Patents

Literature

69results about How to "Simple and reliable mechanical structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

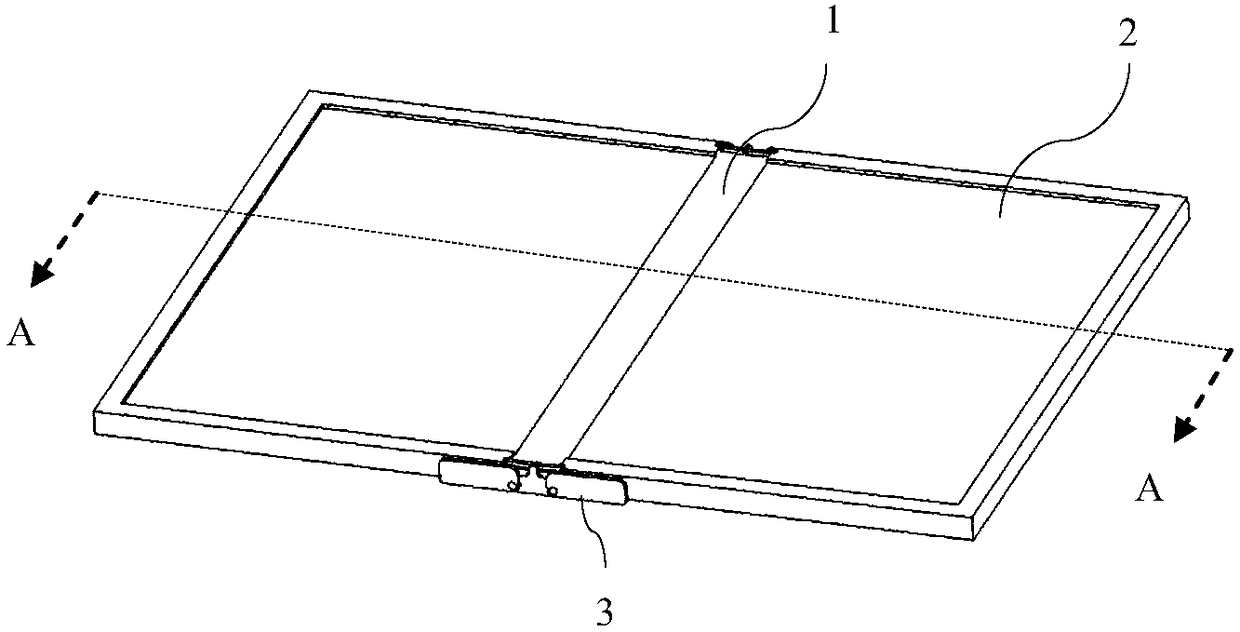

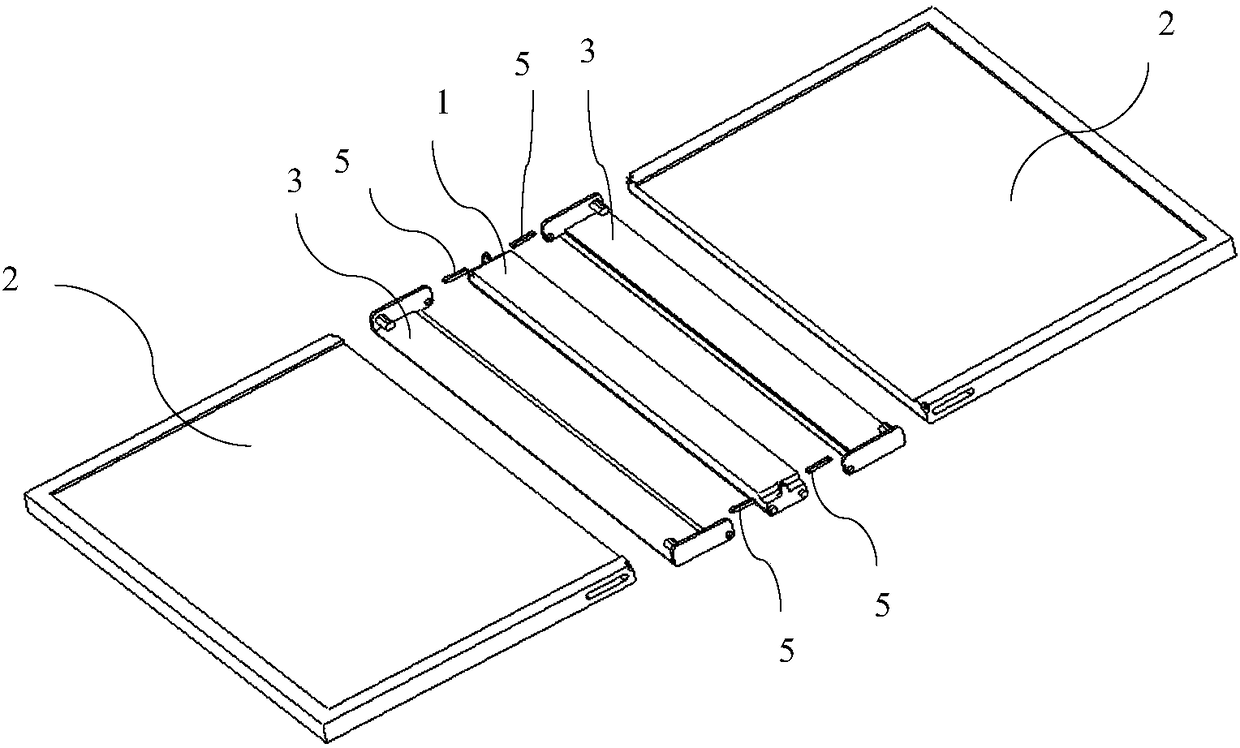

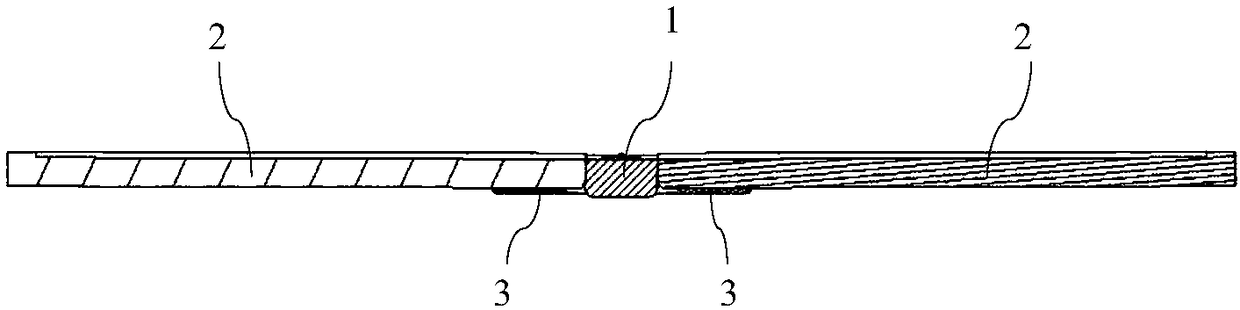

Support protection mechanism of foldable screen and mobile terminal

ActiveCN108520701ASimple and reliable mechanical structureStrong achievabilityDetails for portable computersSubstation equipmentProtection mechanismEngineering

The invention relates to a support protection mechanism of a foldable screen and a mobile terminal. The support protection mechanism comprises a middle support, side shells and side frames, wherein the middle support and the side shells are used for supporting the foldable screen when being unfolded, and the side frames are formed by separating the side shells from the middle support during folding. A containing cavity used for containing and protecting a folding area of the foldable screen is formed when the side frames on the two sides are folded; one side of each side frame is rotationallyconnected with the middle support, and the other side of each side frame is slidably connected with the corresponding side shell; a connecting rod is connected between each side shell and the middle support, and each connecting rod is rotationally connected with the middle support and the corresponding side shell. According to the support protection mechanism of the foldable screen, sliding grooves are ingeniously matched with the connecting rods, so that the overall mechanical structure is simple, reliable, high in implementability and low in manufacturing cost, and the containing cavity canbe reserved during folding to protect the flexible screen while the flexible screen is supported during unfolding.

Owner:NUBIA TECHNOLOGY CO LTD

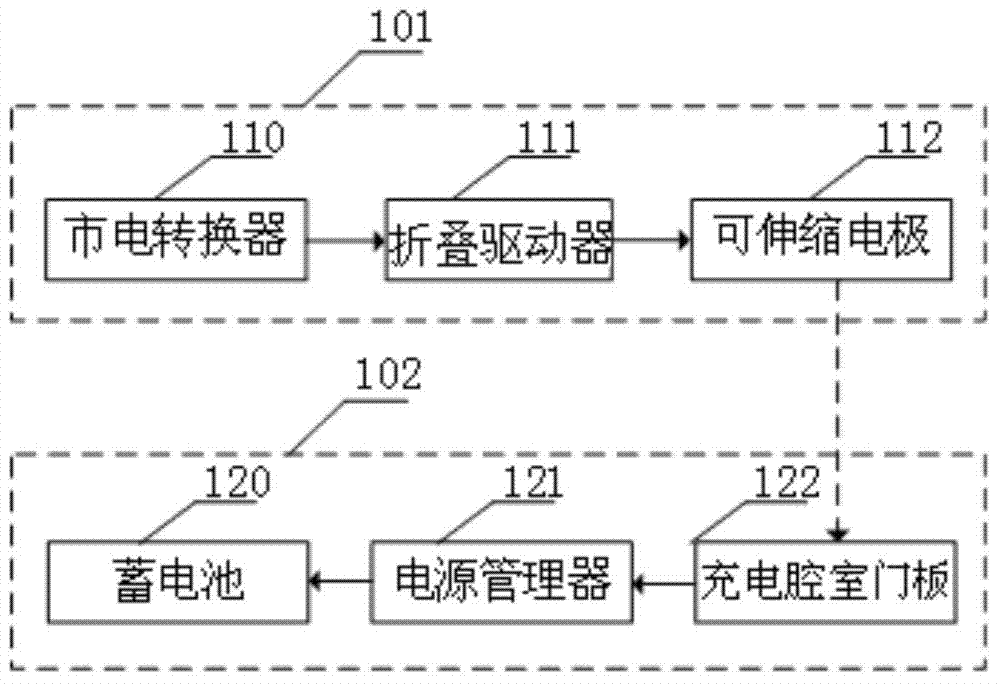

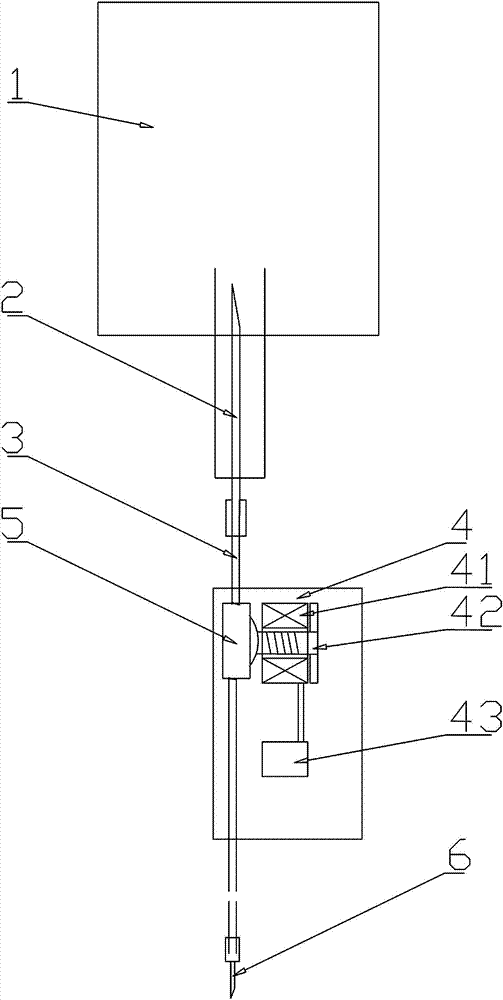

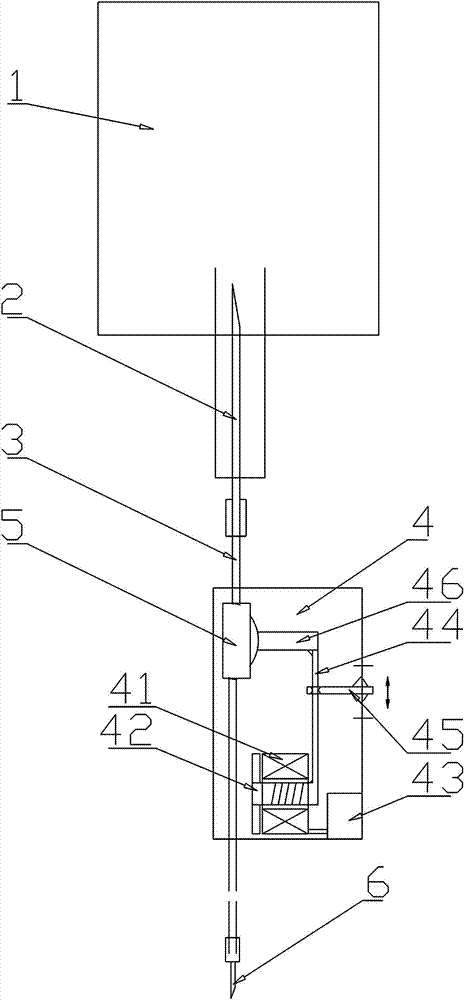

Patrol robot charging system and method

ActiveCN104734291AMeet the requirementsSimplify complexityBatteries circuit arrangementsElectric powerButt jointElectrical and Electronics engineering

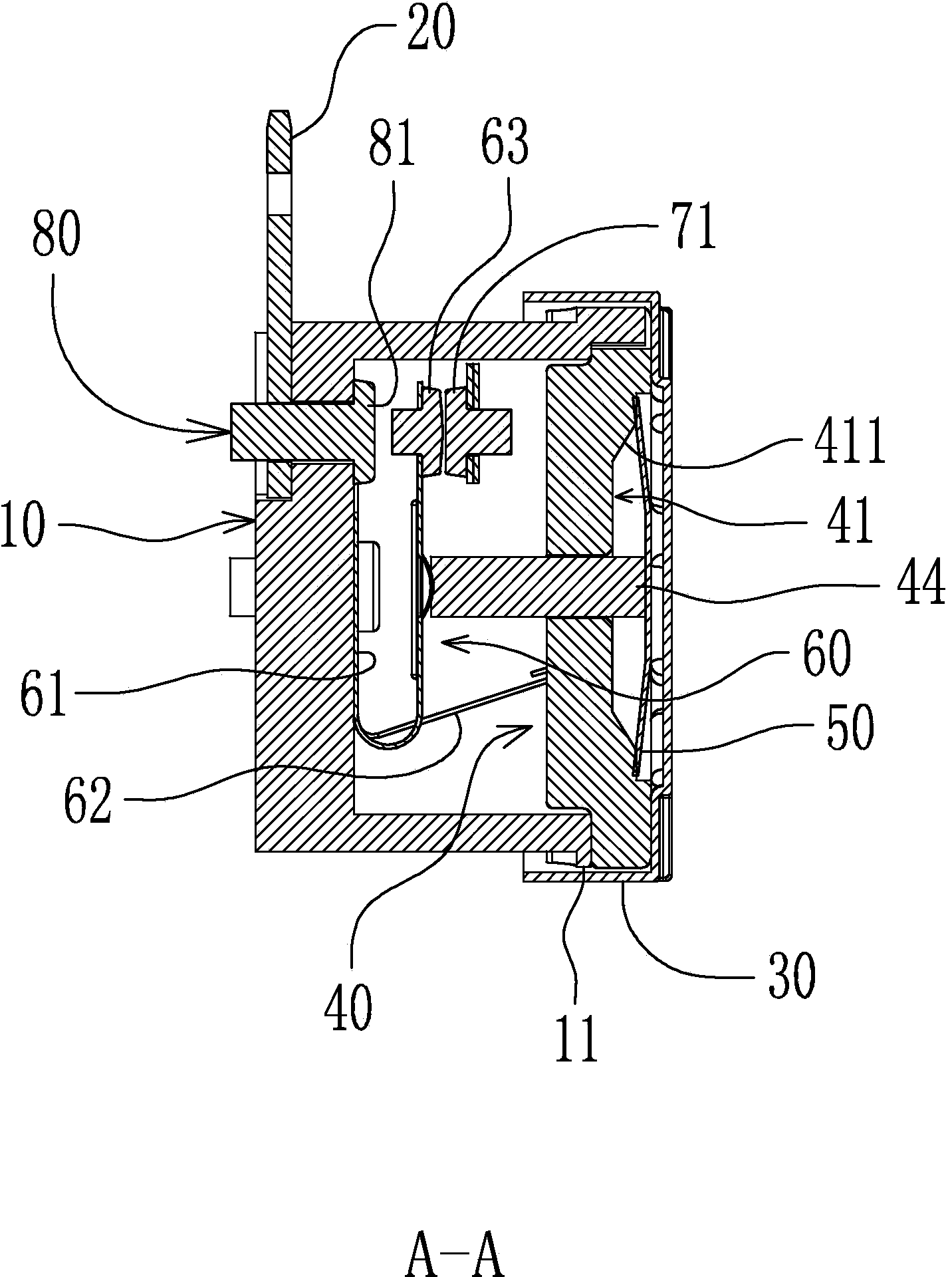

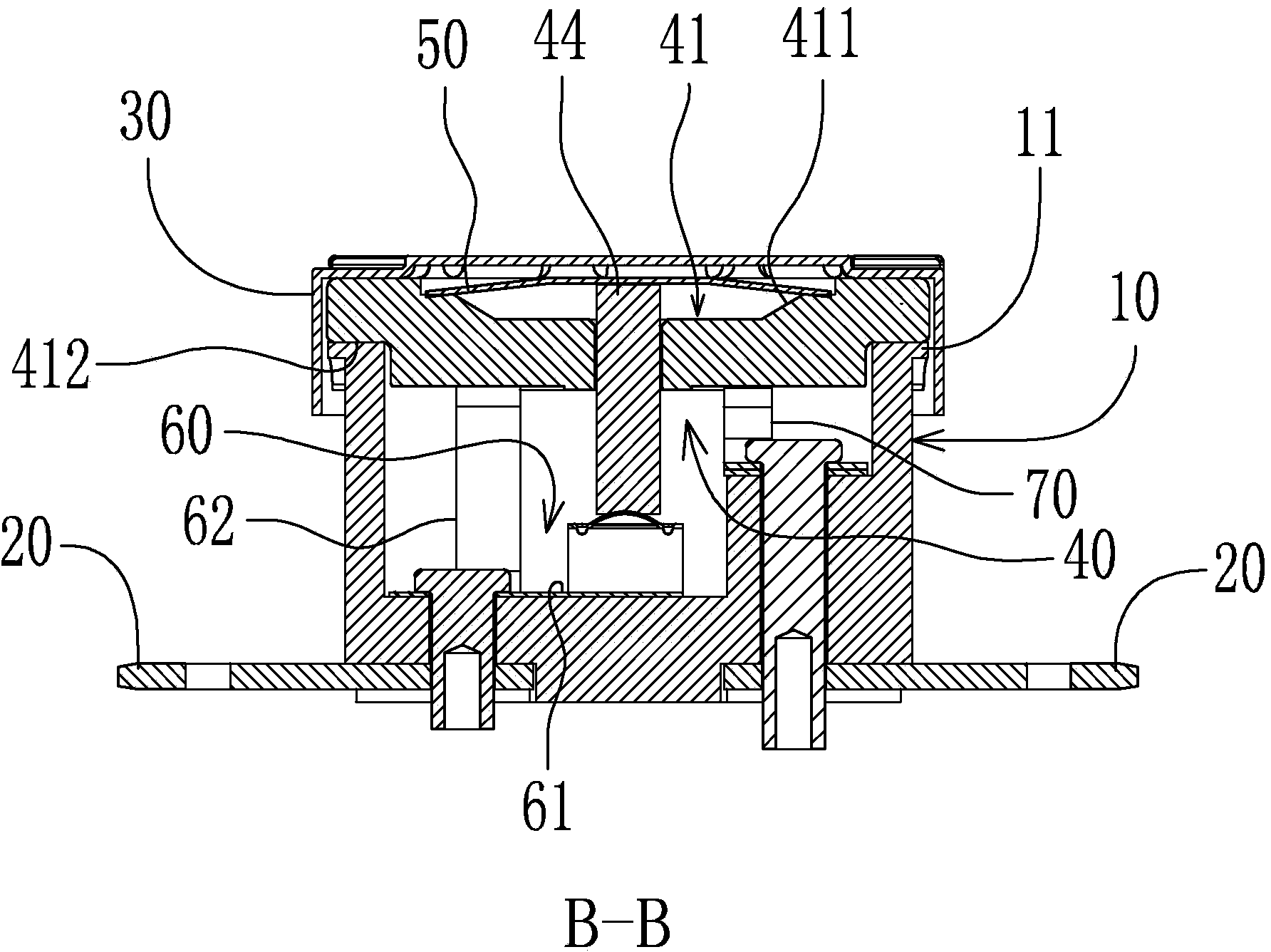

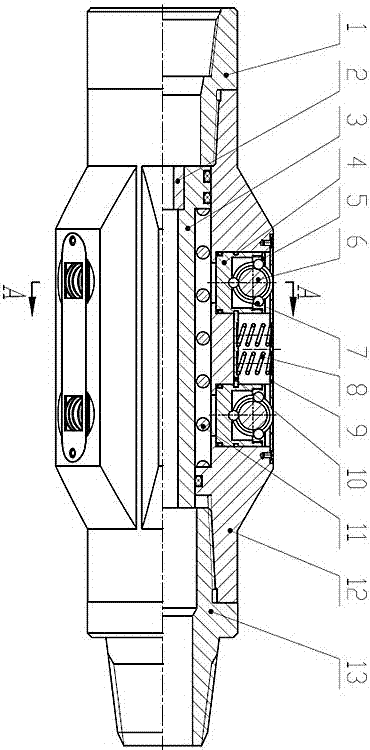

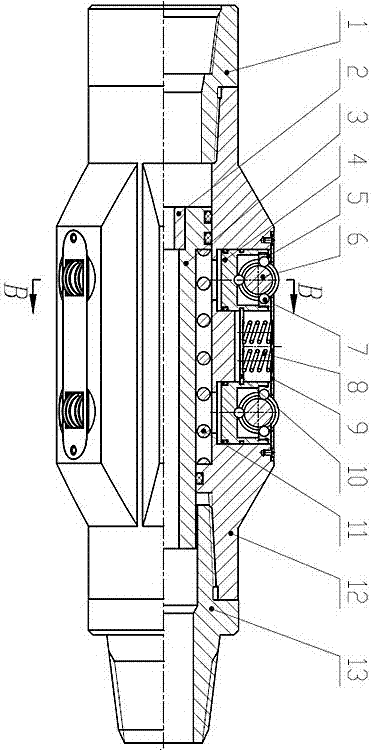

The invention provides a patrol robot charging system which comprises a charging pile base, a patrol robot charging cavity and a foldable telescopic electrode. The outer wall of the charging pile base is provided with an electrode contraction opening. The foldable telescopic electrode is arranged on the charging pile base and located on the upper portion of the electrode contraction opening. The foldable telescopic electrode can rotate around a mounting point and thus can be drawn back and contained in the electrode contraction opening or stretch out of the charging pile base. The foldable telescopic electrode is connected with an electric supply converter arranged on the charging pile base. An electrode plate matched with the foldable telescopic electrode is arranged in the patrol robot charging cavity. According to the patrol robot charging system, the electrode is arranged in the charging pile base, the electrode is designed to be of a telescopic elastic contact type and can be folded and hidden automatically after being used, the butt joint power is supplied by moving of a robot, the complexity of the charging part in the robot is simplified greatly, and meanwhile, the safety and reliability of a device are guaranteed.

Owner:YIJIAHE TECH CO LTD

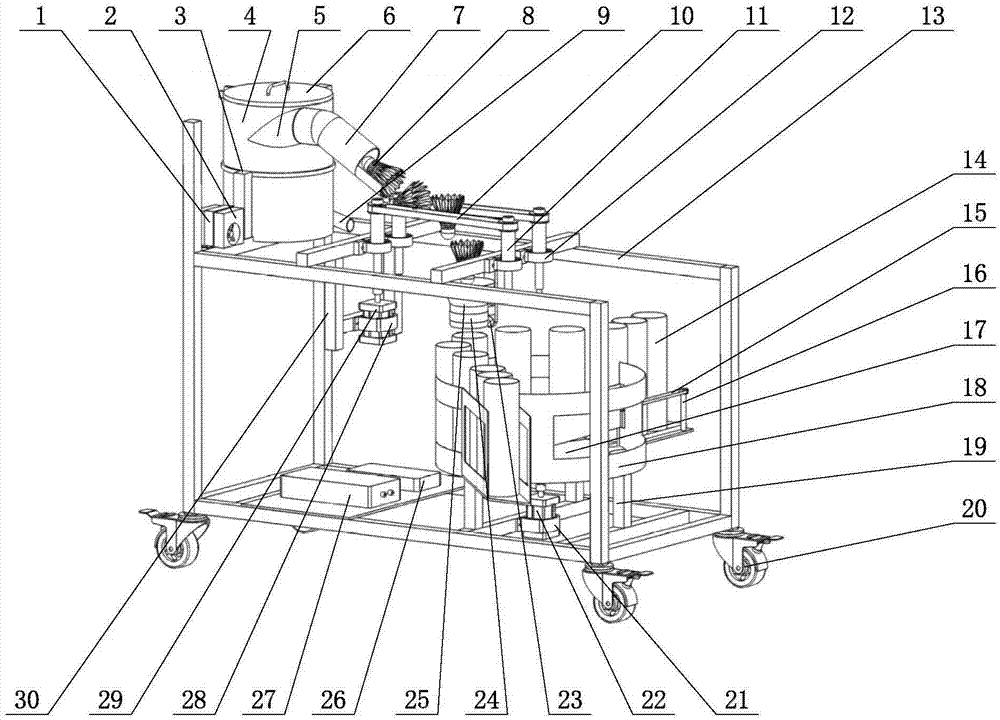

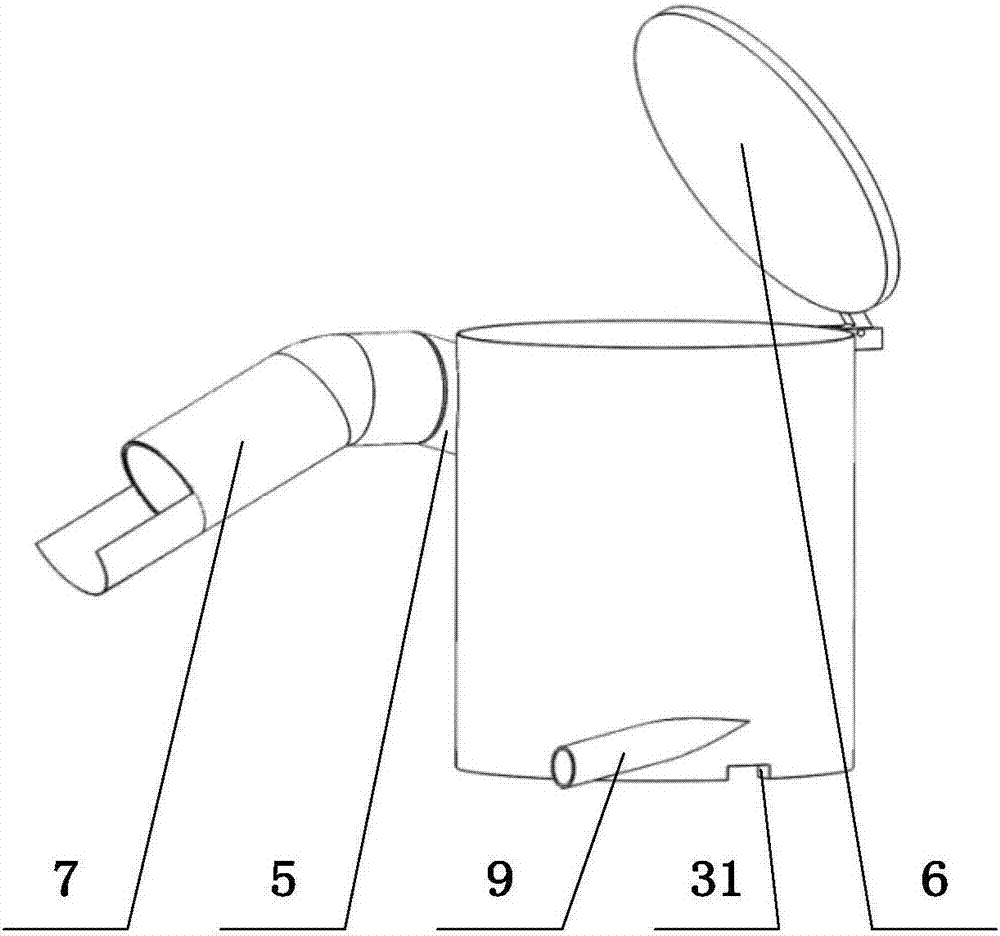

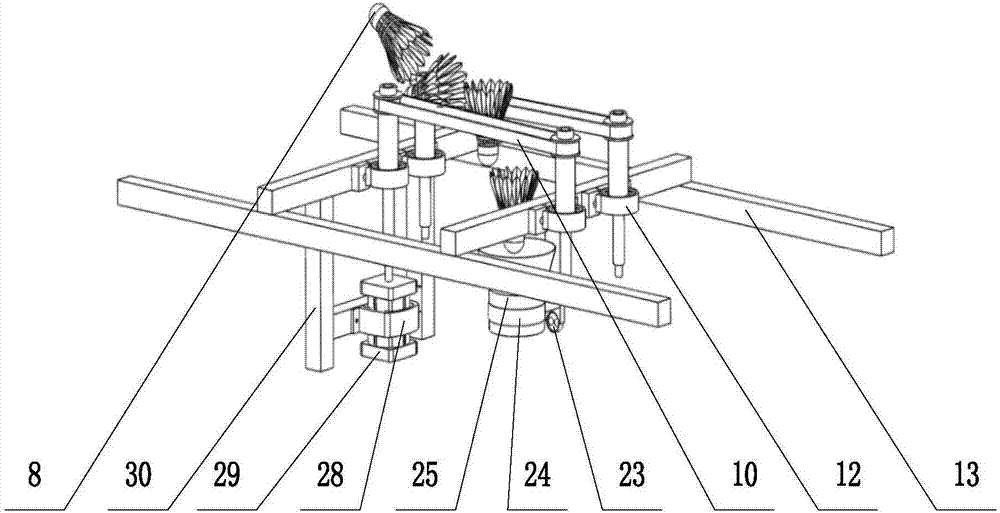

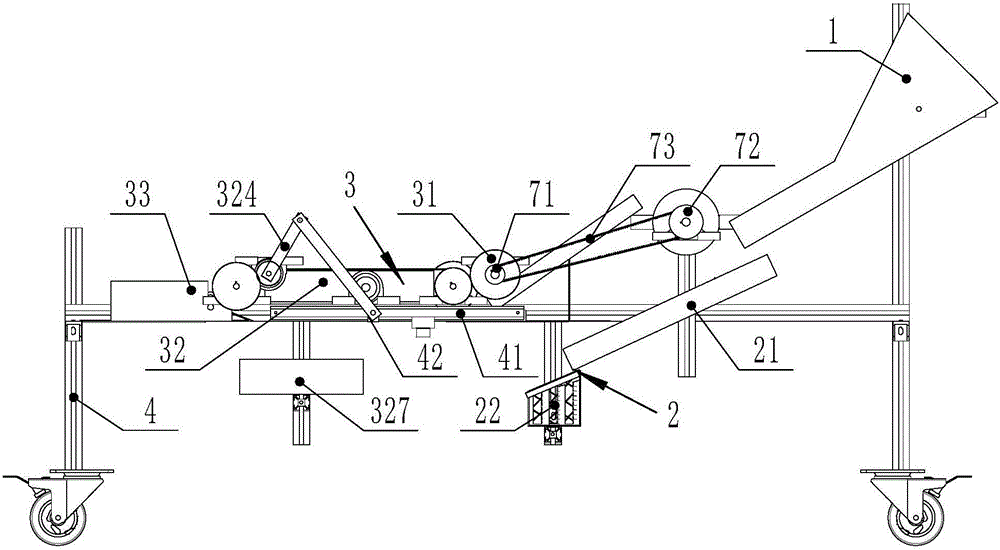

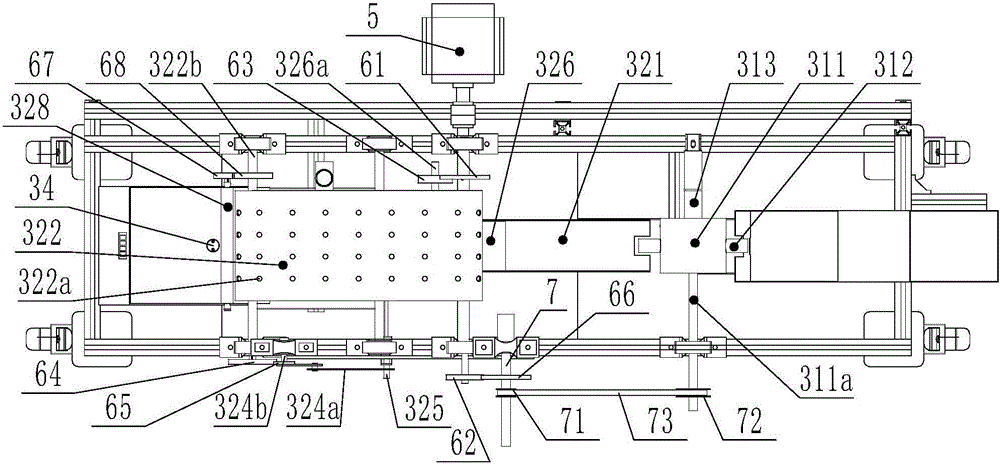

Automatic shuttlecock tidying and collecting device

The invention discloses an automatic shuttlecock tidying and collecting device which comprises a frame and an airflow type conveying system, a directional tidying and conveying system and a replenishable shuttlecock collecting system installed on the frame. The airflow type conveying system comprises an air pump and a shuttlecock collection barrel, the upper end of the shuttlecock collection barrel is provided with a shuttlecock outlet while the lower end is provided with an air inlet channel, and the air inlet channel inclines to the horizontal level in an upward manner. The air outlet end of the air pump is communicated with the air inlet channel, and the shuttlecock outlet is connected with a shuttlecock outlet channel. The directional tidying and conveying system comprises two synchronous belts arranged in a splayed manner and a driving motor II used for driving the synchronous belts to rotate. The replenishable shuttlecock collecting system comprises a guide barrel, a replenishing channel arranged under the guide barrel and a driving motor I used for driving the collecting barrel arranged in the replenishing channel to move along the direction of the replenishing channel. The automatic shuttlecock tidying and collecting device can automatically tidy up a lot of shuttlecocks disordered prior to collection and storage, and efficiency in tidying and collecting is improved.

Owner:SOUTHWEST UNIV

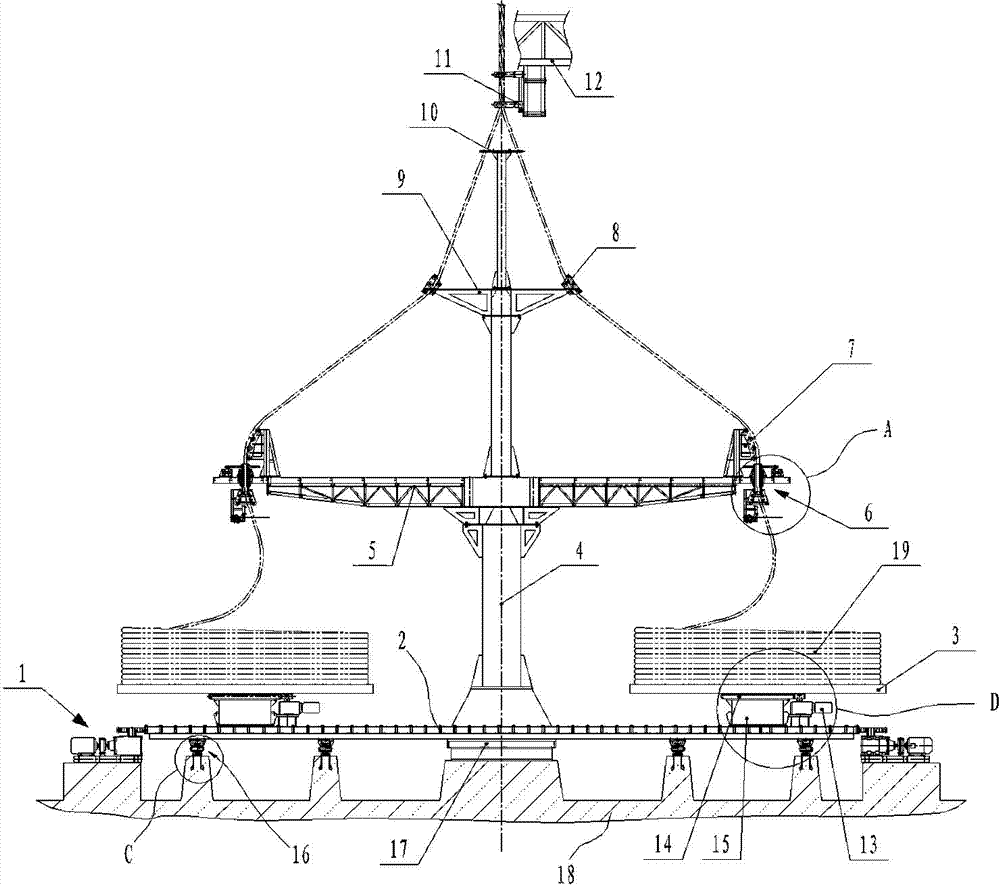

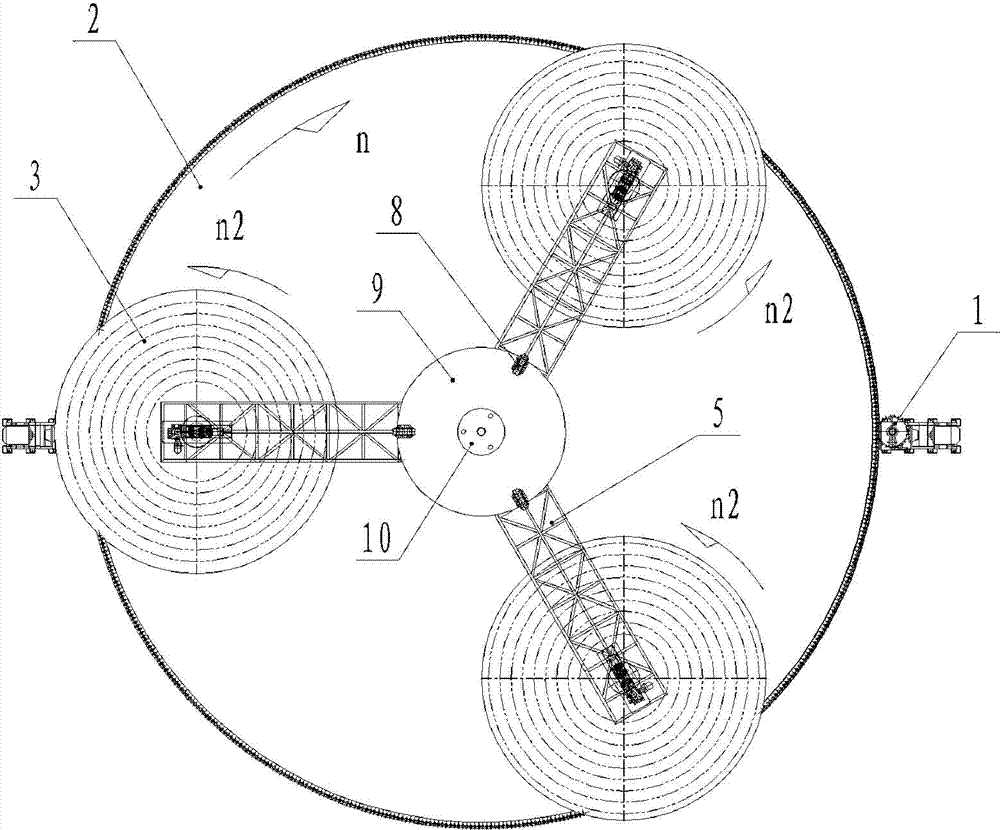

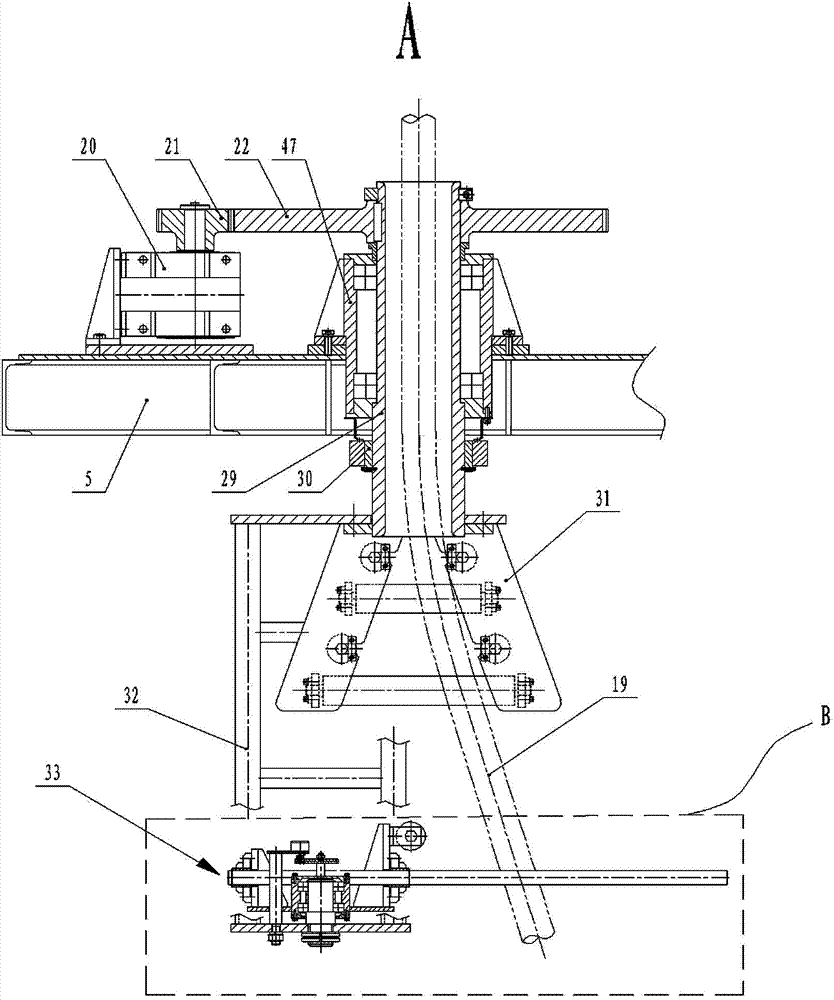

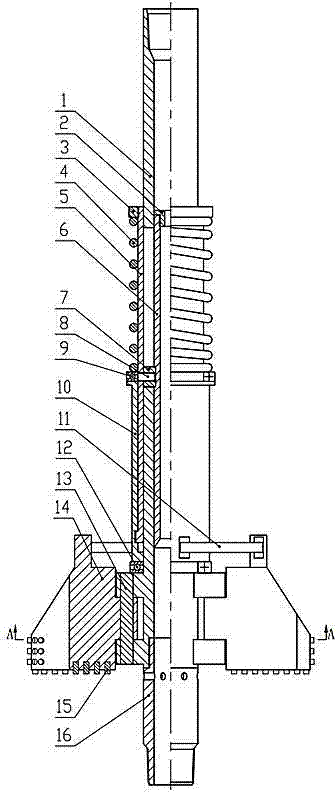

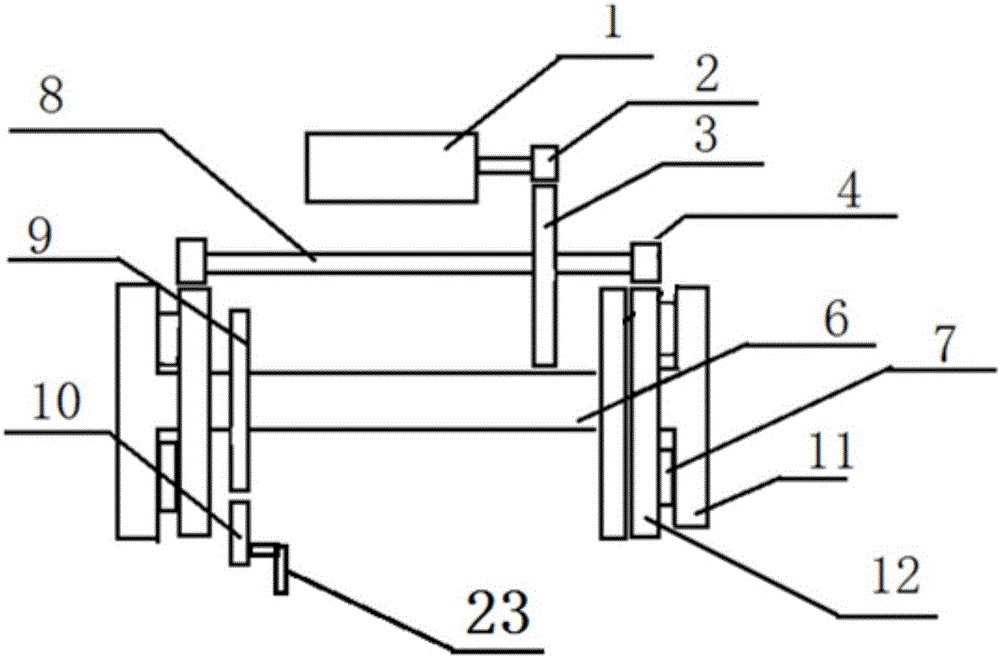

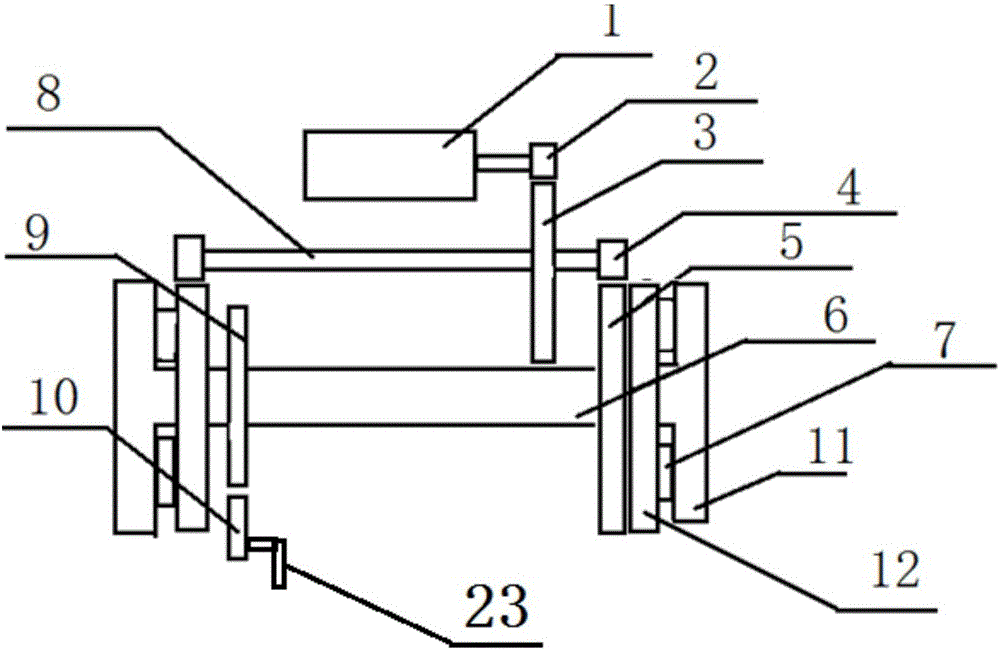

Vertical type cable former with back-twist control function

InactiveCN103578652ALarge loading capacityEnsure that the stranding meets the needs of the production processCable/conductor manufactureElectric cablesWire wrap

The invention relates to a vertical type cable former with the back-twist control function. The vertical type cable former with the back-twist control function comprises a base (18), wherein a rotary table support (17) and supporting wheel devices (16) are arranged on the base; a twisting rotary table (2) is connected to the rotary table support (17) and the supporting wheel devices (16); the rotary table support is further connected with a vertical column (4); the upper end of the vertical column is connected with a wire distribution plate (10) in a matched mode. The vertical type cable former with the back-twist control function is characterized in that a set of winding tray bases (15) are evenly distributed on the twisting rotary table, each winding tray base is connected with a winding rotary table (14), each winding rotary table is connected with a winding tray (3) and a winding tray drive device (13), the vertical column is connected with supporting frames (5), and the front side of each supporting frame is connected with a back-twisting device (6). The vertical type cable former with the back-twist control function has the advantages that the load capacity of wire spool cable cores is increased, the back-twisting and twisting of the cable cores can be achieved by 100%, insufficient or over back-twisting is avoided, and the production quality of submarine cables is ensured.

Owner:安徽长江精工装备科技有限公司

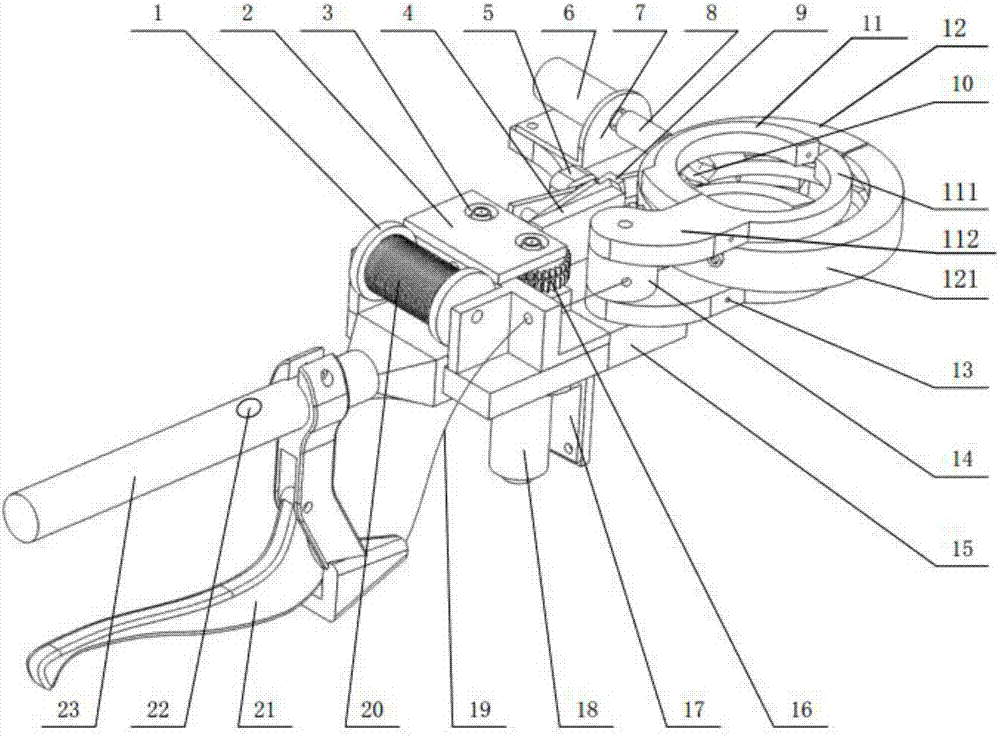

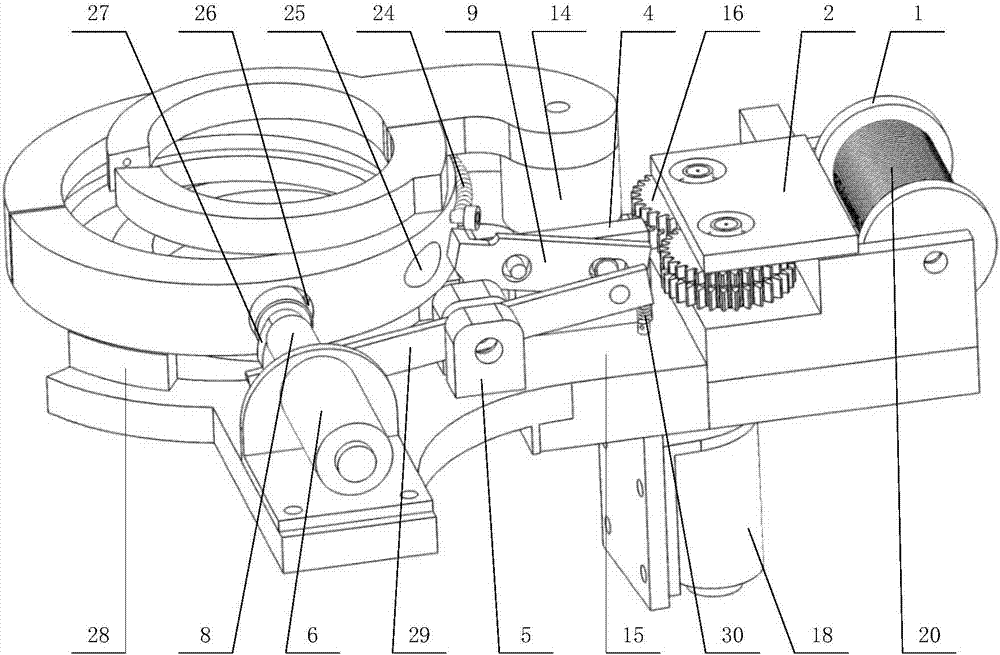

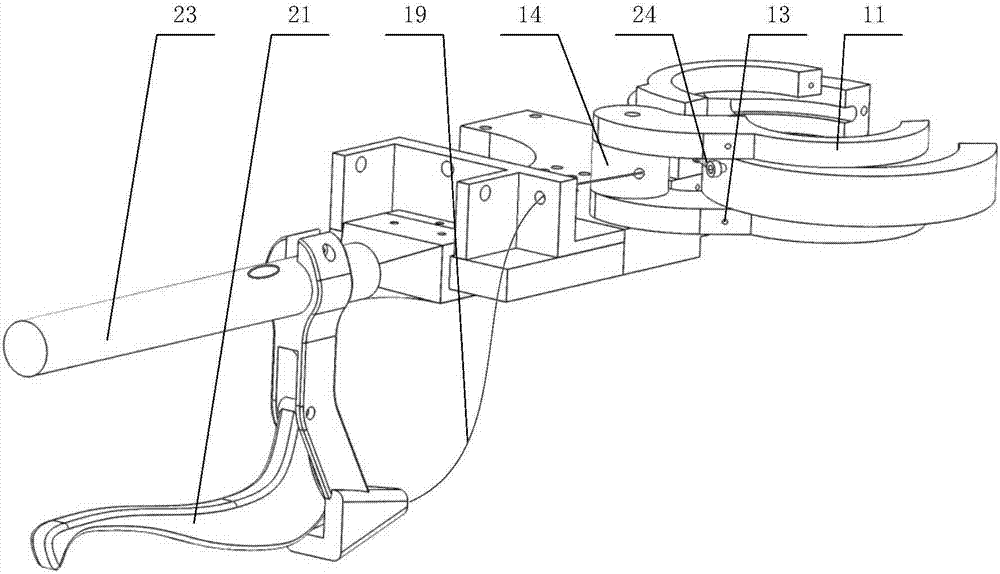

Binding device for tobacco leaf-covering bag

ActiveCN107347477ASimple and reliable mechanical structureLightweight and flexible mechanical structureHorticulture methodsWinding machineBaseboard

The invention discloses a binding device for a tobacco leaf-covering bag. The device comprises a supporting baseboard, a leaf-covering bag necking system, a wire feeding system, a wire shearing system and a wire stranding system, and the leaf-covering bag necking system, the wire feeding system, the wire shearing system and the wire stranding system are installed on the supporting baseboard; the leaf-covering bag necking system comprises a necking mechanism which is used for necking a sealing mouth of the leaf-covering bag, and a wire winding mechanism which is used for winding a binding wire at the sealing mouth of the necked leaf-covering bag; the wire feeding system is used for delivering the binding wire to the winding position of the winding mechanism; the wire shearing system is used for shearing the part, entering a winder, of the binding wire; the wire stranding system is used for stranding the binding wire in the winder to achieve binding of the tobacco leaf-covering bag.

Owner:SOUTHWEST UNIV

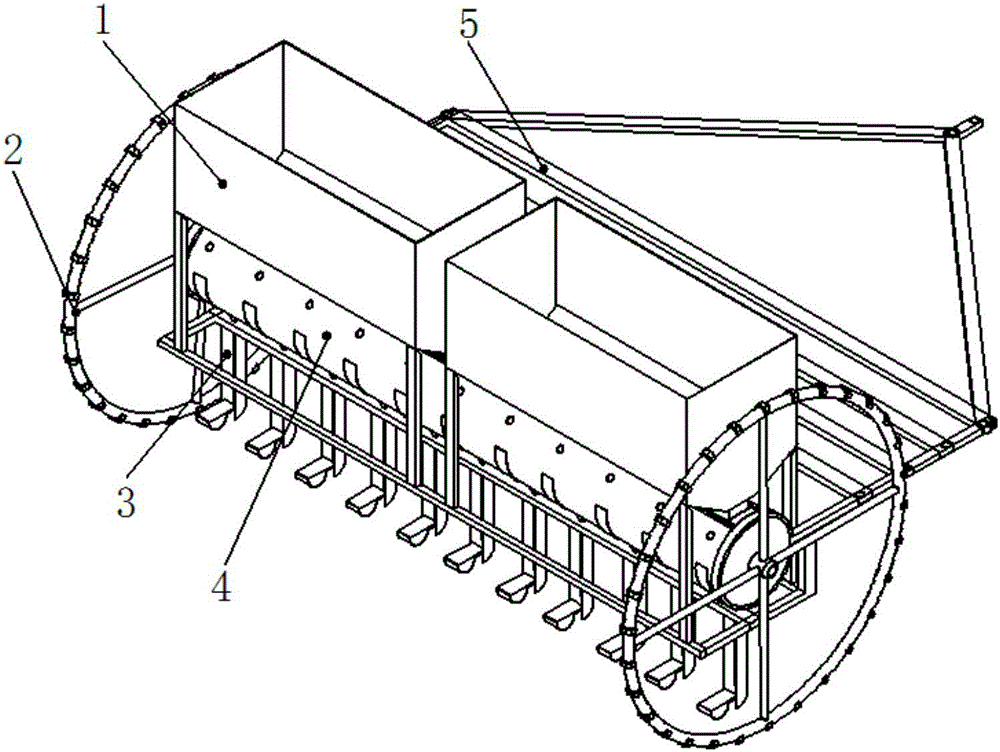

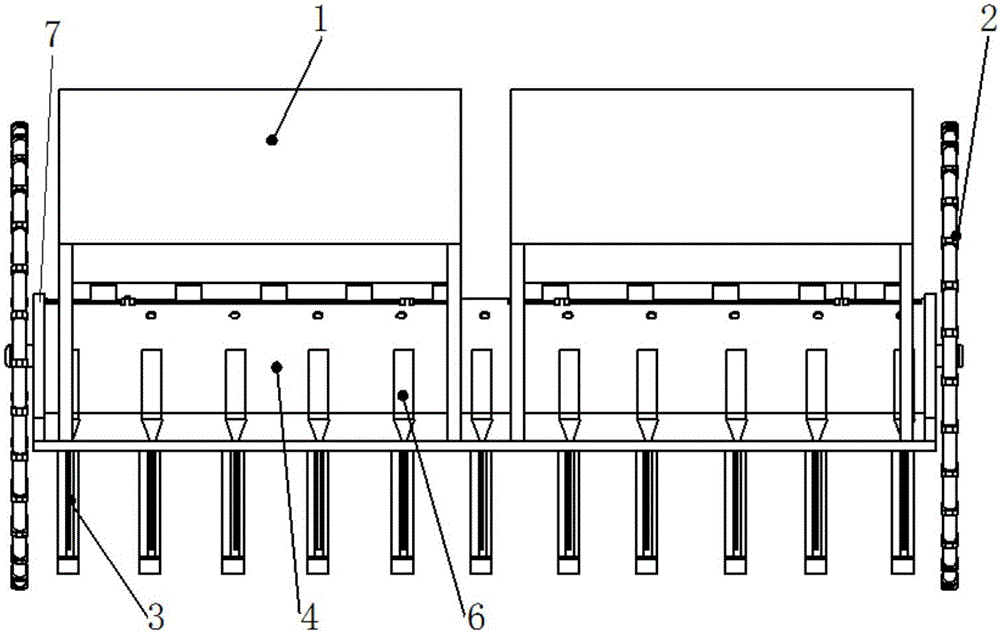

Drum type rice precise hill seeder

InactiveCN106376277ALow levelness requirements for soil preparationPrecise sowingPlantingDibble seedersSeederTraction frame

The invention discloses a drum type rice precise hill seeder, which comprises seed boxes, walking wheels, furrowing devices, a drum device, a traction frame and seed conveying devices, wherein the drum device is arranged on the traction frame, and comprises a tube body; seed collecting openings are formed in the upper end surface of the tube body; a cover plate buckled with each seed collecting opening is arranged in each seed collecting opening position; seed discharging openings distributed at equal intervals are uniformly distributed in the outer circumferential surface of the tube body; a round baffle plate vertical to the axial direction of the tube body is arranged in the tube body between the adjacent seed discharging openings; the walking wheels synchronously rotating together with the drum device are arranged at two ends of the drum device; the seed boxes are arranged at the upper side of the drum device; the lower side of the drum device is provided with the matched seed conveying devices; the furrowing device is arranged at the bottom end of each conveying device. The drum type rice precise hill seeder has the advantages that the structure design is reasonable; rice seeds are in square lattice distribution; rice seeds are enabled to be precisely sowed without damage; the mechanical structure is simple and reliable; the manufacturing cost is low; the popularization is convenient.

Owner:ANHUI AGRICULTURAL UNIVERSITY

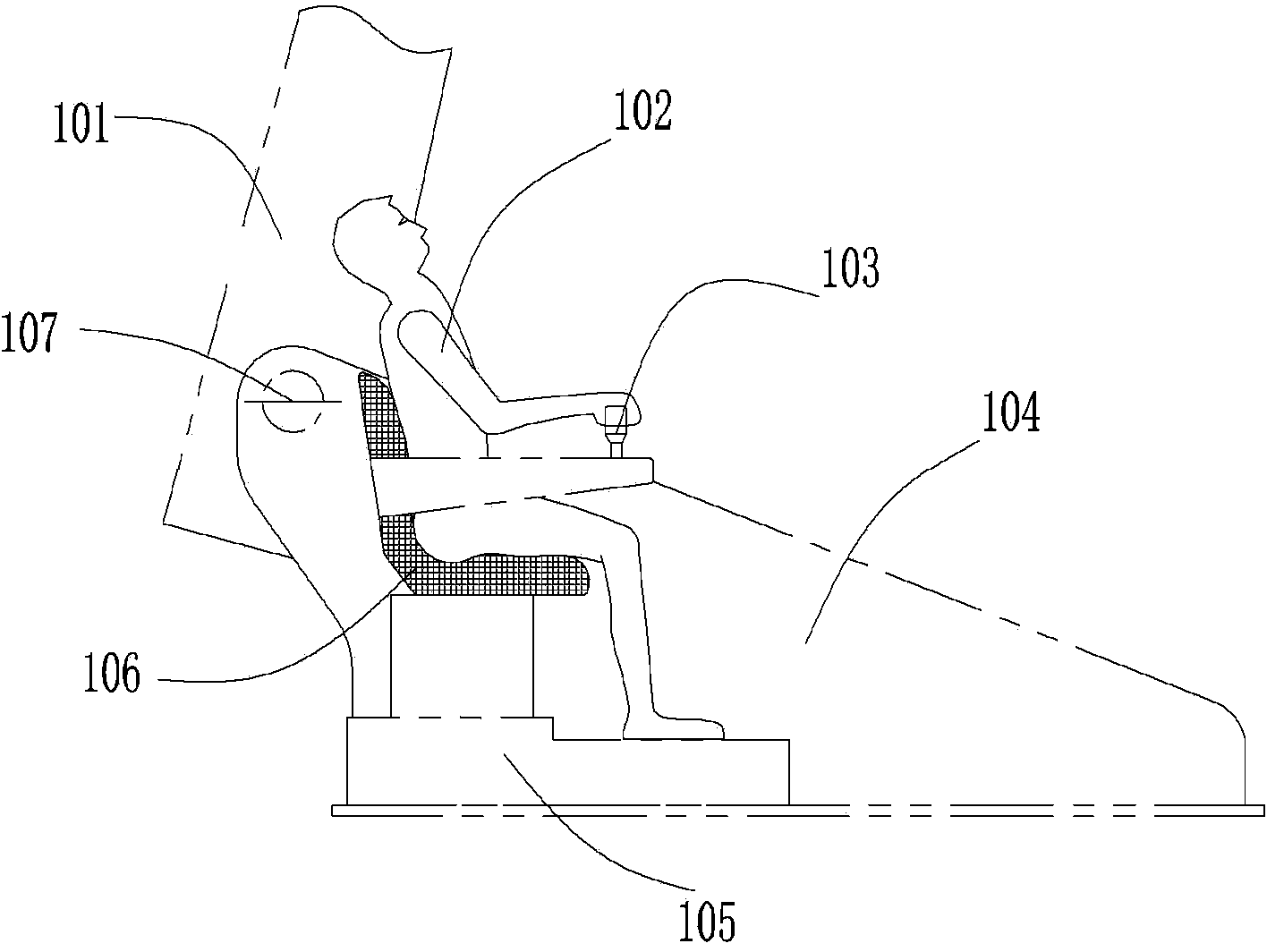

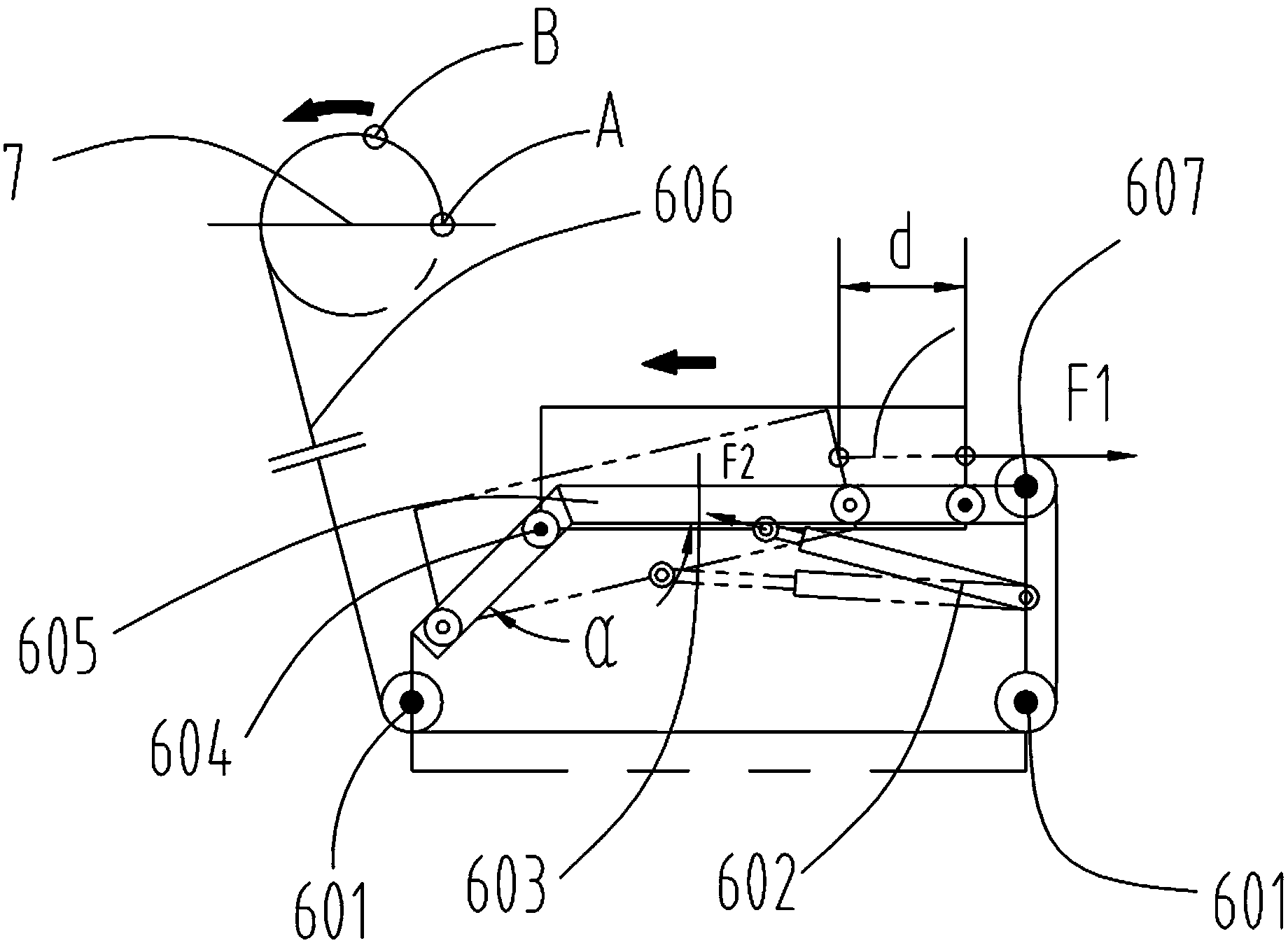

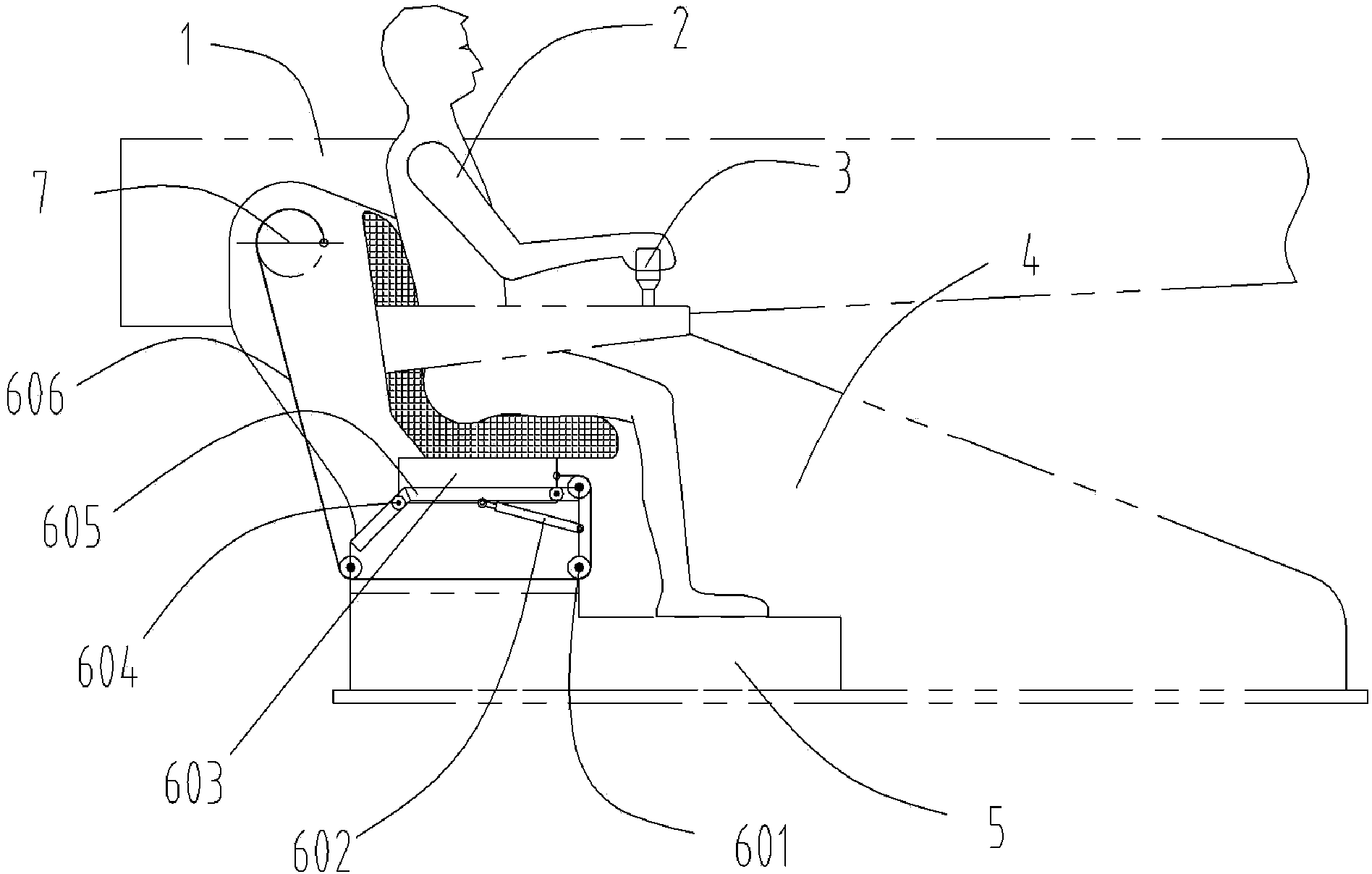

Angle adjustment mechanism for seat, seat and overhead working truck

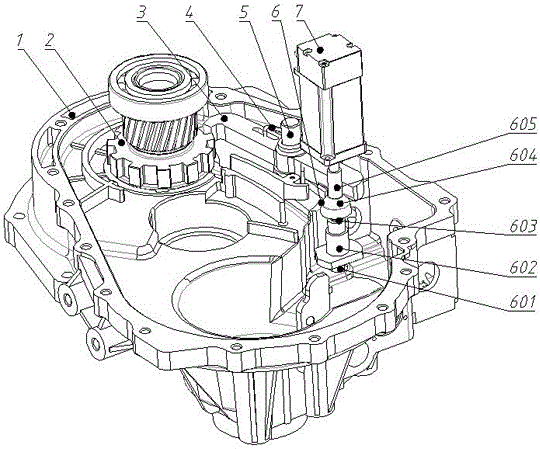

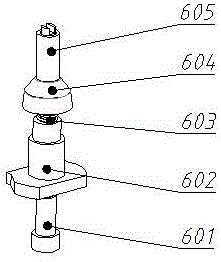

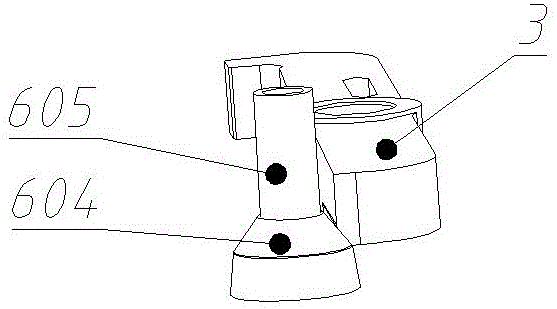

ActiveCN104260646ASimple and reliable mechanical structureGood comfortMovable seatsTruckMoving parts

The invention discloses an angle adjustment mechanism for a seat, the seat and an overhead working truck. The angle adjustment mechanism for the seat is used for angle adjustment of the seat and comprises a base (5), a guide part (605) and a drive assembly. The guide part (605) is fixed on the base (5). A body (603) of the seat is installed on the guide part (605) through a moving part (604) and moves between a first position and a second position along the guide part, and the body (603) at the first position and the body (603) at the second position form an angle. The drive assembly is connected with the body (603) of the seat and used for driving the body (603) of the seat to move along the guide part (605). The angle adjustment mechanism for the seat changes the angle of the seat through movement of the body of the seat between the first position and the second position forming an angle.

Owner:CHANGSHA ZOOMLION FIRE FIGHTING VEHICLE +1

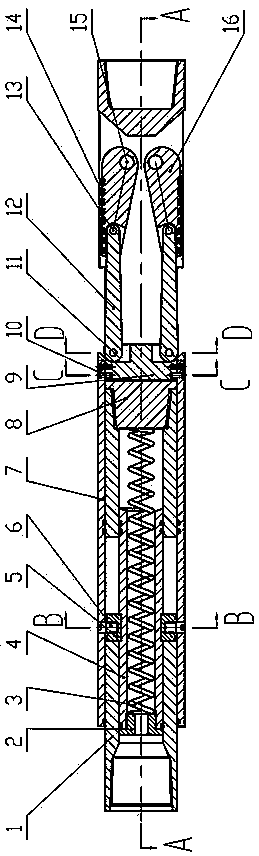

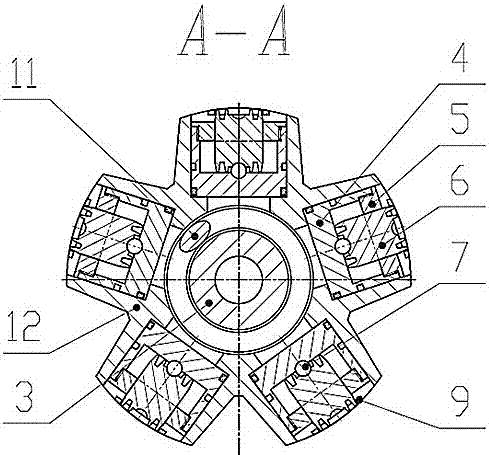

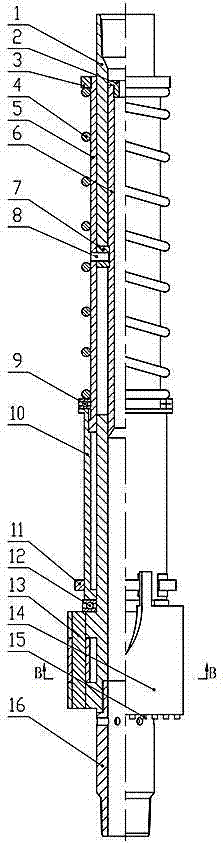

Supporting-rod two-blade large-diameter changing reaming tool

InactiveCN104481404AWide range of variable diameterSimple controlDrilling machines and methodsEngineeringDriving mode

The invention relates to a supporting-rod two-blade large-diameter changing reaming tool for mineral resource exploiting and oil-gas well underground reaming and solves the problem of underground large diameter changing reaming. According to the technical scheme, a main cylinder is in threaded connection with a blade seat, and three through grooves are formed uniformly in the main cylinder peripherally. A water nozzle is in threaded connection with a central tube, and three sliding blocks penetrate the three through grooves to be mounted in an inner central tube circular groove. The middle of an outer central tube is fixedly connected with a sliding block through screws a, and the lower portion is fixedly connected with a supporting rod seat through screws b. Cutting teeth are inlaid in the outsides of the blade wings, and the blade wings are hinged to the blade wing seat through bolts. The ends of supporting rods are hinged to the supporting rod seat, and the other ends are hinged to the blade wings. By means of the tool, the largest diameter after diameter changing can be more than three times of the largest diameter before diameter changing, the mechanical structure is reliable, and a hydraulic drive mode is used, so that the tool is simple to control and is used for underground reaming.

Owner:SOUTHWEST PETROLEUM UNIV

Non-full pipe electromagnetic flowmeter

InactiveCN102023037ASimple and reliable mechanical structureHigh precisionVolume/mass flow by electromagnetic flowmetersEngineeringElectromagnetic flow

The invention provides a non-full pipe electromagnetic flowmeter which comprises a body pipeline arranged on an on-site pipeline, an excitation coil and eccentric flanges. The inner of the body pipeline is provided with a circulation pipeline; the circulation pipeline and the two ends of the body pipeline are welded on eccentric flanges; the center of the circulation pipeline is positioned under the center of eccentric flanges with a distance ranging from 1 / 8 D to 1 / 6 D, wherein the D is the diameter of the body pipeline. The present invention achieves the advantages of reducing fluid circulation areas in non-full pipe occasions through the structures of both eccentric flanges and the circulation pipeline, positioning at the part of the body pipeline and completely converting the non-full pipe flow measurement intoto full pipe flow measurement in application, with same use method with the traditional electromagnetic flow-meters. The invention also has a simple and reliable structure, and can guarantee a high precisionoun of 0.5 grade.

Owner:SHANGHAI HUAQIANG FULUO INSTR +1

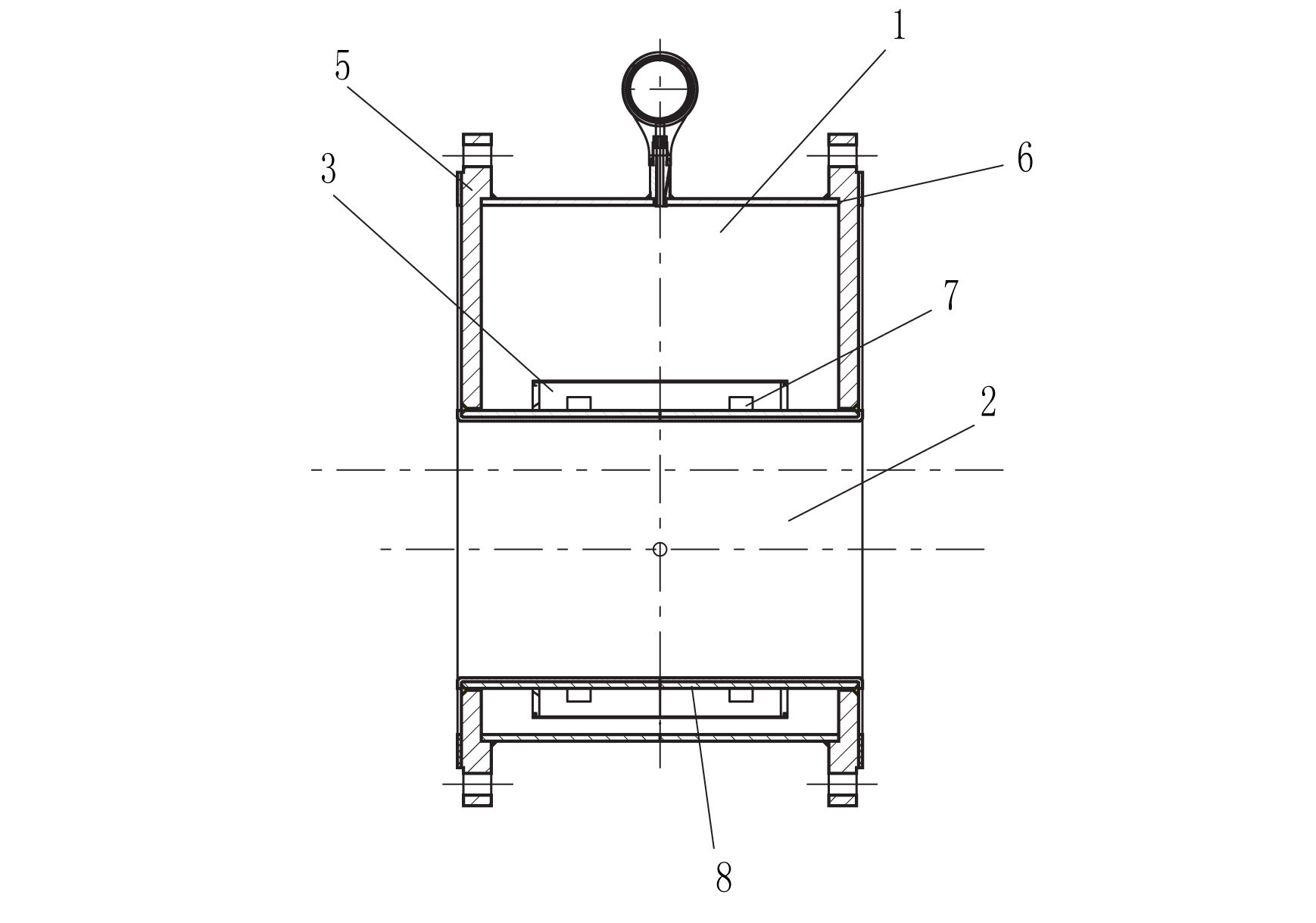

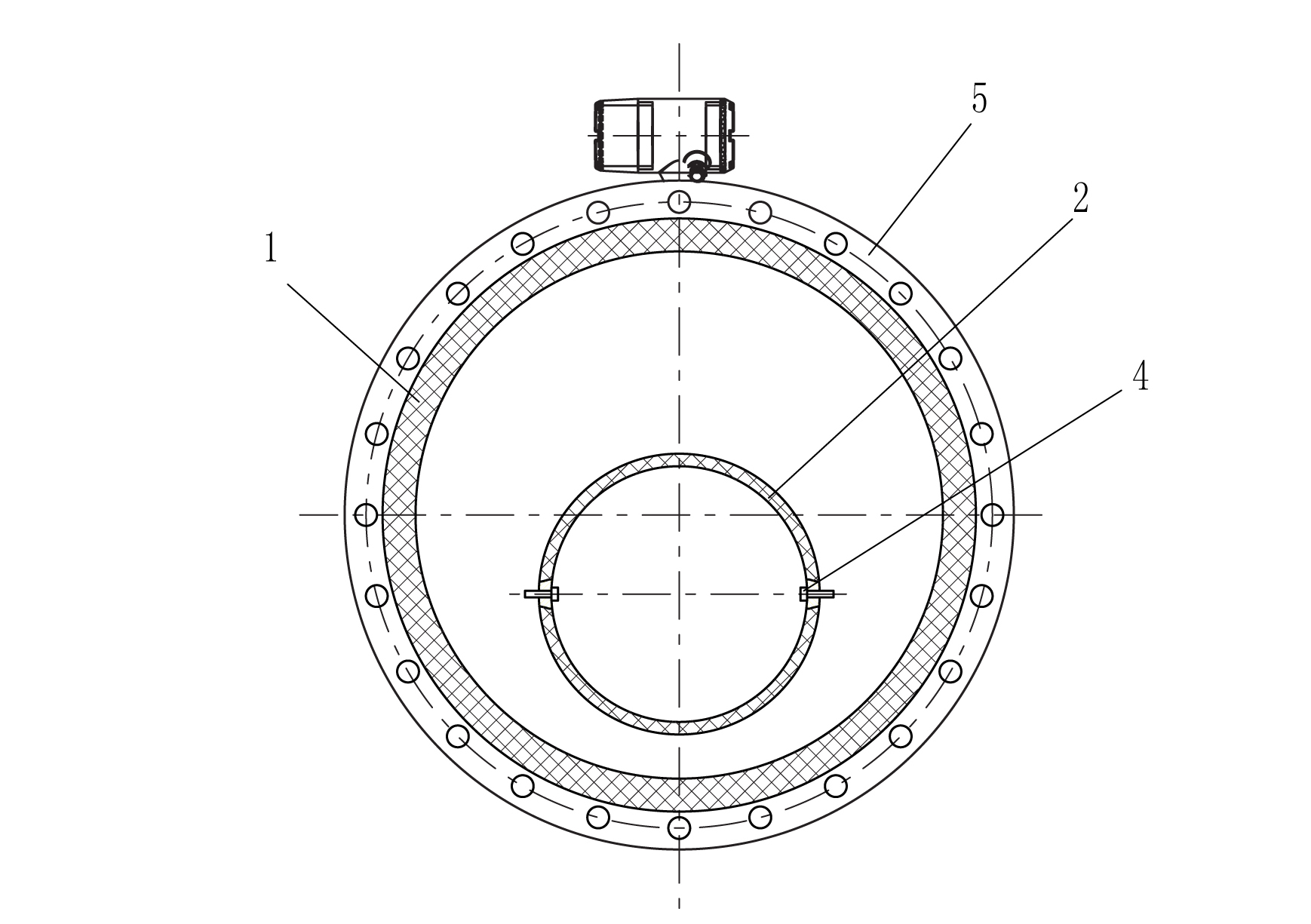

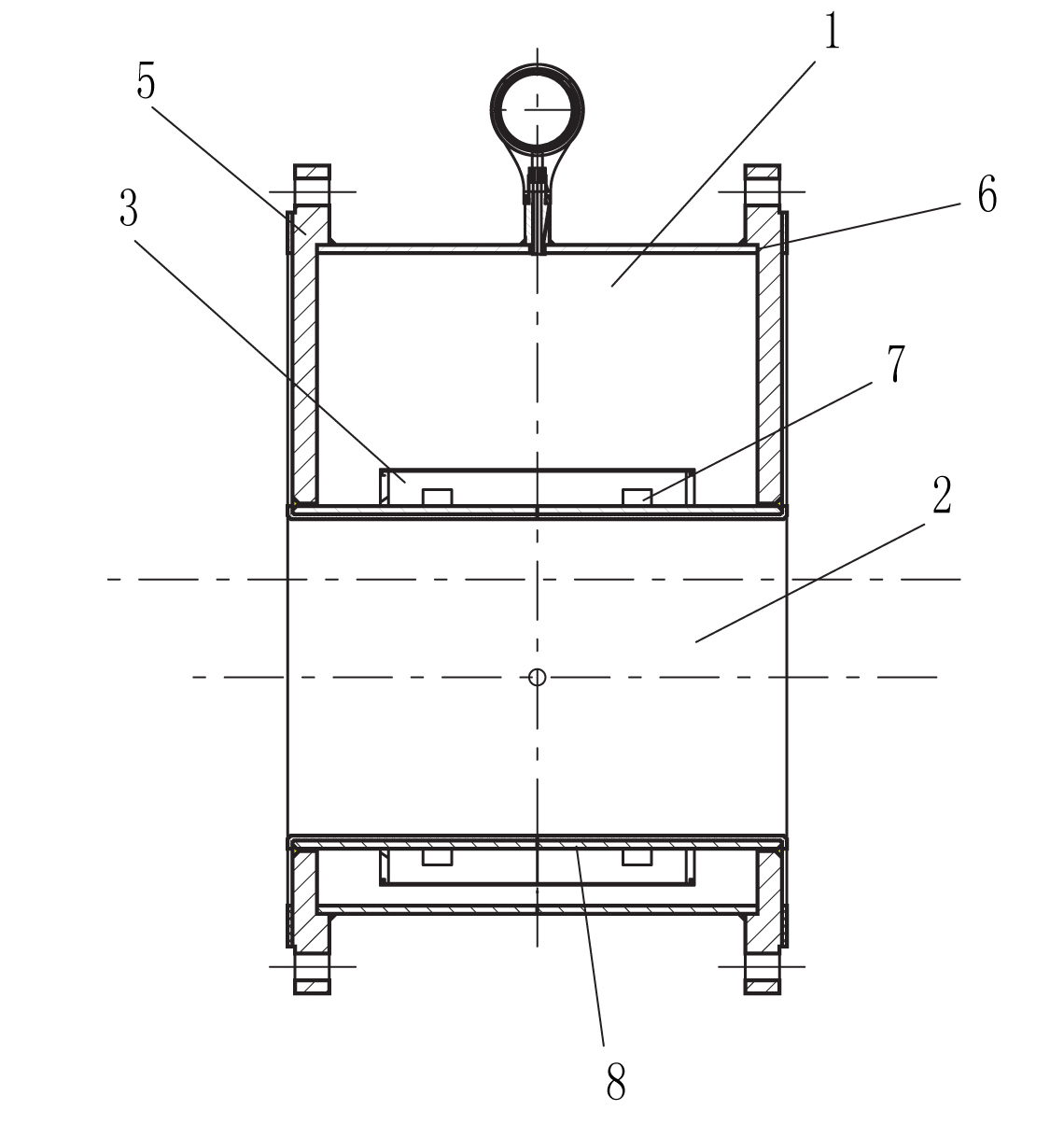

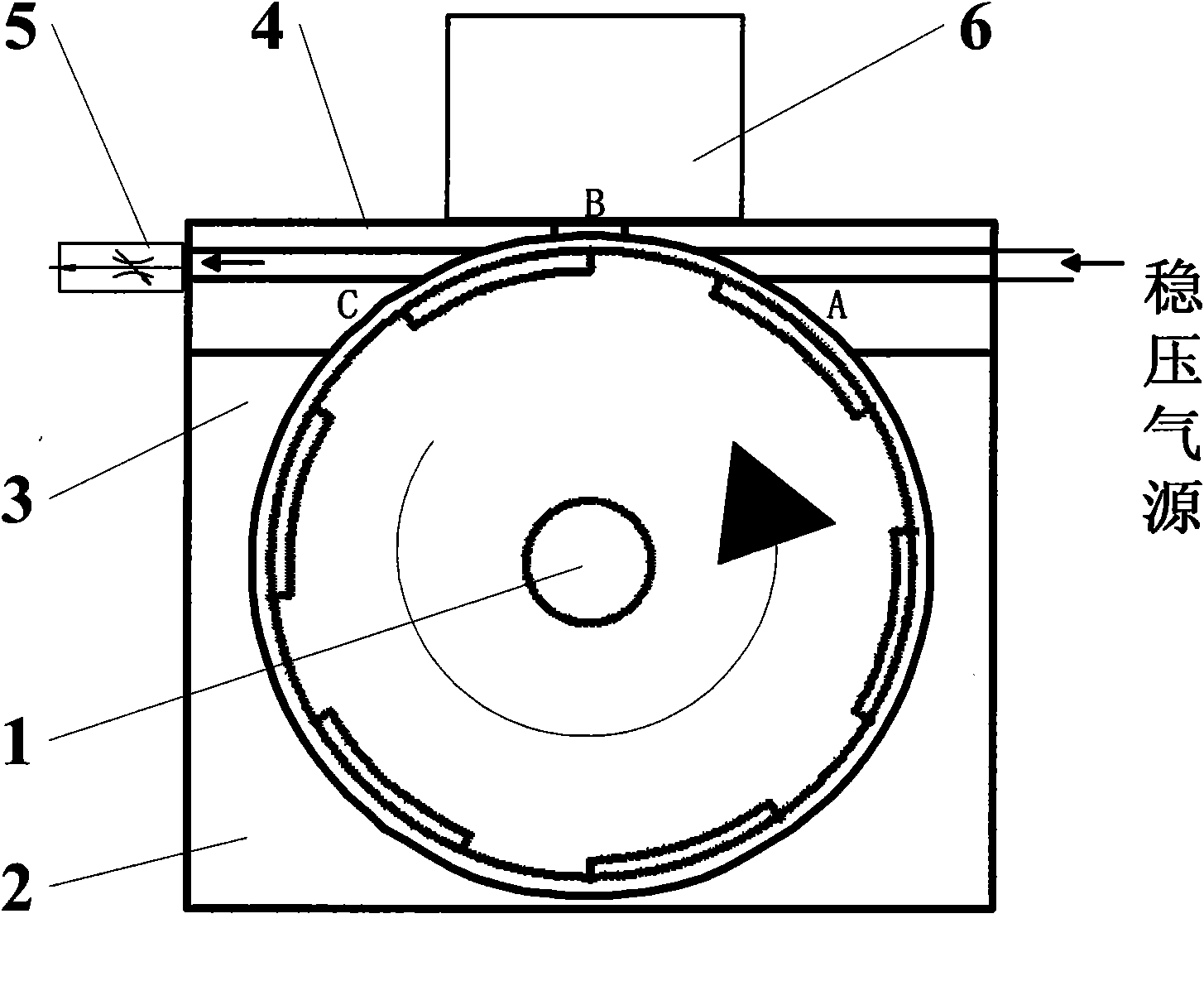

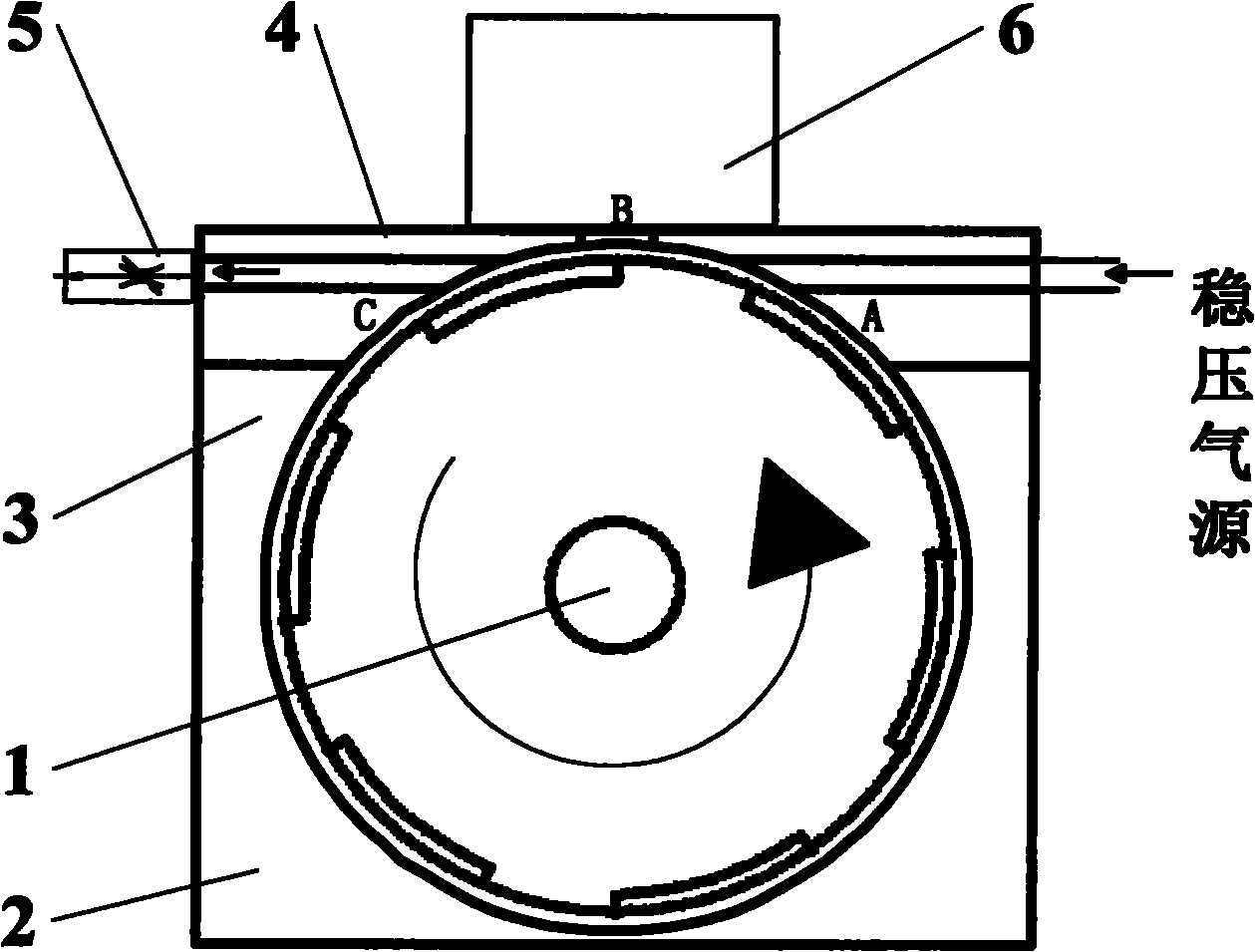

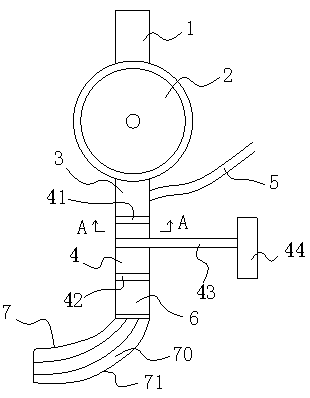

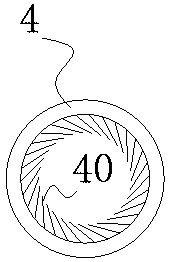

Pressure generator for gas pressure fatigue tester

ActiveCN102042931ASimple and reliable mechanical structureReduce frictionMaterial strength using tensile/compressive forcesContact frictionEngineering

The invention relates to a pressure generator with alternately changed high and low pressure for a gas pressure fatigue tester, belonging to a testing technology. The pressure generator comprises an electric motor, a coupler, a turntable, a pressure chamber, a gas source and a flow valve, wherein the electric motor is connected with the coupler, the coupler is connected with the turntable, and a series of striped grooves are uniformly distributed on the outer circumferential surface of the turntable; the pressure chamber is arranged on a connecting piece, the matched surface of the connecting piece and the turntable is uniformly provided with three exhaust ports, wherein the middle exhaust port is communicated with the pressure chamber, one of the two side exhaust ports is communicated with the atmosphere through the flow valve, and the other side exhaust port is connected with the stable gas source; the grooves on the turntable is long enough to cover two adjacent exhaust ports in the three exhaust ports on the connecting piece, and the distance between the two grooves is larger than the diameter of the exhaust ports; and a gap which is between 0.1m and 0.5 mm is reserved between the turntable and the connecting piece so as to avoid direct contact friction. The high and low pressure values and the frequency of alternately changed pressure fluctuation of the pressure generator can be regulated within a large range, and particularly, the pressure generator has very high durability and reliability.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

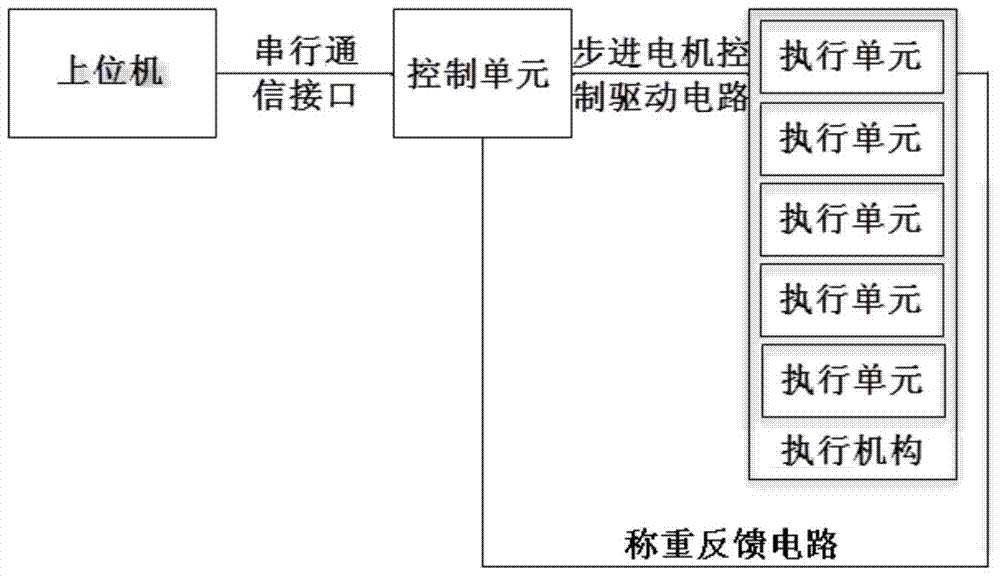

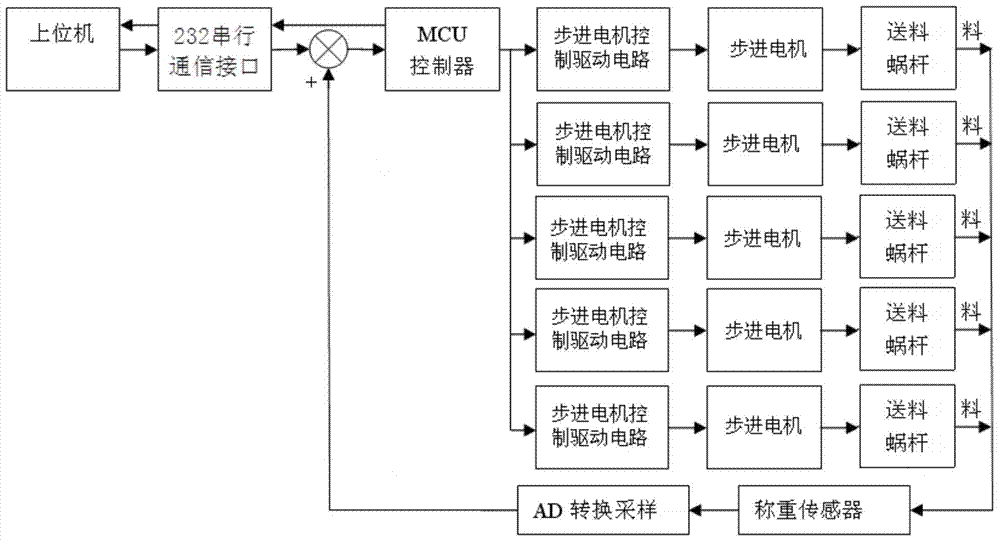

Device for controlling mud sample manufacturing precise proportioning through computer and control method

ActiveCN103884411APrecise and controllable deliveryFully automatedPreparing sample for investigationSpecial purpose weighing apparatusFeedback circuitsExecution unit

The invention relates to a device for controlling mud sample manufacturing precise proportioning through a computer and a control method. The device comprises the upper computer, a control unit and an execution mechanism. The execution mechanism is composed of at least one execution unit. The upper computer is connected with the control unit through a serial communication interface, a stepping motor is connected with the control unit through a stepping motor control driving circuit, and weighing sensors are connected with the control unit through weighing feedback circuits. The invention further relates to a control method for the device. An instruction is sent through the upper computer, so that the control unit controls the execution units independent of one another in the execution mechanism to feed material. The needed proportion in mud sample manufacturing is controlled through the computer, the material is automatically fed into a mixing pool of a mixer, labor intensity of a tester and test preparation time can be reduced, precision of the feeding proportion can be guaranteed, and the device and the control method have good application prospects for a test related with mud sample manufacturing in geotechnical engineering.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

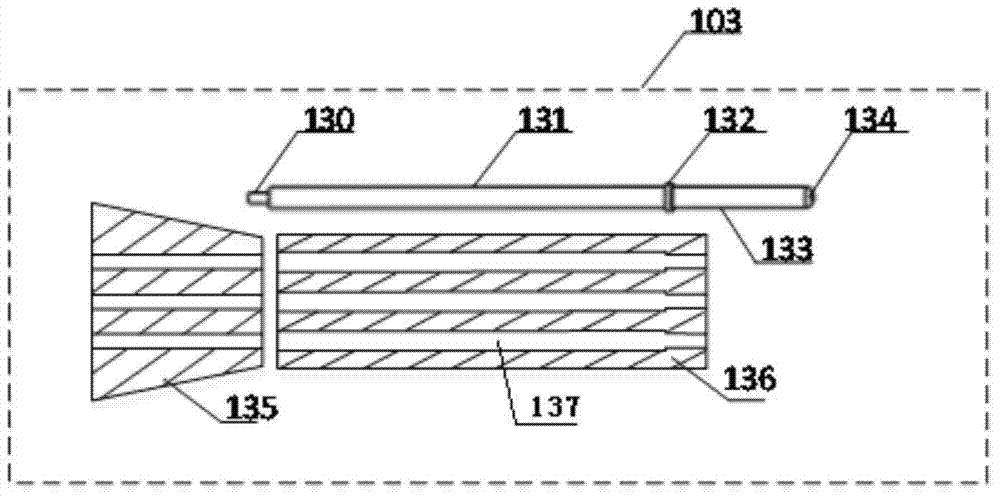

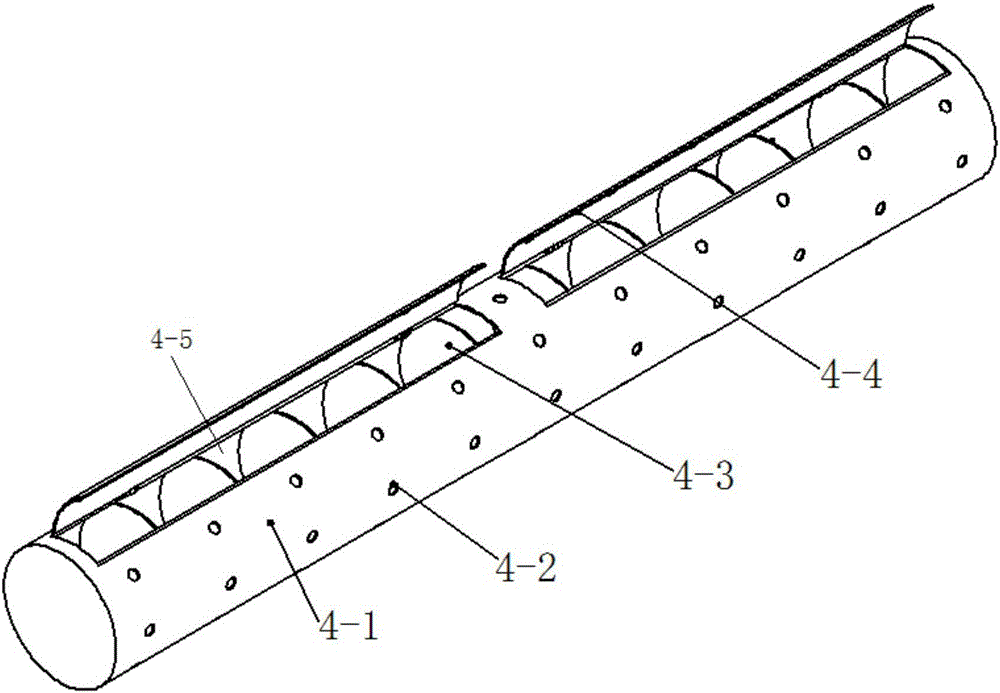

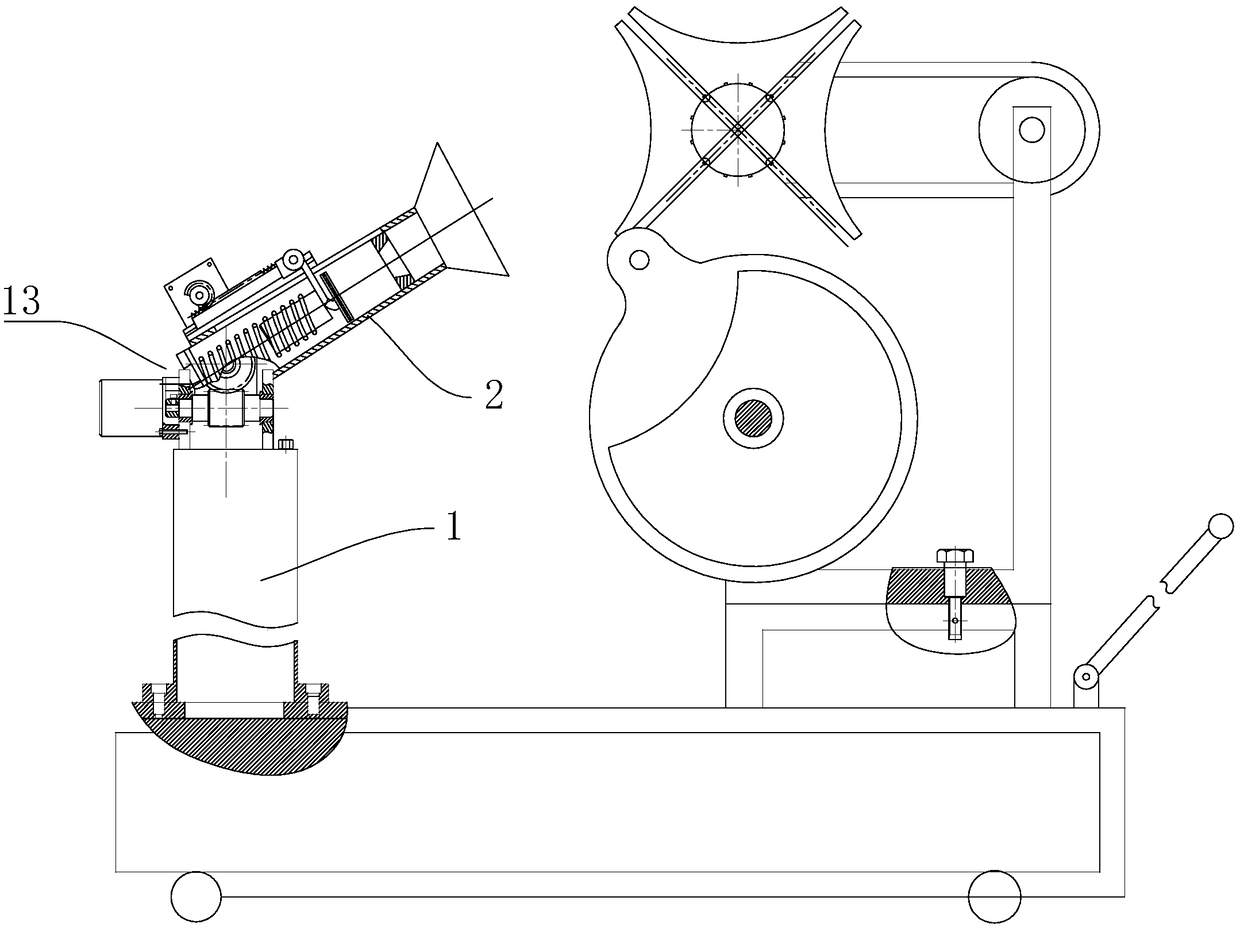

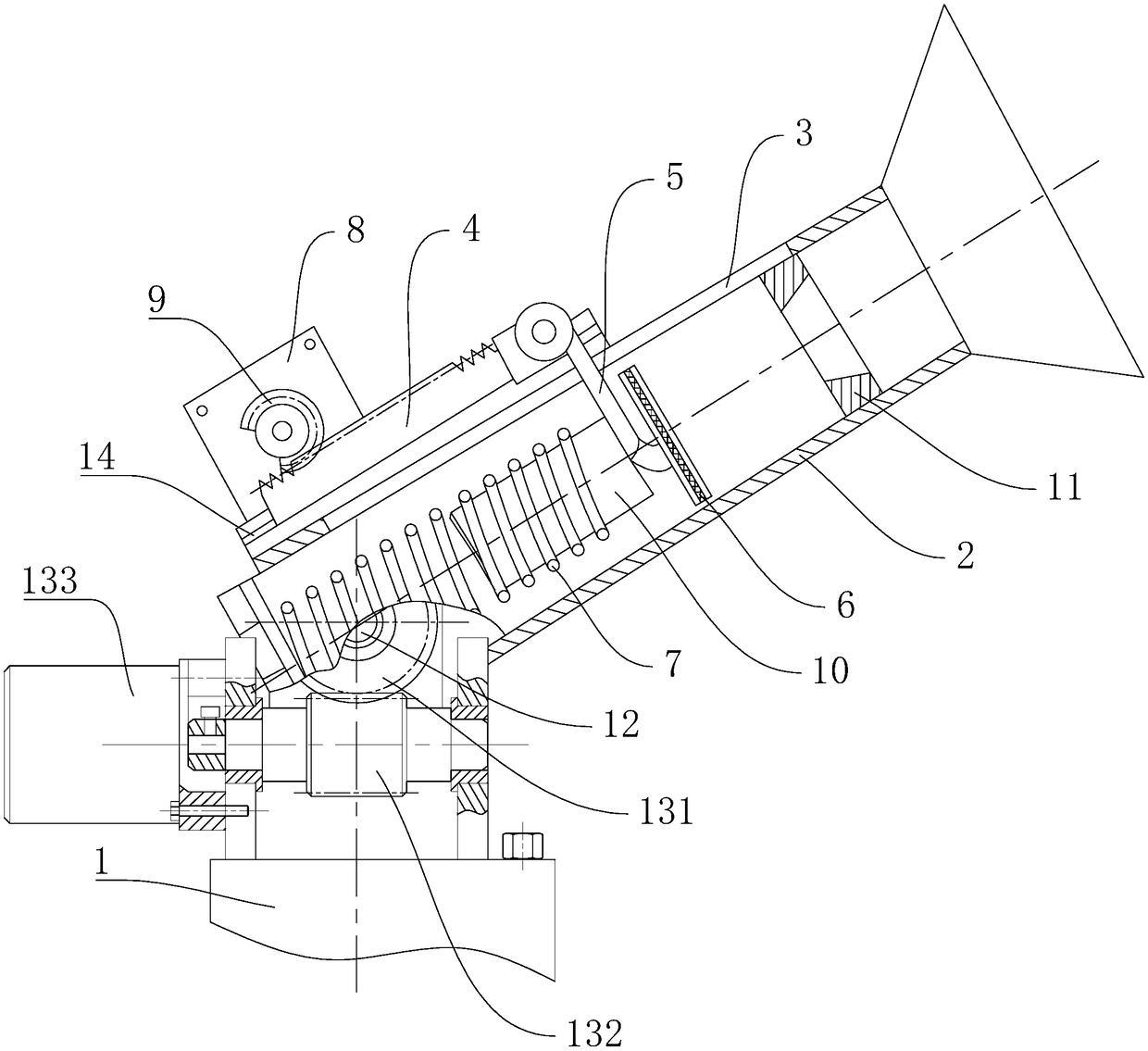

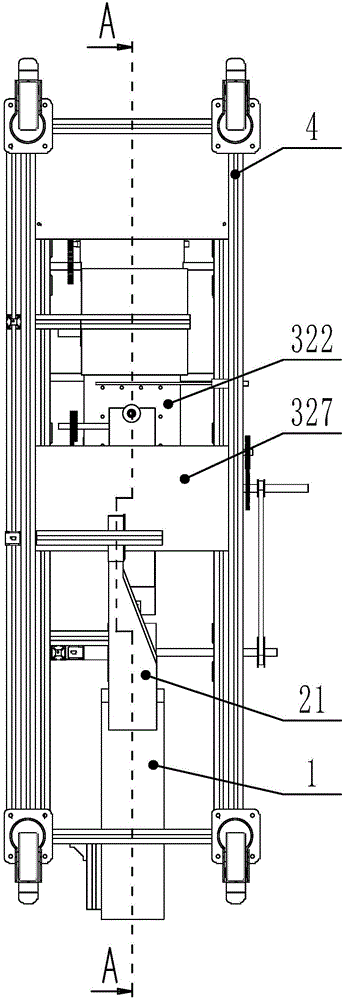

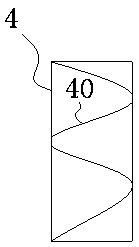

Badminton ball serving robot

InactiveCN109011501ASuitable for useSimple and reliable mechanical structureSport apparatusEngineeringRobot

The invention discloses a badminton ball serving robot. The robot comprises a machine base and a serving tube arranged on the machine base; one end of the serving tube is closed, and the outer peripheral wall of the serving tube is provided with a sliding groove which is communicated with an inner cavity of the serving tube and extends in the axial direction of the serving tube; the serving tube is provided with a rack sliding in the axial direction of the serving tube, the rack is fixedly provided with a stirring claw which penetrates through the sliding groove and is located in the inner cavity of the serving tube, the side, facing the opening end of the serving tube, of the stirring claw is fixedly provided with a racket located in the inner cavity of the serving tube, and the side, where the stirring claw is back to the racket, in the inner cavity of the serving tube is provided with a compression spring; the serving tube is fixedly provided with a first motor, and an incomplete gear which drives the rack to move a certain stroke and then is separated from the rack is arranged between the first motor and the rack. The robot has the following advantages that the mechanical structure is simple and reliable, the cost is low, and the robot is suitable for being used by beginners.

Owner:温州大学苍南研究院

Integrated note-coin separating and classifying sorter

InactiveCN105957231ANovel structurePractical and convenientCoin/currency accepting devicesEngineeringPopulation

The invention discloses an integrated note-coin separating and classifying sorter. The sorter comprises a frame, a currency inlet funnel inclined downwards, a coin classifying sorting system and a note arrangement system, wherein the coin classifying sorting system and the note arrangement system are arranged under the currency inlet funnel, and the currency inlet funnel, the coin classifying sorting system and the note arrangement system are all mounted on the frame; the coin classifying sorting system is provided with a deceleration slideway and a coin collecting and counting box successively from top to bottom, and the deceleration slideway inclines downwardly along the direction far from the coin collecting and counting box; and the note arrangement system is provided with a negative pressure note separating mechanism, a negative pressure note flattening mechanism and a note collecting box successively from the end close to the currency inlet funnel to the other end, and the note arrangement system is further provided with a note counter. Through the above structure, coins can be separated from notes, the coins of different nominal values can be collected in a classified manner, the folio notes can be flattened and counted, the integrated degree is high, the mechanical structure is simple and reliable, the sorting speed and the efficiency are high, and the practicality and population values are extremely high.

Owner:SOUTHWEST UNIVERSITY

Automatic instillation device

InactiveCN102895713ASimple and reliable mechanical structureAvoid enteringInfusion devicesFlow controlPressure.driveResource saving

The invention discloses an automatic instillation device which comprises a pipeline, wherein one end of the pipeline is used for being connected with a liquid storage bag, the other end of the pipeline is used for being connected with an instillation needle, and a liquid supply device used for supplying liquid to the pipeline in a mode of variable volume and a point pressure drive device used for driving the liquid supplying device to be changed in volume are arranged on the pipeline. According to the invention, through the arranged liquid supply device and the point pressure drive device, continuous drops can be automatically provided and are instilled into a human body through the pipeline and the instillation needle, therefore, the liquid storage bag is not needed to be suspended overhead, and a patient is favorably moved. A safety check valve is provided with a safety valve seat, and when the liquid storage bag is pressed, the matching of a valve plug and the safety valve seat in the safety check valve can prevent more liquid from entering the pipeline. The existing liquid storage bag can be adopted, during replacement, the pipeline and the liquid supply pipeline are only discarded, and residual parts can be recycled, therefore, the automatic instillation device is beneficial to resource saving, is simple and reliable in mechanical structure, and is low in manufacture cost.

Owner:FIRST CLINICAL MEDICAL SCI COLLEGE OF CHINA THREE GORGES UNIV

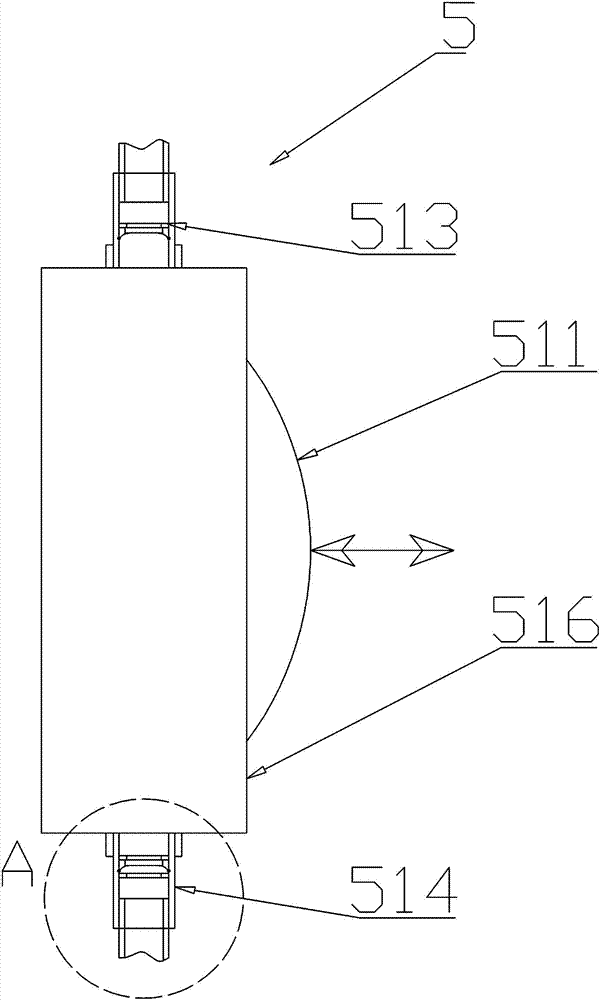

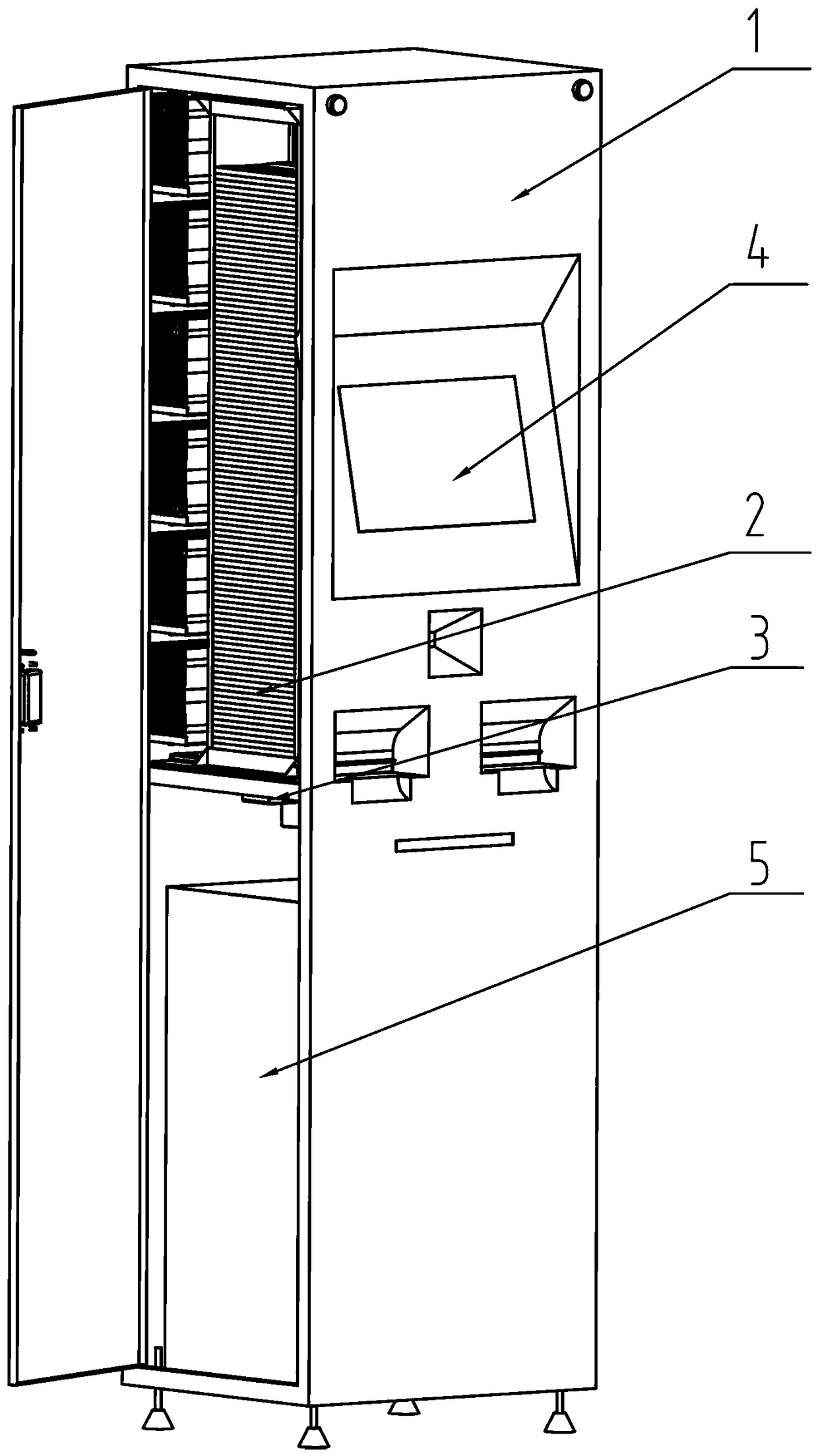

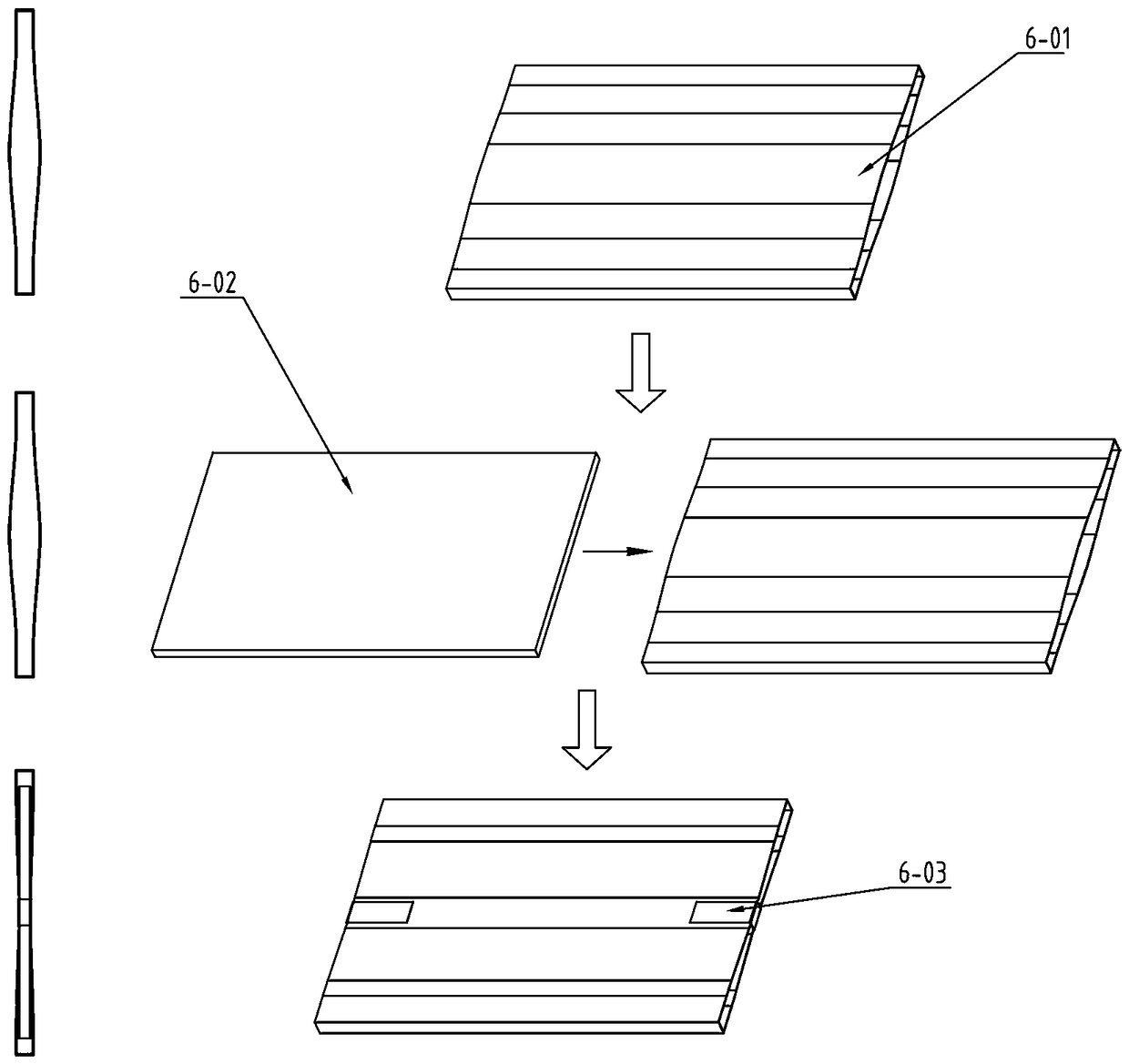

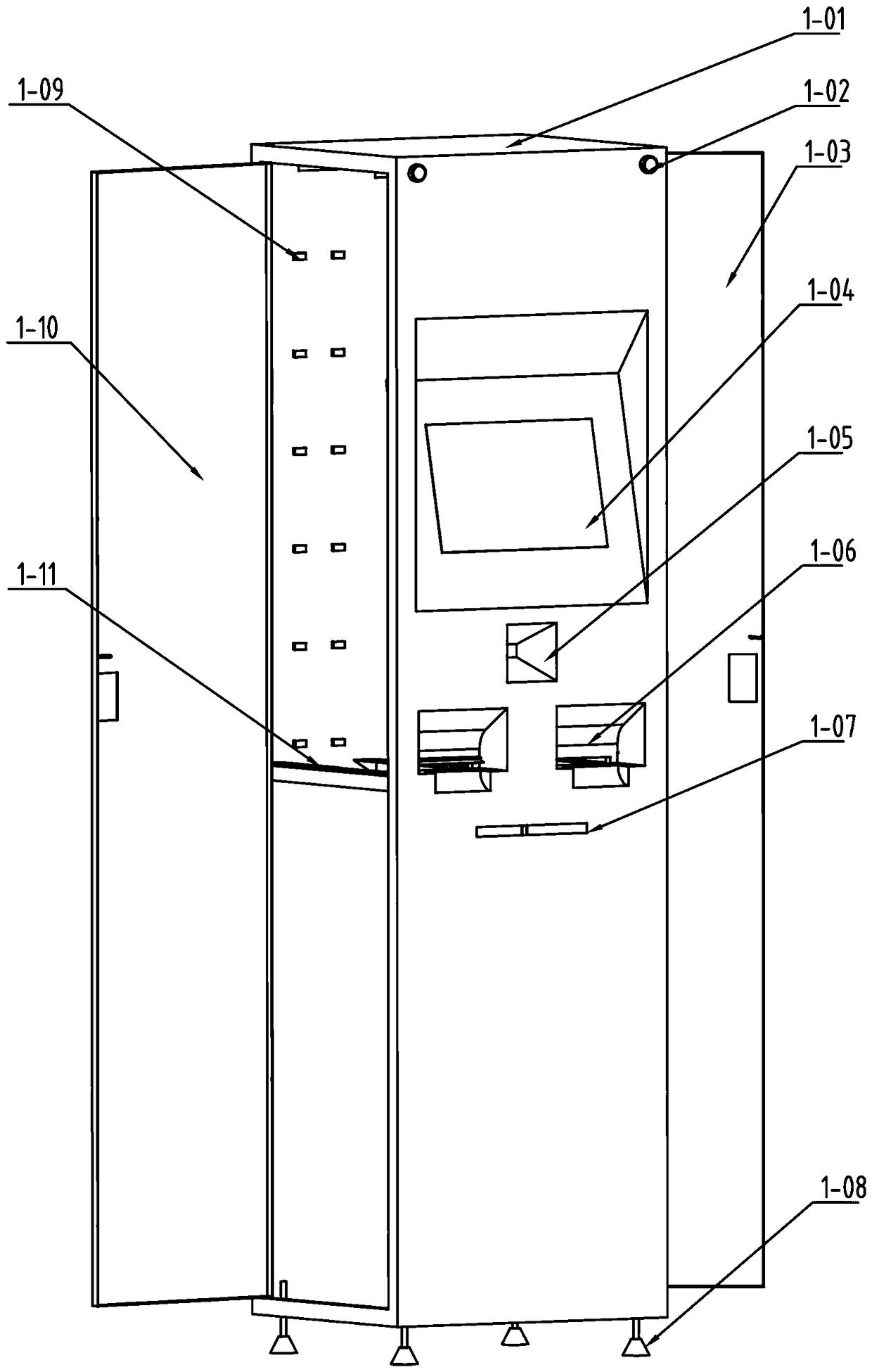

Vertical type disposable raincoat vending machine

PendingCN108550221ASimple and reliable mechanical structureSimple and reliable mechanical structure designAcutation objectsCoin-freed apparatus detailsControl systemSpare time

The invention discloses a vertical type disposable raincoat vending machine. The machine comprises a machine box, storage chambers, pushing mechanisms, a material recovery bucket and a control system,the machine box is made from metal sheet materials and is of a vertical type cuboid structure, and the storage chambers, the pushing mechanisms, the material recovery bucket and the control system are arranged inside the machine box; materials are stacked in a material feeding chamber which feeds materials downward under the gravity effect, the pushing mechanisms comprise slider-crank mechanismsand self-springback material stopping anti-theft mechanisms which are driven by the same plane cam, the slider-crank mechanisms are used for pushing materials, and the self-springback material stopping anti-theft mechanisms are used for stopping the materials and preventing theft during the spare time; the whole pushing mechanisms are arranged below the material feeding chamber, two pairs of storage chambers and two pairs of pushing mechanisms are symmetrically arranged left and right in the machine box to achieve the selling of disposable raincoats of two types, and a the material recovery bucket is arranged at the lower portion inside the machine box and is used for recovering the materials; the control system is used for controlling the whole vending machine to operate and is in communication with a back-end server to achieve remote monitoring, and a purchaser can buy the disposable raincoat by scanning the two-dimensional code on the vending machine or using the APP in the phone.

Owner:陈治金

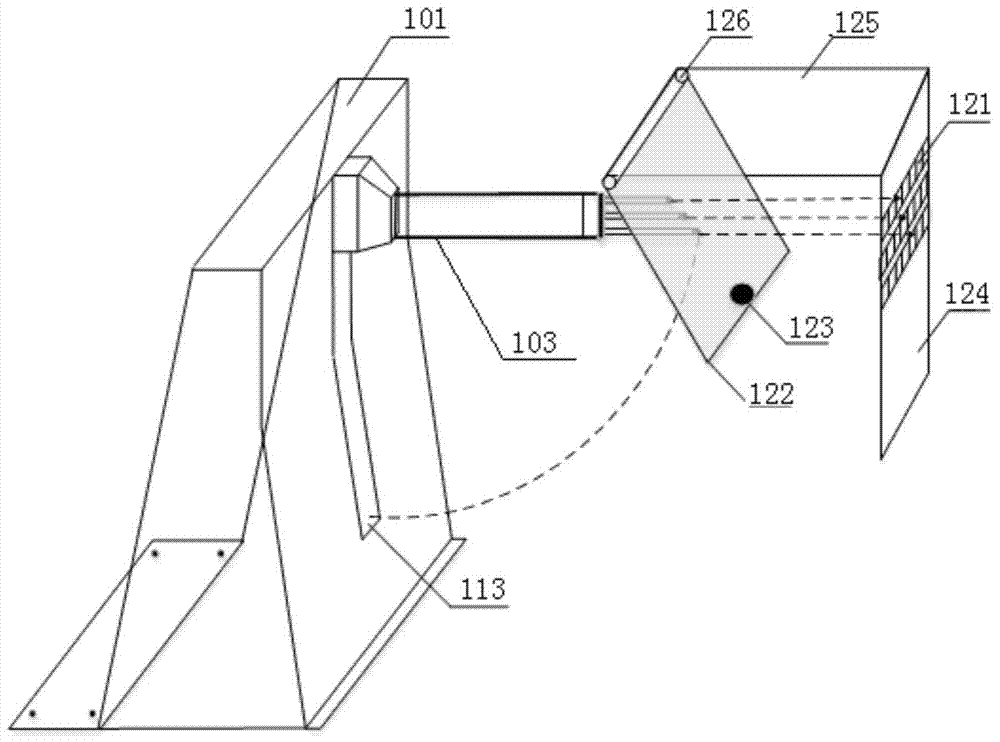

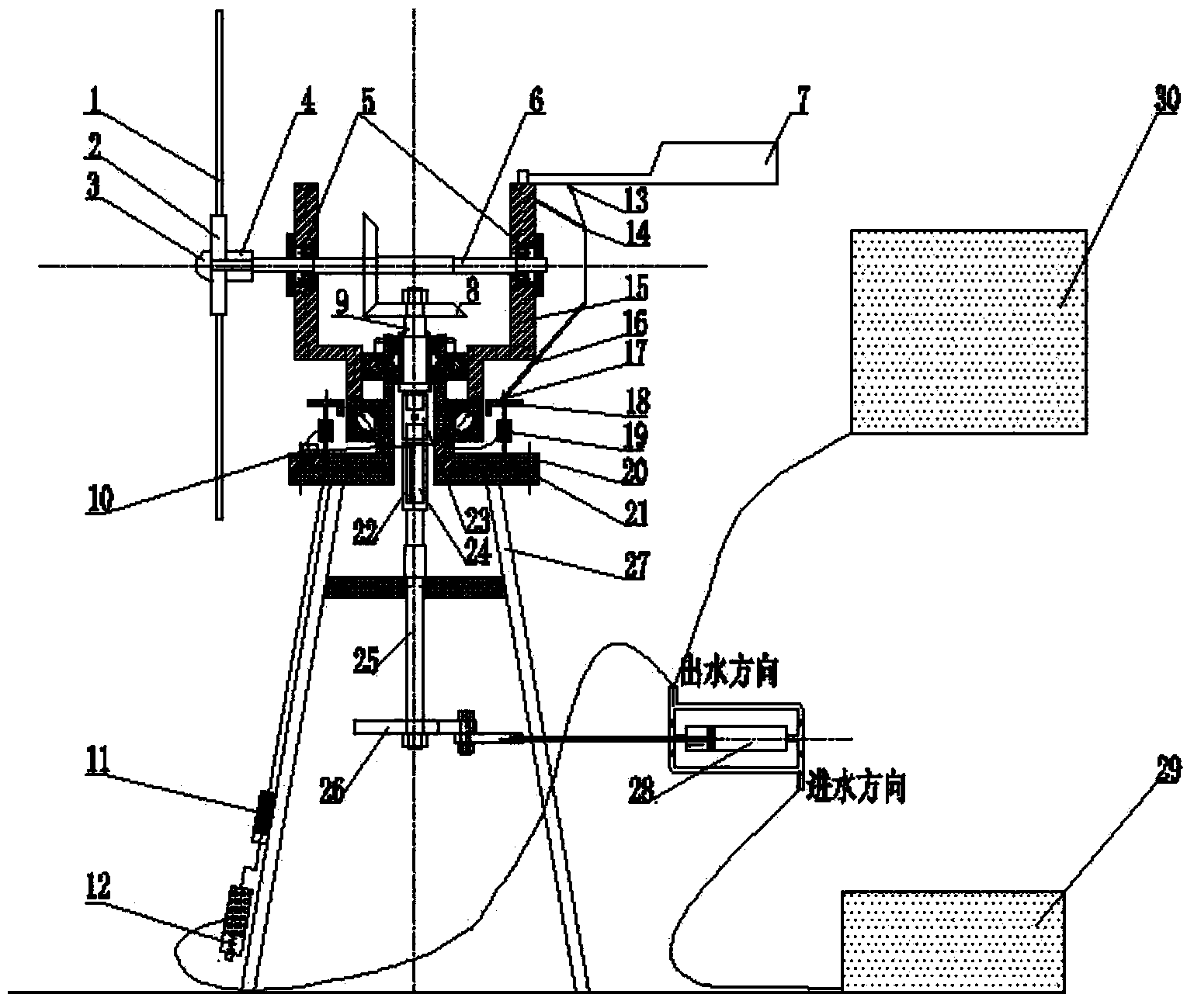

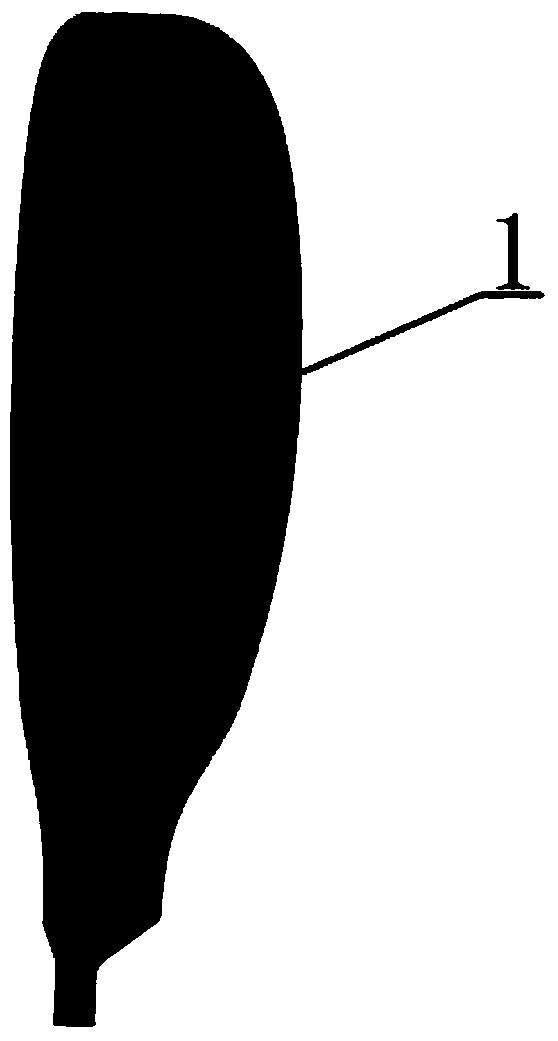

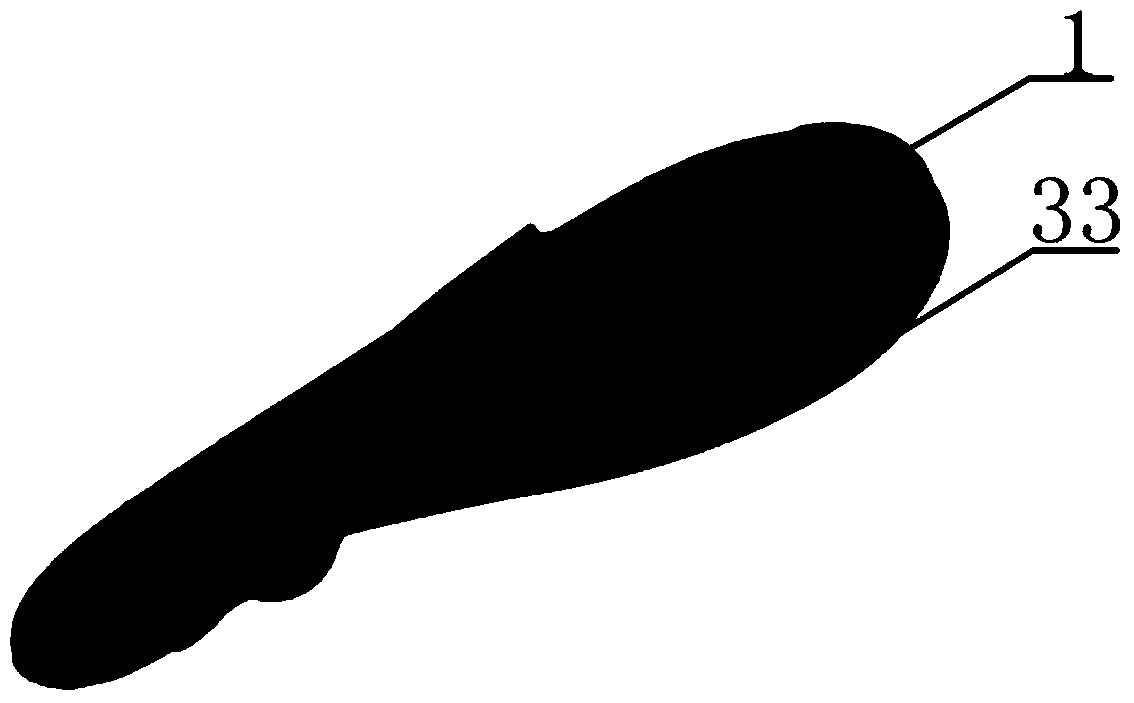

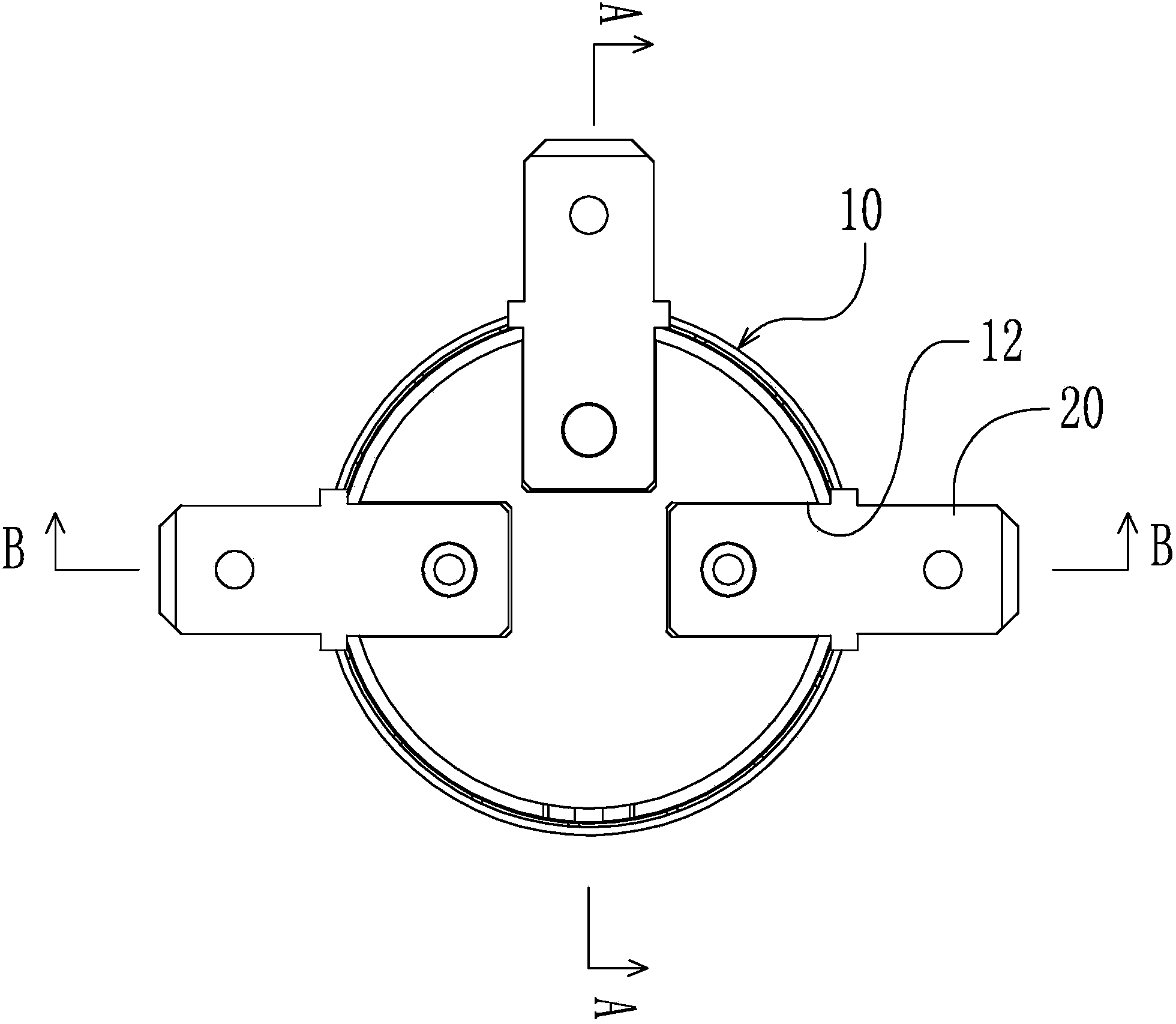

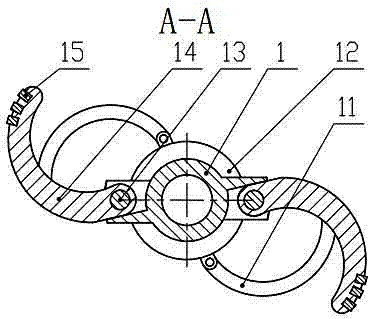

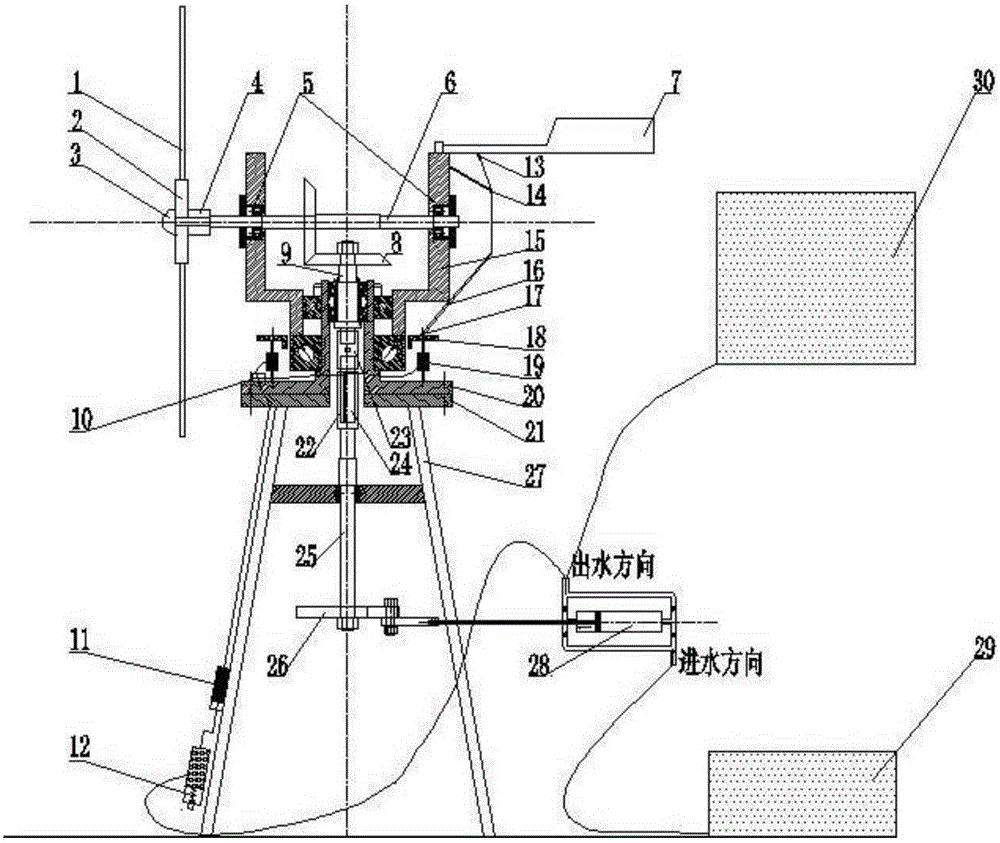

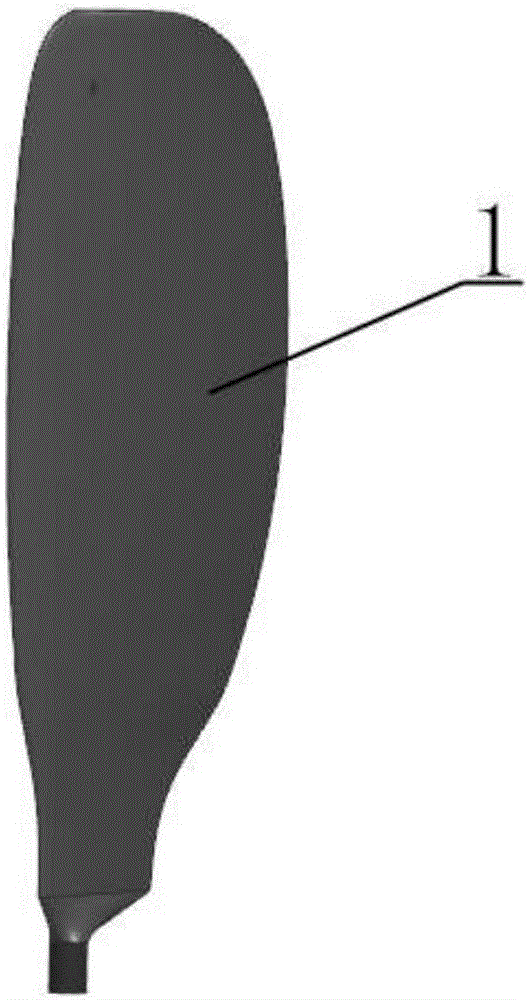

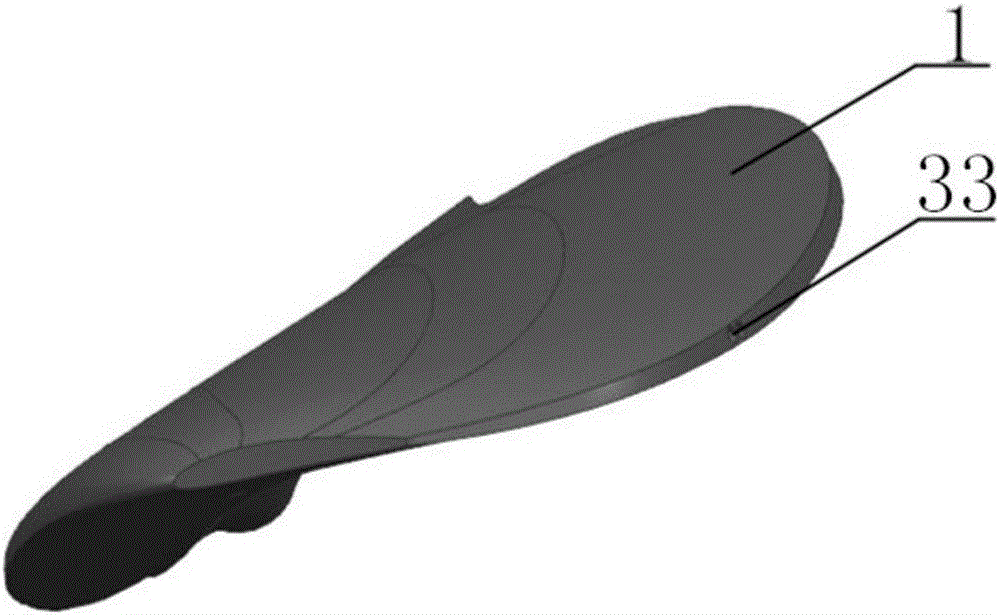

Self-protection wind-driven water lifting system with accelerating vanes

InactiveCN104343626AImprove aerodynamic performanceMany solutionsWind motor controlWind motor combinationsWind drivenLow speed

The invention relates to a self-protection wind-driven water lifting system with accelerating vanes. The self-protection wind-driven water lifting system comprises a water lifting mechanism directly driven by a wind power transmission mechanism and is characterized in that the cross sections of the vanes adopt NACA series wing sections, the streamline accelerating vanes are started at a low wind speed and output high torques, the vanes comprise low-speed vane tips and large-torsion vane roots and are divided into twenty cross sections from the vane roots to the vane tips for setting mounting angles, and the cross sections are in smooth transition with each other; a water outlet of a water pump of the water lifting mechanism is connected with a water-out pressure regulating cylinder of a hydraulic speed regulating mechanism. The problems of the traditional wind-driven water lifting system, such as large vane number and low wind energy utilizing rate are solved. The hydraulic speed regulating mechanism is driven to act through the skillful utilization of the water pressure of the water outlet of the water pump under large wind power, the wind power transmission mechanism is controlled to timely respond to yaw, and the purpose of automatically protecting system units is achieved. The self-protection wind-driven water lifting system is suitable for the farmland irrigating application of remote areas lack of electricity resources.

Owner:HOHAI UNIV +1

Spring-type power failure restoration temperature control switch capable of controlling multiple load circuits

InactiveCN104217895AImprove efficiencyRapid responseThermal switch detailsTemperature controlLoad circuit

Disclosed is a spring-type power failure restoration temperature control switch capable of controlling multiple load circuits. The temperature control switch comprises a metal shell, multiple connection terminals and a metal end cap fixed to the metal shell, a ceramic guide frame heating element arranged between the metal end cap and the metal shell, a ceramic push rod movably and penetratingly arranged on the ceramic guide frame heating element, a bimetallic strip in contact with the ceramic push rod, a movable spring provided with a movable contact, a static contact piece provided with a static contact and a lower contact. When the temperature of loads reaches a set value, the bimetallic strip is heated to kick, and the movable contact and the static contact are separated to open the circuits. The other side of the movable contact is connected with the lower contact in a closed manner, and the ceramic guide frame heating element is energized to emit heat so as to enable the bimetallic strip and the temperature control switch circuit to be kept under the disconnected state. The bimetallic strip can restore only by deenergization so as to enable the temperature control switch circuit to be closed, and the ceramic guide frame heating element circuit is opened.

Owner:DONGGUAN KAIN ELECTRONICS SCI & TECH CO LTD

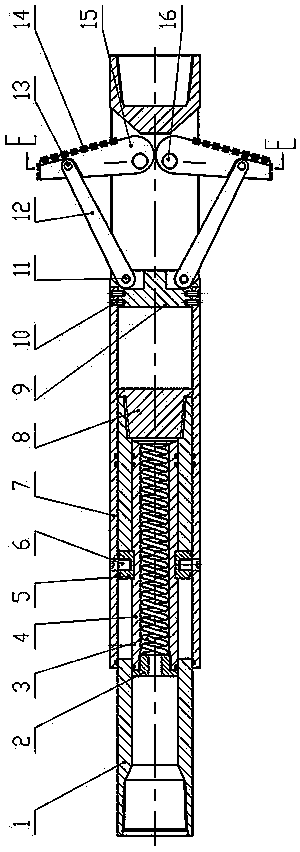

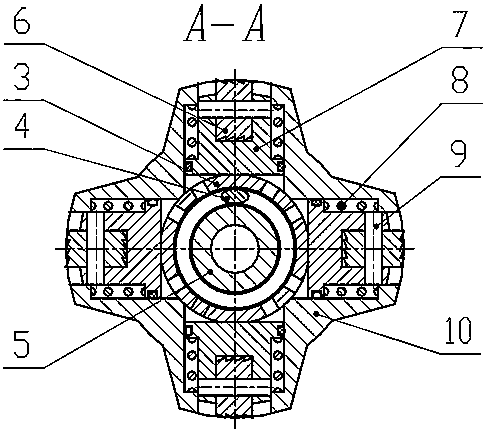

Telescopic type tool face stabilizer

InactiveCN106939767APrevent deviationEasy to operateDrilling rodsDirectional drillingTorsional deformationSteel ball

The invention relates to a telescopic type tool face stabilizer which is used in drilling engineering to prevent off tracking of a drilling tool face due to torsional deformation of a drilling column, and solves the problems that the tool face is difficult to stabilize and easy to off track due to the torsional deformation of the drilling column. The technical scheme is that rollers are mounted in blind holes of roller seats and rectangular through holes of roller covers; three steel balls are arranged in arc-shaped grooves in the middle part of the outer side of each roller; the upper ends of the roller seats are in screwed connection with the roller covers; connection plates and the two overall roller seats form a group; five groups of the connection plates and the overall roller seats are arranged in step through holes and middle sunken slots of five straightening ribs of a stable shell; two reset springs are mounted on the connection plates; a pressure plate is connected with the stable shell through a screw; a closed cavity among a mandrel, the stable shell and the roller seats is filled with hydraulic oil. The telescopic type tool face stabilizer can effectively stabilize the drilling tool face and prevent the off tracking of the drilling tool face due to the torsional deformation of the drilling column, cannot interfere with axial feeding of the drilling column, and improves the precision of a rotatable guide technology.

Owner:SOUTHWEST PETROLEUM UNIV

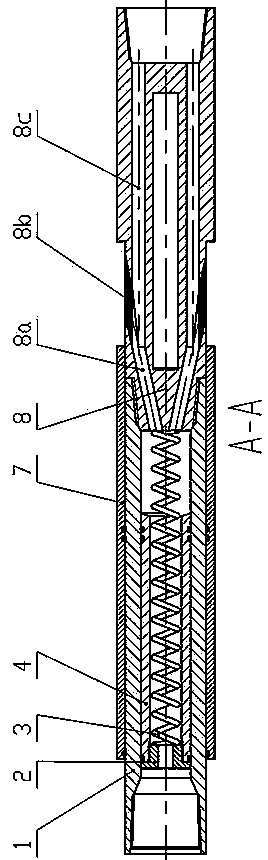

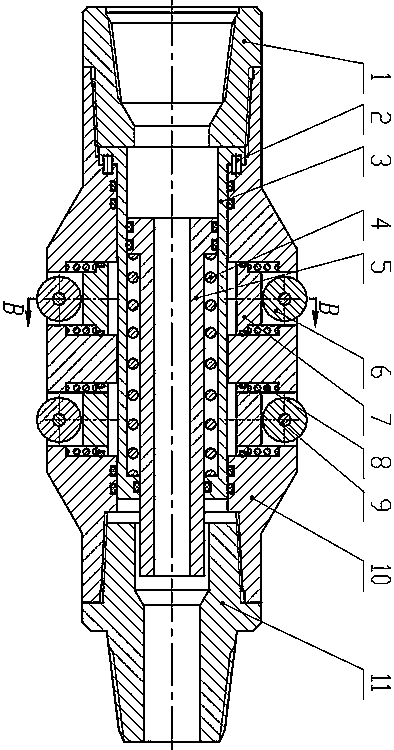

Roller-type drilling tool surface stabilizer

InactiveCN108222858APrevent deviationDoes not hinder axial feedDrilling rodsDrilling casingsUpper jointEngineering

The invention relates to a roller-type drilling tool surface stabilizer for preventing torsion deviation of a drill stem in drilling engineering of the oil and gas industry. The problems that the drill stem is torsionally deformed during the drilling process and the drilling tool surface is difficult to stabilize are solved. According to the technical scheme, rollers are installed in grooves in the upper parts of pistons, wheel shafts penetrate through holes in the centers of the rollers and through holes in the upper parts of the pistons, and piston springs are mounted on convex steps at thelower ends of the pistons; the pistons and the piston springs are arranged in stepped holes of centralizer wings of an outer casing, and the piston springs are in a compressed state; a liner tube is arranged in an inner cavity of the outer casing, and a main spring is mounted on the convex inner edge of the lower end of the liner tube; the upper end of the outer casing is in screwed connection with the lower end of an upper joint, and the lower end of the outer casing is in screwed connection with the upper end of a lower joint; and a central tube, the liner tube, the outer casing and the pistons form closed space filled with hydraulic oil. The roller-type drilling tool surface stabilizer can effectively stabilize the drilling tool surface, the deviation of the drilling tool surface due totorsion deformation of the drill stem is prevented, and the drilling quality of the rotary guiding technology is improved.

Owner:SOUTHWEST PETROLEUM UNIV

Ball screw executing mechanism driven by electric automobile parking P-gear servo motor

The invention discloses a ball screw executing mechanism driven by an electric automobile parking P-gear servo motor. The ball screw executing mechanism comprises a cylinder cover, wherein a ratchet wheel, a pawl and a transmission assembly are arranged in the cylinder cover; the rotatable pawl is returned through a torsion spring; the transmission assembly is connected with a P-gear servo motor; the engagement and the separation of the front end of the pawl and the ratchet wheel are realized through the transmission assembly; the transmission assembly consists of a ball screw, a guide nut, a compression spring, a bevel driving sleeve and a guide sleeve; the compression spring, the bevel driving sleeve and the guide sleeve can be pushed by the guide nut to axially slide along the ball screw; when the bevel driving sleeve and the tail end of the pawl are self-locked through a bevel fit manner, the front end of the pawl and the ratchet wheel are meshed; and after the bevel driving sleeve is separated from the tail end of the pawl, the separation of the front end of the pawl and the ratchet wheel is realized. The ball screw executing mechanism disclosed by the invention has the advantages that the mechanical structure is simple and reliable; the mechanical transmission route is short and convenient to use; the ball screw executing mechanism has a good braking and self-locking effect for an electric automobile; the parking reliability of the electric automobile can be greatly improved; and intelligent control is realized.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

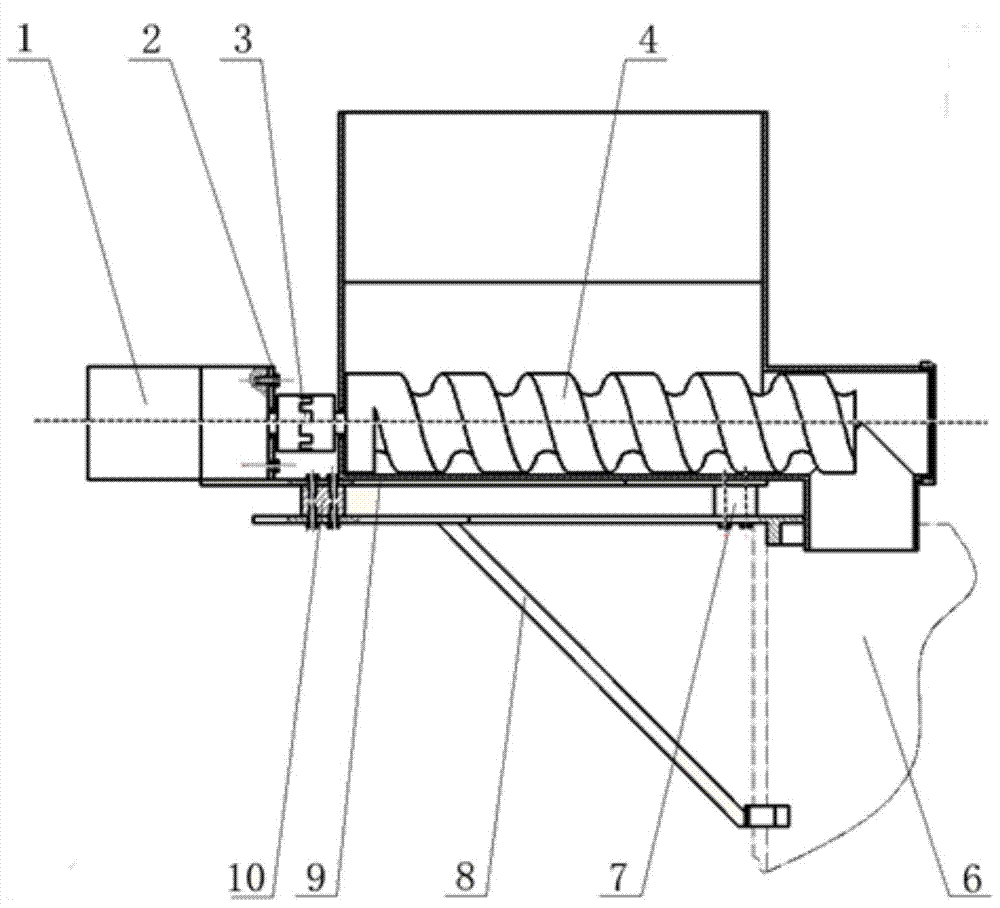

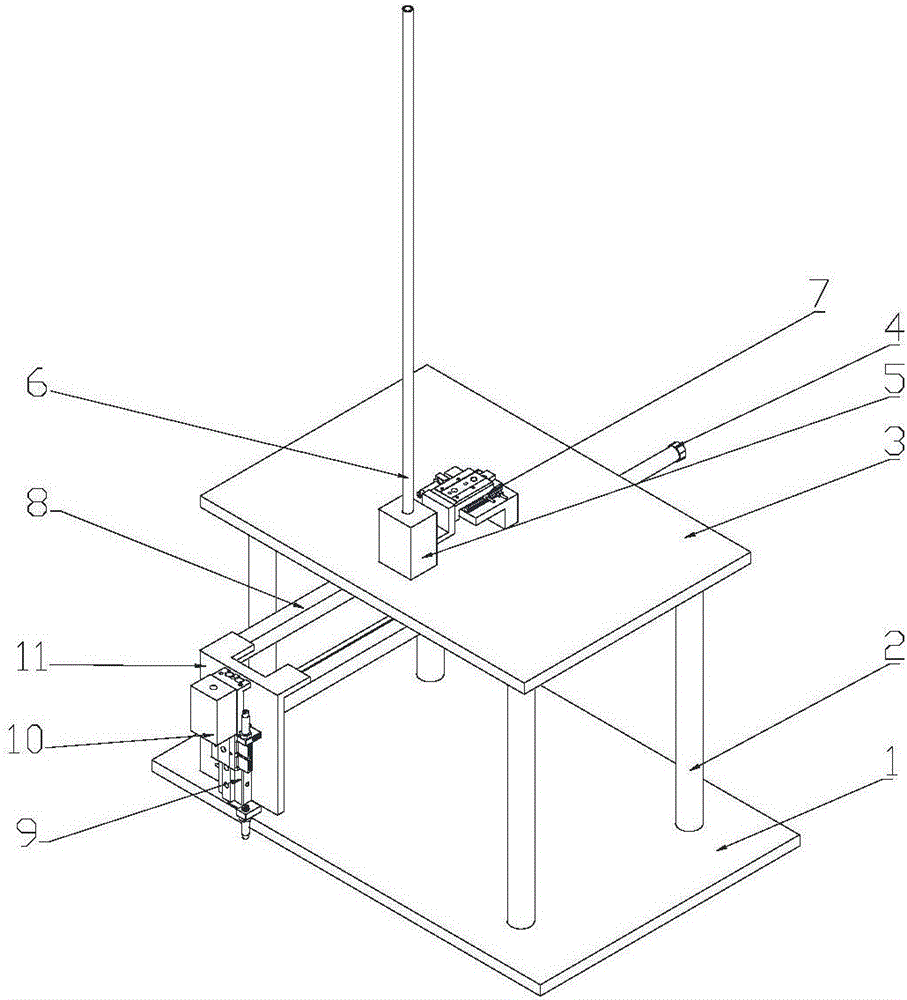

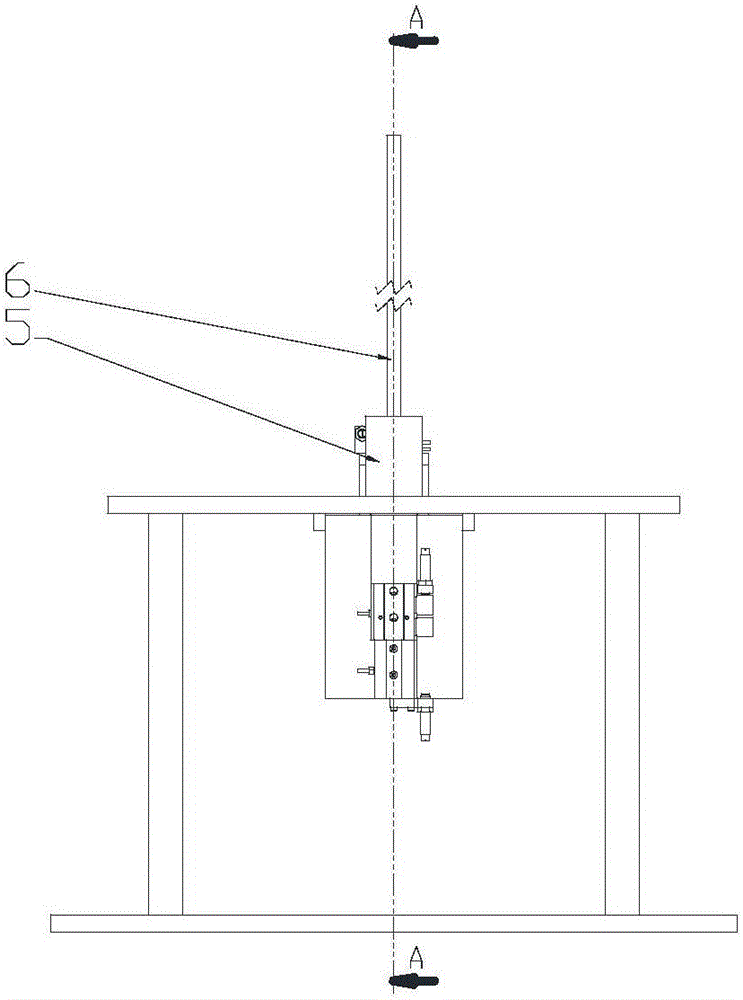

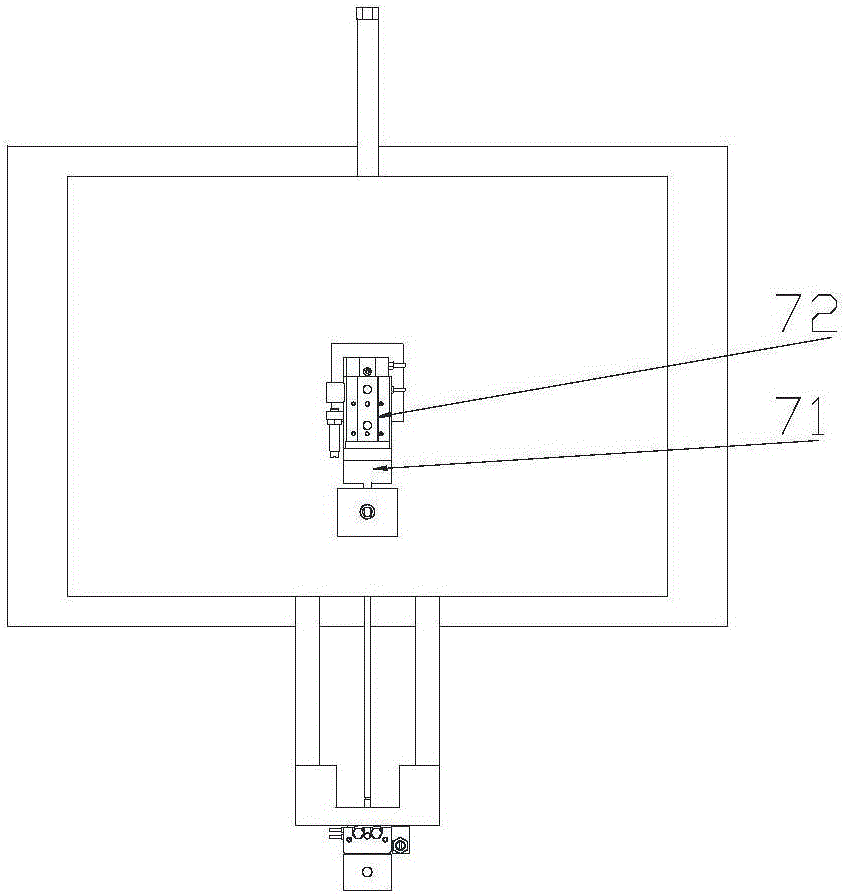

Membrane type gas meter vertical shaft feeding device

ActiveCN105775713ASimple and reliable mechanical structureAccurate feedingConveyor partsMembrane configurationGas meter

The invention provides a membrane type gas meter vertical shaft feeding device. The feeding device comprises a base plate provided with stand columns, and the upper ends of the stand columns are provided with a top plate; a discharging base and a vertical shaft compression mechanism are arranged above the top plate; a discharging pipe is arranged on the discharging base; a linear guideway and an air cylinder are arranged below the top plate, a sliding block is arranged on the linear guideway and fixed to the lower surface of the top plate, a connecting block is arranged at one end, provided with a guide rail, of the linear guideway, the fixed end of the air cylinder is fixed to the top plate, and the stretchable end of the air cylinder is connected with the guide rail and drives the guide rail to slide relative to the sliding block; a pneumatic sliding table is installed on a vertical face of the connecting block, a material receiving block is arranged on a sliding part of the pneumatic sliding table, and a material receiving hole is formed in the material receiving block; and a first material passing hole and a transverse groove communicated with the first discharging hole are formed in the discharging base, and the transverse groove is matched with a pressing head arranged on the vertical shaft compression mechanism. By means of the feeding device, a reliable mechanical structure is used, manpower can be replaced, and rapid and accurate feeding of a vertical shaft is completed.

Owner:滁州市中诺设备模具制造有限公司

Fruit peeler

PendingCN107822159AClean thoroughlySimple and reliable mechanical structureVegetable peelingFood treatmentElectric machineryEngineering

The invention provides a fruit peeler capable of cleaning and removing surface fragments of fruits and helps process the fruits on a full-automatic line. The fruit peeler comprises a feed passage, a peeling roller and a discharge passage and is characterized in that the discharge passage is connected with the upper end of a cleaning duct through a ball bearing, the inner wall of the discharge passage is connected with a spray pipe that faces the cleaning duct, the lower end of the cleaning duct is connected with an outgoing passage through a ball bearing, the bottom of the outgoing passage iscommunicated with a separation passage, the outer wall of the cleaning duct is connected with a motor through a transmission belt, the inner wall of the cleaning duct is provided with a brush, the separation passage is inclined and is composed of a plurality of connection rods in length direction, and a hollow portion allowing cleaning fragments to drop is formed between every two connection rods.

Owner:广东嘉能可食品有限公司

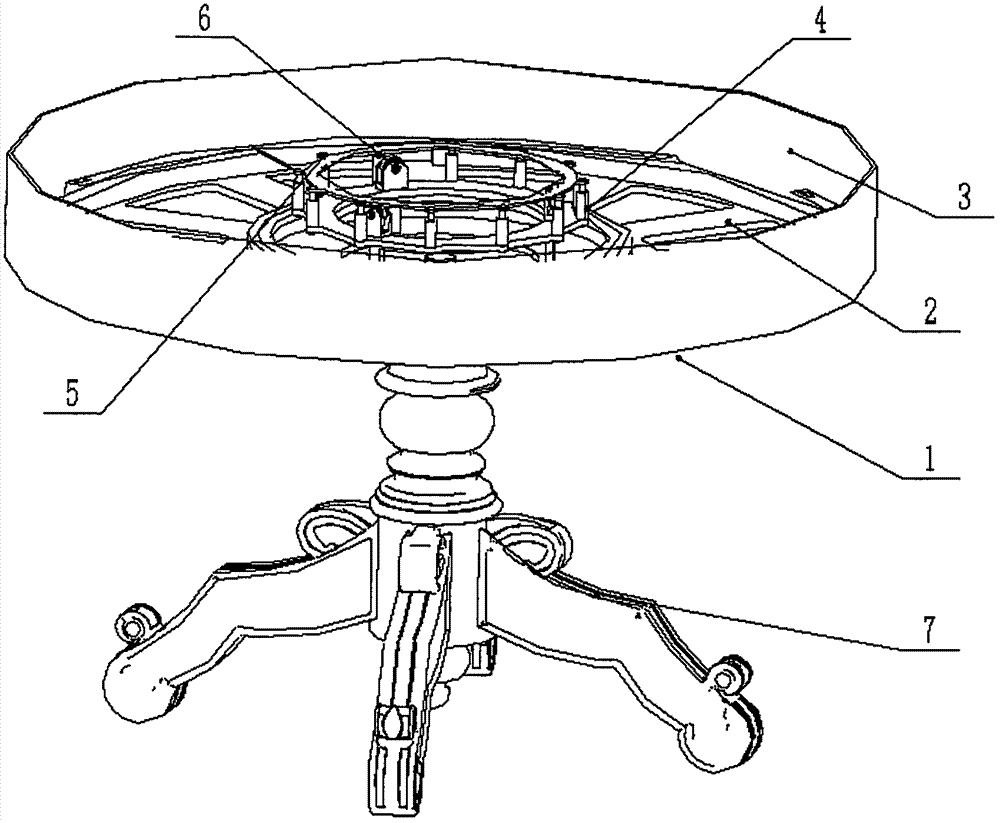

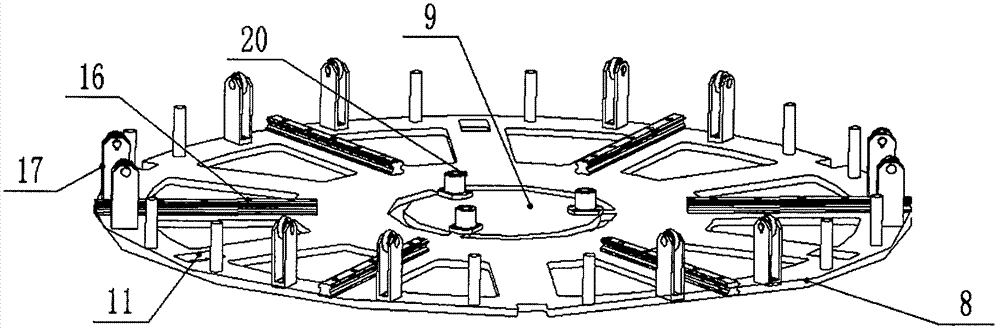

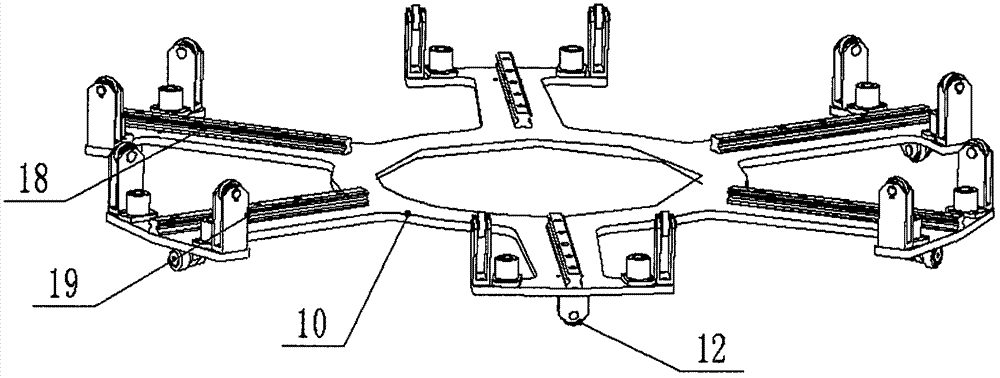

Novel winch-type rotary foldable dining-table

InactiveCN107048726ASimple and reliable mechanical structureLow costServing tablesRevolvable tablesWinchMechanism based

The invention discloses a novel winch-type rotary foldable dining-table. The novel winch-type rotary foldable dining-table comprises a rotary mechanism base, a fan-shaped table top, a fan-shaped table top tray, a V-shaped table top, a V-shaped table top tray, a star-shaped table top, a star-shaped table top tray and table legs, wherein the rotary mechanism base is a housing consisting of a circular support frame and a circular side edge; a support ring is fixed right in the middle of the circular support frame through support rods; three support rollers with the same size are mounted in the support ring; the rotational directions of the support rollers are consistent with the tangential direction of the largest diameter; and the table legs are mounted at the bottom of the rotary mechanism base. The novel winch-type rotary foldable dining-table has the advantages that the mechanical structure is simple and reliable, the cost is lowered and the operation is simple and convenient. Folding cannot be realized until 120-degree rotation is performed in the prior art, while the novel winch-type rotary foldable dining-table can be folded through only 100-degree rotation, so that both time and labor are saved.

Owner:张坤龙

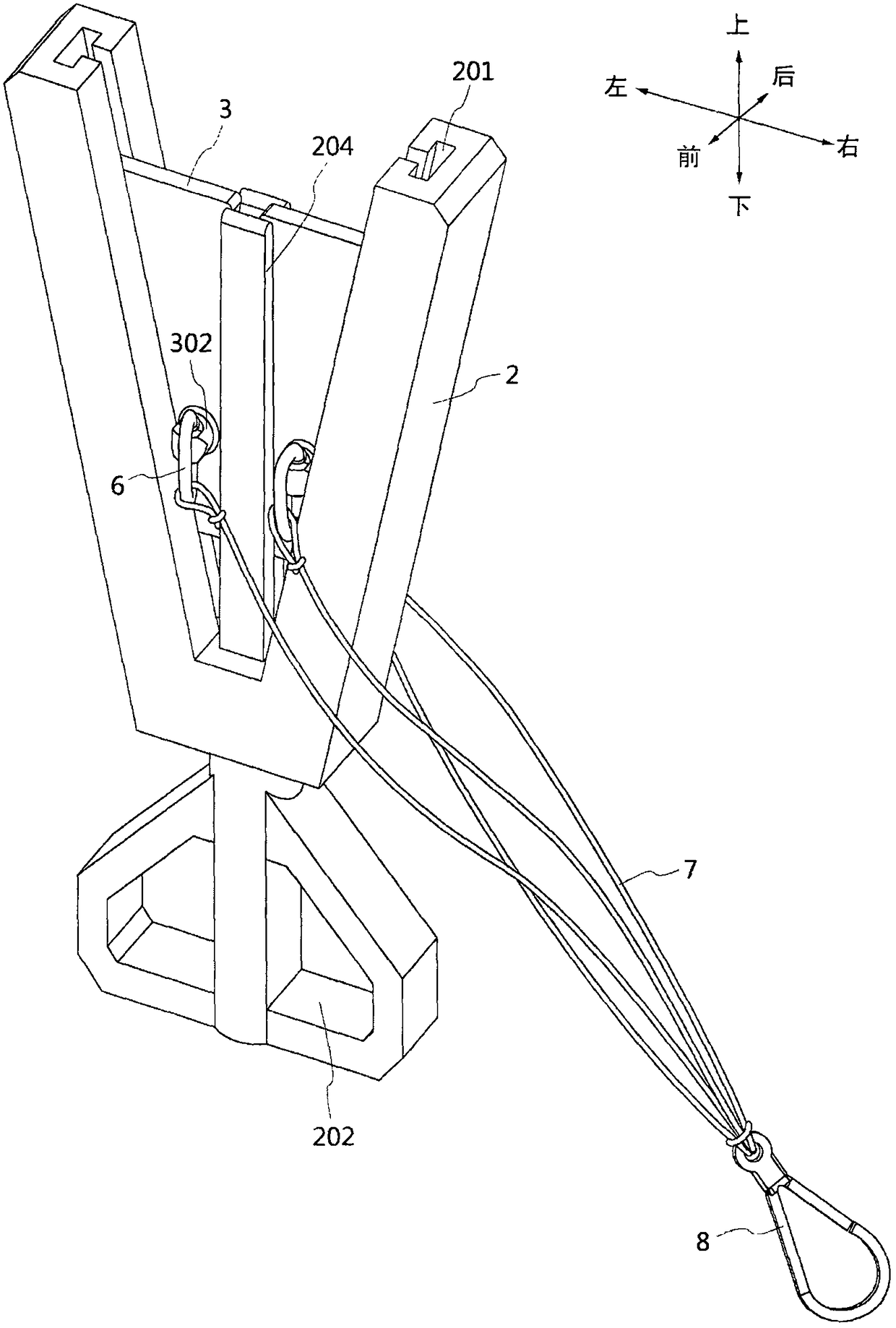

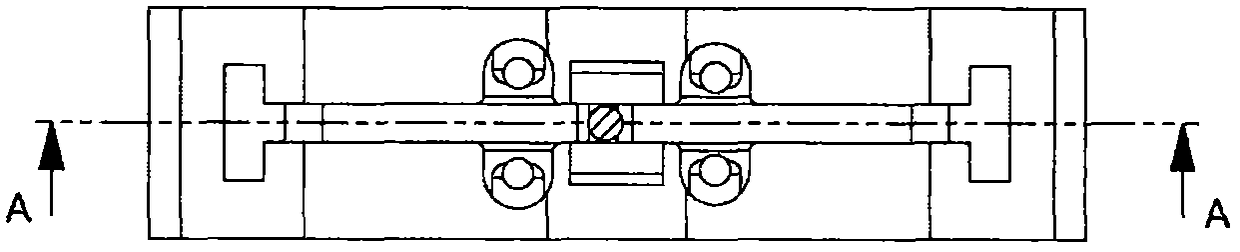

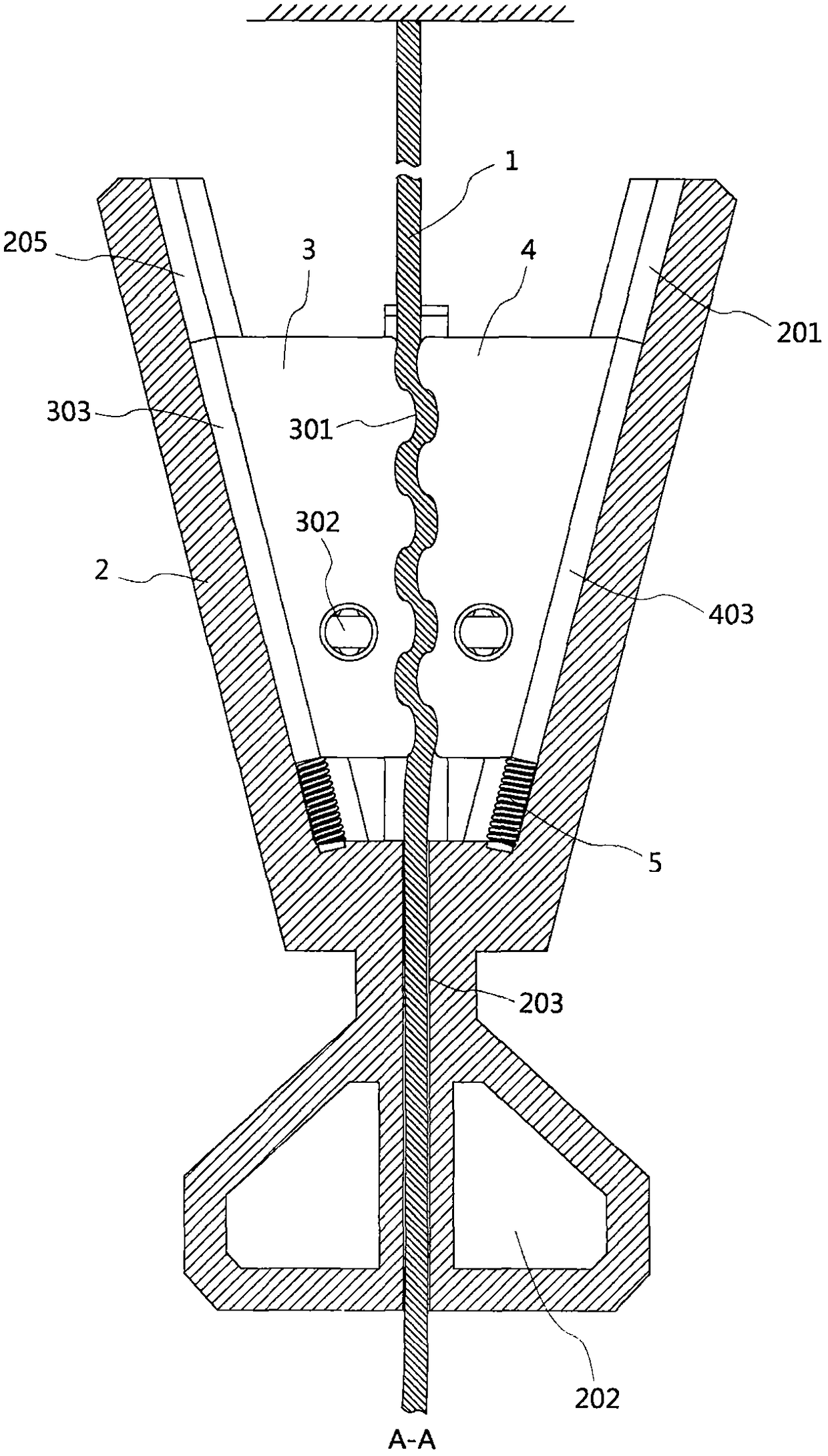

Rope slow descending device

PendingCN108704223ASimple operation logicSimple and reliable mechanical structureBuilding rescueEngineeringAxis of symmetry

The invention relates to the field of security and protection, in particular to a rope slow descending device. The rope slow descending device comprises a base body, a left movable portion, a right movable portion, a force bearing rope and elastic bodies; the base body is of a V-shaped structure and comprises a left sliding groove and a right sliding groove which are mutually symmetric with the V-shaped center line of the base body as the axis of symmetry; guide slide blocks are arranged on the left movable portion and the right movable portion; the guide slide block of the left movable portion is installed in the left sliding groove of the base body and is connected with the base body through the corresponding elastic body; and the guide slide block of the right movable portion is installed in the right sliding groove of the base body and connected with the base body through the corresponding elastic body. Operation is logic and simple, the mechanical structure is reliable, stress concentration of a slowly descending rope is not likely to be generated, the highest descending speed can be restrained by the mechanical structure features, glide being close to a free falling body doesnot occur, and the rope slow descending device is a reliable high-rise escape device.

Owner:INNER MONGOLIA UNIV OF TECH

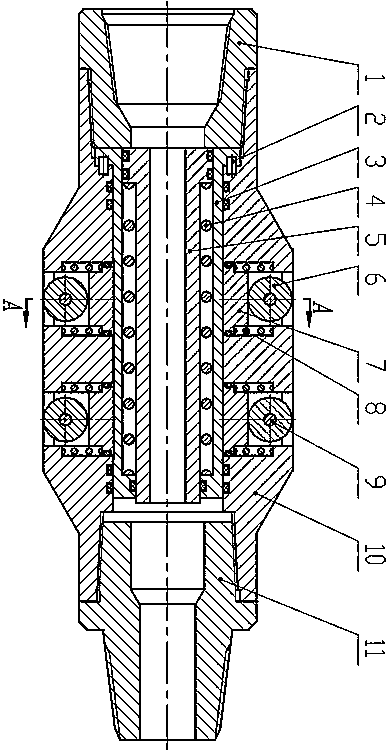

Large changing diameter double-drag-blade hole reaming drill

InactiveCN103556950BWide range of variable diameterSmall starting forceDrill bitsThrust bearingEngineering

The invention relates to a large changing diameter double-drag-blade hole reaming drill for deep stratum mineral exploitation and oil gas well underground hole reaming, and solves the problem that a conventional drill cannot change diameter, or the diameter changing range is too small. The technical scheme is that a main cylinder body is in screw thread connection with a lower joint; two drag blades are hinged to hinge supports of the main cylinder body through pin bolts; a rotary cylinder body is sleeved in the main cylinder body; an outer central pipe is sleeved in the main cylinder body; bulge splines at the outer part of the outer central pipe are embedded into a screw groove in the inner part of the rotary cylinder body; three sliding blocks respectively penetrate through three through grooves of the main cylinder body, and are embedded in a ring-shaped groove in the outer part of an inner central pipe; the outer central pipe is connected with the sliding blocks through bolts; the upper part of the inner central pipe is in screw thread connection with a water nozzle; a thrust bearing a is sleeved in the outer central pipe, and is contacted with the rotary cylinder body; a reset spring is mounted on the upper end surface of the thrust bearing a; a baffle ring is in screw thread connection with the outer central pipe; one ends of arch connecting rods are hinged to the rotary cylinder body, and the other ends of the arch connecting rods are hinged to the drag blades; cutting teeth are embedded on the drag blades. The drill is large in diameter changing range, simple to control and reliable in structure, and can be used for the hole reaming operation.

Owner:SOUTHWEST PETROLEUM UNIV

A self-protected wind-powered water-lifting system with speed-increasing blades

InactiveCN104343626BImprove aerodynamic performanceLow start wind speedWind motor controlWind motor combinationsWind drivenLow speed

The invention relates to a self-protection wind-driven water lifting system with accelerating vanes. The self-protection wind-driven water lifting system comprises a water lifting mechanism directly driven by a wind power transmission mechanism and is characterized in that the cross sections of the vanes adopt NACA series wing sections, the streamline accelerating vanes are started at a low wind speed and output high torques, the vanes comprise low-speed vane tips and large-torsion vane roots and are divided into twenty cross sections from the vane roots to the vane tips for setting mounting angles, and the cross sections are in smooth transition with each other; a water outlet of a water pump of the water lifting mechanism is connected with a water-out pressure regulating cylinder of a hydraulic speed regulating mechanism. The problems of the traditional wind-driven water lifting system, such as large vane number and low wind energy utilizing rate are solved. The hydraulic speed regulating mechanism is driven to act through the skillful utilization of the water pressure of the water outlet of the water pump under large wind power, the wind power transmission mechanism is controlled to timely respond to yaw, and the purpose of automatically protecting system units is achieved. The self-protection wind-driven water lifting system is suitable for the farmland irrigating application of remote areas lack of electricity resources.

Owner:HOHAI UNIV +1

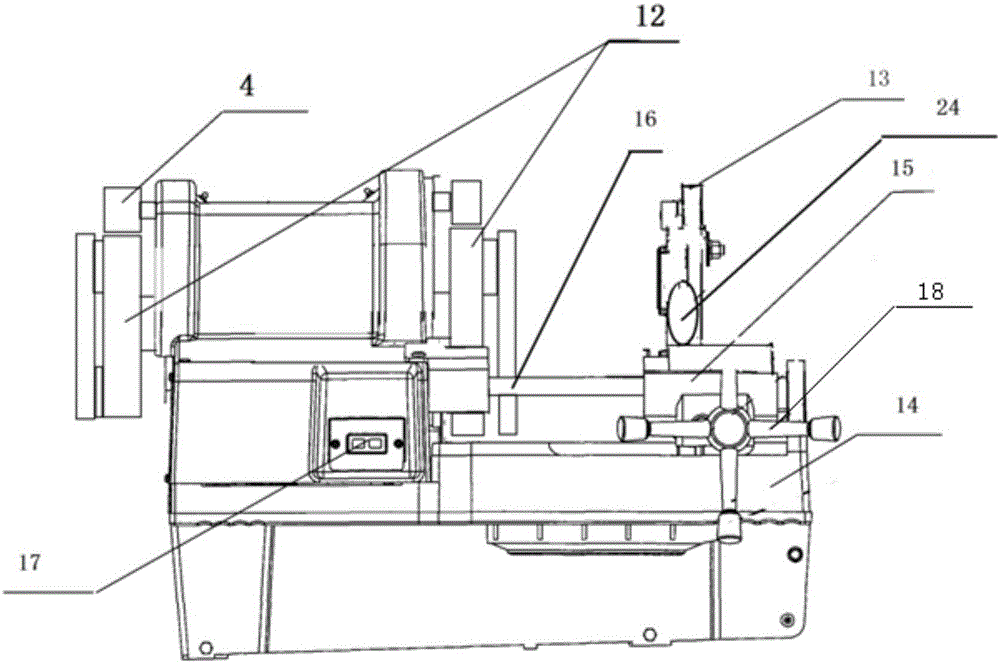

Automatic clamping and automatic clamping loosening threading machine and work method thereof

InactiveCN105903988ASolve technical nodes in automation applicationsWith automatic functionThread cutting machinesChucksEngineeringMachining process

The invention discloses an automatic clamping and automatic clamping loosening threading machine and a work method thereof. The automatic clamping and automatic clamping loosening threading machine comprises a rack, a control device, a motor, a power speed reduction transmission system, an automatic chuck system, a chuck shaft braking system and a sliding frame guide rail, wherein the control device, the motor, the power speed reduction transmission system, the automatic chuck system, the chuck shaft braking system and the sliding frame guide rail are installed on the rack. The motor and the chuck shaft braking system are connected with the control device. The control device controls the motor and the chuck shaft braking system. Power of the motor is transmitted to a chuck through the power speed reduction transmission system. The chuck completes the process of automatic clamping after the starting of the threading machine and the process of automatic clamping loosening after the shutdown of the threading machine under the cooperation of the chuck shaft braking system. By means of the automatic clamping and automatic clamping loosening threading machine and the work method thereof, power is completely provided by the main motor, power maintenance is not needed during clamping, power transmission is totally completed through mechanical transmission, and therefore the production cost is reduced; in addition, during use, the motor does not need to stop in the clamping and machining processes, and one-time operation on the processes of clamping, machining, clamping loosening and the like in the whole process is supported; and the technical nodes of the threading machine on automatic application are avoided.

Owner:SHAOXING JIANHUA METAL LOGISTICS CO LTD

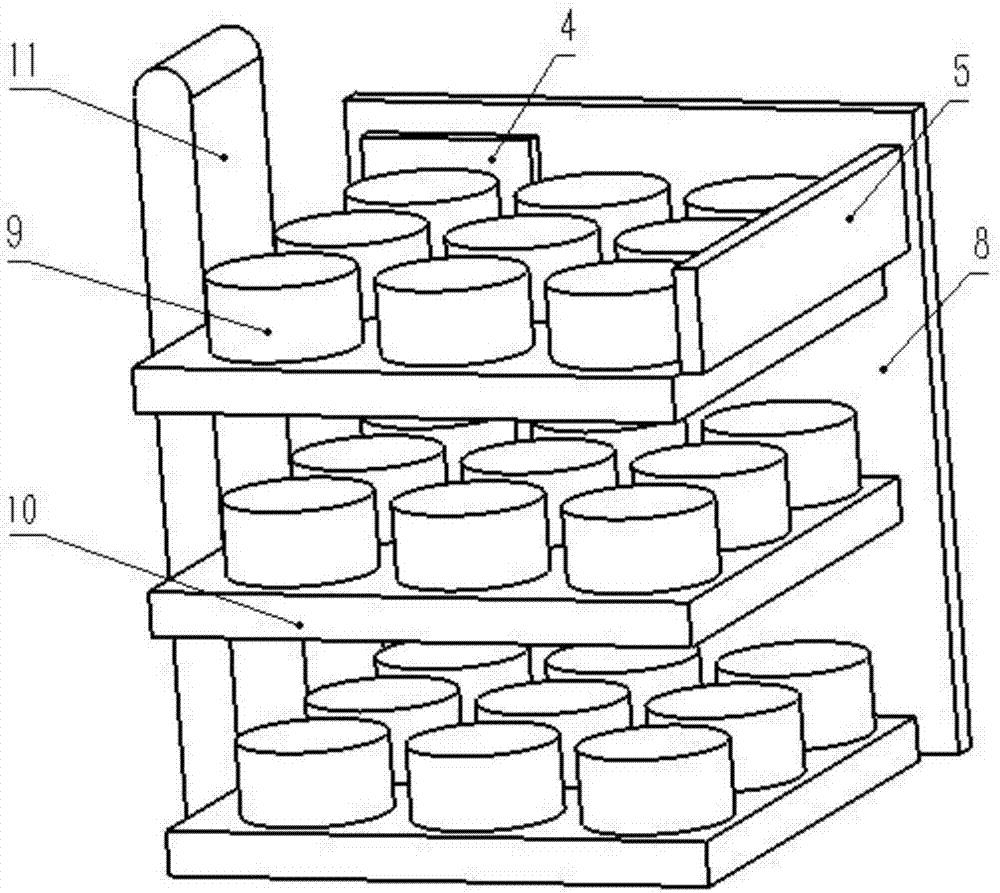

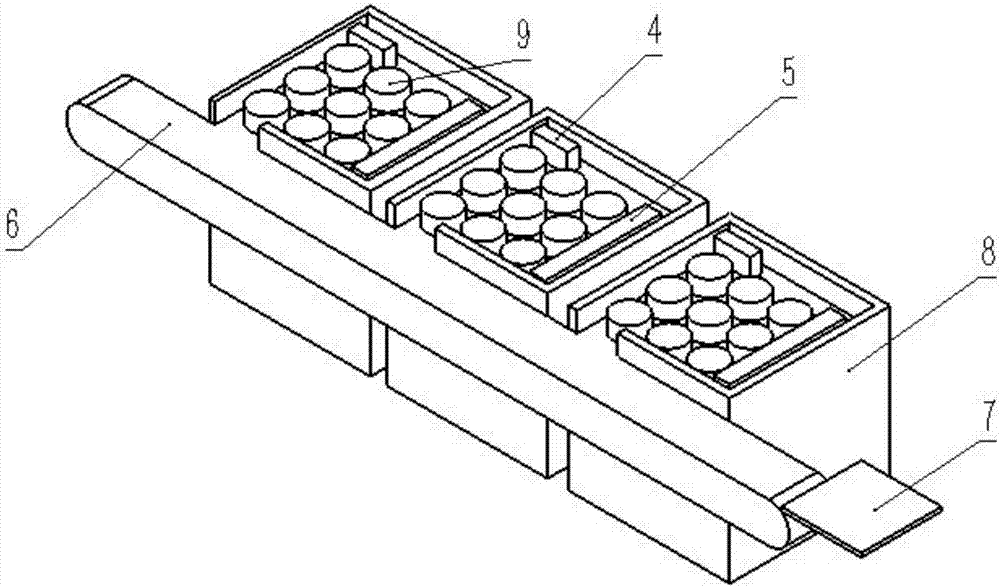

Intelligent food-buying method and device

InactiveCN106945978AImprove dining efficiencySave precious timeConveyorsControl devices for conveyorsMechanical engineeringIndustrial engineering

The invention discloses an intelligent food-buying method and device. The device comprises a plurality of boxes arranged in sequence, a plurality of layers of lifting partition boards arranged in each box from bottom to top and used for accommodating dishes and bowls, an X-direction conveying belt arranged on one sides of the boxes and used for conveying the dishes and the bowls and a tray arranged at the tail end of the X-direction conveying belt and used for receiving the dishes and the bowls conveyed through the X-direction conveying belt. Each lifting partition board is driven by one Z-direction lifting mechanism to ascend to the preset station. The position, corresponding to the X-direction conveying belt, of the side, above the lifting partition boards, of each box is provided with a dish and bowl outlet. Each pushing mechanism used for pushing the dishes and the bowls on the lifting partition boards onto the X-direction conveying belt through the dish and bowl outlet is arranged in one box. According to the intelligent food-buying device, mechanical and electrical integration is achieved, the automation degree is high, the efficiency of having meals in a canteen is greatly improved, precious time of workers in a canteen, teachers and students is saved, and meanwhile, sanitation is further guaranteed. The intelligent food-buying method and device are particularly suitable for large places such as school canteens, canteens, dining rooms for having meals and are wide in application prospect.

Owner:SOUTH CHINA UNIV OF TECH

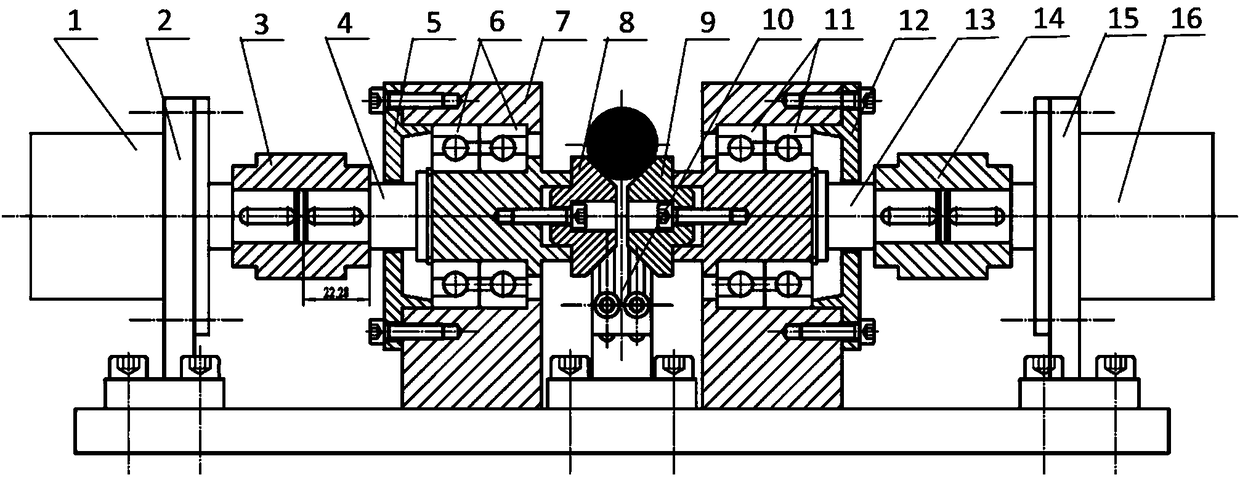

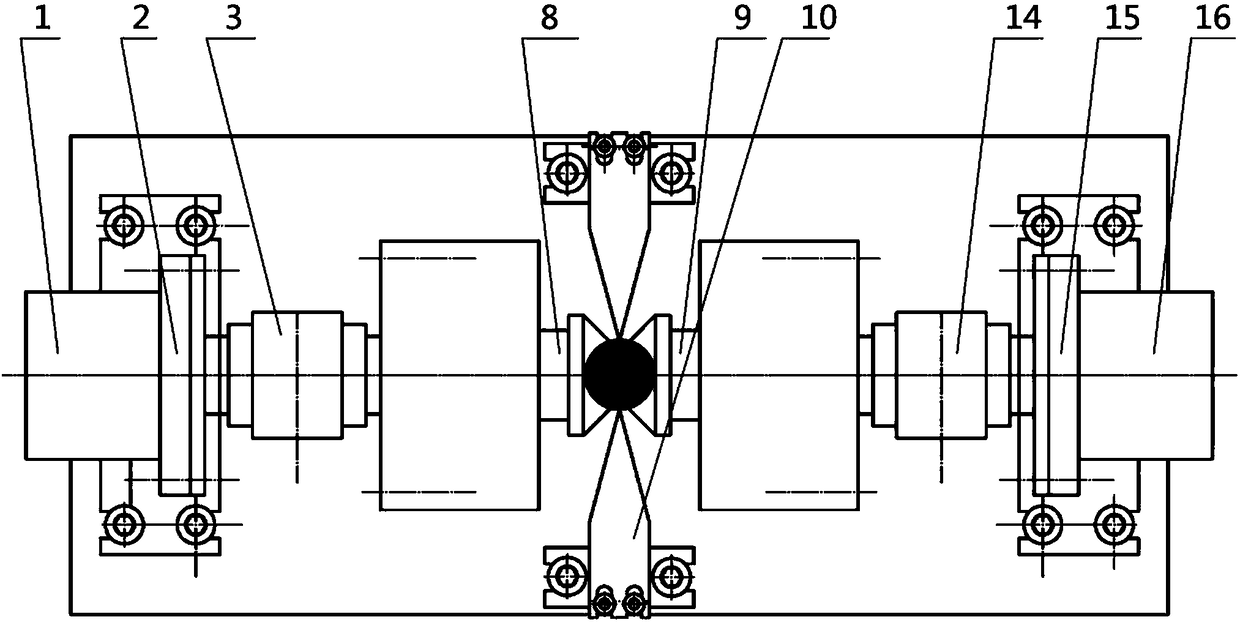

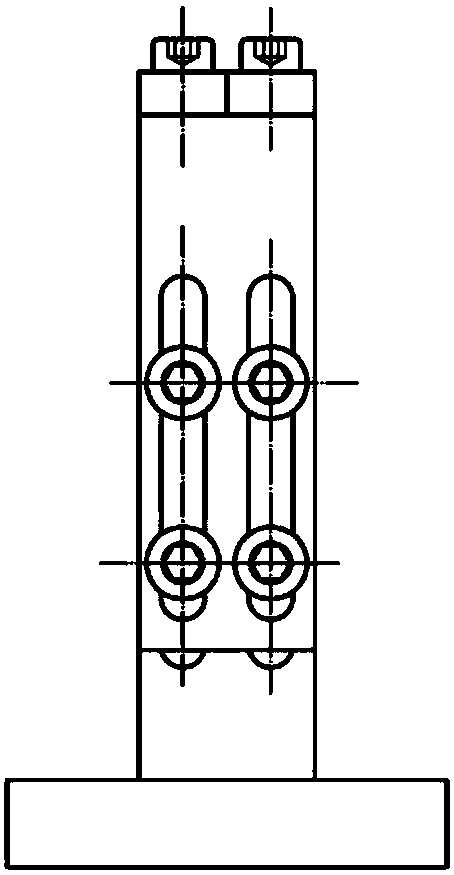

Differential type spherical surface expanding mechanism

InactiveCN108362710AEasy to shapeReduce processing costsMaterial analysis by optical meansDifferential gearingsDrive wheelBall bearing

The invention provides a differential type spherical surface expanding mechanism and belongs to the technical field of spherical surface expanding detection. A first servo motor and a second servo motor are fixed by a first servo motor fixing support and a second servo motor fixing support respectively; a first coupler and a second coupler are connected with the first and second servo motors and adriving axle; the driving axle is connected with a driving wheel; a first bearing end cover is used for fixing first paired angular contact ball bearings; the first paired angular contact ball bearings support the driving axle; a machine body supports the whole mechanism, and the driving wheel and a differential wheel cooperate to drive a detected ball to perform rotary motion and yaw motion; a baffle limits the position of the detected ball; second paired angular contact ball bearings support a differential axle; a second bearing end cover is used for fixing second paired angular contact ball bearings; the differential axle is connected with the differential wheel. The mechanism has clear working principles, is simple and reliable in mechanical structure, controllable in operation process, adaptable to expanding motion of spherical surfaces with different diameters, low in processing and maintenance cost and convenient to replace.

Owner:HARBIN INST OF TECH

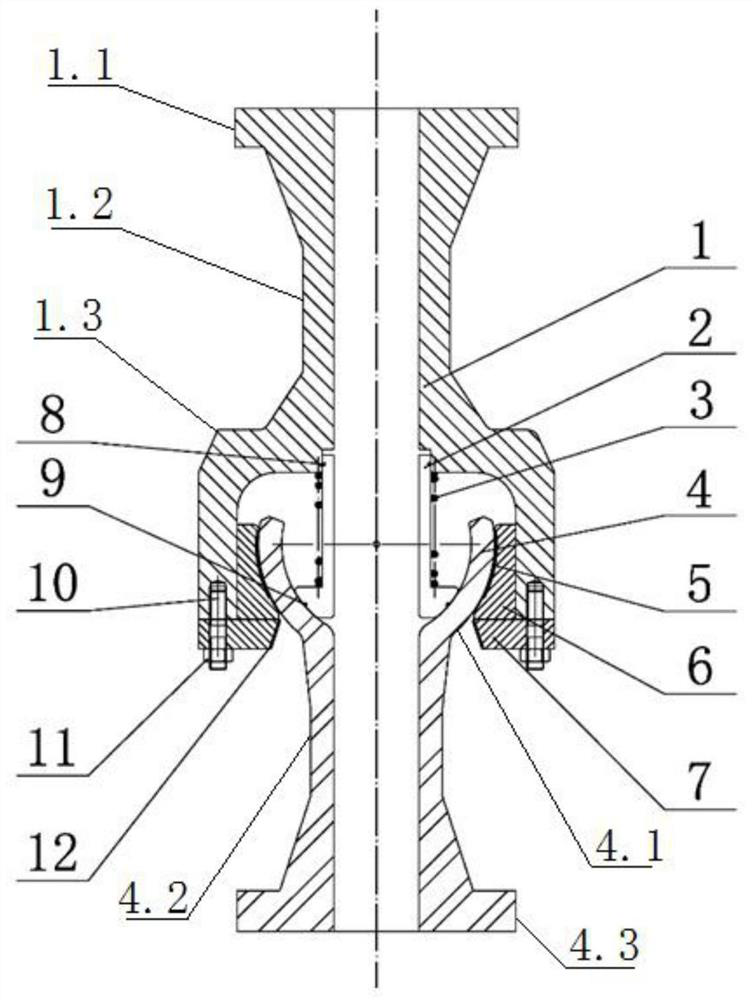

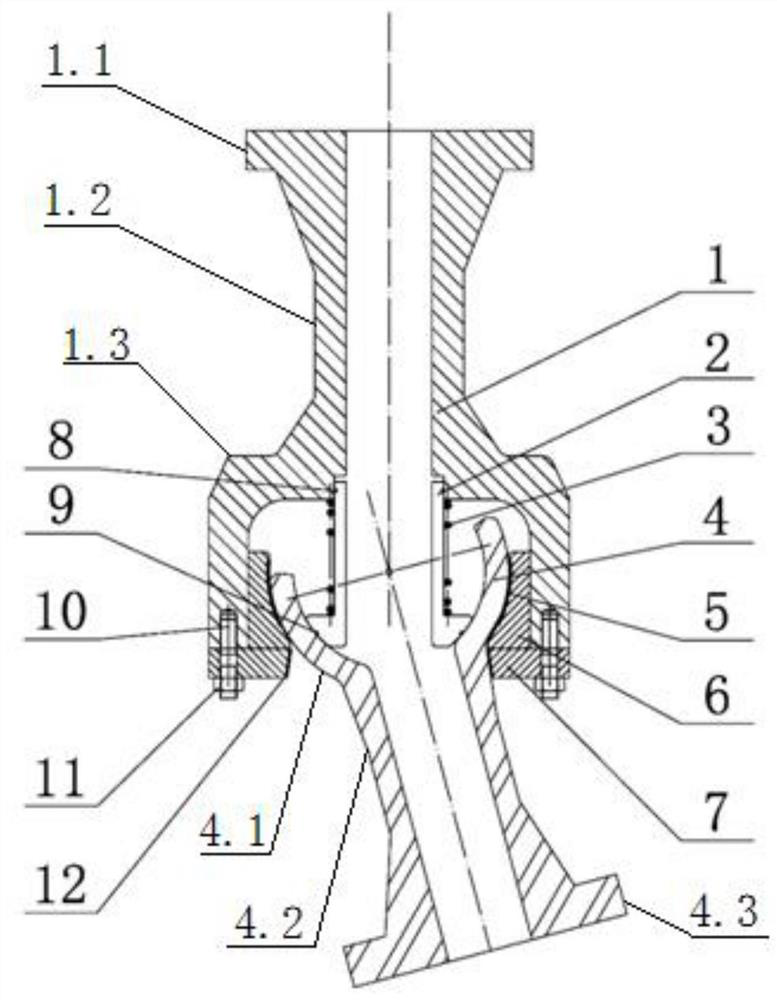

Large-angle compensation heavy-load suspension spherical joint suitable for deep-sea mining operation

PendingCN114576260AAchieve rotationAchieve swingPivotal connectionsPivotsDeep sea miningMarine engineering

The large-angle compensation heavy-load suspension spherical joint comprises an upper shell and a spherical lower joint which are coaxially arranged together in a sleeved mode, the upper shell is connected to a mining operation platform in a suspension mode, and the spherical lower joint is connected with an underwater hard pipe. And the underwater system and the mining operation platform are connected into a whole. As a flexible connecting device, the large-angle compensation heavy-load suspension spherical joint can compensate the angle deviation generated by underwater equipment in ocean current during mining operation or danger avoiding, relieve the bending moment of a mining operation platform and the underwater equipment, prevent an underwater hard pipe from being bent and damaged, and guarantee the safety of the mining operation equipment.

Owner:武汉船舶设计研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com