Flue gas treatment system and method after incineration of hazardous wastes

A flue gas treatment system and hazardous waste technology, applied in the field of flue gas treatment, can solve the problems of large system resistance, increase of auxiliary fuel, high treatment cost, etc., reduce investment cost and operation cost, reduce floor area, and reduce treatment cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

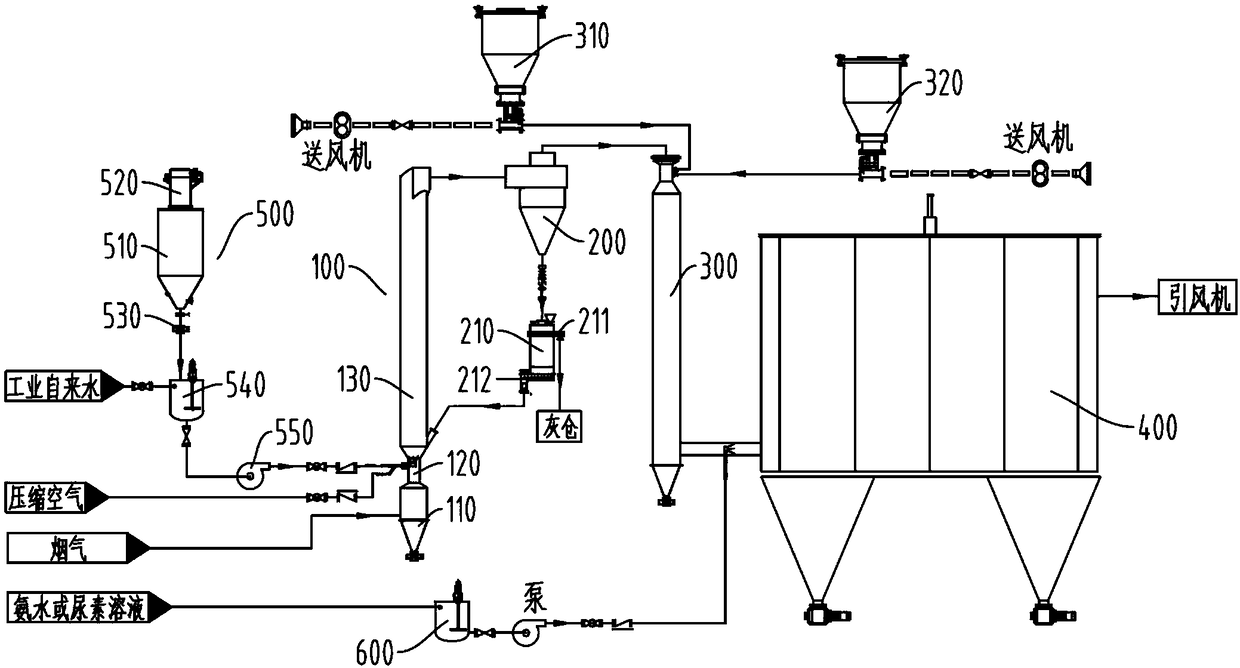

[0035] Such as figure 1 As shown, Embodiment 1 of the present invention provides a flue gas treatment system after hazardous waste incineration, including a semi-dry deacidification tower 100, a cyclone dust collector 200, a dry deacidification tower 300, ceramic Fiber filter tube dedusting reactor 400 and induced draft fan: wherein, the top of the semi-dry type deacidification tower 100 communicates with one side of the cyclone dust collector 200, and the top of the cyclone dust collector 200 communicates with the top of the dry type deacidification tower 300, dry The lower side of the deacidification tower 300 communicates with the lower side of the ceramic fiber filter tube dust removal reactor 400, and the upper side of the ceramic fiber filter tube dust removal reactor 400 is connected with the induced draft fan; the semi-dry deacidification tower 100 is also connected with The lime slurry preparation system 500, the top of the dry deacidification tower 300 is also connec...

Embodiment 2

[0050] According to the system for treating flue gas after incineration of hazardous waste provided in Embodiment 1, this embodiment 2 provides a method for treating flue gas after incineration of hazardous waste, including the following steps:

[0051] S1: The lime slurry preparation system is used to prepare lime slurry. The flue gas from the incineration of hazardous waste enters from the bottom of the semi-dry deacidification tower 100 through the pipeline and reacts with the lime slurry pumped into the bottom of the semi-dry deacidification tower 100. The removal efficiency of sulfur dioxide and HCl in the gas reaches more than 90%;

[0052] S2: The flue gas treated by the semi-dry deacidification tower 100 enters the cyclone dust collector 200 from the top of the semi-dry deacidification tower 100 for treatment, and 90-99% of the dust and inert carrier particles in the flue gas are separated ;

[0053] S3: The flue gas enters from the top of the dry-type deacidification...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com