Fluidized bed deacidification purification device and process

A purification device and fluidized bed technology, which is applied in the direction of silicon oxide, silicon dioxide, etc., can solve the problems affecting the normal operation of the equipment and the deacidification effect, reduce the service life of the equipment, and the deacidification effect is unstable, so as to achieve good deacidification Purification effect, device cost saving, height reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

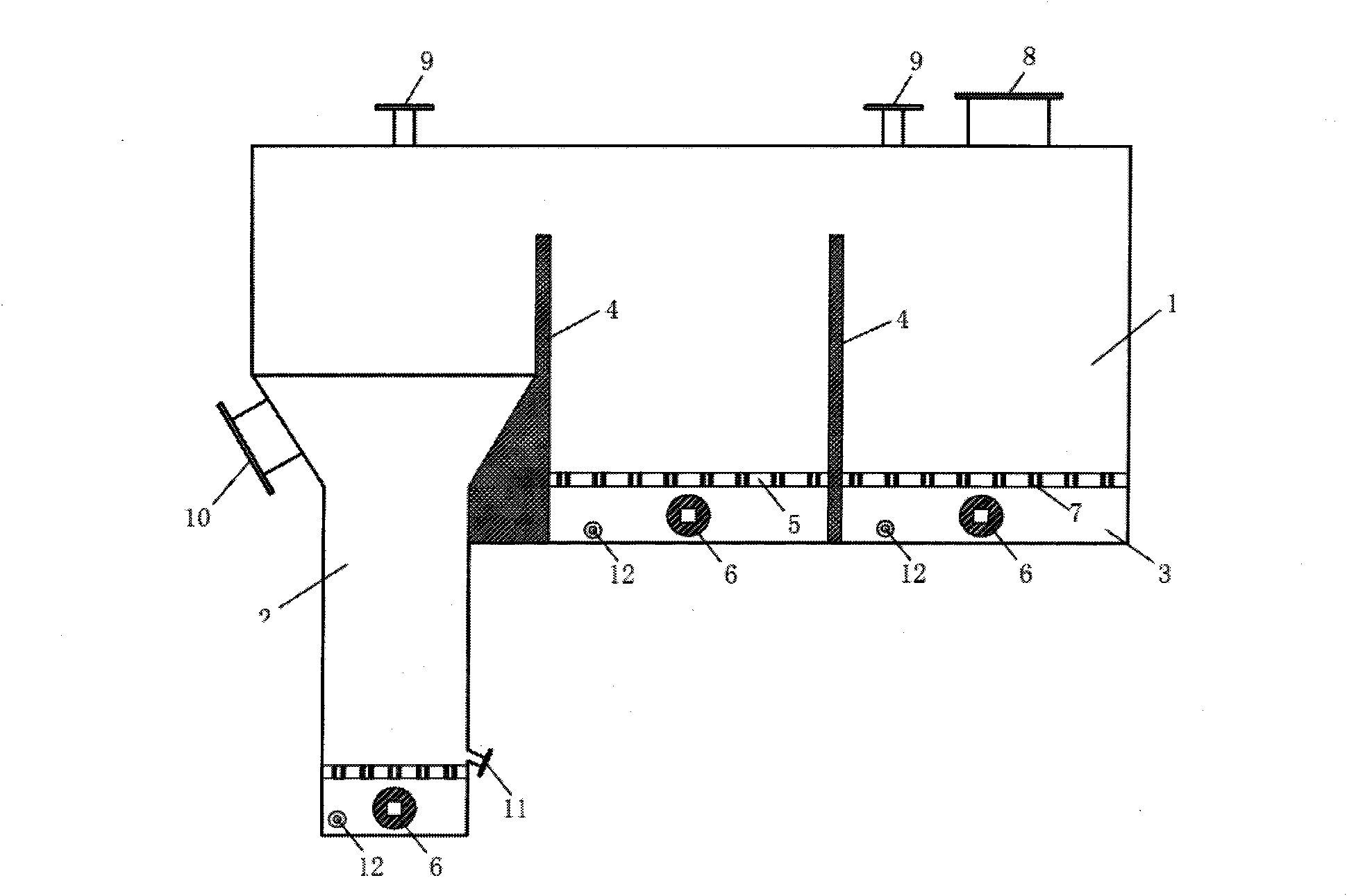

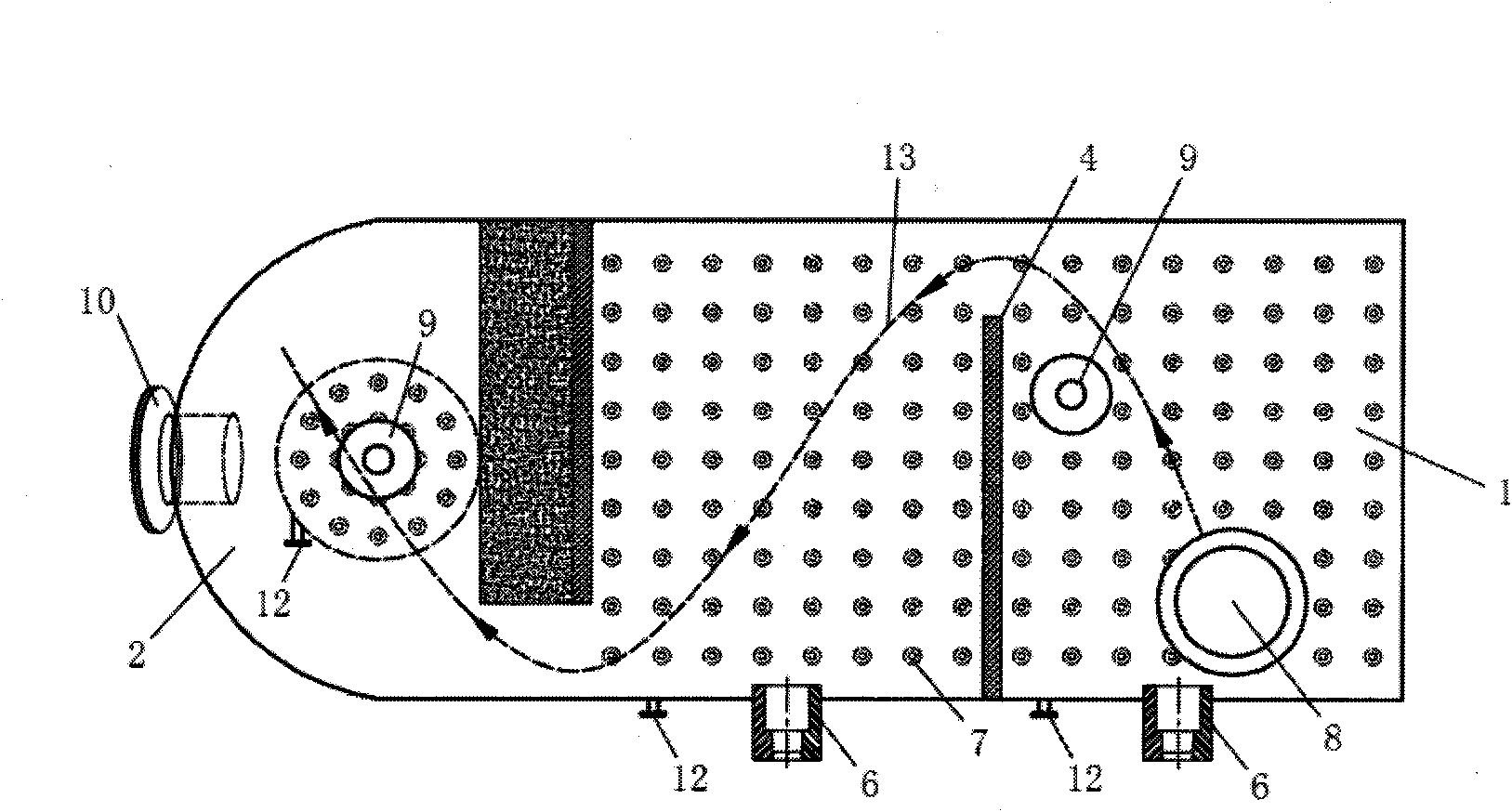

[0025] like figure 1 , figure 2 As shown, the fluidized bed deacidification purification device is generally divided into two parts: horizontal fluidized bed 1 and vertical fluidized bed 2, and each part is divided into upper and lower layers. It is a combustion chamber 3 for hydrogen and air. There is a burner 6 in the combustion chamber 3. The upper and lower layers are separated by a partition 5. There are gas channels 7 on the partition 5. The gas channels 7 can be evenly distributed on the partition 5. The upper layer of the type fluidized bed is divided into several chambers by a number of baffles 4, and there are communication channels between the chambers, so that the material can flow from the feeding chamber to the rear chambers in sequence until the material enters the vertical fluidized bed. The fluidized bed is discharged from the outlet 10 of the self-supporting fluidized bed.

[0026] The passages between the inner chambers of the horizontal fluidized bed 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com