Patents

Literature

43results about How to "Save on sewage charges" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

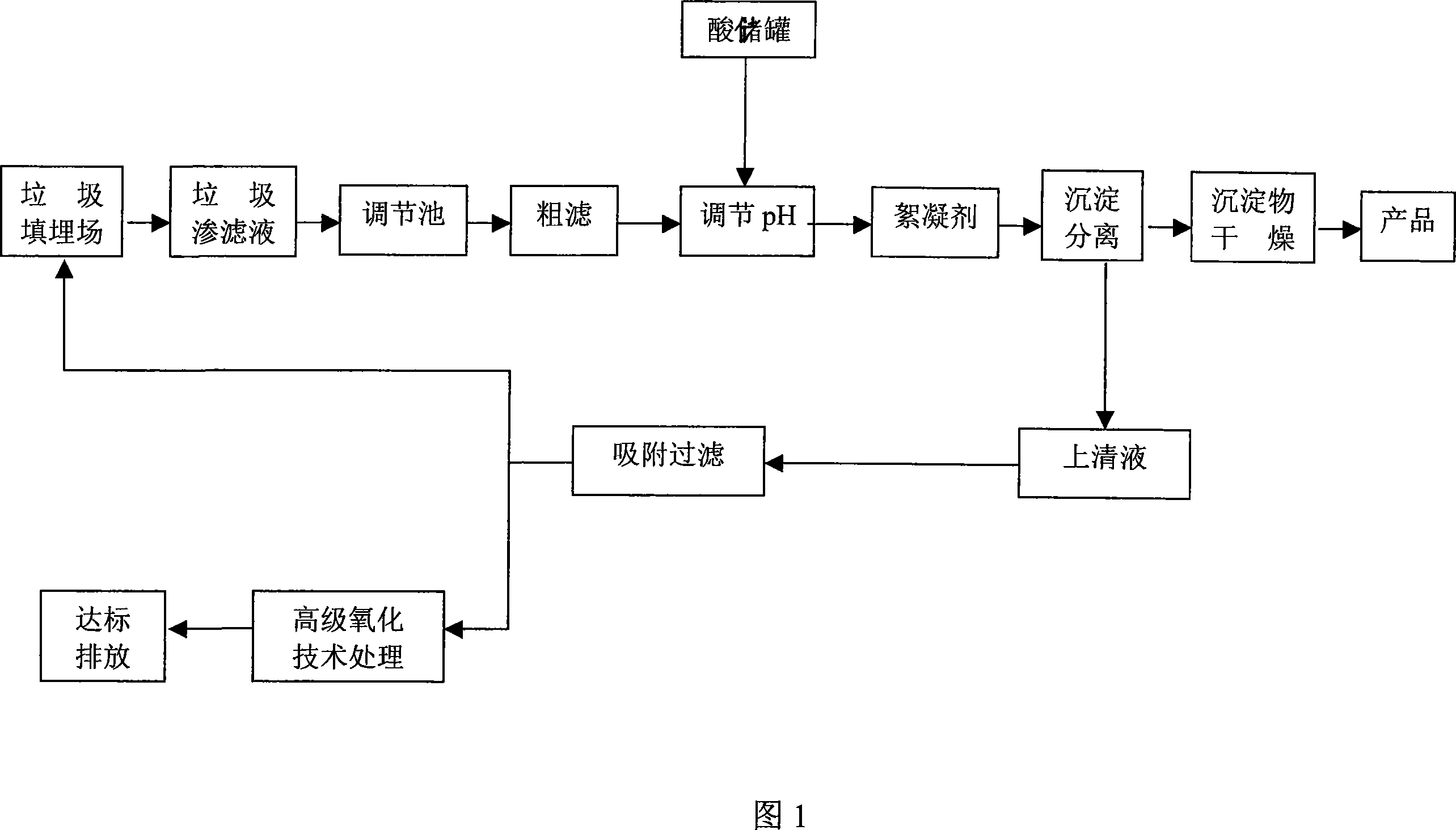

Comprehensive treatment method for recovered and used humic acid in garbage infiltration liquid

InactiveCN101045591AAchieve governanceNo secondary pollutionWater/sewage treatment by irradiationOther chemical processesChemical oxygen demandLitter

A process for reclaiming the humic acid in the percolated liquid of garbage includes such steps as filtering, regulating pH=1.0-5.5, adding flocculant, fast stirring, settling, depositing, separating to obtain humic acid, adsorbing and filtering supernatant, regulating pH=6-8, and reusing it to garbage burying field.

Owner:LANZHOU UNIVERSITY

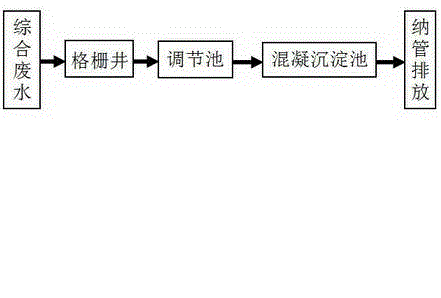

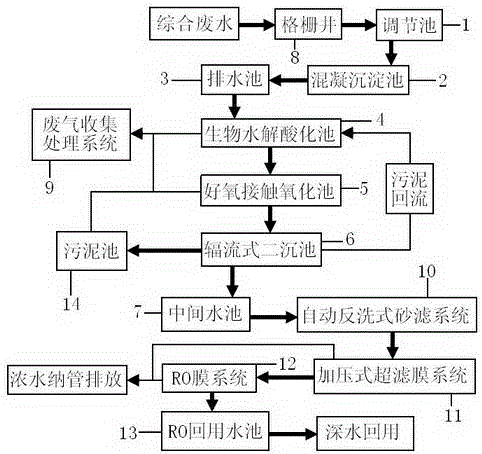

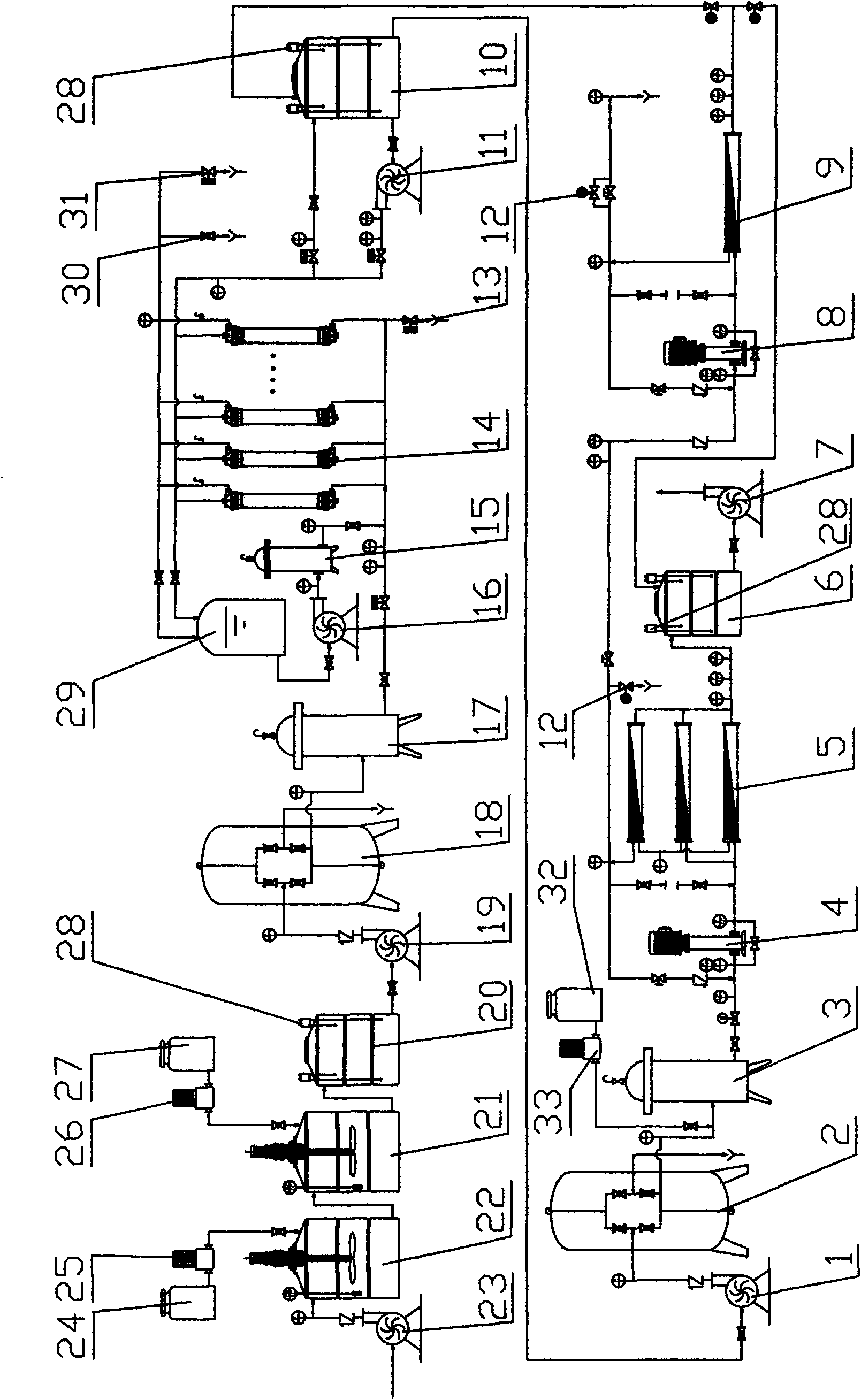

Printing and dyeing wastewater processing system

InactiveCN102616978ASolve the problem of exceeding the standardIncrease water reuseSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentWater dischargeSludge

The invention discloses a printing and dyeing wastewater processing system. The printing and dyeing wastewater processing system comprises a comprehensive wastewater preprocessing system, a depth reuse processing system and a sludge processing system, wherein the sludge processing system comprises a sludge pool; the comprehensive wastewater preprocessing system comprises an adjustment pool, a coagulative precipitation pool, a water discharging pool, a biological hydrolysis-acidification pool, an aerobic contact oxidation pool, a radial flow type secondary sedimentation pool and an intermediate water pool which are sequentially connected; the depth reuse processing system comprises an automatic backwashing sand filtration system, a pressure type ultrafilter membrane system, an RO membrane system and an RO reuse water pool which are sequentially connected; the sludge outlet of the radial flow type secondary sedimentation pool is communicated with the sludge pool; and the water outlet of the intermediate water pool is communicated with the automatic backwashing sand filtration system. According to the invention, the quality of the depth reuse water reaches outlet water quality standards; and the deepwater reuse can saves the water resource, and COD discharge is reduced year by year, so the content of discharged ammonia nitrogen can reach standards.

Owner:SHANGHAI ZHANGHUA FILM PURIFICATION

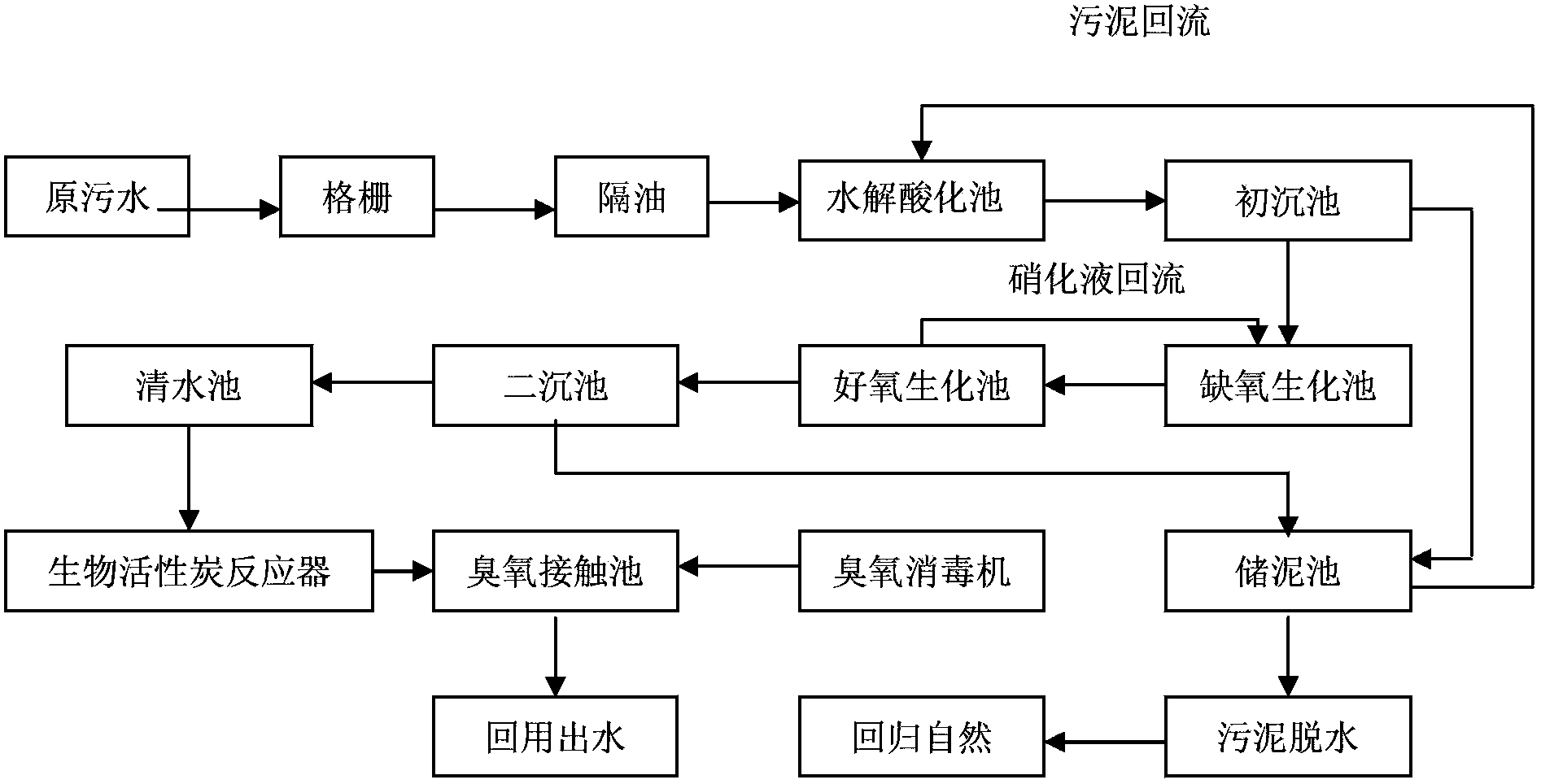

Sewage treatment method

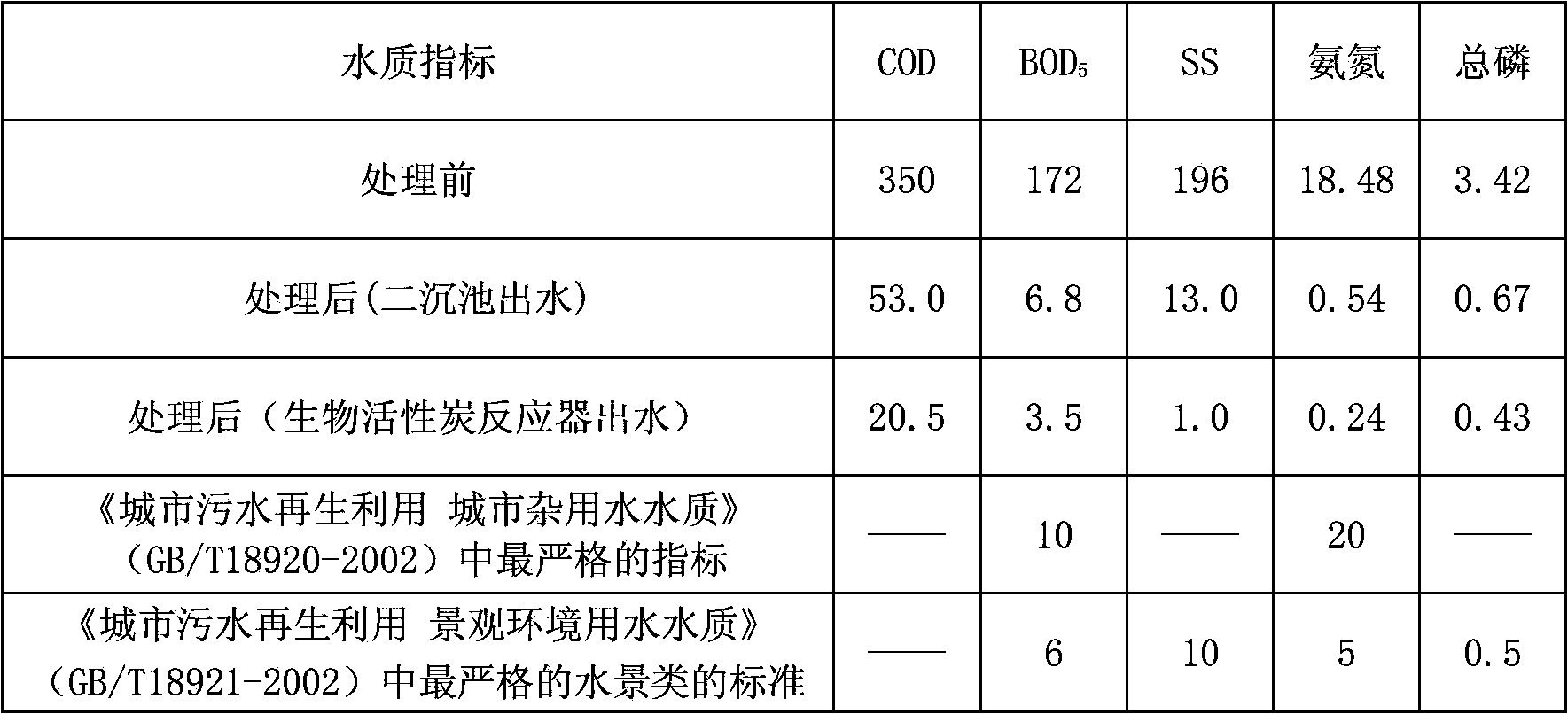

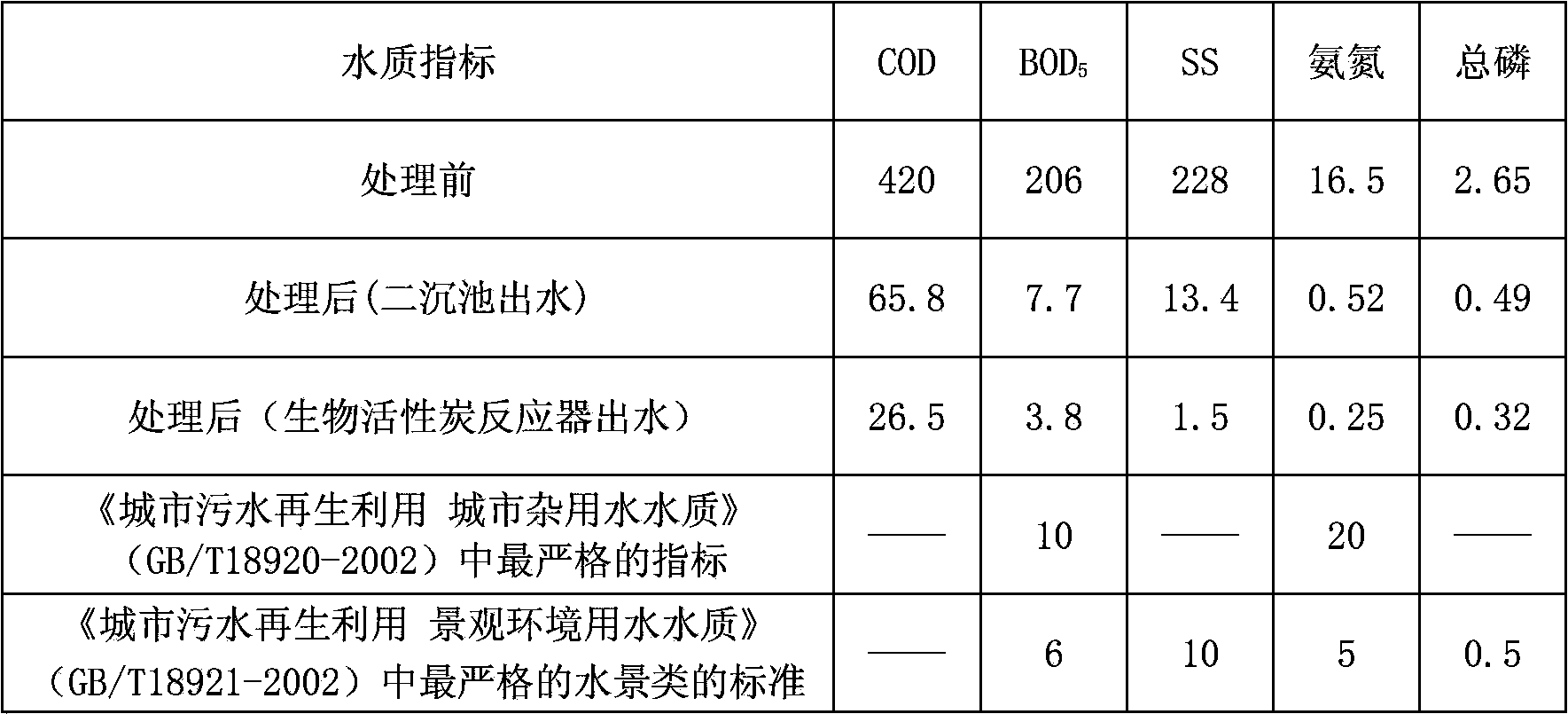

ActiveCN103449658AReduce CODReduce pollutionMultistage water/sewage treatmentSludgeTherapeutic effect

The invention relates to a sewage treatment method. The method is as below: sending domestic sewage into an oil separator through a machinery grating, and then sending the sewage into a hydrolysis-acidification pool to decompose macro-molecular organic matters in the sewage into micromolecular organic matters, so as to remove part of COD; sending the sewage into a primary settling tank to concentrating sludge and discharging the sludge into a sludge storage tank; sending an upper clarified liquor into an anoxic biochemical pool; carrying out an denitrification reaction on the sewage and a nitrated liquid flowing back from an aerobic biochemical pool; introducing effluent into the aerobic biochemical pool for aerobic biochemical reaction, and sending the other part of the sewage into a secondary settling tank through an overflow weir; concentrating the sludge, discharging the sludge into the sludge storage tank and flowing the upper clarified liquor into a clear water tank; part of the sludge in the sludge storage tank flows back to the hydrolysis-acidification pool; and conveying clear water to a biological active carbon reactor, flowing outlet water into an ozone contact pool and disinfecting the water outlet for reuse. The method has stable treatment effect, generates a small amount of sludge; residual sludge returns to the nature; and treated sewage is reused in water-scenery and greening, so as to save sewage charge and reduce environmental pollution.

Owner:PETROCHINA CO LTD

Method for treating atrazine-containing pesticide wastewater

ActiveCN101734821ASolve processing problemsEnsure safetyMultistage water/sewage treatmentWater/sewage treatment by neutralisationSlagEvaporation

The invention relates to a method for treating atrazine-containing pesticide wastewater, which is characterized by comprising: pumping pesticide wastewater into a neutralization pool; adding inorganic acid to regulate pH between 7 and 8; allowing the obtained product to enter a coagulation-sedimentation pool; putting in coagulant for coagulation; allowing the obtained product to enter a sand filter; performing filtration; allowing the obtained product to enter a reduced-pressure evaporation system of a water-collecting pool; discharging condensate which is repeatedly evaporated and concentrated and then is subjected to activated carbon adsorption into a recycled-water storage pool; allowing reactor-bottom residual liquid of evaporated and concentrated under reduced pressure to enter a salting-out tank and cooling the reactor-bottom residual liquid to form salt; and periodically transporting salt slag to a solid waste treatment plant for final treatment. The method has the advantages of realizing the zero wastewater discharge of pesticide production processes, performing safe disposal on solid pollutants, ensuring environmental safety, effectively solving the problem that the wastewater produced during pesticide production is difficult to treat, saving a large amount of cost for pollution discharge, reducing environmental pollution and having high economic and environmental benefit.

Owner:PETROCHINA CO LTD

Coking waste water reuse treatment method

InactiveCN100999366AEfficient removalEfficient retentionWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentChemical treatmentNitrogen

This invention relates to a reclaiming and processing method of charred waste water, which is used in coking industry. It utilizes method of combining physical, chemical processing and reversing osmosis membrane processing to process charring waste water. Its basic processing flow-sheet is: 1. Aerator aerates. 2. Adjust PH to 9-11, add denitrifying agent number one MgCl2.6H2O and number two Na2HPO4, mix,, add positive ion starch-dicyandiamide-formaldehyde-polymerized chloride ferric flocculating agent. 3. Filter with multi-medium filtrator. 4. Remove ammonia nitrogen with deaminizing nitrogen filtrator. 5. Reduction reaction process. 6. Carry out membrane processing by nanometer material compound membrane. Charring waste water processed by this invention has following characteristics: synthesize process cost is low. Operation is easy. Running is stable. It benefits for industrialization.

Owner:SHANDONG DALONG INDAL

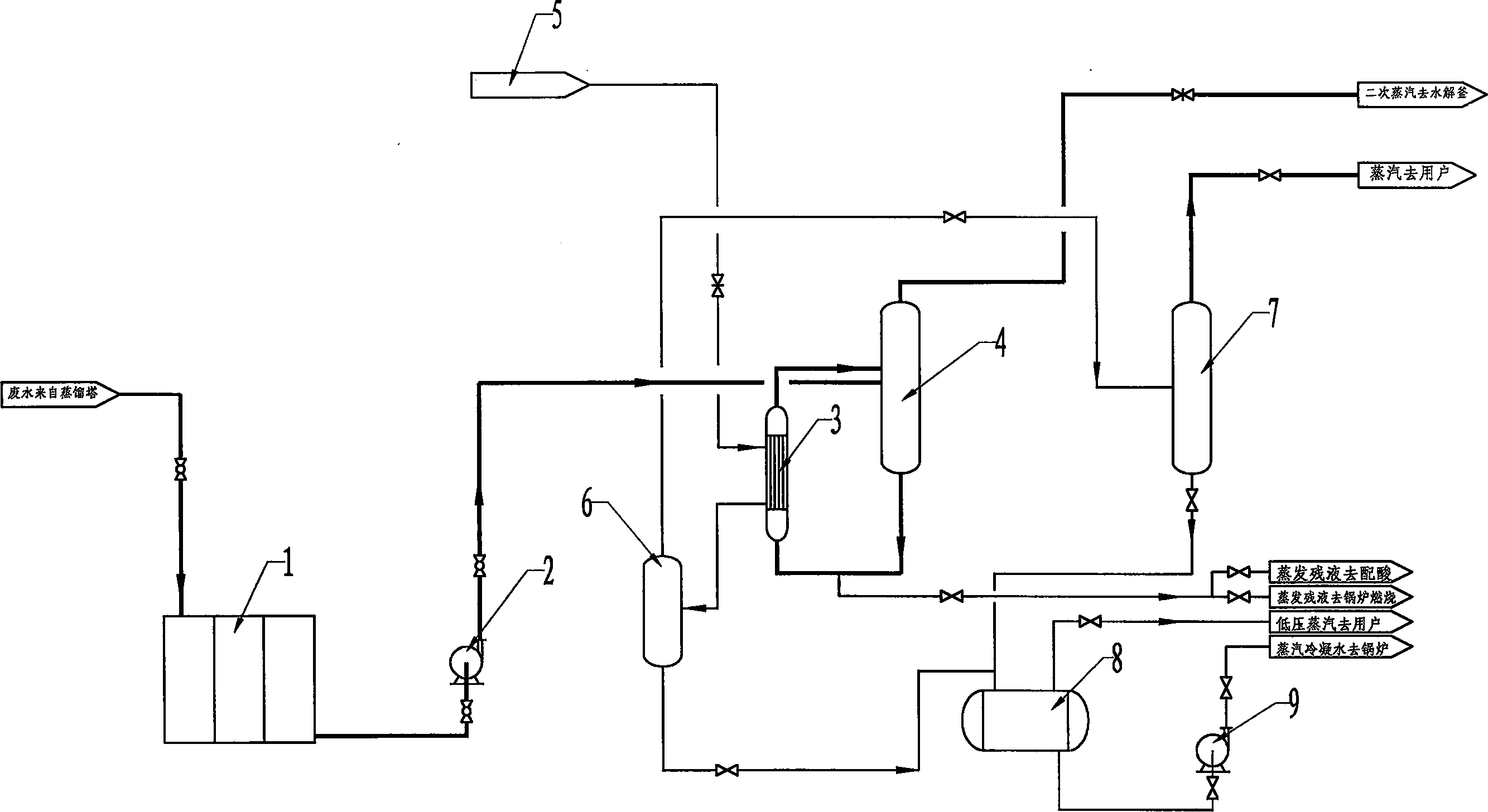

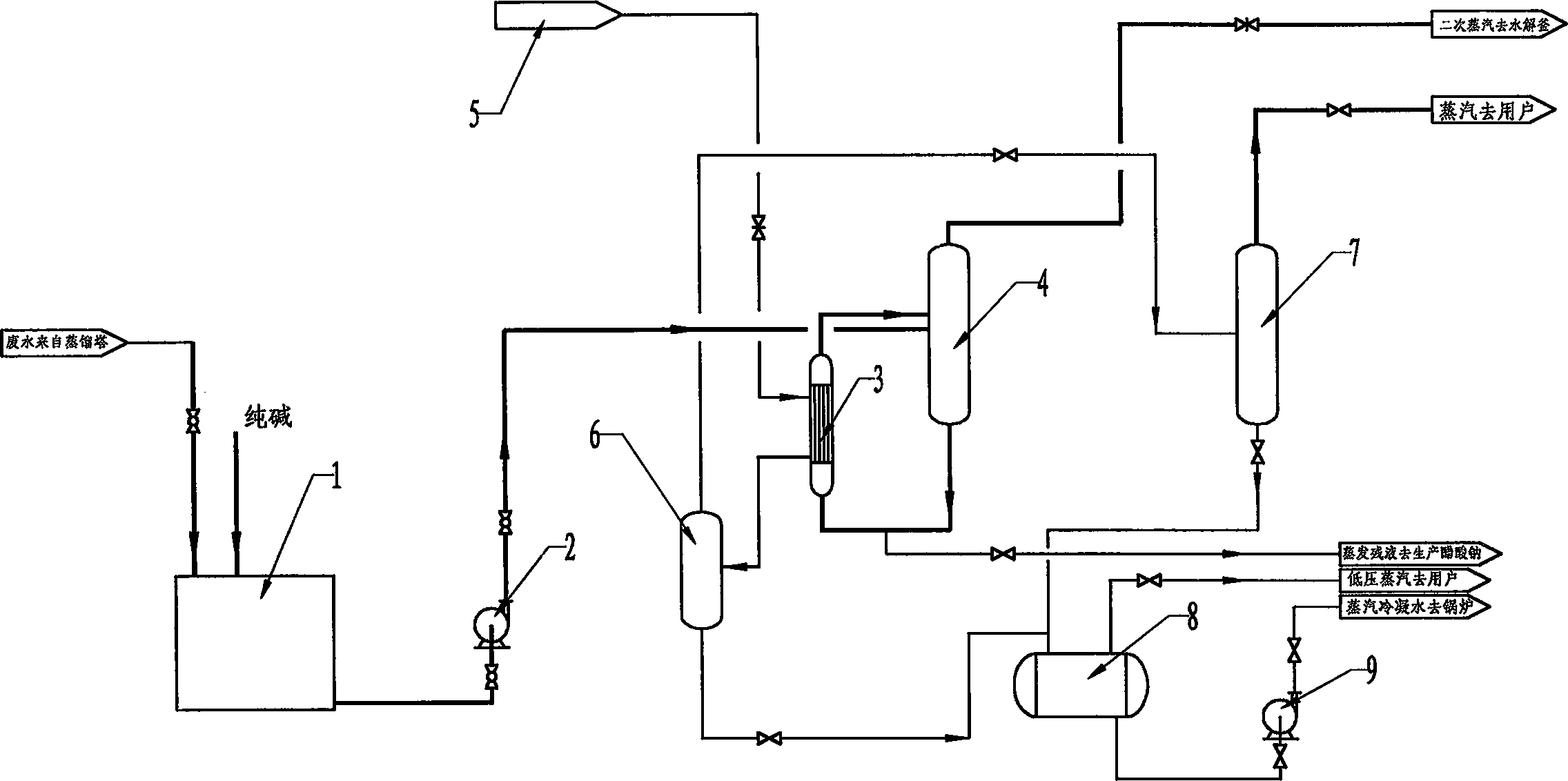

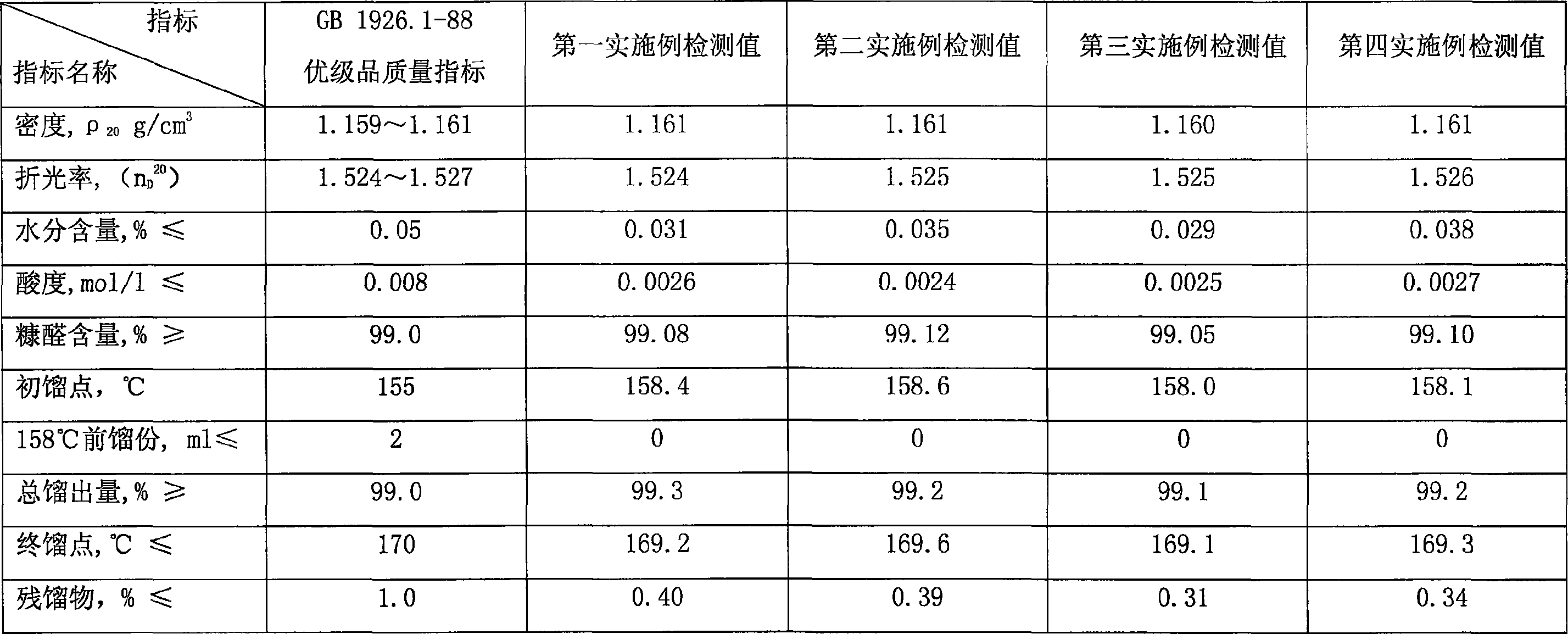

Method for treating wastewater from furfural production

InactiveCN1872726ASolve the shortcomings of large footprintSmall footprintOrganic chemistryDistillation separationSewageSuspended matter

This invention relates to a method a method for treating organic acidic wastewater from furfural production. The method comprises: (1) precipitating the wastewater, and pumping into a wastewater-evaporating system; (2) performing heat exchange with a primary steam to produce a secondary steam that is used for hydrolysis and taking out furfural; (3) introducing the primary steam into a vapor-water separator; (4) introducing steam condensing water from the vapor-water separator and the steam buffering tank into a steam expanding tank, and utilizing the low-pressure steam and condensing water from the steam expanding tank; (5) recycling evaporated residual liquid in the evaporating system, and combusting the precipitates and suspending matters in the precipitating tank. The method has such advantages as low equipment investment, low operation cost, and little secondary pollution. This invention makes full use of available components in furfural production wastewater under the condition of no effect on furfural yield, thus realizing zero wastewater discharge in furfural production process.

Owner:JINAN SHENGQUAN GRP SHARE HLDG CO LTD

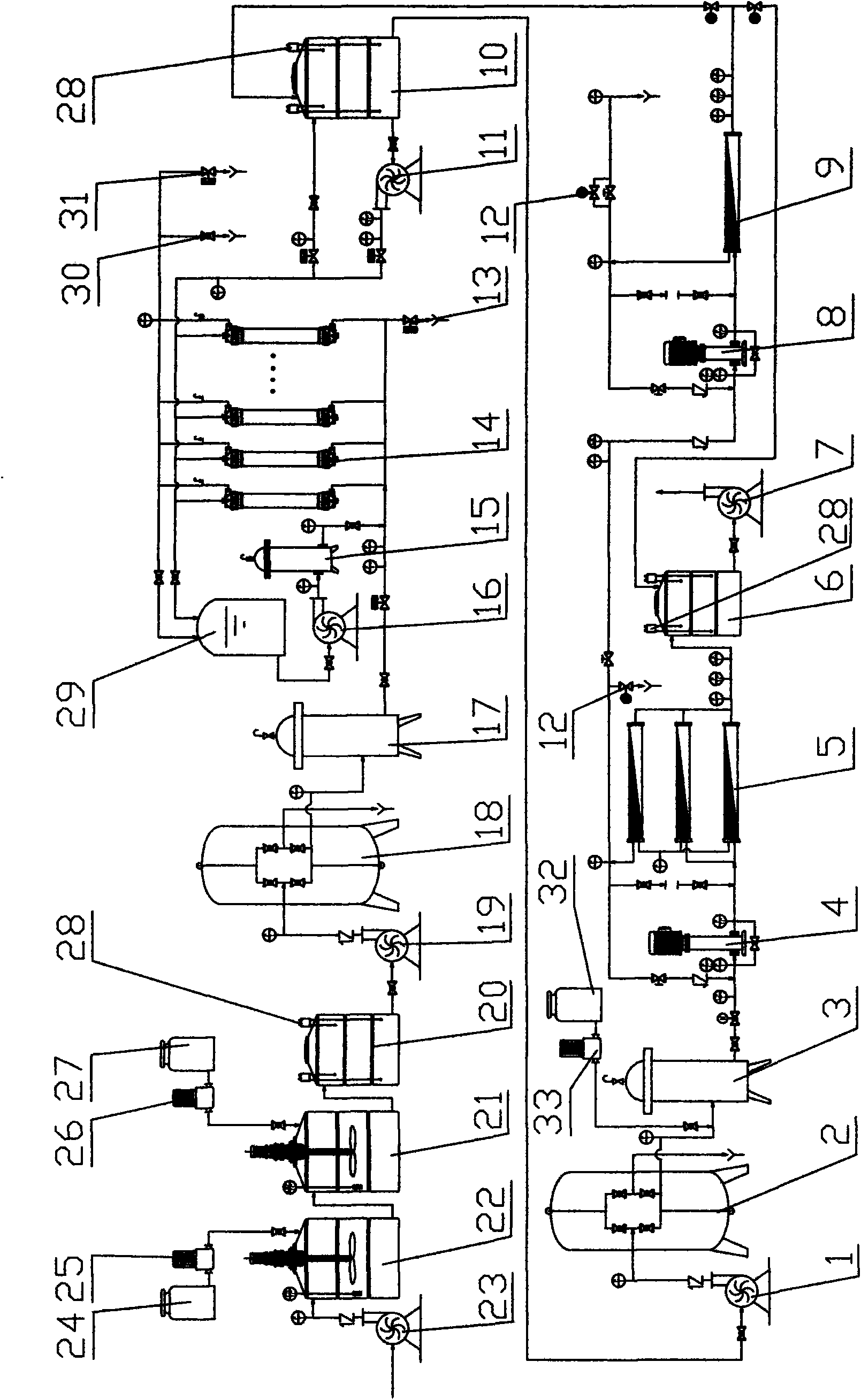

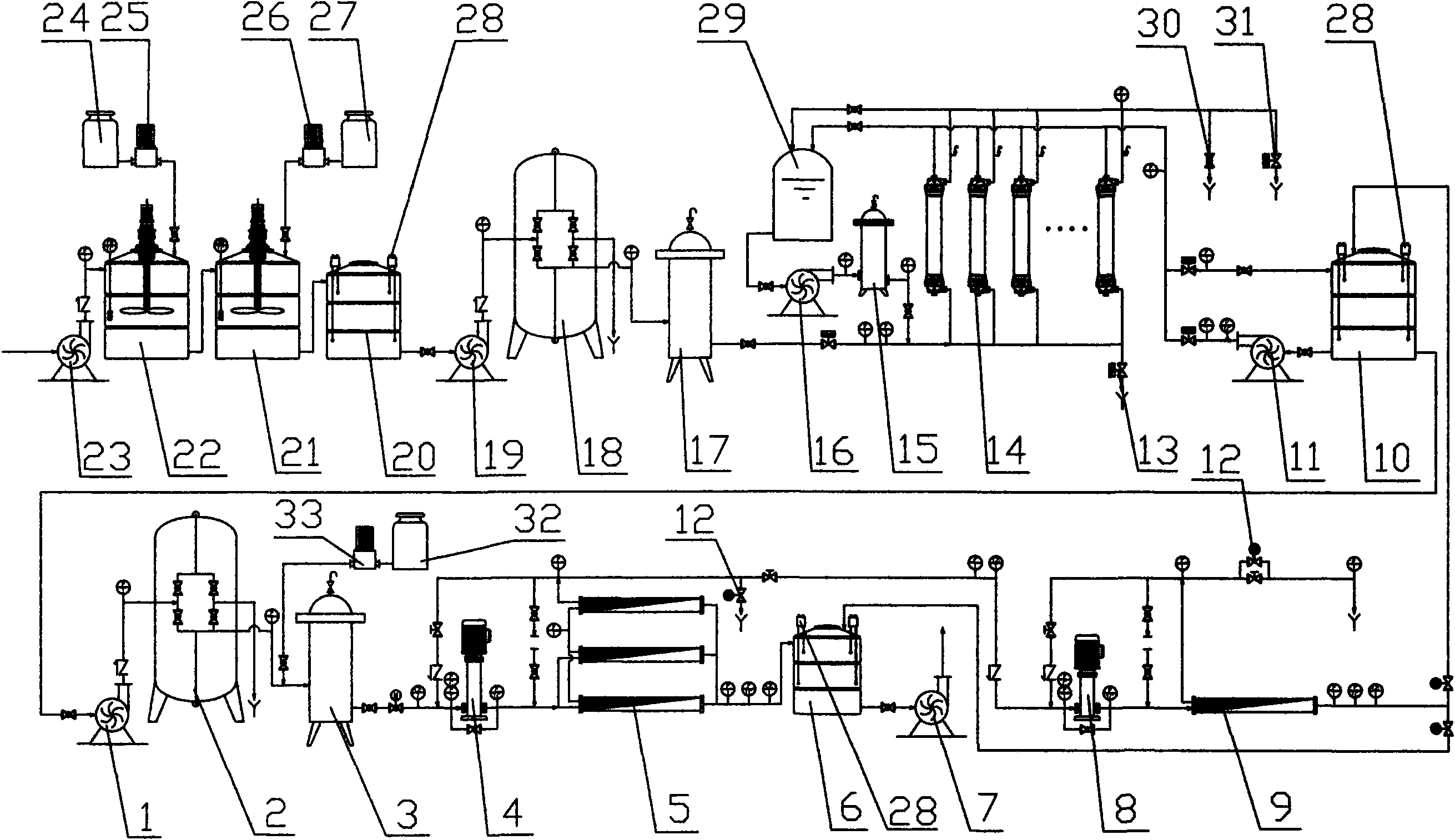

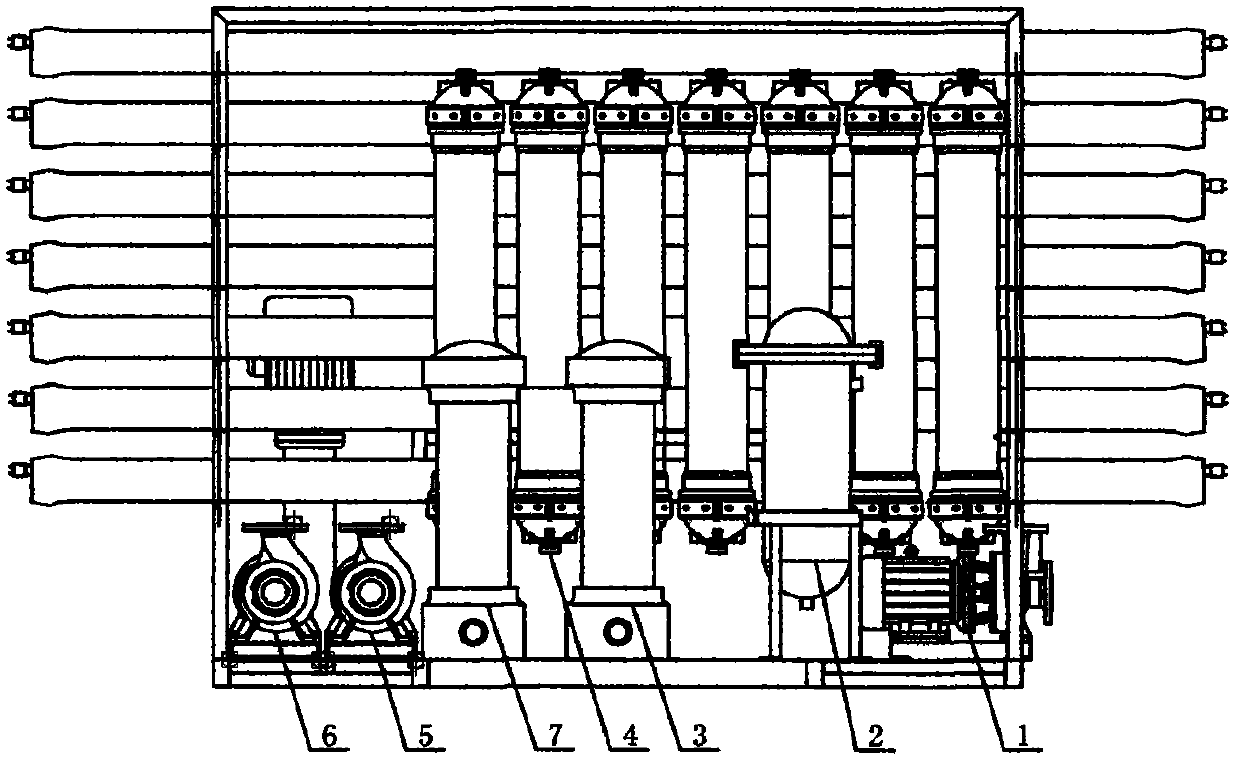

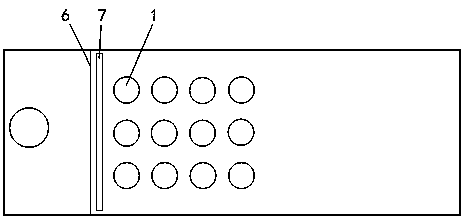

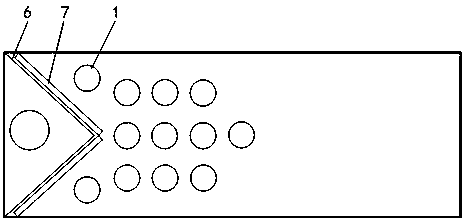

Electroplating reclaimed water recycling and treating system

ActiveCN101838071ASave on sewage chargesSave on water billsWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentUltrafiltrationReclaimed water

The invention relates to an electroplating reclaimed water recycling and treating system, comprising a control device, a preposed adjusting system, an ultrafiltering treating system and a reverse osmosis treating system, wherein the preposed adjusting system, the ultrafiltering treating system and the reverse osmosis treating system are mutually communicated, the preposed adjusting system comprises an ORP (Oxidation-Reduction Potential) adjusting system and a PH adjusting device; the ORP adjusting system comprises an ORP adjusting tank, a reducing agent metering pump, a reducing agent tank and a stirrer; the ulatrafiltering system comprises a water pump, a quartz sand filter, a precise filter and an ultrafiltering membrane assembly; and the reverse osmosis system comprises a water pump, an active carbon filter, a scale inhibitor adding device, a safety filter, a first section of high-pressure pump, a second section of high-pressure pump, a reverse osmosis membrane assembly and a water purified tank. By adopting a device combining membrane separation and the filter to treat the electroplating reclaimed water, the invention has the advantages of favorable treatment effect, low operation cost, convenient operation and capability of long-term continuous operation; and in addition, the invention meets the requirements of environmental protection and cleaning electroplating, not only reduces the pollution and saves the production cost, but also can fully utilize water resources and protect the environment.

Owner:ZHUHAI LANJIN ENVIRONMENTAL PROTECTION TECHCO

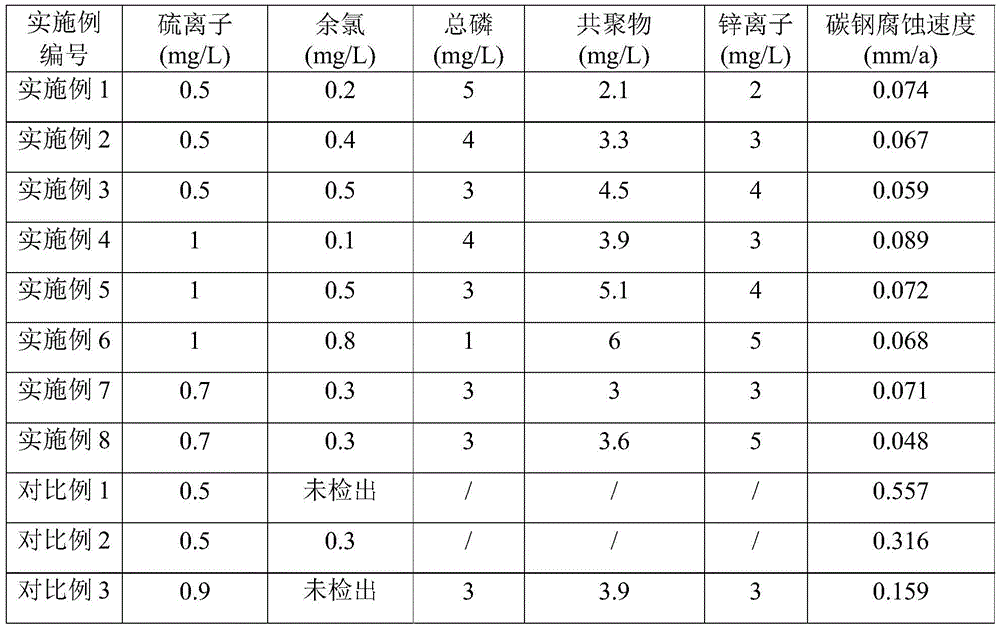

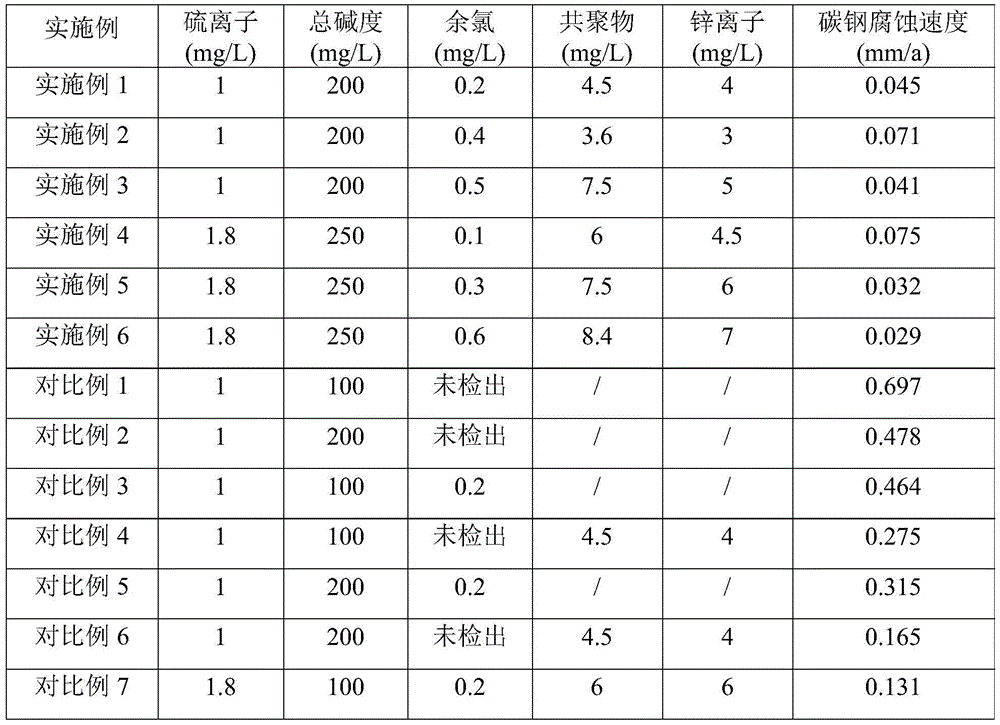

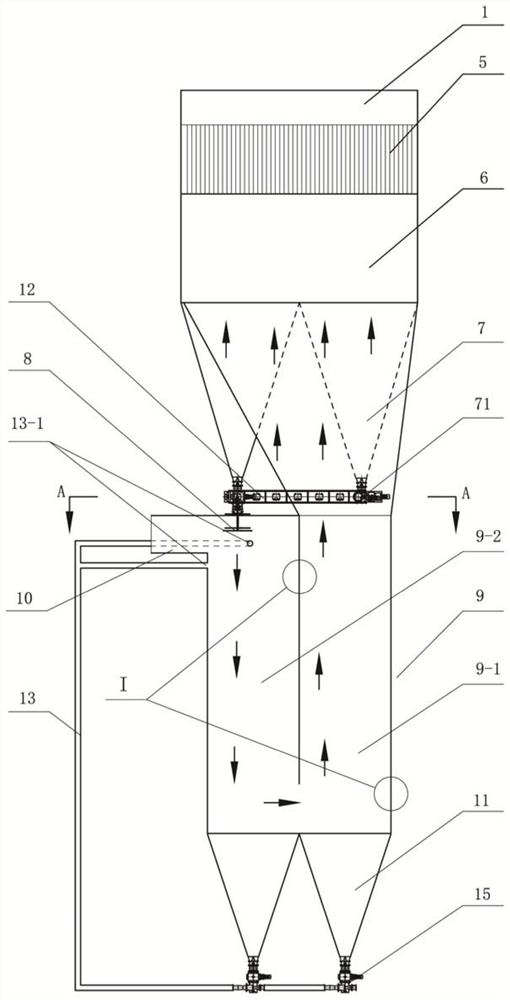

Method for treating sulfur-containing circulating cooling water

InactiveCN106745837ACorrosion controlSave on fresh water billsWater treatment parameter controlSpecific water treatment objectivesSulfur containingOrganic polymer

The present invention relates to the field of water treatment, and discloses a method for treating sulfur-containing circulating cooling water. The method comprises: adding a chlorine-containing oxidizing agent and a composite corrosion inhibitor to sulfur-containing circulating cooling water, and controlling the total alkalinity of the sulfur-containing circulating cooling water at 100-200 mg / L, wherein the residual chlorine in the sulfur-containing circulating cooling water is 0.1-0.8 mg / L with the use amount of the chlorine-containing oxidizing agent, and the composite corrosion inhibitor contains a water-soluble zinc salt, an organic polymer type water treatment agent, and a phosphorus-containing corrosion inhibitor. According to the present invention, by controlling the total alkalinity and the residual chlorine and pouring the specific kind of the composite corrosion inhibitor in the matched manner, the corrosion of the sulfur-containing circulating cooling water can be effectively controlled, the carbon steel corrosion rate meets the technical requirement of less than 0.1 mm / a, and the carbon steel test tube adhesion rate meets the technical requirement of less than 20 mg / (cm2.month); and although the composite corrosion inhibitor containing the water-soluble zinc salt is used, the zinc salt deposition cannot cause the over-standard of the adhesion rate, such that the system does not require the complete replacement after the sulfur-containing material leaks so as to reduce the energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

Treatment method for sulfur-containing circulating cooling water

InactiveCN106745835ACorrosion controlSave money on pharmacyWater treatment parameter controlSpecific water treatment objectivesSulfur containingOrganic polymer

Relating to the field of water treatment, the invention discloses a treatment method for sulfur-containing circulating cooling water. The method includes: adding a chlorine-containing oxidizing agent and a compound corrosion inhibitor into sulfur-containing circulating cooling water, and maintaining the total alkalinity of the sulfur-containing circulating cooling water at 170-300mg / L. Specifically, the dosage of the chlorine-containing oxidizing agent can bring the residual chlorine in the sulfur-containing circulating cooling water at 0.1-0.6mg / L, and the compound corrosion inhibitor contains a water-soluble zinc salt and an organic polymer type water treatment agent. Through control of the total alkalinity and residual chlorine and cooperation with adding of specific type compound corrosion inhibitor, corrosion of sulfur-containing circulating cooling water can be effectively controlled under the circumstance of a low phosphorus content, and the carbon steel corrosion rate satisfies the technical requirement of less than 0.1mm / a. And the carbon steel test tube adhesion rate is less than 20mg / (cm<2>.month). Although the compound corrosion inhibitor containing a water-soluble zinc salt is still used, the adhesion rate does not exceed the standard because of zinc salt deposition. Therefore, complete replacement of a system is unnecessary after leakage of a sulfur-containing substance, and the energy consumption is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

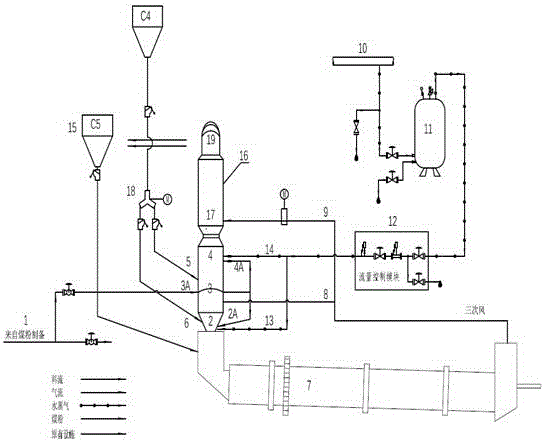

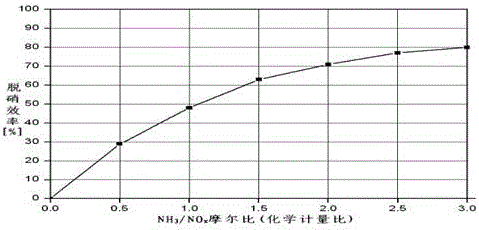

ERD (Efficient Reburning Denitration)+coal saturated steam catalytic combustion denitration device and technique

ActiveCN106675650AReduce the burden onImprove efficiencyGasification processes detailsBulk chemical productionSurge tankSystem stability

The invention discloses an ERD + coal saturated steam catalytic combustion denitration device. The ERD + coal saturated steam catalytic combustion denitration device comprises a decomposing furnace, wherein a secondary air inlet is formed in the bottom of the decomposing furnace, and connected with a cement rotary kiln; the decomposing furnace comprises a reduction zone, a main burning zone, a reburning zone and a burning-out zone from the bottom up, a reduction zone saturated steam catalytic combustor and a reburning zone saturated steam catalytic combustor are respectively mounted in the reduction zone and the reburning zone; the reduction zone saturated steam catalytic combustor and the reburning zone saturated steam catalytic combustor are connected with a steam flow metering device, the steam flow metering device is connected with a steam surge tank, the steam surge tank is connected with a steam main pipe, the main burning zone and the burning-out zone are respectively connected with tertiary air and over-fire air, and are oxygen enriched combustion zones, to ensure that pulverized coal of the system is burnt out. The invention further discloses an ERD + coal saturated steam catalytic combustion denitration technique, and has the advantages of high denitration efficiency, simple and easily operated technological process, low operation cost, high system stability, optimized clinker production technology, energy-saving and consumption-reducing effects and the like.

Owner:上海三融环保工程有限公司 +1

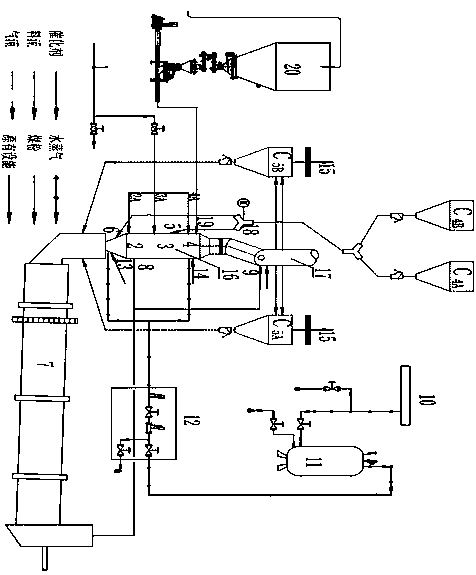

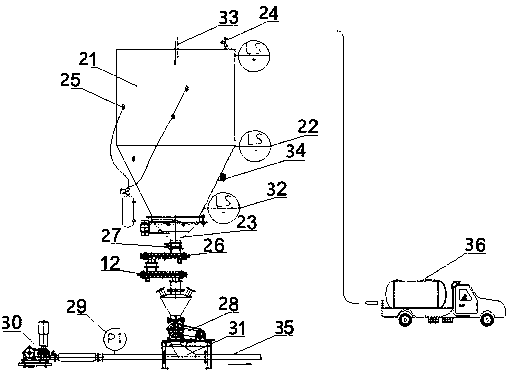

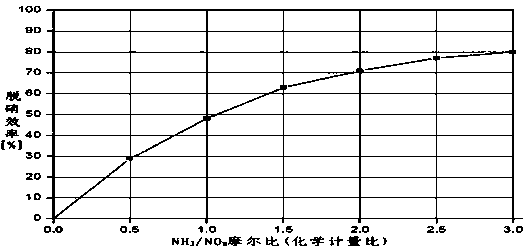

Device and process method for ERDIII cement plant ultra-low emission denitration

PendingCN110218584AReduce escapeReduce the burden of denitrificationGas treatmentDispersed particle separationDecompositionAmmonia

The invention discloses a device and a process method for ERDIII cement plant ultra-low emission denitration. The device for ERDIII cement plant ultra-low emission denitration comprises a decomposition furnace and a powder denitration agent conveying unit, wherein the bottom part of the decomposition furnace is provided with a secondary wind inlet which is connected with a cement rotary kiln; thedecomposition furnace comprises a reducing zone, a main burning zone, a reburning zone and a burnout zone from bottom to top; the reducing zone is equipped with a reducing zone saturated steam catalytic burner; the reburning zone is equipped with a reburning zone saturated steam catalytic burner; the main burning zone is connected with tertiary wind; the burnout zone is connected with burnout wind; and the discharge pipe of the powder denitration agent conveying unit is connected with a denitration agent spray gun which is connected with the reburning zone. According to the invention, throughintroduction of a denitration catalyst, the usage amount of ammonia water for denitration is reduced; the cost is saved; ammonia escape is reduced; more economy and environmental friendliness are achieved; and due to reduction of ammonia escape, corrosion to subsequent equipment is avoided.

Owner:上海三融环保工程有限公司

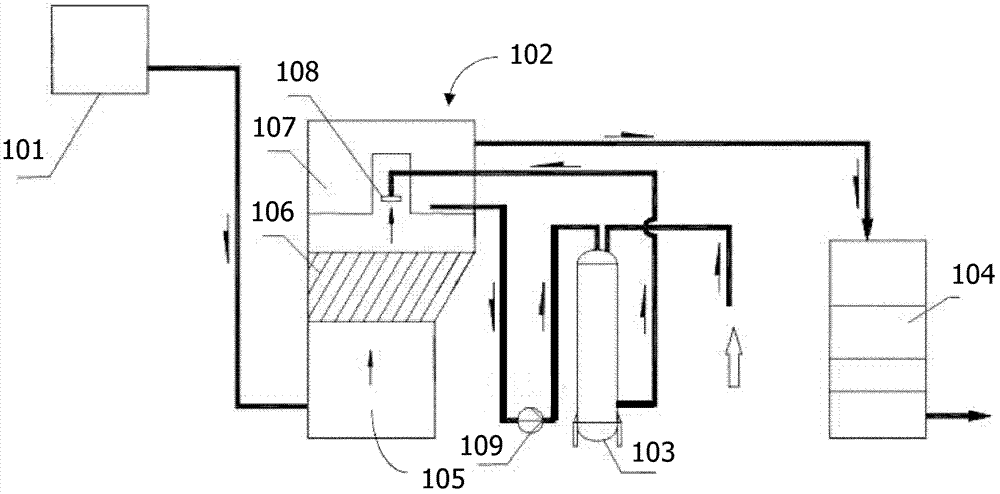

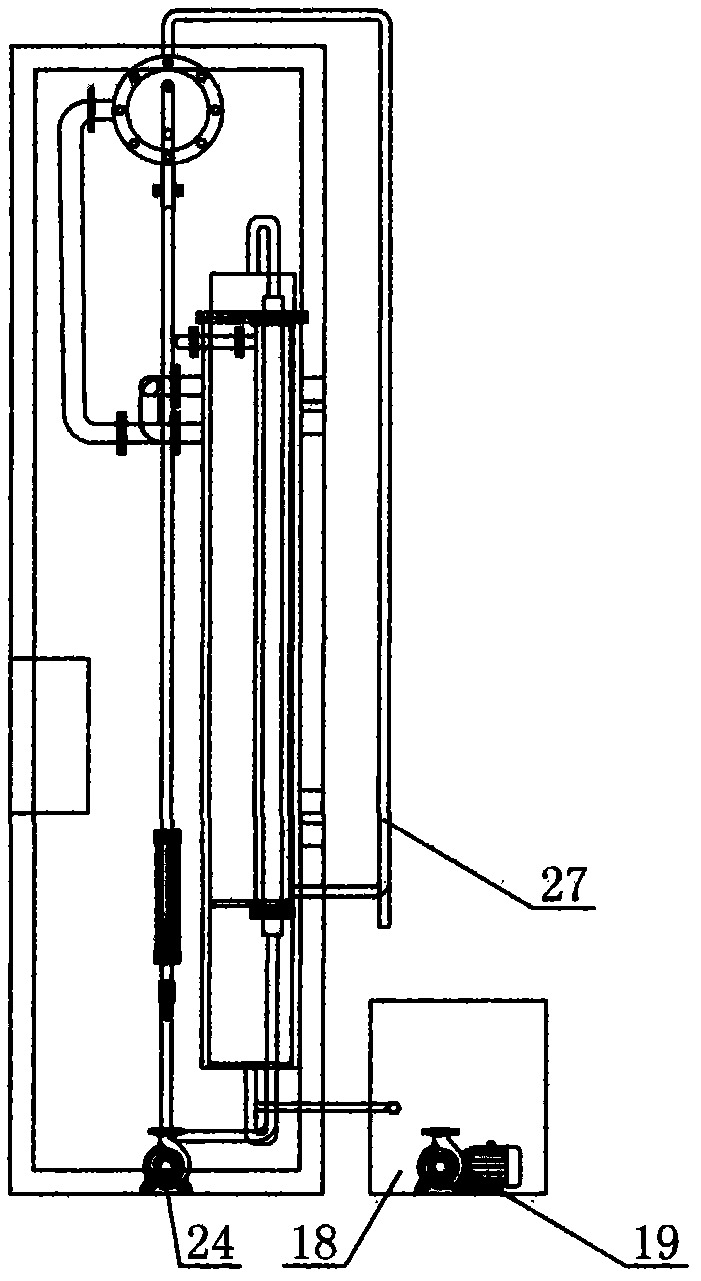

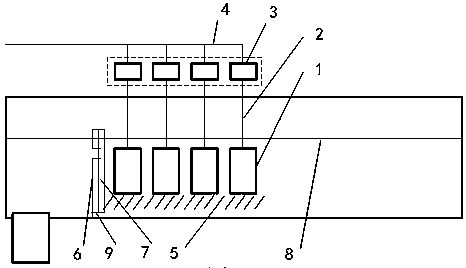

Comprehensive reutilization system of heating boiler wastewater

ActiveCN102951743AProvide clean and efficientSave on sewage chargesMultistage water/sewage treatmentWater/sewage treatment by neutralisationWastewaterCost savings

The invention provides a comprehensive reutilization system of heating boiler wastewater. The system comprises a wastewater collection tank; a precipitate filtering unit receiving the wastewater from the wastewater collection tank and carrying out precipitate filtering treatment of the wastewater, wherein the precipitate filtering unit comprises a precipitating pool positioned at the bottom of the precipitate filtering unit, an automatic alkali addition device positioned on the precipitate pool, a mixing pool positioned above the automatic alkali addition device and used for mixing alkali added wastewater with a medicine, and a water purifying pool positioned above the mixing pool; an automatic medicine device which is connected with the mixing pool and inputs the medicine to the mixing pool; and a concentrating pool for pumping clean water from a clean water pool. The comprehensive reutilization system has the advantages of wastewater recycle efficiency improvement and cost saving.

Owner:上海漕泾热电有限责任公司

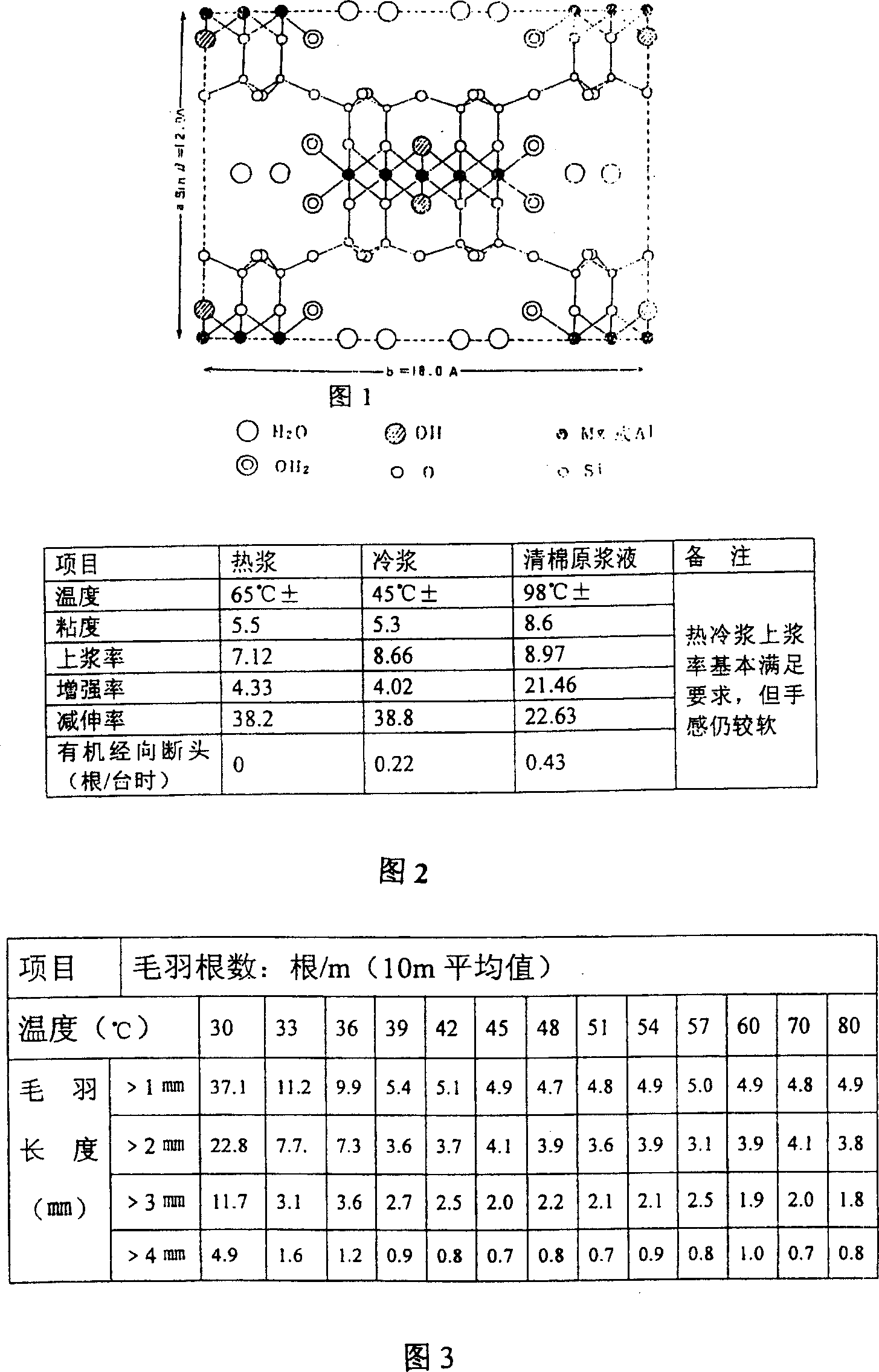

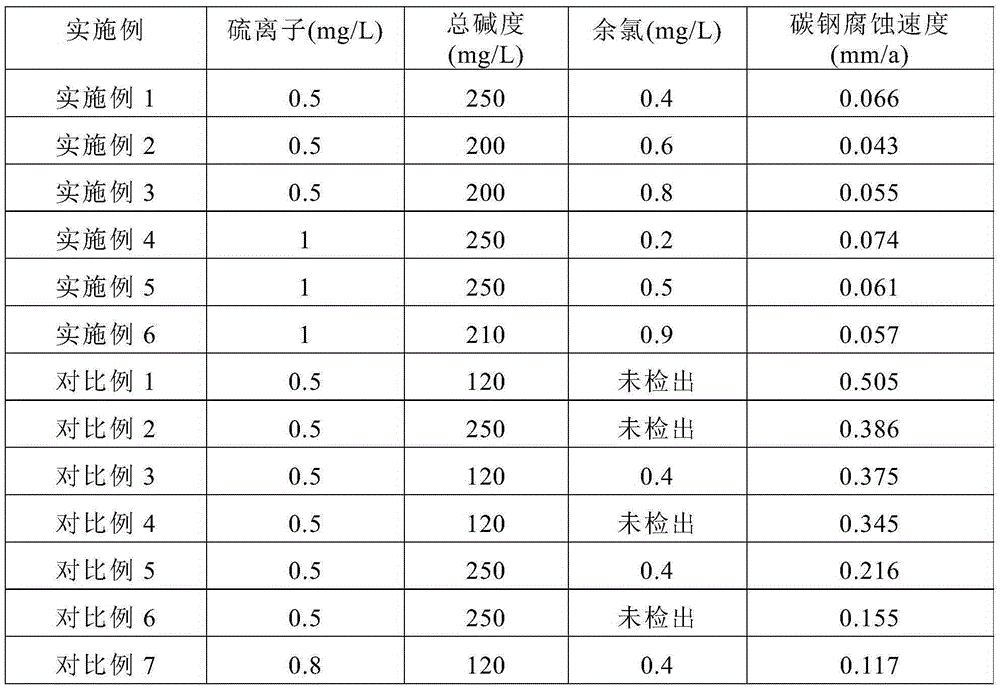

Attapulgite clay textile slashing size and process technology thereof

The present invention discloses an attapulgite clay textile sizing slurry and its production process. Its composition includes (by wt%) 40.0-56.0% of purified attapulgite clay, 23.0-26.0% of water-soluble polyacrylic acid, 18.0-23.0% of carbonyl diamide, 3.0-6.0% of sodium carboxymethyl cellulose, 0-1.5% of hydrolyzed polyacrylonitrile, 0-1.5% of emulsible oil, 0-2.0% of sodium carbonate and 0-0.0003% of polyethylene glycol oxide. Its production process includes the following steps: (1), ore dressing, pulverizing and purification; (2), mixing all the raw materials according to mixing ratio, kneading and pelleting; and (3), shearing, rolling so as to obtain the finished product material.

Owner:SUYUAN GROUP HUAIAN

Method of treatment of sulfur-containing circulating cooling water

InactiveCN106745838ASave money on pharmacyReduce energy consumptionNature of treatment waterTreatment using complexing/solubilising chemicalsResidual chlorineCarbon steel

The invention relates to the field of water treatment and discloses a method of treatment of sulfur-containing circulating cooling water. The method includes the steps of: adding a chlorine-containing oxidant and a compound corrosion inhibitor to the sulfur-containing circulating cooling water, and controlling the total alkalinity of the sulfur-containing circulating cooling water to be 170-300 mg / L, wherein the use amount of the chlorine-containing oxidant ensures that the residual chlorine in the sulfur-containing circulating cooling water is 0.2-1 mg / L. The compound corrosion inhibitor comprises water-soluble zinc salt and an organic-phosphorus corrosion inhibitor. By controlling the total alkalinity and the residual chlorine and adding the compound corrosion inhibitor in a special type, corrosion of the sulfur-containing circulating cooling water is effectively controlled, wherein corrosion rate of carbon steel satisfies the technical demand of being less than 0.1 mm / a and carbon test tube adhesion rate satisfies the technical demand of being less than 20 mg / (cm<2>*month). Although the compound corrosion inhibitor containing the water-soluble zinc salt is employed, the adhesion rate does not exceed the standard due to deposition of the zinc salt, so that complete replacement of the system due to leakage of sulfur containing substances is unnecessary, thereby reducing energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

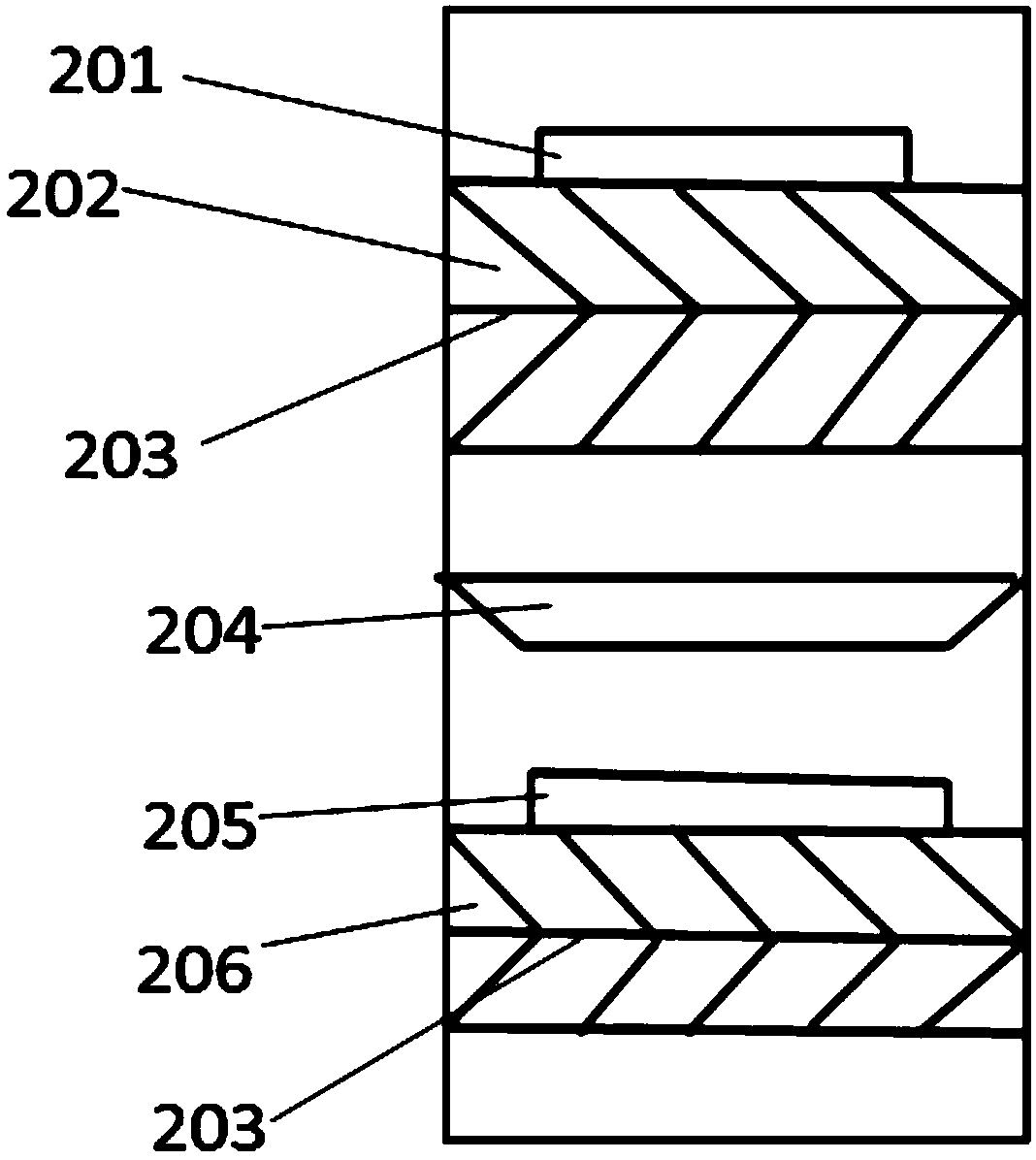

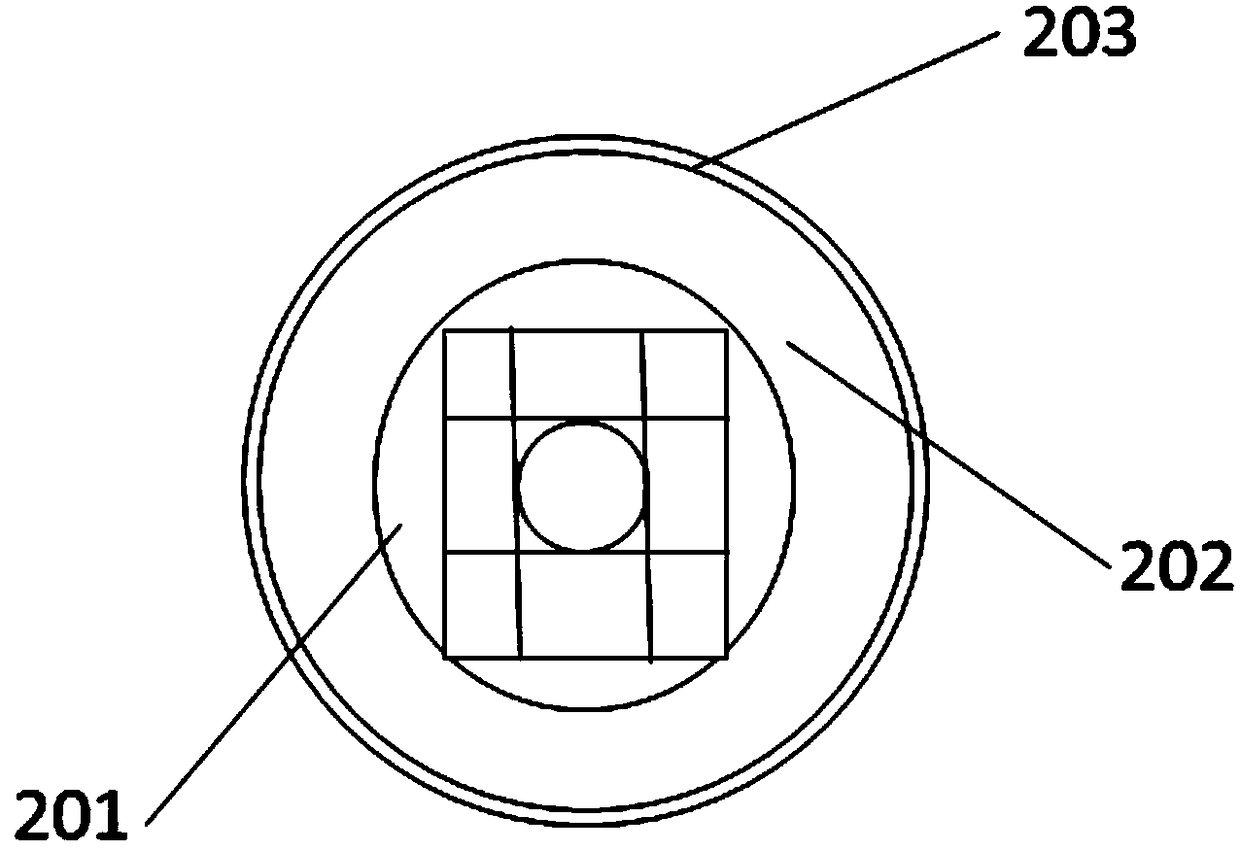

Deacidification-dust removal integrated device for flue gas based on dense phase dry tower

PendingCN113144771AEmission reductionReduce pollutionGas treatmentDispersed particle filtrationFlue gasDust control

The invention provides a deacidification-dust removal integrated device for flue gas based on a dense phase dry tower. The device comprises a dense phase dry tower deacidification device and a special deacidification dust remover, wherein the dense phase dry tower deacidification device comprises a flue gas inlet, a deacidification device body, ash hoppers of the deacidification device body, ash hopper feeders of the deacidification device body, an ash conveying device, a humidifier and a stirrer; the deacidification device body is divided into a gas inlet side and a gas outlet side by a partition plate, the lower ends of the gas inlet side and the gas outlet side communicate with each other, and the ash hoppers of the deacidification device body and the ash hopper feeders of the deacidification device body are arranged at the lower ends of the gas inlet side and the gas outlet side; the ash hopper feeders of the deacidification device body are connected with the ash conveying device; and the flue gas inlet is formed in the upper part of the gas inlet side, the top of the gas inlet side is also connected with a discharge hole of the humidifier, and the stirrer is arranged at the top of the gas inlet side. The deacidification-dust removal integrated device of the invention has the following beneficial effects: flow field distribution is more uniform and reasonable; land occupation and investment can be reduced; and deacidification efficiency is very high, and operation cost is remarkably reduced.

Owner:UNIV OF SCI & TECH BEIJING

Method for treating atrazine-containing pesticide wastewater

ActiveCN101734821BSolve processing problemsEnsure safetyMultistage water/sewage treatmentWater/sewage treatment by neutralisationSlagEvaporation

The invention relates to a method for treating atrazine-containing pesticide wastewater, which is characterized by comprising: pumping pesticide wastewater into a neutralization pool; adding inorganic acid to regulate pH between 7 and 8; allowing the obtained product to enter a coagulation-sedimentation pool; putting in coagulant for coagulation; allowing the obtained product to enter a sand filter; performing filtration; allowing the obtained product to enter a reduced-pressure evaporation system of a water-collecting pool; discharging condensate which is repeatedly evaporated and concentrated and then is subjected to activated carbon adsorption into a recycled-water storage pool; allowing reactor-bottom residual liquid of evaporated and concentrated under reduced pressure to enter a salting-out tank and cooling the reactor-bottom residual liquid to form salt; and periodically transporting salt slag to a solid waste treatment plant for final treatment. The method has the advantages of realizing the zero wastewater discharge of pesticide production processes, performing safe disposal on solid pollutants, ensuring environmental safety, effectively solving the problem that the wastewater produced during pesticide production is difficult to treat, saving a large amount of cost for pollution discharge, reducing environmental pollution and having high economic and environmental benefit.

Owner:PETROCHINA CO LTD

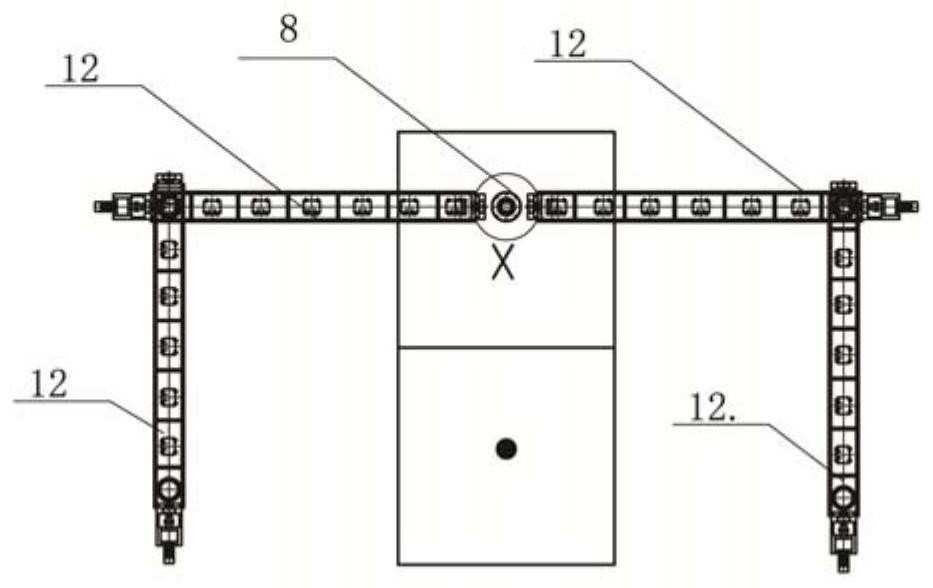

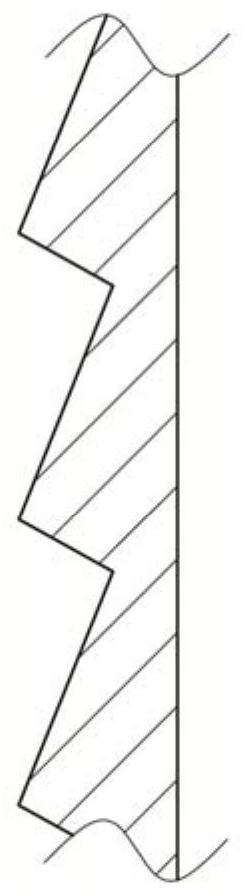

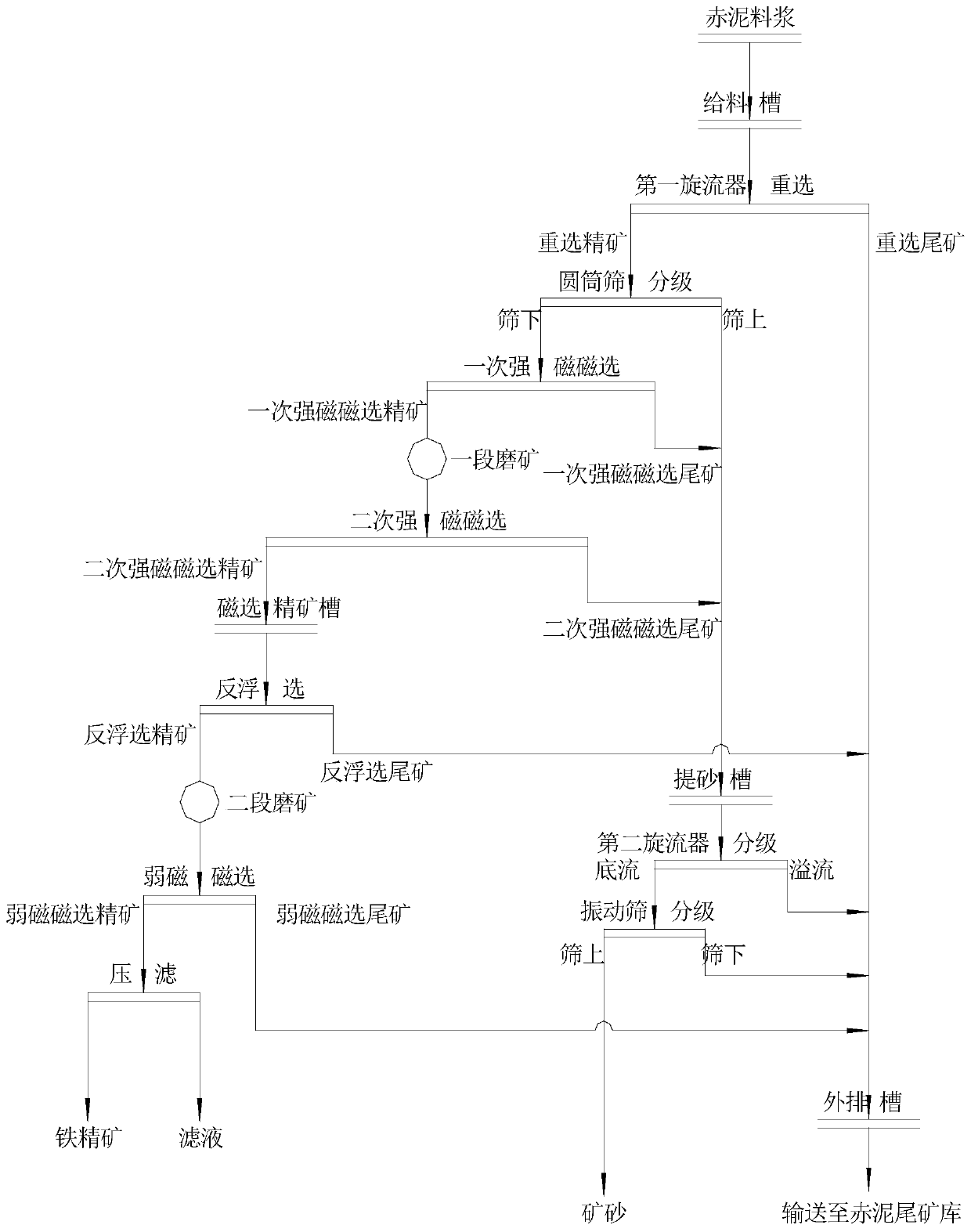

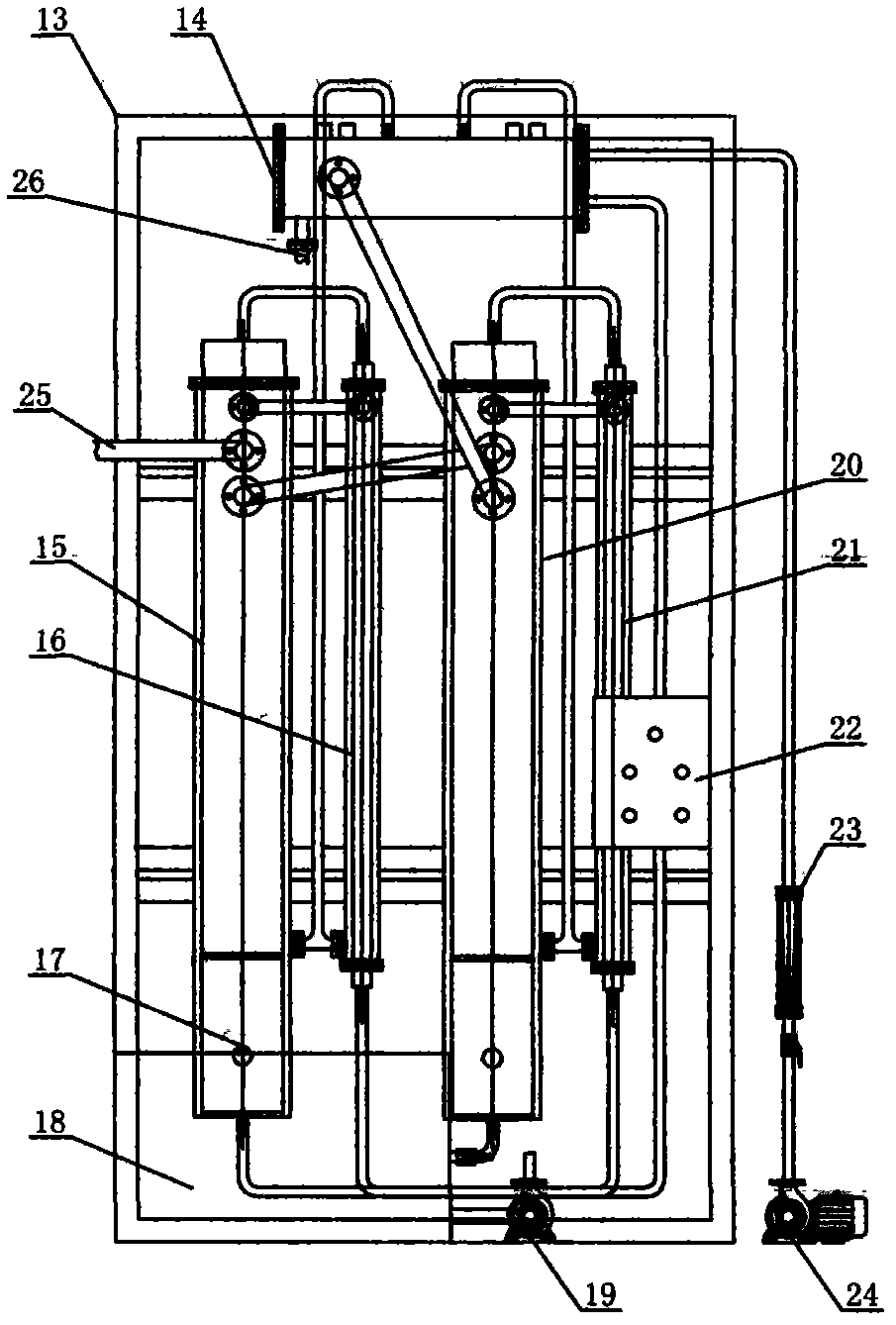

Process for recycling iron ore concentrate and ore sand from aluminum oxide red mud

PendingCN111589572ADecrease stockSave on sewage chargesMagnetic separationWet separationRed mudMining engineering

The invention discloses a process for recycling iron ore concentrate and ore sand from aluminum oxide red mud. The process comprises the following steps that red mud slurry obtained after water is added for premixing is subjected to gravity separation; gravity concentrate is graded, then primary strong magnetic separation is carried out, then primary ore grinding is carried out, and finally secondary strong magnetic separation is carried out; materials in a magnetic concentrate tank are subjected to reverse flotation and secondary ore grinding, then materials obtained after ore grinding are subjected to weak magnetic separation, concentrate obtained after the weak magnetic separation is subjected to filter pressing, and the iron ore concentrate and filtrate are obtained; materials in a sand extraction tank are subjected to grading treatment to obtain an ore sand product; and materials in a discharging tank are conveyed to a red mud tailing pond for stockpiling. The process has the beneficial effects that the available iron ore concentrate and ore sand in the red mud can be extracted through the process of combining hydrocyclone gravity separation, strong magnetic separation, reverse flotation, weak magnetic separation, hydrocyclone grading and vibrating screen grading, waste is turned into wealth, and the stockpiling time of the red mud tailing pond can be prolonged.

Owner:金建工程设计有限公司

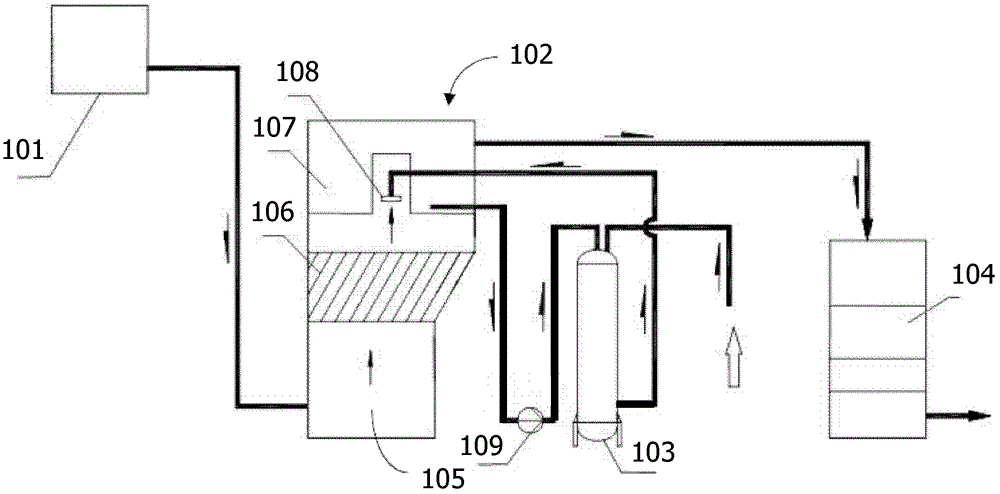

Industrial wastewater recycling processing system

ActiveCN101948205AMeet zero emission requirementsReduce dosageWaste water treatment from metallurgical processWater/sewage treatment bu osmosis/dialysisEvaporationWater quality

The invention relates to an industrial wastewater recycling processing system which comprises a filtering device, a membrane concentrating device and an evaporating device, wherein the filtering device comprises an ultrafiltration water supply pump, a bag filter and a security filter, and the membrane concentrating device comprises an ultrafiltration membrane assembly, a reverse-osmosis water supply pump, a precise filter, a primary high-pressure pump, a secondary high-pressure pump, a reverse-osmosis membrane assembly and a cleaning pump; and the evaporating device comprises a condenser, a single-effect evaporator, a two-effect evaporator, a water tank, a concentrated solution pump and an evaporation water supply pump. The invention thoroughly changes the processing method of electroplating wastewater and has the advantages of good water quality of membrane outlet water, small occupied area of equipment, no need of attendance in operation and convenient use; and the invention does not use a chemical agent, conforms to the requirements of environment-friendly and clean electroplating, can be used for recycling useful metal while processing electroplated rinsing wastewater, and not only can create more economic benefit, but also can bring social benefit and environmental benefit, reduce the pollution, save the resources, protect the environment and benefit the mankind.

Owner:ZHUHAI LANJIN ENVIRONMENTAL PROTECTION TECHCO

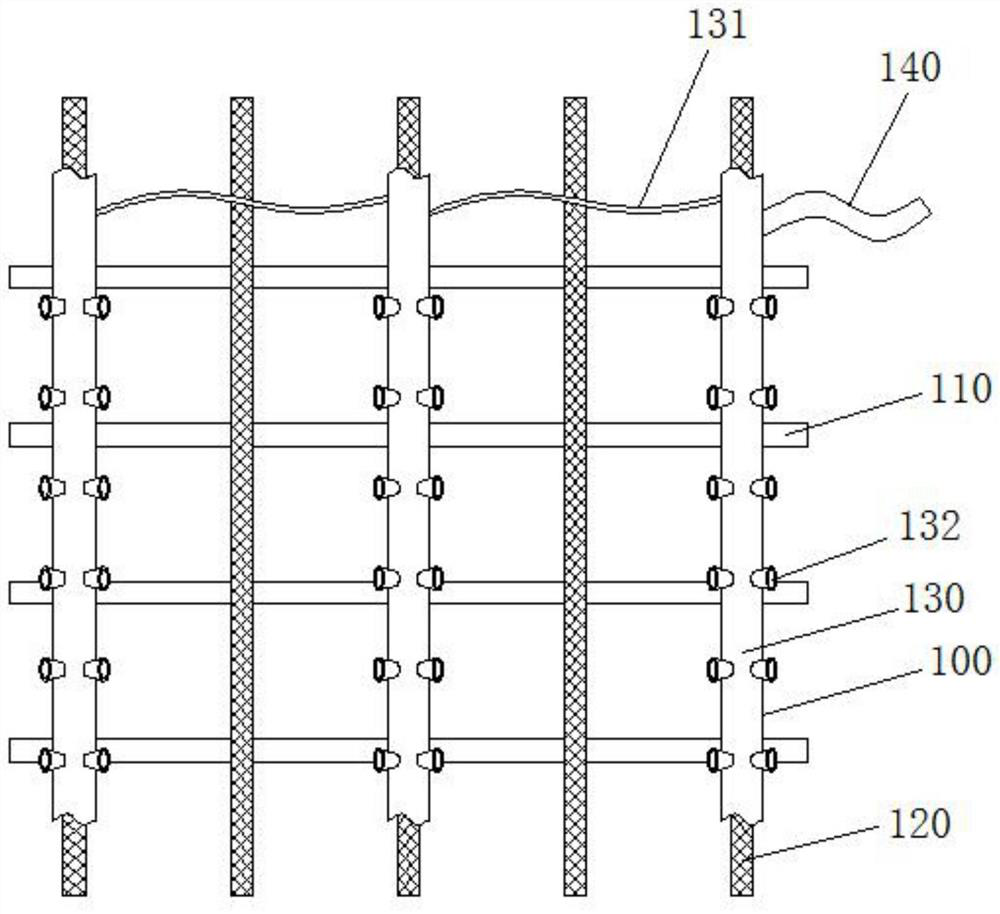

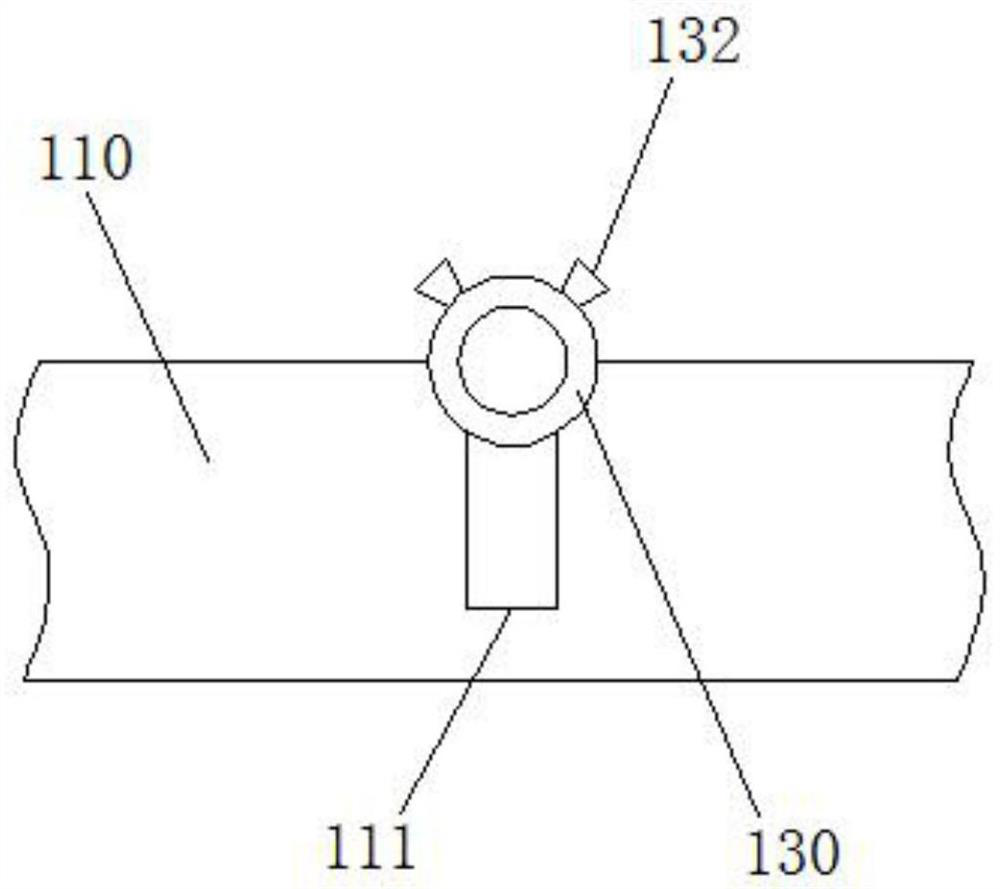

Mine treatment system and treatment method

InactiveCN113463611AIncrease vegetation areaReduce pollutionHops/wine cultivationWatering devicesNatural ecosystemEnvironmental resource management

The invention discloses a mine treatment system and treatment method. The mine treatment system comprises an anti-soil-skid device, the anti-soil-skid device comprises a transverse plate, a vertical plate, a water spraying pipe and a water pipe, a clamping groove is formed in the top of the transverse plate, the transverse plate and the vertical plate are distributed in a crossed mode, the water spraying pipe is embedded in the top of the clamping groove, and spraying heads are inserted into the left side and the right side of the top of the water spraying pipe correspondingly. After the mining area ecological restoration and treatment project is comprehensively implemented, the vegetation area of the mining area is greatly increased, dust can be effectively absorbed, air is purified, the environment air quality is improved, wind prevention and sand fixation can be achieved, water and soil loss is reduced, soil moisture evaporation is reduced, the land utilization condition is improved, pollution of the mining area is reduced through the mining area ecological restoration and treatment project, the ecological environment of the mining area and the surrounding area is improved and restored, harmony and coordination of a natural ecological system of the whole mining area are promoted, the ecological environment of the mining area forms a virtuous circle, and a good living environment is created for the mining area and the surrounding people.

Owner:内蒙古中盛立德环境工程有限公司

Multifunctional water quality stabilizer

PendingCN111977816AEasy to handleReduce water intakeScale removal and water softeningO-Phosphoric AcidMeth-

The invention belongs to the technical field of water quality stability, and particularly relates to a multifunctional water quality stabilizer formula and a production process flow. The production process flow of the multifunctional water quality stabilizer formula comprises the steps of firstly, dissolving and uniformly stirring desalted water, phosphoric acid and inositol hexaphosphate at 40-60DEG C to obtain a mixed solution; then sequentially adding 1-hydroxyethylidene-1,1-diphosphonic acid, 2-phosphonobutane-1,2,4-tricarboxylic acid, acrylic acid-2-methyl-2-acrylamidopropanesulfonic acid copolymer, phosphonohydroxyacetic acid and sulfonic acid into the mixed solution, performing stirring for 90 minutes or more, performing mixing, finally standing for 60 minutes, filtering and sub-packaging the solution to obtain the multifunctional water quality stabilizer. According to the multifunctional water quality stabilizer disclosed by the invention, the operation can be improved by multiple times on the basis of the original concentration multiple without generating a scaling phenomenon, the water intake and the water discharge of a whole plant can be reduced to a greater extent, the environmental protection pressure faced by external water discharge is greatly reduced, and a big problem is solved for enterprises with insufficient water sources or expensive water prices and poorer supplementary water quality.

Owner:重庆采阳科技有限公司

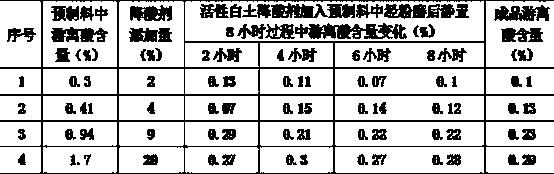

Preparation method of activated clay

InactiveCN109954485ASimple production processShort processOther chemical processesCombustible gas purificationElectricityClay minerals

The invention relates to the technical field of activated clay, and particularly relates to a preparation method of activated clay. The preparation method comprises the following steps: firstly, carrying out beneficiation, activation, pressure filtration and drying on clay minerals to prepare a prefabricated material with an free acid content of 0.30-2.5%, then adding the activated clay acidity-reducing agent into the prefabricated material, carrying out grinding, and then carrying out standing for 8 hours to obtain a finished product, wherein the content of free acid in the prefabricated material is 0.30-2.5%, and 1-20 parts of the activated clay acidity-reducing agent is added into every 100 parts of the prefabricated material. The method disclosed by the invention can be used for preparing an activated clay finished product meeting the national standard or specified standards of consumers, a conventional wet process production process flow is simplified, production water consumptionand electricity consumption are greatly reduced, acid water treatment and emission load are reduced, and production cost of enterprises is reduced.

Owner:金昌红泉膨润土有限责任公司

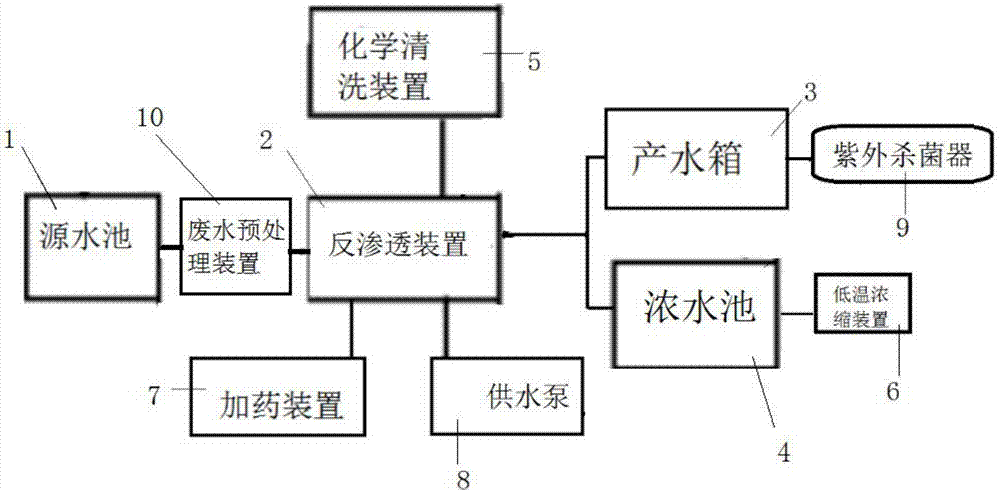

Electroplating wastewater treatment recycling system

PendingCN107879498AAchieve reuseGuaranteed uptimeWater/sewage treatment by irradiationSpecific water treatment objectivesWater treatment systemSewage

The invention belongs to the field of wastewater recycling and in particular discloses an electroplating wastewater treatment recycling system. The reverse osmosis wastewater treatment system comprises a source water tank and a reverse osmosis device connected behind the source water tank, wherein a wastewater pretreatment device is arranged between the source water tank and the reverse osmosis device; a water production tank and a concentrated water tank are respectively connected behind the reverse osmosis device; an explosion-proof membrane is arranged on the outer surface of the reverse osmosis device; a water outlet and a water inlet are formed in two ends of the reverse osmosis device; check valves are arranged at the water outlet and the water inlet; and a low-temperature vacuum concentration device is connected to the rear of the concentrated water tank. Circuit board wastewater is economically and effectively treated and recycled and strictly classified, collected and treated,and the recycled clean wastewater is independently recycled, so that the key point whether the wastewater recycling system can be stably operated is ensured. Pollution discharge fees of the wastewater are greatly reduced, and the wastewater recycling system has excellent market prospects and economic value.

Owner:SHENZHEN HEADWATER ENVIRONMENTAL TECH CO LTD

Low-cost maintenance-free electrochemical treatment technology device system for circulating water scale

InactiveCN110156180AHigh input-output ratioLow input costScale removal and water softeningWater/sewage treatment apparatusEngineeringTherapeutic effect

The invention discloses a low-cost maintenance-free electrochemical treatment technology device system for circulating water scale. The system comprises a circulating water tank; and the interior of the circulating water tank is provided with scale absorbing electrodes, a water level in the circulating water tank submerges the scale-absorbing electrodes, each scale-absorbing electrode is connectedwith one corresponding controller through one corresponding scale absorbing conductor, and the controllers are connected with an input power line. According to the system provided by the invention, an improved application method that the scale-absorbing electrodes are directly put into the water tank is adopted, so that the input costs are less, and full-automatic cleaning of the water scale adsorbed on the electrodes is fully realized, and maintenance-free operation in the operation process is realized; and workers do not need to extract the electrodes frequently, so that the electrodes canbe put in optimal treatment positions in the water tank, and better treatment effects can be realized.

Owner:SHANGHAI BIANJIE ENVIRONMENTAL PROTECTION TECH CO LTD

Wastewater Comprehensive Reuse System for Heating Boilers

ActiveCN102951743BProvide clean and efficientSave on sewage chargesMultistage water/sewage treatmentWater/sewage treatment by neutralisationWastewaterEngineering

The invention provides a comprehensive reutilization system of heating boiler wastewater. The system comprises a wastewater collection tank; a precipitate filtering unit receiving the wastewater from the wastewater collection tank and carrying out precipitate filtering treatment of the wastewater, wherein the precipitate filtering unit comprises a precipitating pool positioned at the bottom of the precipitate filtering unit, an automatic alkali addition device positioned on the precipitate pool, a mixing pool positioned above the automatic alkali addition device and used for mixing alkali added wastewater with a medicine, and a water purifying pool positioned above the mixing pool; an automatic medicine device which is connected with the mixing pool and inputs the medicine to the mixing pool; and a concentrating pool for pumping clean water from a clean water pool. The comprehensive reutilization system has the advantages of wastewater recycle efficiency improvement and cost saving.

Owner:上海漕泾热电有限责任公司

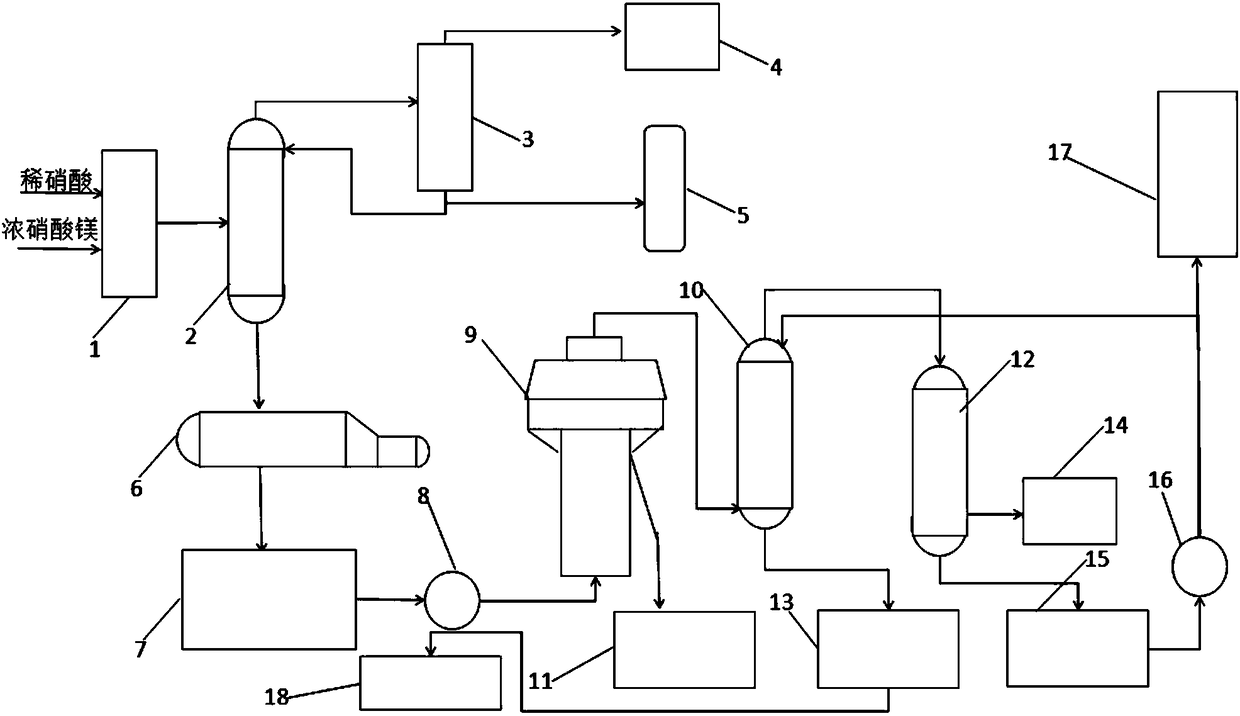

Production equipment for producing concentrated nitric acid through magnesium nitrate method

ActiveCN108557786AReduce nitrateEasy to separateDistillation regulation/controlFractional distillationWastewaterTower

The embodiment of the invention discloses production equipment for producing concentrated nitric acid through a magnesium nitrate method. By the improvement of a concentration tower, the wall flowingand vertical liquid dropping of a magnesium nitrate solution can be effectively avoided, the content of dilute magnesium nitrate can be greatly reduced, and therefore the concentration of tail water of magnesium formed by the condensation of acid vapour steamed by a magnesium nitrate steamer is 0.1% or less. By adding an acid separator, thorough gas liquid exchange between the magnesium tail waterand the acid vapour can be conducted in the acid separator to effectively reduce the concentration of the tail water of a tower. The magnesium tail water is used as production water and delivered toa circulation water tank to act as production supplying water. By the above improvement, the comprehensive utilization of the tail water of the tower and acid waste water of the magnesium tail water can be achieved, and zero emission of the acid waste water is achieved.

Owner:宁夏润夏能源化工有限公司

Technological method of extracting aluminium silicon alloy from fly ash

InactiveCN100334243CSolve processing problemsSolve pollutionProcess efficiency improvementSilicon alloyIngot

A process for extracting AlSi alloy from powdered coal ash includes such steps as proportionally mix powdered coal ash with reducing agent, coke powder, bitumite, bauxite and adhesive, stirring, rolling to become pellets, curing while drying, smelting in ore roaster at 1600-2200 deg.C for 4 hr, discharging, refining at 1400-1800 deg.C while adding refining agent, vacuum filtering, and casting. The content of Al and Si in finished ingot is more than 70%.

Owner:严瑞山

Electroplating reclaimed water recycling and treating system

ActiveCN101838071BSave on sewage chargesSave on electricity billsWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentEnvironmental resistanceUltrafiltration

The invention relates to an electroplating reclaimed water recycling and treating system, comprising a control device, a preposed adjusting system, an ultrafiltering treating system and a reverse osmosis treating system, wherein the preposed adjusting system, the ultrafiltering treating system and the reverse osmosis treating system are mutually communicated, the preposed adjusting system comprises an ORP (Oxidation-Reduction Potential) adjusting system and a PH adjusting device; the ORP adjusting system comprises an ORP adjusting tank, a reducing agent metering pump, a reducing agent tank and a stirrer; the ulatrafiltering system comprises a water pump, a quartz sand filter, a precise filter and an ultrafiltering membrane assembly; and the reverse osmosis system comprises a water pump, an active carbon filter, a scale inhibitor adding device, a safety filter, a first section of high-pressure pump, a second section of high-pressure pump, a reverse osmosis membrane assembly and a water purified tank. By adopting a device combining membrane separation and the filter to treat the electroplating reclaimed water, the invention has the advantages of favorable treatment effect, low operation cost, convenient operation and capability of long-term continuous operation; and in addition, the invention meets the requirements of environmental protection and cleaning electroplating, not only reduces the pollution and saves the production cost, but also can fully utilize water resources and protect the environment.

Owner:ZHUHAI LANJIN ENVIRONMENTAL PROTECTION TECHCO

Fresh cassava soaking and washing method

InactiveCN104522849AReduce productionEmission reductionClimate change adaptationFood treatmentPollutantEngineering

The present invention discloses a fresh cassava soaking and washing method which abandons the traditional cassava leaching process and sends a dry-method mud-removed and peeled cassava into a cassava washing tank to conduct four-stage soaking and washing. The dry-method mud removing and peeling process before soaking and washing can reduce the load in the subsequent steps of soaking and washing, etc., and save cleaning water. Cassava washing water is recycled and reused after the precipitation treatment and the water consumption is also reduced. The innovative structure design of the cassava washing tank can reduce production water and the waste water discharged volume. The purpose of terminal emission reduction is realized by the measures, the waste water discharged volume per ton of cassava starch is reduced to about 9.6-10 m<3> with a decrease by about 50%, and the entire production system has a high degree of automation, uses less labor and is easy to operate. By means of strengthening the control from the source, reducing the process emission, recycling and other means, the fresh cassava soaking and washing method improves the utilization of water resources, reduces the amount of pollutants to the maximum, and ultimately realizes balance between economic growth and environment-friendliness.

Owner:广西南宁市武鸣安宁淀粉有限责任公司 +1

Phosphorus-free, fluorine-free and heavy metal-free phosphorus displacing agent and preparation method thereof

ActiveCN102409329BAvoid harmSave on sewage chargesMetallic material coating processesEcological environmentWastewater

The invention discloses a phosphorus-free, fluorine-free and heavy metal-free phosphorus displacing agent and a preparation method thereof. The phosphorus displacing agent is prepared from the following raw materials in percentage by weight: 1-28% of salt, 1- 15% of acid, 1-15% of alkali, 0.1-5% of additive, 0.1-9% of screening agent and the balance of tap water. The preparation method comprises the following steps of: a, preparing the materials; b, preparing the screening agent; c, preparing the additive; d, adding the balance of tap water into a plastic reaction kettle, heating and cooling the mixed solution, adding the acid and adding the alkali to regulate a pH value to 4 to 6; e, adding the additive; and f, adding the screening agent, and filtering the mixture to obtain a filtrate product. By the phosphorus-free, fluorine-free and heavy metal-free phosphorus displacing agent and the preparation method thereof, the phosphorus-free, fluorine-free and heavy metal-free raw materials are adopted, waste water produced in production and using processes does not contain pollutants such as phosphorus, fluorine, heavy metals and the like, is not required to be purified and can be directly discharged, and hazardous solid wastes are avoided, so pollution to the environment and damages to human bodies are avoided, pollution discharge cost is greatly saved and the protection of an ecological environment is facilitated; and when the phosphorus displacing agent is used, a film formed on the surface of the product is uniform, compact, continuous, highly adhesive and highly anticorrosive, and the phosphorus displacing agent can completely replace a bonderite.

Owner:金华市弗鲁克特科技有限公司

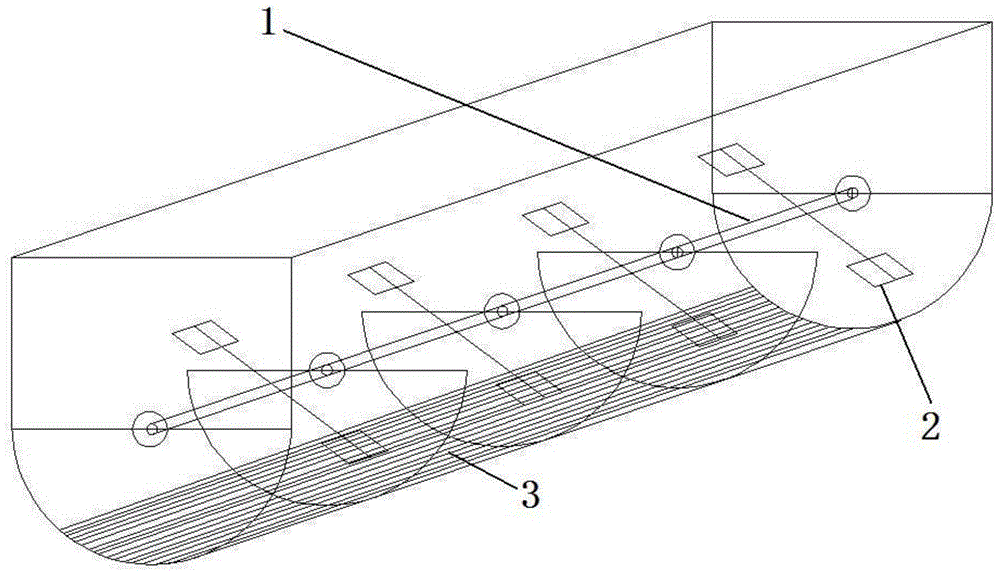

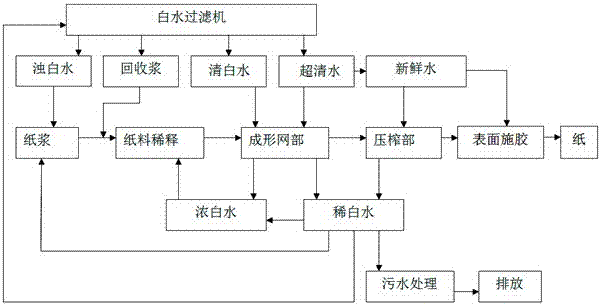

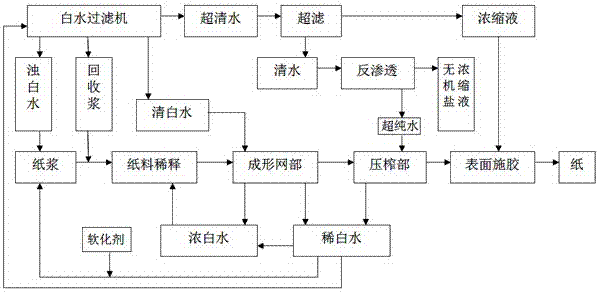

A method for reducing waste water in papermaking clean production

ActiveCN105198116BReduce generationReduce hardnessCellulosic pulp after-treatmentMultistage water/sewage treatmentWater softeningStarch gelatinization

The invention discloses a method for reducing the generation of waste water in the clean production of papermaking. Part of the dilute white water produced in the process enters the paper stock dilution process for repeated use with concentrated white water, and part of it enters a white water filter for filtering treatment, and the remaining dilute white water is After adding softener, it is input into paper pulp for use; after dilute white water is processed by white water filter, the ultra-clear water produced enters the ultrafiltration process; the concentrated liquid produced by the ultra-filtration process is used for starch gelatinization in the surface sizing process, and the produced clear water enters directly Reverse osmosis process: The ultrapure water produced by the reverse osmosis process is used in the press section process, and at the same time, a trace amount of inorganic salt concentrate is generated as waste water for treatment. The method for reducing waste water in papermaking clean production of the present invention, by realizing water softening and purification in papermaking production process, eliminates Ca 2+ , Mg 2+ , The system accumulation of DCS realizes the clean production of papermaking and the micro treatment and discharge of papermaking wastewater.

Owner:江苏宁沭纸业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com