Flue gas treatment system biogas utilization method and system

A flue gas treatment system and flue gas treatment technology, applied in the direction of combustion methods, combustion types, incinerators, etc., can solve the problems of waste of resources, waste of biogas with high calorific value, etc., and achieve the effect of saving electricity and improving overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

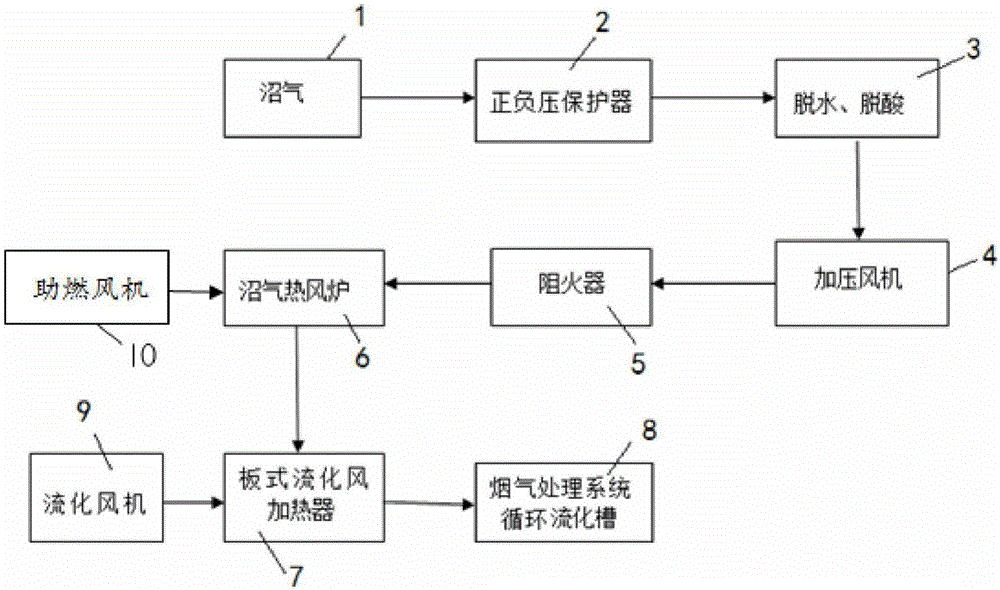

[0017] Embodiment 1: as figure 1 as shown,

[0018] A biogas utilization system, the biogas device 1 is connected to the positive and negative pressure protector 2, the positive and negative pressure protector 2 is connected to the dehydration and desulfurization device 3, the dehydration and desulfurization device 3 is connected to the biogas pressurization fan 4, and the biogas pressurization fan 4 is connected to the flame arrester 5 , the flame arrester 5 is connected to the biogas hot blast stove 6, and the combustion-supporting fan 10 sends air into the biogas hot blast stove 6. After ignition, the biogas stove automatically burns to generate high-temperature flue gas, which is sent to the plate-type fluidized air heater 7, and the fluidized fan 9 will flow After pressurized, the fluidizing air is sent to the plate-type fluidizing air heater 7, and the heated fluidizing air is sent to the bottom 8 of the circulating fluidizing tank of the flue gas treatment system.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com