Waste gas dust removal and adsorption treatment device

A technology for adsorption treatment and waste gas, which is applied in gas treatment, combined device, transportation and packaging, etc. It can solve the problems of wasting time, trouble, and troublesome replacement of activated carbon plates, and achieve the effect of increasing the contact area and improving the deacidification efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

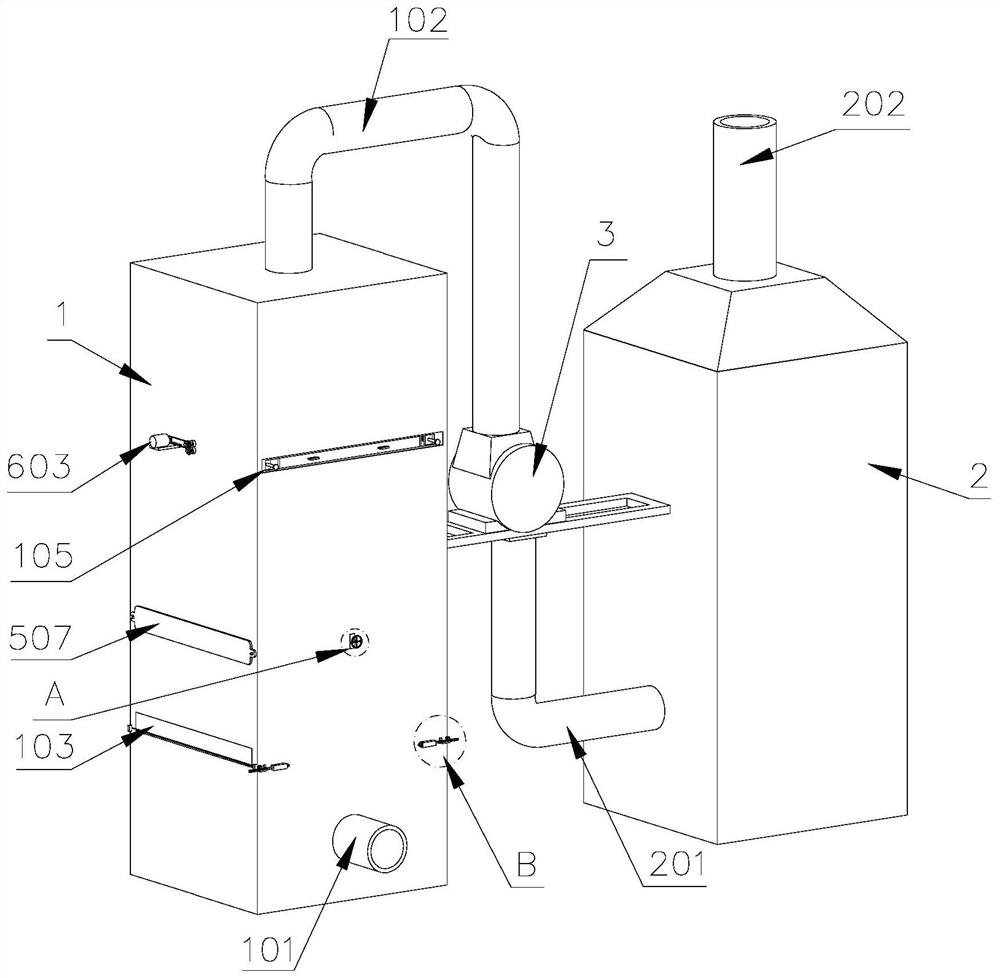

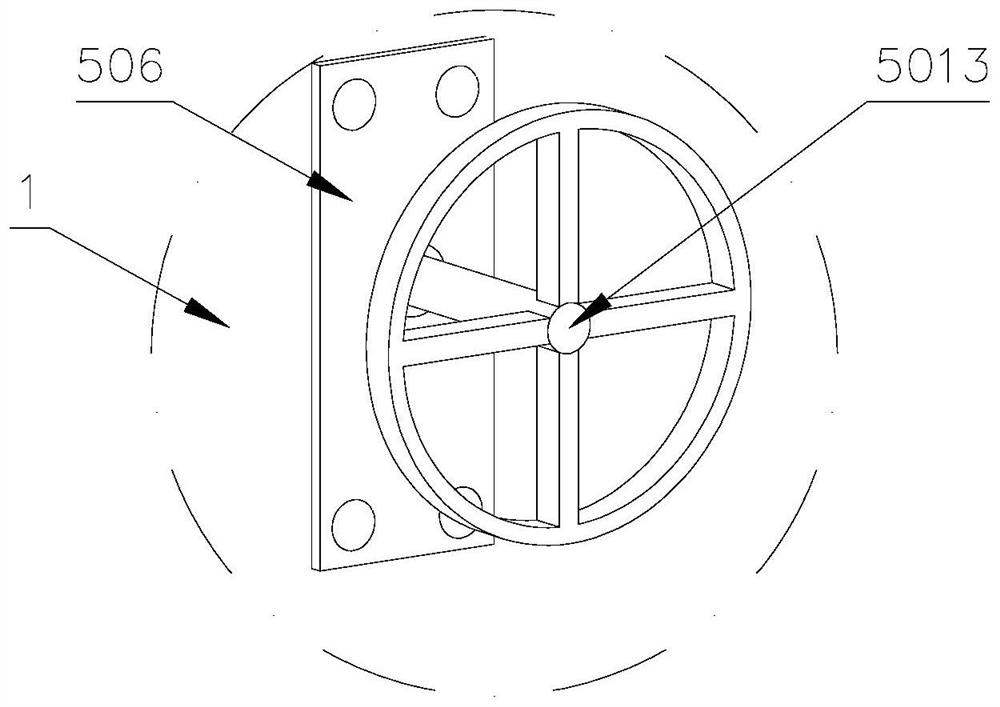

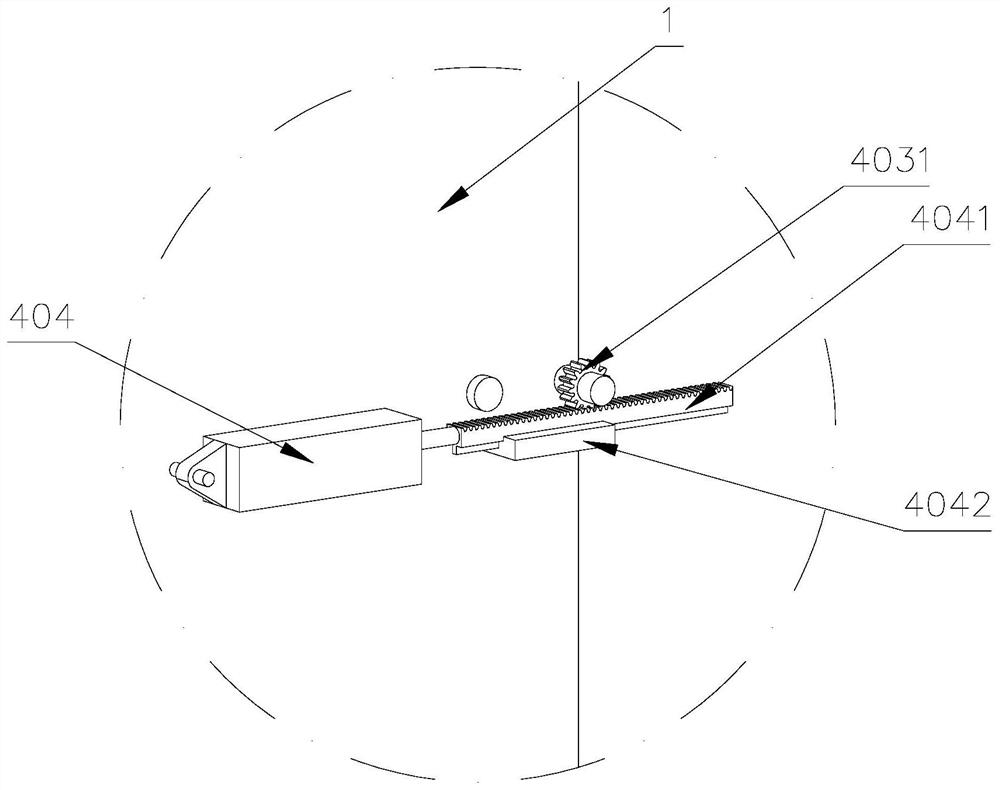

[0032] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-11 , to further specifically describe the technical solution of the present invention.

[0033]An exhaust gas dedusting adsorption treatment device, box body I1, box body II2, induced draft fan 3, adjustment mechanism 4, filter mechanism 5, adsorption mechanism 6, deacidification mechanism 7; box body I1 is set on the side of box body II2; induced draft fan 3 is set between the box body I1 and the box body II2 and is connected to each other through pipelines; the adjustment mechanism 4, the filter mechanism 5, and the adsorption mechanism 6 are set inside the box body I1, the adjustment mechanism 4 is set at the bottom of the box body I1, and the adsorption mechanism 6 Set on the top of the box I1, the filter mechanism 5 is set between the adjustment mechanism 4 and the adsorption mechanism 6; the deacidification mechanism 7 is set inside the box II; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com