Hazardous waste incineration flue gas comprehensive absorption deacidification system

A technology for incinerating flue gas and hazardous waste, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc. High acid efficiency to achieve the effect of sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

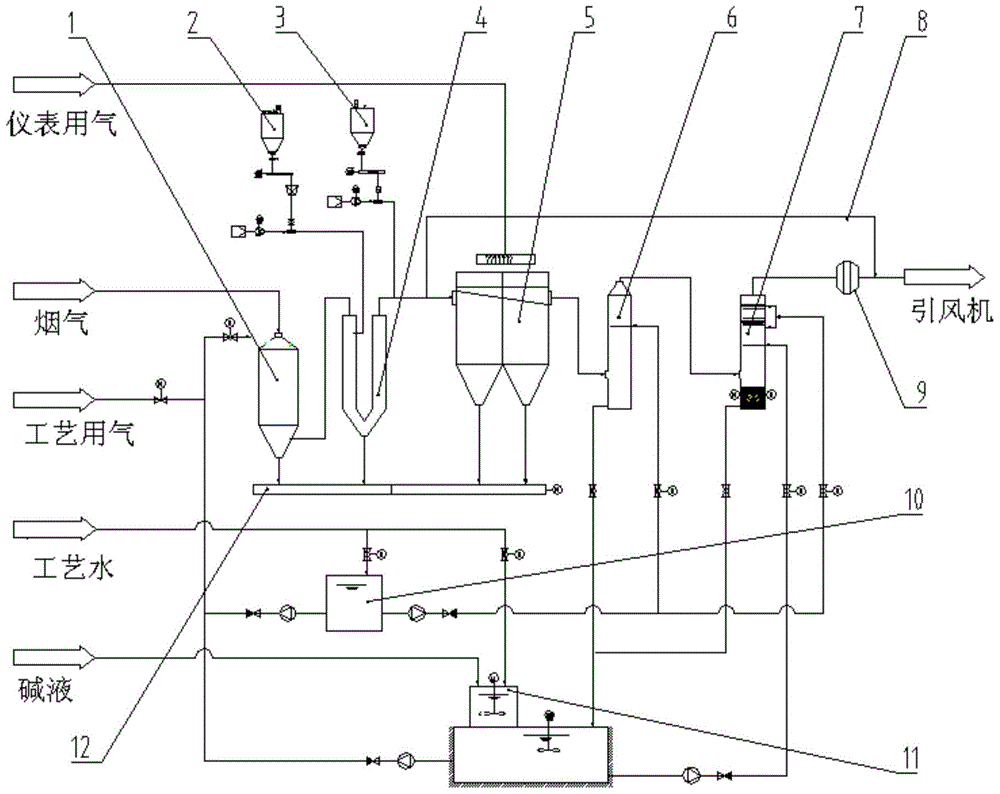

[0020] Such as figure 1 , Hazardous waste incineration flue gas comprehensive absorption deacidification system, including quenching tower 1, sodium bicarbonate powder injection tower 2, activated carbon powder injection tower 3, flue reactor 4, bag filter 5, pickling tower 6, Base washing tower 7, flue gas bypass 8, heat exchanger 9, quenching water tower 10, lye preparation tower 11, fly ash storage and transportation tower 12.

[0021] The high-temperature flue gas produced by the incineration of hazardous waste is purified and treated by the quench tower 1, the flue reactor 4, the bag filter 5, the pickling tower 6, the base washing tower 7, and the heat exchanger 9, and is drawn out by the induced draft fan and passed through the chimney. released into the atmosphere. Spray cooling medium into the quench tower 1 to make the flue gas cross the dangerous temperature area at the fastest speed. The specific process requirement is that the high-temperature flue gas quickly dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com