Combined split mounting type hoisting bracket and hoisting method

An assembled and hanger technology, applied in safety devices, transportation and packaging, load hanging components, etc., can solve the problems of high-altitude falling, high cost, poor versatility of components, and achieve the effect of enhancing versatility and ensuring hoisting safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. According to the following description, the purpose, technical solution and advantages of the present invention will be more clear. It should be noted that the described embodiments are preferred embodiments of the present invention, but not all embodiments.

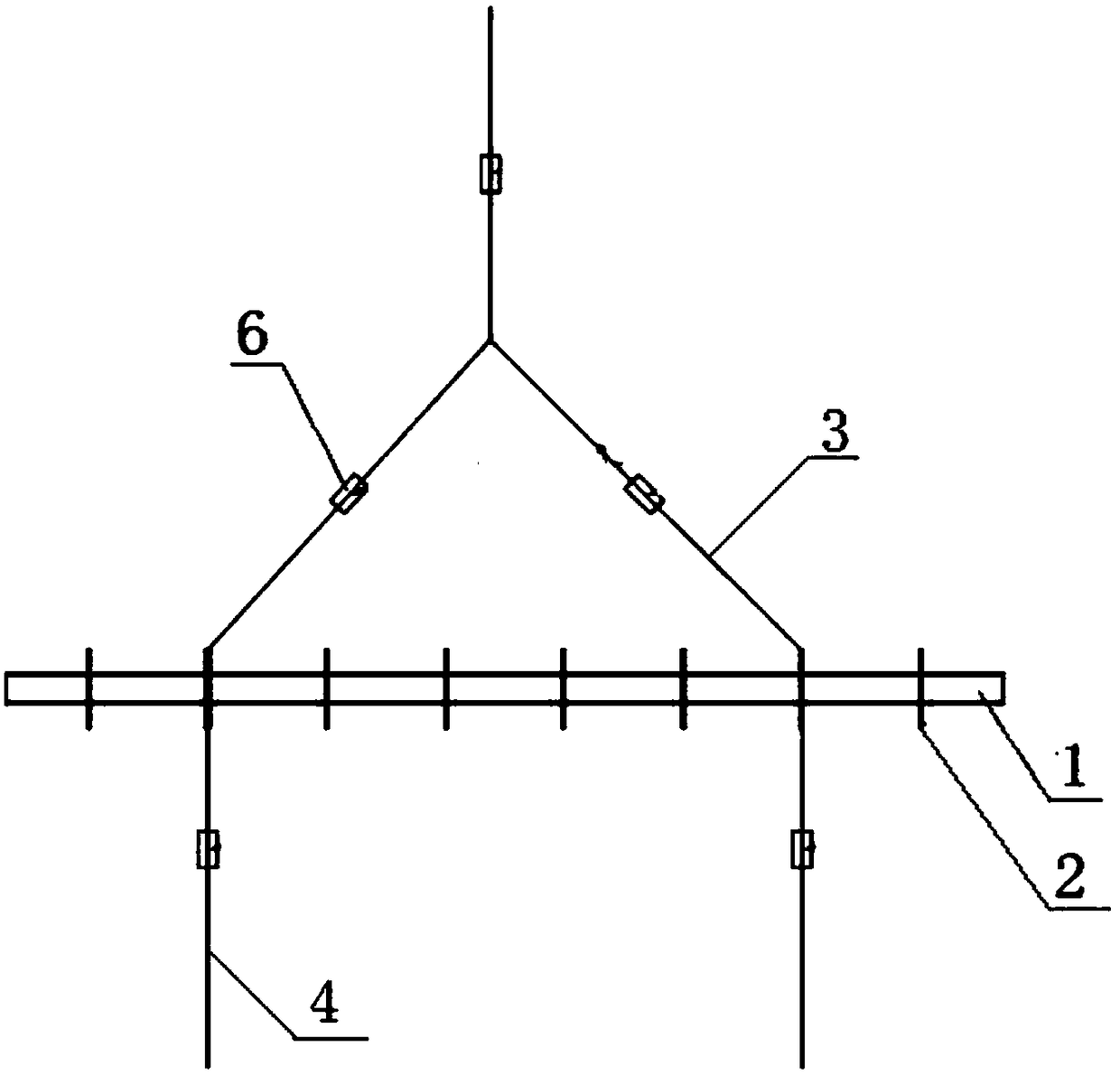

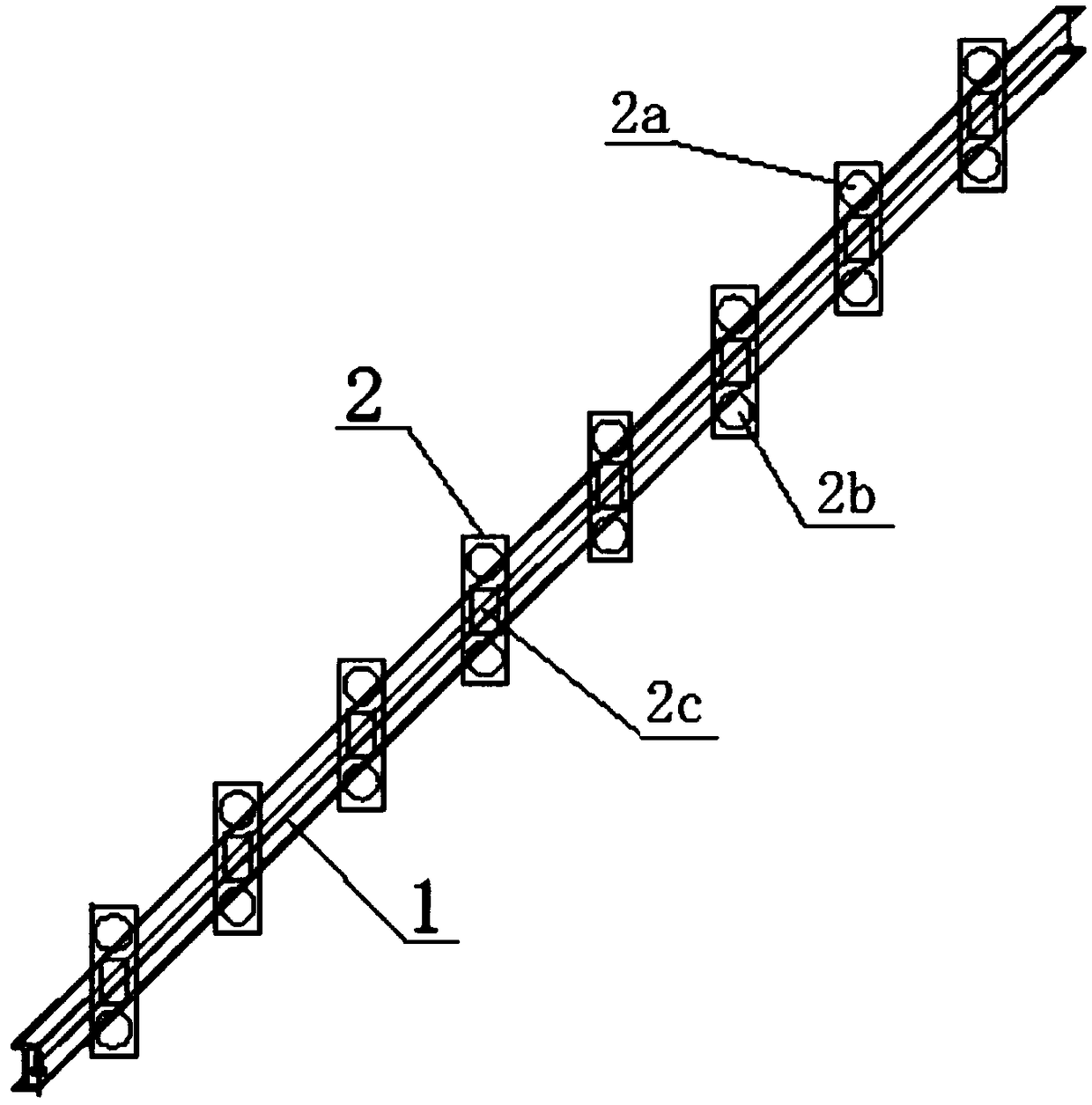

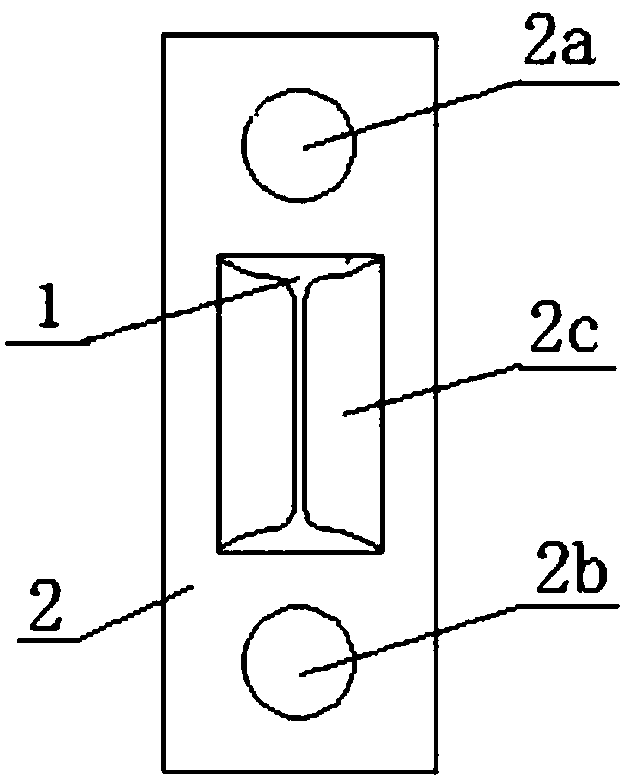

[0024] combine figure 1 with figure 2 As shown, a combined assembled hanger includes a beam 1 made of I-shaped steel, several hanging plates 2 equidistant and vertically fixed on the beam 1, several hanger wire ropes 3 and component connecting wire ropes 4. The upper and lower ends of the suspension plate 2 are provided with an upper hole 2a and a lower hole 2b respectively, the steel wire rope 3 of the spreader is connected in the symmetrical upper hole 2a, and the component connecting wire rope 4 is connected in the lower hole symmetrical within 2b. Preferably, the shape of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com