Depickling method of cold-pressed peony seed oil

A technology of peony seed oil and deacidification method, which is applied in the direction of oil/fat refining, fat production, etc., can solve the problems of complex process, environmental pollution and high energy consumption, and achieves high deacidification efficiency, high safety, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: the preparation of deacidifying agent

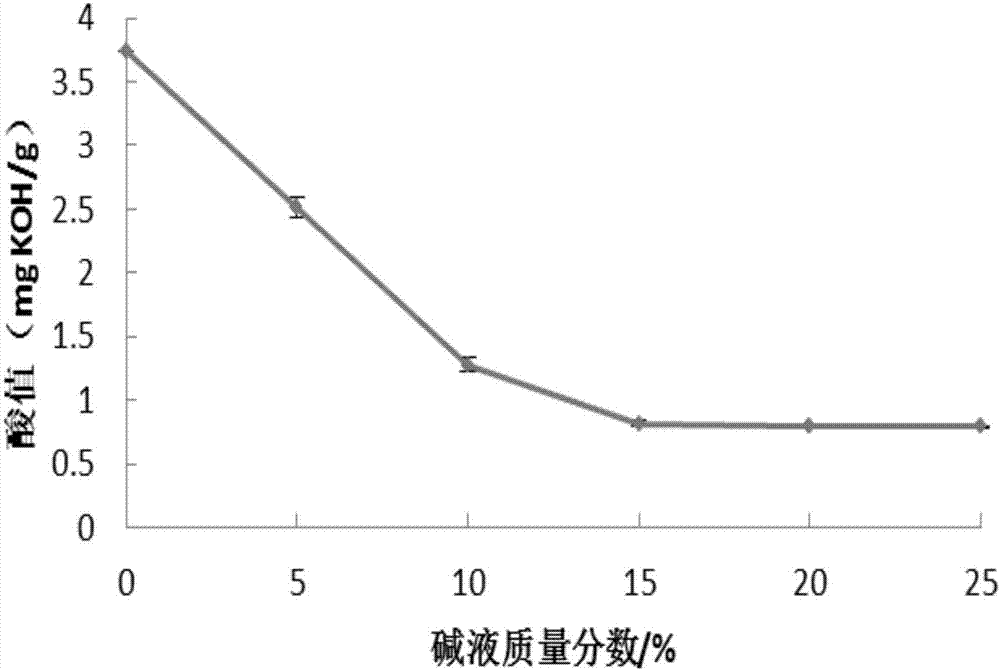

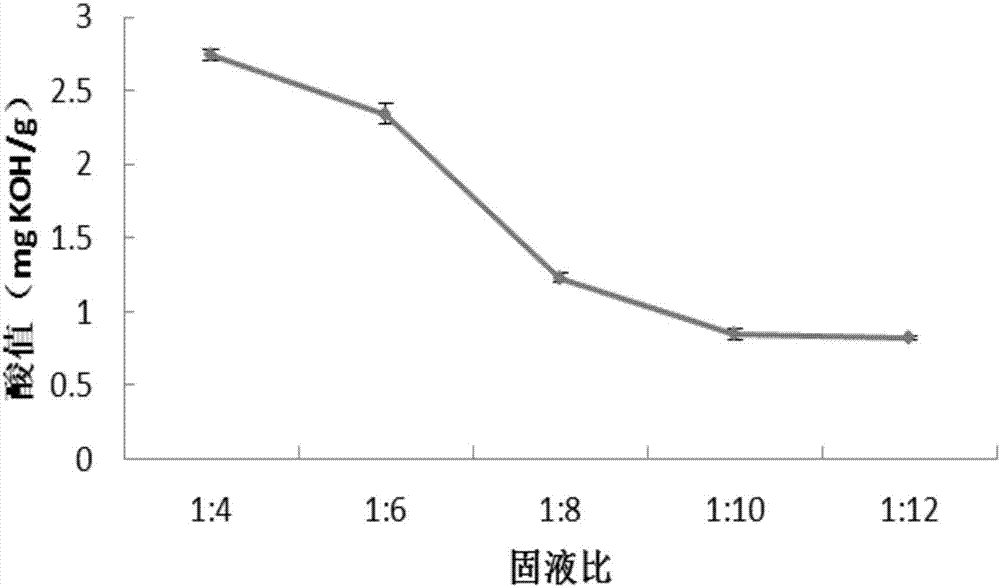

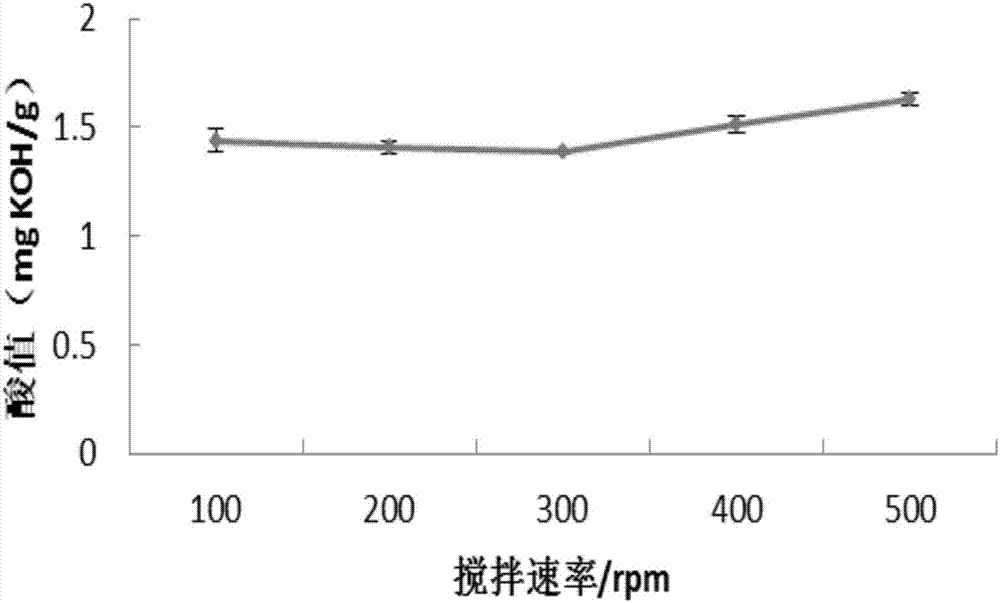

[0037] The present invention utilizes the alkaline solid deacidification agent prepared by sodium hydroxide and diatomite to deacidify cold-pressed peony seed degummed oil, and the process steps are: diatomite powder and hydrogen with a mass fraction of 5-25% The sodium oxide solution was mixed according to the solid-to-liquid ratio of 1:4-1:12, stirred and reacted at 100-500rpm at 30-70°C for 25-65min, and then spun and centrifuged at 8000rpm for 15min to obtain a precipitate; Rinse the precipitate with 95% ethanol, dry it in an oven at 60°C, and crush the dried product to 60 mesh to obtain alkaline diatomite. The acid value of peony seed oil was measured before and after deacidification, and the deacidification rate was calculated. The acid value of peony seed oil was determined by the neutralization titration method in GB / T 5530-2005 "Animal and Vegetable Fats and Fats: Determination of Acid Value and Acidity". ...

Embodiment 2

[0051] Embodiment 2: Deacidification condition optimization

[0052] Weighing 30g of cold-pressed peony seed degummed oil, adding 0.5-3.0% of the weight of peony seed oil with alkaline diatomite, and performing ultrasonic-assisted deacidification at a temperature of 25-50°C with a power of 60-110W for 8-14min, Then rotate and centrifuge at 8000rpm for 10 minutes, centrifuge twice, and pour out the supernatant, which is cold-pressed peony seed deacidified oil.

[0053] The present invention selects 4 factors of deacidification agent addition amount, deacidification temperature, ultrasonic power and ultrasonic time as a single factor, and their influence on the deacidification effect of peony seed oil is shown in Figure 6 , Figure 7 , Figure 8 and Figure 9 . Based on the single factor test results, the ultrasonic-assisted deacidification time was selected as 14 minutes in the deacidification process of cold-pressed peony seed oil, and then L was designed. 9 (3 3 ) that...

Embodiment 3

[0066] Example 3: Preparation of deacidification agent by replacing diatomite with mesoporous carbon

[0067] The mesoporous carbon powder and the sodium hydroxide solution with a mass fraction of 15% were mixed at a solid-to-liquid ratio of 1:8, stirred and reacted at 100 rpm for 55 min at 60°C, and then spun and centrifuged at 8000 rpm for 15 min. Obtain the precipitate; wash the precipitate with 95% ethanol, place it in a 60°C oven for drying, and crush the dried product to 60 meshes to obtain alkaline mesoporous carbon; in the degummed oil of cold-pressed peony seeds, add Alkaline mesoporous carbon with 2.0% weight of peony seed oil, under the temperature condition of 45 ℃, use ultrasonic power of 90W to assist deacidification for 14min, then spin and centrifuge at 8000rpm for 10min, centrifuge twice, and pour out the supernatant , which is cold-pressed peony seed deacidified oil. The acid value of the obtained peony seed degummed oil was 1.07mg KOH / g, and compared with t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com