Spinning type stripping packed tower and method for applying same to deacidification and deodorization of fatty acid ester

A packed tower and spin-type technology is used in the field of deodorization and deacidification of animal and vegetable oils, which can solve the problems of low stripping tower efficiency and poor deacidification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

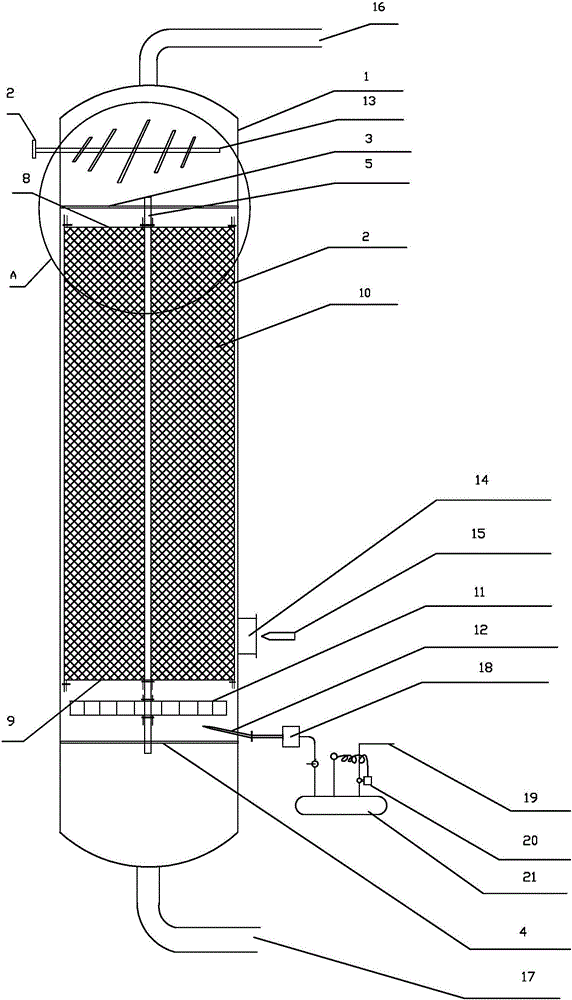

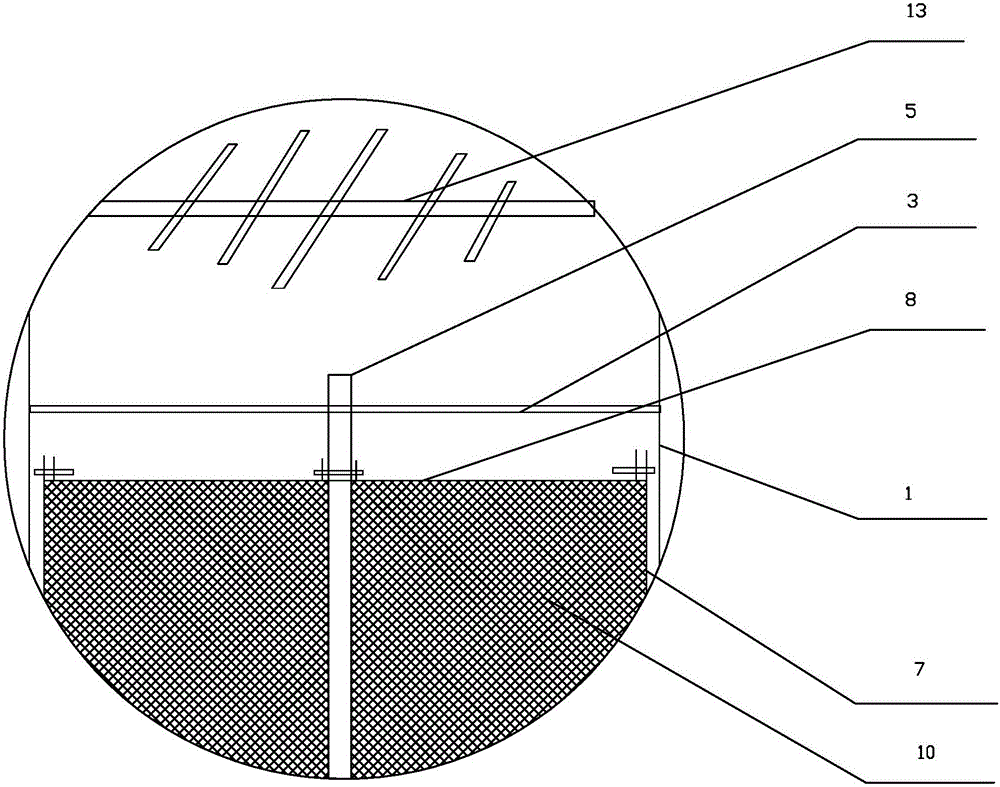

[0033] Such as figure 1 As shown, the present invention provides a spin-type stripping packed tower, comprising a tower body 1, an upper support frame 3, a lower support frame 4, a central shaft 5, a tower inner cylinder, and a feed device 2 positioned above the tower inner cylinder , the driving device located below the tower inner barrel; the feeding device 2 includes a conventional pressure distributor 13, which can evenly spray the material on the tower inner barrel;

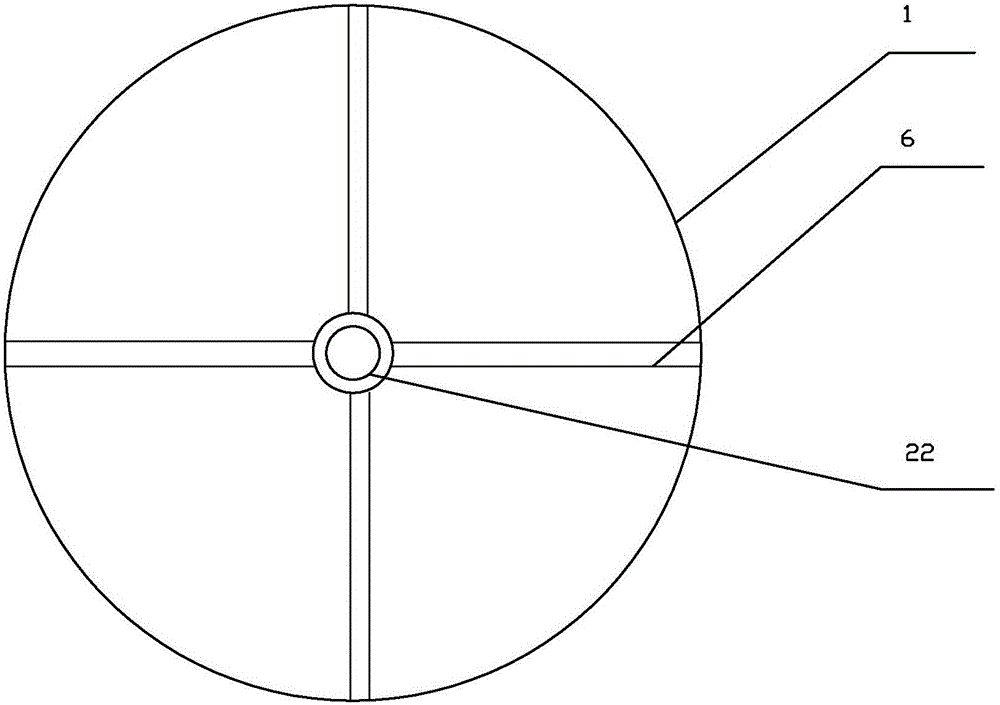

[0034] Such as image 3 The shown upper support frame 3 and the lower support frame 4 are provided with a central hole matching the central shaft 5, extending 3-6 with the legs 6 centered on the central hole, and the ends of the legs 6 are welded to the tower body 1; the central shaft 5 is connected to the upper support The frame 3 and the lower support frame 4 are connected by ball bearings; the central shaft and the support frame connect the tower inner barrel and the driving device to the tower body 1, w...

Embodiment 2

[0044] Embodiment 2: The impeller 11 is located below the lower support frame 4, and the rest are the same as Embodiment 1.

Embodiment 3

[0045] Embodiment 3: Investigate the rotating speed and deacidification effect of the inner cylinder:

[0046] Conditions: spin stripping tower in Example 1, tower body diameter DN1000; packing specification: CY700 type; height: 3000mm;

[0047] step:

[0048] a. The top of the tower is vacuumed, and the vacuum residual pressure on the top of the tower is controlled: ≤200pa;

[0049] b. Inject steam into the steam nozzle and control the speed of the inner cylinder of the tower to about 80 rpm by adjusting the amount of steam injected;

[0050] c. The feeding device sprays isopropyl myristate at 220°C, and the feeding speed is 1500L / hour;

[0051] d. After the material and steam are fully mixed in the tower, the steam is discharged from the upper pipe of the tower and condensed as waste. The product flowing out of the lower pipe of the tower is collected and the content of free acid is checked. The results are shown in Table 1 below.

[0052] Table 1: Inner barrel speed and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com