Deacidification-dust removal integrated device for flue gas based on dense phase dry tower

A dust removal device and deacidification technology, used in gas treatment, chemical instruments and methods, dispersed particle filtration, etc., to reduce the emission of acidic waste gas and particulate matter, high deacidification efficiency, and improve utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] An integrated flue gas deacidification and dust removal device based on a dense phase dry tower described in this embodiment is used for deacidification treatment of sintering flue gas in a steel company, and its flue gas volume is 100×10 4 m 3 / h, SO before entering the deacidification unit 2 The concentration is 1000mg / m 3 .

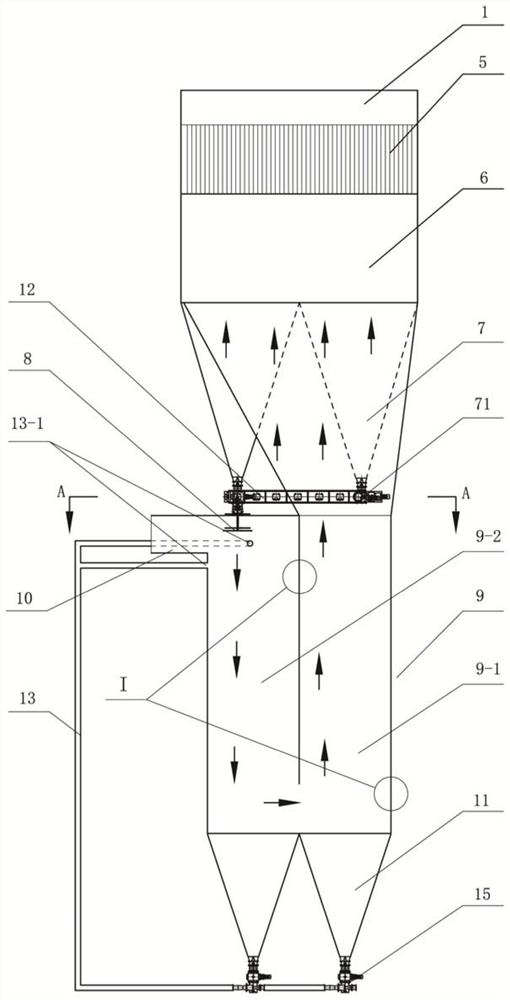

[0023] An integrated flue gas deacidification and dust removal device based on a dense phase dry tower is composed of a flue gas deacidification device of a dense phase dry tower and a special dust removal device for deacidification.

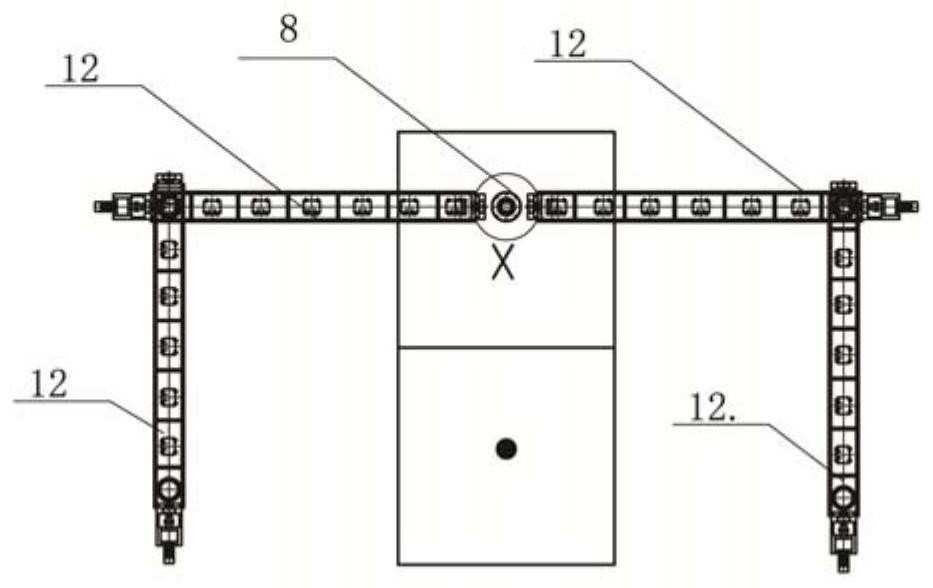

[0024] The flue gas deacidification device of the dense phase dry tower comprises a flue gas inlet 10, a deacidification device body 9, a deacidification device body ash hopper 11, a deacidification device body ash hopper feeder 15, an ash conveying device 13, a humidifier 12. Stirrer 8.

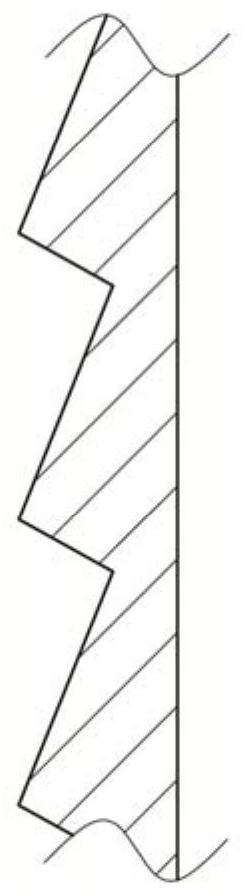

[0025] The deacidification device body 9 described in this embodiment is divided into an air outlet side 9-1 and an air in...

Embodiment 2

[0037] An integrated flue gas deacidification and dust removal device based on a dense phase dry tower described in this embodiment is used to deacidify the flue gas of a chemical enterprise, and its flue gas volume is 40×10 4 m3 / h, the HF concentration before entering the deacidification device is 2000mg / m 3 .

[0038] An integrated flue gas deacidification and dust removal device based on a dense phase dry tower is composed of a flue gas deacidification device of a dense phase dry tower and a special dust removal device for deacidification.

[0039] The flue gas deacidification device of the dense phase dry tower comprises a flue gas inlet 10, a deacidification device body 9, a deacidification device body ash hopper 11, a deacidification device body ash hopper feeder 15, an ash conveying device 13, a humidifier 12. Stirrer 8.

[0040] The deacidification device body 9 described in this embodiment is divided into an air outlet side 9-1 and an air inlet side 9-2 by a partit...

Embodiment 3

[0051] An integrated flue gas deacidification and dust removal device based on a dense phase dry tower described in this embodiment is used to deacidify the flue gas of an enterprise, and its flue gas volume is 10×10 4 m 3 / h, the HCl concentration before entering the deacidification device is 300mg / m 3 .

[0052] An integrated flue gas deacidification and dust removal device based on a dense phase dry tower is composed of a flue gas deacidification device of a dense phase dry tower and a special dust removal device for deacidification.

[0053] The flue gas deacidification device of the dense phase dry tower comprises a flue gas inlet 10, a deacidification device body 9, a deacidification device body ash hopper 11, a deacidification device body ash hopper feeder 15, an ash conveying device 13, a humidifier 12. Stirrer 8.

[0054] The deacidification device body 9 described in this embodiment is divided into an air outlet side 9-1 and an air inlet side 9-2 by a partition, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com