprove current sharing effectDispersed particle separationEvaporationInlet manifold

The invention relates to a smoke gas purification device by a semidry process, which is provided with an independent desuperheating tower, comprising a reaction tower provided with an smoke inlet box, a smoke gas outlet, a venturi tube type tower wall arranged on a tower bottom, a water injector arranged on the tower wall and a nozzle for lime dry powder and revert dust; and the smoke gas outlet is connected with an inertia separator, an activated carbon mixer, a bag-type dust remover and a draught fan. The invention is characterized in that the invention is also provided with the desuperheating tower which is provided with a boiler smoke gas inlet manifold, a single-stage water injector, an ash bucket with an ash hole and a gas flue; the gas flue of the desuperheating tower is connected with the smoke inlet box into one unit. The boiler smoke gas disperses within the two towers for cooling, thereby improving the adaptability of a system to a load; the boiler smoke gas particularly can be cooled down urgently to a set temperature in the desuperheating tower; and the reaction tower can be humidified only by evaporation with a little water to complete a deacidifying reaction and remove dioxin, thereby avoiding the disadvantages of scale formation on the tower wall of the prior reaction tower and bag burning of the bag-type dust remover, guaranteeing a sustaining and stable smoke purification process and having the advantages of good purification effect and low energy consumption.

Owner:HANGZHOU NEW CENTURY ENERGY ENVIRONMENTAL PROTECTION ENG CO LTD

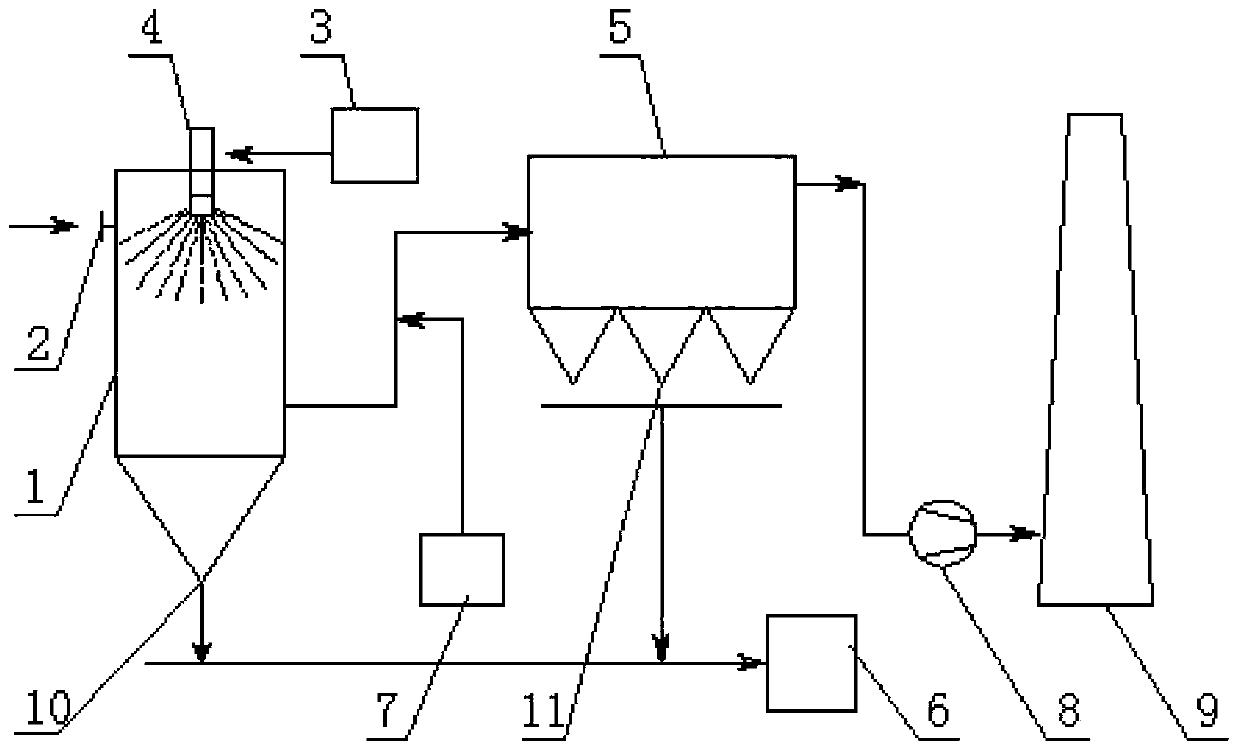

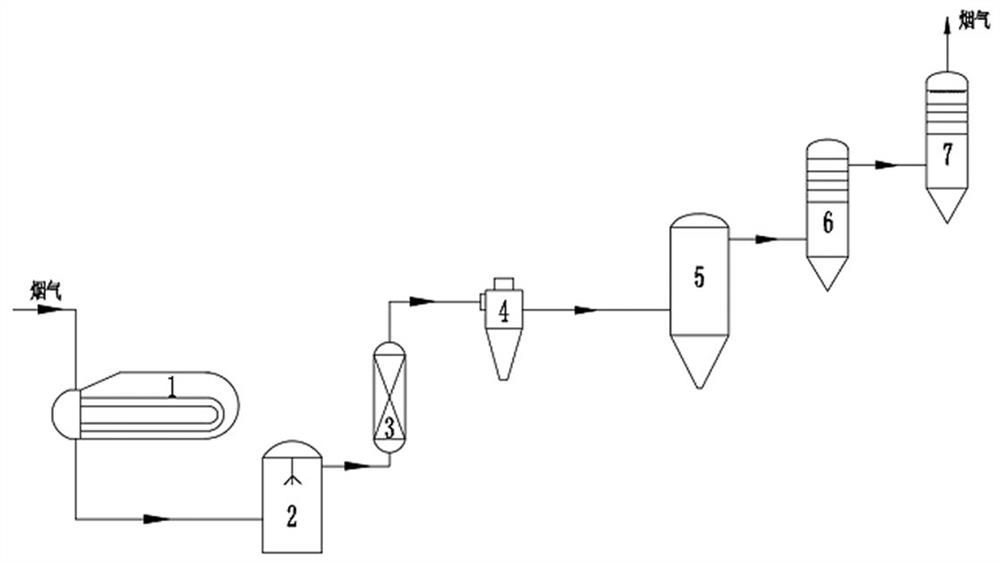

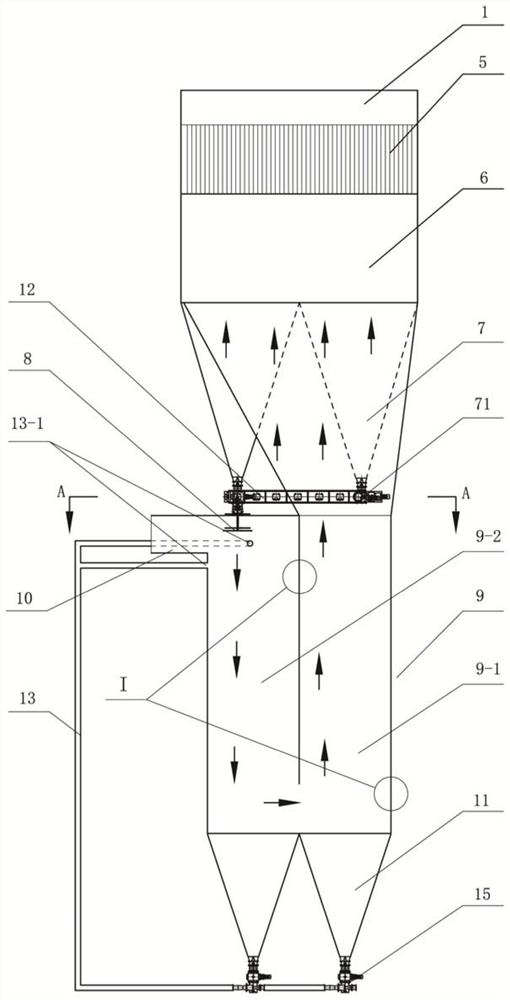

Combined purification system for waste incineration smoke and technology of combined purification system

ActiveCN103185346AReduce operating costsMeet environmental emission standardsLighting and heating apparatusDispersed particle separationAtmospheric airWater resources

The invention discloses a combined purification system for waste incineration smoke and a technology of the combined purification system. The combined purification system comprises a spraying deacidification system, a dust remover, a smoke cooler, a smoke washing tower and a smoke reheater. Firstly, smoke passes through the spraying deacidification system to be subjected to pre-deacidification, then passes through the dust remover, so that solid particles in the smoke are removed, and enters the smoke washing tower for deep washing after cooled by the smoke cooler; and purified smoke is discharged into the air by an induced draft fan after heated by the smoke reheater. Waste water produced by the smoke washing tower is firstly used as a heat conduction medium for the smoke cooler and the smoke reheater and then used as an absorbing agent for the spraying deacidification system to prepare water, engineering investment and operation costs required by a traditional wet process technology for treating a large amount of waste water are saved, water consumption of a smoke treatment system is reduced, and a large number of water resources are saved; and waste heat in the smoke is fully used, and energy consumption is reduced, environment-friendly emission indexes are improved, and the stability operation level of equipment is improved.

Owner:RE ENERGY TECH +1

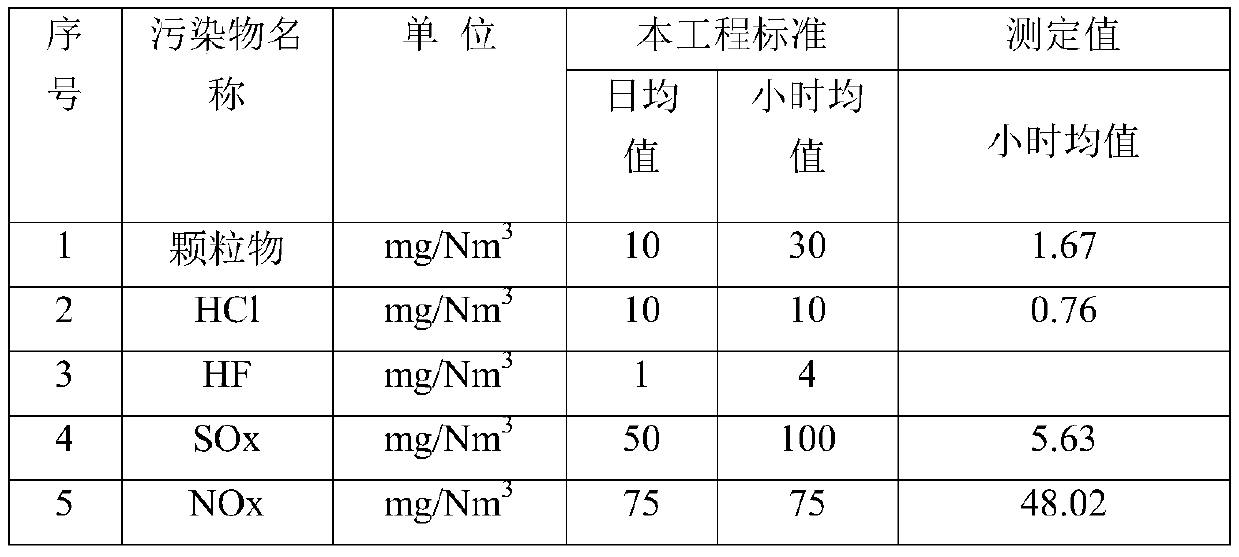

Waste incineration flue gas purifying system and process

ActiveCN103432887AImprove deacidification efficiencyGood removal effectCombination devicesDispersed particle filtrationSprayerDust control

The invention discloses a waste incineration flue gas purifying system and a waste incineration flue gas purifying process. The waste incineration flue gas purifying system comprises a semi-dry type adsorption tower, a lime slurry preparation system, an active carbon injection system and a bag type dust remover, wherein a rotary sprayer is connected with the lime slurry preparation system; the rotary sprayer is arranged at the top end of the semi-dry type adsorption tower; an exhaustion port of the semi-dry type absorption tower is formed in the bottom end of the semi-dry type adsorption tower; a gas inlet of a flue gas pipeline is connected with the semi-dry type adsorption tower; the active carbon injection system is arranged on a flue gas pipeline arranged between the semi-dry type adsorption tower and the bag type dust remover; the bag type dust remover is connected with a gas outlet of the flue gas pipeline; a filter medium adopted in the bag type dust remover is a dust-removing bag; an exhaustion port of the bag type dust remover is formed in the bottom end of the dust-removing bag; a centrifugal air blower and a chimney are arranged at an air outlet. According to the purifying system and the purifying process disclosed by the invention, wastewater is not generated, the water consumption amount is less than that of a wet-type washing tower, the process is simple, and the investment and operation cost is relatively lower.

Owner:大连滨航生态环保工程有限公司

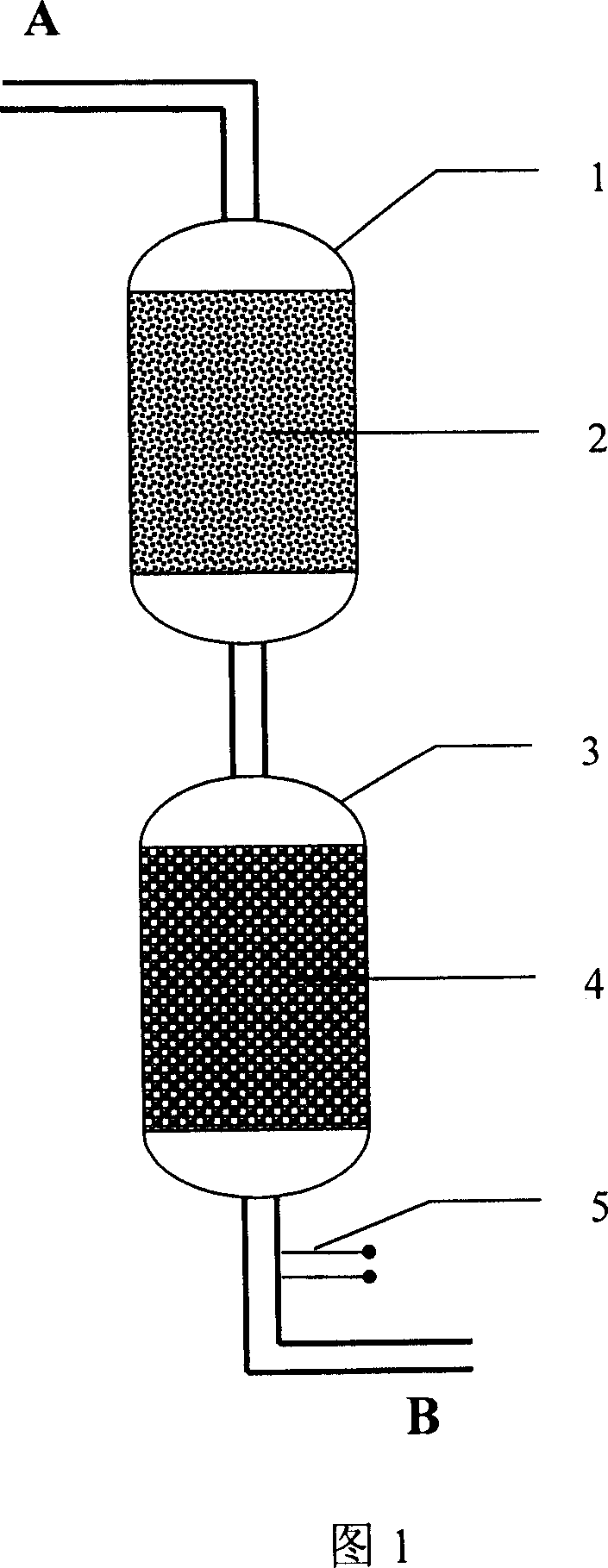

Electrolysing solution acid stripping method and apparatus

The invention provides an electrolyte disacidifying method, comprising: contacting electrolyte with anion exchange resin, where the anion exchange resin comprises at least a segment of weakly alkali anion exchange resin and at least a segment of strongly alkali anion exchange resin. And the invention provides an electrolyte disacidifying device. And the invention disacidifies the electrolyte by combining at least a segment of weakly alkali anion exchange resin and at least a segment of strongly alkali anion exchange resin. As compared with singly using weakly alkali anion exchange resin, the invention largely raises the disacidifying efficiency.

Owner:BYD CO LTD

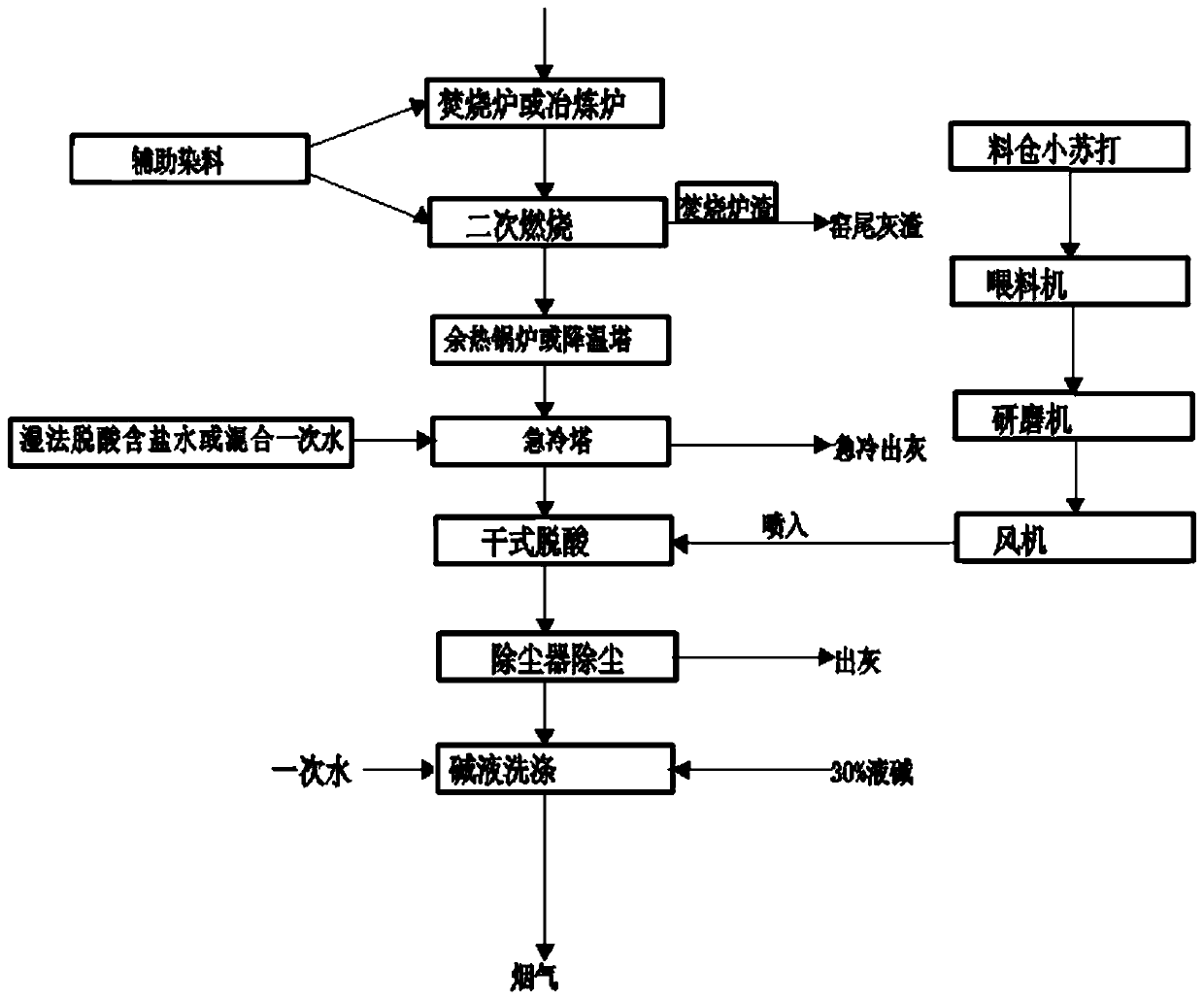

Method of using sodium bicarbonate for deacidifying incineration flue gas and realizing zero discharge of sewage

ActiveCN110314509AAchieve zero effluxImprove deacidification efficiencyGas treatmentLighting and heating apparatusSodium bicarbonateFlue gas

The invention discloses a method of using sodium bicarbonate for deacidifying incineration flue gas and realizing zero discharge of sewage. The method comprises the steps that after high-temperature flue gas enters a quenching tower, the temperature is suddenly lowered to 200 DEG C or below under the action of water or salt-containing water, at that moment, ground sodium bicarbonate is timely sprayed for deacidification, and the salt-containing wastewater or other wastewater subjected to wet deacidification is sprayed back into the quenching tower. The flue gas is subjected to dry deacidification, sodium bicarbonate is used for replacing slaked lime, the deacidification efficiency is improved, and the operation cost is reduced; when the flue gas contains a large number of acids, wet deacidification is carried out, and by introducing a salt inhibitor, the problems are solved that after high-salt wastewater is sprayed into the quenching tower, salts are accumulated and stable productionis thus influenced; zero discharge of sewage in an incineration system is realized.

Owner:潍坊帕尔曼粉体设备有限公司

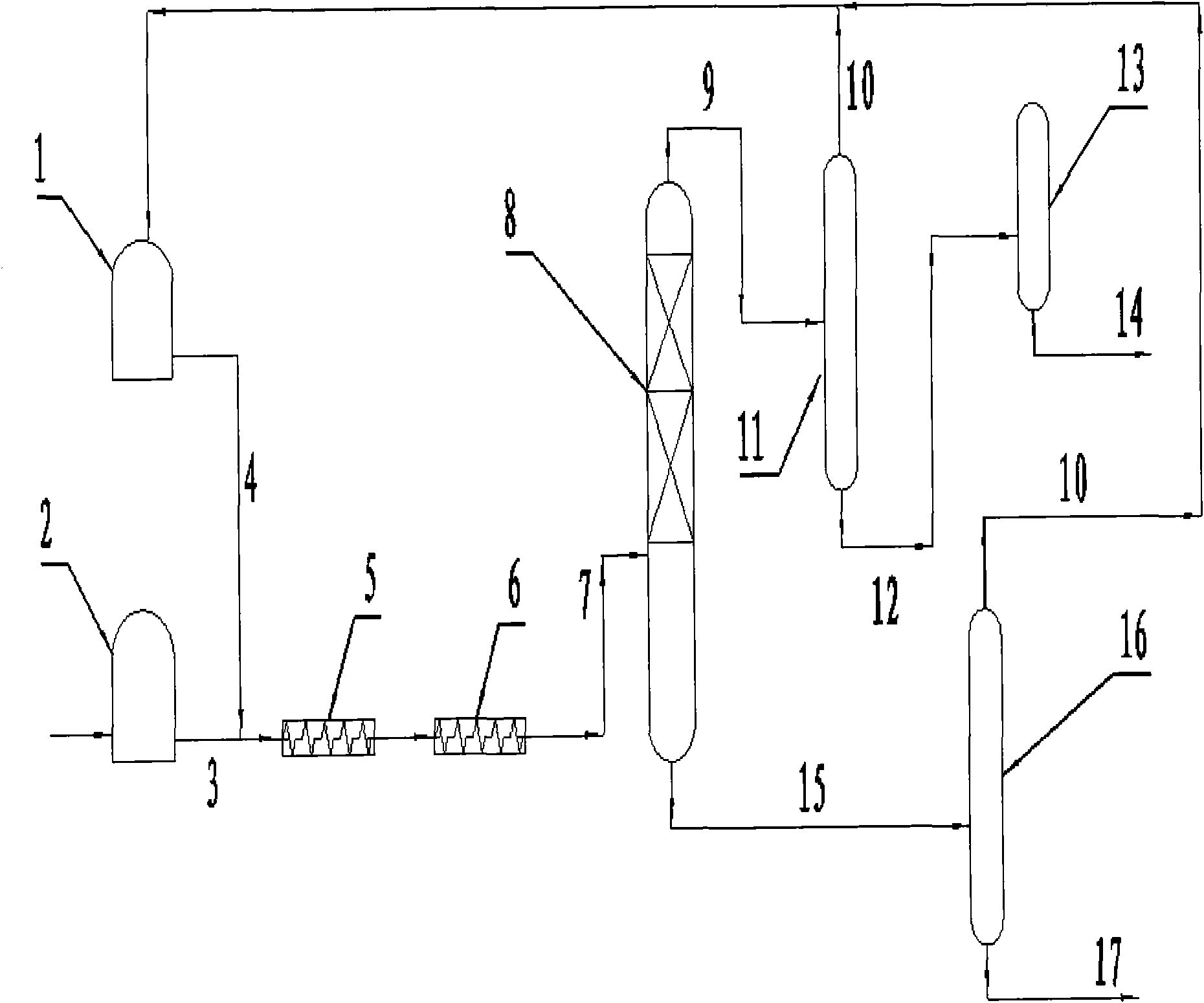

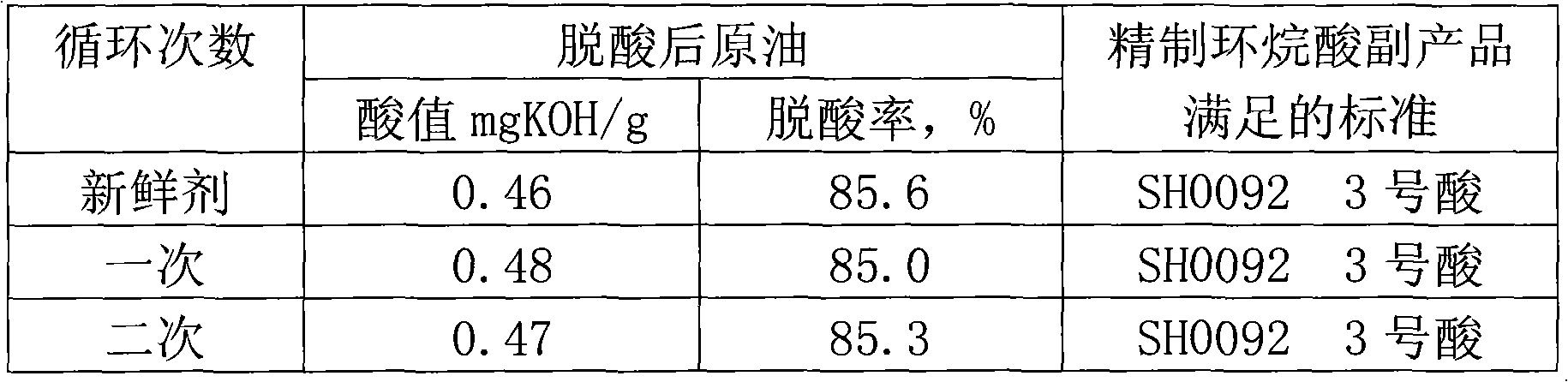

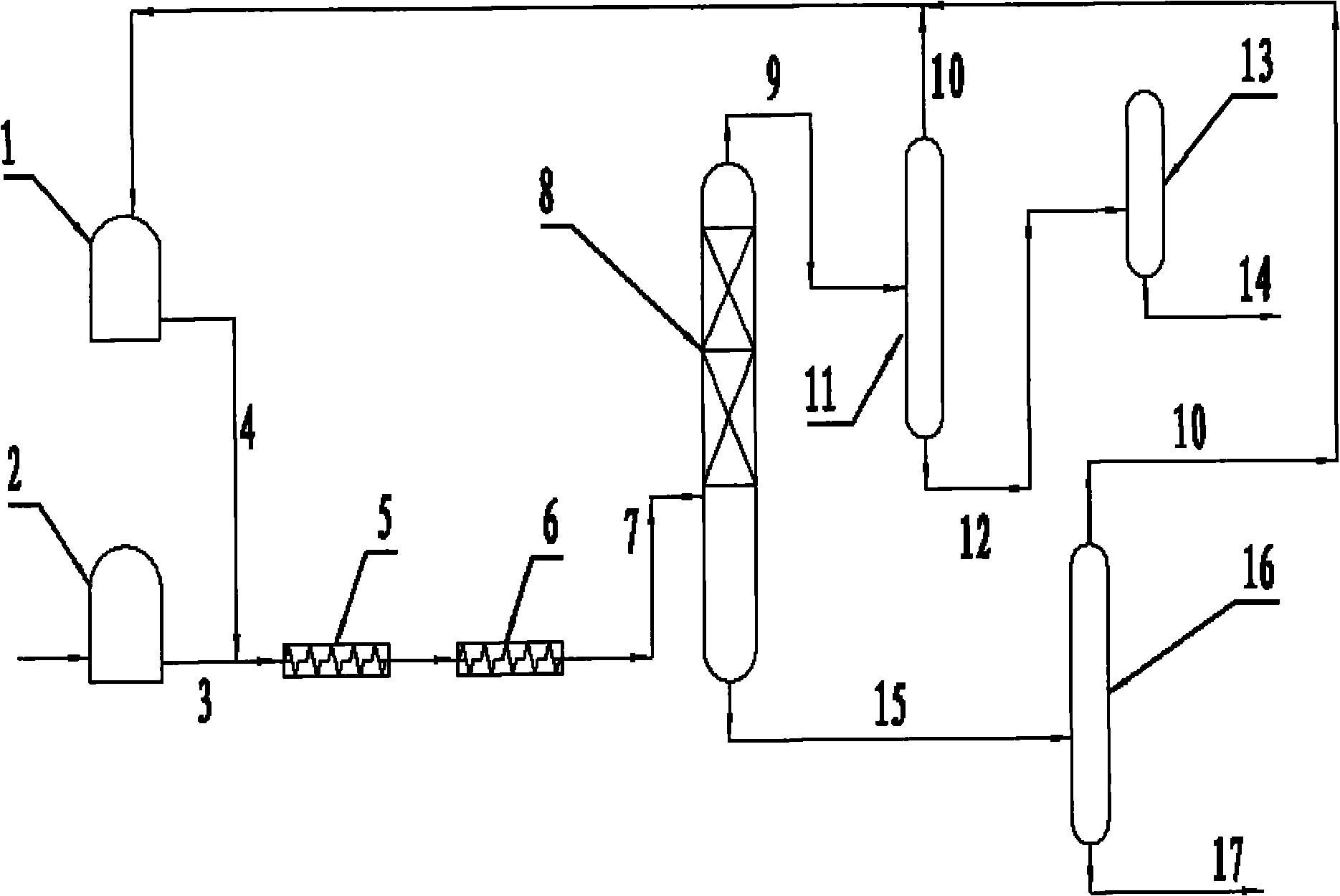

Method for recovering naphthenic acid from hydrocarbon oil and device thereof

InactiveCN102311775AImprove deacidification efficiencyFast layeringTreatment with plural serial refining stagesCarboxylic compound separation/purificationSolventChemistry

The invention provides a method for recovering naphthenic acid from hydrocarbon oil and a device thereof. The method comprises: reacting a raw material oil and deacidified solvent in a static mixer, and delivering the oil and agent mixture obtained after reaction into a settling separation tower, wherein the mixture is divided into two layers in the tower, the upper naphthenic-acid-containing deacidified solvent is distilled in a decomposing distillation tower for distillation, the deacidified solvent evaporated out is returned to a deacidified solvent tank to be circularly used, and coarse naphthenic acid discharged from the bottom of the decomposing distillation tower is delivered into a naphthenic acid refining tank for refining treatment and thus refined naphthenic acid is obtained; and the lower deacidified raw material oil in the settling separator tower is delivered to a raw material distillation tower, a small amount of deacidified solvent is evaporated out from the top of the tower and is returned to a deacidified solvent tank to be used circularly, and the deacidified raw material oil is discharged out from a raw material distillation tower. When the method and the device are used, the acidity and corrosion of the oil can be reduced, the naphthenic acid byproduct with high added value can be obtained, the deacidified solvent is cheap and readily available and can be circularly used for a plurality of times, and waste gas, waste water and waste residue are not discharged.

Owner:CHINA PETROLEUM & CHEM CORP +1

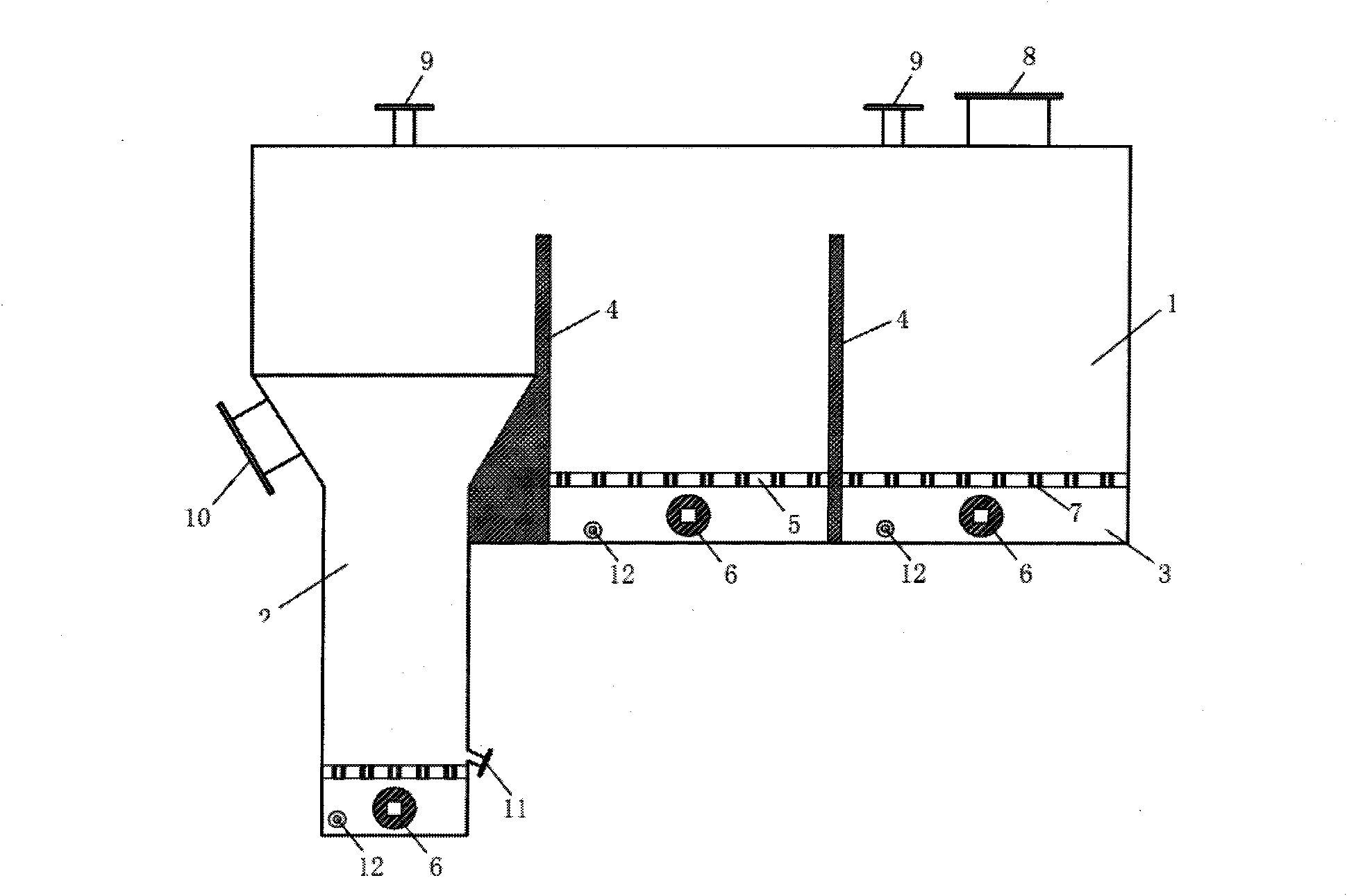

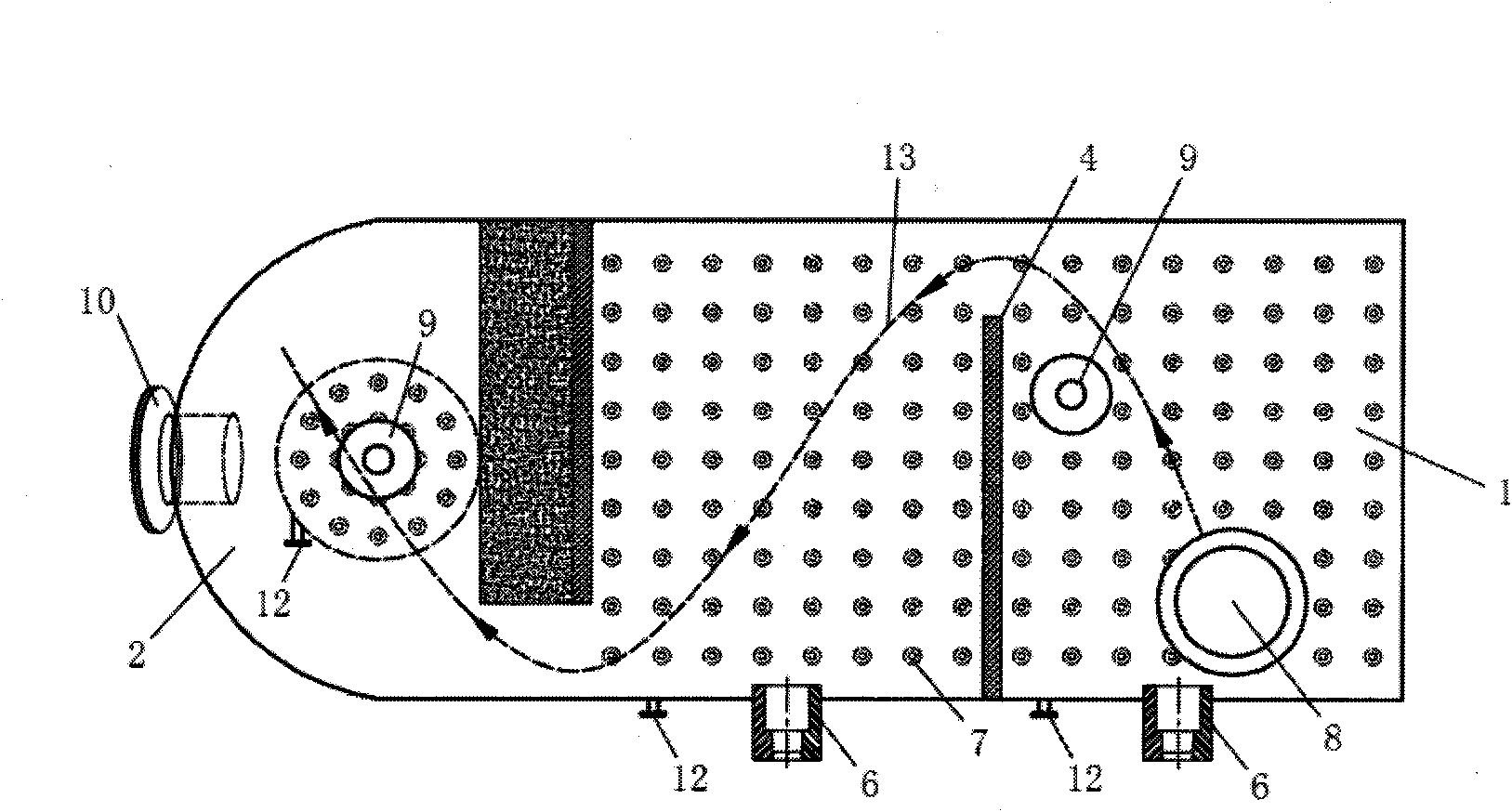

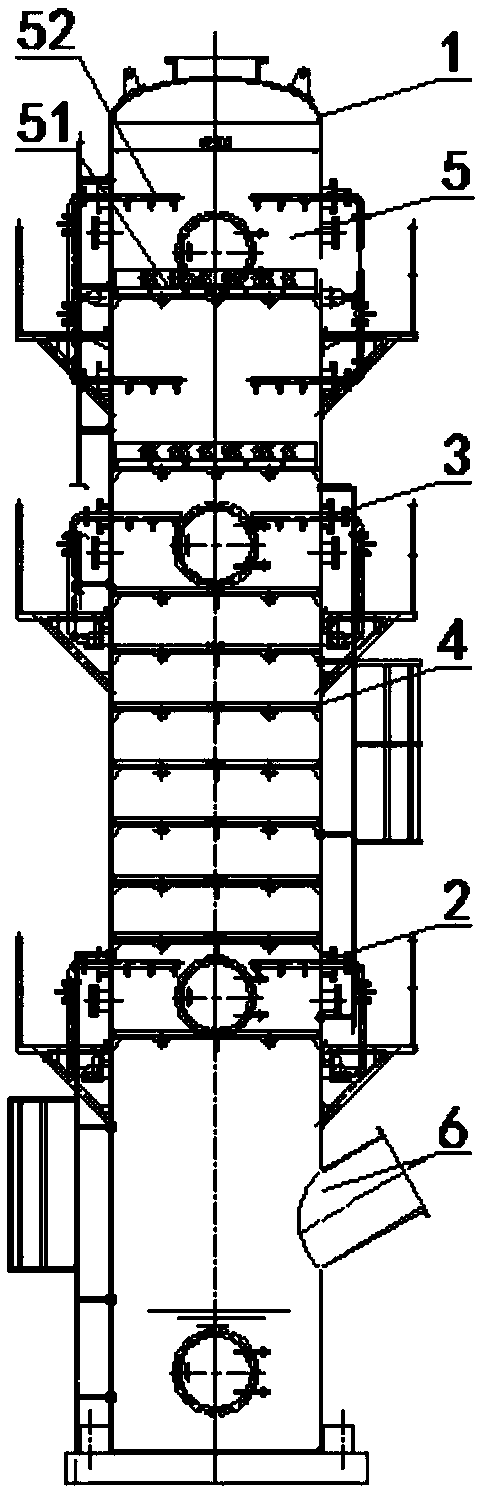

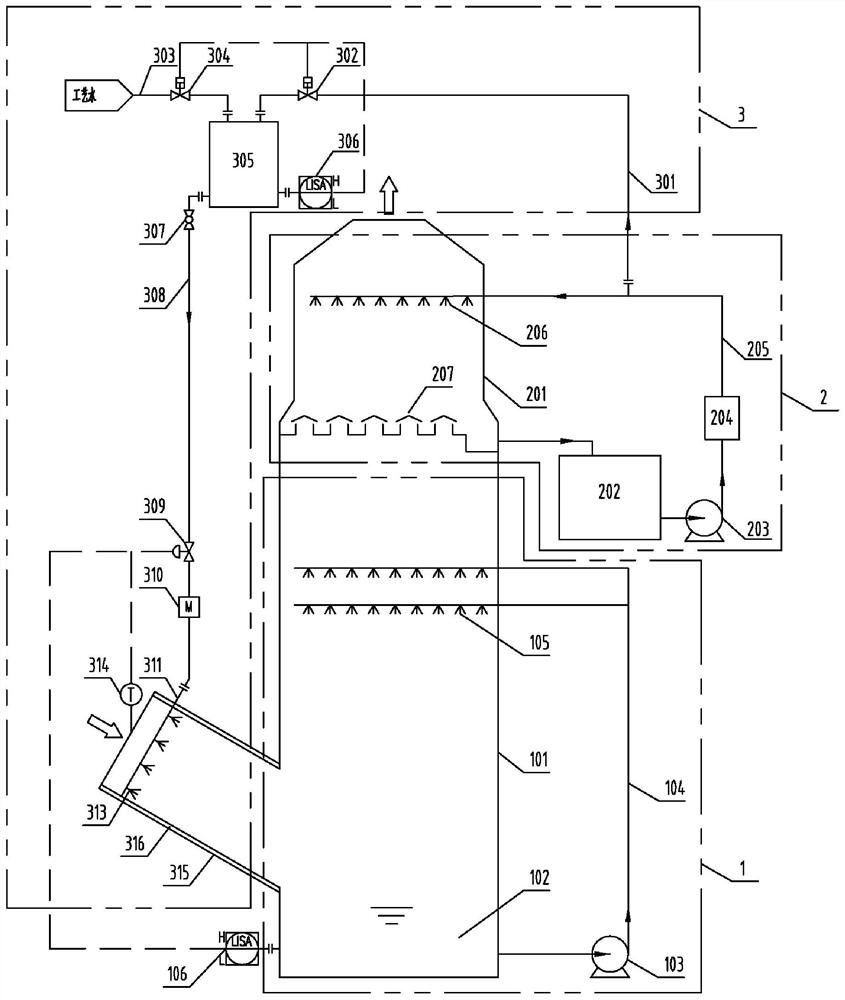

Fluidized bed deacidification purification device and process

The invention discloses a fluidized bed deacidification purification device and process, and belongs to the field of inorganic fine chemical engineering. The device is generally divided into a horizontal fluidized bed part and a vertical fluidized bed part, wherein each part is divided into an upper layer and a lower layer; each upper layer is a fluidized bed part for conveying materials; each lower layer is a combustion chamber of hydrogen and air; each combustion chamber is internally provided with a combustor; the upper layers and the lower layers are separated by partition plates; each partition plate is provided with a gas channel; the upper layer of the horizontal fluidized bed is separated into a plurality of chambers by a plurality of baffles; through channels are formed among the chambers, so that the materials can pass through from a feeding chamber to the following chambers sequentially until the materials flow into the vertical fluidized bed and are discharged from a discharge port of the vertical fluidized bed; and a vapor-phase silicon dioxide material after being deacidified by the horizontal fluidized bed enters the vertical fluidized bed for deacidification. Compared with the prior art, the deacidification technology disclosed by the invention enables the pH of white carbon black to be stabilized in a range from 4.3 to 4.6 by utilizing two-stage deacidification and improves product quality of SiO2 by using a vapor phase method.

Owner:赤峰盛森硅业科技发展有限公司

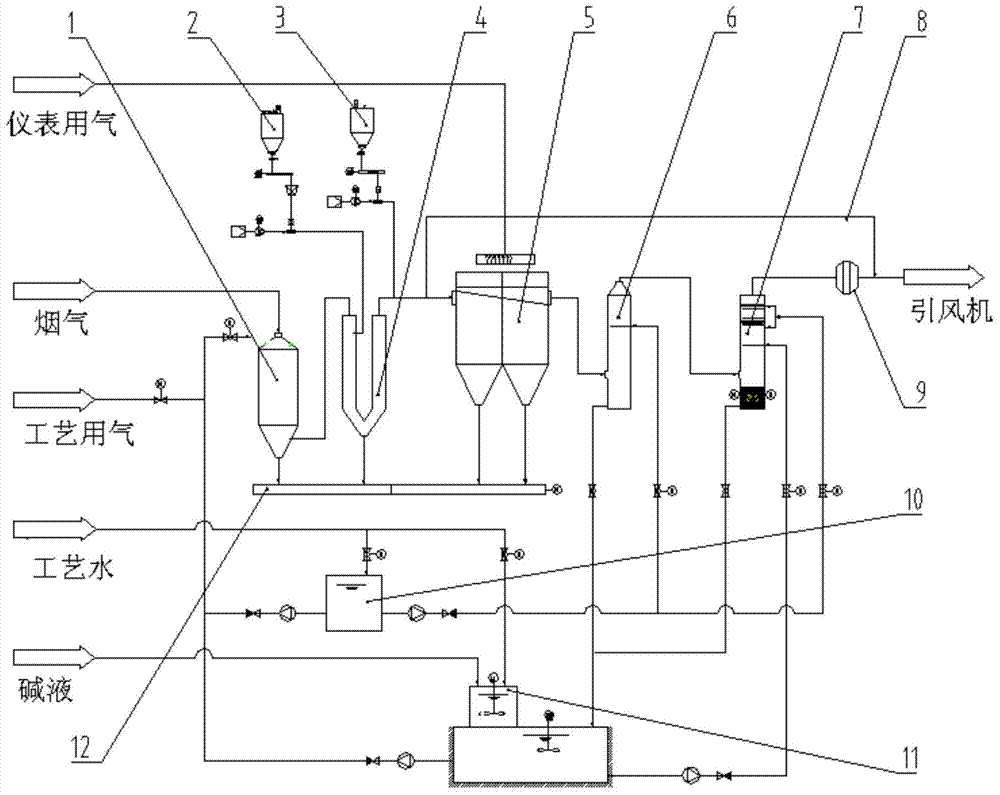

Comprehensive absorption and deacidification system for dangerous and medical waste incineration flue gas

InactiveCN104324590AImprove deacidification efficiencyStable guaranteed emission targetsDispersed particle separationMedical treatmentDust collector

The invention discloses a comprehensive absorption and deacidification system for dangerous and medical waste incineration flue gas. The system comprises a quenching tower, a sodium hydrogen carbonate powder spraying tower, an activated carbon powder spraying tower, a flue reactor, a cloth bag dust collector, an acid pickling tower, a base washing tower, a flue gas bypass, a heat exchanger, a quenching water tower, an alkali liquor preparation tower and a fly ash storage and transportation tower. The adaptive temperature range of the system is wide, the system can adapt to high-temperature flue gas with the temperature of 200-900 DEG C, and the process requirement on incineration equipment is not severe; the deacidification efficiency is high, the discharging index can be stably guaranteed and is superior to the GB18484-2001 standard; no sewage treatment equipment is needed in the production process, and zero sewage discharging is realized.

Owner:ANHUI SHENGYUN ENVIRONMENTAL ENG

Semi-dry process smoke eliminator with independent temperature-reducing column

ActiveCN101342458BImprove current sharing effectGuarantee continuous and stable operationDispersed particle separationEvaporationInlet manifold

The invention relates to a smoke gas purification device by a semidry process, which is provided with an independent desuperheating tower, comprising a reaction tower provided with an smoke inlet box, a smoke gas outlet, a venturi tube type tower wall arranged on a tower bottom, a water injector arranged on the tower wall and a nozzle for lime dry powder and revert dust; and the smoke gas outlet is connected with an inertia separator, an activated carbon mixer, a bag-type dust remover and a draught fan. The invention is characterized in that the invention is also provided with the desuperheating tower which is provided with a boiler smoke gas inlet manifold, a single-stage water injector, an ash bucket with an ash hole and a gas flue; the gas flue of the desuperheating tower is connected with the smoke inlet box into one unit. The boiler smoke gas disperses within the two towers for cooling, thereby improving the adaptability of a system to a load; the boiler smoke gas particularly can be cooled down urgently to a set temperature in the desuperheating tower; and the reaction tower can be humidified only by evaporation with a little water to complete a deacidifying reaction and remove dioxin, thereby avoiding the disadvantages of scale formation on the tower wall of the prior reaction tower and bag burning of the bag-type dust remover, guaranteeing a sustaining and stable smokepurification process and having the advantages of good purification effect and low energy consumption.

Owner:HANGZHOU NEW CENTURY ENERGY ENVIRONMENTAL PROTECTION ENG CO LTD

Waste incineration flue gas purification method and system

InactiveCN112742201ASave energyInhibition of resynthesisHuman health protectionCombination devicesPurification methodsFlue gas

The invention discloses a waste incineration flue gas purification method and system. The system comprises a flue gas waste heat recovery and denitration system, a quench tower system, a reaction tower system, a dust remover system, a deacidification system and the like. After the waste incineration flue gas is conveyed to the waste heat recovery and denitration system for flue gas waste heat recovery and denitration, the flue gas is conveyed to the quench tower system for rapid cooling, then conveyed to the reaction tower system for reaction, conveyed to the dust remover system for dust removal, finally conveyed to the deacidification system for deacidification, and discharged after reaching the standard. The waste incineration flue gas purification method and system have the advantages of being good in energy-saving and environment-friendly performance, high in denitration and deacidification efficiency, capable of effectively inhibiting secondary synthesis of dioxin, remarkable in dust removal and heavy metal removal effect and the like. The novel waste incineration flue gas purification method and system are energy-saving and consumption-reducing, easy to operate and good in running economic benefit, the flue gas can be directly discharged, and no pollution is caused to the environment.

Owner:JIANGSU MORAL ENVIRONMENTAL PROTECTION TECH CO LTD

Waste gas dust removal and adsorption treatment device

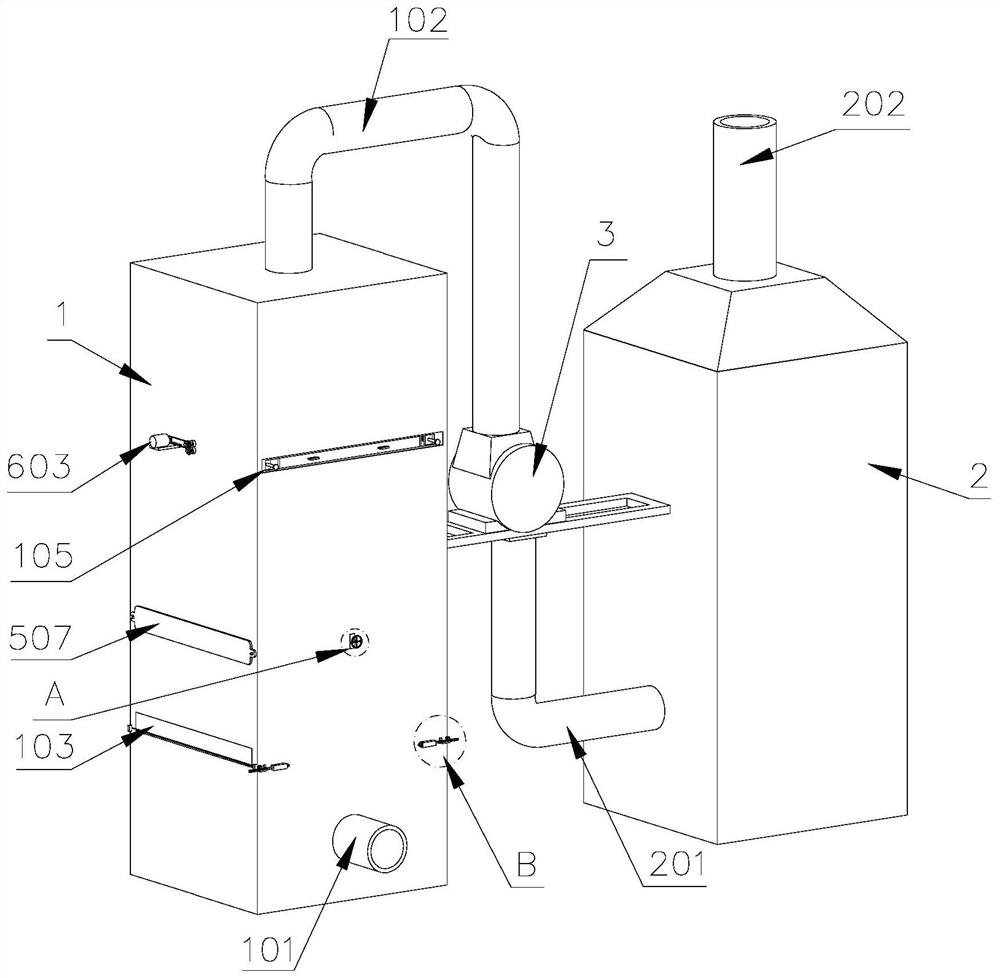

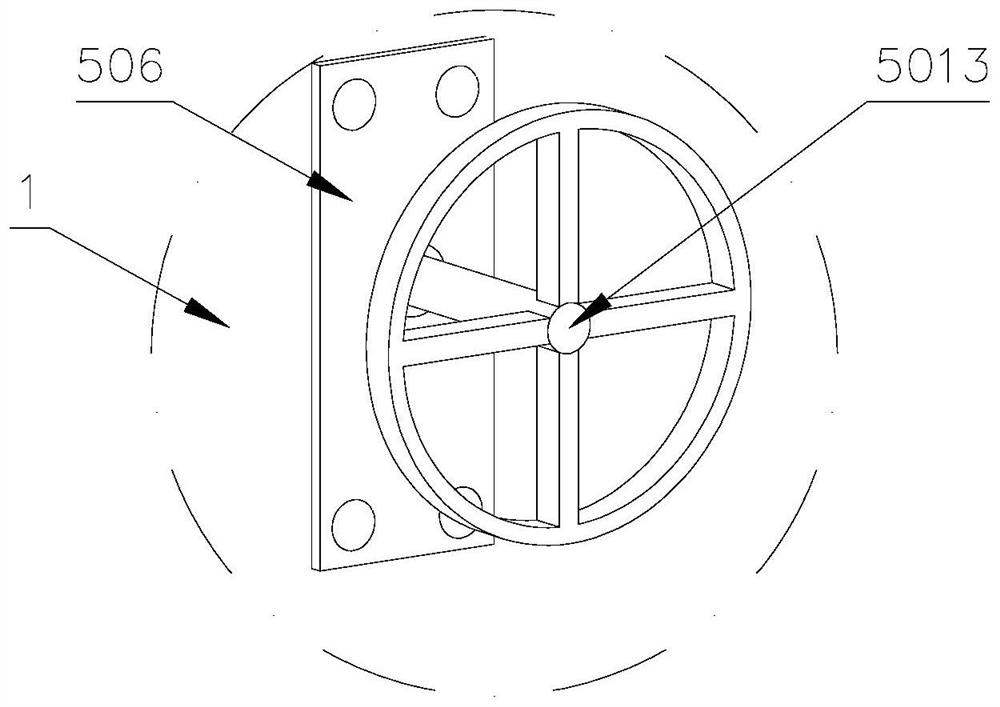

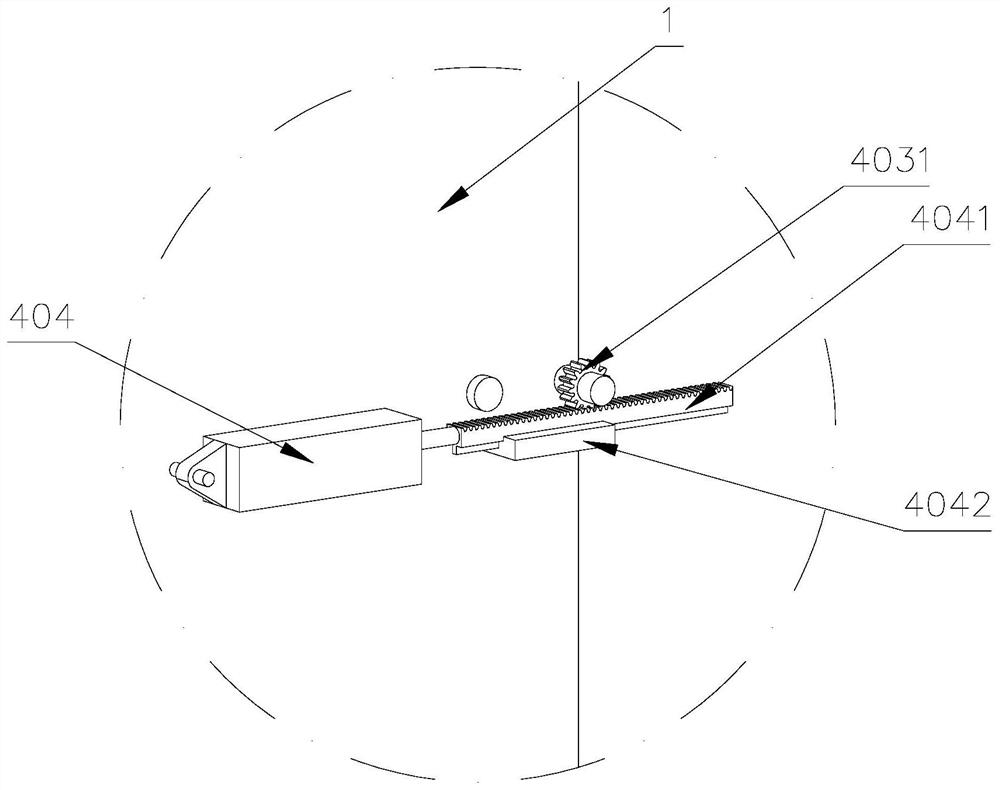

ActiveCN114471045AAvoid the drawbacks of needing frequent replacementAvoid the disadvantages of frequent replacementCombination devicesGas treatmentDust controlEnvironmental engineering

The invention discloses a waste gas dust removal and adsorption treatment device which comprises a box body I, a box body II, an induced draft fan, an adjusting mechanism, a filtering mechanism, an adsorption mechanism and a deacidification mechanism, the box body I is arranged on one side of the box body II; the induced draft fan is arranged between the box body I and the box body II and connected with each other through a pipeline; the adjusting mechanism, the filtering mechanism and the adsorption mechanism are arranged in the box body I, the adjusting mechanism is arranged at the bottom end of the box body I, the adsorption mechanism is arranged at the top end of the box body I, and the filtering mechanism is arranged between the adjusting mechanism and the adsorption mechanism; the deacidification mechanism is arranged in the box body II; an air inlet pipe I is arranged at the bottom of the box body I, an air outlet pipe I is arranged at the top and connected with an induced draft fan, a discharge port and a replacement port I are formed in one side of the box body I, and a replacement port II is formed in the other side of the box body I; an air inlet pipe II is arranged at the bottom of the box body II and connected with the induced draft fan; an air outlet pipe II is arranged at the top of the box body II. By using the filtering mechanism and the adsorption mechanism, the waste gas treatment efficiency can be improved.

Owner:山东绿立冠环保科技有限公司

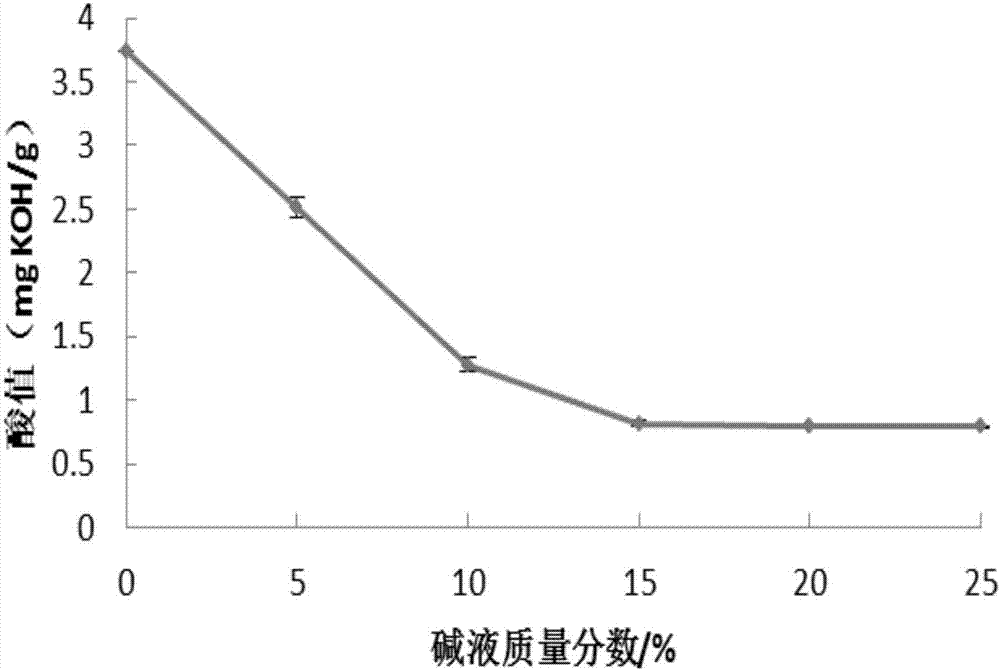

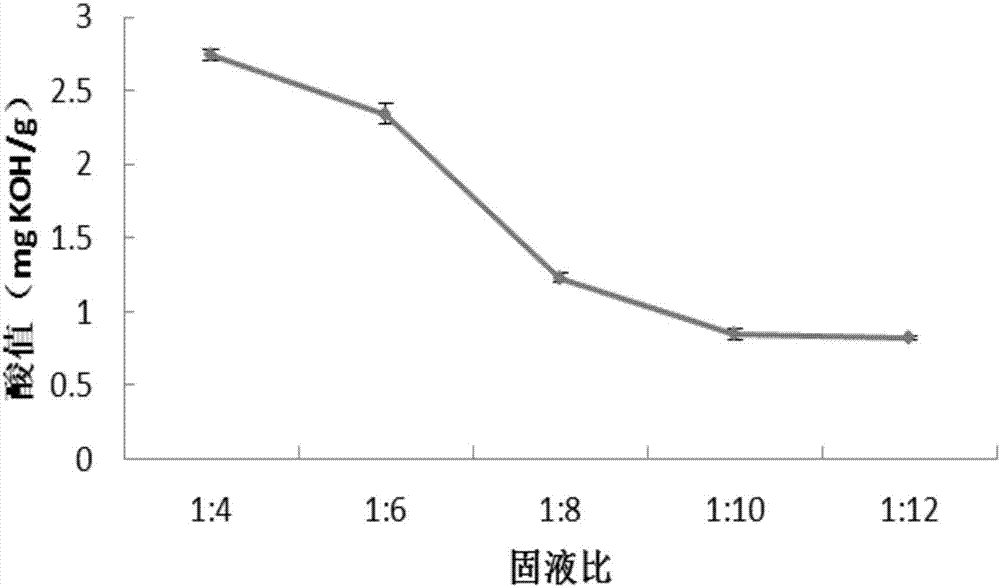

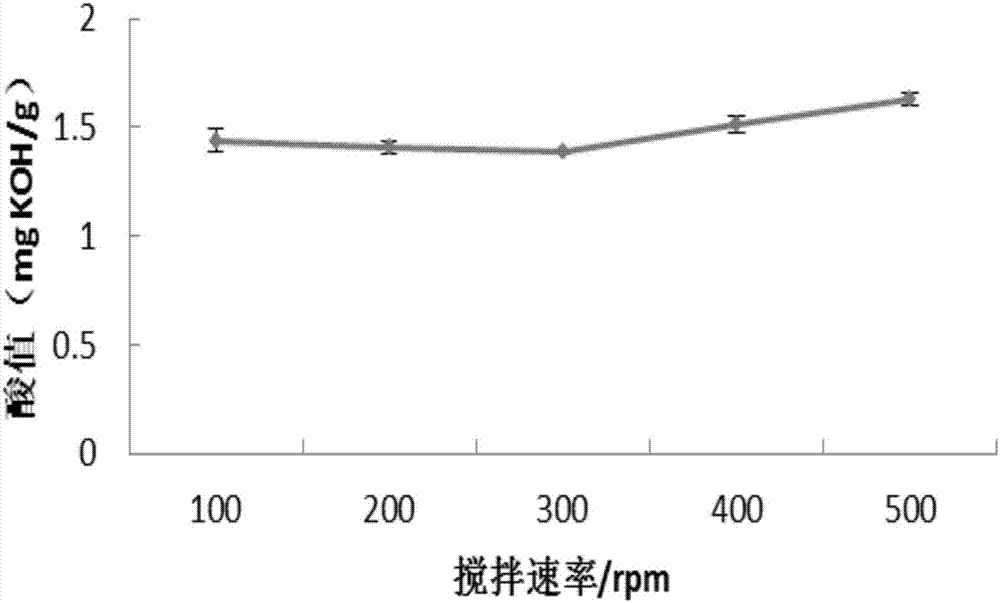

Depickling method of cold-pressed peony seed oil

InactiveCN107384587AImprove deacidification efficiencyOptimization of deacidification efficiencyFatty-oils/fats refiningFlavorUltrasonic assisted

The invention belongs to the field of deep processing and comprehensive utilization of agricultural and sideline products and provides a depickling method of cold-pressed peony seed oil. according to the method, cold-pressed peony seed degummed oil is used as a raw material, sodium hydroxide and diatomite are selected for the preparation of an alkaline diatomite depickling agent, and an ultrasonic-assisted method is adopted for cooperative depickling of peony seed oil. The method has integrated effects of physical adsorption and chemical adsorption. On one hand, depickling efficiency of peony seed oil is raised by accelerating an acid-base reaction rate; and on the other hand, quality of peony seed oil is improved and the flavor of peony seed oil is maintained. The method has advantages of simple operation, short time consumption, high depickling efficiency, less energy consumption and high safety. In addition, quality of cold-pressed peony seed oil is optimized and flavor of peony seed oil is maintained. And the problem of large equipment investment is also solved.

Owner:INST OF FORESTRY & FRUIT TREE WUHAN ACADEMY OF AGRI SCI & TECH

Waste incineration exhaust gas deacidification treatment system

InactiveCN111442285ALarge atomization areaComprehensive deacidification treatmentUsing liquid separation agentIncinerator apparatusParticulatesExhaust fumes

The invention discloses a waste incineration exhaust gas deacidification treatment system. The waste incineration exhaust gas deacidification treatment system structurally comprises waste incinerationequipment, an incineration exhaust gas pipeline, a smoke pipeline, a water supply pipe, a smoke discharge pipe, a circulating water tank, a high-pressure water pump, a smoke purifier and a deacidification water mist spraying tower, and the waste incineration equipment is connected with the deacidification water mist spraying tower through the incineration exhaust gas pipeline. Compared with the prior art, the waste incineration exhaust gas deacidification treatment system has the beneficial effects that through combination arrangement of parts such as a tilting nozzle, a top arc plate, an exterior plate, an inner supporting plate, a bottom arc plate and a separation arc plate, a novel spraying pipe is constituted, a function of preventing blocking of particulate matter is achieved, the particulate matter can be effectively prevented from making contact with a spray head, the spray area can further be enlarged, thus all exhaust gas can be subjected to spraying deacidification, and thusspraying deacidification is more comprehensive, higher in efficiency and better in effect; and meanwhile, the spray head can be prevented from being blocked by the particulate matter, thus the deacidified gas can be normal discharged, and the efficiency of waste incineration treatment is advantageously improved.

Owner:汪志辉

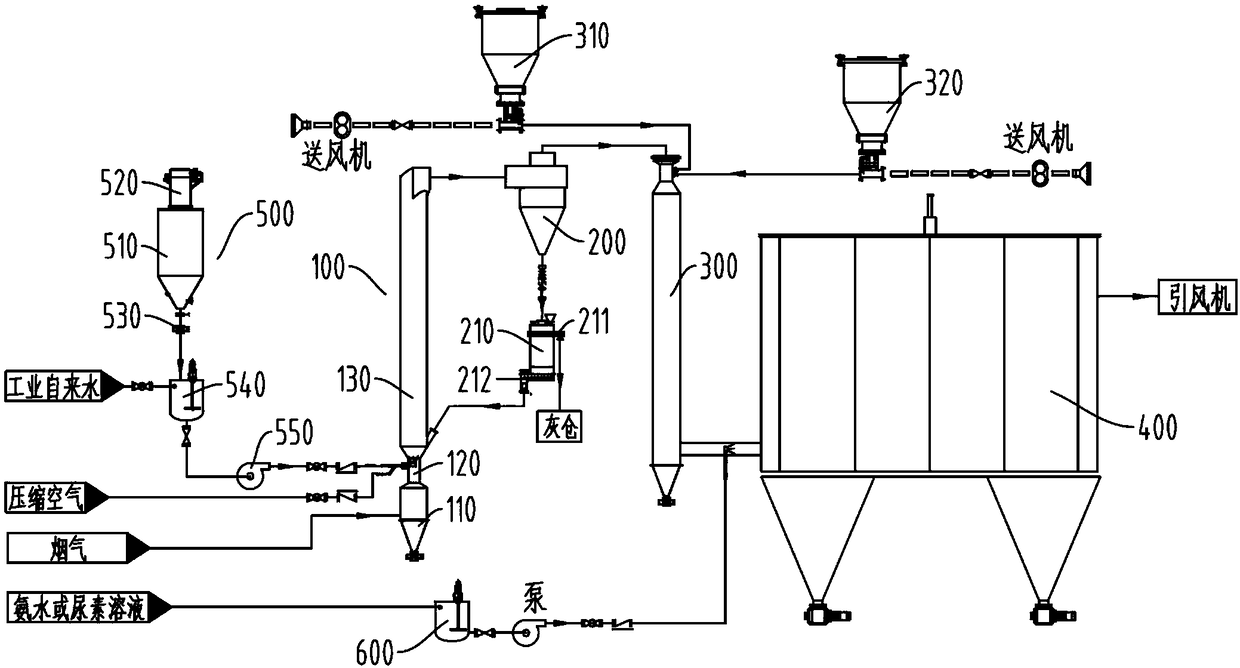

Flue gas treatment system and method after incineration of hazardous wastes

PendingCN108905615AReduce processing costsImprove deacidification efficiencyCombination devicesGas treatmentFiberSlurry

The invention discloses a flue gas treatment system and method after incineration of hazardous wastes. The system comprises a semi-dry deacidification tower, a cyclone dust collector, a dry deacidification tower, a ceramic fiber filter tube dedusting reactor and an induced draft fan and the above units are orderly connected through pipes. The top of the semi-dry deacidification tower is communicated with one side of the cyclone dust collector. The top of the cyclone dust collector is communicated with the top of the semi-dry deacidification tower. The lower side of the dry deacidification tower is communicated with the lower side of the ceramic fiber filter tube dedusting reactor. The upper side of the ceramic fiber filter tube dedusting reactor is connected to the induced draft fan. The semi-dry deacidification tower is connected to a lime slurry preparation system. The top of the dry deacidification tower is respectively connected to a baking soda bin and an activated carbon bin. Thejoint of the dry deacidification tower and the ceramic fiber filter tube dedusting reactor is connected to an ammonia water tank or a urea tank. The system can effectively reduce the cost and energyconsumption of the flue gas treatment and has high flue gas treatment efficiency.

Owner:江苏绿景环保设备有限公司

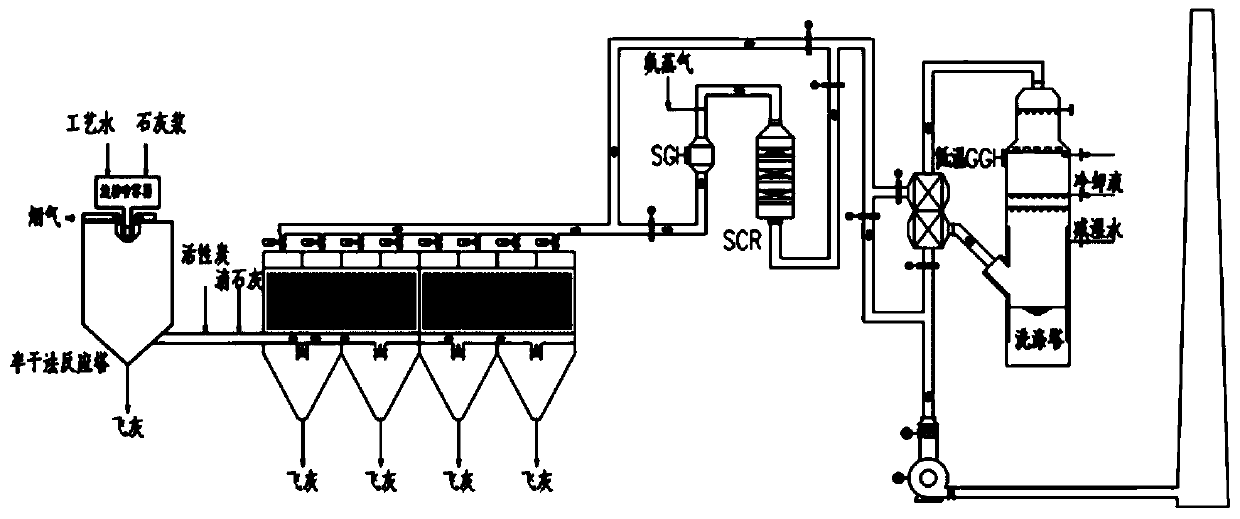

Waste incineration flue gas purification method and system

InactiveCN110876886AImprove denitrification efficiencyReduce consumptionGas treatmentDispersed particle separationActivated carbonPurification methods

The invention discloses a waste incineration flue gas purification method and a system. The waste incineration flue gas purification method comprises the following steps: (1) enabling waste incineration flue gas to flow through an SNCR treatment system to be subjected to denitration treatment; (2) enabling outlet flue gas of the SNCR treatment system to enter a semi-dry reaction tower for deacidification treatment; (3) introducing outlet gas of the semi-dry reaction tower into a bag type dust collector for dust removal treatment; (4) heating outlet gas of the bag type dust collector, and enabling the heated outlet gas of the bag type dust collector to enter into an SCR reaction tower for further denitration treatment; and (5) cooling outlet gas of the SCR reaction tower, and feeding the cooled outlet gas into a wet-process washing tower for further deacidification treatment, thereby realizing purification of the waste incineration flue gas. The treatment process of SNCR-semi-dry method-activated carbon adsorption-bag type dust removal-SCR-wet method is adopted, and efficient purification treatment of the household garbage incineration flue gas can be achieved.

Owner:CHINA URBAN CONSTR DESIGN & RES INST CO LTD

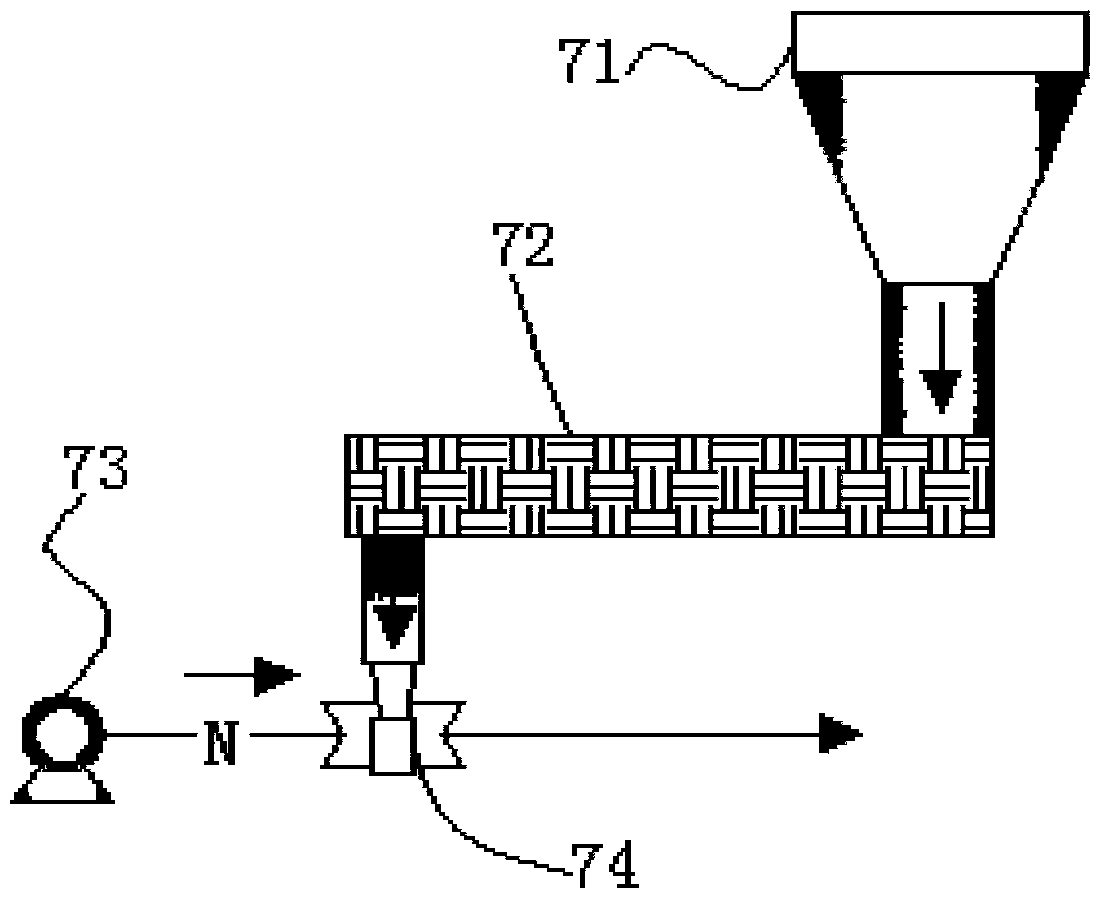

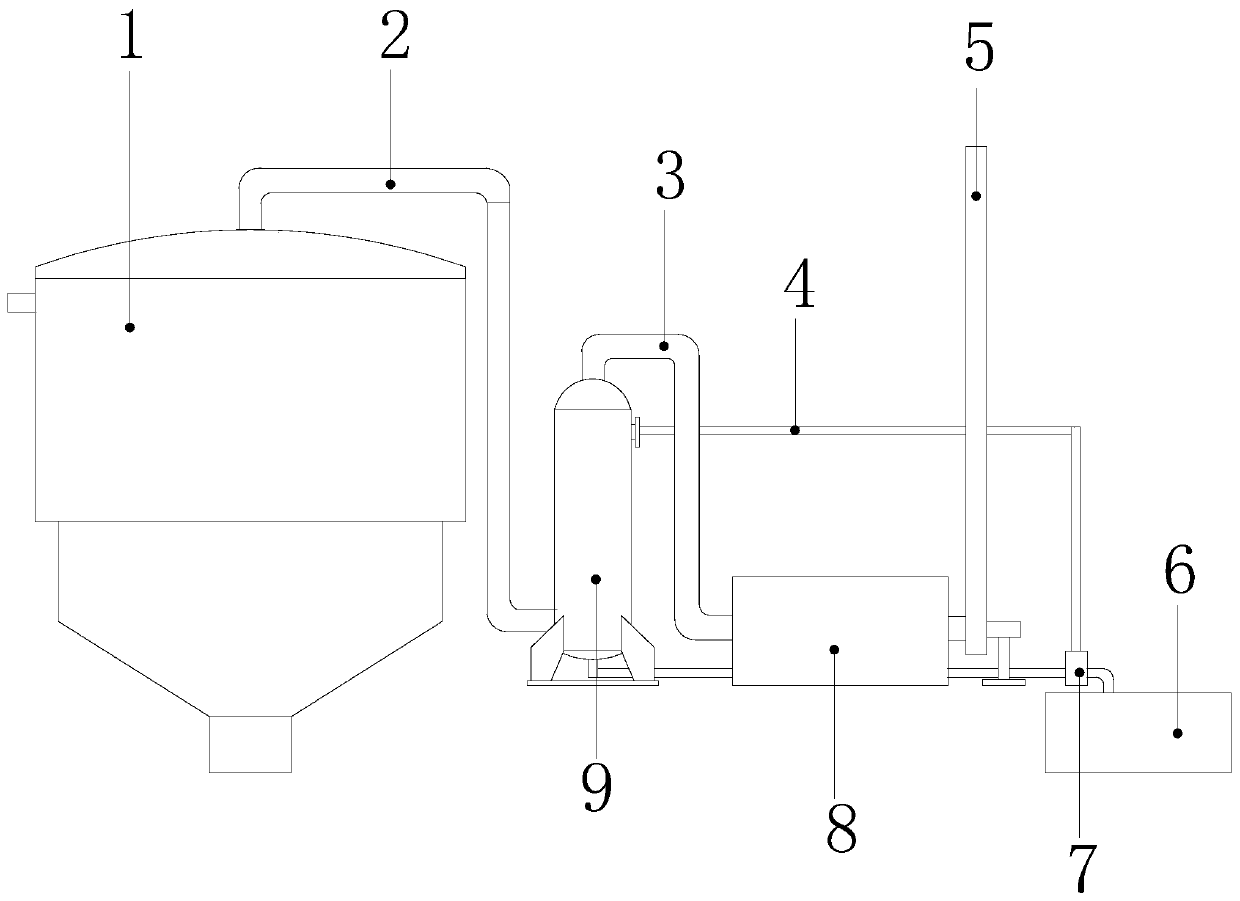

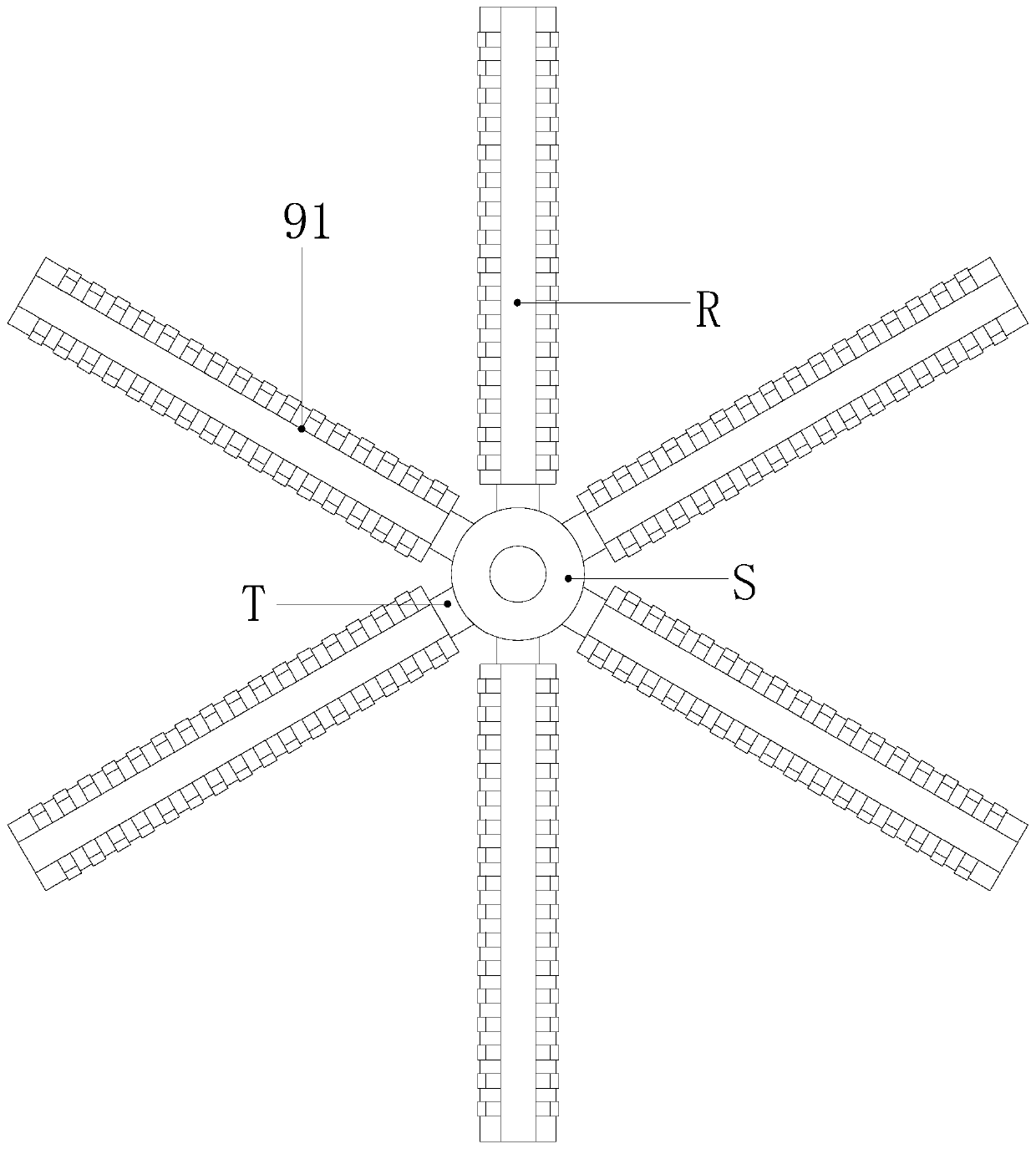

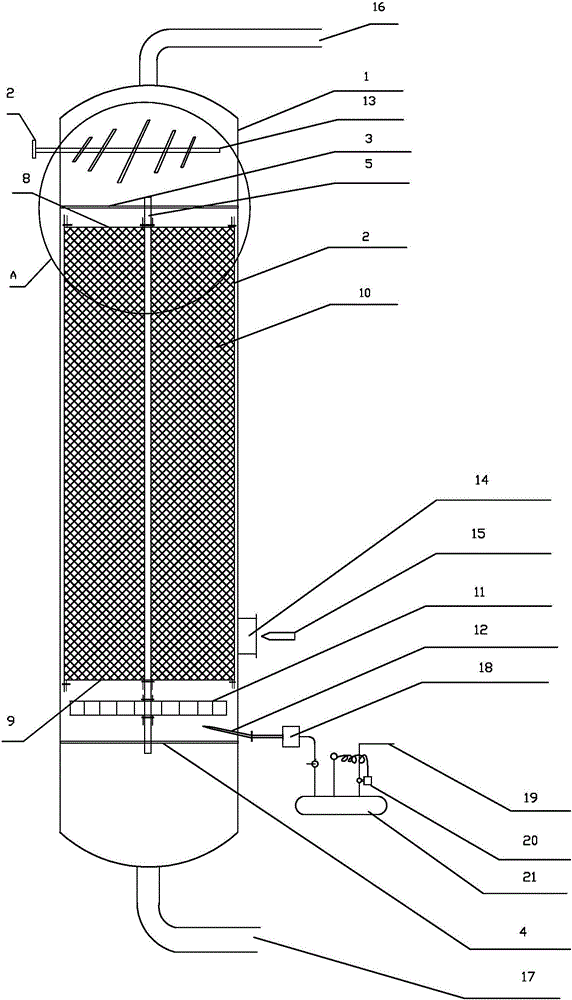

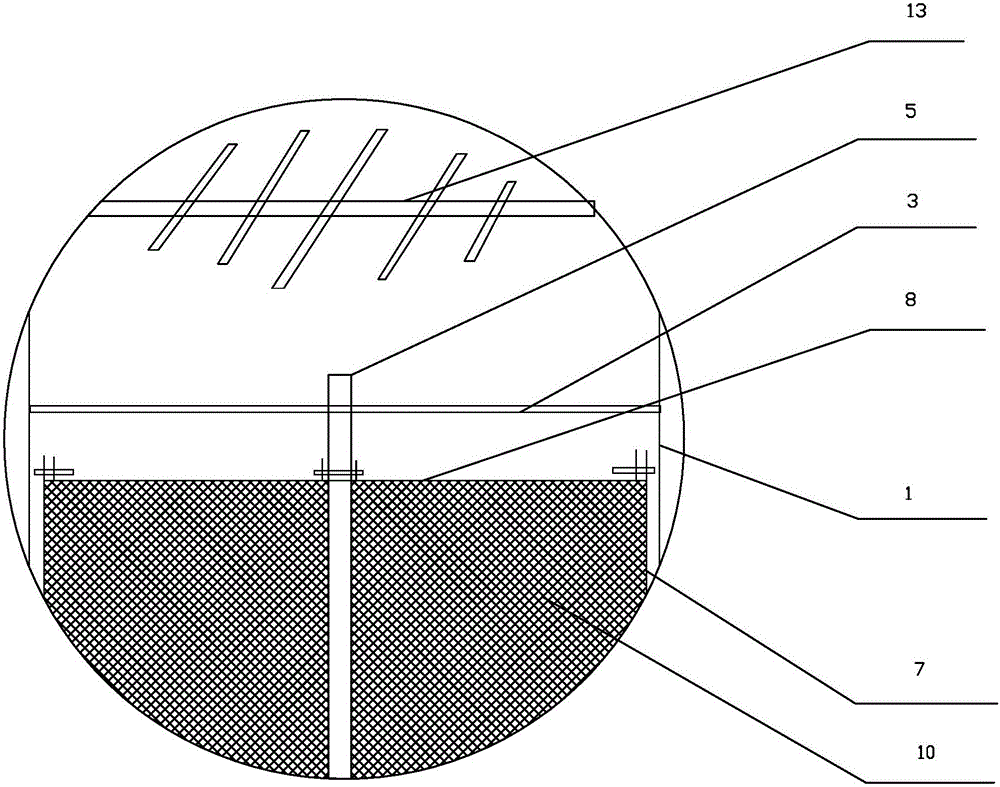

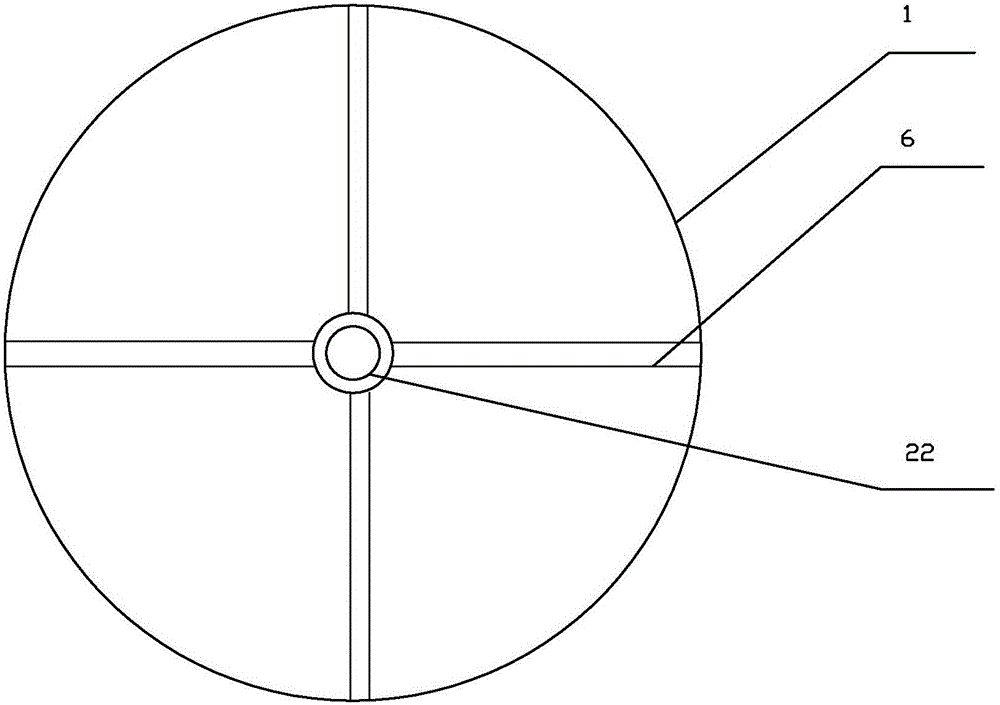

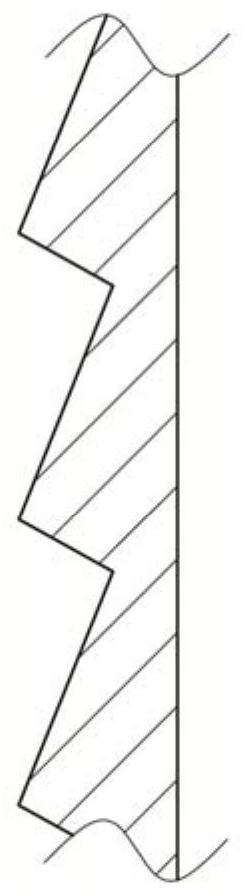

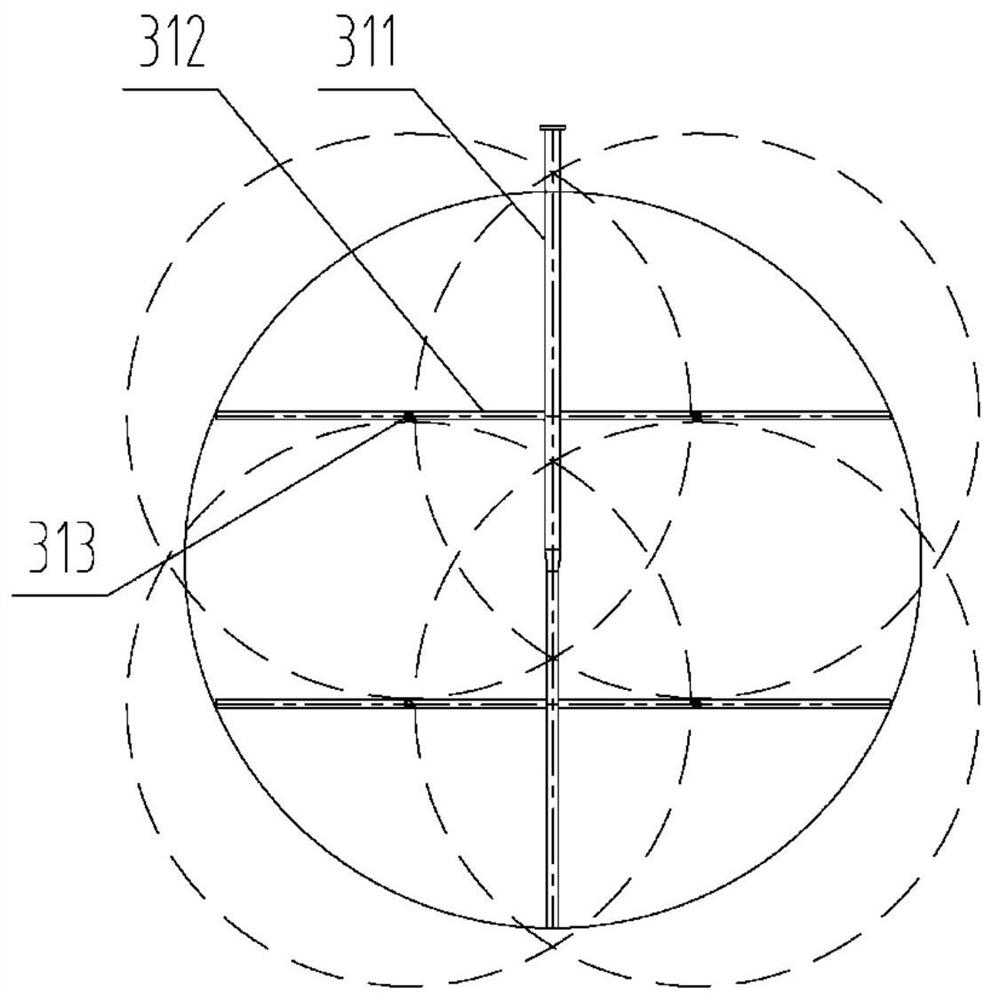

Spinning type stripping packed tower and method for applying same to deacidification and deodorization of fatty acid ester

ActiveCN106010787AImprove deacidification efficiencyImprove product qualityFatty-oils/fats refiningSteam distillationSpinningEngineering

The invention discloses a spinning type stripping packed tower and a method for applying the same to deacidification and deodorization of fatty acid ester. The spinning type stripping packed tower comprises a tower body, an upper bracing frame, a lower bracing frame, a central shaft, an inner container, a feeding device arranged above the inner container and a drive unit located below the inner container. According to the invention, steam is used as power for rotation of the inner container; a wire mesh in the inner container can cut and disperse fatty acid ester injected from the upper part of the inner container into numerous fine liquid drops under the condition of high-speed rotation so as to allow the fatty acid ester to become mist-like, so the surface area of liquid fatty acid ester is greatly increased, the contact surface of the liquid and the steam entering from the lower part is increased, free fatty acid in the liquid can be more easily evaporated and dissolved in the steam, the mist-like liquid fatty acid ester realizes full coverage, and no dead angle is left on the surface of a filling material. The spinning type stripping packed tower greatly improved efficiency of the filling material, thereby achieving the purpose of thorough separation of the free fatty acid from stink and fatty acid ester.

Owner:海盐县精细化工有限公司

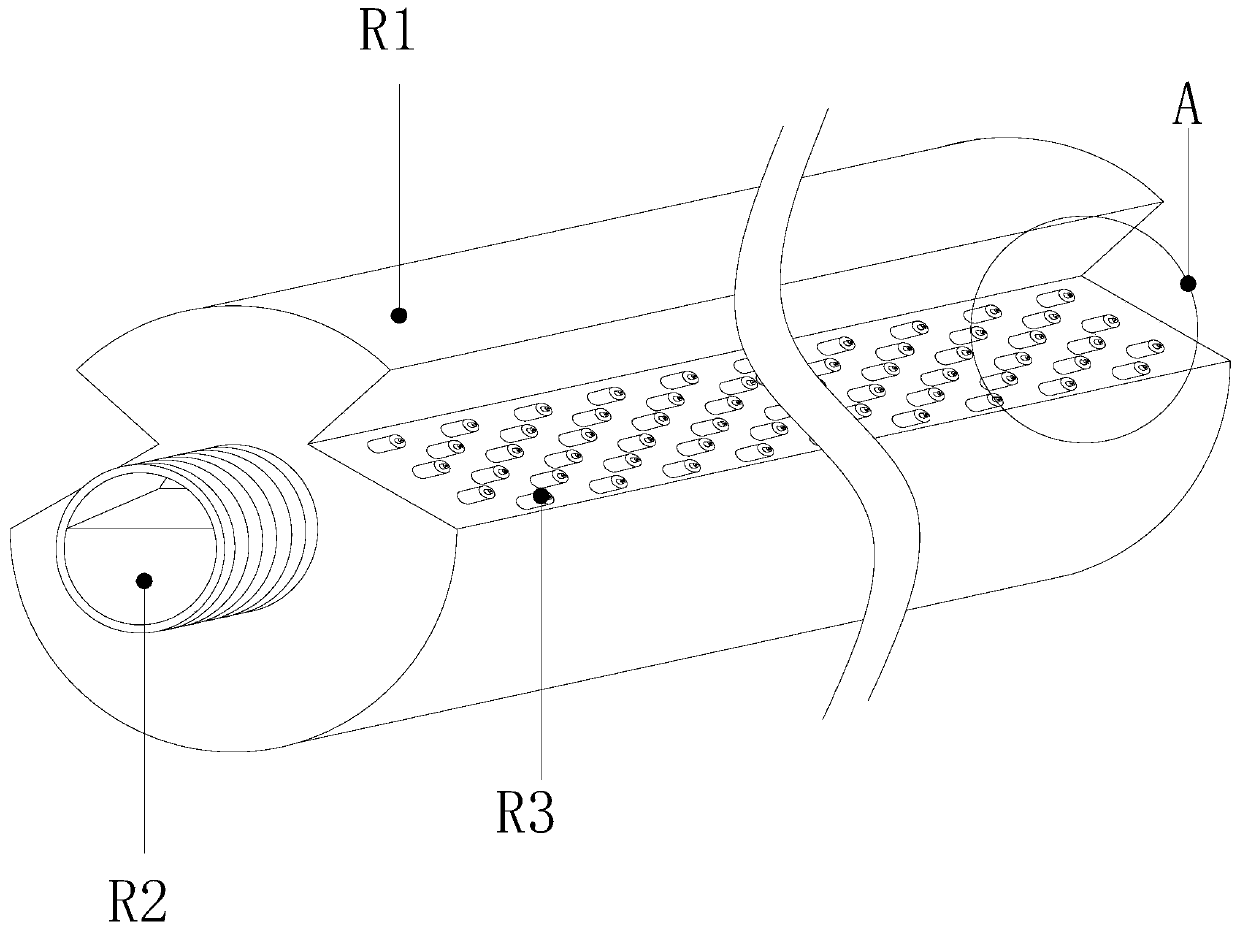

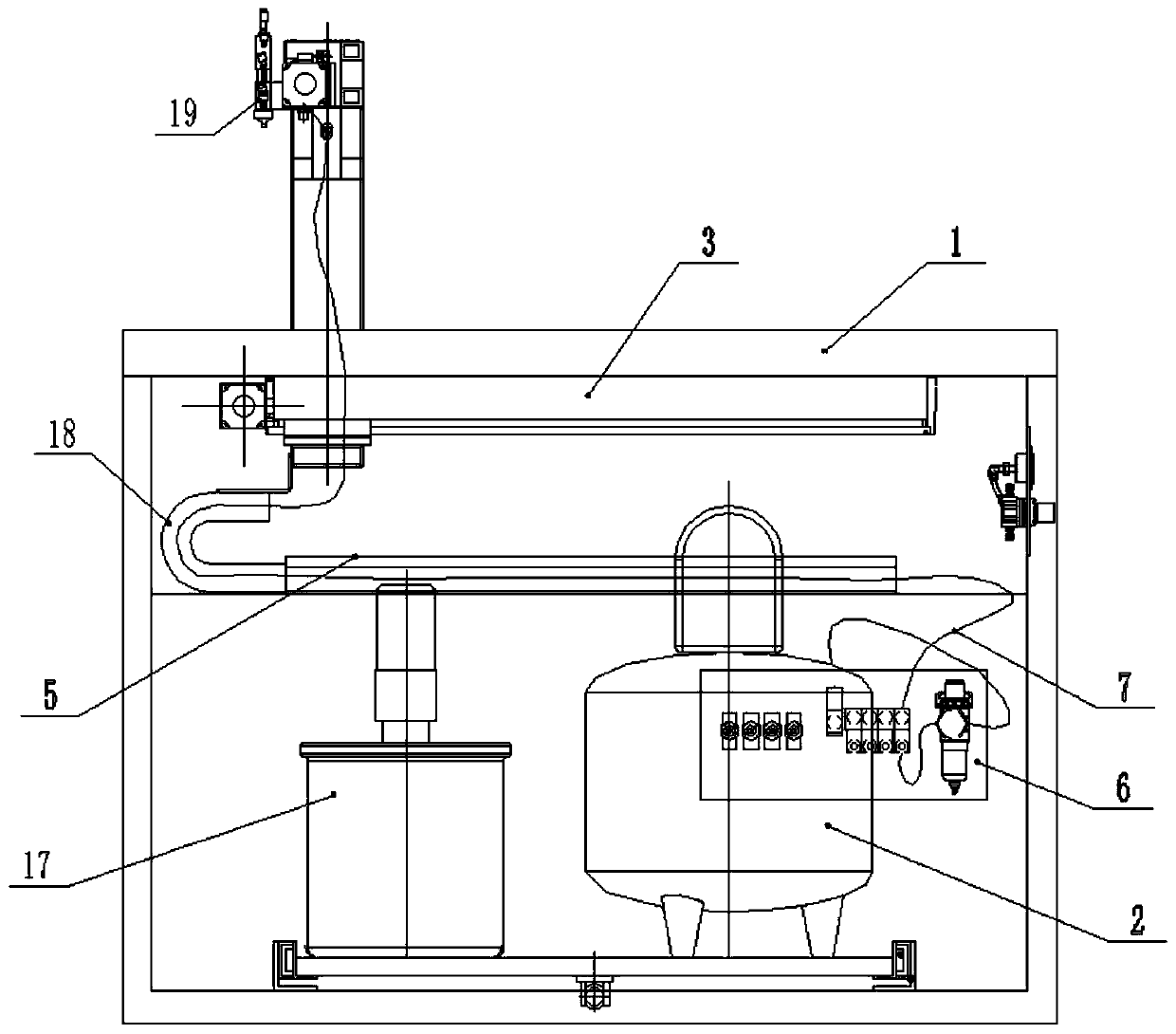

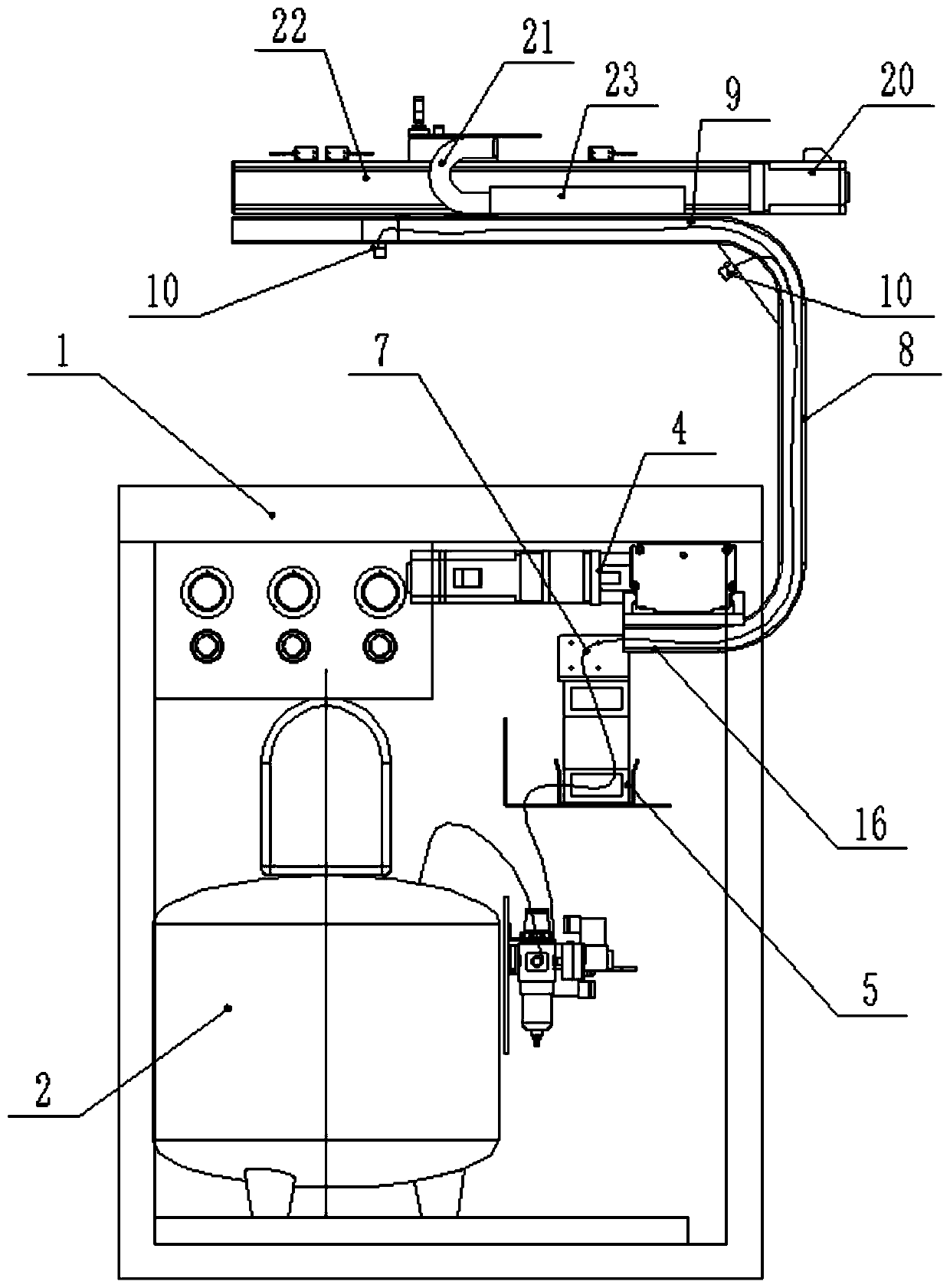

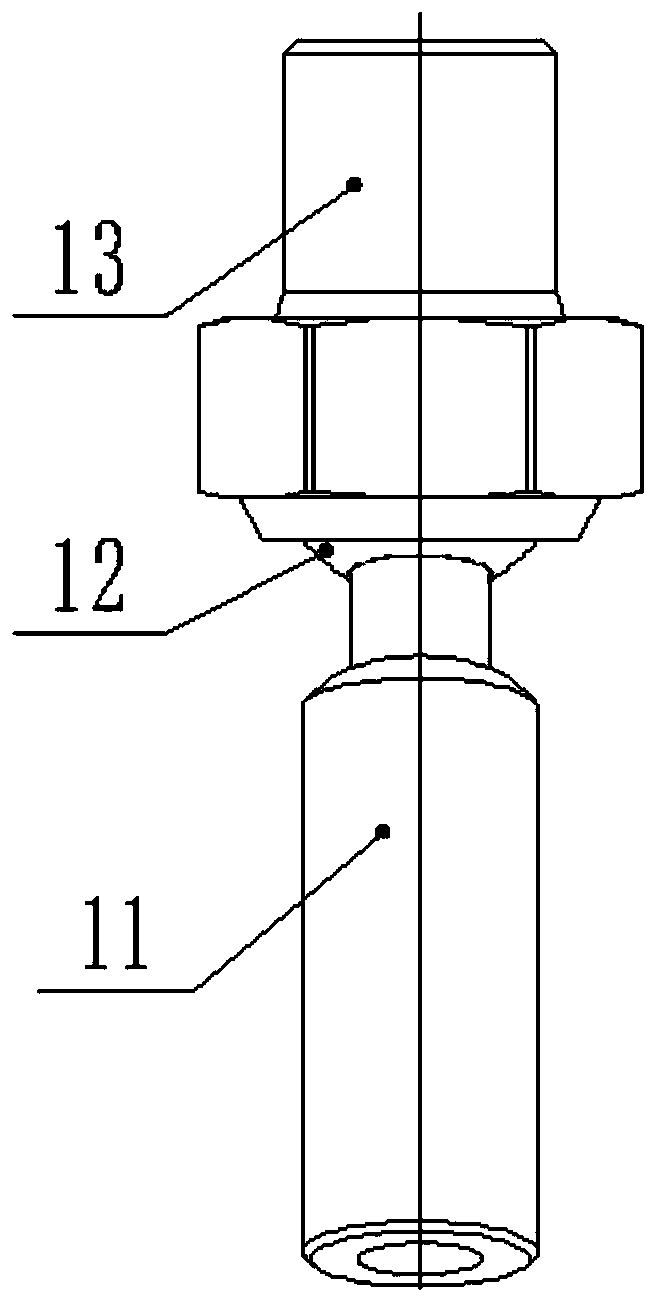

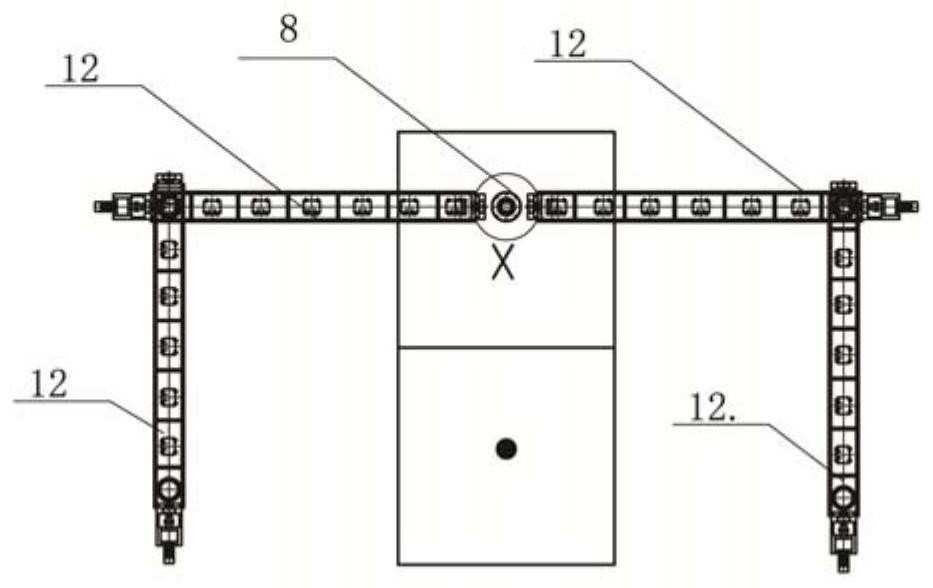

Paper deacidification device

ActiveCN110158358AReliable adsorption and fixationSimple structurePaper/cardboardOld paper after-treatmentGas compressorPulp and paper industry

The invention discloses a paper deacidification device, belonging to the technical field of paper deacidification. The paper deacidification device comprises a workbench panel, wherein the bottom partof the workbench panel is provided with a mounting cavity; a stirring tank and an air compressor are arranged in the mounting cavity; the paper deacidification device also comprises a mechanical armassembly and an air-blowing diffusion unit; the mechanical arm assembly comprises an X-axis mechanical arm arranged at the lower part of the workbench panel and running along the long-side direction of the workbench panel, a Y-axis mechanical arm arranged at the upper part of the workbench panel and running along the wide-side direction of the workbench panel, and a U-shaped support used for connecting the X-axis mechanical arm and the Y-axis mechanical arm; a liquid spray head used for spraying a deacidification liquid is arranged on the Y-axis mechanical arm; the liquid spray head and the stirring tank are in connection; the air-blowing diffusion unit comprises an air-controlled valve group, an air pipe and an air spray head; the air spray head is arranged on the Y-axis mechanical arm; one end of the air pipe is connected with the air compressor through the air-controlled valve group; and the other end of the air pipe is connected with the air spray head.

Owner:四川锐立文物保护科技有限公司

Deacidification-dust removal integrated device for flue gas based on dense phase dry tower

PendingCN113144771AEmission reductionReduce pollutionGas treatmentDispersed particle filtrationFlue gasDust control

The invention provides a deacidification-dust removal integrated device for flue gas based on a dense phase dry tower. The device comprises a dense phase dry tower deacidification device and a special deacidification dust remover, wherein the dense phase dry tower deacidification device comprises a flue gas inlet, a deacidification device body, ash hoppers of the deacidification device body, ash hopper feeders of the deacidification device body, an ash conveying device, a humidifier and a stirrer; the deacidification device body is divided into a gas inlet side and a gas outlet side by a partition plate, the lower ends of the gas inlet side and the gas outlet side communicate with each other, and the ash hoppers of the deacidification device body and the ash hopper feeders of the deacidification device body are arranged at the lower ends of the gas inlet side and the gas outlet side; the ash hopper feeders of the deacidification device body are connected with the ash conveying device; and the flue gas inlet is formed in the upper part of the gas inlet side, the top of the gas inlet side is also connected with a discharge hole of the humidifier, and the stirrer is arranged at the top of the gas inlet side. The deacidification-dust removal integrated device of the invention has the following beneficial effects: flow field distribution is more uniform and reasonable; land occupation and investment can be reduced; and deacidification efficiency is very high, and operation cost is remarkably reduced.

Owner:UNIV OF SCI & TECH BEIJING

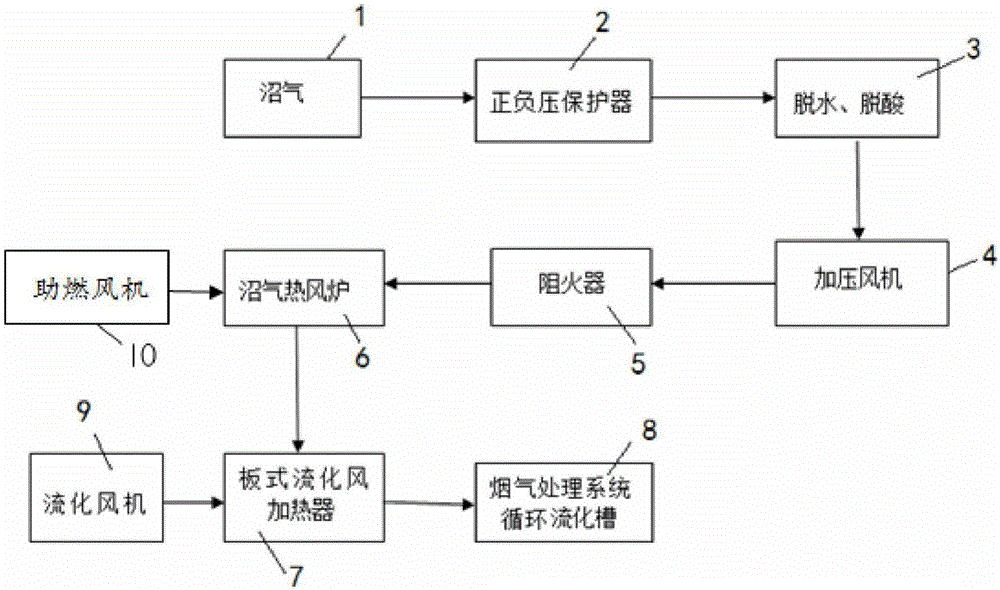

Flue gas treatment system biogas utilization method and system

ActiveCN106765213ATake advantage ofRealize resource utilizationIncinerator apparatusElectricityCombustion

The invention relates to a flue gas treatment system biogas utilization method, and belongs to the field of flue gas treatment technology. Biogas is connected with a dehydration and desulfurization device through a positive and negative pressure protection device, the dehydration and desulfurization device is connected with a pressure fan, the pressure fan is connected a flame arrester, the flame arrester is connected to a biogas furnace, a combustion fan feeds air into the biogas furnace, the biogas furnace is connected to a fluidized air plate heater, fluidized air is heated via the plate heater with the aid of biogas burning heat, and the electric heating step of fluidized air is replaced. The method has the advantages that the original fluidized air electric heater is replaced with the biogas hot blast furnace. The high-temperature flue gas after the combustion of biogas heats circulating fluidized air through the fluidized air plate heater to realize waste recycling and save electricity, and environmental pollution caused by biogas is reduced.

Owner:北京高安屯垃圾焚烧有限公司

Preparation method of alkaline nano sieve for reducing oil-soluble acidity of jatropha curcas insulating oil

PendingCN113563971AClear and transparent colorImprove deacidification efficiencyOther chemical processesFatty-oils/fats refiningMolecular sieveStrong acids

The invention relates to a preparation method of an alkaline nano sieve for reducing oil-soluble acidity of jatropha curcas insulating oil. The method comprises the following specific steps: S1, pretreatment: pretreating a molecular sieve with strong acid to enhance the adsorption capacity of the molecular sieve; and S2, preparing a modified molecular sieve: carrying out alkalization modification on the molecular sieve to prepare an alkaline nano molecular sieve for a jatropha curcas deacidification process. The step S1 specifically comprises the following steps: S11, adding a proper amount of 6mol / L hydrochloric acid into the molecular sieve, and dipping for 2 hours; and S12, roasting the molecular sieve modified by hydrochloric acid at a high temperature of 400 DEG C for 1 hour to obtain the high-activity molecular sieve. The alkaline nano molecular sieve prepared by the method has strong adsorption capacity, can be used for removing acid through a physical process and a chemical process, can also be used for effectively removing impurities with small molecular weight of which the molecular radius is less than 10, and meanwhile, the molecular sieve has a large specific surface area and is in full contact with jatropha curcas oil, so that the reaction time is shortened, and the deacidification effect is good.

Owner:CHONGQING UNIV

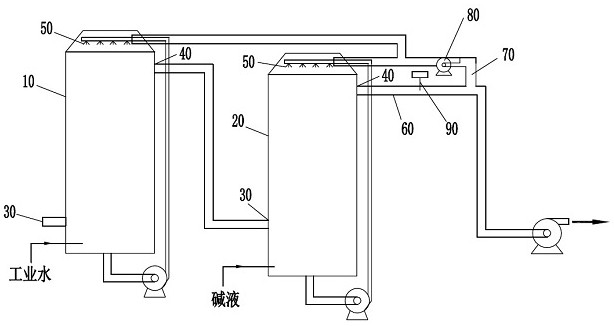

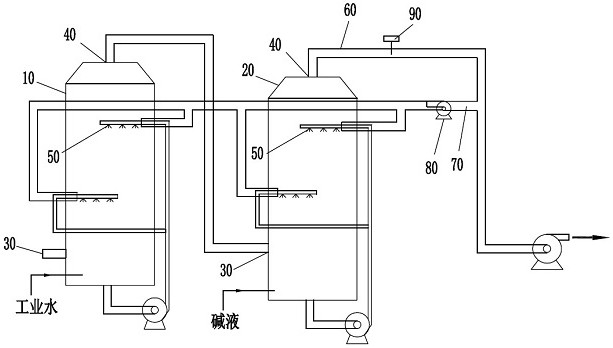

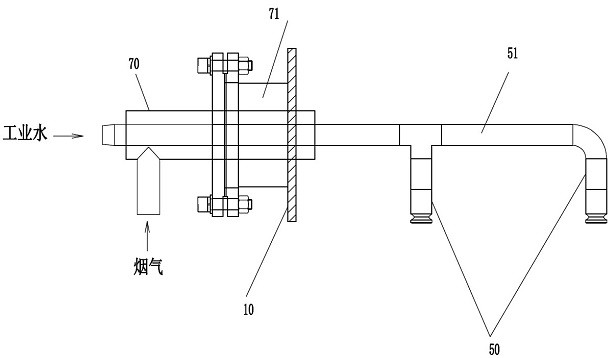

Method and device for deacidifying hot flue gas

PendingCN113996166AImprove cooling efficiencyImprove deacidification efficiencyGas treatmentUsing liquid separation agentThermodynamicsFlue gas

The invention relates to the technical field of heat treatment, in particular to a method and a device for deacidifying hot flue gas. The method for deacidifying the hot flue gas sequentially comprises a pre-cooling step and a deacidifying step. In the pre-cooling step, a spray header is used for spraying cooling water to the hot flue gas. In the deacidification step, a spray header is used for spraying alkali liquor on the hot flue gas to obtain deacidified flue gas, a part of the deacidified flue gas is guided back to the pre-cooling step and / or the deacidification step, and the returned deacidified flue gas is used for performing gas washing on the spray header. When the method and the device provided by the invention are used for carrying out deacidification treatment on the acidic hot flue gas, the cooling and deacidification efficiency can be improved, and meanwhile, the probability that the spray header is corroded and blocked can be reduced.

Owner:ZHE JIANG ECO ENVIRONMENTAL TECH CO LTD

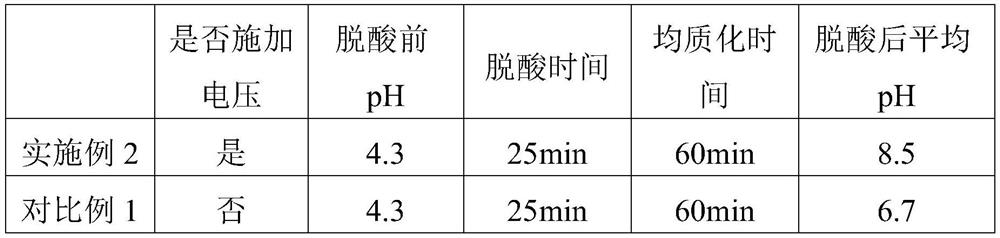

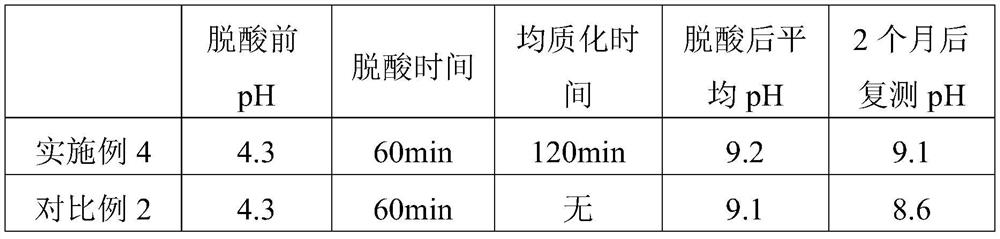

Method for deacidifying whole volume of paper

ActiveCN113863053ASolve storage problemsSolve shipping problemsOld paper after-treatmentChemical vapor deposition coatingAC - Alternating currentProcess engineering

The invention discloses a method for deacidifying a whole volume of paper. The method is used for deacidifying a whole book in three steps of prepressing, rapid deacidifying and homogenizing. On the basis of a static pressure whole volume deacidification method, a homogenization process is added, so that the deacidification effect stability is improved; and the high-voltage alternating current is used on the basis of the existing low-voltage direct current adsorption technology, so that the deacidification efficiency of the whole book is effectively improved, and meanwhile, the problem of non-uniform deacidification of the book caused by enrichment of anions and cations on a certain electrode is avoided. The deacidification operation is convenient, the deacidification process is environment-friendly, and accurate deacidification can be realized.

Owner:HANGZHOU ZHONGCAI TECH CO LTD

Incinerator flue gas deacidification and denitration device

InactiveCN105879616AReduce dosageIncrease profitLighting and heating apparatusDispersed particle separationInlet valveHeat pipe heat exchanger

An incinerator flue gas deacidification and denitration device comprises an incinerator, an electric air inlet valve, a reaction tower, a bag-type dust remover, a heat pipe exchanger, an SCR reactor and an ammonia vaporizer and is characterized in that the incinerator is sequentially connected with the electric air inlet valve, the reaction tower, the bag-type dust remover, the heat pipe exchanger, the SCR reactor and the ammonia vaporizer, a bypass pipeline is connected between the incinerator and an inlet of the electric air inlet valve and connected with an inlet of a main fan, an outlet of the main fan is connected with a chimney, a bypass valve is arranged on the bypass pipeline, an outlet of the electric air inlet valve is connected with a gas inlet of the reaction tower, the lower portion of the gas inlet of the reaction tower is connected with a conical dust collecting groove, the conical dust collecting groove is connected with an electric cindervalve, and the upper portion of the gas inlet of the reaction tower is connected with a throat pipe. Acid gas and nitric oxide in flue gas generated in the household garbage incinerator can be removed, and harmful pollutant such as dioxin and heavy metal in the flue gas are adsorbed so that the flue gas can be exhausted in an up-to-standard mode and prevented from polluting the environment.

Owner:WUXI HUAXING ELECTRIC POWER ENVIRONMENTAL PROTECTION REPAIRING & MFG

Flue gas deacidifying device and flue gas deacidifying method

PendingCN109126427ASimple deacidification processReduce use costGas treatmentDispersed particle separationFlue gasEngineering

The invention discloses a flue gas deacidifying device, the flue gas deacidifying device comprises a tower body, the tower body is internally provided with a first spraying part and a second sprayingpart, the first spraying part is used for spraying out a circulating fluid to deacidify the flue gas, the second spraying part is located at the upper part of the first spraying part, a plurality of sieve plate parts used for triggering the diffusion of the circulating fluid to deacidify the flue gas when the circulating fluid is sprayed out are further arranged in the inner part of the tower body, the sieve plate parts are located between the first spraying part and the second spraying part, and a filtering part used for separating the gas from the liquid is further arranged at the upper partof the second spraying part. The invention further discloses a flue gas deacidifying method. The flue gas deacidifying device and the flue gas deacidifying method have an efficient deacidifying effect, are low in use cost, and are stronger in applicability particularly under the conditions that the concentration of the acid of the flue gas is relatively high and the space is limited.

Owner:SHANGHAI SHENGJIAN ENVIRONMENTAL SYST TECH

Hazardous waste incineration flue gas comprehensive absorption deacidification system

InactiveCN104324590BNo process requirementsNo strict process requirementsDispersed particle separationEngineeringQuenching

The invention discloses a comprehensive absorption and deacidification system for dangerous and medical waste incineration flue gas. The system comprises a quenching tower, a sodium hydrogen carbonate powder spraying tower, an activated carbon powder spraying tower, a flue reactor, a cloth bag dust collector, an acid pickling tower, a base washing tower, a flue gas bypass, a heat exchanger, a quenching water tower, an alkali liquor preparation tower and a fly ash storage and transportation tower. The adaptive temperature range of the system is wide, the system can adapt to high-temperature flue gas with the temperature of 200-900 DEG C, and the process requirement on incineration equipment is not severe; the deacidification efficiency is high, the discharging index can be stably guaranteed and is superior to the GB18484-2001 standard; no sewage treatment equipment is needed in the production process, and zero sewage discharging is realized.

Owner:ANHUI SHENGYUN ENVIRONMENTAL ENG

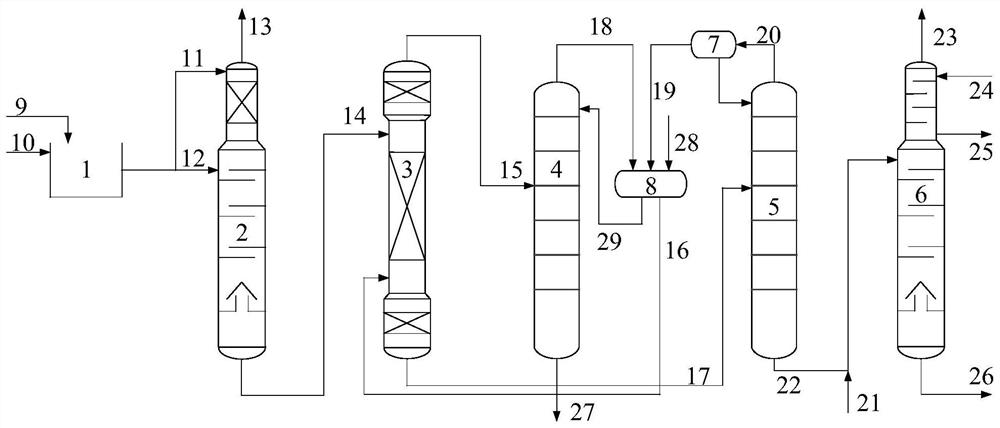

A method and device for treating semi-coke wastewater

ActiveCN111646620BImprove removal efficiencyReduce chromaFatty/oily/floating substances removal devicesWater contaminantsCoking wastewaterTreatment system

The invention belongs to the technical field of sewage treatment, and discloses a method and a device for treating blue charcoal wastewater. The method is as follows: adjust the pH value of the semi-coke wastewater through an acid adding device, and then let it stand to realize gravity degreasing and separate recovery; the hot and cold streams of the effluent water enter the stripping tower from the upper and middle upper parts of the deacidification tower, and remove The acid gas in the wastewater is sent to the tail gas treatment device; the kettle liquid and the extractant are extracted countercurrently, and the extract phase is separated by rectification to recover the extractant and obtain crude phenol products; The ammonia nitrogen in the water is removed by tower steaming to prepare concentrated ammonia water; the invention can realize the efficient separation and recovery of light oil, heavy oil, acid gas, phenols, and ammonia nitrogen in the semi-coke wastewater, and realize the resource utilization of pollutants. It can be recycled in the wastewater treatment process, and the wastewater treatment system does not introduce new impurities, so it has a good application prospect.

Owner:SOUTH CHINA UNIV OF TECH

Wet washing device and cooling method during flue gas washing

PendingCN113731146AReduce the temperatureImprove reliabilityGas treatmentDispersed particle separationThermodynamicsFlue gas

The invention provides a wet washing device and a cooling method during flue gas washing, the wet washing device comprises a flue gas washing circulating system and a dehumidification circulating system, the flue gas washing circulating system is used for washing flue gas, the dehumidification circulating system is used for dehumidifying the flue gas, the wet washing device further comprises an inlet spraying system, the inlet spraying system comprises a water tank, a spraying liquid conveying pipeline, a spraying piece and an inlet flue, the water tank is connected with the spraying liquid conveying pipeline, the spraying liquid conveying pipeline is connected with the spraying piece, and the spraying piece extends into the inlet flue for spraying. When the wet washing device is used for washing the flue gas, the flue gas is sprayed to the inlet flue through the inlet spraying system so as to reduce the heat of the flue gas.

Owner:EVERBRIGHT ENVIRONMENTAL TECH CHINA CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com