Inflaming-retarding fabric and preparation method thereof

A flame retardant, fabric technology, applied in the direction of textile, yarn, fabric, etc., can solve the problem that the flame retardant effect of flame retardant textile fabric can not meet the requirements of use, poor softness, etc., to enhance strength and toughness, improve flame retardancy, The effect of good comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

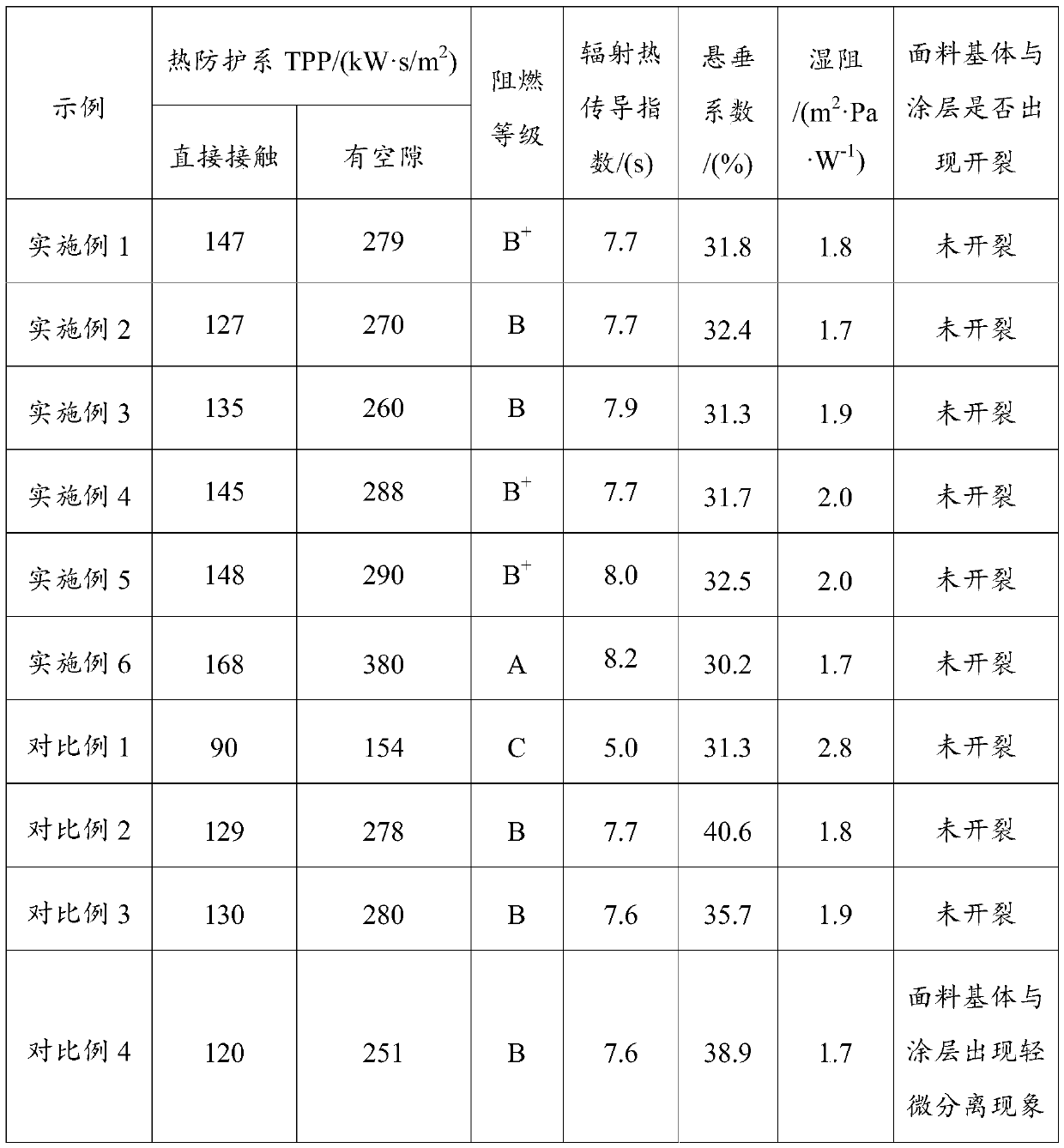

Examples

Embodiment 1

[0046] This embodiment provides a flame-retardant fabric and a preparation method thereof. The flame-retardant fabric includes a fabric substrate and a flame-retardant coating coated on the surface of the fabric substrate;

[0047] Fabric matrix includes warp and weft; warp raw materials include 1kg polyacrylonitrile fiber, 4kg modal fiber and 5kg chitin fiber; weft raw material includes 2kg stainless steel fiber, 4kg polybendazole fiber and 4kg polylactic acid fiber;

[0048]The raw materials of flame retardant coating include 10kg polybutadiene epoxy resin, 5kg polyparaphenylene terephthalamide, 4kg polymethacrylate, 5kg modified polysiloxane X-200, 4kg γ-aminopropyl Triethoxysilane, 6kg 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, 3kg polyether (ethylene oxide / propylene oxide block copolymer) and 4kg Wood fiber powder.

[0049] The preparation method of the above-mentioned flame-retardant fabric includes,

[0050] Install the warp and weft in the weaving machine re...

Embodiment 2

[0056] This embodiment provides a flame-retardant fabric and a preparation method thereof. The flame-retardant fabric includes a fabric substrate and a flame-retardant coating coated on the surface of the fabric substrate;

[0057] Fabric matrix includes warp and weft; warp raw materials include 1kg polyacrylonitrile fiber, 3kg modal fiber and 6kg chitin fiber; weft raw material includes 1.5kg stainless steel fiber, 4.5kg polybendazole fiber and 4kg polylactic acid fiber;

[0058] The raw materials of flame retardant coating include 20kg polybutadiene epoxy resin, 15kg polyparaphenylene terephthalamide, 10kg polymethacrylate, 15kg modified polysiloxane X-200, 10kg γ-aminopropyl Triethoxysilane, 10kg 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, 9kg polyether (ethylene oxide / propylene oxide block copolymer) and 10kg Wood fiber powder.

[0059] The preparation method of the above-mentioned flame-retardant fabric includes,

[0060] Install the warp and weft in the weaving...

Embodiment 3

[0066] This embodiment provides a flame-retardant fabric and a preparation method thereof. The flame-retardant fabric includes a fabric substrate and a flame-retardant coating coated on the surface of the fabric substrate;

[0067] Fabric matrix includes warp and weft; warp raw materials include 1kg polyacrylonitrile fiber, 4kg modal fiber and 5kg chitin fiber; weft raw material includes 2kg stainless steel fiber, 4kg polybendazole fiber and 4kg polylactic acid fiber;

[0068] The raw materials of the flame retardant coating include 12kg polybutadiene epoxy resin, 6kg polyparaphenylene terephthalamide, 5kg polymethacrylate, 7kg modified polysiloxane X-200, 6kg γ-aminopropyl Triethoxysilane, 7kg 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, 4kg polyether (ethylene oxide / propylene oxide block copolymer) and 5kg Wood fiber powder.

[0069] The preparation method of the above-mentioned flame-retardant fabric includes,

[0070] Install the warp and weft in the weaving machi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com