Method for deacidifying whole volume of paper

A deacidification method and paper technology, applied in waste paper post-treatment, gaseous chemical plating, coating, etc., can solve the problems of paper acid return, deacidification agent volatile storage, transportation, etc., to solve the problem of adhesion, reduce Replacement frequency and cleaning difficulty, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Book "Science and Outlook on Life", 89 pages in total, machine-made paper, basis weight 50g / m 2 , A5 size, original pH=5.5, lined with slow-release membrane at 0.4kg / cm 2 After 10 minutes of static pressure, direct current is applied, the forward energization time is 4 minutes, the reverse energization time is 4 minutes, the voltage is 20V, and the deacidification time is 16 minutes; the temperature of the precision constant temperature and humidity box is 50 ° C, the humidity is 90%, and the homogenization time is 120 minutes; After the acid is finished, the average pH is 9.3, and the paper has no wrinkles and no fading.

[0053] The sustained-release film is prepared by absorbing a calcium-based water-based deacidification agent on absorbent paper with a thickness of 0.2 mm; the adsorption capacity of the absorbent paper is twice its own weight.

[0054] The electrode plate adopts graphite inert electrode plate.

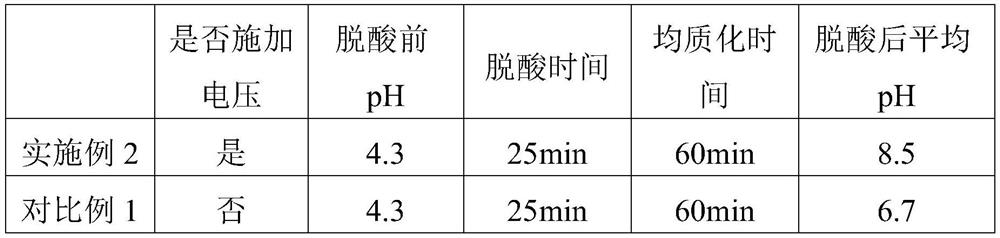

Embodiment 2

[0056] Book "Chunqiu Zuo Shi Zhuan", a total of 36 pages, handmade paper, weight 20g / m 2 , A4 size, original pH=4.3, lined with slow-release membrane at 0.4kg / cm 2 Apply cosine alternating current after 30 min of static pressure, voltage size 20V, alternating current frequency 30 Hz, deacidification time 25 min; precision constant temperature and humidity box temperature 45 ℃, humidity 90% homogenization time 60 min; average pH after deacidification is 8.5, Paper is wrinkle-free and does not appear to fade.

[0057] The sustained-release film is prepared by absorbing a calcium-based water-based deacidification agent on absorbent paper with a thickness of 0.2 mm; the adsorption capacity of the absorbent paper is twice its own weight.

[0058] The electrode plate adopts graphite inert electrode plate.

Embodiment 3

[0060] Book "Mathematics and Physics Equations and Special Functions", a total of 83 pages, machine-made paper, weight 56g / m 2 , A5 size, original pH=3.9, lined with slow-release membrane at 0.4kg / cm 2 After 40 minutes of static pressure, apply a square wave AC voltage of 36V, AC frequency 30Hz, deacidification time 24min; precision constant temperature and humidity box temperature 55 ℃, humidity 90%, homogenization time 90min; after deacidification, the average pH is 8.4, the paper has no wrinkles and no fading.

[0061] The sustained-release film is prepared by absorbing a calcium-based water-based deacidification agent on absorbent paper with a thickness of 0.2 mm; the adsorption capacity of the absorbent paper is twice its own weight.

[0062] The electrode plate adopts graphite inert electrode plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com