Method for treating wastewater from furfural production

A technology for producing wastewater and treatment methods, which is applied in water/sewage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc., and can solve the problems of large investment in wastewater treatment facilities, difficulty in meeting sewage standards, and high operating costs. Achieve the effect of small footprint, easy operation and saving of sewage charges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

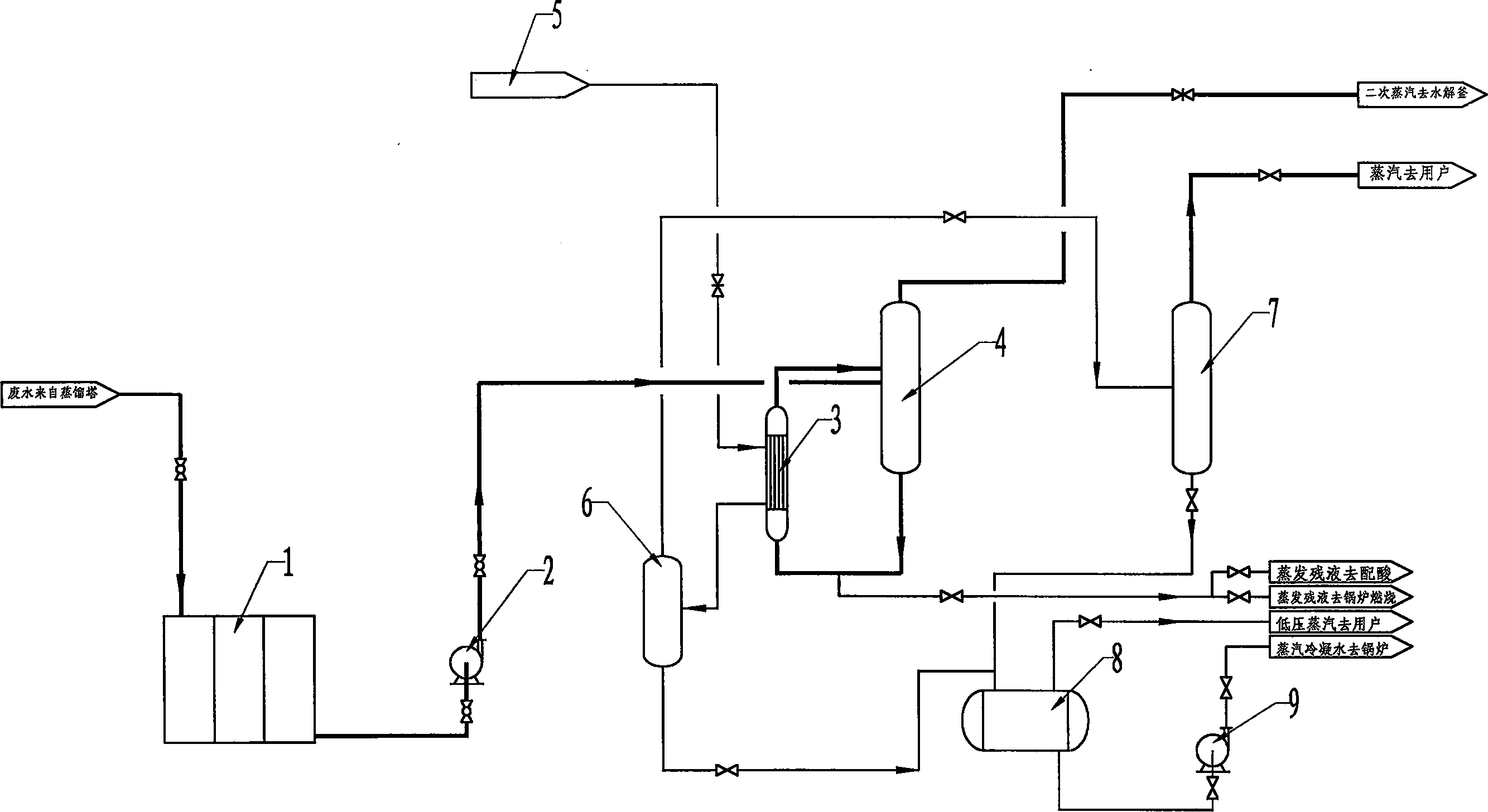

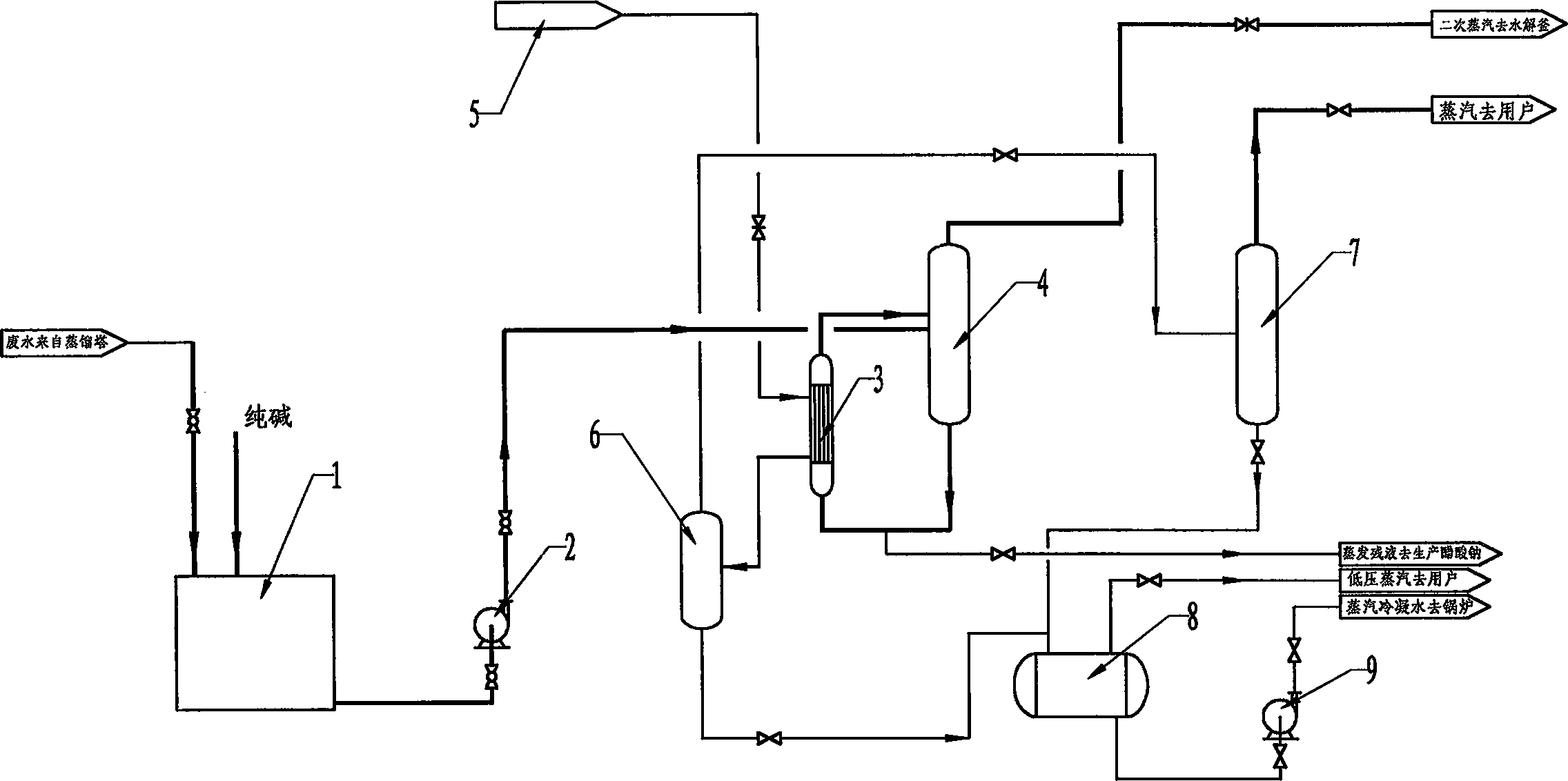

Method used

Image

Examples

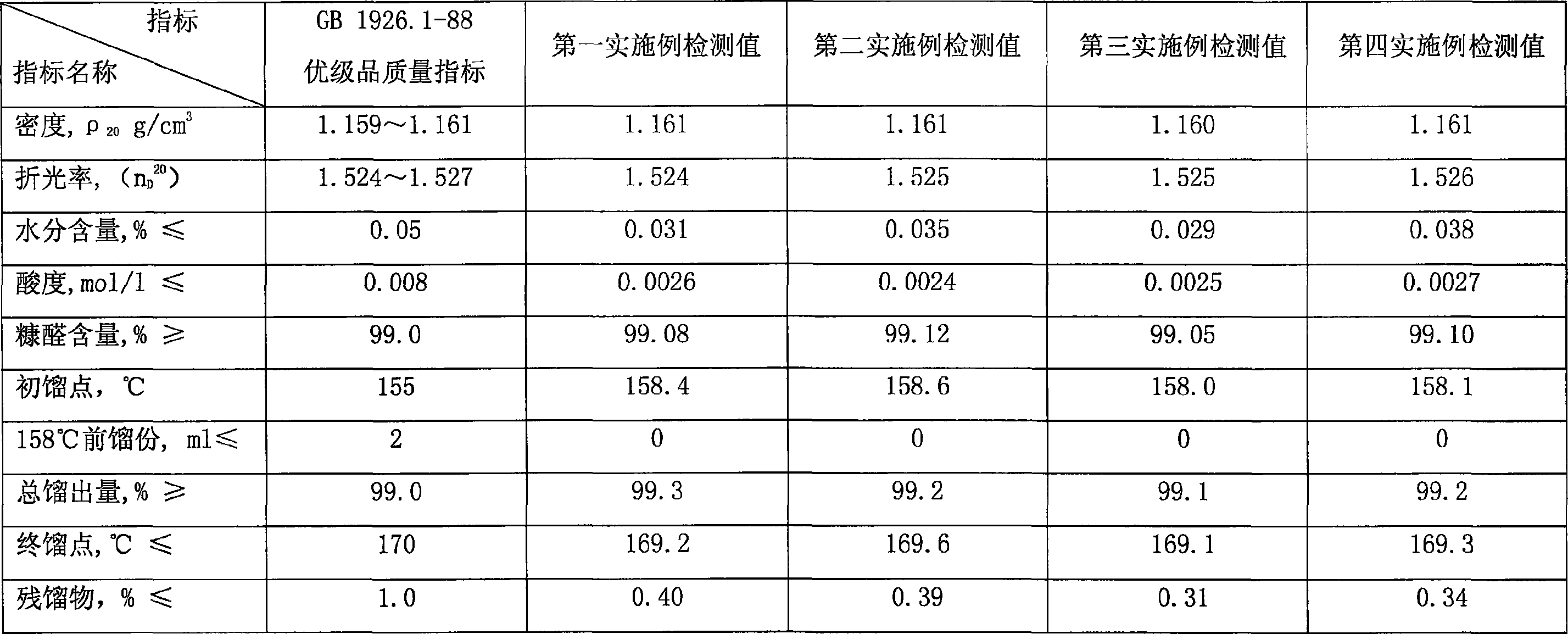

Embodiment 1

[0044] The raw material is corncobs air-dried in spring, and its water content is 23%. After the corncob is dedusted by a vibrating screen, it is crushed into 1-1.5cm corncob particles by a hammer mill, and then transported by the elevator to the acid mixing truck for acid mixing. The acid concentration is 5-10%, and the amount of acid used is kept at With a specific solid-to-liquid ratio, it is sent to the hydrolysis kettle through a belt conveyor. The volume of the hydrolysis kettle is 10 cubic meters. It is operated in series with two kettles. The temperature is 145-180°C, and the hydrolysis takes 2 hours to 4 hours. The furfural stock solution obtained by hydrolysis is introduced into the subsequent process, and the gross aldehyde is extracted, and the furfural is continuously refined to obtain commercial furfural. The wastewater at the bottom of the furfural tower goes to the sewage station for treatment through the wastewater pipeline, and the treatment method adopts th...

Embodiment 2

[0046] The raw material is corncobs air-dried in spring, and its water content is 23%. After the corncob is dedusted by a vibrating screen, it is crushed into 1-1.5cm corncob particles by a hammer mill, and then transported by the elevator to the acid mixing truck for acid mixing. The acid concentration is 5-10%, and the amount of acid used is kept at With a specific solid-to-liquid ratio, it is sent to the hydrolysis kettle through a belt conveyor. The volume of the hydrolysis kettle is 10 cubic meters. It is operated in series with two kettles. Secondary steam, the hydrolysis temperature is 145-180°C, and the hydrolysis takes 1 hour, 45 minutes to 3.5 hours. The furfural stock solution obtained by hydrolysis is introduced into the subsequent process, and the gross aldehyde is extracted, and the furfural is continuously refined to obtain commercial furfural. Wastewater treatment adopts the method of the present invention. The material of the evaporation system equipment is 1...

Embodiment 3

[0048] The raw material is corncobs air-dried in spring, and its water content is 23%. After the corncob is dedusted by a vibrating screen, it is crushed into 1-1.5cm corncob particles by a hammer mill, and then transported by the elevator to the acid mixing truck for acid mixing. The acid concentration is 5-10%, and the amount of acid used is kept at With a specific solid-to-liquid ratio, it is sent to the hydrolysis kettle through a belt conveyor. The volume of the hydrolysis kettle is 10 cubic meters. It is operated in series with two kettles. Secondary steam, the hydrolysis temperature is 145-180°C, and the hydrolysis takes 1 hour, 45 minutes to 3.5 hours. The furfural stock solution obtained by hydrolysis is introduced into the subsequent process, and the gross aldehyde is extracted, and the furfural is continuously refined to obtain commercial furfural. Wastewater treatment adopts the method of the present invention, the material of the evaporation system equipment is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com