Low-cost maintenance-free electrochemical treatment technology device system for circulating water scale

A maintenance-free, low-cost technology, applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc., can solve the problems of highly targeted chemicals, complex equipment structure, and the need for regular cleaning , to achieve the effect of reducing operation and maintenance costs, good treatment effect, and reducing the number of times to replace circulating water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

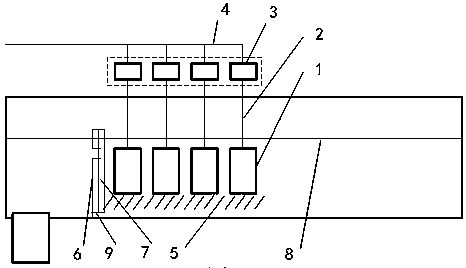

[0042] Such as figure 1 As shown, the low-cost maintenance-free circulating water electrochemical fouling treatment technology device system provided for this valve includes a circulating water tank 8, which is equipped with several scale suction electrodes 1, and the circulating water interface in the circulating water tank 8 is not over-absorbed. The scale electrode 1, the scale suction electrode 1 is connected with the controller 3 through the scale suction wire 2, and the controller 3 is connected with the input power line 4.

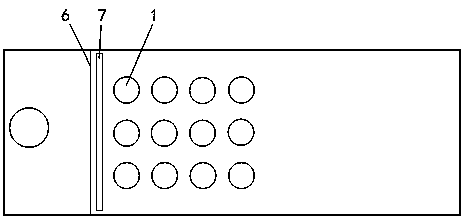

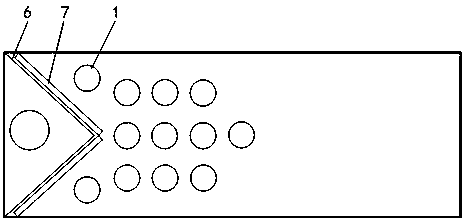

[0043] Such as figure 2 and image 3 As shown, the placement position of the scale suction electrode 1 is arranged around the outlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com