Organic/inorganic nanometer function particle modified organosilicon fabric coating agent preparation method

A technology of inorganic nanometer and functional particles, which is applied in plant fibers, textiles, papermaking, fiber treatment, etc. It can solve the problems of poor washing resistance, low adhesion of fabrics, poor moisture permeability and air permeability, etc., and achieve simple and convenient operation process and application The effect of broad prospects and high input-output ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

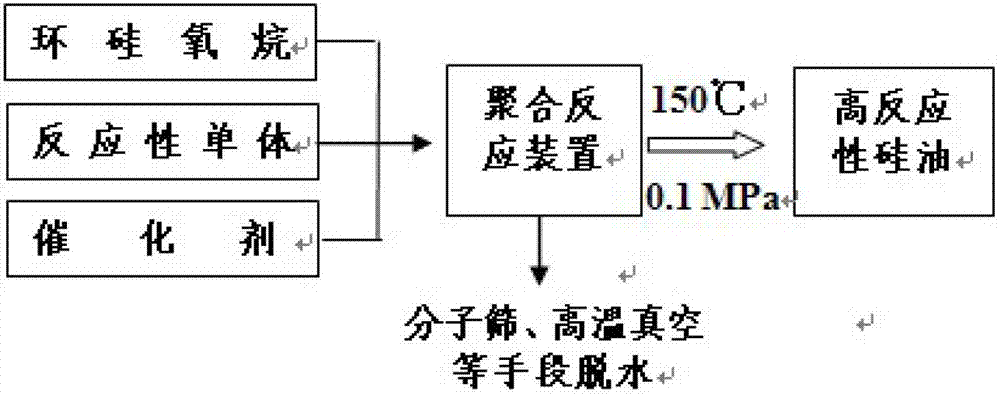

[0037] Add 200 g of dimethylcyclosiloxane mixture, 120 g of tetramethyltetravinylcyclotetrasiloxane and 0.9 g of potassium hydroxide successively into the reaction kettle equipped with stirrer, thermometer and condenser tube, under nitrogen protection Raise the temperature to 150 o C. After constant temperature reaction for 3 h, after depressurized distillation to remove small molecular water, a transparent oily high-reactivity silicone oil was obtained.

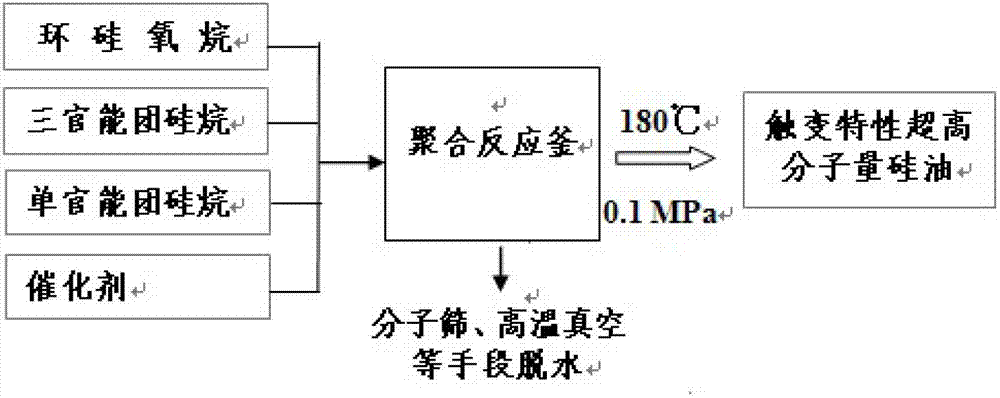

[0038] Add 200 g of dimethylcyclosiloxane mixture, 8 g of allyltrimethoxysilane, 0.5 g of trimethylethoxysilane and 0.8 g of hydrogen into a reaction kettle equipped with a stirrer, a thermometer, and a condenser Potassium oxide, under the protection of nitrogen, the temperature was raised to 180 o C. After constant temperature reaction for 4 hours, after decompression distillation to remove small molecular water, a transparent oily thixotropic ultra-high molecular weight silicone oil was obtained, with a molecu...

Embodiment 2

[0043] Same as Example 1, but the amount of highly reactive silicone oil in step (4) is changed from 100 g to 120 g, the amount of thixotropic ultra-high molecular weight silicone oil is changed from 100 g to 80 g, and the others remain unchanged.

Embodiment 3

[0045] Same as Example 1, but the amount of highly reactive silicone oil in step (4) is changed from 100 g to 80 g, the amount of thixotropic ultra-high molecular weight silicone oil is changed from 100 g to 120 g, and the others remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com